Fireproof moisture-proof easily-laid environmentally-friendly ceramic tile with locking buckles and production method

A ceramic tile and environmental protection technology, applied in the ceramic tile field, can solve the problems that users cannot replace the tiles by themselves, the cement sand looseness is different, the tiles are thermally expanded and contracted, etc., and the replacement and maintenance are simple and convenient, and the clamping is simple and convenient. , reduce the effect of thermal expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

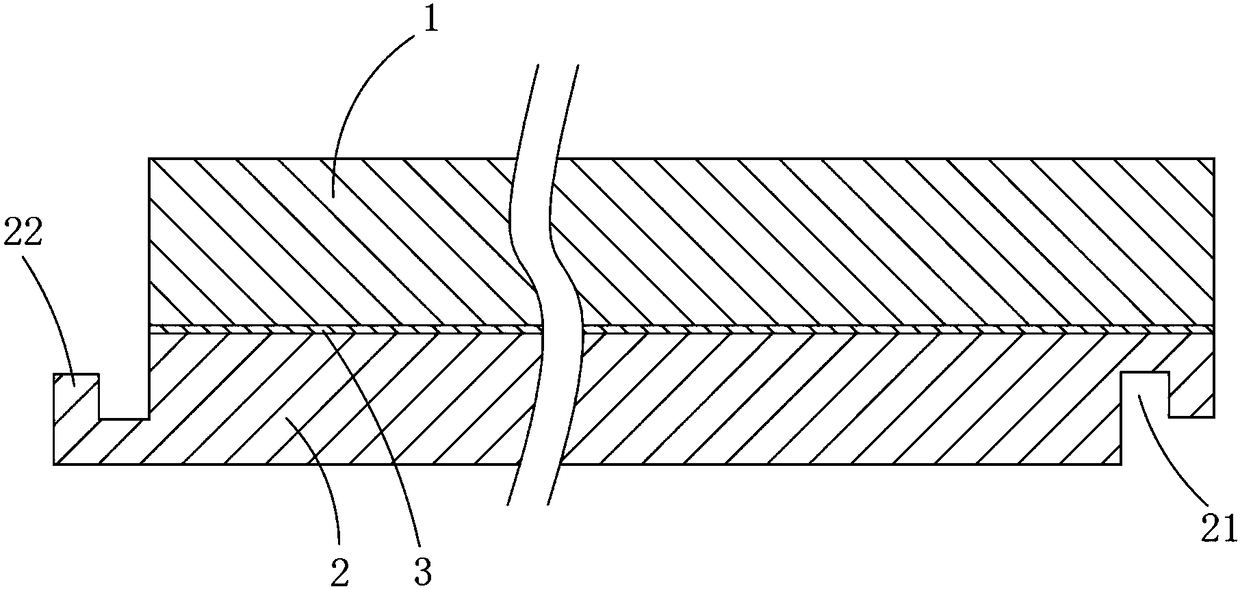

[0064] A kind of fire-proof, moisture-proof and easy-to-pave environmentally friendly tiles with locks, figure 1 with 2 As shown, it includes a tile body layer 1 located on the upper layer. The tile body layer 1 is made of ceramic or stone ceramic tile base material. The bottom surface has an adhesive surface formed with fine holes and coarse grains.

[0065] A waterproof substrate layer 2 is compounded on the bottom surface of the ceramic tile main layer 1, and the waterproof substrate layer 2 is made of degradable wood-plastic board, waterproof medium-density board, waterproof high-density board, rubber board, resin board, magnesium oxide board or plastic board. made base material.

[0066] Among them, wood-plastic panels include wood-plastic composite materials, the English name is Wood Plastic Composite, and the abbreviation is WPC.

[0067] Plastic sheets include sheets made of a single plastic material as the main component and composite plastic material sheets made o...

Embodiment 2

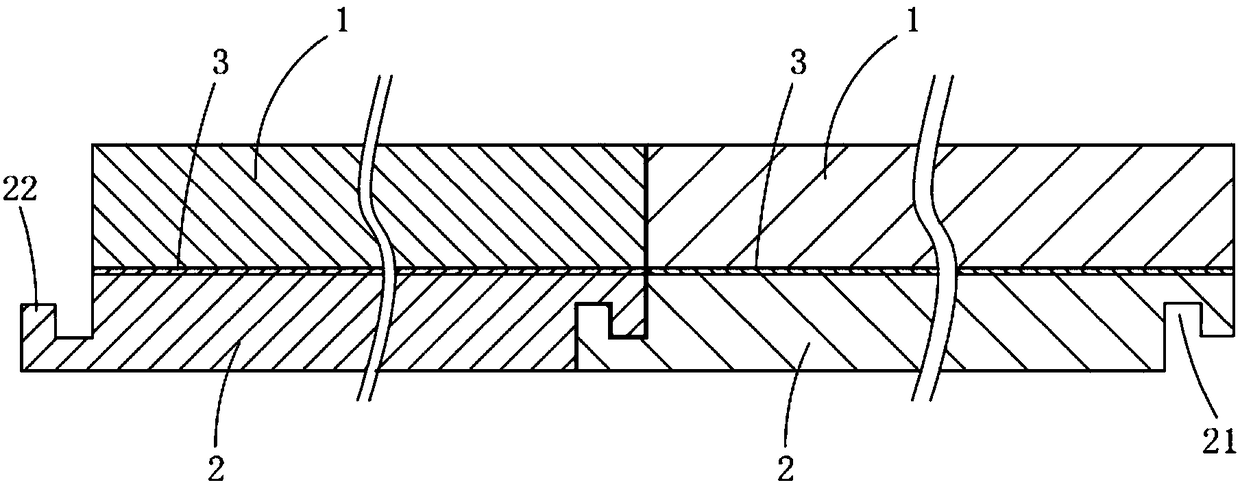

[0092] A kind of fire-proof, moisture-proof and easy-to-pave environmentally friendly tiles with locks, image 3 As shown, it includes the ceramic tile main layer 1 and the waterproof base material layer 2 on the upper layer, the bottom surface of the ceramic tile main body layer 1 is coated with an adhesive layer 3, and the waterproof base material layer 2 is pasted and fixed on the bottom surface of the ceramic tile main body layer 1 through the adhesive layer 3 , the main structure and advantages of this embodiment are the same as those of Embodiment 1, and will not be repeated here. After splicing two environmentally friendly ceramic tiles, a brick seam 8 is formed between the two ceramic tile main layers 1 of two adjacent environmentally friendly ceramic tiles, and the waterproof base material layers 2 of the adjacent two environmentally friendly ceramic tiles are connected into one.

[0093]The existence of the brick joint 8 is more convenient when connecting two adjacen...

Embodiment 3

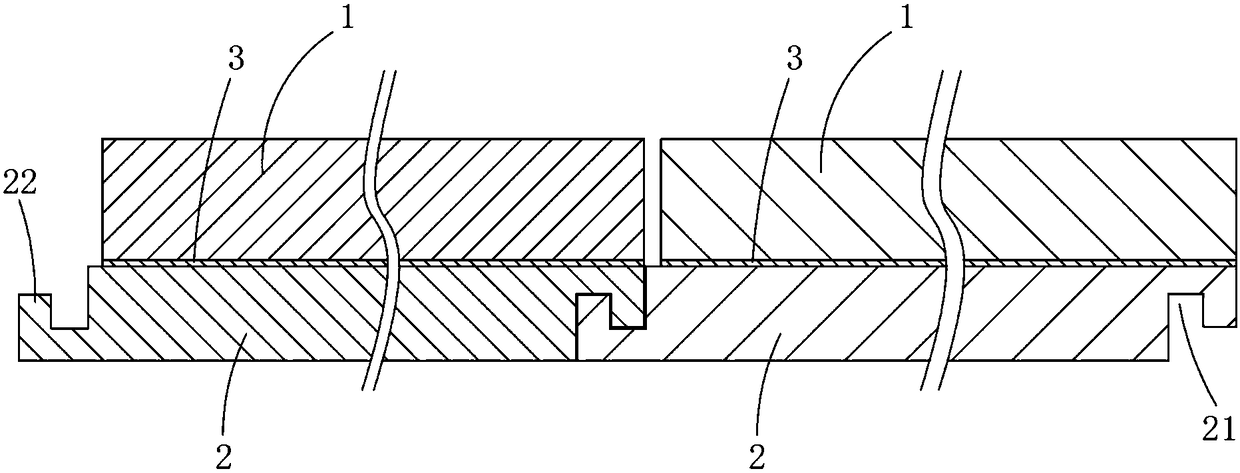

[0097] A kind of fire-proof, moisture-proof and easy-to-pave environmentally friendly tiles with locks, Figure 4 As shown, including the ceramic tile main body layer 1 and the waterproof substrate layer 2 on the upper layer, the main structure and advantages of this embodiment are the same as those of Embodiment 1, and will not be repeated here. The difference is that the waterproof substrate layer 2 passes through The in-mold molding process is directly formed and fixed on the bottom surface of the ceramic tile main layer 1, or the waterproof base material layer 2 is directly compounded and fixed on the bottom surface of the ceramic tile main layer 1 through a hot pressing process.

[0098] The waterproof base material layer 2 is directly compounded on the bottom surface of the ceramic tile main body layer 1, the bonding force between the waterproof base material layer 2 and the ceramic tile main body layer 1 is stronger, the production efficiency is higher, the production pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com