Wood moisture content detection method based on radar waves

A moisture content and radar wave technology, which is applied in the direction of using microwaves to test moisture content and weighing by removing certain components, can solve the problems of increasing the tediousness of measurement, unable to continuously detect moisture content on-line, etc., and achieve a large measurement range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

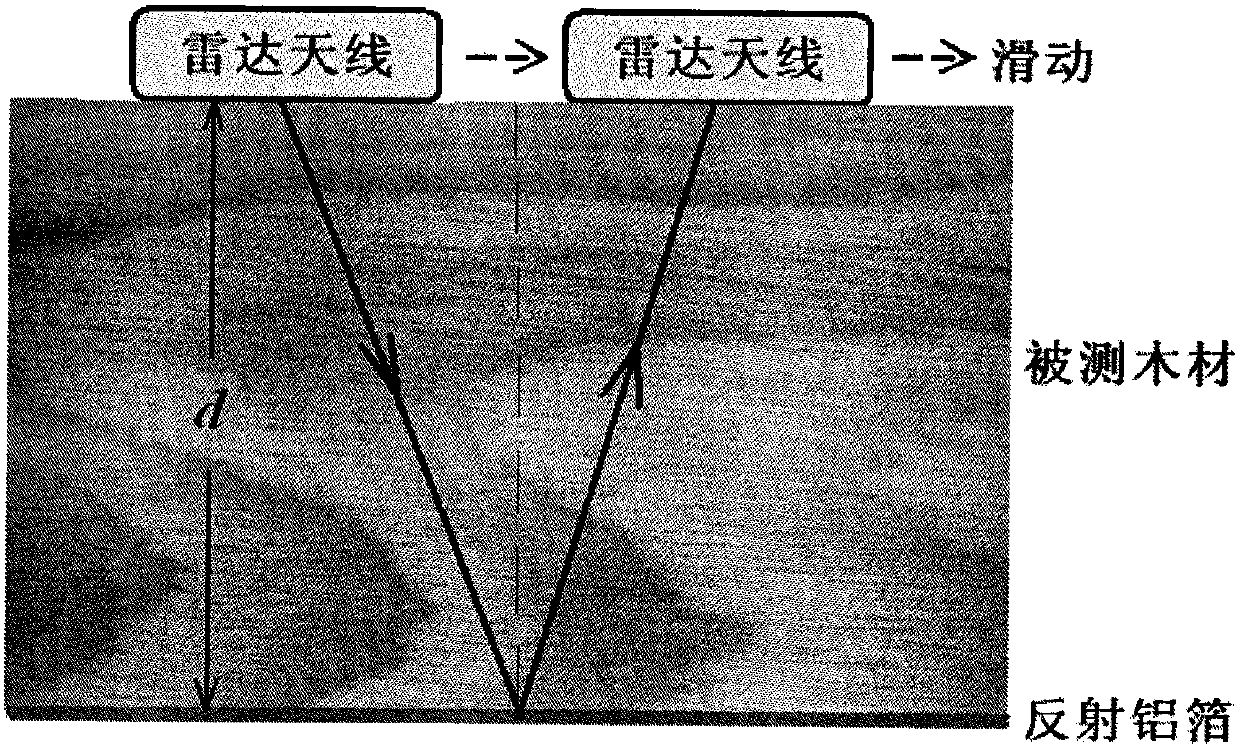

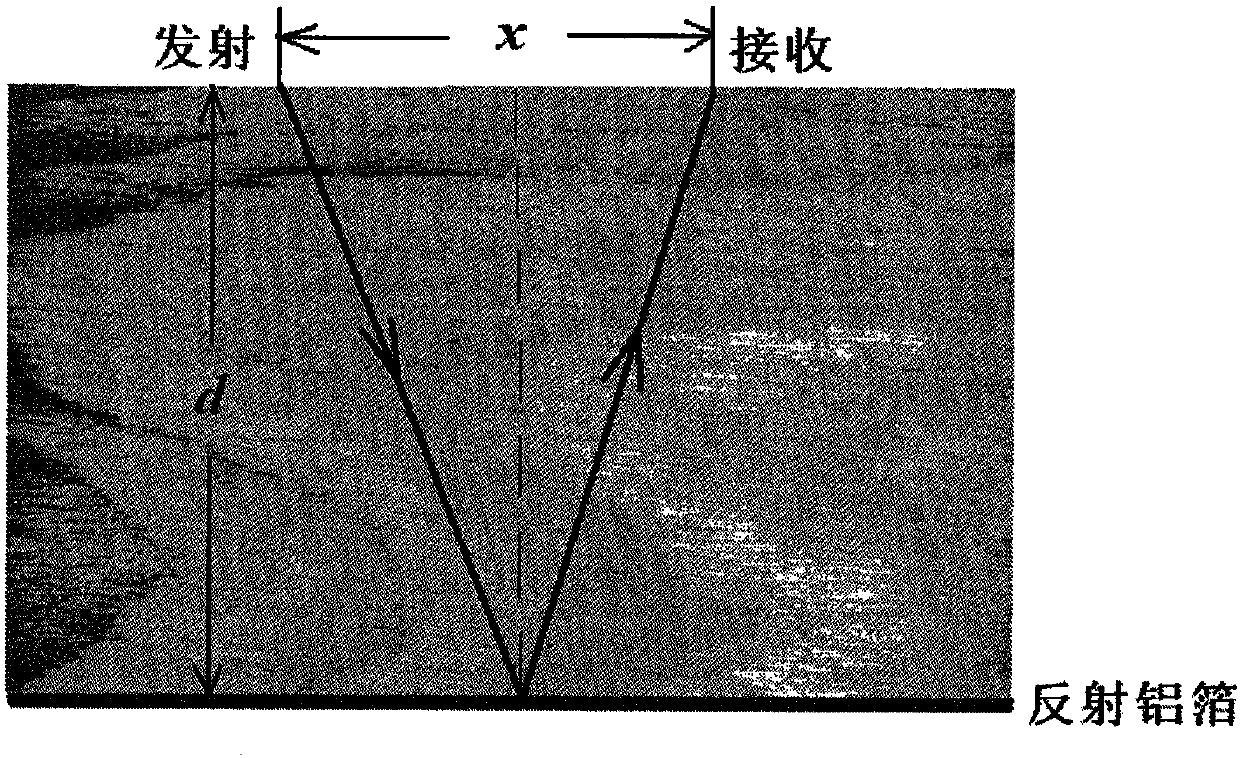

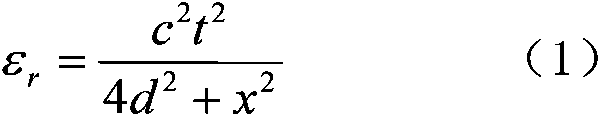

[0016] Moisture content is a very critical parameter in the drying process of wood, and it is also an important index that needs to be referred to in the maintenance of wooden beams and columns in ancient buildings, the production of wooden furniture and the use of geothermal wood floors. The most commonly used measurement methods for wood moisture content are the weighing method and the resistance method, but there are shortcomings in the measurement, such as: the weighing method is cumbersome to measure the wood moisture content, the measurement range of the resistance method is limited, and the damage. To this end, a radar wave-based wood moisture content detection method is invented, which mainly includes three parts: radar antenna, data manager and the relationship model between relative permittivity and moisture content of wood;

[0017] Among them, the radar antenna contains a radar wave transmitting device and a receiving device, which are placed in a square protective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com