Installation and construction method for energy-dissipating type buckling-restrained brace

A technology of buckling constraints and construction methods, applied in the direction of building types, building components, earthquake resistance, etc., can solve the problems that the support does not achieve the ideal anti-seismic effect, the wall is prone to cracks, and the precision requirements are high, so as to achieve strong promotion and application value and easy installation Quick and wide application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

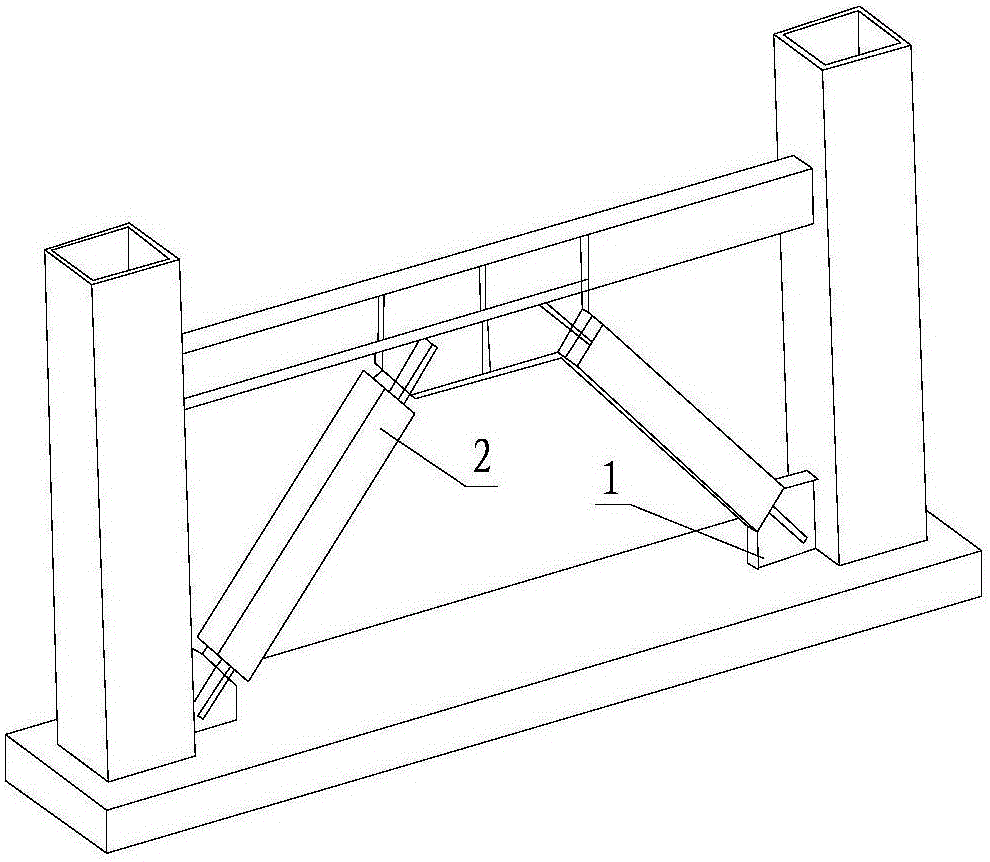

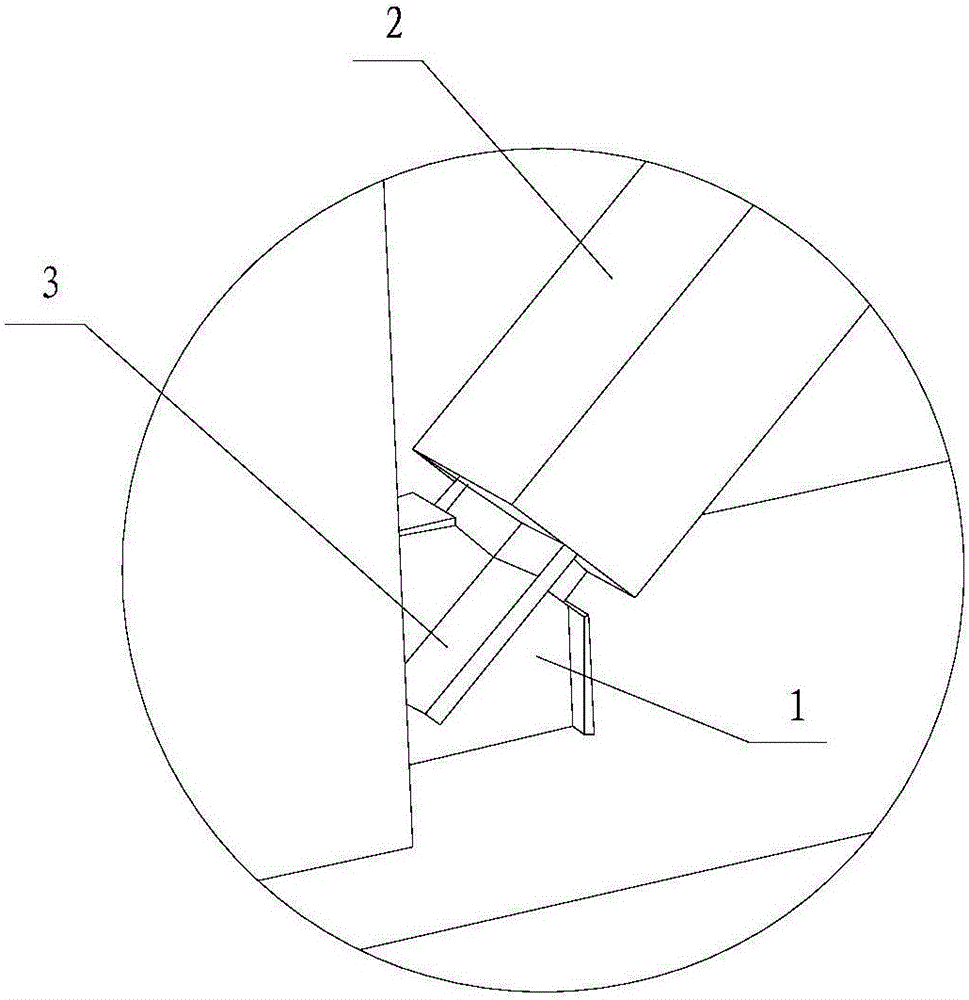

[0036] A project project with a total construction area of 206089m 2, the structure types are frame-shear wall structure, frame-core tube and frame structure, which are composed of A, B towers and podium buildings. Tower A has 23 floors above ground, 99.8m high, Tower B has 21 floors above ground, 88.5m high, the podium has 7 floors above ground, 36.8m high, and 4 floors in the basement. A total of 56 BRB energy-dissipating buckling restraints are used, of which the maximum weight of a single component is about 4.5t, the maximum yield bearing capacity is 3500Kn, and the length is 7743mm. parts.

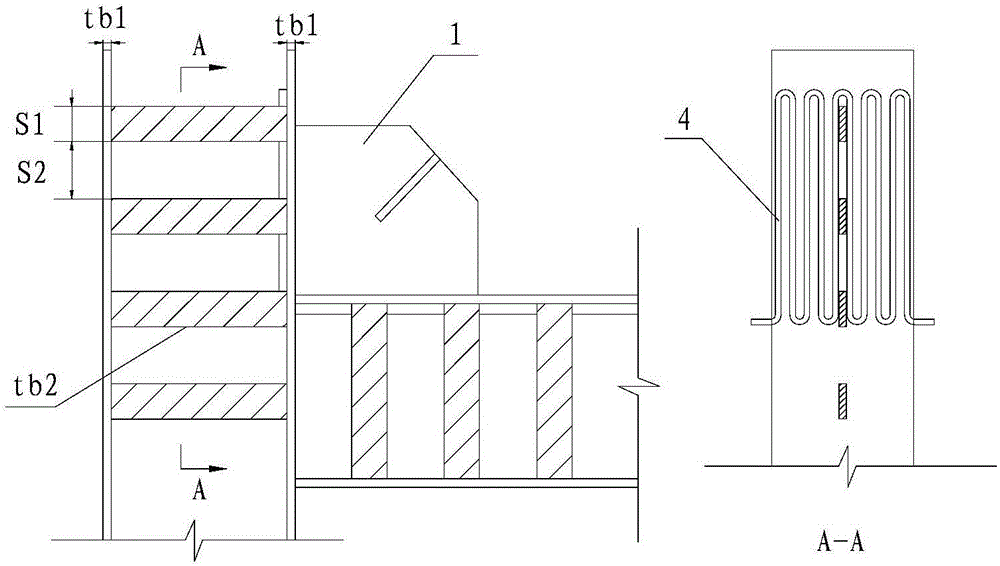

[0037] The specification requirements of embedded parts during support installation are as follows:

[0038] Table 1 Specifications of embedded parts

[0039]

[0040] The installation accuracy requirements of the gusset plate are shown in the following table:

[0041] Table 2 Allowable range of gusset plate offset

[0042] Node plate thickness t(mm)

Deviation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com