Self-bonded macromolecular composite waterproof roll with large waste rubber powder doping amount

A waterproof membrane, self-adhesive technology, applied in the direction of layered products, rubber layered products, synthetic resin layered products, etc. limited problems, to achieve the effect of excellent interface properties, enhanced strength and thickness, and low glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Formula of waste vulcanized rubber powder-based thermoplastic resin layer (parts by mass):

[0024] Waste vulcanized rubber powder: 65

[0025] Polyethylene-based elastomer: 13

[0026] Polypropylene-based elastomer: 15

[0027] Compatibilizer: 5

[0028] Antioxidant: 1.0

[0029] Crosslinker: 1.0

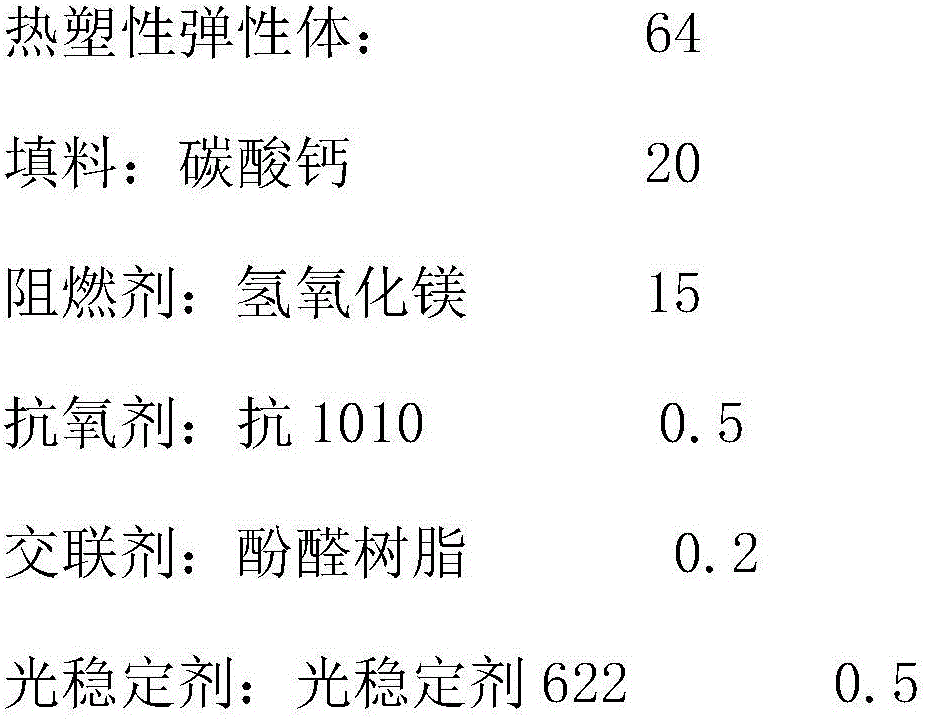

[0030] 2. Micro-crosslinked thermoplastic elastomer layer (parts by mass):

[0031]

[0032] 3. Hot-melt pressure-sensitive adhesive layer (mass parts):

[0033] Hot melt butyl rubber pressure sensitive adhesive: 100

[0034] 4. Isolation layer

[0035] Silicone paper

[0036] 5. Preparation of self-adhesive polymer composite waterproof membrane

[0037] (1) Weigh waste vulcanized rubber powder, polyethylene-based elastomer, polypropylene-based elastomer, compatibilizer, antioxidant and cross-linking agent according to the formula, put it in a high-speed mixing mixer, stir for 3 to 7 minutes, and mix well After discharge; then the uniformly mixed raw raw materi...

Embodiment 2

[0041] 1. Formula of waste vulcanized rubber powder-based thermoplastic resin layer (parts by mass):

[0042] Waste vulcanized rubber powder: 85

[0043] Polyethylene-based elastomer: 4

[0044] Polypropylene-based elastomer: 7

[0045] Compatibilizer: 3

[0046] Antioxidant: 0.5

[0047] Cross-linking agent: 0.5

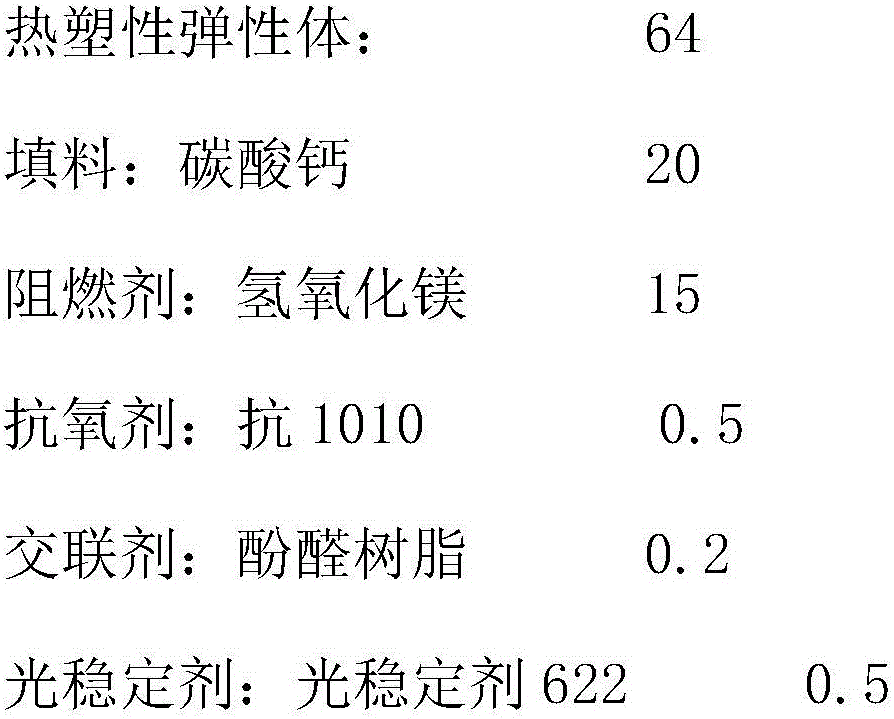

[0048] 2. Micro-crosslinked thermoplastic elastomer layer (parts by mass):

[0049]

[0050] 3. Hot-melt pressure-sensitive adhesive layer (parts by mass):

[0051] Hot melt butyl rubber pressure sensitive adhesive: 100

[0052] 4. Isolation layer

[0053] Silicone paper

[0054] 5. Preparation of self-adhesive polymer composite waterproof membrane: Compared with Example 1, only the dosage of each formulation is different.

Embodiment 3

[0056] 1. Formula of waste vulcanized rubber powder-based thermoplastic resin layer (parts by mass):

[0057] Waste vulcanized rubber powder: 75

[0058] Polyethylene-based elastomer: 9

[0059] Polypropylene-based elastomer: 11

[0060] Compatibilizer: 4

[0061] Antioxidant: 0.5

[0062] Cross-linking agent: 0.5

[0063] 2. Micro-crosslinked thermoplastic elastomer layer (parts by mass):

[0064]

[0065]

[0066] 3. Hot-melt pressure-sensitive adhesive layer (parts by mass):

[0067] Hot melt butyl rubber pressure sensitive adhesive: 100

[0068] 4. Isolation layer

[0069] Silicone paper

[0070] 5. Preparation of self-adhesive polymer composite waterproof membrane: Compared with Example 1, only the dosage of each formulation is different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com