Assembled wall plate connected by metal connecting members

A metal connector, assembling technology, applied in the field of building wall materials, can solve the problems of wall panels without connectors connected to each other, shrinkage and cracking at the joints, and the connection is not stable enough, so as to enhance the overall structural performance of the wall, It is not easy to crack, and the effect of saving materials and man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

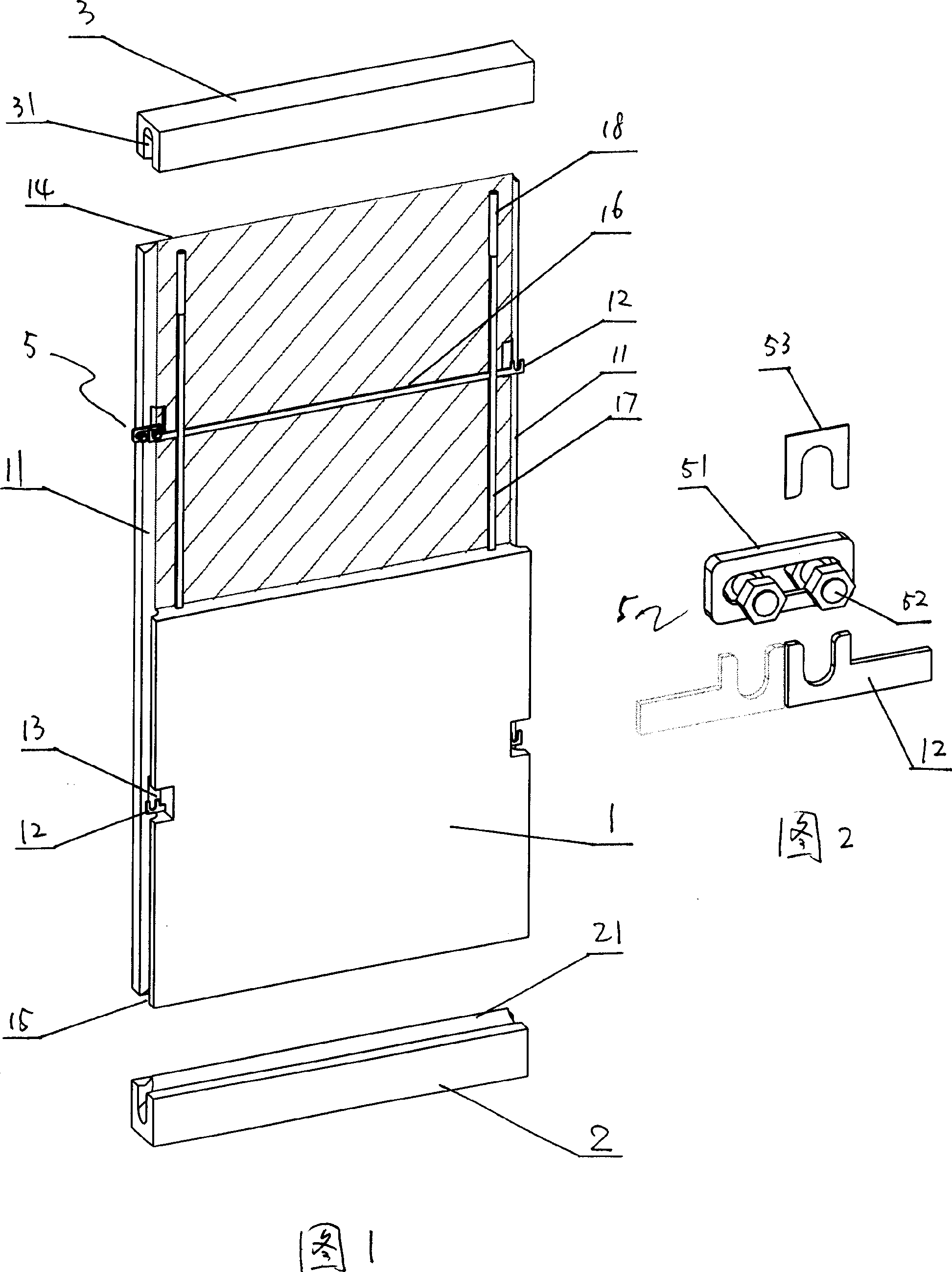

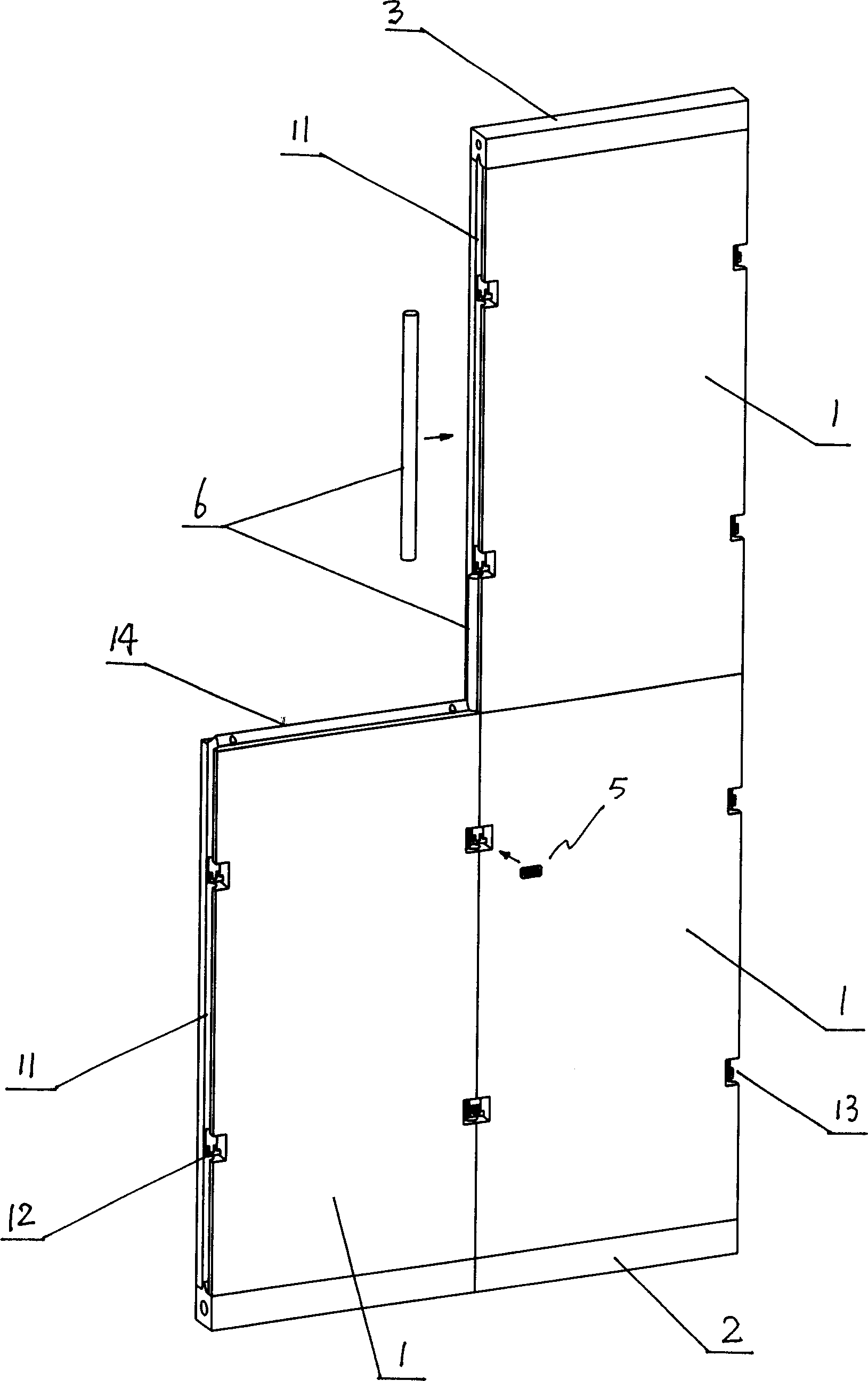

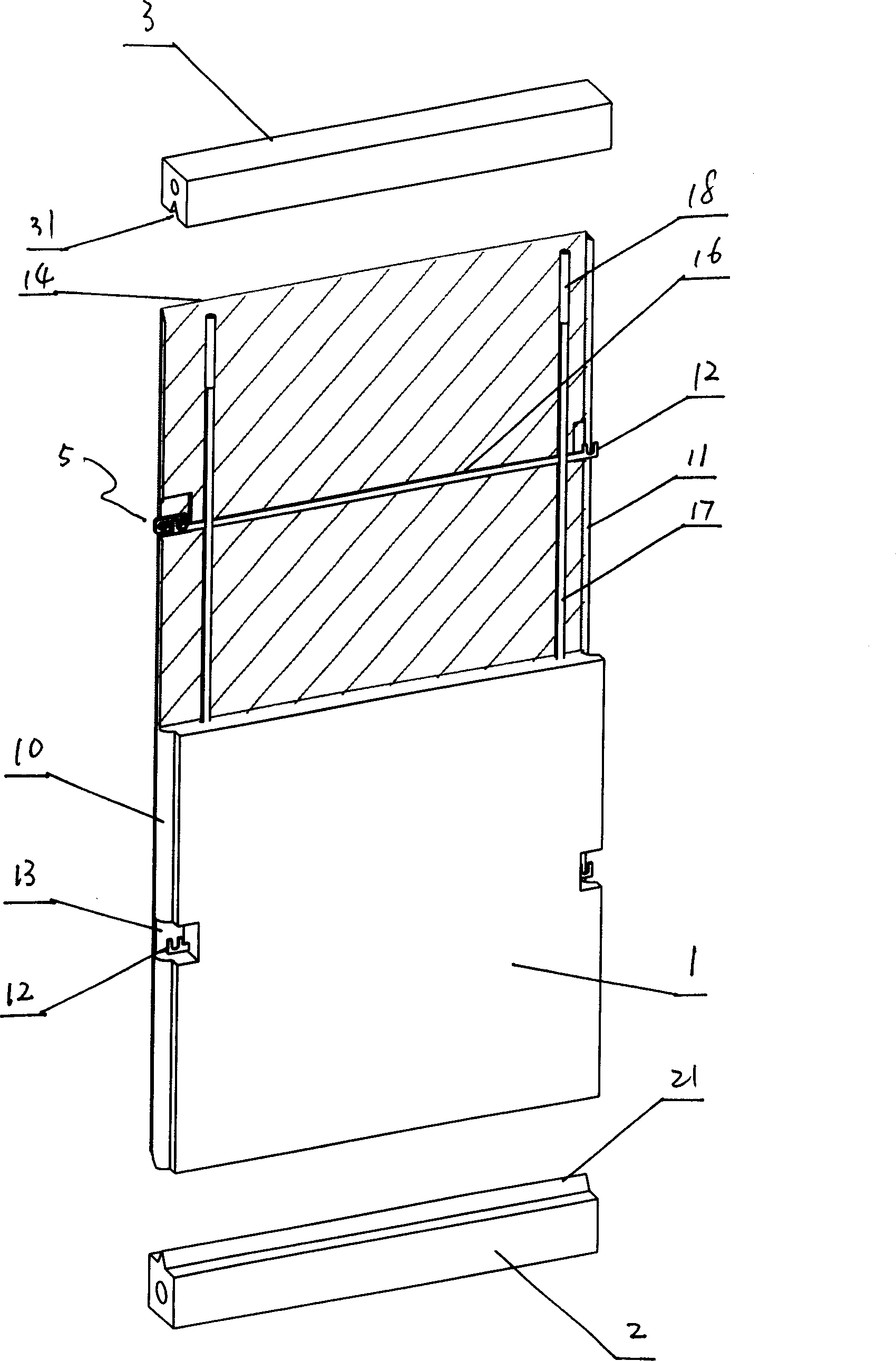

[0030] Embodiment 1, a feasible embodiment of the present invention as shown in Fig. 1 and Fig. 2 provides a kind of assembled wallboard connected by metal connectors, which includes a board body 1, an optional accessory lower support block 2 and The top block 3, the inside of the plate body 1 is provided with a steel wire grid (not shown in the figure), and it is characterized in that: the vertical sides of the plate body 1 are provided with mutually symmetrical grooves 11, and the left and right grooves 11 There are upper and lower sets of metal connectors 12 respectively (of course, it can also be one or more groups, depending on the specifications of the board body 1), and the board body 1 at the connector 12 has an operation gap 13, The metal connectors 12 located in the grooves 11 on both sides of the board body 1 are connected by the transverse stiffeners 16 penetrating through the inside of the board body 1 .

[0031] There are 2 (or more) longitudinal rib plates 17 lo...

Embodiment 2

[0044] Embodiment two, such as Figure 4 Another feasible embodiment of the present invention shown provides an assembled wall panel connected by metal connectors, which includes a panel body 1, an optional accessory lower support block 2 and a top block 3, and the interior of the panel body 1 is provided with There is a steel wire grid frame (not shown in the figure), and its feature is that the vertical sides of the plate body 1 are respectively provided with grooves 11 and flanges 10 corresponding to each other, and other components and structures are the same as in the first embodiment.

[0045] The assembly of this wallboard does not use the sealing positioning column 6, the assembly method is roughly the same as that of Embodiment 1, and the wallboard after assembly is similar image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com