Composite energy saving building blocks and method for making same

A production method and block technology, which can be applied to building materials and other directions, can solve problems such as hidden dangers in construction, surface layer peeling, rust and corrosion, etc., and achieve the effect of enhancing thermal insulation performance and improving and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

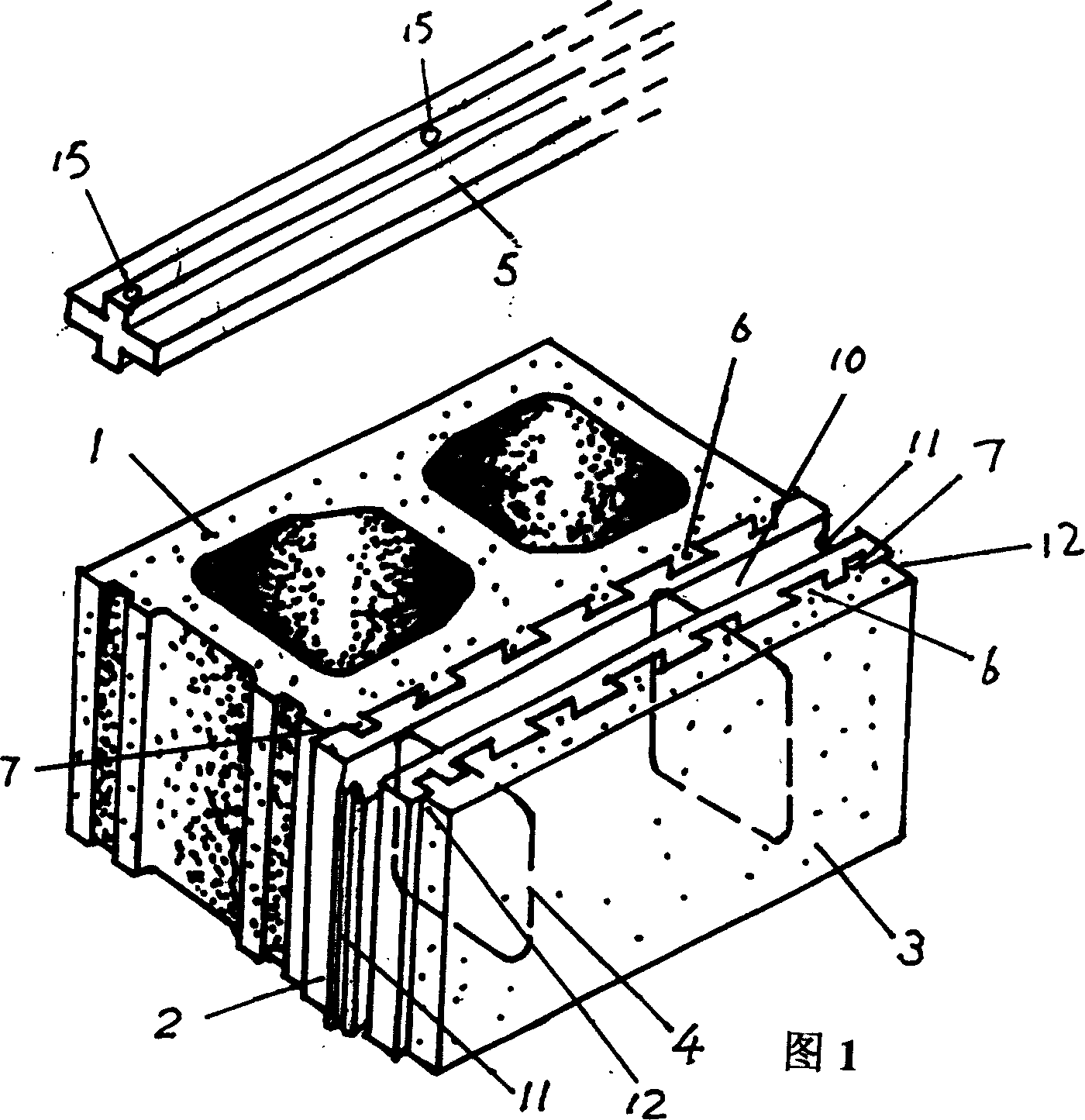

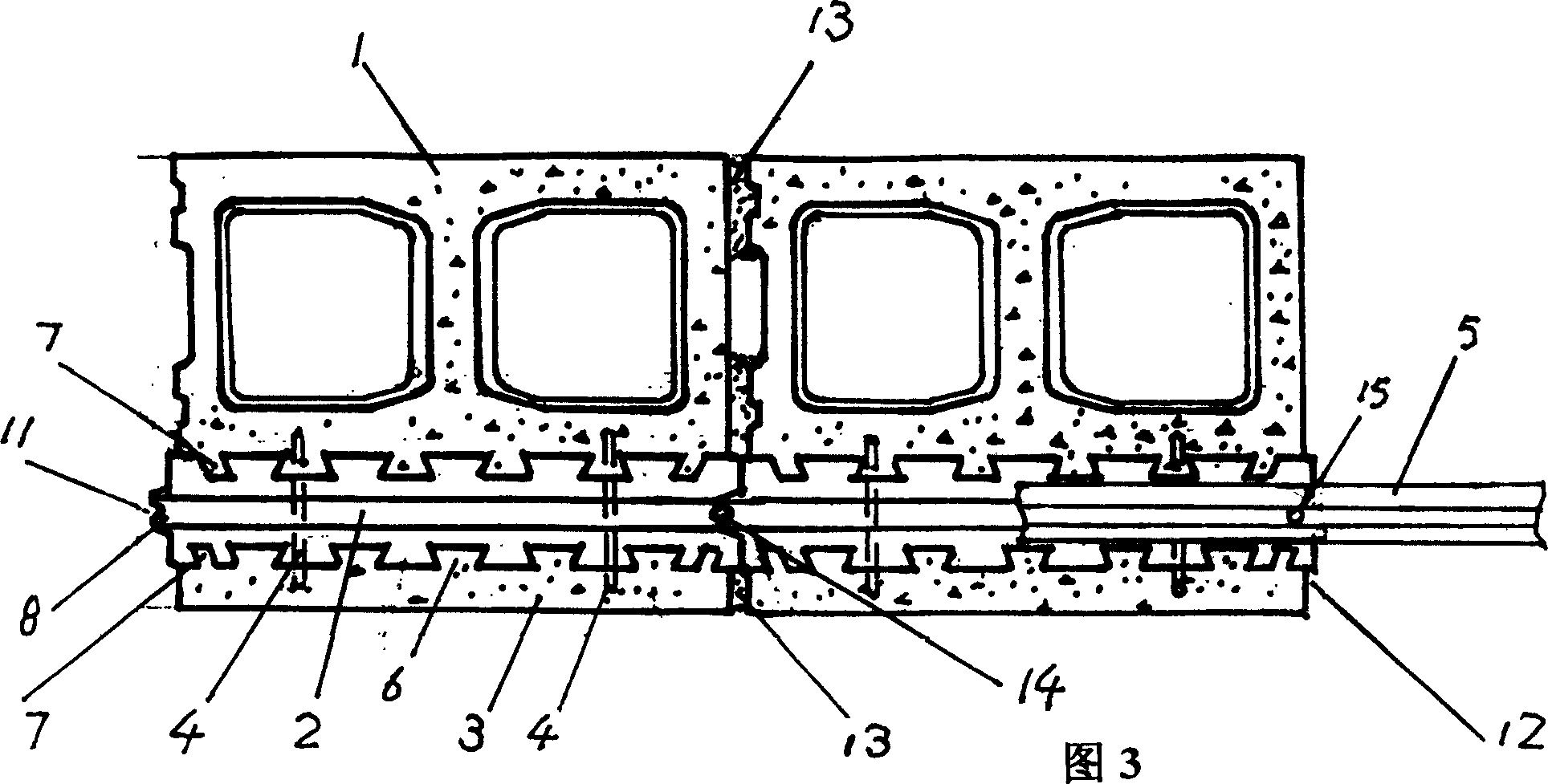

[0051] Production of load-bearing composite energy-saving blocks (structure as shown in Figure 1)

[0052] Specifications: 390 mm × 320 mm × 190 mm (length × width × height)

[0053] Strength grade: 13.1MPa

[0054] Make 1000 pieces (23.8m 3 ) The required materials are as follows:

[0055] 1. Insulation board: specifications 415 mm × 80 mm × 190 mm (length × width × height)

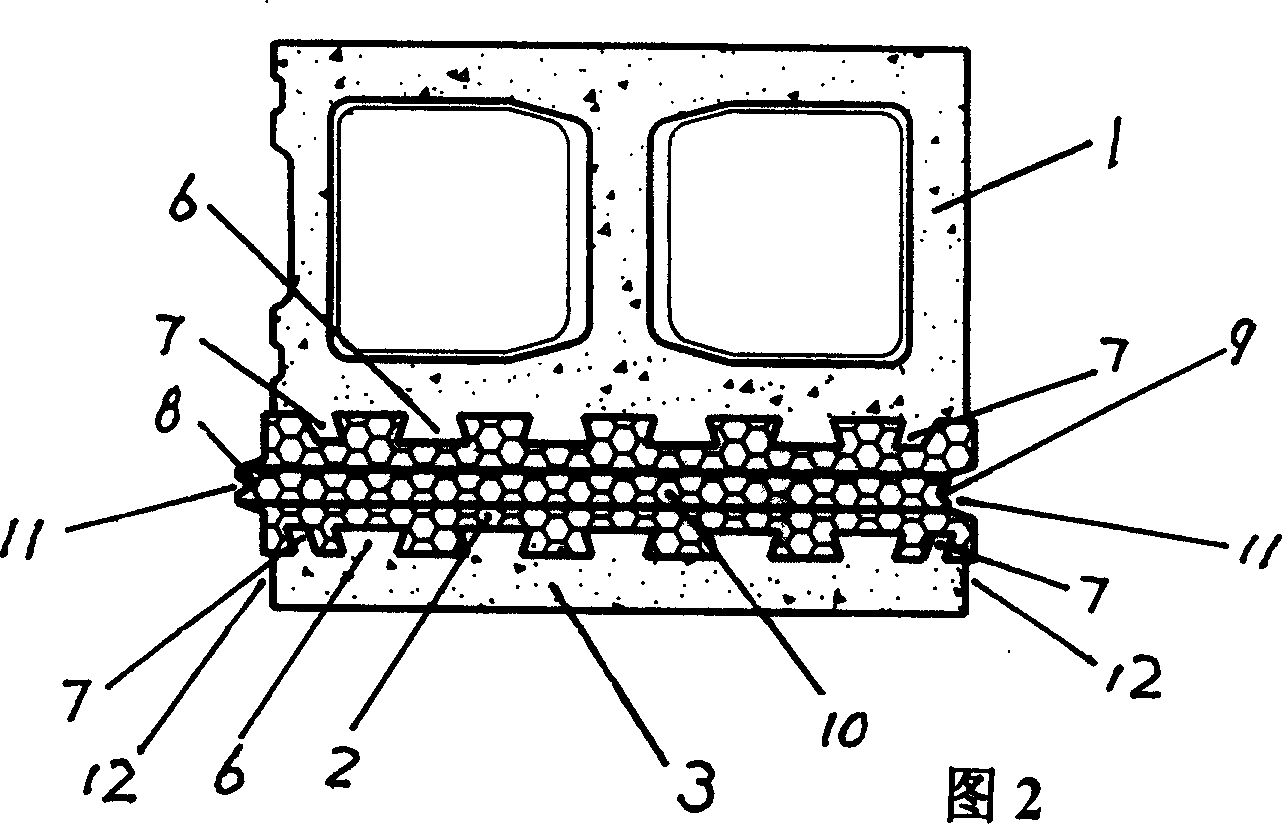

[0056] The insulation board is provided with 5 dovetail grooves on one side and 4 dovetail grooves on the other side. The groove depth is 12 mm, the bottom width of the dovetail groove is 34.5 mm, and the bottom angle is 25°. There are two oblique anti-cracking grooves on each side, with an average width of 16 mm and a distance of 12 mm from the end face of the insulation board. The exhaust groove is semicircular with a radius of 5 mm.

[0057] The flame-retardant expandable polystyrene beads are used as raw materials, and the existing technology is used for one-time heating and molding.

[0058] Each piece ...

Embodiment 2

[0080] Production of non-heavy-duty composite energy-saving blocks (structure as shown in Figure 1)

[0081] Specification: 390mm×300mm×190mm

[0082] Strength grade: 2.5MPa

[0083] Make 1000 pieces (22.2m 3 ) The required materials are as follows:

[0084] 1. Insulation board: Specification 415mm×80mm×190mm

[0085] The insulation board is provided with 5 dovetail grooves on one side and 4 dovetail grooves on the other side. The groove depth is 15 mm, the bottom width of the dovetail groove is 34.5 mm, and the bottom angle is 25°. There are two oblique anti-cracking grooves on each side, with an average width of 16 mm and a distance of 12 mm from the end face of the insulation board. The exhaust groove is semicircular with a radius of 5 mm.

[0086] The flame-retardant expandable polystyrene beads are used as raw materials, and the existing technology is used for one-time heating and molding.

[0087] Each piece weighs 105 grams, a total of 1,000 pieces are required, and the tot...

Embodiment 3

[0108] Example 3 and test 1:

[0109] Preparation and comparative test of anti-rust low conductivity liquid

[0110] Table 3 shows the ratio of the raw materials for the preparation of rust-proof low-conductivity liquid.

[0111] example 1

[0112] All raw materials in the examples are selected from commercially available qualified products:

[0113] Raw material manufacturer

[0114] No. 30 Petroleum Bitumen Jilin Chemical Group Oil Refining Plant

[0115] Coal Tar Daqing Oil Refinery

[0116] Emulsion coke chemical plant in Changyi District, Jilin City

[0117] Sodium Nitrite Jinzhou Chemical Plant

[0118] Urea Jilin Chemical Group Fertilizer Plant

[0119] Graphite Powder Graphite Factory in Longtan District, Jilin City

[0120] Stone powder Jilin Quartz Factory

[0121] Test 1 used the load-bearing and non-heavy-duty composite energy-saving blocks obtained in Examples 1 and 2 and the existing composite blocks with the same specifications of metal tie bars wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com