Method and system for drying wet polytetrafluoroethylene dispersion resin particles

A technology of polytetrafluoroethylene and dispersing resin, which is applied in the direction of drying granular materials, drying solid materials, and handling dry goods. It can solve the problems of slow drying speed, affecting the quality of finished products, and high moisture content, so as to avoid the impact of the environment and facilitate feedback. Control, the effect of low exhaust flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

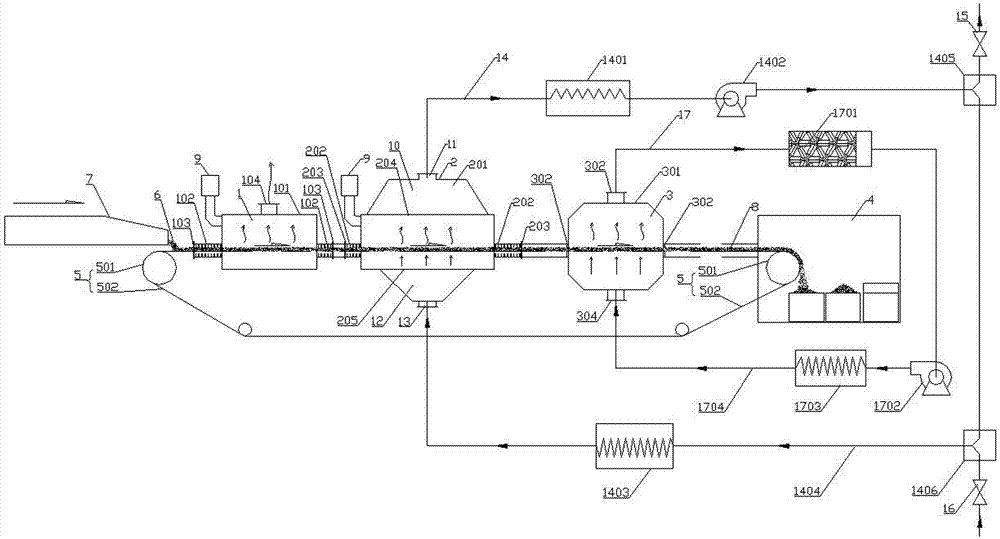

[0048] A polytetrafluoroethylene dispersed resin particle wet material drying system, comprising a drying device 1, an impurity removal device 2, a low-temperature air-cooling device 3 and a sealed packaging device 4, the drying device 1, an impurity removal device 2, a low-temperature air-cooling device 3 and The airtight packaging device 4 is connected successively by the mesh belt conveying device 5, the mesh belt conveying device 5 includes a transmission roller 501 and a conveying mesh belt 502, and the driving roller 501 drives the conveying mesh belt 502 to move, and the conveying mesh belt 502 passes through the drying device 1, The impurity removal device 2, the low-temperature air cooling device 3 and the airtight packaging device 4 form a circular conveying loop; the front side of the drying device 1 station is provided with a system feed section 6, and the system feed section 6 is arranged on the conveyor belt 502 above, and above the station of the system feed sect...

Embodiment 2

[0069] A polytetrafluoroethylene dispersed resin particle wet material drying system, comprising a drying device 1, an impurity removal device 2, a low-temperature air-cooling device 3 and a sealed packaging device 4, the drying device 1, an impurity removal device 2, a low-temperature air-cooling device 3 and The airtight packaging device 4 is connected successively by the mesh belt conveying device 5, the mesh belt conveying device 5 includes a transmission roller 501 and a conveying mesh belt 502, and the driving roller 501 drives the conveying mesh belt 502 to move, and the conveying mesh belt 502 passes through the drying device 1, The impurity removal device 2, the low-temperature air cooling device 3 and the airtight packaging device 4 form a circular conveying loop; the front side of the drying device 1 station is provided with a system feed section 6, and the system feed section 6 is arranged on the conveyor belt 502 above, and above the station of the feeding section ...

Embodiment 3

[0090] Such as figure 1 Shown: a polytetrafluoroethylene dispersed resin particle wet material drying system, including drying device 1, impurity removal device 2, low-temperature air cooling device 3 and airtight packaging device 4, drying device 1, impurity removal device 2, low-temperature air The cooling device 3 and the airtight packaging device 4 are connected successively through the mesh belt conveying device 5. The mesh belt conveying device 5 includes a transmission roller 501 and a conveying mesh belt 502. The driving roller 501 drives the conveying mesh belt 502 to move, and the conveying mesh belt 502 passes through the Drying device 1, impurity removal device 2, low-temperature air cooling device 3 and airtight packaging device 4 form a circular conveying loop; the front side of the drying device 1 station is provided with a system feed section 6, and the system feed section 6 is arranged on On the conveying mesh belt 502, and above the station of the system feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com