Module assembly-type wall surface and shed surface coating, screeding and polishing device

A combined, shed surface technology, applied in the construction, building structure and other directions, can solve the problem that the wall and shed surface can not be coated, smoothed, polished and dust collected at the same time, increase the work intensity of the operator, and the operation is cumbersome. Flexible and other issues, to achieve the effect of convenient transportation and handling, light weight, and avoid cumbersome construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

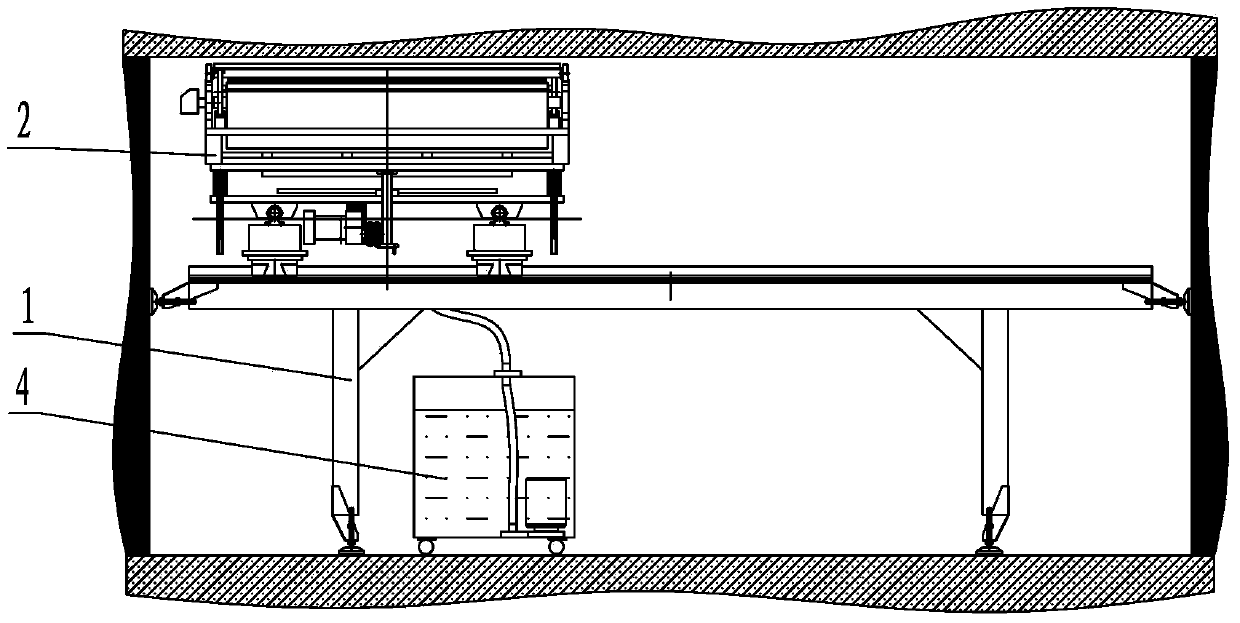

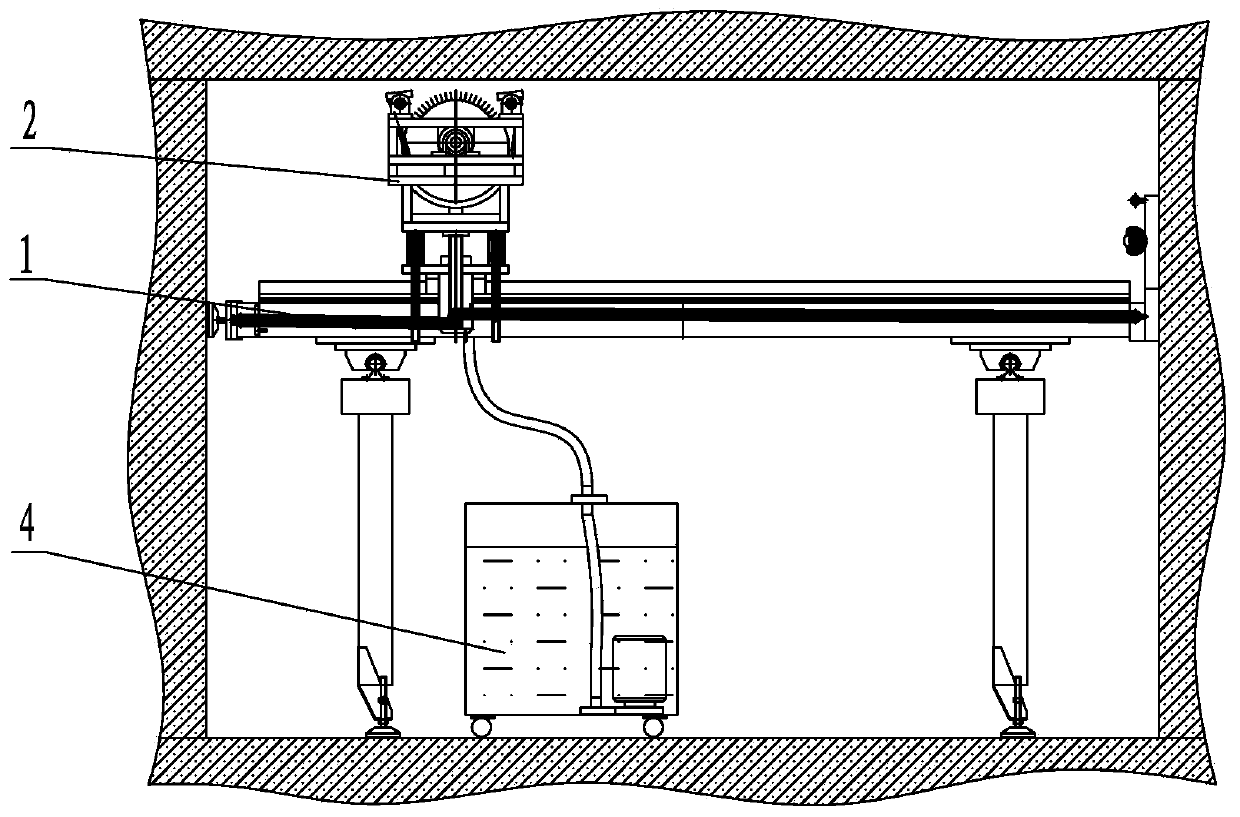

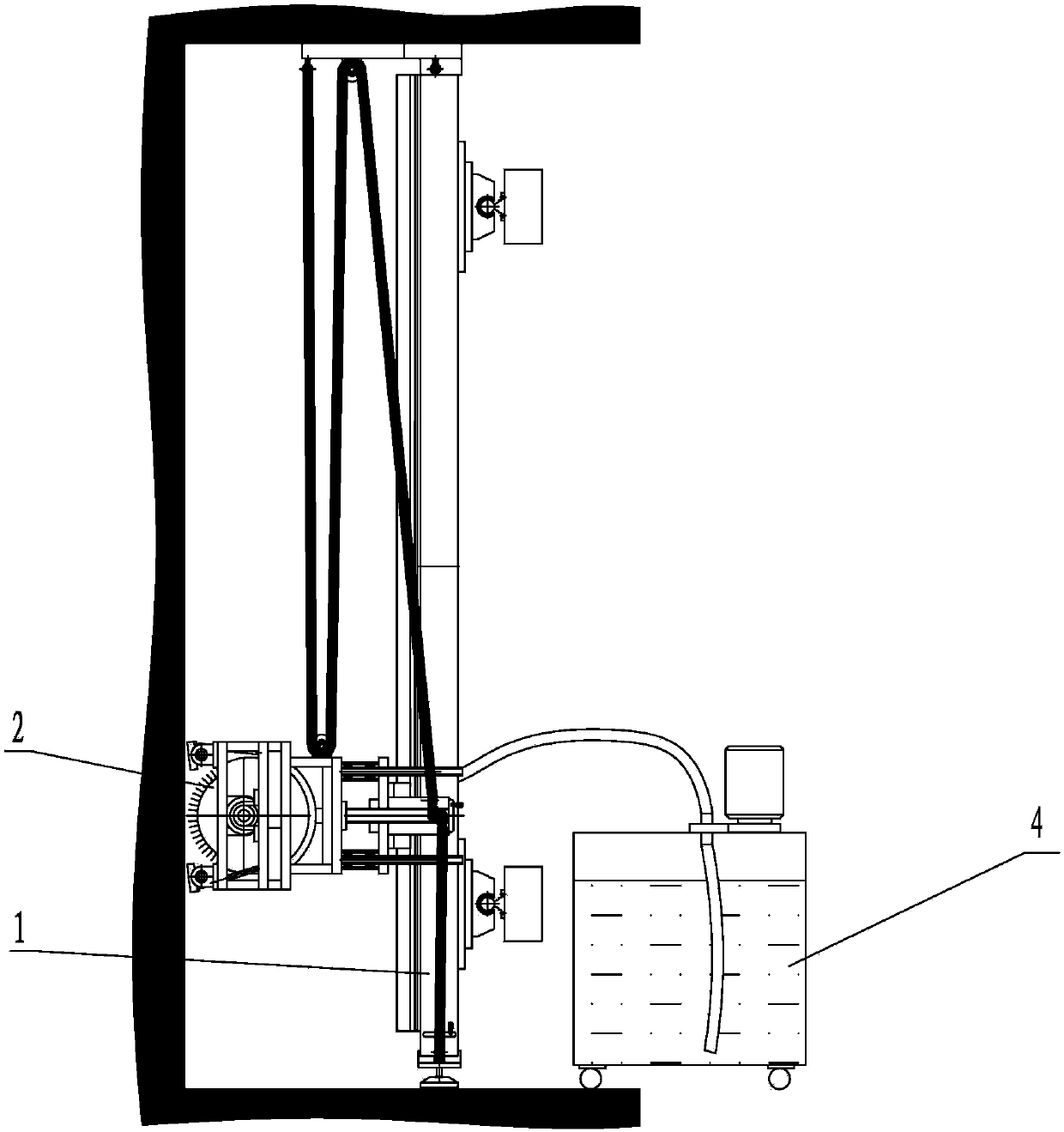

[0007] Specific implementation mode one: combine Figure 1 to Figure 10 Describe this embodiment, a modular combined wall shed surface coating, troweling and polishing device described in this embodiment includes a load-bearing installation bracket 1, a splash-type coating and troweling mechanism 2, a polishing and dust-absorbing mechanism 3, and a feeding and dust-collecting mechanism. Mechanism 4, bearing installation bracket 1 includes fixed slide rail unit 1-1, traverse slide rail unit 1-2, walking lifting bracket mechanism 1-3 and multiple supporting columns 1-4, fixed slide rail unit 1 -1 is composed of two first rails 1-1-1 arranged side by side in parallel, the traversing track unit 1-2 is composed of two second rails 1-2-1 arranged side by side in parallel, the traversing track The unit 1-2 is installed on the fixed slide rail unit 1-1, and the direction of the two second rails 1-2-1 of the traversing slide rail unit 1-2 is the same as that of the fixed slide rail uni...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Figure 11 to Figure 17 To illustrate this embodiment, the fixed slide rail unit 1-1 of a modular combined wall and shed surface coating, troweling and polishing device in this embodiment includes two first rails 1-1-1, a top-fixed adjustment foot 1-1-2, the first linear guide rail 1-1-3, the first linear bearing seat 1-1-4 and the first plate connector 1-1-5, each first track 1-1-1 Both ends of each are provided with top-fixed adjusting feet 1-1-2, and the upper surface of each first track 1-1-1 is fixedly equipped with a first linear guide rail 1-1-3, and each first linear The first linear bearing seats 1-1-4 with linear bearings are respectively installed on the guide rails 1-1-3, and the first plate connectors 1 are fixedly installed on each first linear bearing seat 1-1-4 -1-5.

[0010] The technical effect of this embodiment is: fixed slide rail unit 1-1 is the operation of the whole working system of the device of t...

specific Embodiment approach 3

[0011] Specific implementation mode three: combination Figure 11 to Figure 17To illustrate this embodiment, the traversing slide rail unit 1-2 of a modular wall shed surface coating, smoothing and polishing device described in this embodiment includes two second rails 1-2-1, a second straight line Guide rail 1-2-2, second linear bearing seat 1-2-3, second plate connector 1-2-4, sliding connector 1-2-5, plug 1-2-6, T-shaped track arrangement Spacing positioning plate 1-2-7, rectangular track arrangement spacing positioning plate 1-2-8, first cable buckle 1-2-9, jacking screw 1-2-10, handwheel 1-2-11, Disc type top foot 1-2-12, second cable buckle 1-2-13, fixed pulley 1-2-14, third steel cable buckle 1-2-15 and connection key 1-2-16 , the upper surface of each second track 1-2-1 is fixedly installed with a second linear guide rail 1-2-2, and each second linear guide rail 1-2-2 is equipped with a second linear guide rail 1-2-2 with a linear bearing. Bearing seat 1-2-3, second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com