Patents

Literature

77results about How to "No hollowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction method of anti-plastering putty for concrete structure wall

InactiveCN101363269AThin thickness and small weightLight weightCovering/liningsResource consumptionPutty

The invention discloses a construction method of a wall putty of a plaster-free concrete structure. The construction method comprises the following steps: construction preparation, base course treatment, concave-convex line construction, a first full application of wall putty, flattening, a second full application of wall putty and flattening. The construction method has the advantages of less workload, short construction time, little resource consumption, no hollow drum and crack of the floated coat, no crack at the joint of the primary structure and the secondary structure.

Owner:中建五局第三建设有限公司 +1

Method for making self-temperature-regulating phase-change heat-insulation wall and product thereof

InactiveCN101025037AAbility to raise room temperatureImprove the insulation effectCovering/liningsSolid waste managementFiberConstruction aggregate

The invention discloses a temperature-selfadjusting phase transition composite high temperature wall body manufacturing method, comprising: coating the wall body with temperature selfadjusting phase transition mortar, coating heat preservation putty and then coating elastic putty, and finally coating heat insulating paint, where the said temperature selfadjusting phase transition mortar is composed in weight percent of: temperature selfadjusting phase transition material 10-40%, hollow fiber material 5-35%, dispersible glue powder 8-38%, cement 12-42%, and lightweight aggregate 35-65%. And the invention provides a temperature-selfadjusting phase transition composite heat preservation wall body manufacturing method and the product. And the product has features of better heat preservation effect, high antifire performance, low wall body foundation requirements, high fastness of heat preservation layer, good decorative effect, no pollution, long service life, able to make large-area spreading and application, etc.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

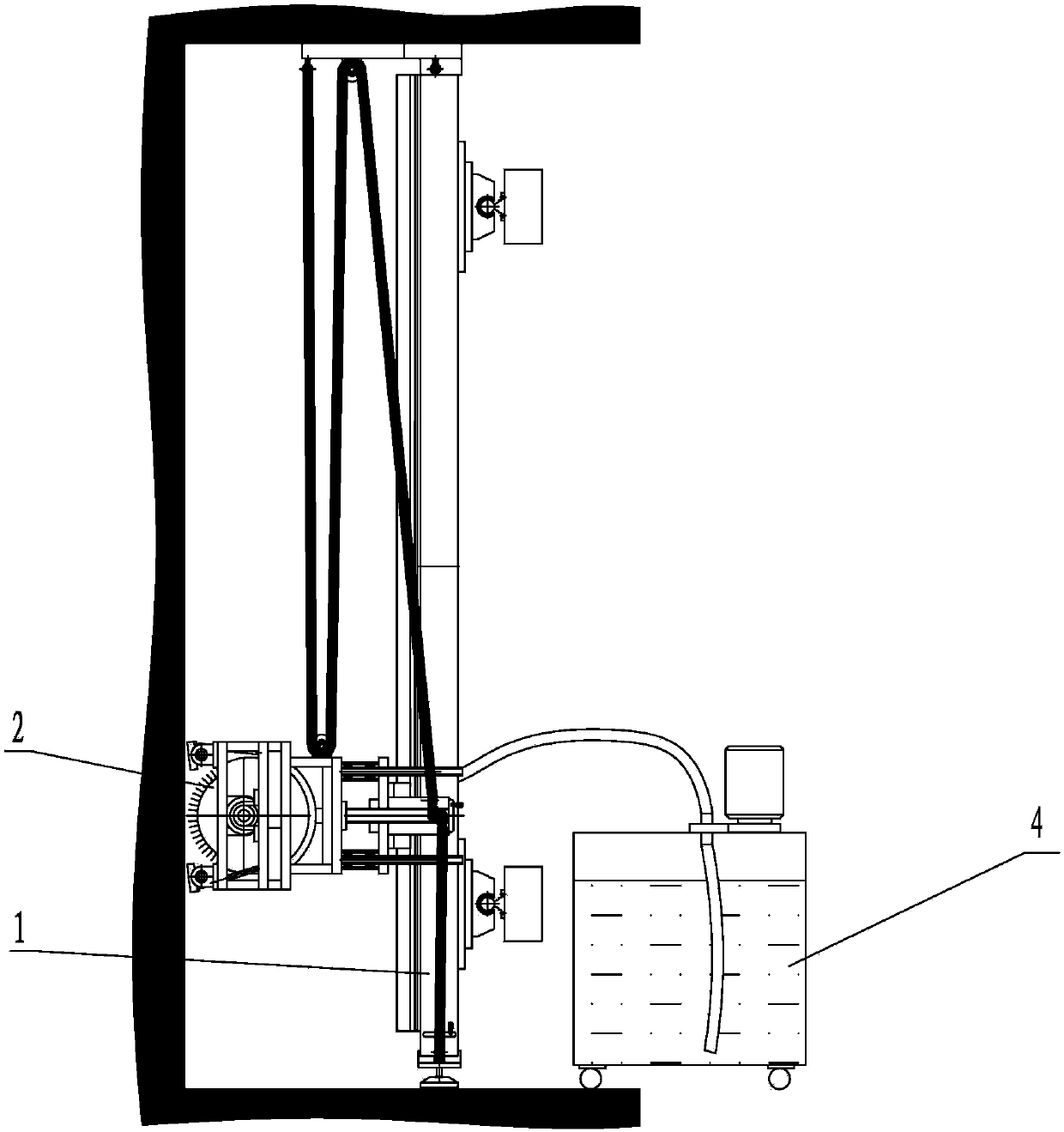

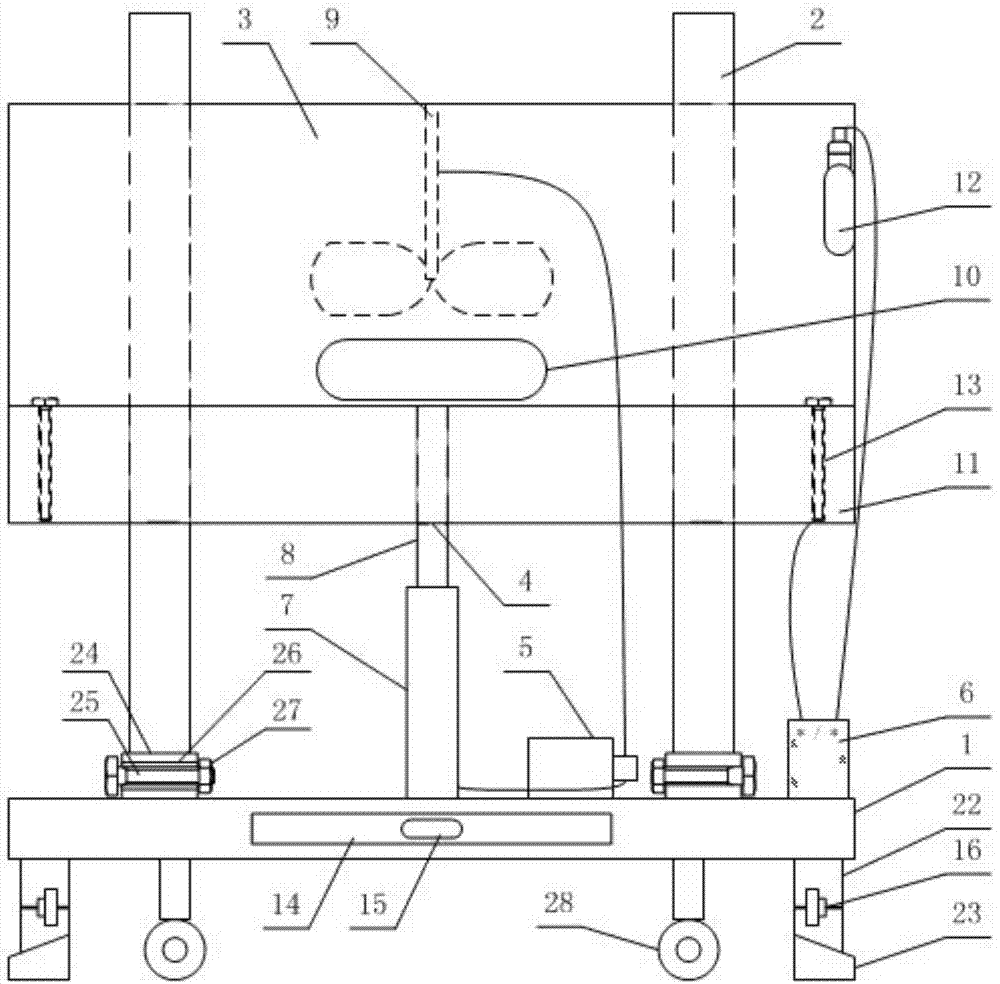

Fully automatic wall surface and shed surface spray coating grinding device

InactiveCN104563458AImprove adaptabilityImprove toleranceBuilding constructionsPlane surface grinding machinesSpray coatingFully automatic

The invention discloses a fully automatic wall surface and shed surface spray coating grinding device, which comprises a moving mechanism, a bearing installing platform and an automatic moving arm, and is characterized in that the moving mechanism adopts a manual moving mechanism or an automatic moving mechanism, a fixing plate of the bearing installing platform is arranged on a regulating bearing or a ball head of the moving mechanism, the regulating bearing or the ball head is connected onto a regulating foot driven by an electric cylinder, the electric cylinder is connected onto the bottom plate of the moving mechanism, the bottom plate is moved by the moving mechanism, the automatic moving arm is arranged on the bearing installing platform, and a spray coating device, a grasping mechanism or an anti-collision grinding dust sucking mechanism is arranged on the front end of the automatic moving arm. The fully automatic wall surface and shed surface spray coating grinding device has the advantages that the flexible splicing layout can be realized according to the room area, wall surface and shed surface coating, trowelling and whole surface flattening and putty grinding dust collection work can be simultaneously completed according to different requirements, and the problems of dust pollution and high work intensity of operators can be thoroughly solved.

Owner:董旺建

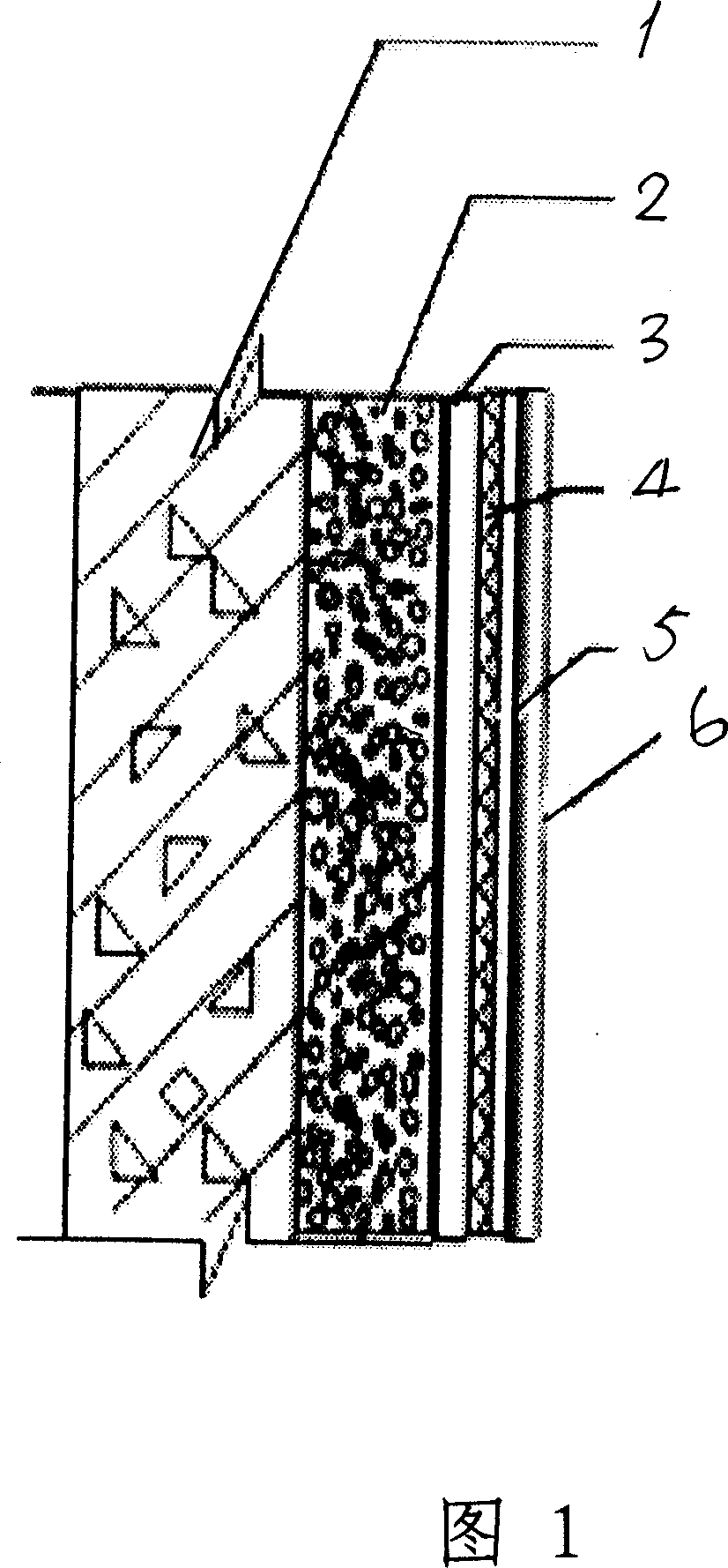

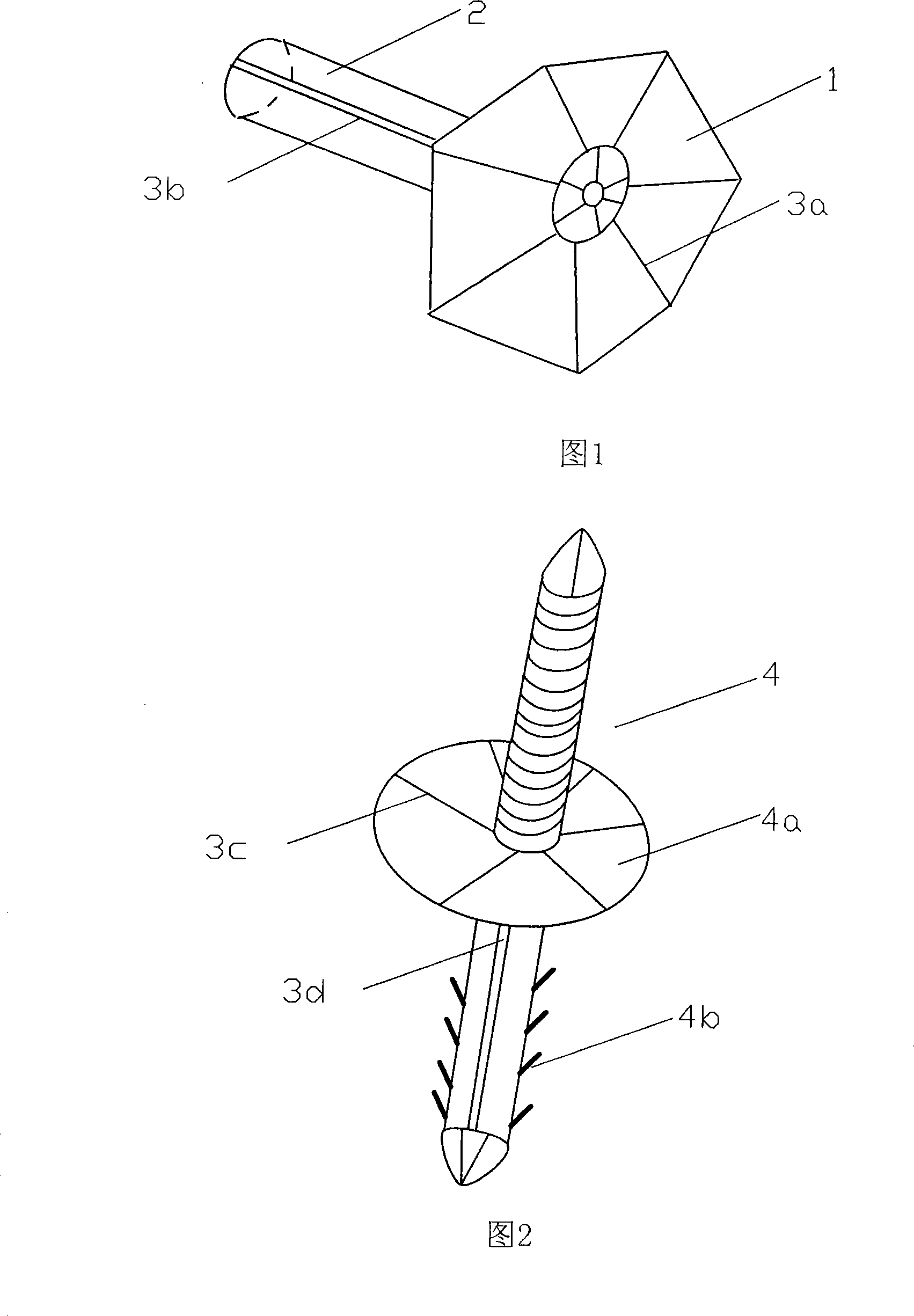

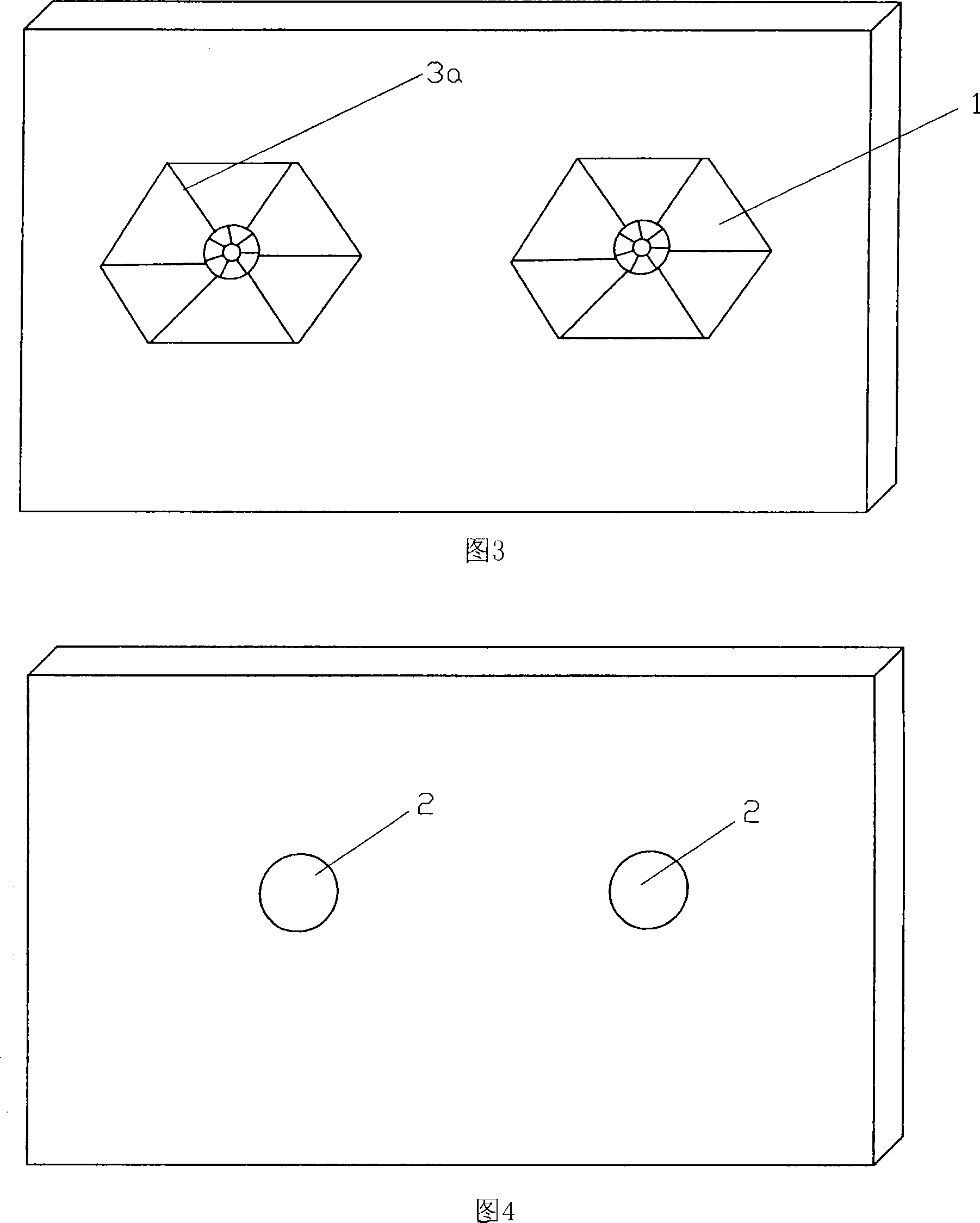

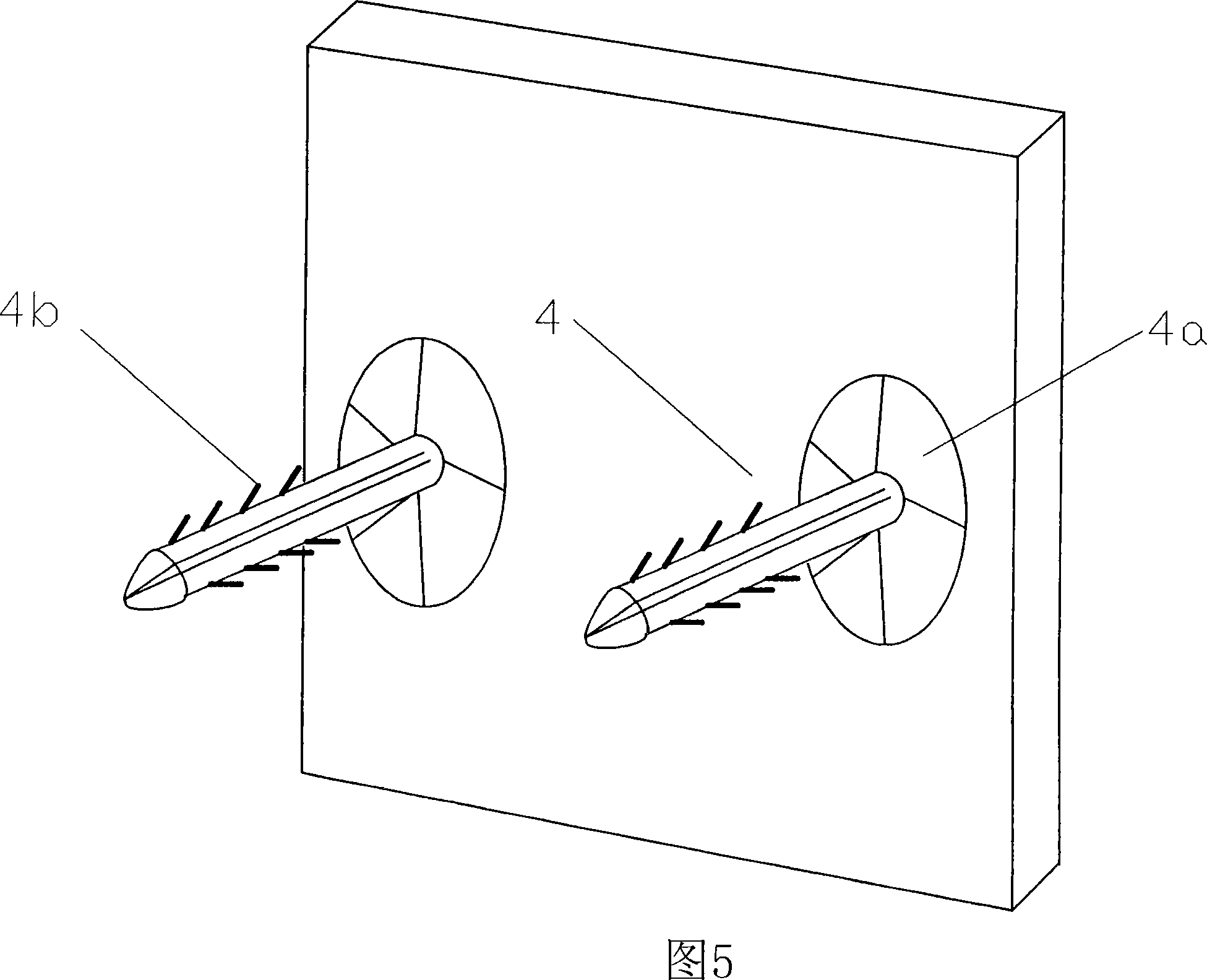

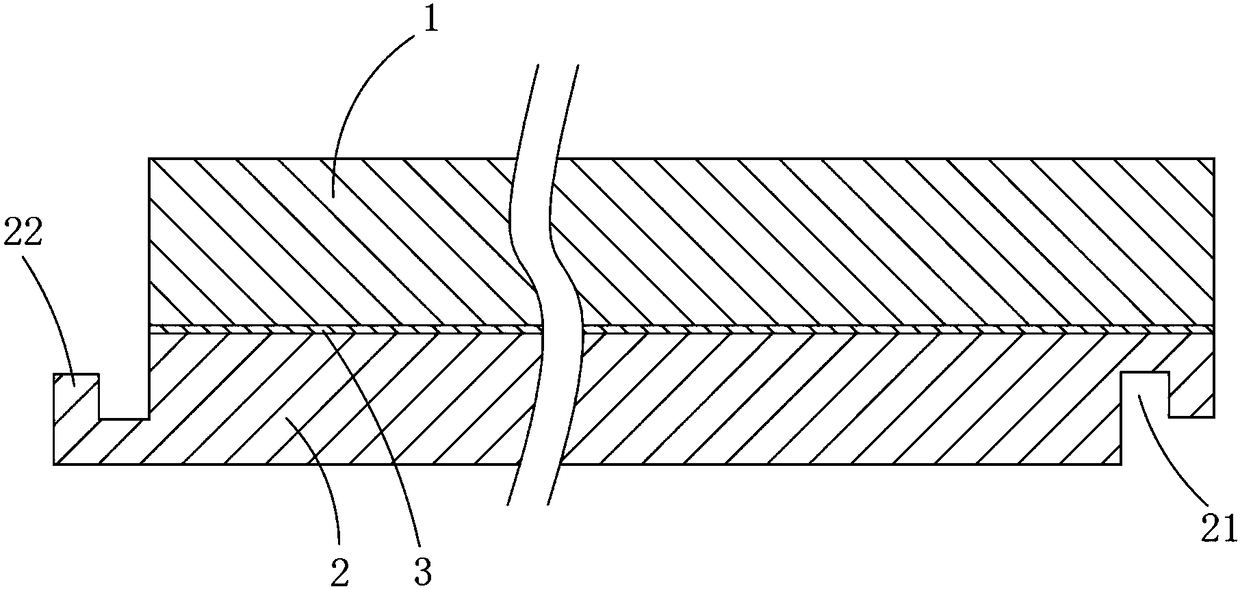

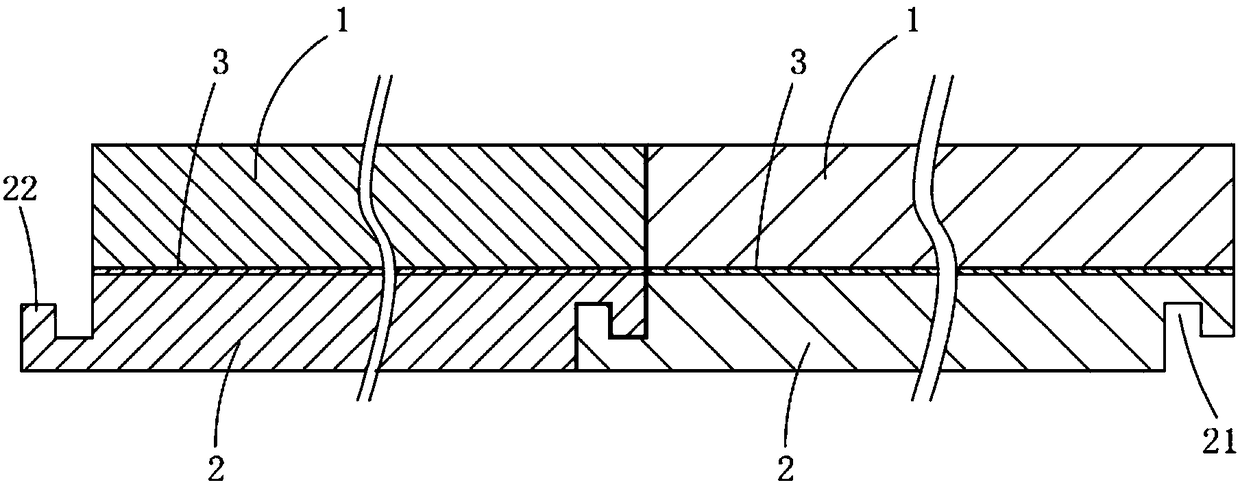

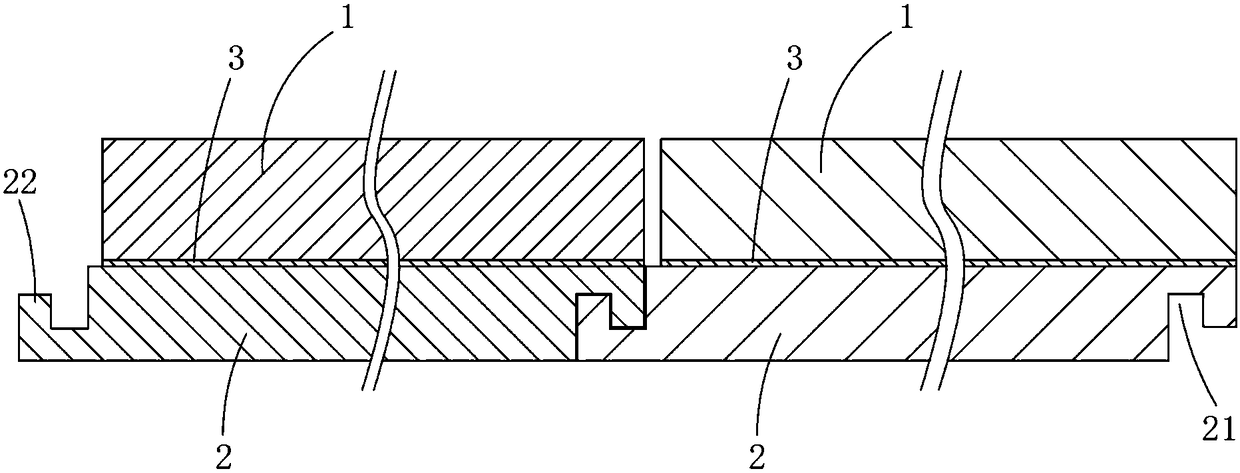

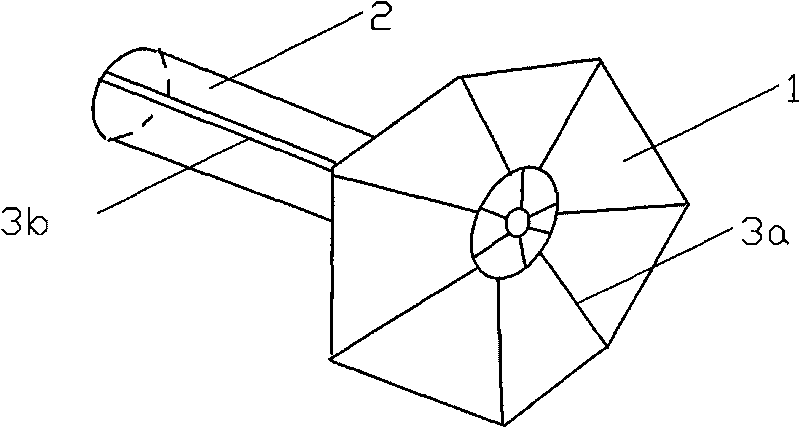

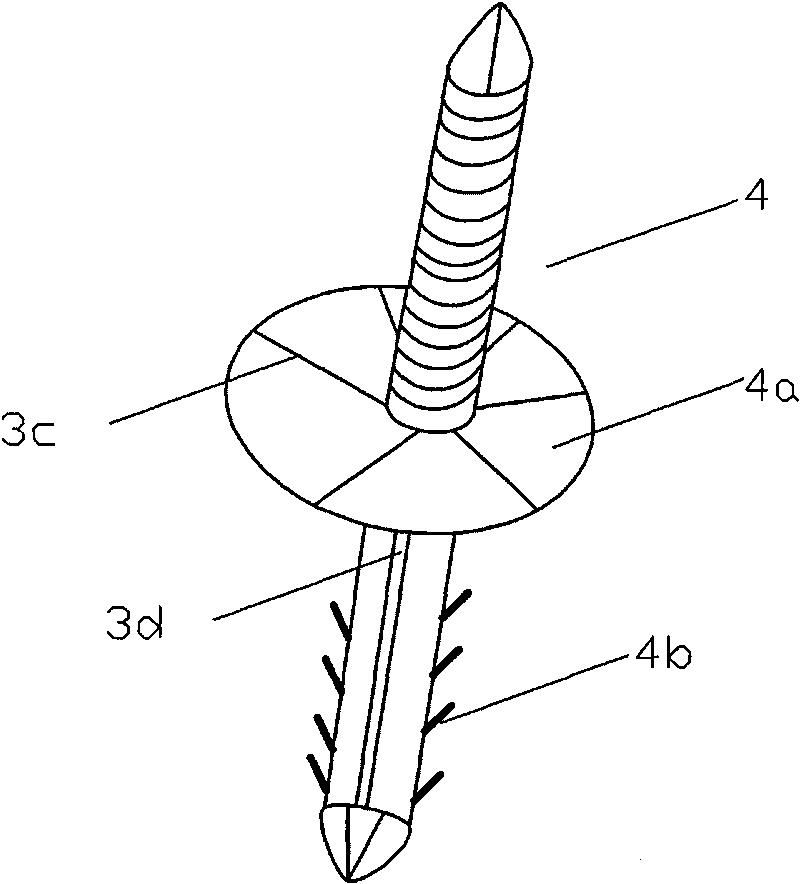

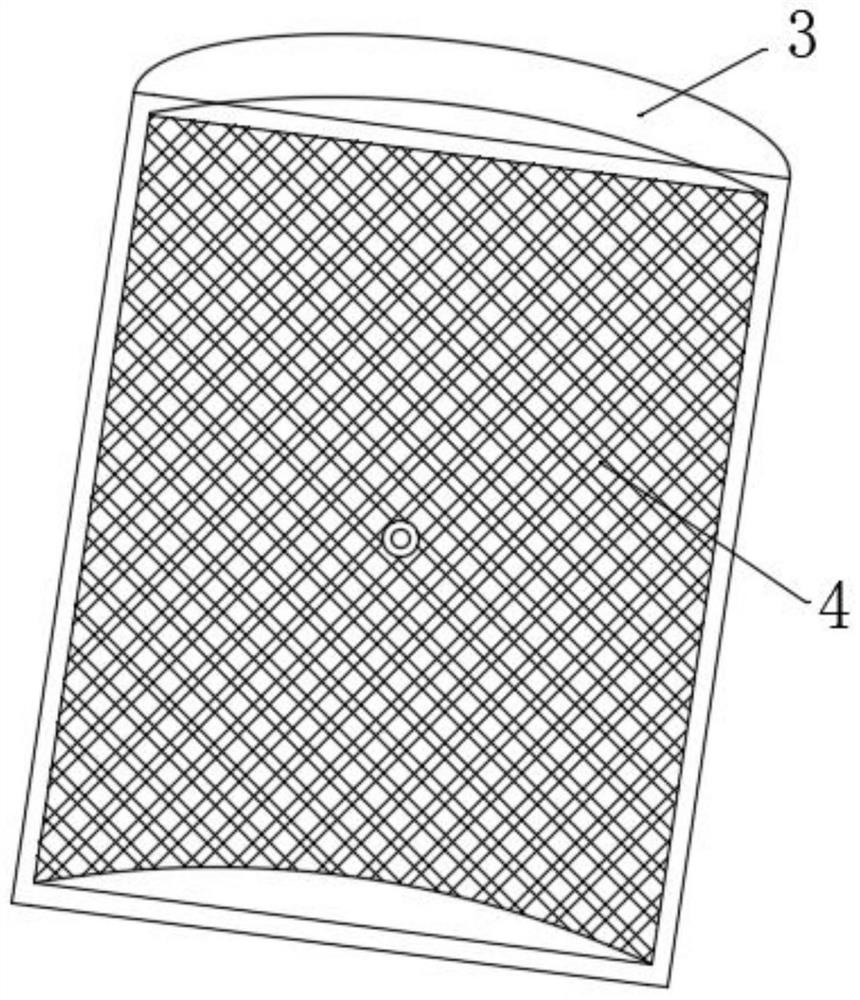

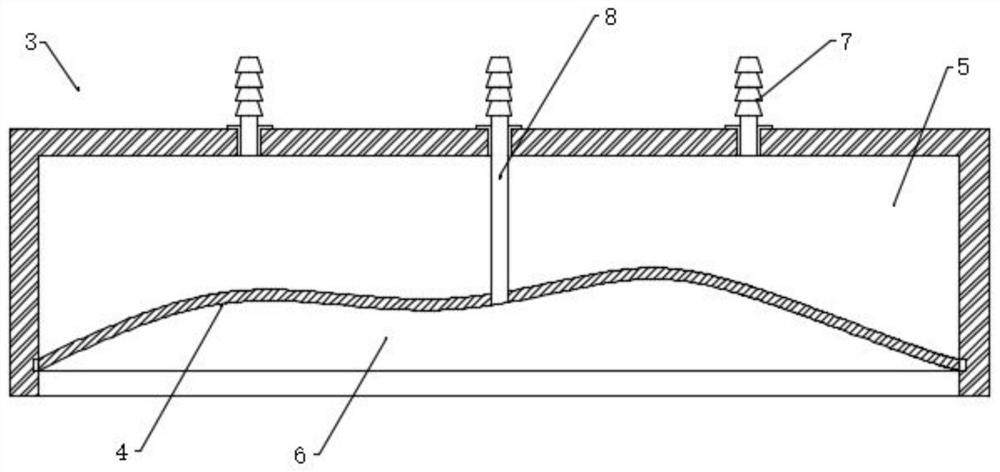

External wall heat insulation decorative board concealed anchor bolt and integral quick-mounting board for external wall heat insulation and decoration

The invention discloses an invisible anchor bolt of an external wall insulating decoration plate and an external wall insulating decoration integration packaged plate. The invisible anchor bolt comprises an inner tabletting with a column-shaped presser foot and a fastener, and the inner tabletting is embedded and inserted in a heat-insulating board, the pressure foot is an inner screw thread, one end of the fastener with an outer screw thread is connected with the pressure foot, and the outer wall of the other end is provided with a barb which is inserted in a mounting hole of the wall body, and the waist portion is provided with an outer tabletting which is vertical with the fastener, when the fastener is tightly screwed on the pressure foot, the outer tabletting is tightly clung on the surface of the packaged plate. The external wall insulating decoration integration packaged plate comprises a heated board whose inner surface is tightly clung on the wall body, and an alkali-fast break fiber web checked cloth layer and a decoration layer which are adhered on the outer surface of the plate one by one, the inner tabletting with the pressure foot are embedded into the heated board, and the surface of the pressure foot and the inner tabletting are all fell into the heated board, and the pressure foot is provided with an inner screw thread which is connected with the fastener. The invention has the advantages of simple structure, beauty and firmness, convenient transporting, and fast assemblage, which achieves a possibility of the industrialized production of external wall insulating decoration packaged plate.

Owner:合肥乐千年涂料有限公司

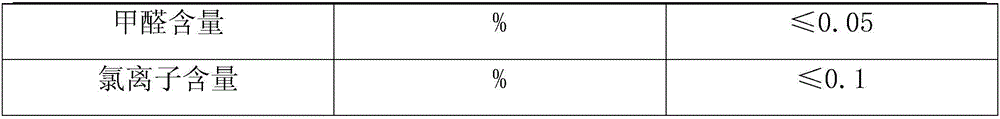

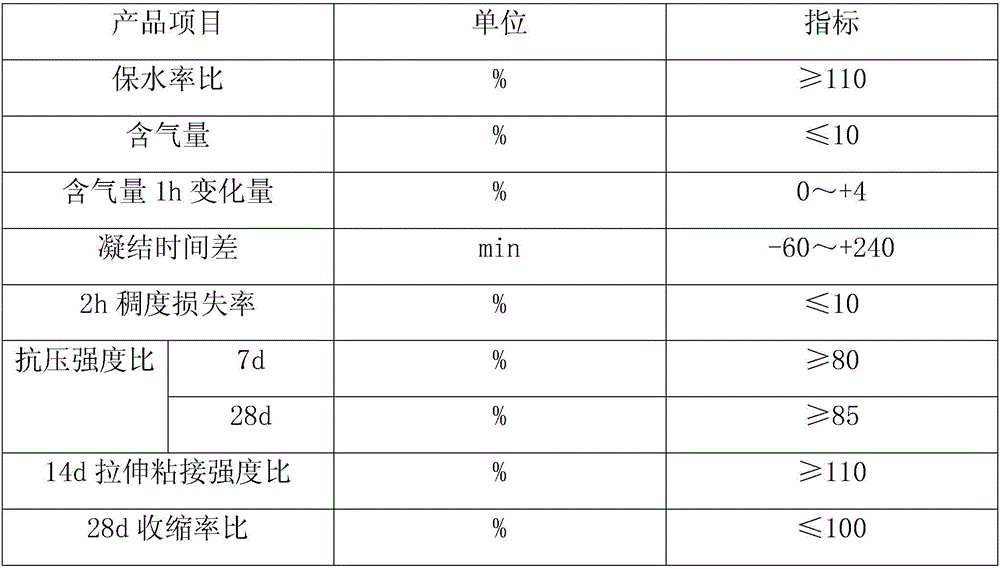

Efficient-spraying type dry-mixing and wet-mixing mortar plasticizer composition as well as preparation method and application method thereof

The invention discloses an efficient-spraying type dry-mixing and wet-mixing mortar plasticizer composition as well as a preparation method and an application method thereof. The composition comprises the following components in percentage by weight (100% in total): 1%-5% of a plasticizer, 15%-30% of a thickening agent, 30%-50% of a retarder, 10%-25% of an anti-cracking agent, 1-5% of a water-retaining agent, 5%-10% of an enhancer, and 1%-5% of a binding agent. By utilizing the composition, the workability, water-retaining property, adhesive property and cracking resistance of coating mortar can be remarkably improved, the cracking, hollowing and falling of the mortar are avoided, and various performance indexes such as the strength and permeability resistance of the mortar can be improved; and furthermore, cement can be saved, and the disadvantages of easiness in ash blasting, high shrinkage, low strength and the like of the cement mixed mortar are overcome.

Owner:四川巨星新型材料有限公司

Gypsum heat preservation painting mortar construction process

The invention relates to a gypsum heat preservation painting mortar construction process which comprises the steps that firstly, a base-layer wall is processed; secondly, according to the smoothness and perpendicularity of the surface of the base-layer wall, one wall is used as the datum, and a perpendicular square-setting elastic control line is hoisted; thirdly, gypsum bases are painted with mortar and used as angle beads; fourthly, the gypsum bases are painted with mortar and used as ash cakes and punching ribs; fifthly, gypsum heat preservation painting mortar is sprayed; sixthly, the gypsum heat preservation painting mortar is flattened and compacted, wherein the step of hanging nets on the junctions of different materials is further included between the second step and the third step; in the fourth step, after the ash cakes are manufactured and hardened, distribution cakes are manufactured and arranged through flax threads by controlling the ash cakes, so that the horizontal spacing between all the distribution cakes is not larger than 1500 mm; the steps of rib grinding and rib alignment are further included between the fourth step and the fifth step. Compared with the prior art, the gypsum heat preservation painting mortar construction process has the advantages that construction is convenient, plastering, scraping and repair are easy, the labor intensity is low, material consumption is lowered, the construction period is shortened, and construction cost is saved.

Owner:SHANGHAI LONGZHEN CONSTR ENG CO LTD

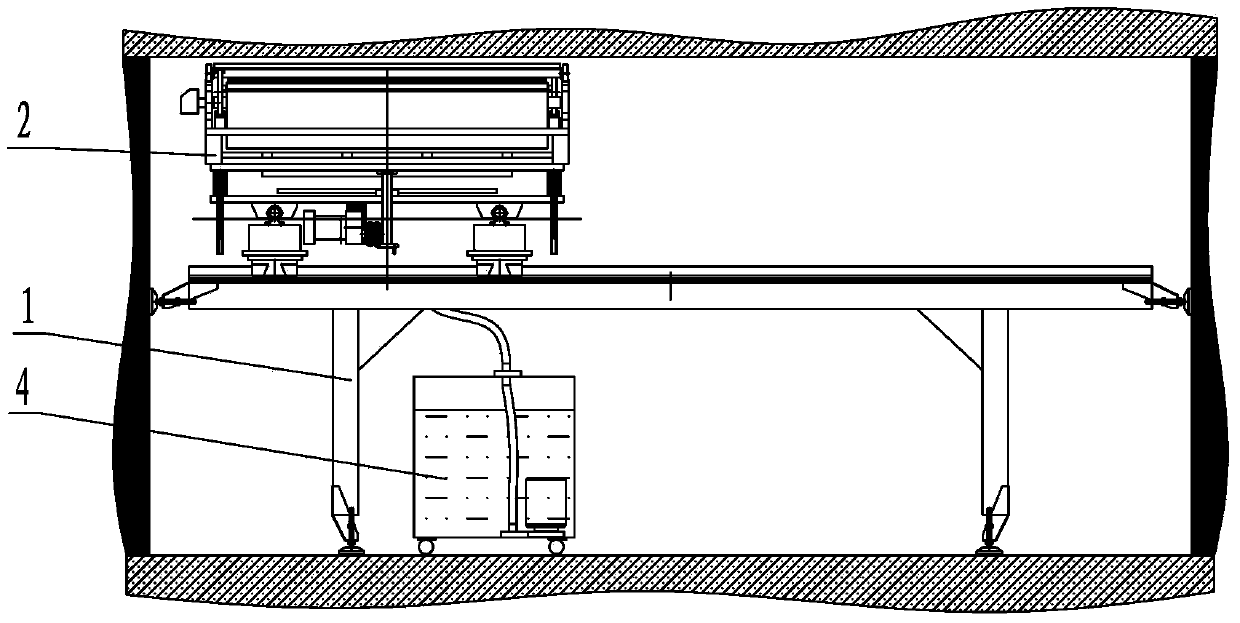

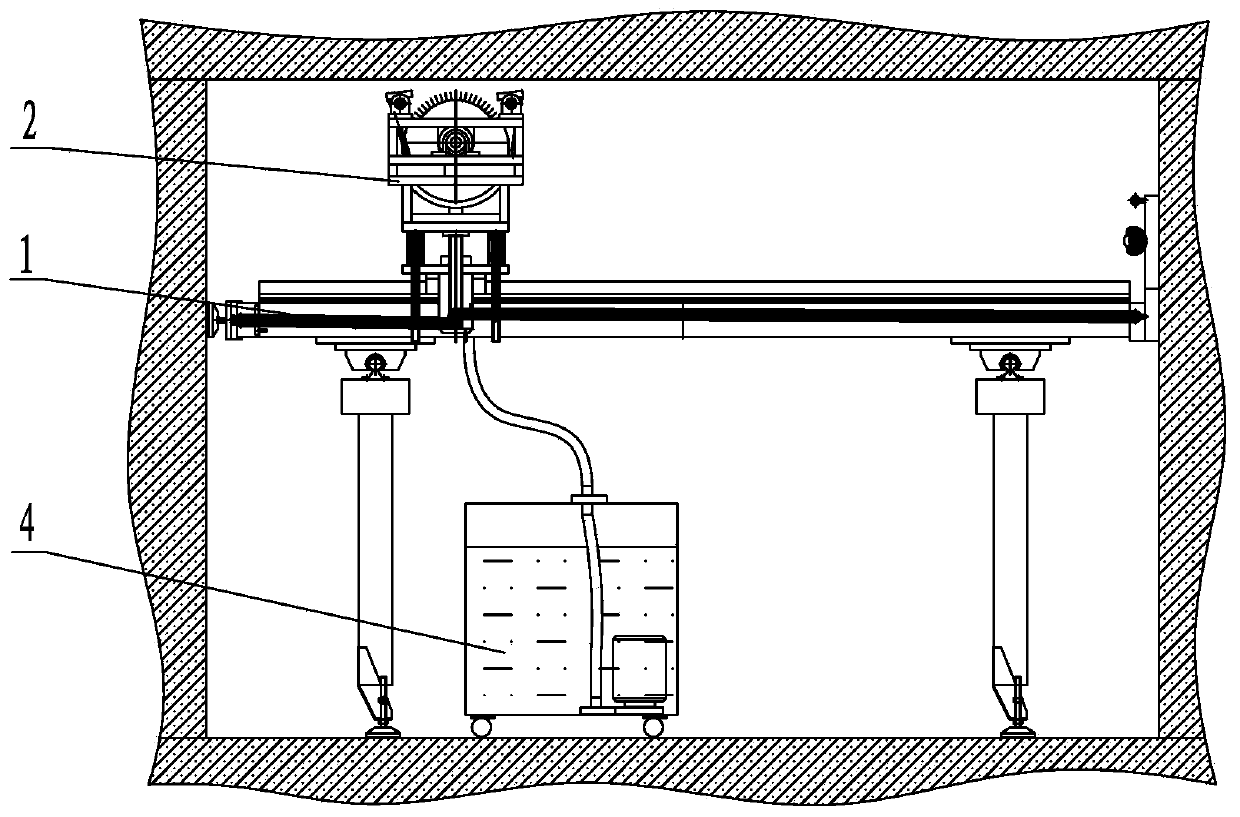

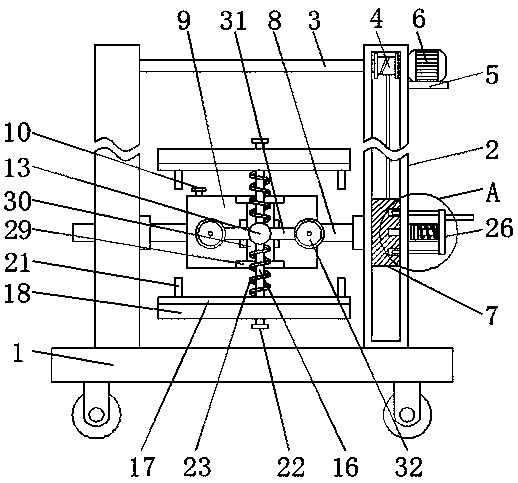

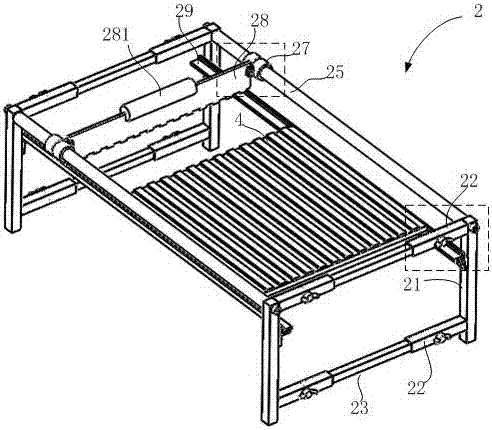

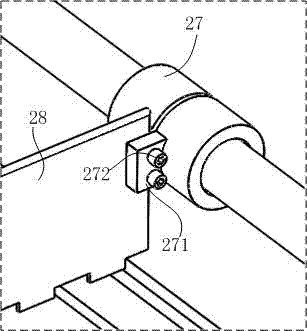

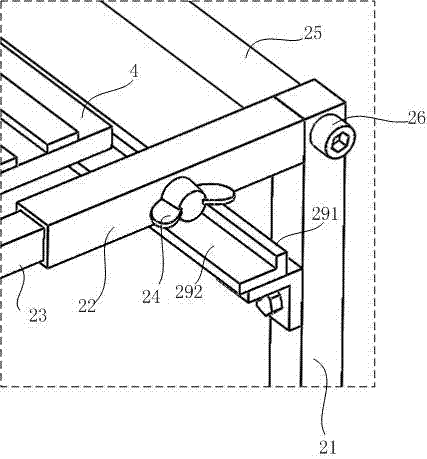

Module assembly-type wall surface and shed surface coating, screeding and polishing device

InactiveCN104047416AImprove adaptabilityImprove toleranceBuilding constructionsEngineeringUltimate tensile strength

The invention belongs to the field of building and relates to a wall surface and shed surface coating, screeding and polishing device, in particular to a module assembly-type wall surface and shed surface coating, screeding and polishing device. The module assembly-type wall surface and shed surface coating, screeding and polishing device aims to solve the problems that an existing wall wiping device cannot conduct coating, floating, polishing and dust collecting at the same time on a wall surface and a shed surface, operation is complex and inflexible, and the work intensity of operators is enhanced. A transversely-moving sliding rail unit is composed of two second rails arranged in parallel side by side and is installed on the upper face of a fixed sliding rail unit. A traveling lifting bracket mechanism is installed on the transversely-moving sliding rail unit. A splashing-type coating and screeding mechanism and a polishing and dust collecting mechanism are installed on the traveling lifting bracket mechanism in an alternate mode and can be connected with a material supplying and dust collecting mechanism in an alternate mode. The lower surface of a first rail of the fixed sliding rail unit is provided with a plurality of supporting uprights provided with adjusting supporting feet at the bottoms.

Owner:哈尔滨佳饰达科技开发有限公司

PTB (Phenacyl Thiazolium Bromide) waterproof ventilated type aerated concrete block surfactant and use method thereof

InactiveCN101823861AReduce the possibilityHave the ability to deformSolid waste managementCeramicwareEconomic benefitsSURFACTANT BLEND

The invention relates to a waterproof ventilated type aerated concrete block surfactant which simultaneously has better adhesive property, moisture retention property, waterproof property, weather resisting property and air permeability, can solve the difficult problem bothering people for a long time in the application of aerated concrete blocks, is suitable for large-scale popularization and application and has remarkable economic benefit.

Owner:福建康波力特阳光建材有限公司

Tile fixing machine capable of preventing hollowing and large vertical flatness errors

InactiveCN108560889ANo hollowingImprove paste qualityBuilding constructionsArchitectural engineeringEngineering

The invention relates to the technical field of building equipment and discloses a tile fixing machine capable of preventing hollowing and large vertical flatness errors. The tile fixing machine comprises a base, wherein support pipes are fixedly connected to two sides of the top of the base, the top ends of the two support pipes are movably sleeved with a rotating shaft, two ends of the rotatingshaft is fixed sleeved with reels which are located in the two support pipes, a support plate is fixedly connected to the top of the side surface of one support pipe, and a driving motor is fixedly mounted at the top of the support plate. According to the tile fixing machine, a tile is adsorbed through a suction disc, two sides of the tile are clamped through tension forces of two second tension springs, cement mortar is added to the tile, and the cement mortar on the tile is paved to be level with one ends of side plates on two sides and is uniformly distributed, so that a hollowing phenomenon is avoided after the tile is fixed to a wall, and the adhesion quality of the tile is improved.

Owner:北京鼎翰科技有限公司

Production formula and process for real stone paint

InactiveCN105219197APerformance is not affectedImprove performanceCoatingsCelluloseHydroxyethyl cellulose

The invention provides a production formula and process for a real stone paint. The production process comprises the following steps: (1) adding water into a stirring machine according to proportions of the formula at first; (2) starting the stirring machine, slowly adding hydroxyethyl cellulose and bentonite into the stirring machine, stirring, then adding a conditioning agent, and further stirring until white viscous emulsion is stirred out; (3) sequentially adding silicone acrylic emulsion, glycol, a coalescing agent, a preservative and color sand into the white viscous emulsion while stirring; and (4) after stirring the materials in the step (3) uniformly, adding a thickening agent, and stirring uniformly to obtain a finished product. The produced product is relatively strong in cohesive force and relatively high in minimum film forming temperature, thereby fundamentally solving the problems of too soft coating layers and the like; and the product is simple in production process, low in cost and excellent in performance, cannot fall off easily, does not have potential safety hazards, is strong in decorativeness and wide in applicable range, is aqueous and environment-friendly, is good in pollution resistance and long in service life, and is economical and cost-effective.

Owner:赵彬

Method for constructing wear-resistant and crack-resistant hardened ground

InactiveCN101886457AImprove bonding fastnessShorten construction timeFlooringCement slurryWear resistant

The invention discloses a method for constructing wear-resistant and crack-resistant hardened ground, which is applied to hardened ground of buildings such as modern industrial factory buildings, shopping malls, exhibition buildings, indoor parking lots, warehouses and the like. The method sequentially comprises the following steps of: brushing slurry on the surface of a base layer, namely watering to wet and clean the base layer and uniformly brushing a layer of 801 glue-doped cement slurry on the surface of the base layer; pouring, compacting and trowelling a polypropylene fiber concrete floor with the thickness of 50mm, removing bubbles and free water from the polypropylene fiber concrete by using a vacuum water absorption device, and removing laitance on the surface of the concrete after the concrete is initially set; laying a hardened wear-resistant layer and trowelling for 1 to 2 hours; calendaring by using a trowelling machine; and spreading a layer of BZK-15 surface liquid molded concrete curing agent to cure the ground. The hardened ground poured by the construction method has the characteristics of high durability, permeability resistance and crack resistance, and low construction cost.

Owner:中利建设集团有限公司

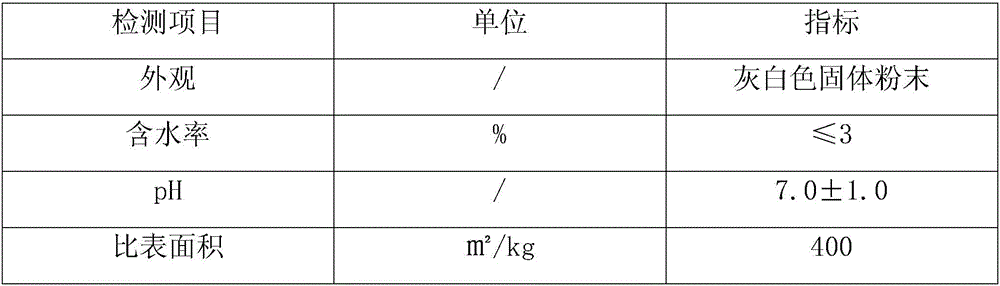

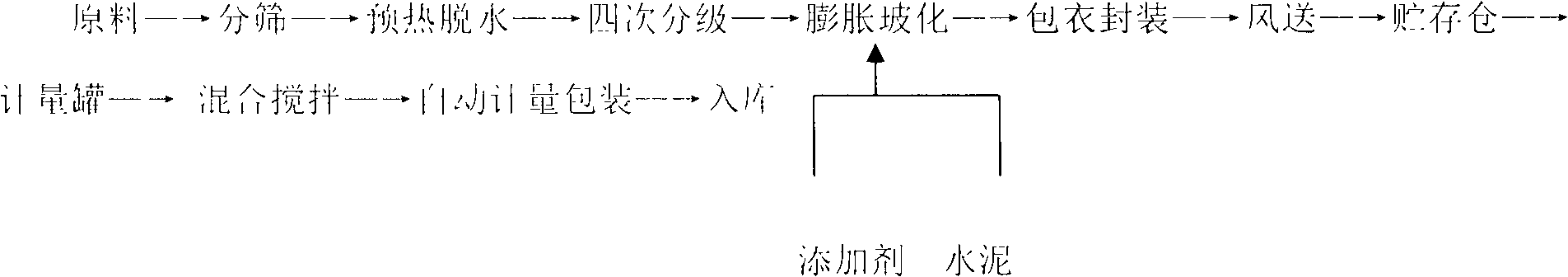

Phosphogypsum non-sintered ceramsite light aggregate and preparation method thereof

ActiveUS20210163353A1Reduce energy consumptionLow bulk densitySolid waste managementPhysical chemistryPhosphogypsum

A phosphogypsum non-sintered ceramsite light aggregate composed of water and a mixture composed of phosphogypsum, mineral powder and cement. Raw materials of the mixture have weight percentages of phosphogypsum 80-90%, mineral powder 3.3-10%, cement 6.5-10%; the water has a weight of 17% of the total weight of the mixture. A method of preparing the phosphogypsum non-sintered ceramsite light aggregate. The phosphogypsum non-sintered ceramsite light aggregate is prepared by modification, granulation, curing, crushing, sieving and other processes by using phosphogypsum as a main material, cement as an alkaline activator, mineral powder as an active material.

Owner:HUBEI CHANG YAOXIN MATERIALS LIMITED BY SHARE

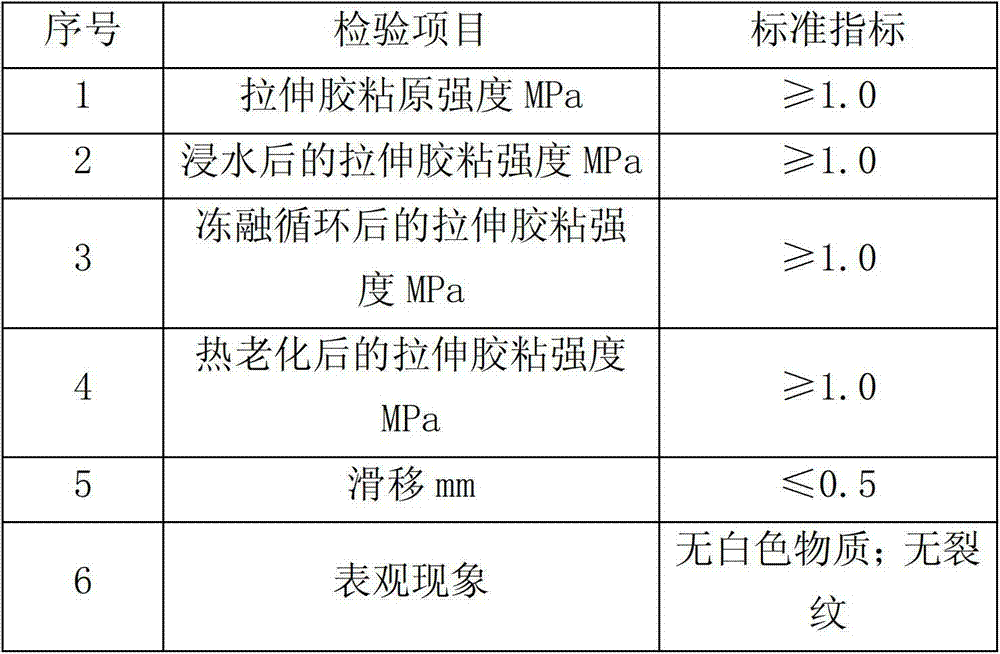

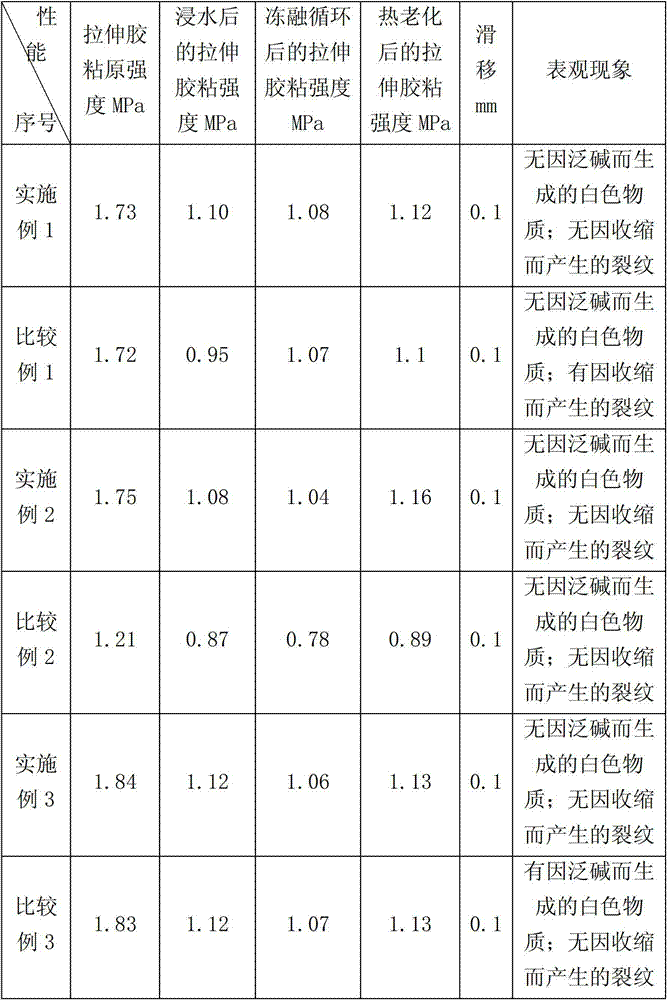

Tile glue for ceramic thin plate

The invention discloses tile glue for a ceramic thin plate. The tile glue for the ceramic thin plate comprises the following components in percentage by weight: 20 to 32 percent of silicate cement, 40 to 48 percent of quartz sand, 0.8 to 6.4 percent of concrete expanding agent, 0.8 to 4 percent of dispersible latex powder, 0.08 to 0.48 percent of cellulose ether, 0.08 to 0.8 percent of early strength agent, 0.08 to 0.48 percent of thixotropic lubricant, 0.08 to 0.8 percent of wood fiber, 0.08 to 0.48 percent of water repellent, 0.08 to 0.48 percent of anti-whiskering agent and 16 to 24 percent of emulsion. The tile glue for the ceramic thin plate is energy-saving and environmentally-friendly, has excellent performance, can inhibit contraction, prevents cracking, avoids hollowing and has the advantages of slippage resistance, whiskering resistance, low water absorption, high wear resistance and the like.

Owner:能高共建(北京)新型建材有限公司

Fireproof moisture-proof easily-laid environmentally-friendly ceramic tile with locking buckles and production method

InactiveCN108442645APaving is simple and convenientPaving is simple, fast and convenientFlooring insulationsTemperature resistanceMoisture

The invention discloses a fireproof moisture-proof easily-laid environmentally-friendly ceramic tile with locking buckles and a production method. According to the production method of the environmentally-friendly ceramic tile, a waterproof substrate layer is composited on the back surface of a ceramic tile body layer by a pressing overlaying process or an in-mold forming process. The environmentally-friendly ceramic tile comprises the ceramic tile body layer located on the upper layer, the waterproof substrate layer is composited on the bottom surface of the ceramic tile body layer, a clamping slot or a clamping tenon is formed in the side surface of the waterproof substrate layer, and the clamping slot and the clamping tenon are connected with each other in a clamped and matched mode, sothat every two environmentally-friendly ceramic tiles can be assembled and connected together. The fireproof moisture-proof easily-laid environmentally-friendly ceramic tile has simple structure, thewaterproof substrate layer enables the environmentally-friendly ceramic tile to have high temperature resistance, fireproof, moisture proof and waterproof functions, and the environmentally-friendlyceramic tile is directly laid on the ground during laying; during the laying process, the clamped connection is directly achieved by the clamping slot or the clamping tenon, and the clamped connectionis simple and convenient; the environmentally-friendly ceramic tile is automatically leveled by the waterproof substrate layer, and no hollowing phenomenon exists; and after the laying, the laid environmentally-friendly ceramic tile can be used without brushing the ground or pre-filling or flattening cement sand, and the ceramic tile laying is simpler, faster and more convenient.

Owner:郑素梅

Heat insulation board capable of blocking hot and cold bridge, and preparation method thereof

The invention relates to the field of building materials, and particularly relates to a heat insulation board capable of blocking hot and cold bridge, and a preparation method thereof. At present, heat insulation materials used for outer walls are not ideal. The technical solution adopted by the invention is as follows: raw materials comprise, by weight, 40-45 parts of cement, 8-35 parts of redispersible rubber powder, 0.1-0.5 parts of cellulosic fiber, 10-15 parts of polyphenyl particles, 20-25 parts of fly ash, 5-10 parts of defoaming stone, 1-5 parts of light calcium carbonate, 1-5 parts of heavy calcium carbonate, 10-15 parts of a heat insulation material and 20-50 parts of expanded glass beads. The raw materials are distributed for three times and shaped in one time. The heat insulation board has the following beneficial effects of good flame retardant performance, incombustiblity, good heat insulation effect, good cohesiveness and high strength. Due to the board shape, the heat insulation board is convenient for construction and use, is reasonable in price, has the same service life with buildings, is suitable for being used by outer wall surfaces of various buildings, and has good economic benefits and social benefits.

Owner:陕西亿丰绿色建筑材料有限公司

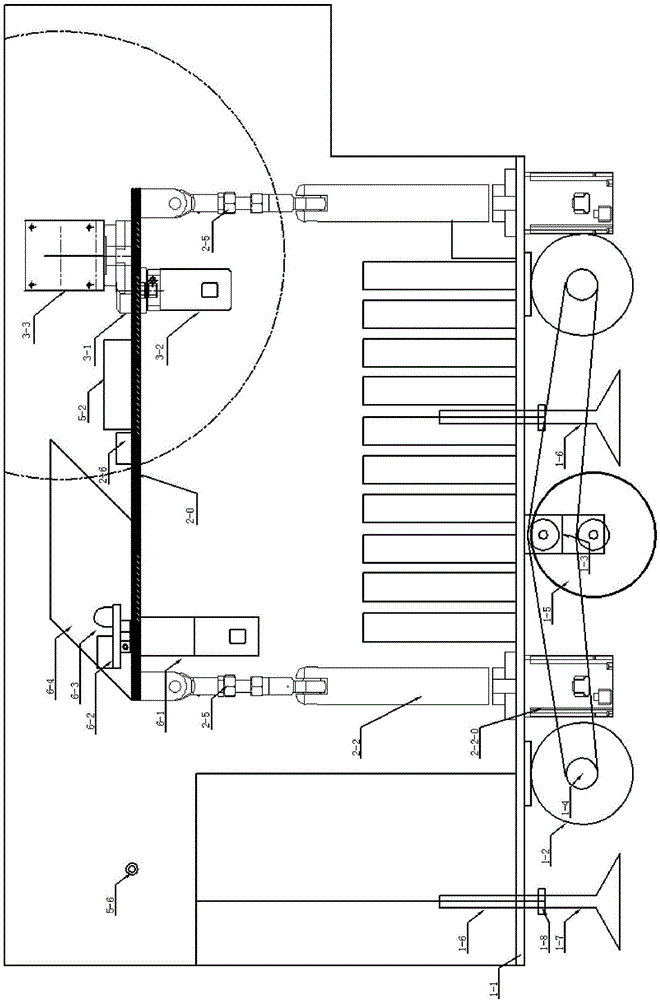

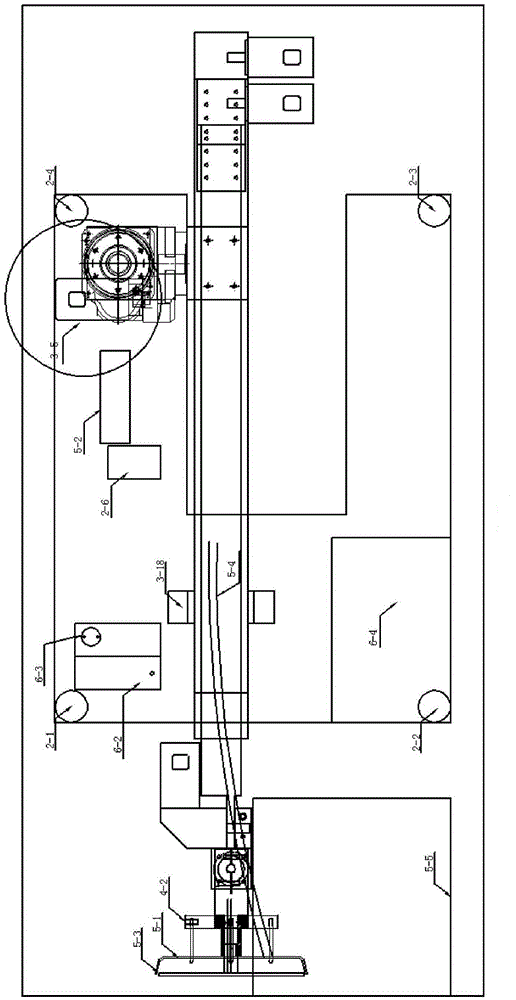

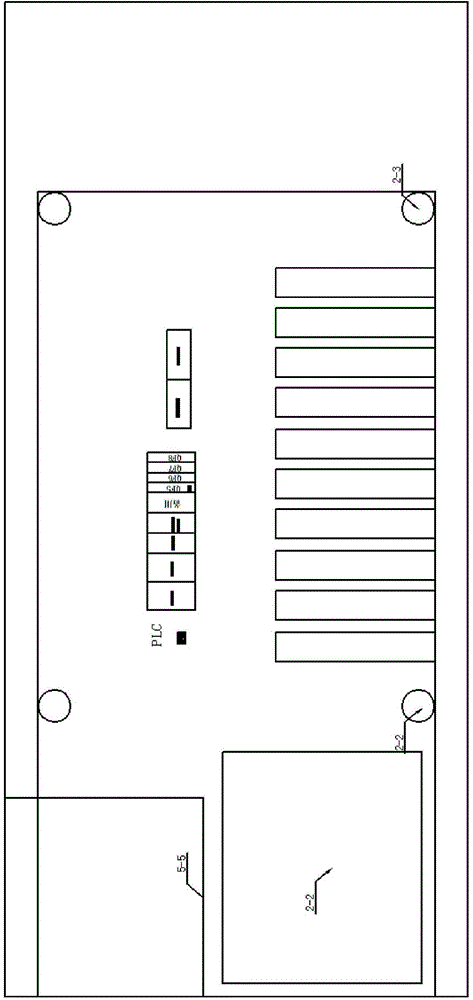

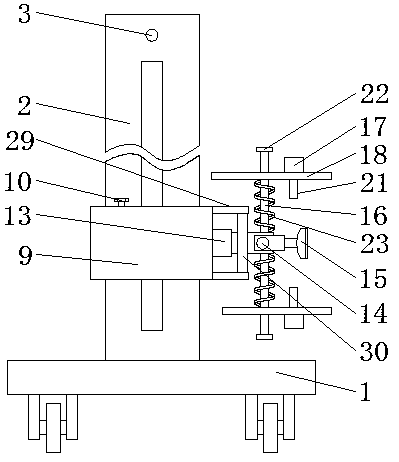

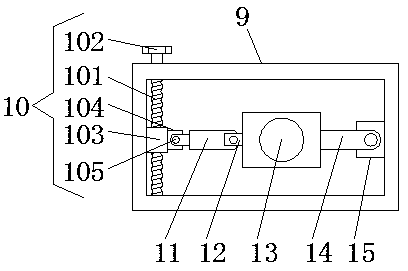

Automatic wall whitewashing machine

The invention relates to the technical field of building machines and discloses an automatic wall whitewashing machine. The automatic wall whitewashing machine comprises a chassis (1), a vertical rod (2) perpendicularly connected with the chassis (1), and a plastering device (3) lifted up and down along the vertical rod (2). A hydraulic lifting system (4) is connected to the bottom of the plastering device (3), a stirring and extruding paddle (9) is arranged in the plastering device (3), a mortar discharging port (10) is formed in the plastering device (3), a plastering board (11) is connected below the mortar discharging port (10), a PLC control circuit (6) is arranged on the chassis (1), a laser thickness gauge (12) is arranged on the plastering device (3), a hydraulic rod (13) is connected to the back face of the plastering board (11), and the laser thickness gauge (12) and the hydraulic rod (13) are respectively connected with the PLC control circuit (6). According to the automatic wall whitewashing machine, because the whitewashing thickness is monitored through the laser thickness gauge and adjusted by adjusting the pressure of the hydraulic rod, the whitewashed wall is uniform and attractive, manpower is effectively saved, and production efficiency is greatly improved.

Owner:HANGZHOU RUIKAI MACHINERY

Cement foaming fireproofing insulation board

InactiveCN103265257AGood temperature stabilityGood chemical stabilityHeat proofingCeramicwareFireproofingFire resistance

The invention relates to a cement foaming fireproofing insulation board which is characterized in that 600# cement, sulphoaluminate rapid hardening cement, powdery carbonized rice husk, cement foaming master batch, polypropylene fiber, water with the temperature of 35 DEG C to 40 DEG C and hydrogen peroxide are adopted as raw materials; and the cement foaming fireproofing insulation board is prepared by adopting the following process steps of: placing the materials in a stirrer to mix and stir uniformly; adding the hydrogen peroxide to oxidize; pouring the mixture into a die for foaming molding and natural withering; cutting to specification shapes; and detecting and packaging. After testing, the cement foaming fireproofing insulation board has the characteristics of terrific temperature stability and chemical stability, acid-base resistance, no cracking, no falling, high stability, no aging, greening, environment protection, harmlessness, fire resistance, no combustion, good safety, high strength, high bonding strength with a base layer of a building, no crack and hollowing and same life with a building body. The construction is simple and convenient, the comprehensive cost is low, the construction period is short, the quality is good, the application scope is wide, and the cement foaming fireproofing insulation board can be used for insulation of the external wall and also used for internal insulation of the external wall, or simultaneous insulation of the internal wall and the external wall.

Owner:HAICHENG YONGFA HIGH TEMPERATURE INSULATION MATERIAL

Construction method of junction part of heat-insulating mortar in outer wall

InactiveCN107761968AImprove crack resistanceSolve the problem that the alkali-resistant glass fiber mesh cloth cannot be dry-laidHeat proofingCrack resistanceThermal insulation

The present invention relates to the construction method of the thermal insulation mortar transfer part in the outer wall, comprising the following steps: (1) preparing the base; (2) hanging the vertical line, springing the control line, sticking the cake and punching the ribs; (3) re-testing the flatness of the base; (4) ) painting the interface mortar; (5) wiping the thermal insulation mortar layer; (6) painting the adhesive mortar; (7) installing the anti-cracking mortar board; (8) painting the waterproof coating layer; The thermal insulation mortar and anti-cracking mortar board described in the invention are safe, environmentally friendly, cost-saving, and easy to construct, so that the thermal insulation, crack resistance, fire resistance and load-bearing performance of the wall are superior to those of the relevant wall.

Owner:江苏特福特建材有限公司

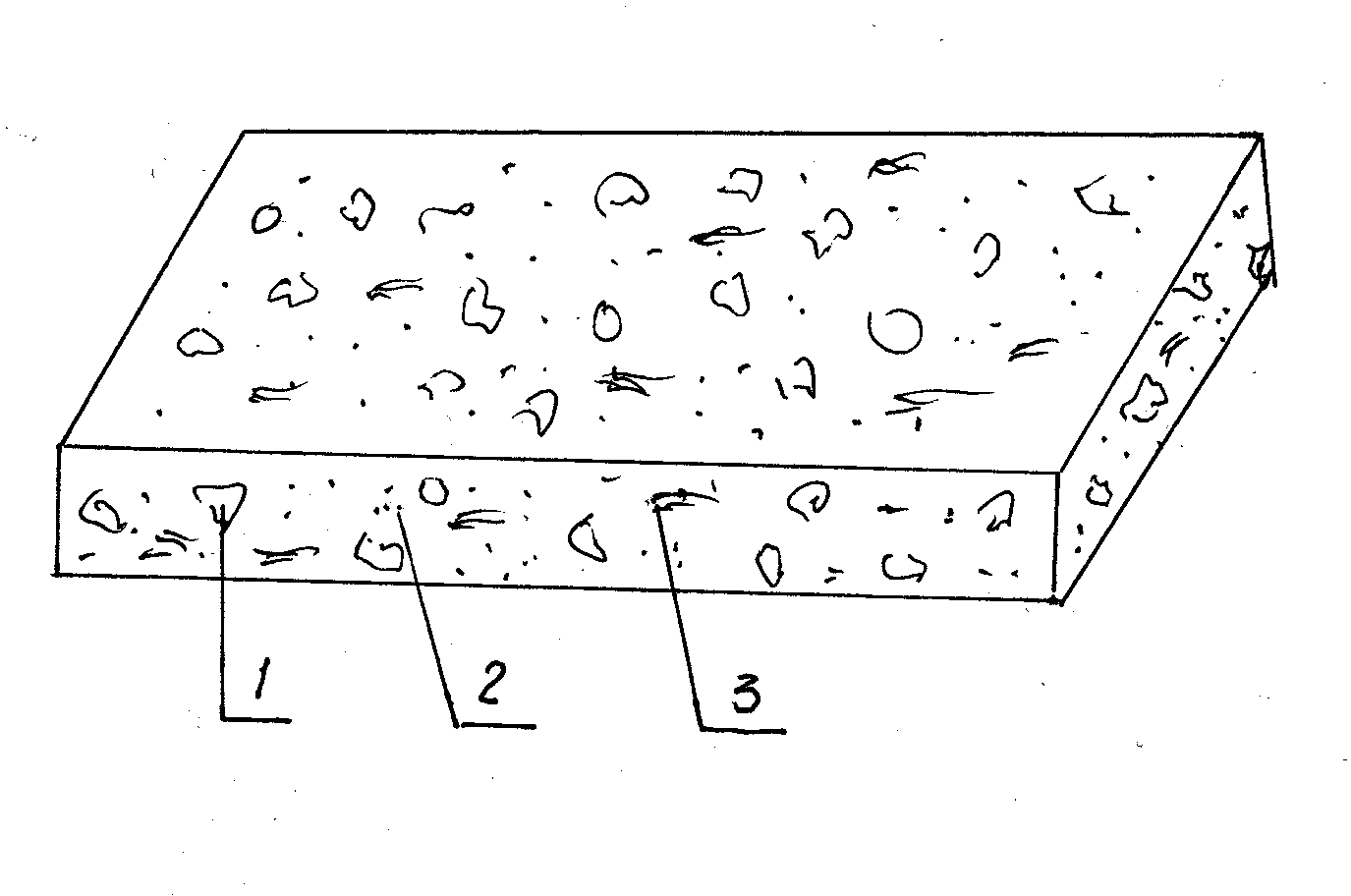

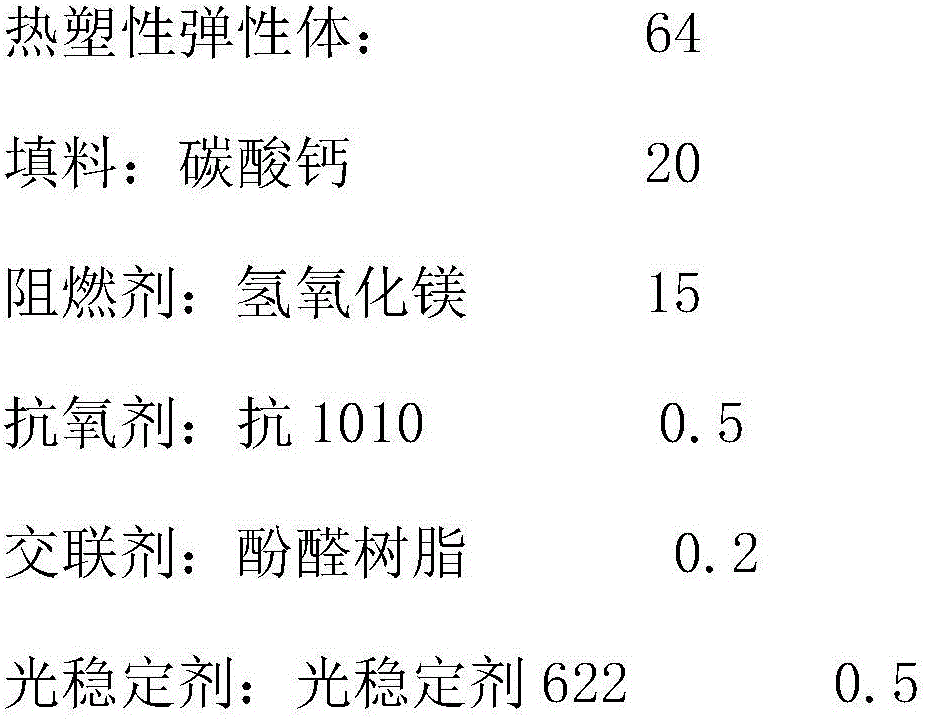

Self-bonded macromolecular composite waterproof roll with large waste rubber powder doping amount

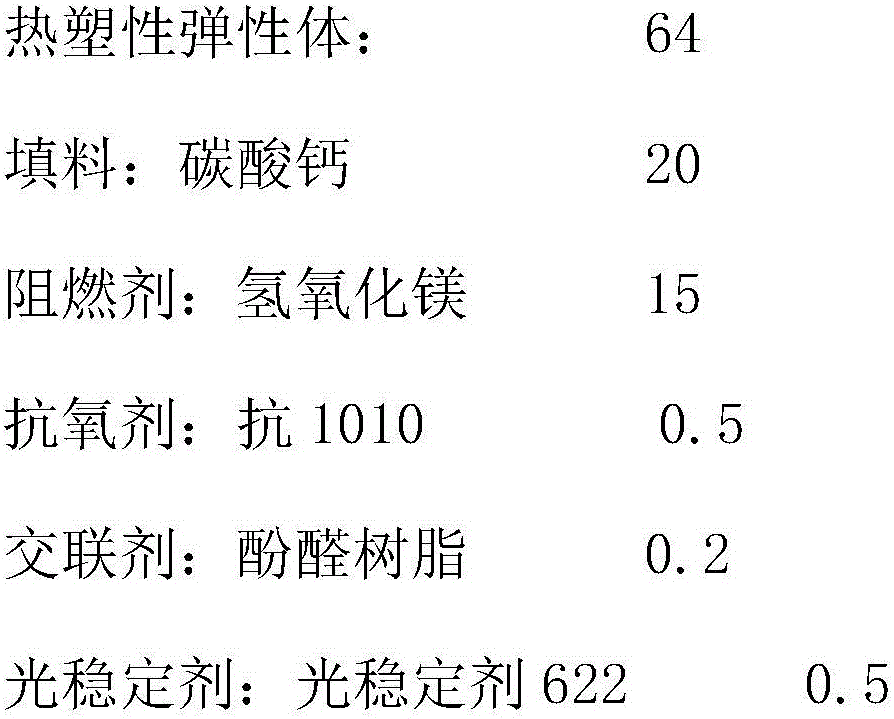

ActiveCN106313807AGood interface propertiesImprove dispersionSynthetic resin layered productsPaper/cardboard layered productsPressure sensitiveTotal thickness

Provided are a self-bonded macromolecular composite waterproof roll with a large waste rubber powder doping amount and a preparation method thereof. The self-bonded macromolecular composite waterproof roll is composed of an upper surface micro-crosslinking thermoplastic elastomer layer, an upper middle waste vulcanized rubber powder resin layer, a lower middle hot melting pressure-sensitive rubber layer and a bottom face isolating layer. The overall thickness ranges from 1.2 mm to 2.0 mm, the thickness of the micro-crosslinking thermoplastic elastomer layer accounts for 17% to 35% of the total thickness, the thickness of the hot melting pressure-sensitive rubber layer is 0.35 mm, the thickness of the isolating layer is 0.15 mm, and the rest is the waste vulcanized rubber powder resin layer. The self-bonded macromolecular composite waterproof roll is free of plasticizer, has high durability, high mechanical performance and prominent low-temperature flexibility, and meanwhile has the advantages of being excellent in waterproofness, thermal weldability and yellowing resistance, long in service life, convenient to construct and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Outer wall thermal insulation decoration integrated quick-equipping plate

The invention discloses an outer wall thermal insulation decoration integrated quick-equipping plate. The quick-equipping plate comprises an insulation sheet of which inner surface sticks to the wall and an interface agent layer, an alkali resistance fiberglass mesh layer or a steel mesh layer, a crack resistance trowel finish layer and a facing layer which adhere to the surface of the thermal insulation board in turn; an internal pressure plate with a cylindrical presser foot is embedded in the thermal insulation board, the presser foot is provided with a thread which is connected with a fastening piece outside the thermal insulation board; the overall fastening piece is cylindrical, one end of the fastening piece is connected with the thread of the presser foot, the other end is inserted in an installing hole in the wall, and the waist part of the fastening piece is provided with an outer pressing sheet which is vertical to the fastening piece. The quick-equipping plate of the invention has simple structure, beautiful appearance, long service life and fast installation, thus the industrialized production of the outer wall thermal insulation finishing quick-equipping plate can be realized.

Owner:RES INST OF ENERGY SAVING BUILDING MATERIAL HEFEI LEQIANNIAN PAINT

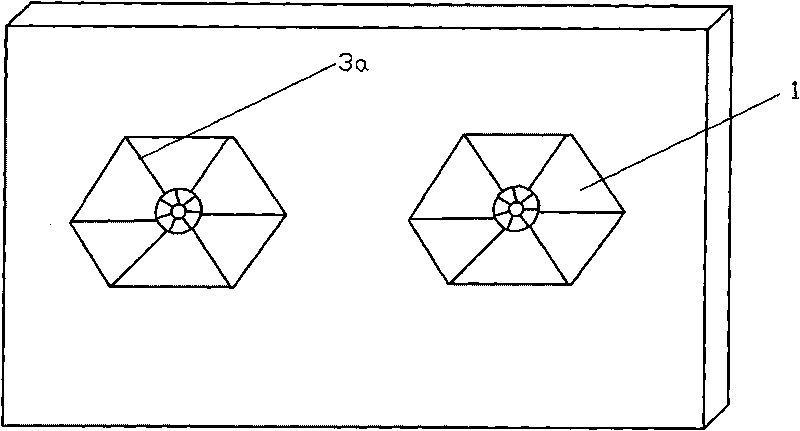

Ceramic tile building block

The invention relates to a ceramic tile building block, which is characterized in that a splayed inclined edge is arranged in the middle of a horizontal hooked character stroke for forming a ceramic tile in a shape shown as the accompanying drawing, or the splayed inclined edge is arranged in the middle of a stroke formed by a right-falling character stroke and the horizontal hooked character stroke to form a ceramic tile in a shape shown as the accompanying drawing; after a metal strip in a shape like a Chinese character 'yu' is inserted into the back surface of the ceramic tile, the ceramic tile is put into a building block moulding press to be pressed together with a mixture of mineral slag, cement gel liquid and glass fiber short strips; the ceramic tile edge and acute angle spaces at the upper side of the ceramic tile building block can be firmly integrated with cement mortar; a plurality of trapezoidal spaces are formed in the built inner wall surface; hollowing and cracking phenomena cannot occur after cement mortar painting; the formed ceramic surface cannot generate loosening, falling or unexpected people injury phenomena; and the time and the labor are saved during construction.

Owner:施红

Method for repairing wall crack of building

The invention provides a method for repairing a wall crack of a building. Firstly, impurity removal and wall surface shoveling are carried out on the position, where the crack is generated, of the wall surface, then puttying is carried out, a bottom material is applied, and an adhesive is applied on the cleaned outer wall surface; then smaller holes and crack are filled up, and drying is carried out for more than 12 hours; then fine mesh gauze is used for binding the crack, the fine mesh gauze is roller-coated with a waterproof binder, and finally, after roller-coating of a primer is completed, finish paint is sprayed. If an empty drum is generated on the wall surface, repairing padding is injected into the empty drum of the wall crack, and after an empty drum groove is filled and leveledup, a crack-sealer is used for leveling the empty drum and the wall surface. The method for efficiently and rapidly repairing the wall crack has the advantages that the manpower can be effectively saved, the construction period is not delayed, the repairing effect of the crack is good, and the empty drum cannot be generated and the calcimine cannot peel off after repairing is completed.

Owner:新昌县鼎绑机电有限公司

Cold-resistant crack-resistant concrete mold release agent and preparation method thereof

The invention discloses a cold-resistant crack-resistant concrete mold release agent and a preparation method thereof. The cold-resistant crack-resistant concrete mold release agent is composed of the following raw materials in parts by weight: 33-35 parts of epoxy resin, 25-30 parts of modified tung oil, 4-5 parts of propanediol, 0.8-1.2 parts of Peregal O, 4-5 parts of sodium carbonate, 0.2-0.4 part of chitin, 0.5-0.6 part of sodium alginate, 0.2-0.4 part of fumaric acid, 4-5 parts of sodium acetate, 0.8-1.0 part of dimethyl phthalate, 2-4 parts of barium sulfate, 0.4-0.5 part of maleic anhydride, 4-5 parts of linoleic acid and 400-500 parts of deionized water. The cold-resistant crack-resistant concrete mold release agent ensures the water retention property during concrete finishing, prevents the concrete from sticking to the mold, and ensures the smoothness of the concrete. The prepared concrete does not have the phenomenon of hollowing, peeling or the like, and has the advantages of excellent crack resistance, favorable constructability and low cost.

Owner:蒙城县科技创业服务中心

Wall surface construction technology

InactiveCN103469978ASimple and fast operationControl verticalityCovering/liningsSurface constructionEngineering

The invention discloses a wall surface construction technology, wherein the traditional wall surface plastering is transformed to be wall body grinding; and paintings are painted on a grinded wall body. The use space of a room is enlarged, and deviation values of the verticality and the flatness of a wall surface are further reduced by the technology. The construction quality of the wall surface is improved; plastering materials and plastering procedures are not adopted, so that construction materials are lessened and expenses of labor are reduced.

Owner:郭矿平

Polymer repair mortar and preparation method thereof

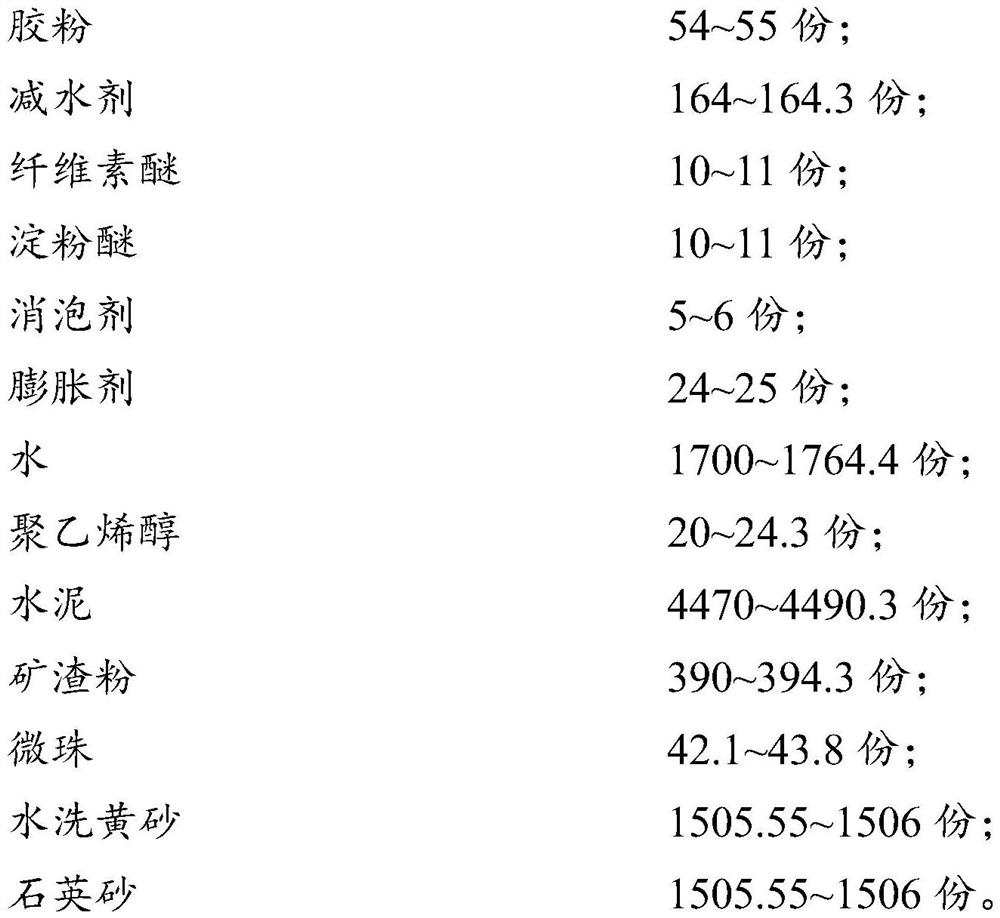

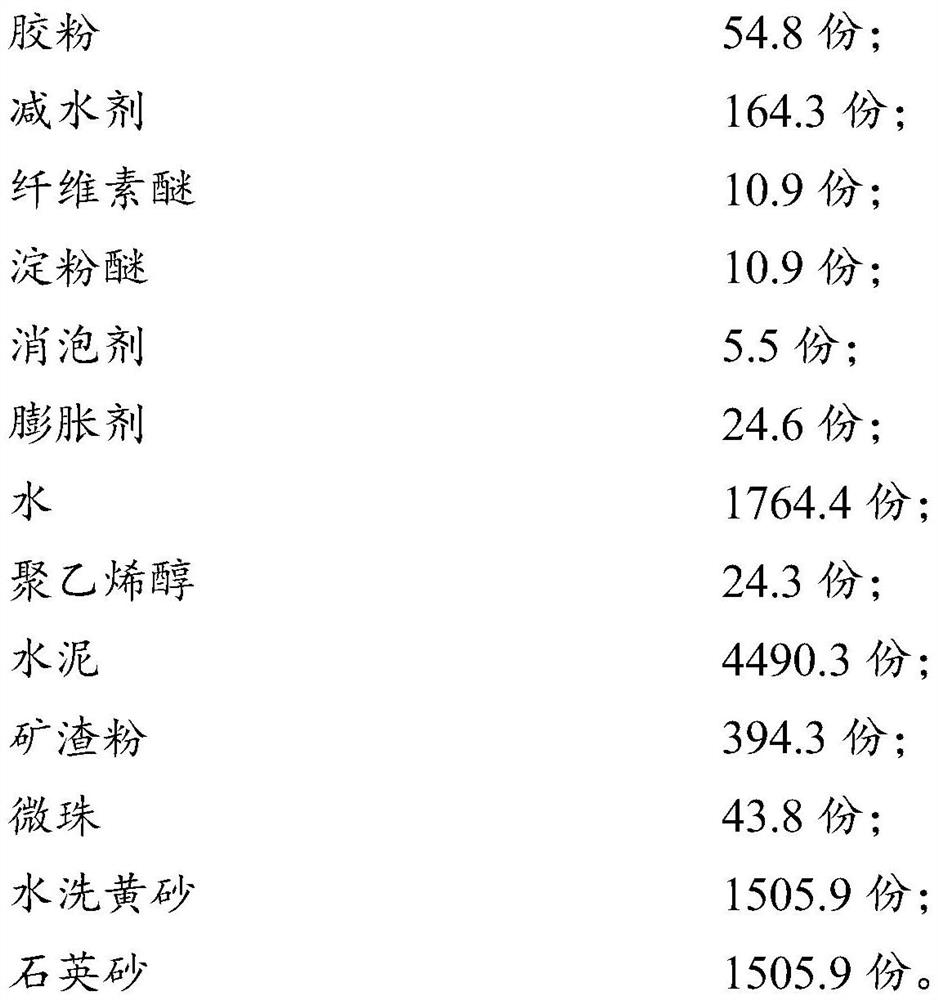

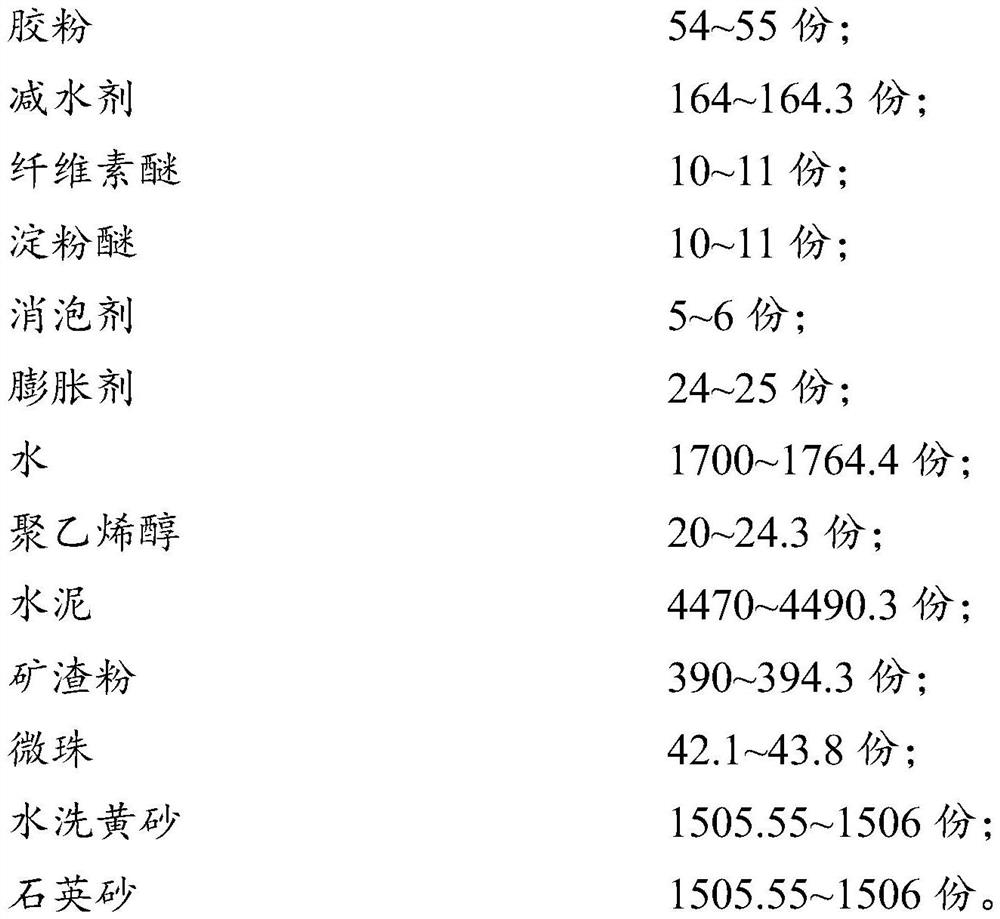

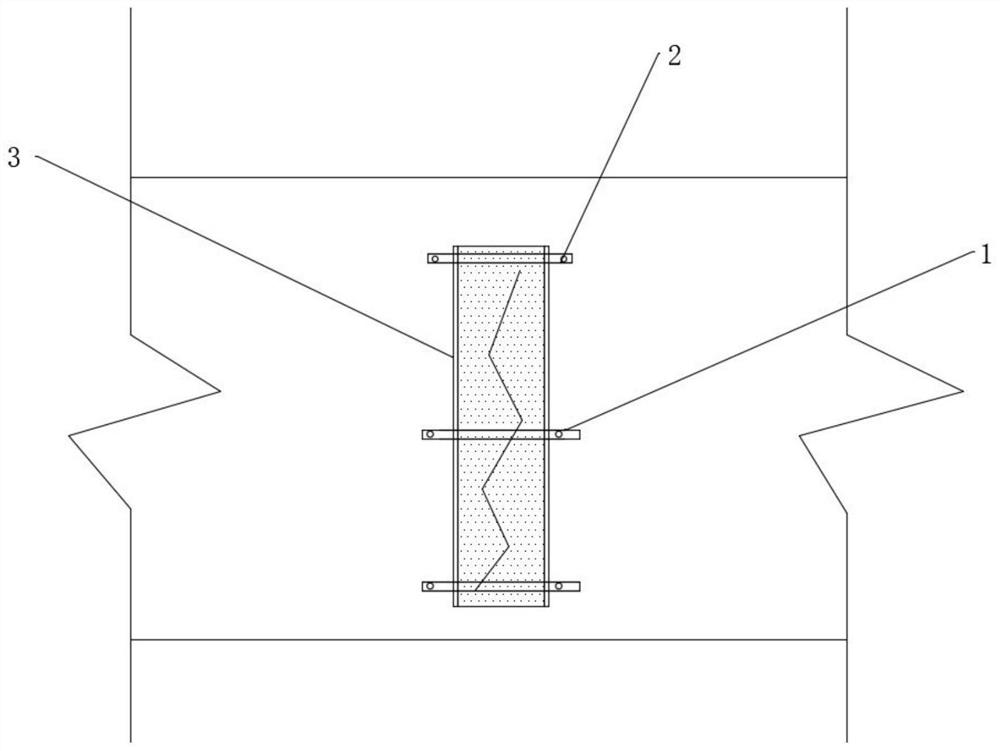

The invention provides polymer repair mortar and a preparation method thereof. The polymer repair mortar comprises the following components in parts by weight: 54 to 55 parts of rubber powder, 164 to 164.3 parts of a water reducing agent, 10 to 11 parts of cellulose ether, 10 to 11 parts of starch ether, 5 to 6 parts of a defoaming agent, 24 to 25 parts of an expanding agent, 1700 to 1764.4 parts of water, 20 to 24.3 parts of polyvinyl alcohol, 4470 to 4490.3 parts of cement, 390 to 394.3 parts of slag powder, 42.1 to 43.8 parts of micro beads, 1505.55 to 1506 parts of washed yellow sand and 1505.55 to 1506 parts of quartz sand. The polymer repairing mortar mainly takes an inorganic material as a reinforcing material, is convenient and simple in material taking and low in price, and can be matched with an alkali-resistant glass fiber mesh to repair and reinforce a masonry wall; and the polymer repair mortar has good tensile adhesive strength, and is beneficial to enhancing the stability of the masonry wall.

Owner:HEBEI UNIV OF TECH

Basement outer wall crack waterproof treatment device and crack blocking method

PendingCN113718969AImprove durabilityTo achieve a complete sealing effectBuilding repairsBuilding insulationsArchitectural engineeringEngineering

The invention discloses a basement outer wall crack waterproof treatment device and a crack blocking method, and belongs to the field of building crack blocking construction. The waterproof treatment device comprises a fixing mechanism installed on a wall structure and a pressurization plugging mechanism installed on the fixing mechanism and covering the periphery of a crack, waterproof and weather-proof glue is pressed into the crack through the pressurization plugging mechanism, and the crack of the inner side wall of the wall structure is coated with a plugging agent in advance. A pressurized injection type is adopted for plugging the crack for waterproof treatment, a pressurized protective cover covers the outer side of the crack, waterproof and weather-proof glue is injected in a pressurized mode through a flexible isolation piece, then the outer side is pressurized, the waterproof and weather-proof glue on the inner side of the flexible isolation piece is pressed into the inner side of the crack, the complete plugging effect is achieved, and DuLouWang in the cracks and at the inner side cracks can be connected into a whole, so that the durability of the plugging materials is better facilitated.

Owner:CHINA MCC17 GRP

Aerogel heat preservation and insulation system and construction process thereof

InactiveCN111961385ARealize thermal insulation functionFit tightlyCovering/liningsHeat proofingProcess engineeringInsulation system

The invention relates to the technical field of building structure heat preservation, in particular to an aerogel heat preservation and insulation system and a construction process thereof, and aims to solve the technical problems that an existing building structure heat preservation and insulation system is thick and heavy in structure, a plastering layer is prone to hollowing, falling and cracking, the construction process is complex, and the labor intensity of operators is high. According to the technical scheme, the aerogel heat preservation and insulation system is formed by sequentiallycoating a water-based multifunctional bottom coating, an aerogel heat preservation and insulation middle coating and an aerogel reflection and insulation surface coating which are specific in component. The construction process of the aerogel heat preservation and insulation system is divided into three major steps of water-based multifunctional bottom coating construction, aerogel heat preservation and insulation middle coating construction and aerogel reflection and heat insulation surface coating construction, each step comprises several substeps, the whole construction process is simple and easy to operate, and the labor intensity of operators can be greatly reduced.

Owner:山西宏厦建筑工程第三有限公司

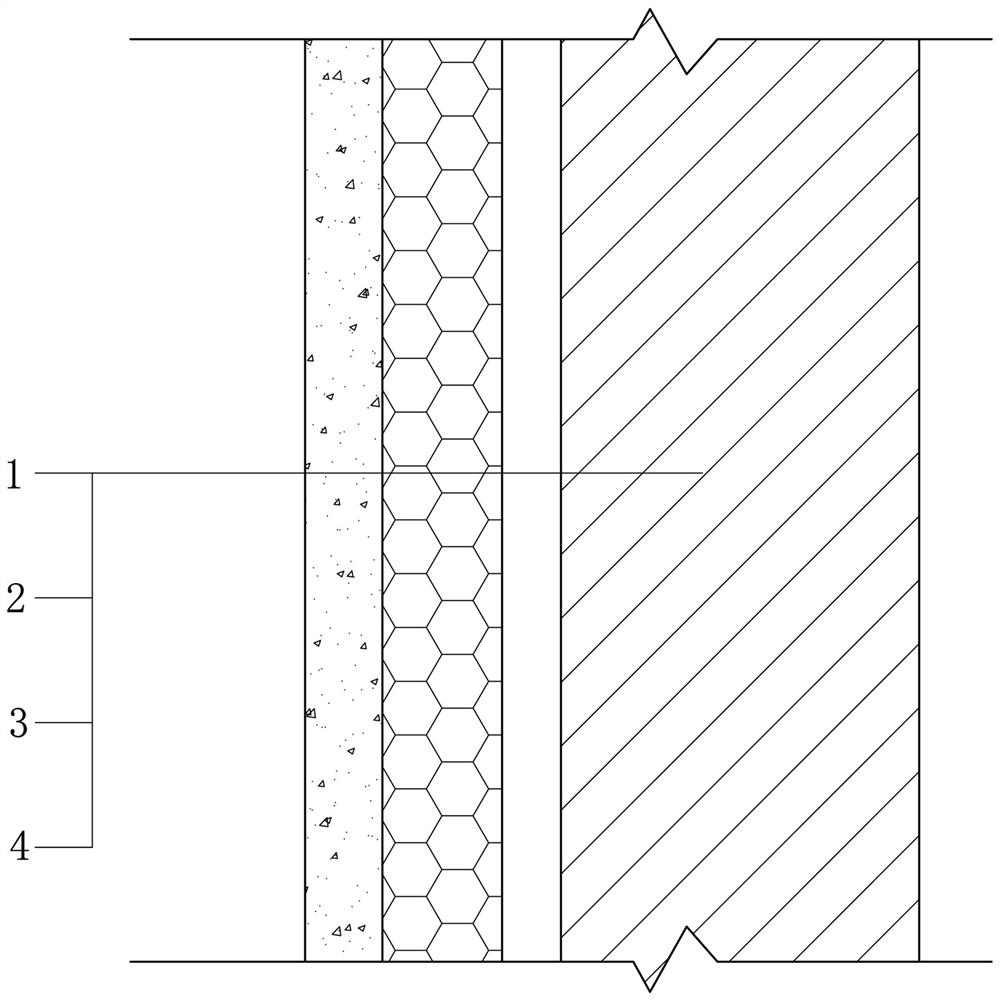

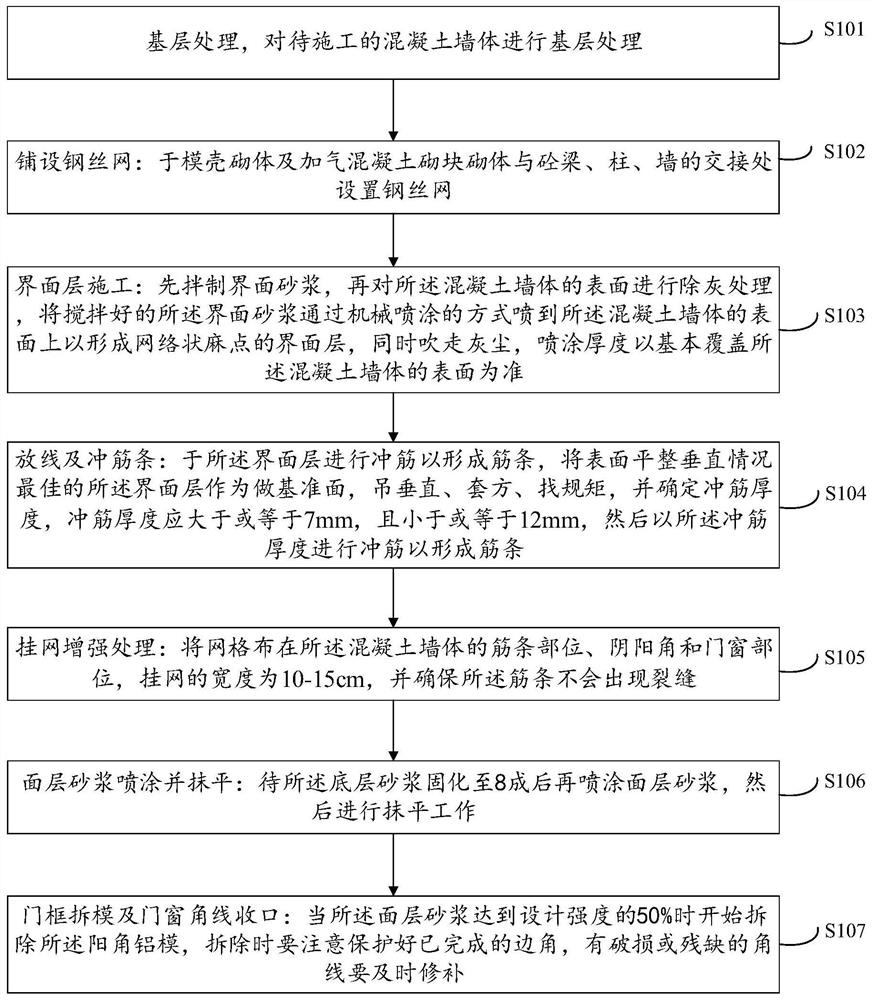

Mechanical spraying plastering construction method

InactiveCN113216541ANo hollowingNo crackingCovering/liningsCement mixing apparatusConcrete beamsArchitectural engineering

The invention discloses a mechanical spraying plastering construction method. The method comprises the following steps that base layer treatment is carried out, base layer treatment is carried out on a to-be-constructed concrete wall body; steel wire meshes are laid, steel wire meshes are arranged at the joints of a formwork brickwork and an aerated concrete block brickwork with a concrete beam, a concrete column and a concrete wall; interface layer construction is carried out, interface mortar is sprayed to the surface of the concrete wall in a mechanical spraying mode to form an interface layer; paying off and screeding are carried out, screeding is conducted on the interface layer to form ribs; mesh hanging reinforcement treatment is conducted, specifically, gridding cloth is arranged on rib parts, internal and external corners and door and window parts of the concrete wall body; surface layer mortar is sprayed and flattened; and through two-time reinforcement treatment, it is guaranteed that hollowing and cracking of the wall cannot occur.

Owner:长沙三树新材料科技有限公司

Ground ceramic tile paving method capable of preventing bulges

The invention discloses a ground ceramic tile paving method capable of preventing bulges. A special mortarboard, a ceramic tile mortar coating machine and a seam partition / flattening device are used; notches are uniformly formed in one long side edge of the special mortarboard, and a strip-shaped mortar layer with the consistent thickness can be paved on the ground; the back surfaces of ground ceramic tiles of different specifications can be coated with a strip-shaped mortar layer with the consistent thickness through the ceramic tile mortar coating machine, gaps with the uniform and consistent width can be spaced between the ground ceramic tiles by the seam partition / flattening device through vertical plates of T-shaped plastic partition plates, and the levelness on the ceramic tiles can be consistent through plastic wedges; and the construction steps of the ground ceramic tile paving method comprise coating of the ground strip-shaped mortar coating layer, coating of the strip-shaped mortar coating layer of the back surfaces of the ground ceramic tiles, paving of the benchmark ceramic tiles according to the mode that the strip-shaped mortar layers are perpendicularly staggered, paving of the other ceramic tiles according to the mode that the strip-shaped mortar layers are perpendicularly staggered, clearing of the vertical plates of the T-shaped plastic partition plates and filling of the gaps. According to the ground ceramic tile paving method capable of preventing the bulges, the bulging phenomenon is avoided, meanwhile the hollowing phenomenon is avoided, and construction efficiency is high.

Owner:来安县永阳知识产权运营有限公司

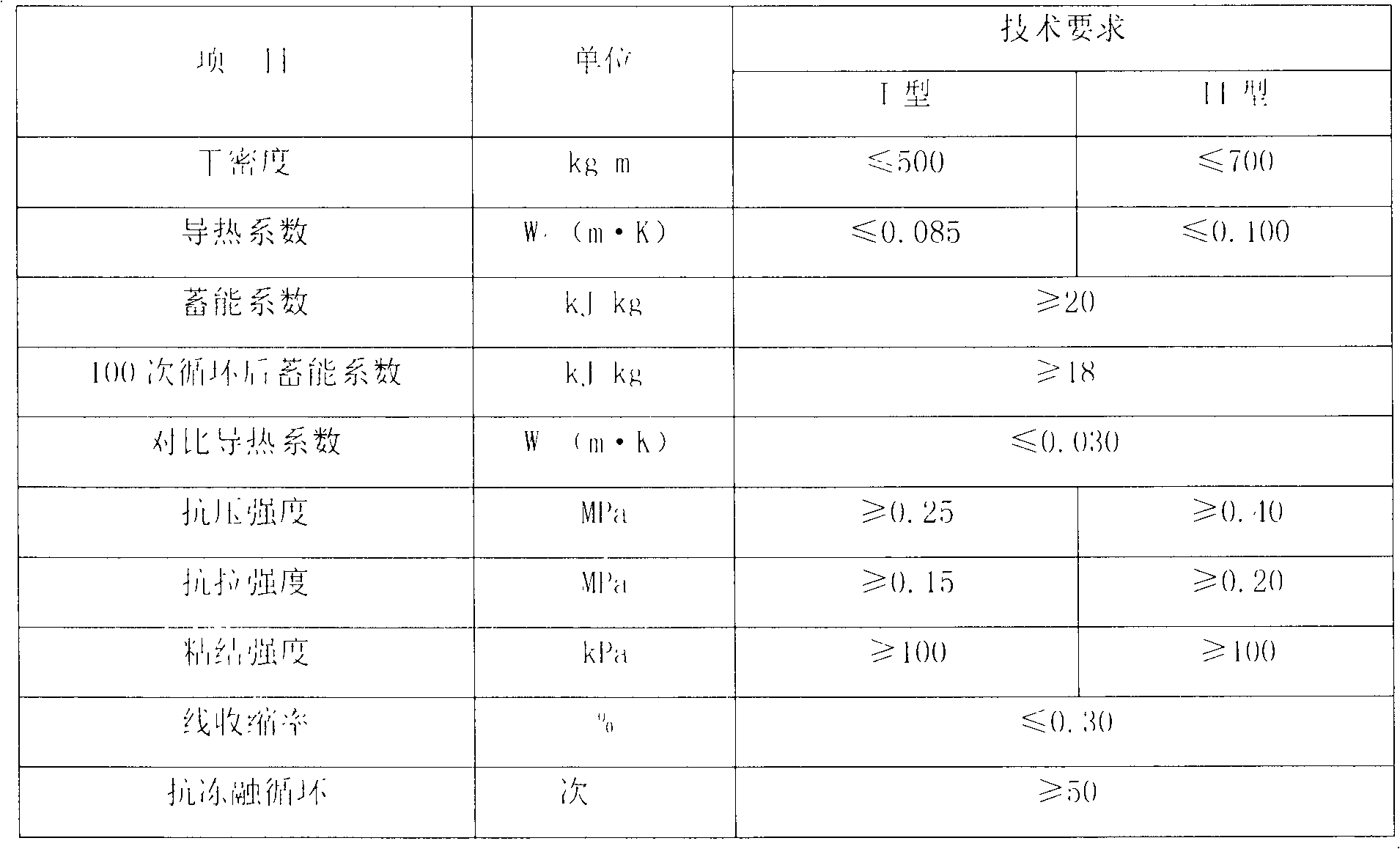

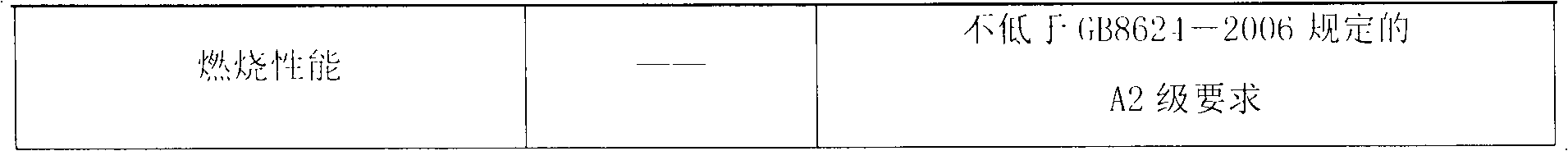

Production method and application of pitchstone expansion vitrified micro-bead energy storage material

InactiveCN102417314AHigh strengthLow thermal conductivityHeat proofingFreeze thawingWeather resistance

The invention discloses a production method and application of a pitchstone expansion vitrified micro-bead energy storage material, belonging to the field of building thermal-insulation temperature-adaptable materials. In the existing thermal-insulation energy saving building materials, expanded polystyrene boards and extruded polystyrene boards as represented by thermal-insulation materials are difficult to satisfy the 65% energy saving requirement, and have the disadvantages of short service life, bad flame resistance and the like. The pitchstone expansion vitrified micro-bead energy storage material disclosed herein overcomes the disadvantages of the material in the prior art, and achieves the following advantages: 1, long service life: the material has the same service life with the building body; 2, good flame resistance: the material achieves the grade-A standard required by GB8621-2006; and 3, good weather resistance: the number of freeze-thaw cycles of the material is 50. Simultaneously, the material has a temperature adjustment function, when the indoor ambient temperature in the daytime is too high, the material can absorb heat in the environment, and when the indoor ambient temperature in the night is low, the material can release heat to the environment, thus the indoor temperature fluctuation is controlled, the use of the air-conditioners and heating systems is reduced, and the energy is saved. The material can be widely applied in building wall, the thermal insulation projects of wall surface, roof, and floor, and the like.

Owner:逄增彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com