Construction method for using layering method to construct double-curved-surface stainless steel curtain wall

A construction method and technology of hyperboloid curtains, applied in the treatment of walls, building materials, building components, etc., to achieve the effects of fast and convenient construction, accurate forming, and accurate processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

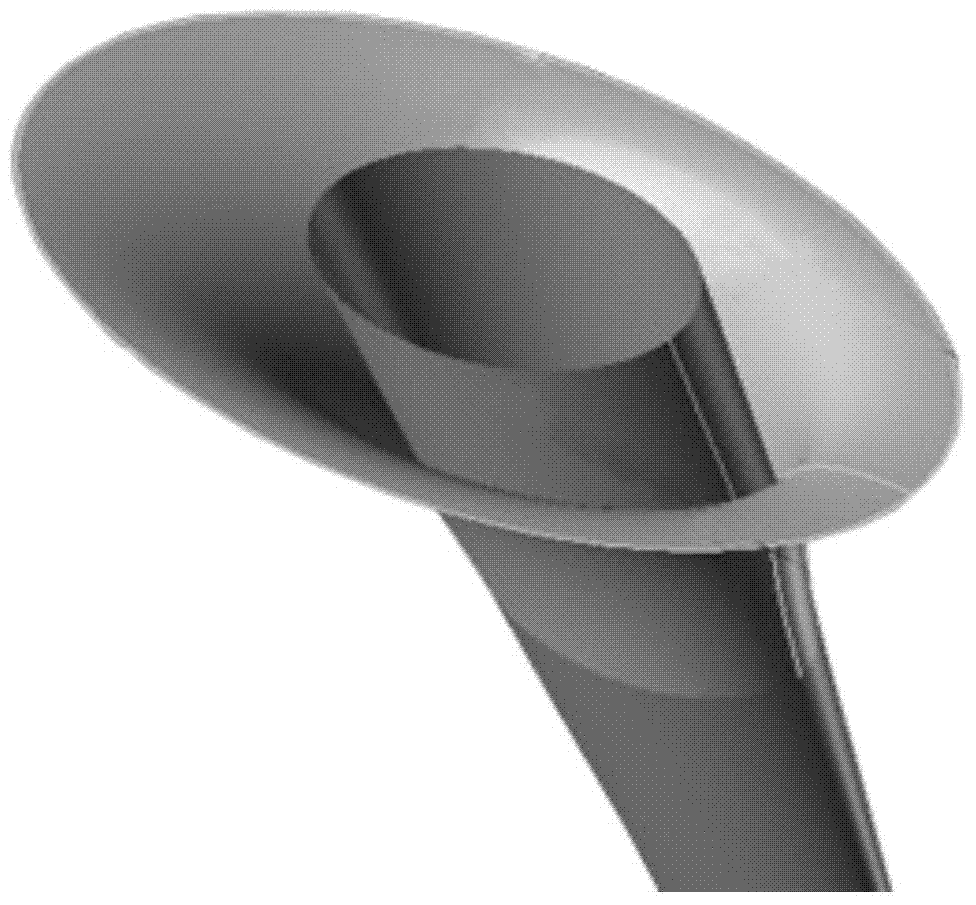

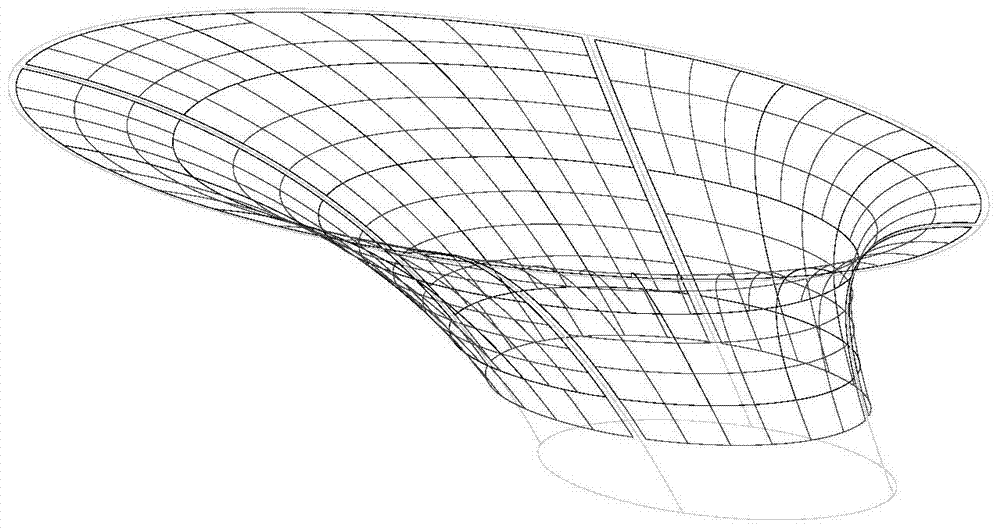

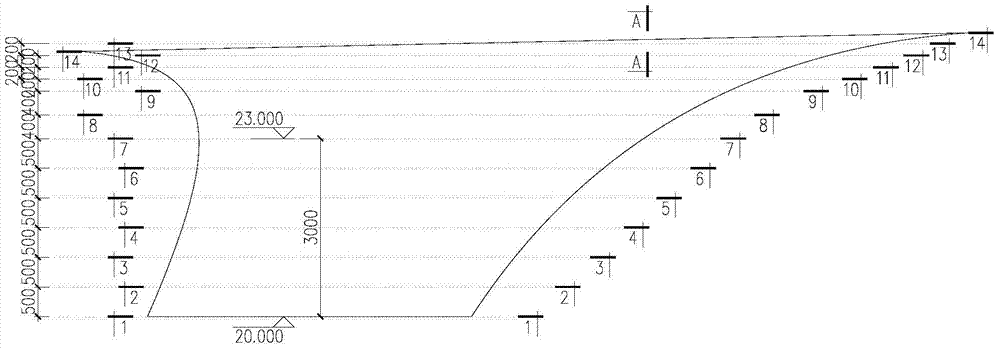

[0028] The construction method of making hyperboloid stainless steel curtain wall by layering method specifically includes the following steps:

[0029] (1) Hyperboloid stainless steel curtain wall flipping

[0030] Model establishment: AUTOCAD drawing software is used to draw a three-dimensional model of the hyperboloid curtain wall data provided by the design. This model provides technical support for the fabrication of the skin layer positioning skeleton, skin layer hoisting, and keel layer construction positioning. Through the model nodes and sections Detailed decomposition can form the construction deepening diagram of each part.

[0031] Structural decomposition: After the model is established, in order to ensure the accuracy and integrity of the curved surface of the curtain wall, according to the structure of the three-dimensional model, the hyperbolic curtain wall structure is decomposed into a skin layer and a keel layer. The skin layer is composed of stainless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com