Degradable high barrier active preservative film and preparation method thereof

A cling film, high barrier technology, applied in climate sustainability, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of high cost of cling film, hinder the popularization and application of polylactic acid, etc., to avoid oxidation and degradation , prolong the shelf life effect, improve the stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

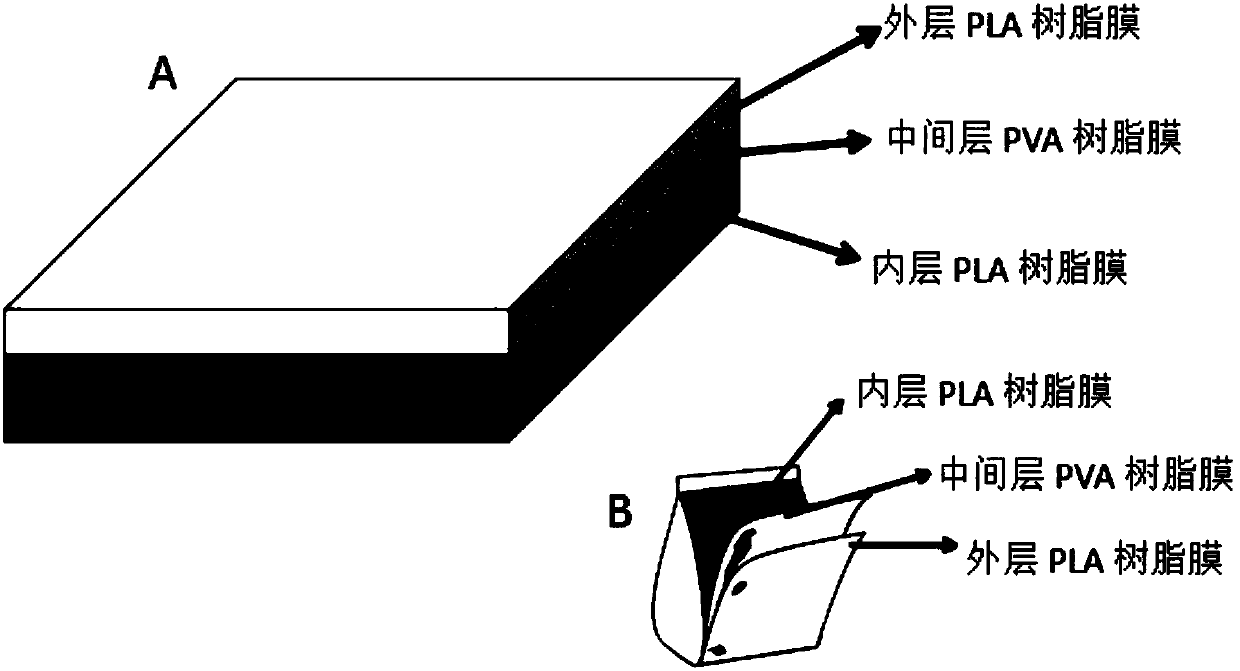

Method used

Image

Examples

Embodiment 1

[0044] (1) prepare outer layer PLA resin particle, base material is PLA and PHA, auxiliary agent is TMP6000, Irganox245 and EBS (ethylene bis stearic acid amide), base material accounts for 97.8% of this layer resin gross mass, auxiliary agent Accounting for 2.2% of the total mass of resin in this layer; pre-dry 750g PLA and 228g PHA at 80°C, the mass ratio of PLA to PHA is 3.29:1, dry the PLA and PHA, 10g TMP6000, 2g Irganox245, 10g After the EBS is stirred and homogenized, it is extruded and granulated by a twin-screw granulator. The mass ratio of TMP6000, Irganox245 and EBS is 5:1:5. Among them, the heating temperature of the first zone is 165°C, the heating temperature of the second zone is 175°C, the heating temperature of the third zone is 185°C, the heating temperature of the fourth zone is 190°C, the heating temperature of the fifth zone is 185°C, and the heating temperature of the sixth zone is 180°C. The heating temperature in the seventh zone is 180°C.

[0045] (2)...

Embodiment 2

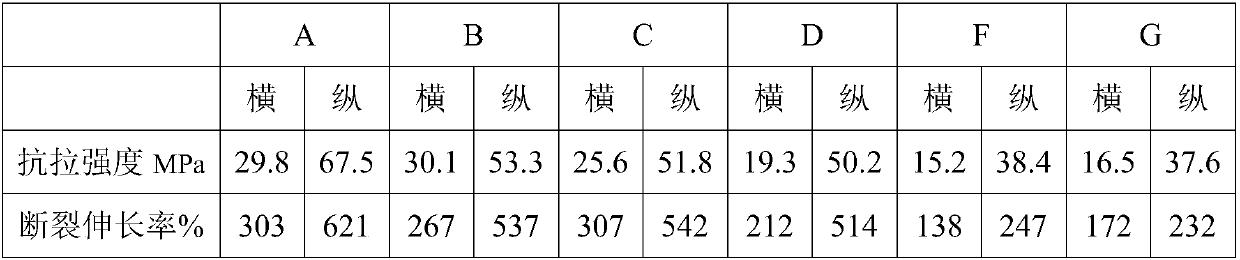

[0051] In order to investigate the effect of the die lip temperature of the main machine on the multi-layer co-extrusion casting machine and the speed of the roll (including the casting roll, the back pressure roll and the traction roll) on the adhesion between the layers of the multi-layer food preservation film, in the implementation On the basis of the formula composition and preparation method of Example 1, the parallel experimental group is set as the investigation variable with the die lip temperature and the roll speed. The experimental group settings and experimental results are as shown in Table 2:

[0052] Table 2

[0053] Die lip temperature (℃)

[0054] The results in Table 2 show that when the host of the multi-layer co-extrusion casting machine selects the die lip temperature of 180°C and the roll speed of 1r / min, the peel strength between the layers of the obtained food preservation film is 3.52N / mm, which is higher than other For the experimental grou...

Embodiment 3

[0056] (1) Prepare the outer layer of PLA resin particles, the base material is PLA and PHA, the auxiliary agents are TMP6000, Irganox245 and EBS, the base material accounts for 98.9% of the total mass of the layer of resin, and the auxiliary agent accounts for 1.1% of the total mass of the layer of resin; The amount of PLA is 761g, the amount of PHA is 228g, the amount of TMP6000 is 5g, the amount of Irganox245 is 1g, the amount of EBS is 5g, and the mass ratio of PLA and PHA is 3.34:1; The preparation method of this step resin particle is implemented with example 1.

[0057] (2) Prepare the PVA resin particles in the middle layer, this step is the same as in Example 1.

[0058] (3) Prepare inner PLA resin particles, the base material is PLA and PHA, the auxiliary agents are TMP6000, Irganox245 and EBS, the antibacterial active ingredient is oregano essential oil, the base material accounts for 95.9% of the total mass of the resin, and the auxiliary agent accounts for 1.1% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com