Wood single-plate microwave drying device and drying method

A technology of microwave drying and wood veneer, which is applied in the direction of preliminary treatment to promote the drying of solid materials, heating devices, and drying of solid materials. It can solve the problems of unstable drying quality, increased production costs, and difficulty in large-scale promotion, and avoid The effect of excessive gas vapor pressure, reducing energy consumption and cost, and ensuring drying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

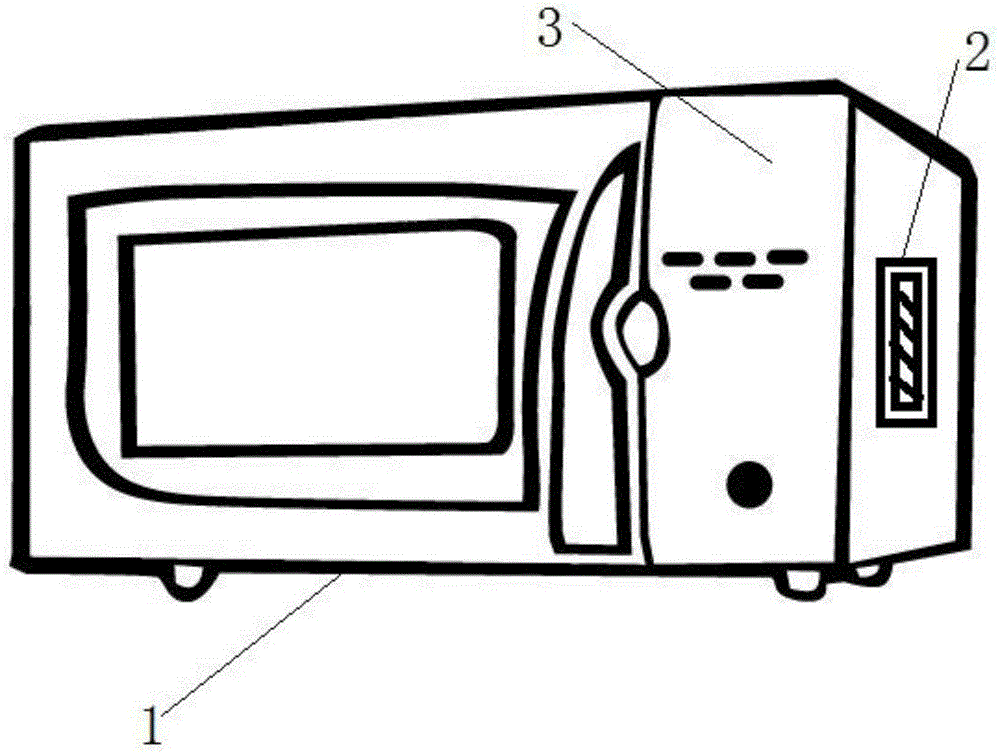

[0046] A wood veneer microwave drying device, comprising a microwave heating device 1, a ventilation device 2 for controlling the ventilation rate of the microwave heating device, and a metering device 3 for measuring the power consumption of the microwave heating device, the ventilation device 2 is arranged on the microwave heating device 1 side, the air in the microwave drying device enters the ventilation device through the vent on one side of the microwave heating device 1 and then discharges; in the working state: the metering device records the moisture evaporation of wood as G 水 When the power consumption E of the microwave heating device 1 is used to obtain the microwave wood veneer drying water extraction rate value η 水 .

[0047] Microwave wood drying is the use of high-frequency electromagnetic waves in a closed space (container) to directly radiate "in vivo" heating of wood. Wood drying (wooddrying) refers to the process of removing wood moisture by evaporation or...

Embodiment 2

[0072] 1. Calculation of water extraction rate for microwave wood veneer drying

[0073] ①. Laboratory wood veneer preparation: sample size (length×width×thickness): 200mm×100mm×1.2~1.4mm×n 层数 →②. Wood veneer sample weighing G 初 →Initial moisture content MC of wood veneer 初 Determination→③. Calculate the target moisture content MC 目标 (Process setting value)→④. Calculate the target veneer weight G 目标 →⑤. Calculation of moisture evaporation for microwave wood veneer drying: G 目标水 =G 初 -G 目标 →⑥. Weigh the veneer for the test (the number of layers corresponds to the number of layers in the pilot test and production test, and the range of the number of layers: 1 to 21) →⑦. After weighing, put the veneer into the "Wood Drying Microwave Water Lifting Rate Measuring Device" "→⑧. "Microwave radiation ←→ weighing"→⑨. After repeated many times, the weight reaches G 目标 →⑩.Based on test data: Electric energy consumption E kw·h , Microwave radiation time T min , The actual evaporat...

Embodiment 3

[0078] The difference between this embodiment and Embodiment 1 is that a clamp power meter is further used as a metering device for detecting the power consumption of a microwave oven.

[0079] The optimum microwave radiation time t of the willow determined by the above method and the optimum microwave drying time t of the willow determined by the conventional method 真 The deviation is 1s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com