Dripping arrow irrigation automatic control system, manufacturing method of dripping arrow irrigation automatic control system and dripping arrow irrigation method

An automatic control system, dripping arrow technology, applied in the field of irrigation systems, can solve problems such as excessive irrigation intensity, loss of irrigation water, uneven irrigation in planting pots, etc., and achieve the effects of good crop growth, labor-saving management, and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

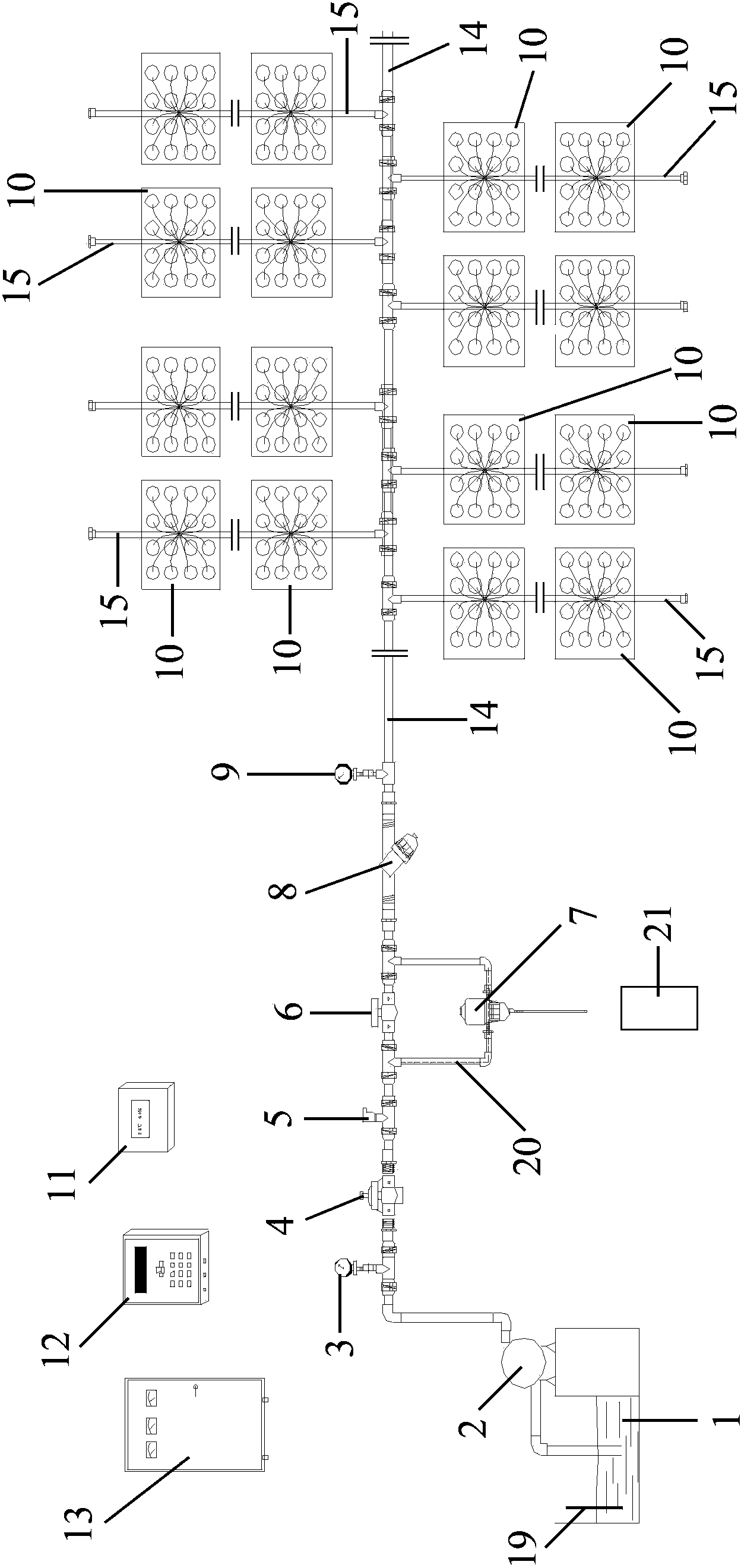

[0086] It consists of a reservoir (1), a water pump (2), a water level sensor (19), a main delivery pipeline (14), a fertilization pipeline (20), a delivery branch pipeline (15), a temperature sensor (11), a main controller ( 12), start controller (13), water intake pressure gauge (3), solenoid valve (4), intake and exhaust valve (5), fertilization control valve (6), filter (8) and water delivery pressure gauge (9 ), a reservoir (1) is set at the beginning of the main conveying pipeline (14), the reservoir (1) is box-shaped as a whole, a water level sensor (19) is arranged in the reservoir (1), and the water level sensor (19 ) is connected with the main controller (12), the water level sensor (19) is directly set in the reservoir (1), the water level sensor (19) monitors the water storage condition of the reservoir (1), and turns the reservoir ( The water level in 1) is transmitted to the main controller (12), and the main controller (12) will give an alarm if the water level ...

Embodiment 2

[0092] Fertilization conveying pipeline (20) is arranged on the initial section of conveying main pipeline (14), and the fertilization conveying pipeline (20) is U-shaped as a whole, and the two ends of fertilizing conveying pipeline (20) are installed on the fertilization control valve ( 6) On the main conveying pipeline (14) at both ends, the fertilization conveying pipeline (20) connects with the main conveying pipeline (14) to form a bypass pipeline, and the fertilizer applicator (7) is installed on the fertilizing conveying pipeline (20) The input end of the device (7) is connected to the fertilizer bucket (21), the fertilization control valve (6) is opened to communicate with the main conveying pipeline (14), the fertilization control valve (6) is closed to communicate with the fertilization conveying pipeline (20), and the water pump (2 ) to deliver the water source to the main delivery pipeline (14), the water source enters the fertilization delivery pipeline (20) from ...

Embodiment 3

[0095] A water delivery pressure gauge (9) is installed at the end of the initial section of the main delivery pipeline (14), and the water delivery pressure gauge (9) is connected to the main controller (12) through a line to transmit the digital information of the water pressure when delivering the water source .

[0096] The temperature sensor (11) is set at the dripping arrow irrigation place to monitor the temperature of the environment where the plant is located. The temperature sensor (11) is connected to the main controller (12) through a line to transmit digital information on the temperature of the environment where the plant is located, such as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com