Online detection method and device for wood moisture content

A detection method and technology for moisture content are applied in the online detection of moisture content in the drying process of wood, and in the field of online detection of moisture content of wood. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

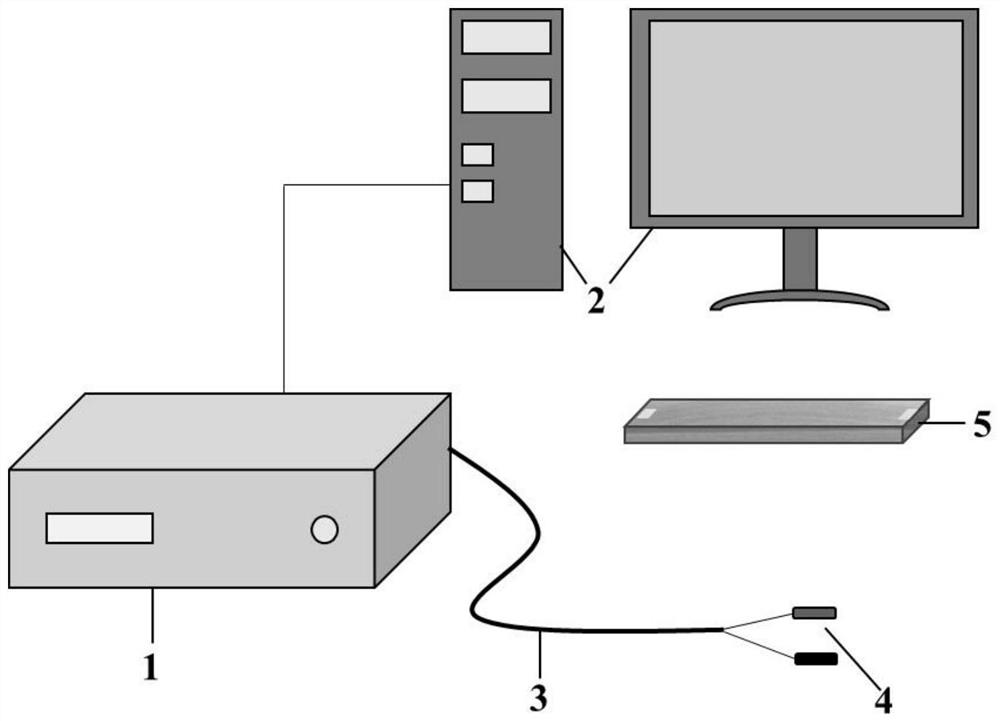

Method used

Image

Examples

Embodiment 1

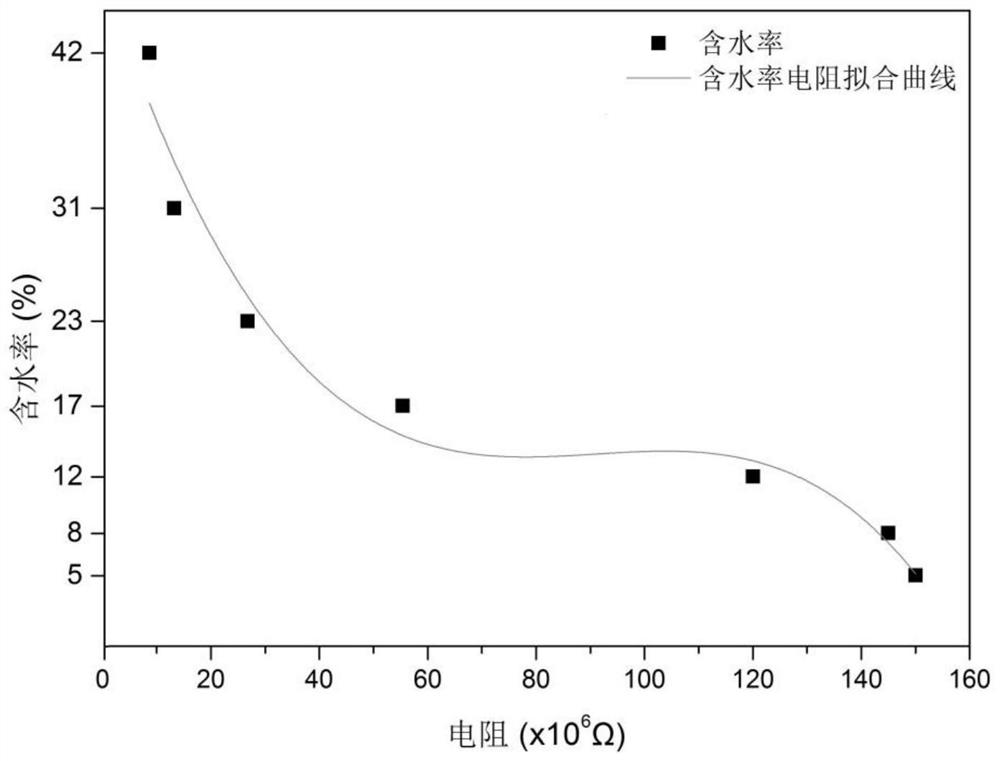

[0092] Preparation of Standard Curve

[0093] The test material was eucalyptus (Eucalyptus exserta) collected from Gaozhou City, Guangdong Province, China. A chord-sawn board with a size of 120 mm (chord direction)×25 mm (radial direction)×900 mm (longitudinal direction) without visible defects was sawn from a eucalyptus log, and the initial moisture content of the test material was 42%.

[0094] Wood samples with a size of 120 mm (chord direction) × 25 mm (radial direction) × 10 mm (longitudinal) were sawn from the above-mentioned chord-cut boards for measuring electrical resistance and moisture content, and then making a standard curve.

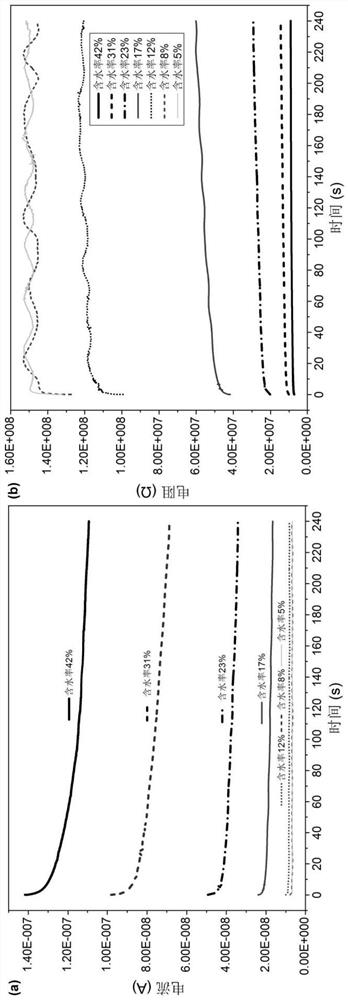

[0095] First, the initial weight of the wood sample was obtained, and electrochemical tests were performed on the wood sample. Afterwards, the wood samples were dried at a constant temperature of 60 °C in a DKN611 drying oven (Daiwa Scientific Co., Ltd., Japan) to obtain different moisture contents. Take out the wood samples from the dr...

Embodiment 2

[0128] The sample to be tested in embodiment 1 is replaced, still adopts the eucalyptus (Eucalyptusexserta) of Gaozhou City, Guangdong Province, China, but the sample used for the standard curve is taken from a different tree strain and is different from the eucalyptus in embodiment 1 . Saw-sawn eucalyptus logs have a size of 120 mm (chord direction) x 25 mm (radial direction) x 900 mm (longitudinal) without visible defects, and the initial moisture content of the test material is 45%.

[0129] A sample to be tested with a size of 120 mm (chord direction)×25 mm (radial direction)×10 mm (longitudinal direction) was sawed from the above-mentioned chord-cut board for resistance measurement.

[0130] The electrochemical workstation was used to measure the current and resistance. The parameters of the electrochemical workstation were set as follows: the initial potential was 1V, the sampling interval was 0.1s, the running time was 240s, and the sensitivity was 0.01A / V. Before the ...

Embodiment 3

[0140] Preparation of Standard Curve

[0141] The cork oak wood was collected from the Tanjiahe Ecological Protection Center of Nanwan Forest Farm, a state-owned Xinyang City, Henan Province. The sampling site was 200m above sea level, 113°55′ east longitude, 31°52′ north latitude. The trees are all 60 years old, and the average diameter of the cork oak is 38cm. It is sawed into several plates of 900 mm (length) × 120 mm (width) × 25 mm (thickness), and the initial moisture content of the test material is 50%. Select a chord-cut board with no visible defects and saw it into a wood sample with a size of 120 mm (chord direction) × 25 mm (radial direction) × 10 mm (longitudinal) for the measurement of electrical resistance and moisture content, and then make a standard curve .

[0142] First, the initial weight of the wood sample was obtained, and electrochemical tests were performed on the wood sample. Afterwards, the wood samples were dried at a constant temperature of 60 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com