Decorative panel

A decorative panel and panel technology, applied in the field of building decoration materials, can solve the problems of low thermal conductivity, easy cracking of the surface, large deformation, etc., and achieve the effect of high thermal conductivity, not easy to crack, and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

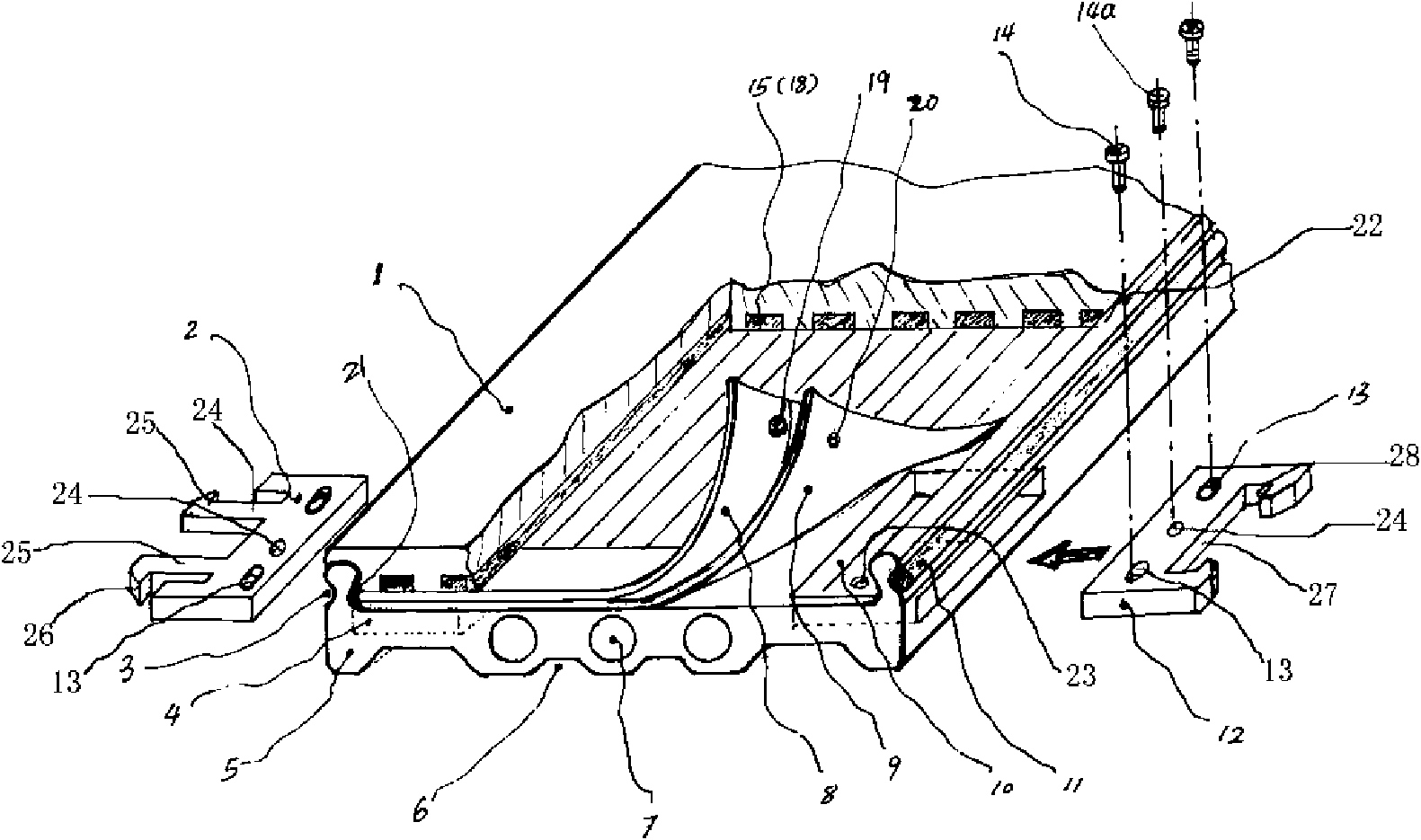

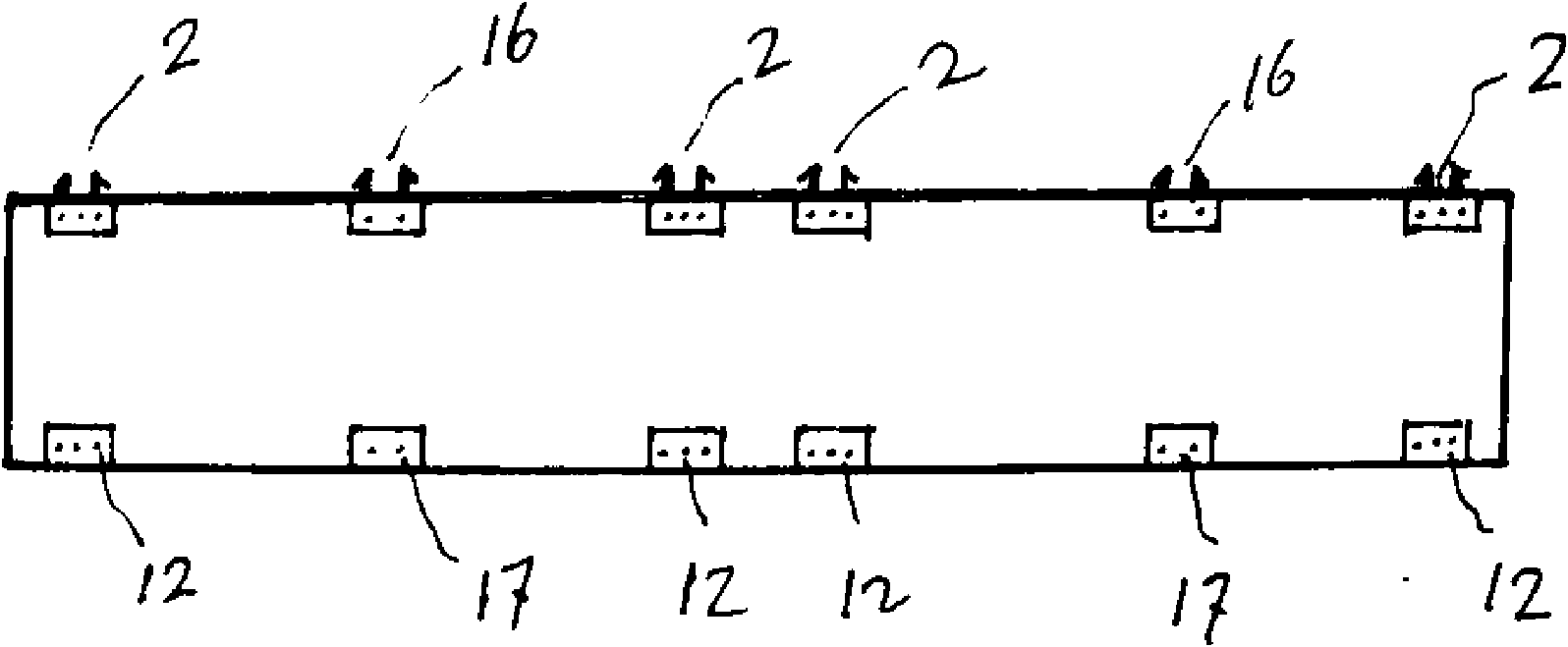

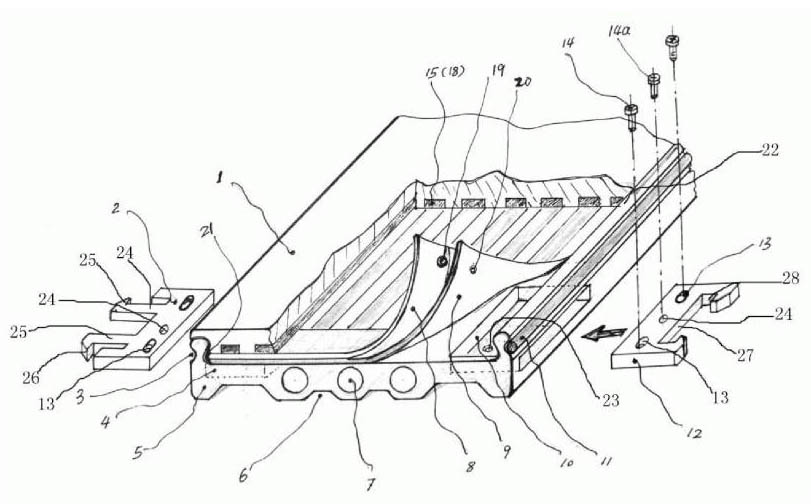

[0020] Embodiment 1: as figure 1 and figure 2 As shown, a panel 1 is arranged on a rectangular base plate 5, the base plate 5 can be formed by extrusion or injection molding of rubber-plastic material or wood-plastic material, and the panel 1 can be made of wood, bamboo veneer, MDF veneer or ceramic material; The upper edges of the left and right sides of the bottom plate 5 are respectively formed with upwardly protruding clamping strips 22, and the inside of the upper end of the clamping strips 22 forms an arc-shaped inward convex structure, thereby forming a dovetail between the two clamping strips 22 of the bottom plate 5. Groove structure, the lower edge of both sides of the panel is formed with a clip groove 21 that matches the clip 22 on the bottom plate, so that the panel snap fits on the bottom plate 5 to form a reliable assembly connection; the upper surface of the bottom plate 5 and the panel 1 correspond to An electrothermal film 8 and a heat insulating layer 9 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com