Automatic wall whitewashing machine

A plastering machine and automatic technology, which is applied in the direction of construction and building construction, can solve the problems of uncontrollable plastering thickness and poor plastering quality, and achieve the effects of saving manpower, light weight, and avoiding dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

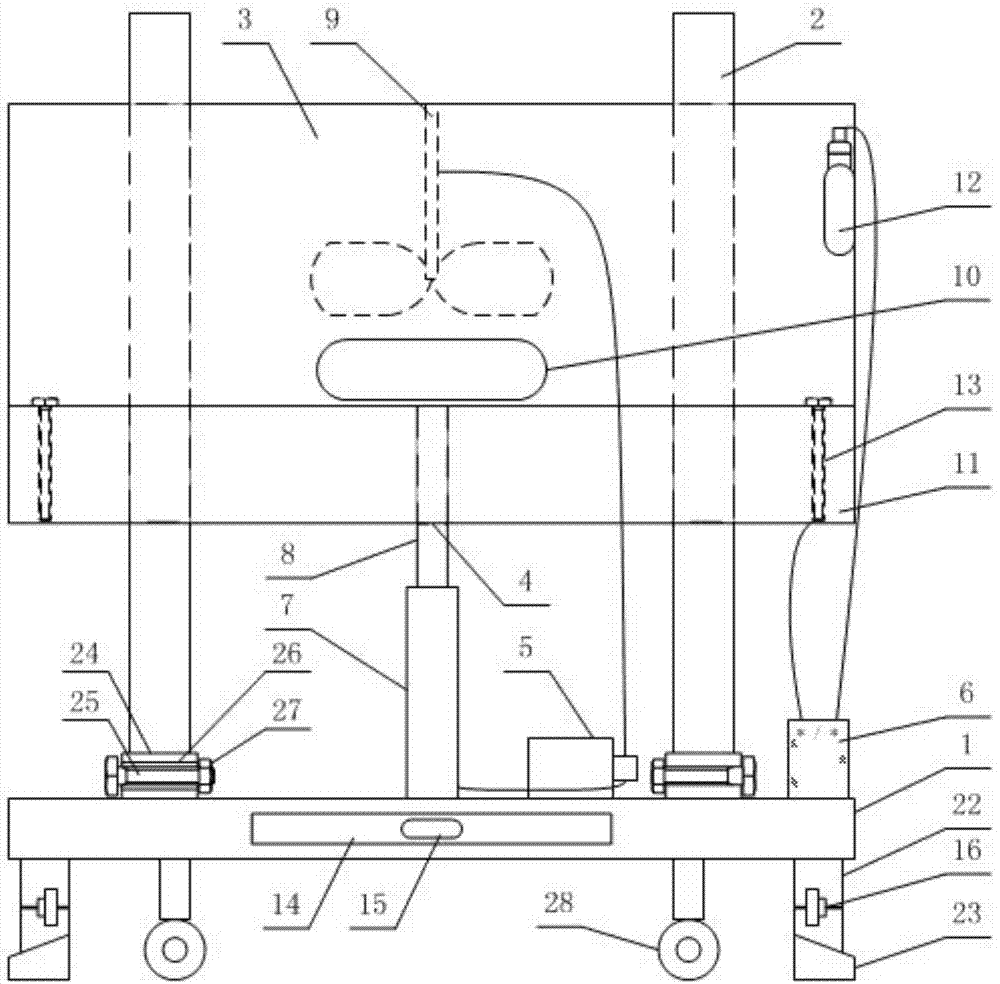

[0021] An automatic powder wall machine, such as figure 1 As shown, it includes a chassis 1, a vertical pole 2 vertically connected to the chassis 1, and a plastering device 3 that lifts along the vertical pole 2. The bottom of the plastering device 3 is connected with a hydraulic lifting system 4, the hydraulic lifting system 4 includes a motor 5, an oil cylinder 7 and a piston rod 8, the oil cylinder 7 is fixed on the chassis 1, the output shaft of the motor 5 is connected with the oil cylinder 7, and one end of the piston rod 8 is connected to the The oil cylinder 7 is connected, and the other end is connected with the bottom of the plastering device 3. The plastering device 3 is also provided with a stirring and extruding paddle 9. The stirring and extruding paddle 9 is connected with the output shaft of the motor 5. There is a mortar outlet on the side of the plastering device 3. Material opening 10, plastering board 11 is connected below the mortar discharge port 10 of p...

Embodiment 2

[0025] Embodiment 2 is the same as Embodiment 1, except that four sets of adjustment mechanisms 16 and support rods 22 are provided on the lower surface of the chassis 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com