Patents

Literature

30results about How to "Small thermal expansion and contraction coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

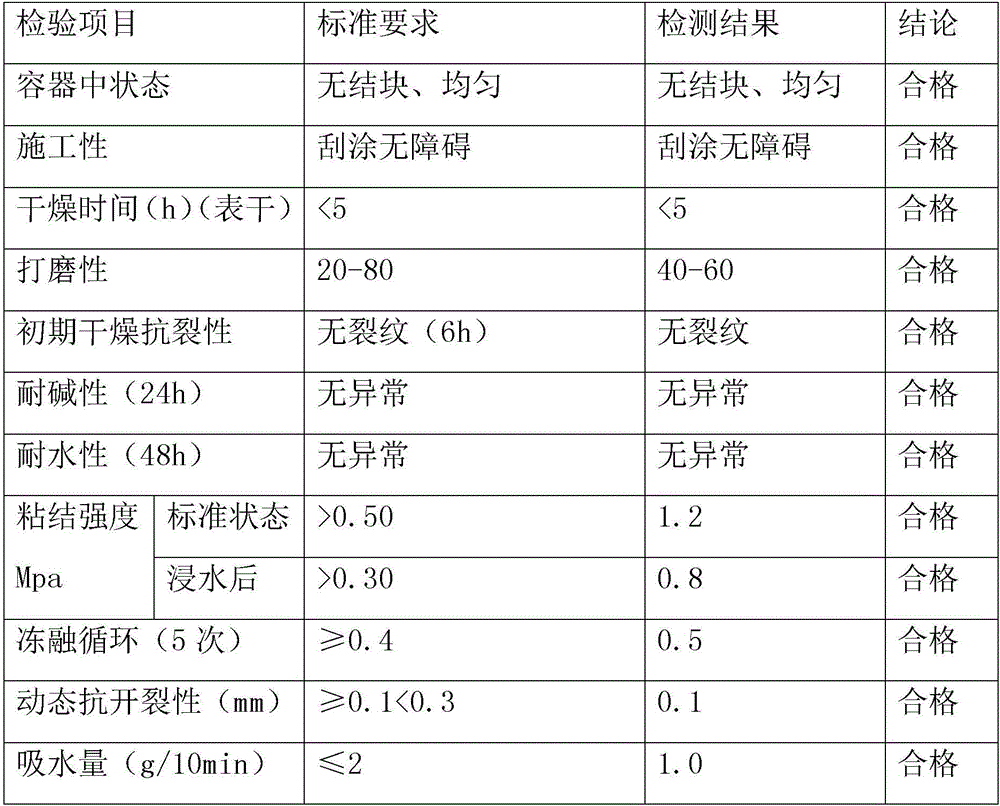

Anti-cracking exterior wall putty powder

The invention discloses anti-cracking exterior wall putty powder which is prepared from the following raw materials in parts by weight: 600-700 parts of heavy calcium carbonate powder, 30-70 parts of ash-calcium-powder, 260-320 parts of white cement, 3.5-5.5 parts of hydroxypropyl methyl cellulose and 0.6-1.5 parts of wood fibers. The anti-cracking exterior wall putty powder disclosed by the invention not only has extremely strong water resistance and cohesiveness, but also further has the advantages of resistance to high and low temperature changes, anti-cracking property and the like, so that the problem that existing exterior wall putty powder is poorer in weather ability is solved.

Owner:CHONGQING TAIRUI NEW BUILDING MATERIALS

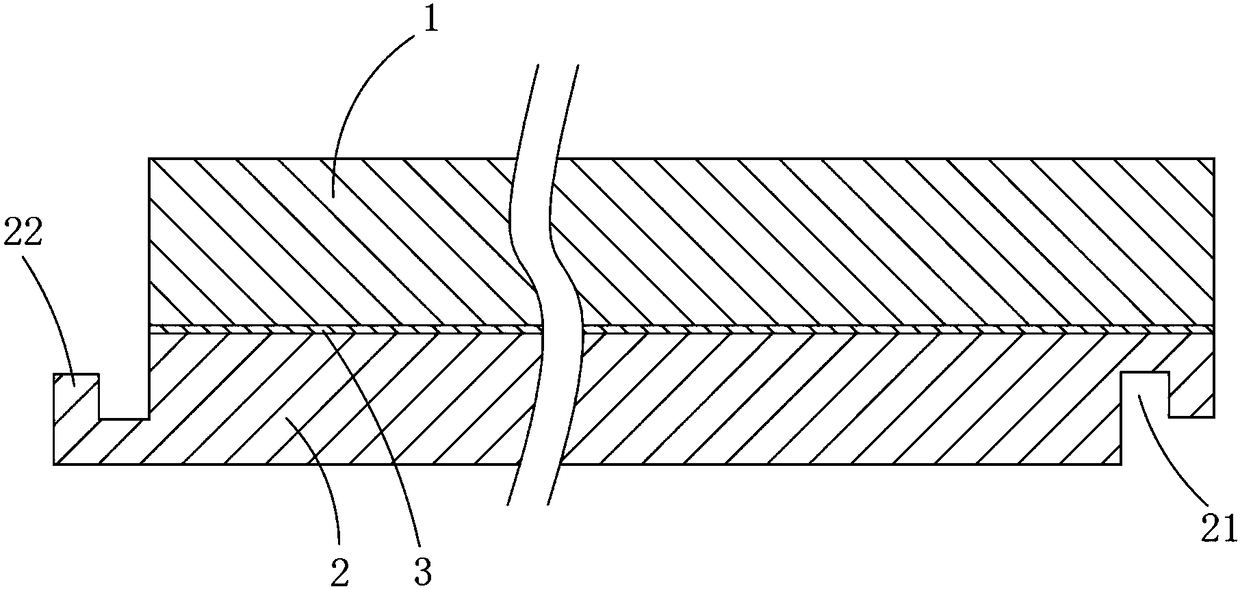

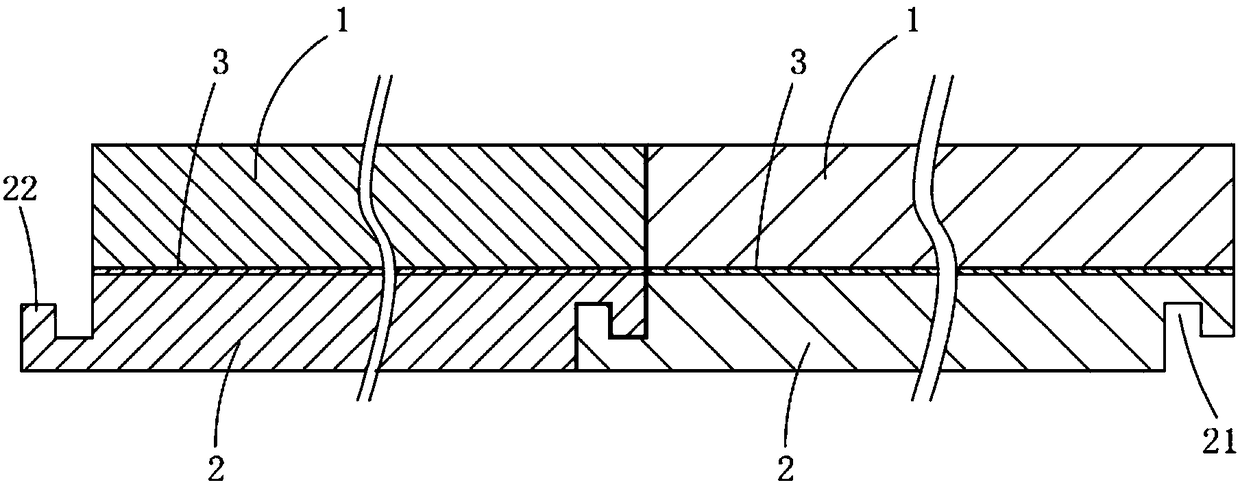

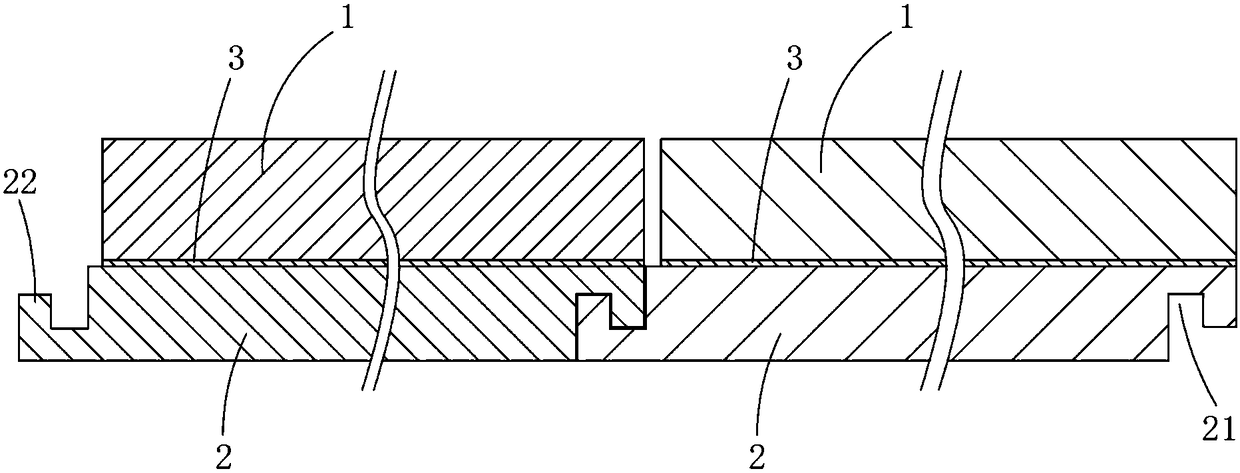

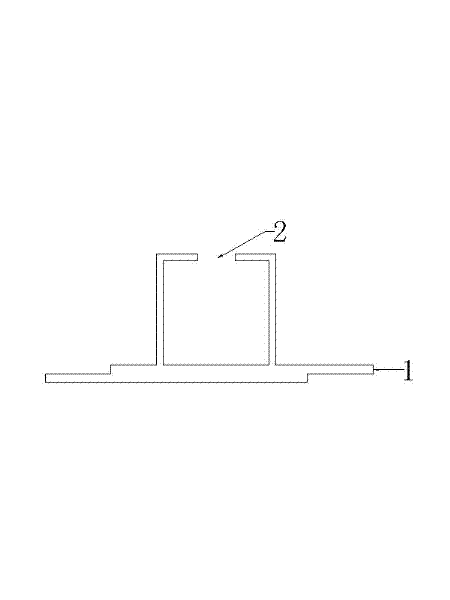

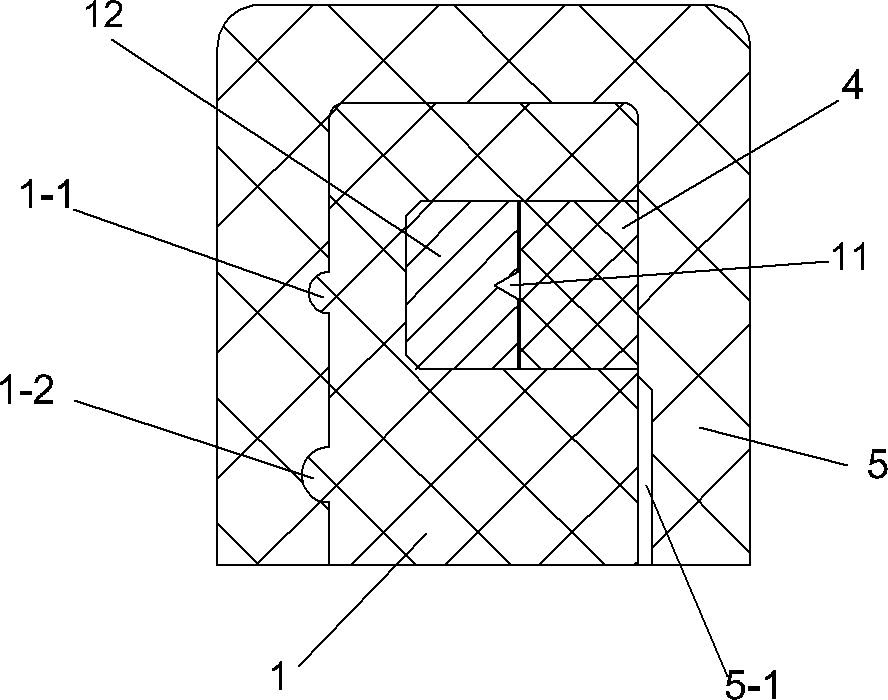

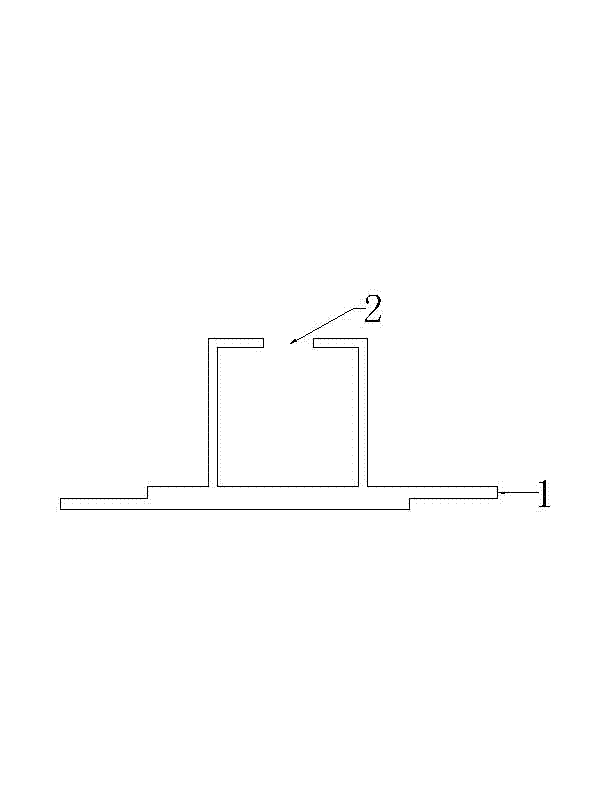

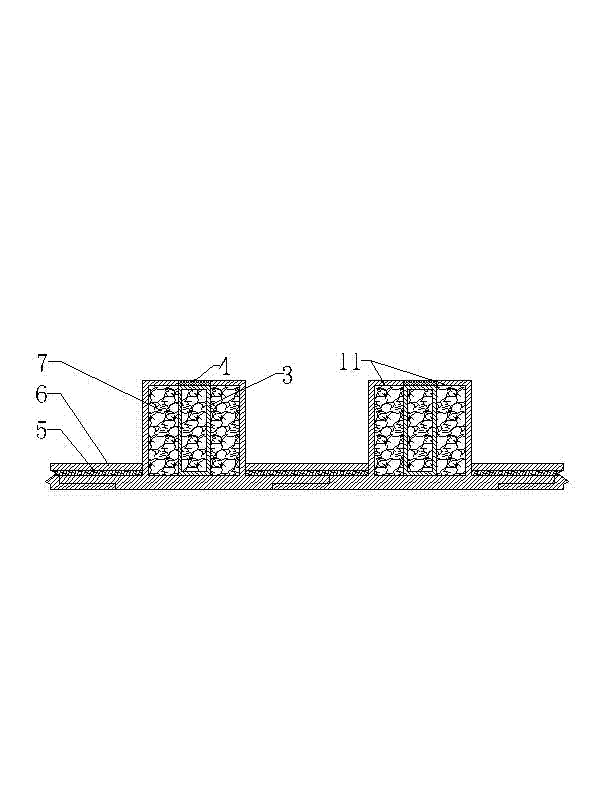

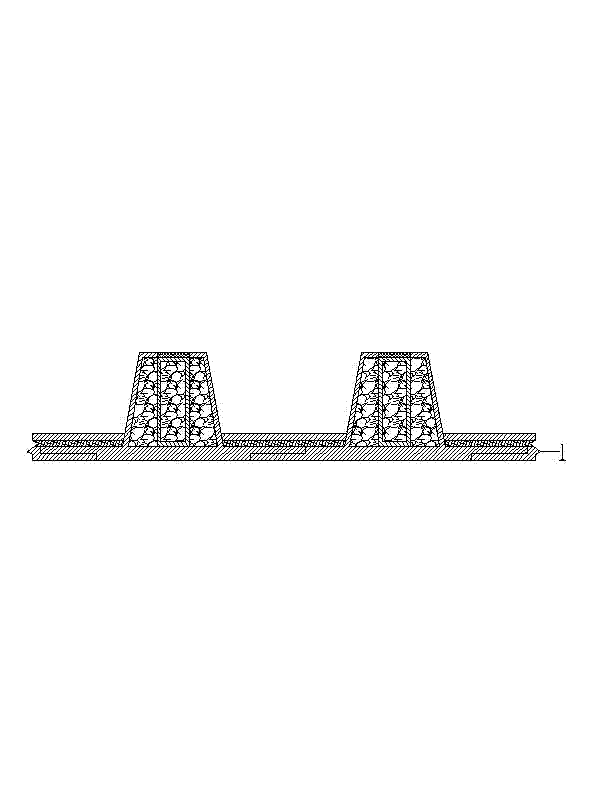

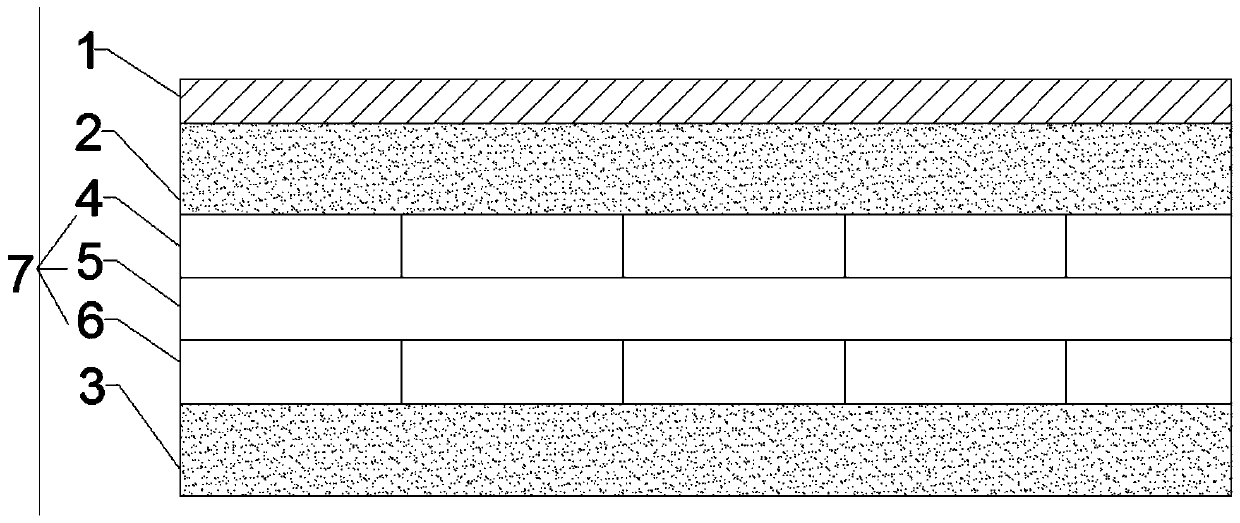

Fireproof moisture-proof easily-laid environmentally-friendly ceramic tile with locking buckles and production method

InactiveCN108442645APaving is simple and convenientPaving is simple, fast and convenientFlooring insulationsTemperature resistanceMoisture

The invention discloses a fireproof moisture-proof easily-laid environmentally-friendly ceramic tile with locking buckles and a production method. According to the production method of the environmentally-friendly ceramic tile, a waterproof substrate layer is composited on the back surface of a ceramic tile body layer by a pressing overlaying process or an in-mold forming process. The environmentally-friendly ceramic tile comprises the ceramic tile body layer located on the upper layer, the waterproof substrate layer is composited on the bottom surface of the ceramic tile body layer, a clamping slot or a clamping tenon is formed in the side surface of the waterproof substrate layer, and the clamping slot and the clamping tenon are connected with each other in a clamped and matched mode, sothat every two environmentally-friendly ceramic tiles can be assembled and connected together. The fireproof moisture-proof easily-laid environmentally-friendly ceramic tile has simple structure, thewaterproof substrate layer enables the environmentally-friendly ceramic tile to have high temperature resistance, fireproof, moisture proof and waterproof functions, and the environmentally-friendlyceramic tile is directly laid on the ground during laying; during the laying process, the clamped connection is directly achieved by the clamping slot or the clamping tenon, and the clamped connectionis simple and convenient; the environmentally-friendly ceramic tile is automatically leveled by the waterproof substrate layer, and no hollowing phenomenon exists; and after the laying, the laid environmentally-friendly ceramic tile can be used without brushing the ground or pre-filling or flattening cement sand, and the ceramic tile laying is simpler, faster and more convenient.

Owner:郑素梅

Gas steam/hot water/boiled water three-heat-in-one stainless steel round tube and round liner heat exchanger

InactiveCN105042554ALower discharge temperatureReduce volumePressure-fired steam boilersSteam generation using pressureCombustion chamberEngineering

The invention discloses a gas steam / hot water / boiled water three-heat-in-one stainless steel round tube and round liner heat exchanger. The heat exchanger comprises a main liner body and an automatic water feeding tank, wherein the main liner body comprises a water holding barrel, a burning chamber, an upper plate, a cover plate and multiple quick heat exchange tubes; a water holding space is formed between the upper plate and the burning chamber; the cover plate is positioned rightly above the upper plate; a tail gas smoke collecting chamber is formed between the cover plate and the upper plate; the heat exchanger is manufactured by using a food grade stainless steel material, accords with the sanitary safety standard of food manufacturing, is high in efficiency of heat utilization design technology, is low in tail gas discharge temperature, saves the energy, protects the environment, is small in volume, and can be matched in multiple forms to be applied to the production of finished products; an innovative energy-saving three-heat-in-one heat exchange technology synchronously provides three heat exchange results of steam, hot water and boiled water; the pressure leakage of high-pressure air of the heat exchanger is detected; the stainless steel structure of the heat exchanger is fixed by a maximum value; the metal fatigue resistance is improved; the heat expansion and cold contraction coefficient is reduced; and the product durability is improved.

Owner:DONGGUAN TIEJIAN ENERGY SAVING KITCHEN TOOLS EQUIP CO LTD

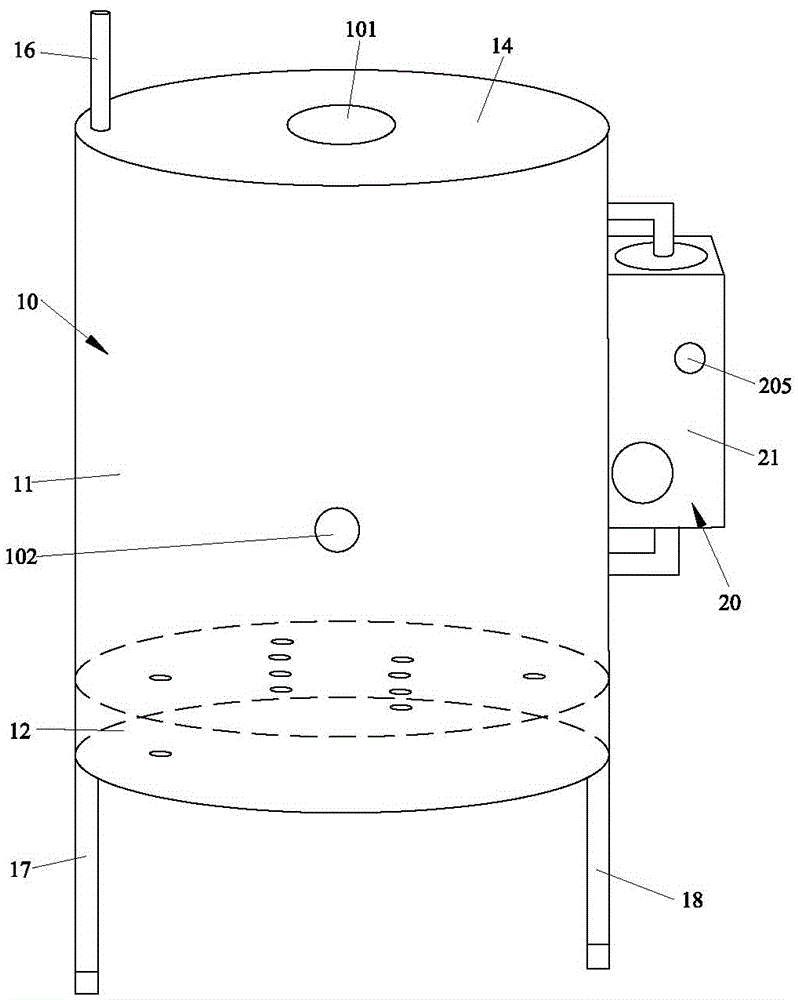

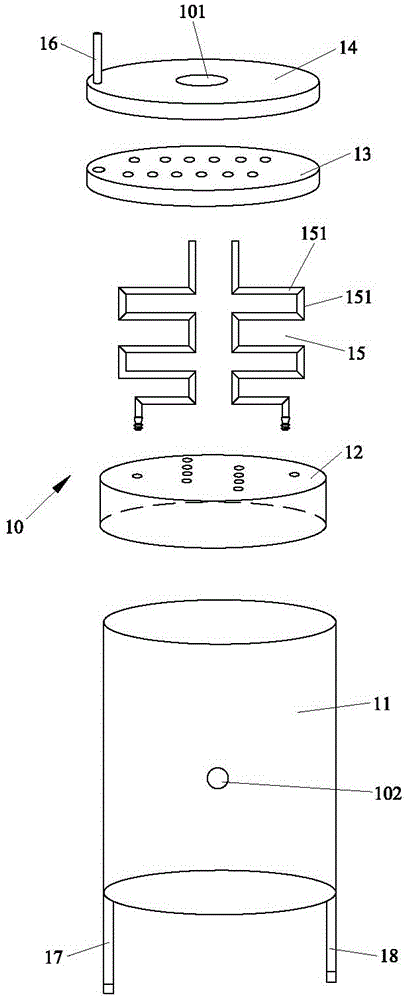

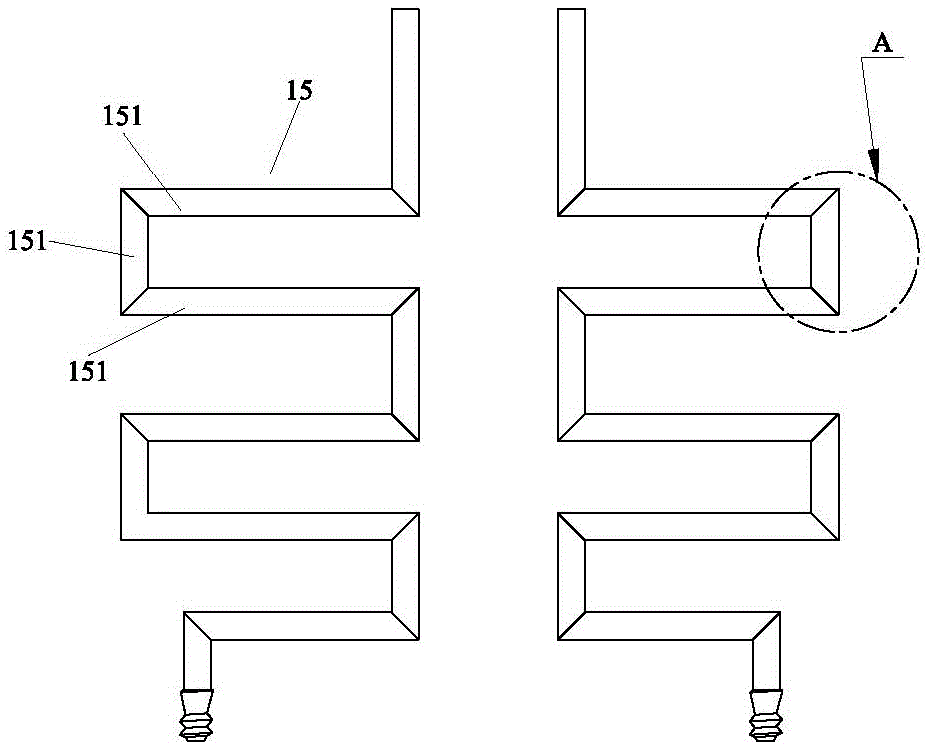

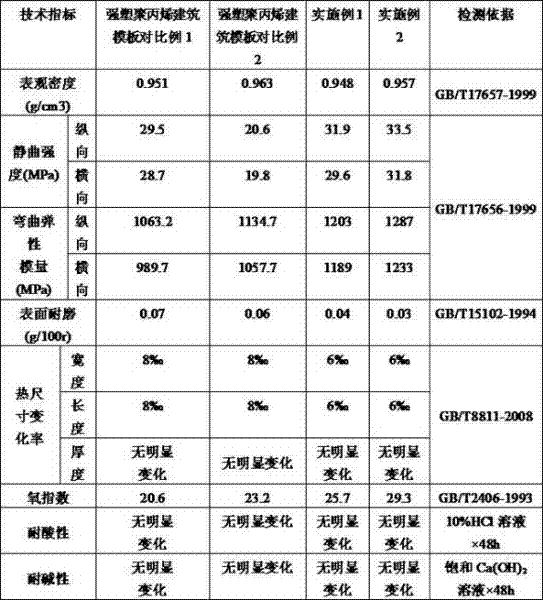

Novel environment-friendly composite reinforced polypropylene building template

InactiveCN102604205AImprove melt strengthDegree of crystallinityForming/stuttering elementsEnvironmental resistanceThermal expansion

The invention relates to a novel environment-friendly composite reinforced polypropylene building template, belonging to the technical field of building template preparation. By virtue of the interaction between fine powder of waste tires and polypropylene-styrene dibromide graft copolymer and aluminum hydroxide / polypropylene, the bonding force among the components is increased, the reinforced plastic polypropylene building template is subjected to physical blending and chemical modification, so that not only the overall properties of the reinforced plastic polypropylene building template areimproved and the flame retardant function of the reinforced plastic polypropylene building template is enhanced, but also a new field of recycling waste tires is opened. Through the composite reinforced polypropylene building template provided by the invention, the problems that the strength and rigidity of the existing composite plastic building template cannot meet the construction requirements, the thermal expansion and cold contraction coefficient is large and the electric welding dregs are likely to scald a face plate are solved, and a large amount of natural rubber and petroleum resources are saved. The composite reinforced polypropylene building template has the advantages of high strength, good flame retardant effect, easily-accessible raw materials and simplicity in production, and can be widely used as the construction template in construction engineering, hydroelectric structures, irregular design of bridges and tunnels and the like.

Owner:HUBEI XINLONG PLASTICS

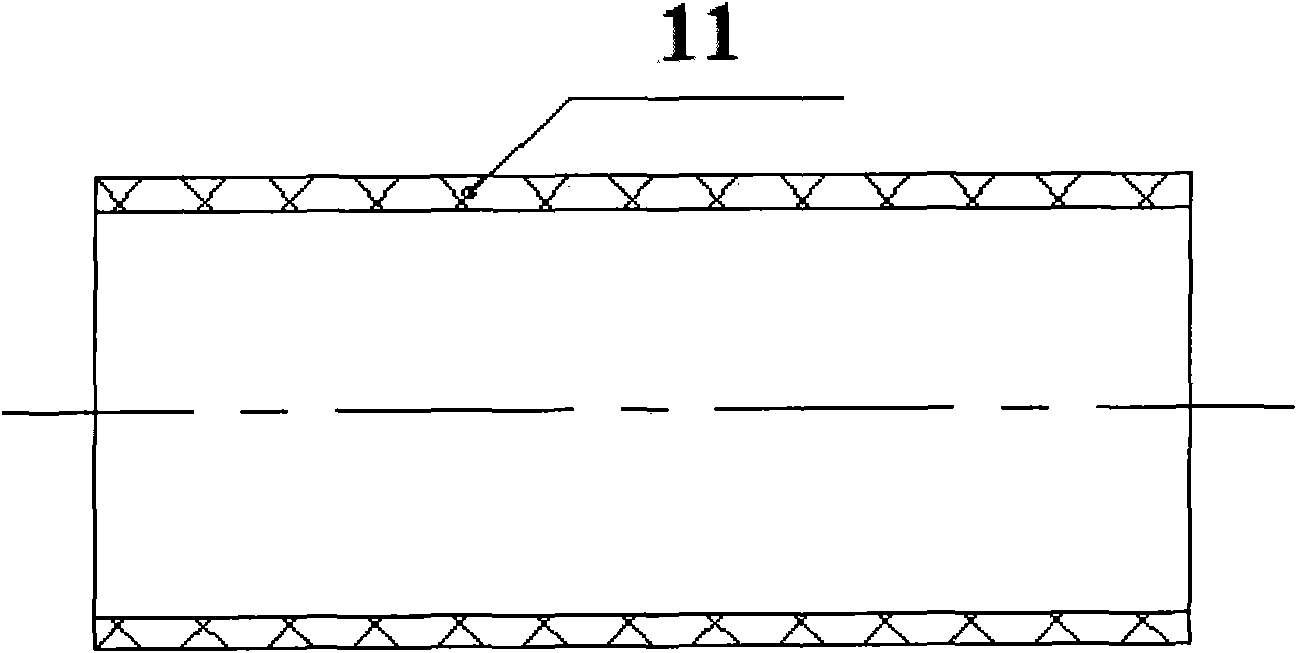

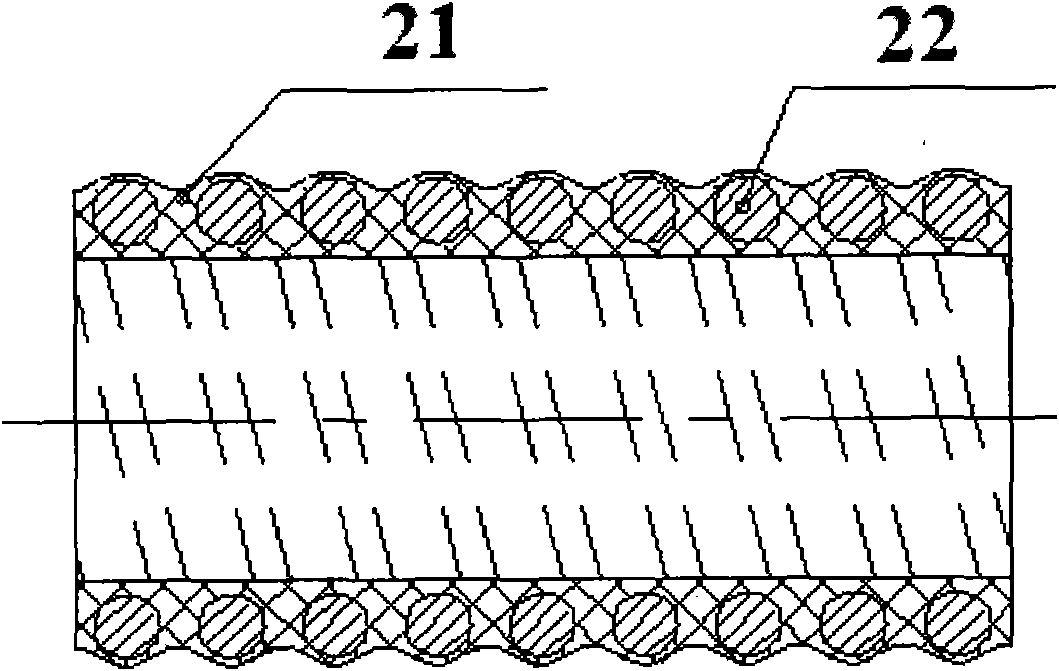

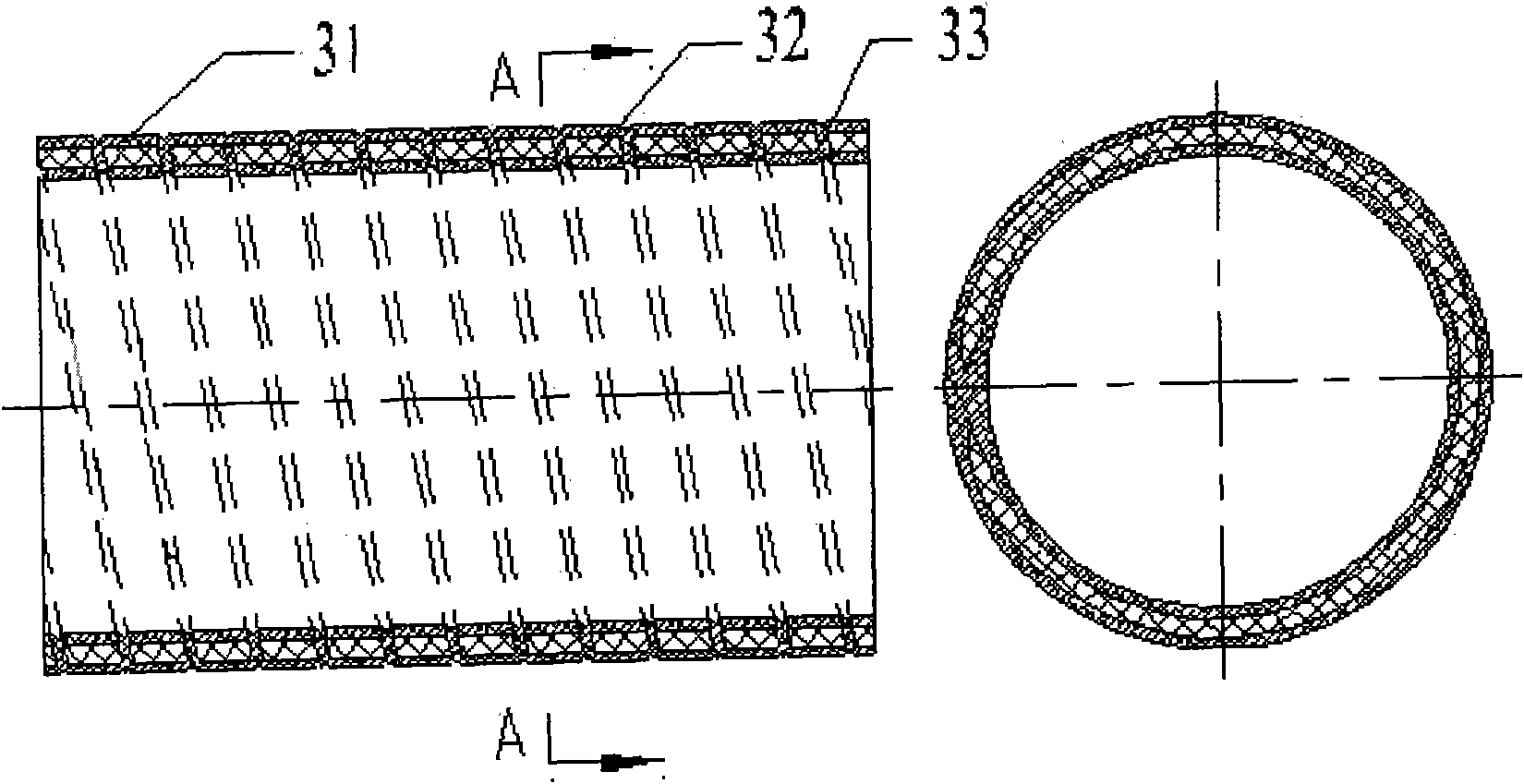

Method for producing steel-plastic multi-element composite pipes

ActiveCN102230554APrevent looseningIncrease resistance to longitudinal forceRigid pipesFiberPolyvinyl chloride

The invention provides a method for producing steel-plastic multi-element composite pipes, which comprises the following steps of: modifying high-density polyethylene (HDPE) or polyvinyl chloride (PVC) plastics and manufacturing plastic plate strips; manufacturing hollow reinforcing ribs of which two side edges are recessed and overlapped; welding notches of the recessed bottoms of the reinforcing ribs by using continuous welding equipment; synchronously winding the welded reinforcing ribs with the plastic plate strips to form an inner wall of a pipe; coating and rolling on the wound pipe wall; coating a fiber mesh or winding a fiber strip and rolling on the rolled pipe wall; coating and rolling on a fiber layer to form an outer wall of the pipe; cutting the pipe which is finished in the seventh step at fixed length; sealing a port of each reinforcing rib at one end of the cut pipe, and injecting prepared cement slurry into each square reinforcing rib at the other end of the pipe by using grouting equipment; and finally, vertically erecting and fixing the pipe which is injected with the cement slurry, so that the cement slurry is solidified to form a finished pipe. The invention has the advantages that: the pipe can resist internal and external pressures and prevent cracking, an expansion on heating and contraction on cooling coefficient of the pipe is reduced, and the reinforcing ribs are prevented from rusting.

Owner:娄底市朝阳塑胶有限公司

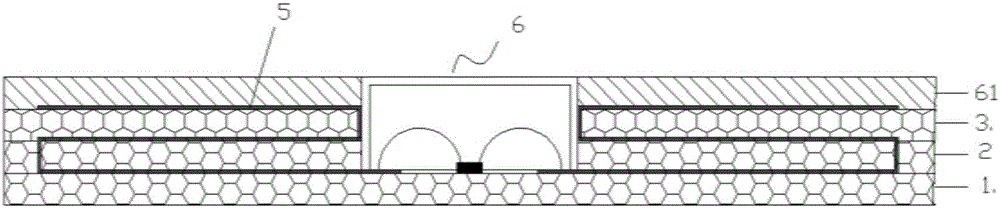

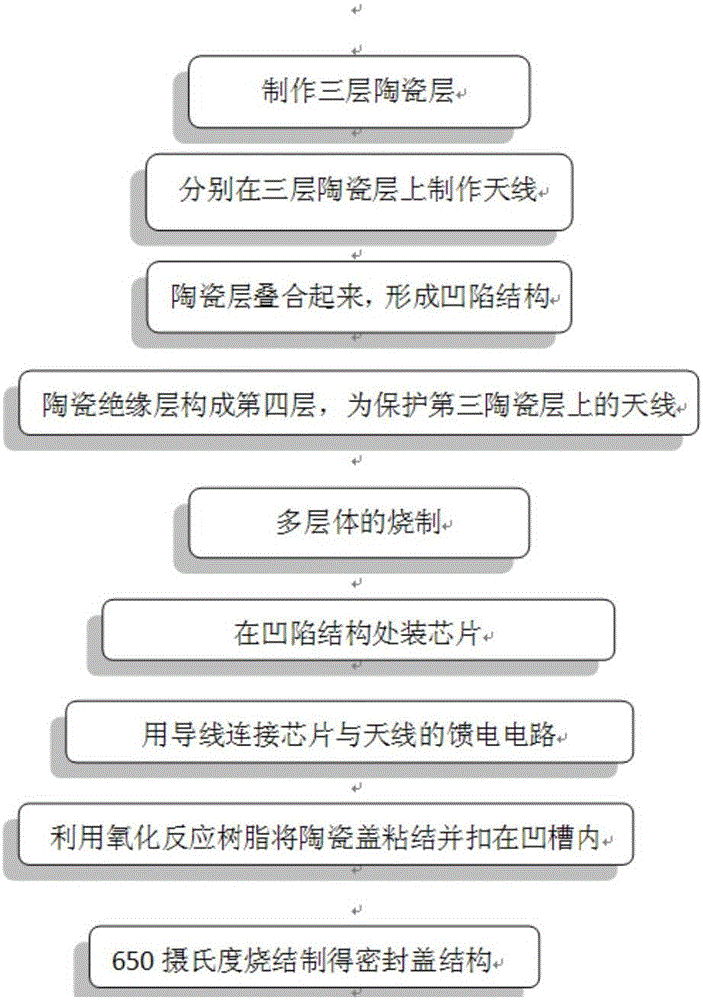

Novel electronic tag production process

The invention discloses a novel electronic tag production process, which comprises the following steps of step 1.sintering and curing a printed antenna and a substrate to form an antenna substrate through the existing conventional process; step 2.placing an IC chip into a groove structure of the antenna substrate and adopting the existing conventional technical method to bind the IC chip on a feeding point of the antenna in the groove without epoxy resin dripping protection; step 3.providing a ceramic cover; step 4.bucklling the cover in the step 3 on the groove structure of the substrate and pre-coating oxidizing reaction glue on a contact place, wherein the IC chip is arranged in the cover, and two sides of the cover are ends of the antenna, which are used for adjusting a tag frequency band; and step 5.sintering at high temperature (the field is usually within the range of 600-700 DEG C), and reacting and sintering the oxidizing reaction to make the ceramic cover and the ceramic substrate form a whole body on the groove structure and form a closed space. A product obtained by the process of the invention is suitable for various high and low temperature application environments.

Owner:SHANGHAI BIZGRID INFORMATION TECH

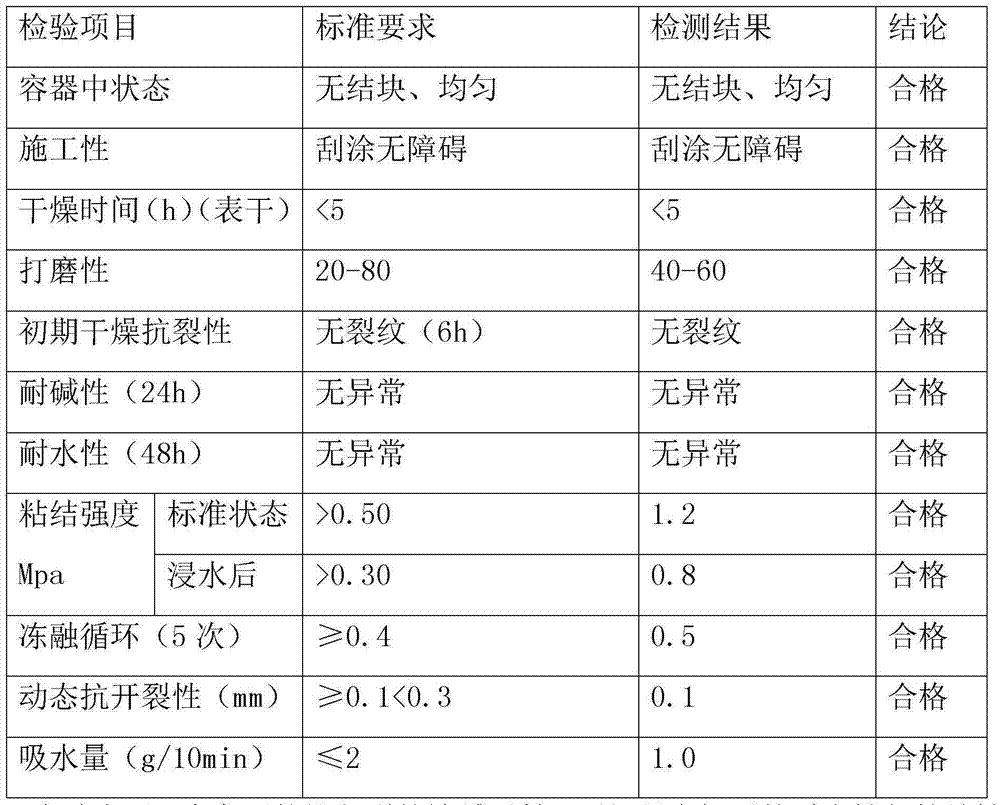

Waterproof and anti-crack outer wall putty powder and preparation method thereof

InactiveCN107090203AStable structureSmooth and delicate appearanceFilling pastesCrack resistanceAnhydrous Calcium Sulfate

The invention discloses a waterproof and anti-crack outer wall putty powder and a preparation method thereof. The outer wall putty powder is prepared from, by weight, 60-80 parts of talcum powder, 10-20 parts of attapulgite clay, 10-18 parts of ground calcium carbonate, 2-8 parts of sodium bentonite, 5-10 parts of calcium oxide, 5-10 parts of anhydrous calcium sulfate, 1-5 parts of polyacrylamide, 0.6-3 parts of carboxymethylcellulose sodium, 2-5 parts of pulverized fuel ash, 0.2-0.5 part of pure iron powder and 0.4-0.8 part of a water repellent. The preparation method comprises the steps of attapulgite clay acidification, vibrating screen grinding, co-heat superfine crushing and the like. The putty powder is firm in structure and smooth and delicate in appearance and has good adhesive force with wall, watertightness, corrosion resistance and cracking resistance are achieved, the preparation method is simple and easy to implement, construction is easy and convenient, and blade coating and leveling performances are excellent.

Owner:合肥市一片叶装饰工程有限公司

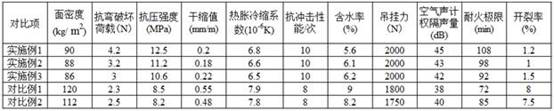

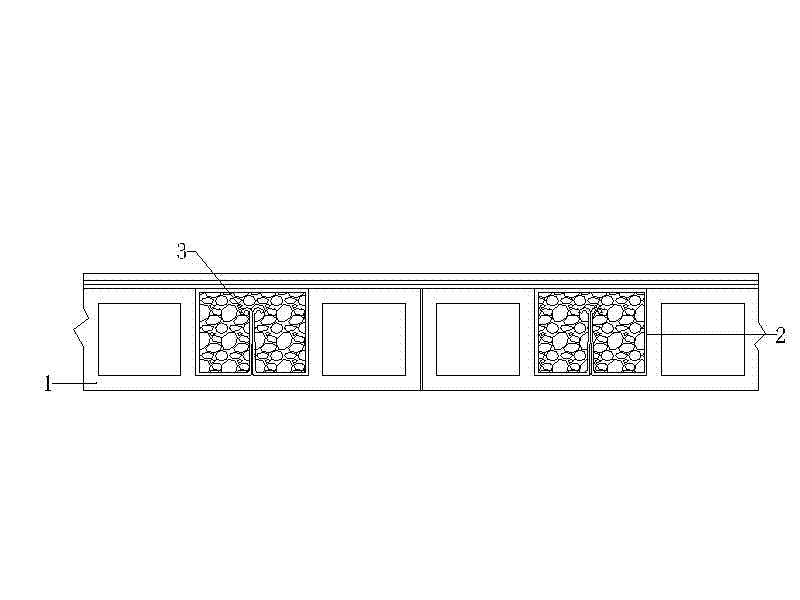

Concrete extrusion wallboard and preparation method thereof

PendingCN112265112ALightweight and high strengthLow areal densityCeramic shaping apparatusAluminateVibration amplitude

The invention relates to a concrete extrusion wallboard and a preparation method thereof, and relates to the technical field of building materials. The preparation method of the concrete extrusion wallboard comprises the following steps that portland cement, sulphate aluminium cement, gypsum, aggregate and water are mixed and stirred to prepare a concrete blank; and vibration extrusion is conducted on the concrete blank to prepare the concrete extrusion wallboard. The technological parameters of vibration extrusion comprise the vibration amplitude of vibration of 0.9 mm to 1.1 mm, and the mainvibration frequency of 45Hz to 55Hz; and the spiral spacing of a reamer of 65 mm to 80 mm, the spiral length of 290 mm to 310 mm, the taper of the spiral bottom diameter of 35 degrees to 45 degrees,and the rotating speed of the reamer of 210r / min to 230r / min; And the assisting frequency of the advancing speed of the concrete blank is controlled to be 35Hz to 39Hz. The prepared concrete extrusionwallboard is small in surface density, large in compactness, high in strength, large in drying shrinkage value, small in thermal expansion and cold contraction coefficient and small in cracking rateafter installation.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

PVC (polyvinyl chloride) dual-resistant flexible pipe

InactiveCN102032400AImprove antistatic performanceImprove flame retardant performanceFlexible pipesAntistatic agentCombustion

The invention discloses a PVC (polyvinyl chloride) flexible pipe for drawing and releasing gas in a coal mine underground, wherein the flexible pipe comprises soft PVC and a casing ply embedded in the soft PVC, and the casing ply is composed of a non-plasticization PVC hard strip. Because the non-plasticization PVC hard strip is adopted as the casing ply for the PVC flexible pipe provided by the invention, the hard strip and the soft PVC belong to homogeneous material, the consistency of the hard strip and the soft PVC is excellent, the difference of coefficients of creepage and heat expansion and cold contraction is minimum, and separation of the hard strip and the soft PVC does not happen under the aging effect and the temperature fluctuation effect; and in addition, an anti-static agent and flame retardant are added in the soft PVC, the antistatic property and the flame retardant property of the flexible pipe are enhanced, and the combustion resistant and antistatic flexible pipe standard used at the coal mine underground is reached.

Owner:SHANXI QINGKE HENGAN MINING NEW MATERIAL

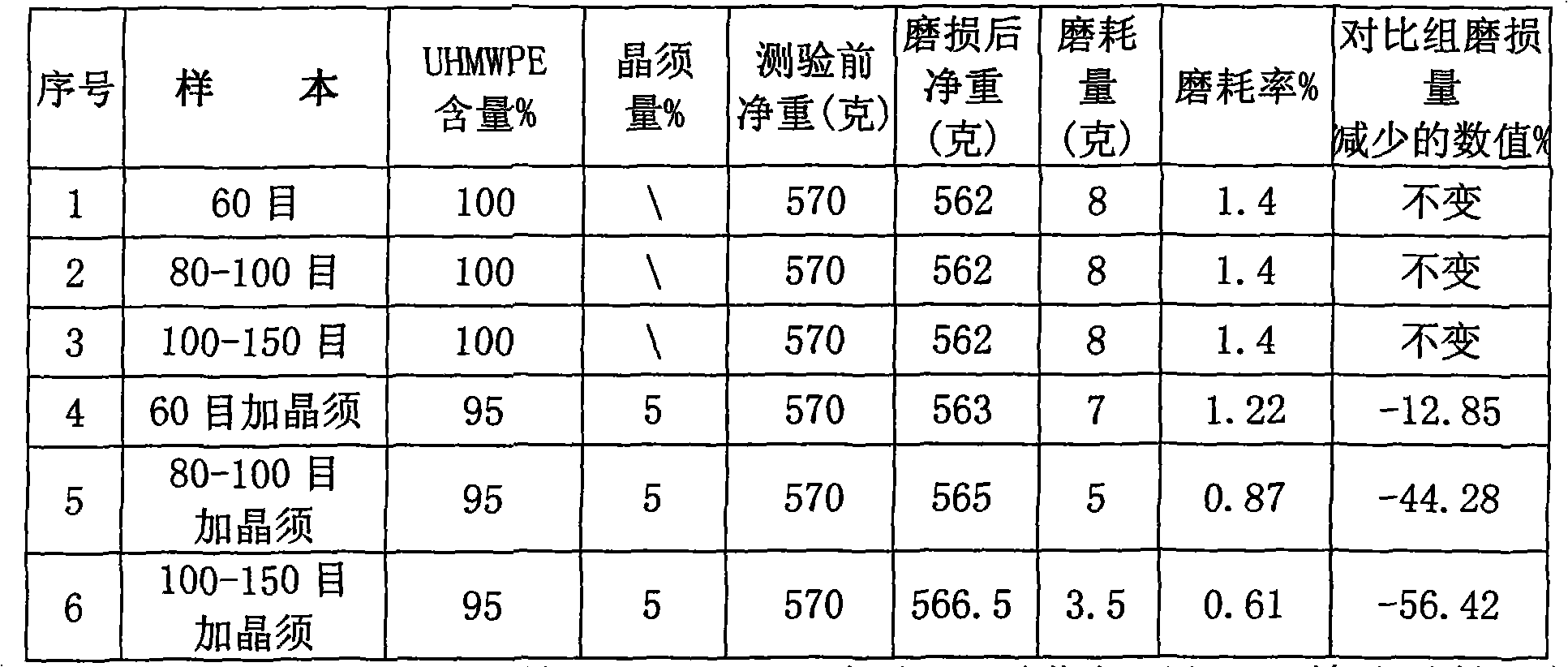

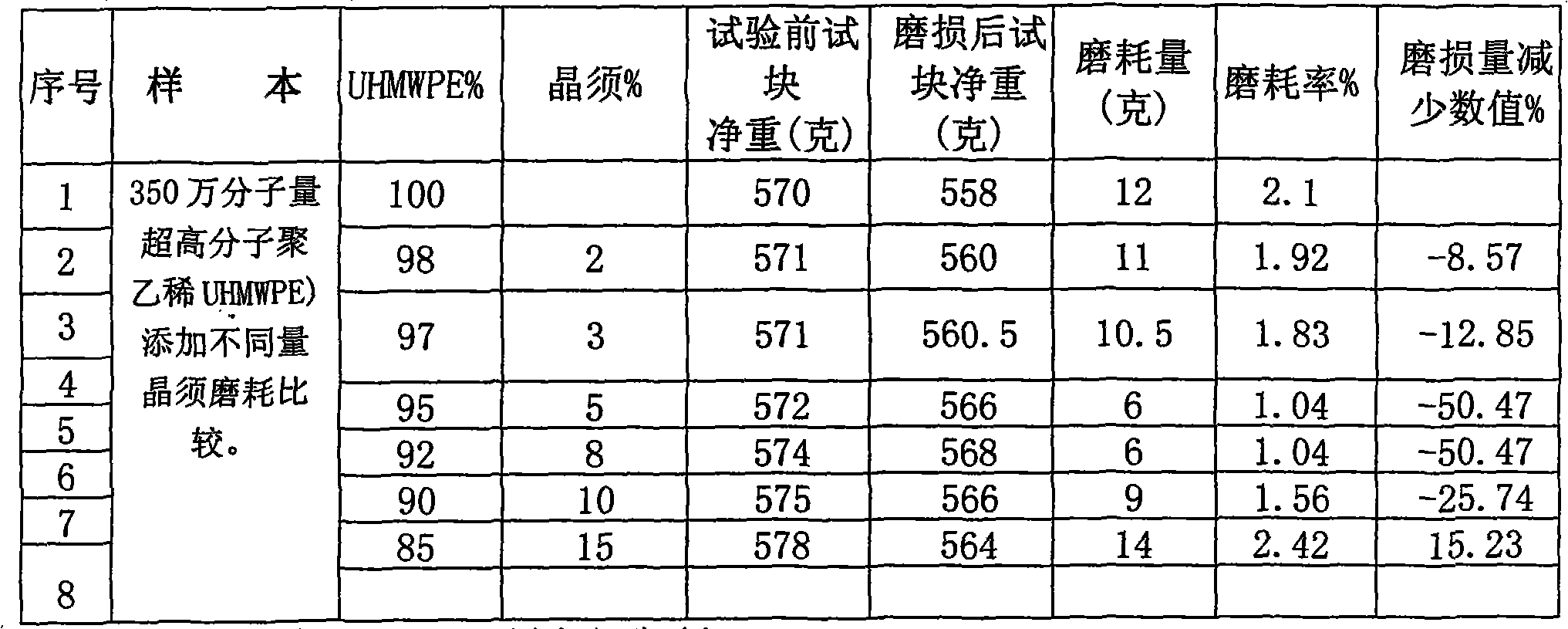

Modified ultra-high molecular weight polyethylene (UHMWPE) and application thereof on centrifugal pump

InactiveCN101857688AImprove mechanical stabilityImprove yieldPump componentsPumpsPolymer scienceThermal expansion

The invention relates to a modified ultra-high molecular weight polyethylene (UHMWPE) that is characterized by being prepared by mixing 85 to 98 wt% of ultra-high molecular weight polyethylene with the molecular weight (measured by viscosimetry) of 1.5 to 5 millions and 2 to 15 wt% of potassium carbonate whisker processed by a coupling agent. The invention not only greatly improves the abrasion resistance of the UHMWPE, but also has the comprehensive effects of raising of use temperature, reduction of coefficient of thermal expansion and improvement of melting performance, processing and molding performance, production efficiency and product quality; and in particular, the invention is suitable for anti-corrosive and wear-resisting centrifugal pumps.

Owner:宜兴市宙斯泵业有限公司

UV transfer printing process for wall decorative sheet

InactiveCN108177474ADifficult to breedImprove sound insulationDecorative surface effectsPretreated surfacesBenzeneUltraviolet

The invention relates to a UV transfer printing process for a wall decorative sheet. The process comprises the following steps: (1) processing a substrate; (2) carrying out roller painting on the front surface; (3) carrying out transfer printing; and (4) carrying out film covering. No harmful gas such as formaldehyde and benzene are released in the process, so that the process is green and environment-friendly. By adopting a product with inorganic and fluorocarbon coatings, the anti-ultraviolet property of the product in an application of an exterior wall is improved greatly; the product is smooth in surface and is coated with a special antibacterial coating, so that bacteria are unlikely to breed, and the product shows an excellent antibacterial performance; a panel is high in areal density and has a good sound isolating property, and a cavity is formed in a mounting system to achieve a sound absorbing effect; by adopting a special antistatic coating, the surface of the product has the antistatic function; the cold and hot expansion shrinkage coefficient is small, and the size of the panel is scarcely changed as the temperature changes. The process provided by the invention is good in durability, light in weight, easy to clean, energy-saving and environment-friendly, easy to process, waterproof and excellent in drug resistance.

Owner:江苏建院欧野科技有限公司

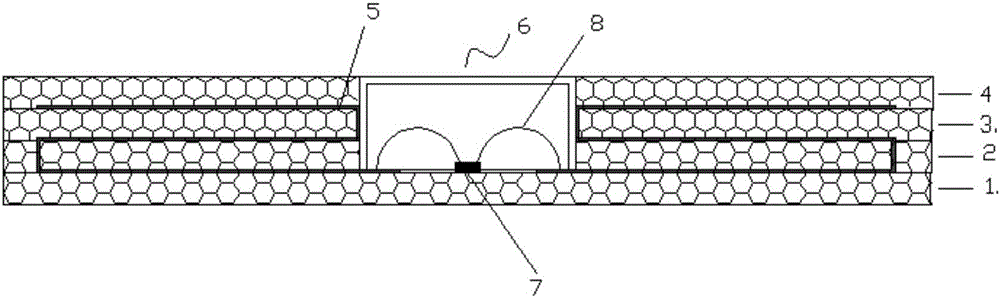

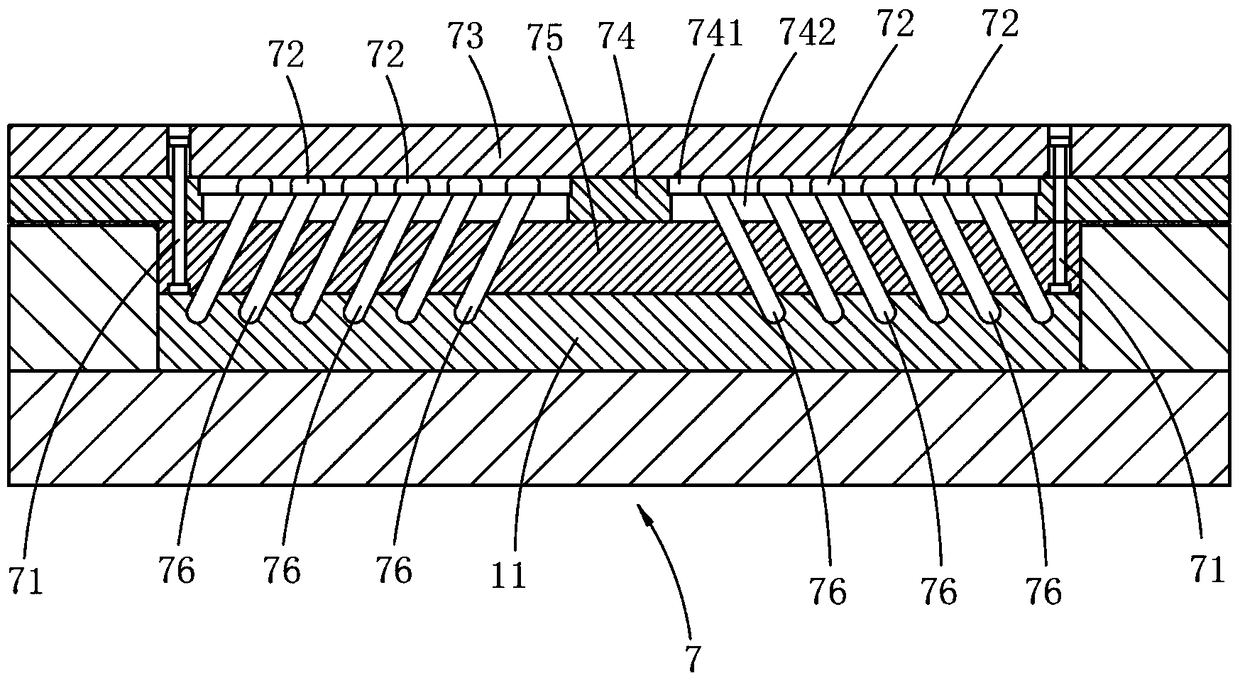

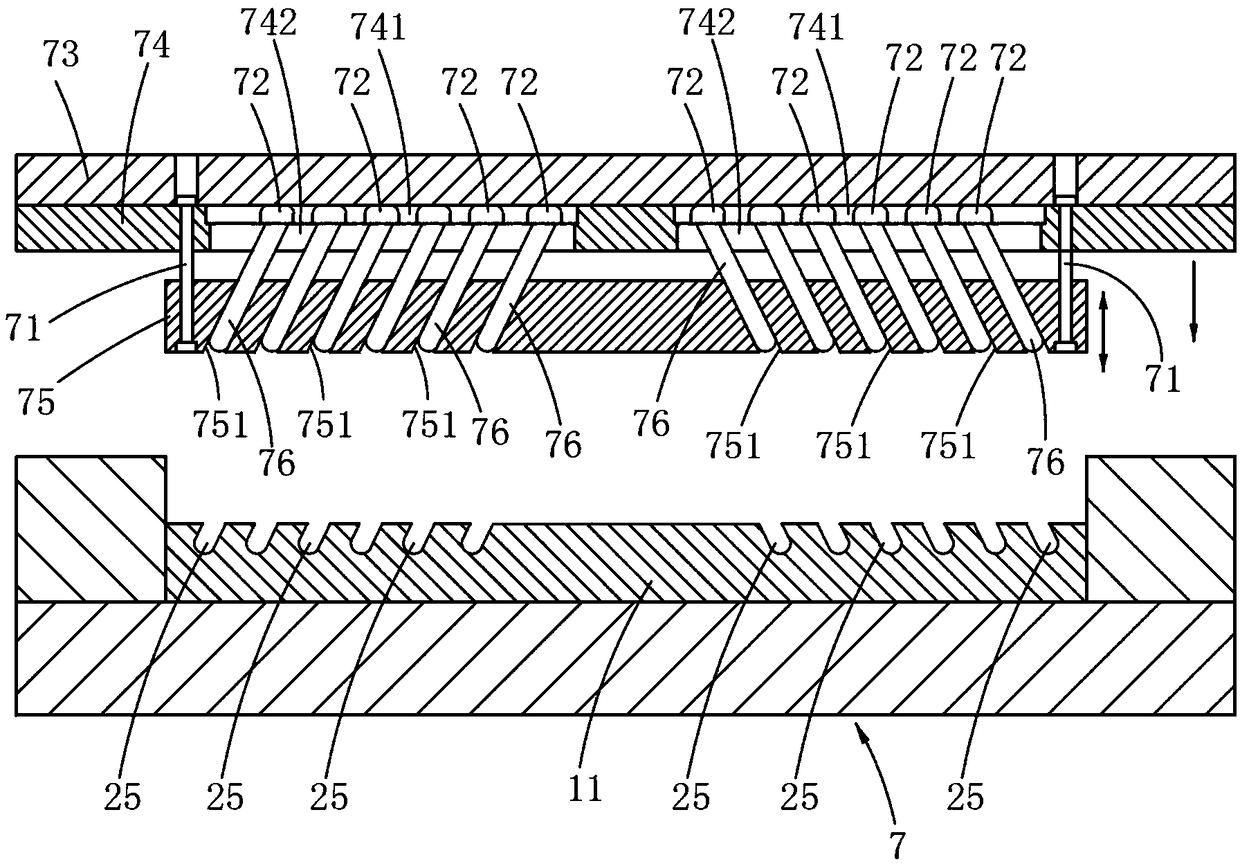

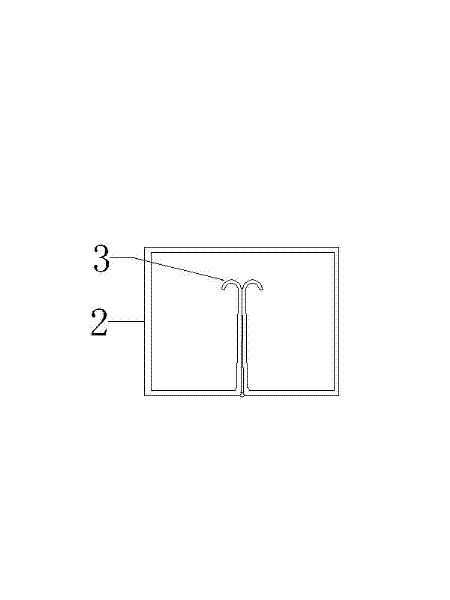

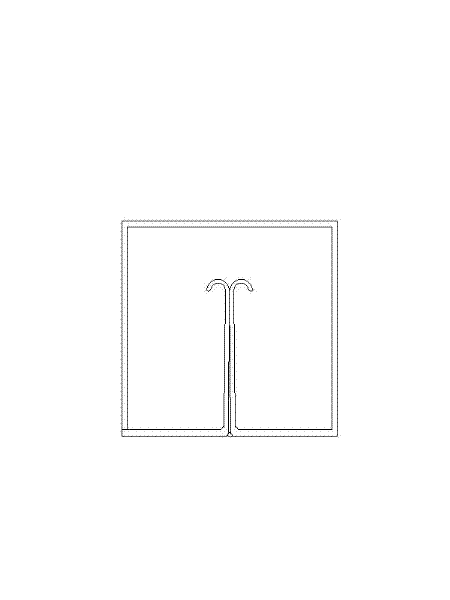

Integrated ceramic tile easy to lay and production method of integrated ceramic tile easy to lay

PendingCN109016083AHigh dimensional accuracyReduced dimensional accuracy requirementsCeramic extrusion diesThermal expansionMaterials science

The invention discloses a production method of an integrated ceramic tile easy to lay. A plurality of slotted holes with different directions are formed in the bottom face of a ceramic tile body mud blank, the ceramic tile body mud blank is sintered and formed, and a ceramic tile body layer is obtained; the ceramic tile body layer is placed in a cavity of a lower die of a forming die, the integrated ceramic tile easy to lay is obtained through die interior forming, an integrally-formed plastic base material layer is combined to the bottom face of the ceramic tile body layer of the integrated ceramic tile easy to lay, and a chase mortise structure is integrally formed on the periphery of the plastic base material layer; surrounding edges are integrally formed on the periphery of the top face of the plastic base material layer, the surrounding edges wrap the side face of the periphery of the ceramic tile body layer, the surrounding edges on the periphery of the plastic base material layer are connected into a whole, and the ceramic tile body layer and the plastic base material layer are firmly combined; and production is easy, the production speed is high, the production cost is low,and the size error of the ceramic tile body layer can be eliminated through the surrounding edges in the die interior forming technology; and through the die interior forming technology, the requirement for the size precision of the ceramic tile body layer is lowered through the die interior forming technology, the ceramic tile body layer can be effectively protected through the surrounding edges, and heat expansion and cold shrinkage between the ceramic tile body layer and the plastic base material layer can be balanced through the surrounding edges.

Owner:郑素梅

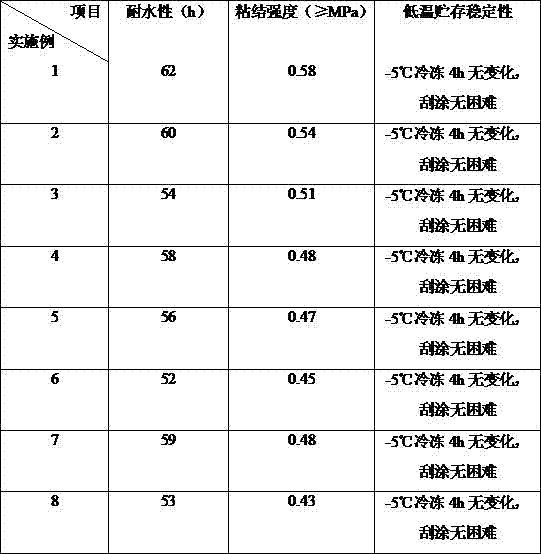

Anti-cracking exterior wall putty powder and preparation method thereof

InactiveCN111995897AGood adhesionImprove waterproof performanceFilling pastesWeather resistanceLatex rubber

The invention discloses anti-cracking exterior wall putty powder. The anti-cracking exterior wall putty powder is prepared from the following raw materials in parts by weight: 60 to 100 parts of puttypowder base material; 15 to 30 parts of heavy calcium carbonate powder; 30 to 50 parts of anti-cracking additive; and 0.3 to 0.5 part of redispersible latex powder. The preparation method comprises the following steps of: (1) adding the putty powder base material and the heavy calcium carbonate powder into a mixer, and stirring the materials for 25-30 minutes at the stirring speed of 550-650r / minto obtain a mixture; and (2) adding the anti-cracking additive and redispersible latex powder into the mixture obtained in the step (1), heating to 60-75 DEG C, stirring again for 30-40 minutes at the stirring speed of 650-750 r / min, and then performing drying. The formula of the anti-cracking exterior wall putty powder is reasonable; the preparation method is simple and easy to implement; the prepared putty powder is good in bonding performance and waterproof performance; polymethyl methacrylate improves the weather resistance of the exterior wall putty powder and can prevent the exterior wall putty powder from cracking; tungsten zirconate can reduce the thermal expansion and cold contraction coefficient of the exterior wall putty powder; the tungsten zirconate is matched with the polymethyl methacrylate to well prevent the exterior wall putty powder from cracking.

Owner:贵州贵安碳酸钙实业发展有限公司

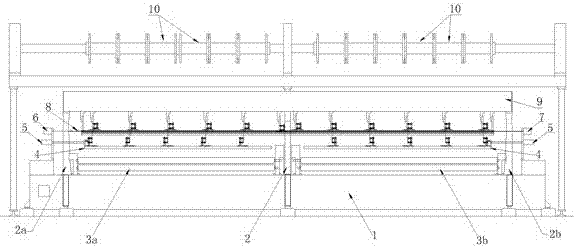

Wide-breadth multi-guide-bar jacquard warp knitting machine with yarn pressing plate

InactiveCN107354573AIncrease productivityWith pattern three-dimensional effectFlat warp knitting machinesFull widthWarp knitting

The invention discloses a wide-breadth multi-guide-bar jacquard warp knitting machine with a yarn pressing plate. The machine is characterized in that the width of the warp knitting machine is at least 240 inches and can reach 268 inches. A slot needle bed, a needle core bed, a knocking-over piece and the yarn pressing plate of the warp knitting machine are all divided into a left part and a right part from the middle. A main beam of the warp knitting machine is jointly supported by a left wallboard, a right wallboard and a middle wallboard. Guide bars include the pattern guide bar, the ground guide bar and the jacquard guide bar. The pattern guide bar transversely penetrates through the middle wallboard along the full width of a needle bed and is installed on a guide bar base, a pattern needle is installed on the pattern guide bar, the pattern needle and the pattern guide bar are assembled and disassembled in a pluggable mode, and the pattern guide bar is driven by a servo motor at one end and a cylinder at the other end to transversely move in an opposite-pull. The ground guide bar and the jacquard guide bar are both divided into a left section and a right section at the position of the middle wallboard, and the transverse movements of the ground guide bar and the jacquard guide bar are driven by guide bar transverse movement devices installed at a machine head and at a machine tail respectively. The middle wallboard is additionally arranged in the middle of a machine table to support the main beam, the span of the main beam is reduced, vibration of the machine table in the operation process is reduced, and the stable operation of the machine table is guaranteed.

Owner:FUJIAN XIN GANG TEXTILE MACHINERY

Method for producing steel-plastic multi-element composite pipes

ActiveCN102230554BPrevent looseningImprove deformation resistanceRigid pipesTubular articlesFiberPolyvinyl chloride

The invention provides a method for producing steel-plastic multi-element composite pipes, which comprises the following steps of: modifying high-density polyethylene (HDPE) or polyvinyl chloride (PVC) plastics and manufacturing plastic plate strips; manufacturing hollow reinforcing ribs of which two side edges are recessed and overlapped; welding notches of the recessed bottoms of the reinforcing ribs by using continuous welding equipment; synchronously winding the welded reinforcing ribs with the plastic plate strips to form an inner wall of a pipe; coating and rolling on the wound pipe wall; coating a fiber mesh or winding a fiber strip and rolling on the rolled pipe wall; coating and rolling on a fiber layer to form an outer wall of the pipe; cutting the pipe which is finished in the seventh step at fixed length; sealing a port of each reinforcing rib at one end of the cut pipe, and injecting prepared cement slurry into each square reinforcing rib at the other end of the pipe by using grouting equipment; and finally, vertically erecting and fixing the pipe which is injected with the cement slurry, so that the cement slurry is solidified to form a finished pipe. The invention has the advantages that: the pipe can resist internal and external pressures and prevent cracking, an expansion on heating and contraction on cooling coefficient of the pipe is reduced, and the reinforcing ribs are prevented from rusting.

Owner:娄底市朝阳塑胶有限公司

Attapulgite interior wall putty powder and preparation method thereof

InactiveCN106978001AImprove adsorption capacitySmall thermal expansion and contraction coefficientFilling pastesAnhydrous Calcium SulfateThermal expansion

The invention discloses attapulgite interior wall putty powder and a preparation method thereof. The attapulgite interior wall putty powder is prepared from the following raw materials in parts by weight: 15-28 parts of attapulgite clay, 10-18 parts of white cement, 5-10 parts of calcium oxide, 18-25 parts of anhydrous calcium sulfate, 1-5 parts of polyacrylamide, 0.6-3 parts of hydroxypropylmethyl cellulose, 2-5 parts of fly ash and 0.2-0.5 part of pure iron powder. By adopting the attapulgite clay with high variable area and strong adsorption and combining with the calcium oxide, the anhydrous calcium sulfate, the polyacrylamide and the fly ash, the attapulgite interior wall putty powder is environmentally friendly and pure white, is strong in adhesive power, resists acid and base corrosion and is stable in storage; and in addition, by adding the pure iron powder, the thermal expansion and cold contraction coefficient of the putty powder is much lowered, the putty powder cannot chap because of large temperature difference variation, the weatherability is improved, and indoor harmful electromagnetic radiation can also be absorbed.

Owner:明光市安盛非金属材料厂

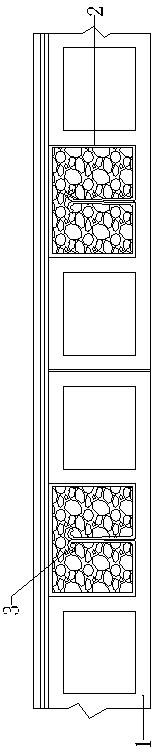

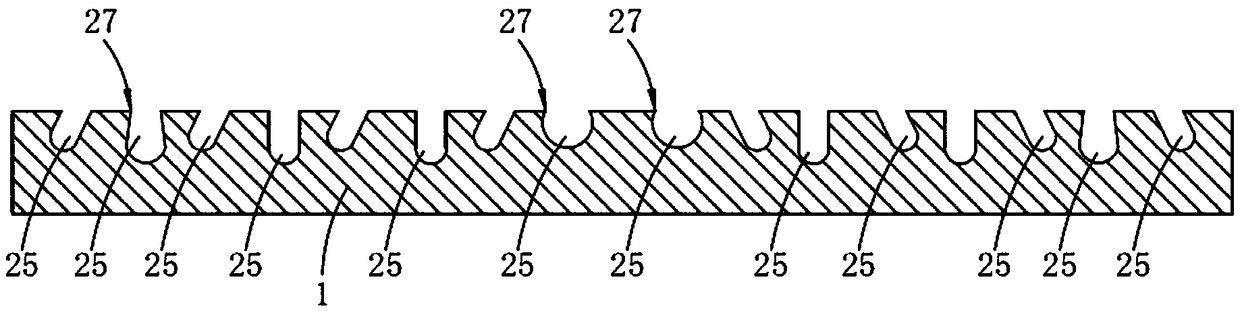

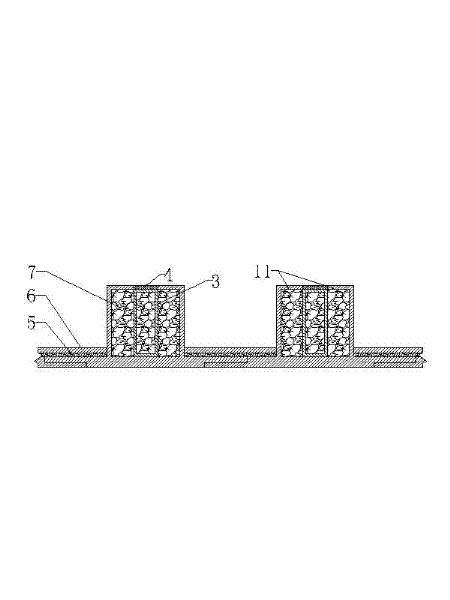

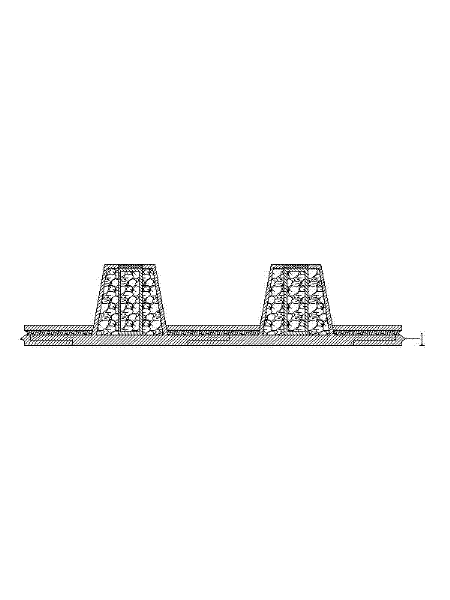

A plastic, concrete and fiber composite pipe with reinforcing ribs

The invention provides a plastic, concrete and fiber composite pipe with a reinforcing rib. The pipe comprises a plastic plate strip, wherein the edges of the plastic plate strip are lapped or welded to form a pipe wall; a clamping groove is formed on the plastic plate strip; the reinforcing rib is embedded into the clamping groove; a concrete cavity is formed between the outer side wall of the reinforcing rib and the inner side wall of the clamping groove; notches of the clamping groove are sealed by a sealing layer; a fiber layer made of a fiber mesh or a fiber strip is wound on the outer wall of the weld of the plastic plate strip; an anti-cracking layer is formed on the outer wall of the fiber layer through glue coating; and concrete is filled in the concrete cavity. The pipe has the advantages that: 1, the concrete is poured into a hollow ridge, and a reinforcing rib steel strip is not required to be wound any more, so that raw materials are saved, and the production cost of the pipe is greatly reduced; 2, the outer wall of the weld is coated with the fiber layer, so that the pressure resistance of the weld of the plastic plate strip is greatly improved; 3, after the steel strip is arranged, the pressure resistance of the pipe is greatly improved; and 4, by rolling a hole on the steel strip, the concrete, the steel strip and the plastic plate strip can be well combined into a body, an expansion and contraction coefficient among different materials is reduced, the pipe is effectively prevented from being cracked or deformed, and the reinforcing rib is prevented from being rusted.

Owner:娄底市朝阳塑胶有限公司

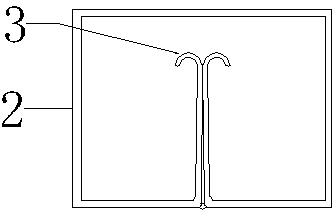

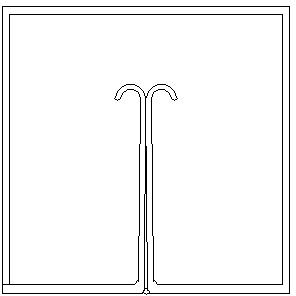

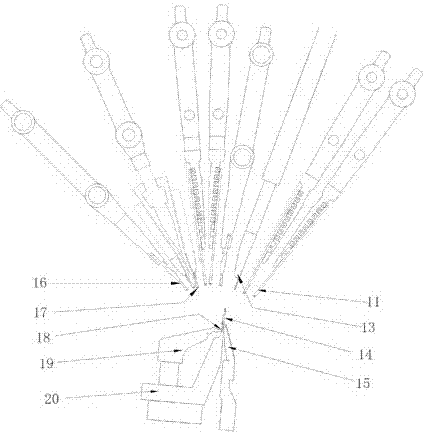

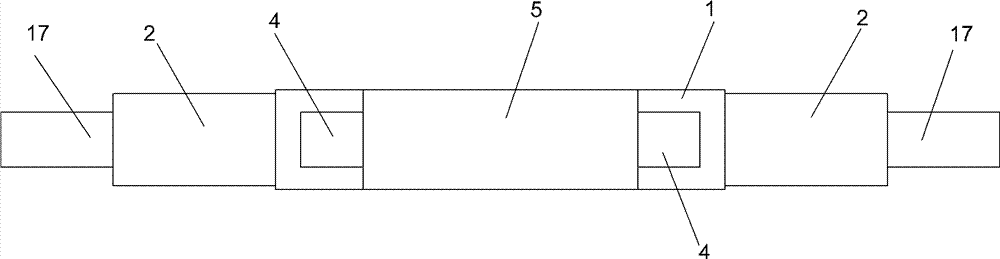

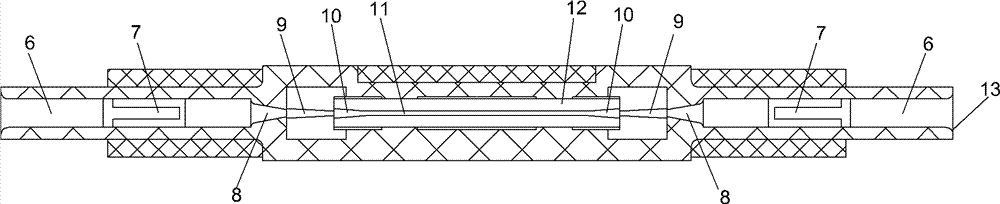

Optical mechanical cold connector

The invention relates to an optical mechanical cold connector, which solves the technical problem that the provided mechanical cold connector can realize rapid and stable connection of an optical fiber without a special connection tool and has the characteristics of convenience for use and simple structure. The technical scheme is as follows: the optical mechanical cold connector is characterizedby comprising a main body housing provided with a fixed groove at the middle, wherein a metal block is embedded in the fixed groove and provided with a V-shaped groove extending along the axial line direction of the main body housing, openings of the fixed groove and the V-shaped groove face towards the front side of the main body housing, the fixed groove is internally provided with a movable pressure cover for pressing the optical fiber in the V-shaped groove, and the middle of the front side surface of the movable pressure cover is provided with a protruding pretightening block, and the left end and the right end of the movable pressure cover are embedded in movable pressure cover installation grooves at the left side and the right side of the fixed groove.

Owner:WANMA TECH CO LTD

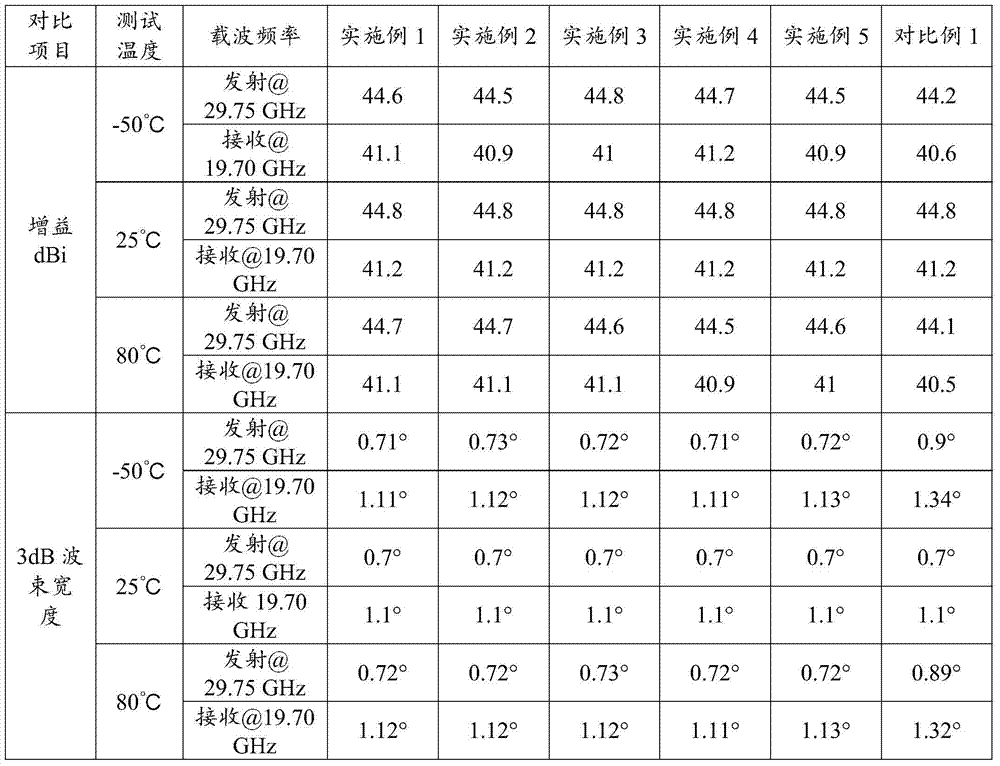

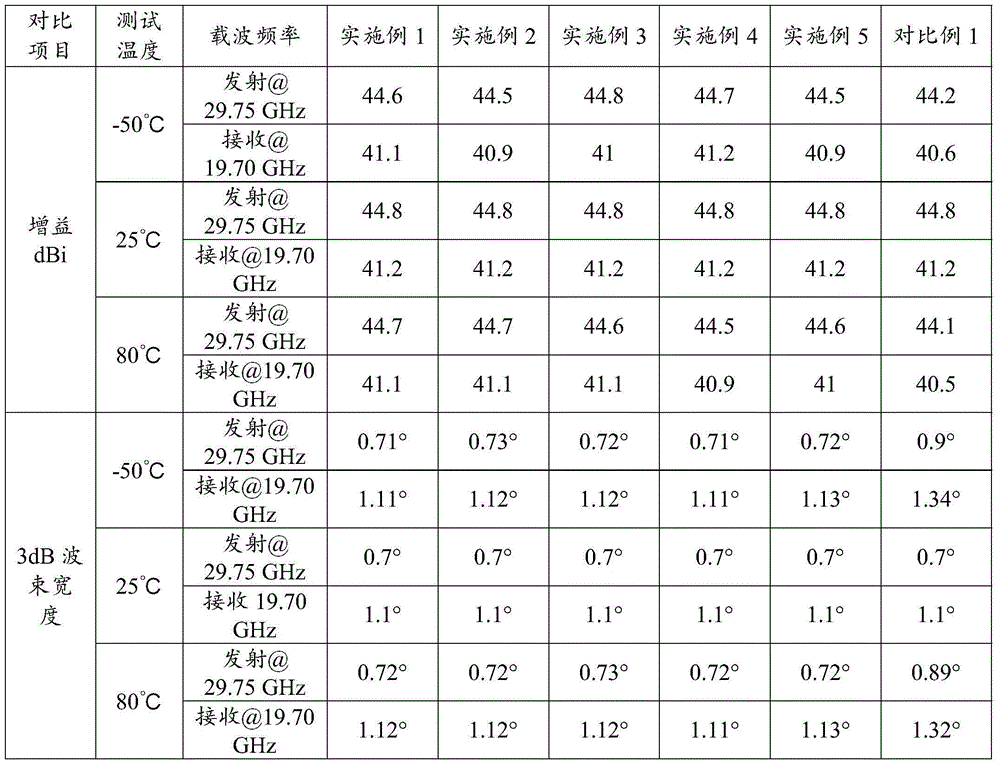

Heat treatment method of ka band parabolic antenna

ActiveCN104882678BReduce the impact of accuracyImprove rigidityFurnace typesAntennasAntenna designThermal expansion

The invention discloses a heat treatment method for a Ka-band parabolic antenna, comprising: forming a steel plate into a parabolic steel plate in a mold; placing the mold equipped with the parabolic steel plate in salt water for heat treatment; opening the mold after the heat treatment After the mold is closed, the parabolic steel plate is pressed together. The rigidity of the parabolic antenna obtained by the method of the present invention is better. When the bad weather changes, the thermal expansion and contraction coefficient of the antenna steel material becomes extremely small, which ensures the directivity of the antenna design, high focused radiation, and low disturbed characteristics.

Owner:深圳市华讯方舟光电技术有限公司 +1

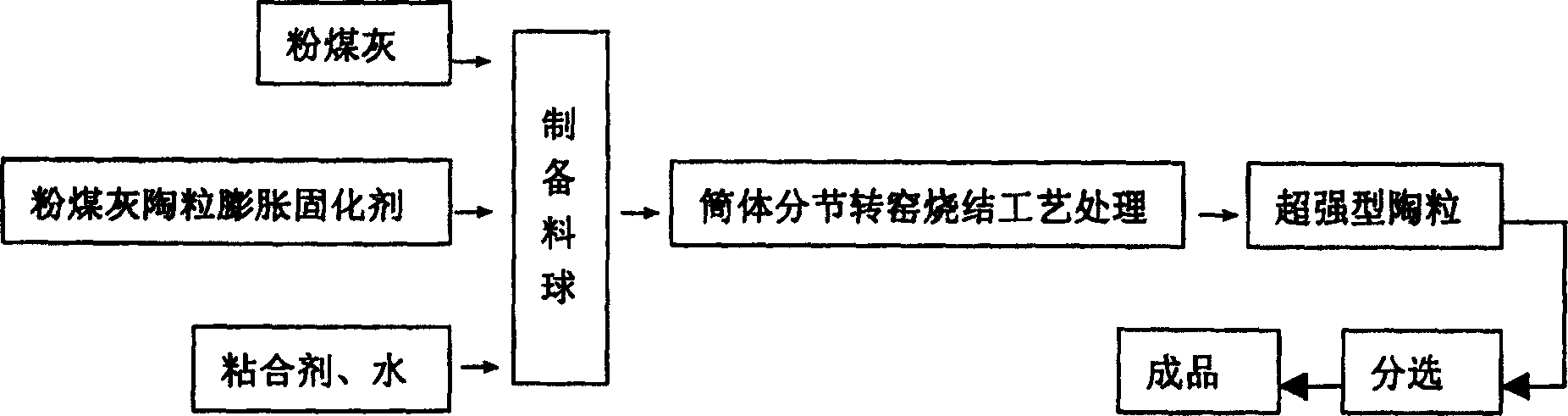

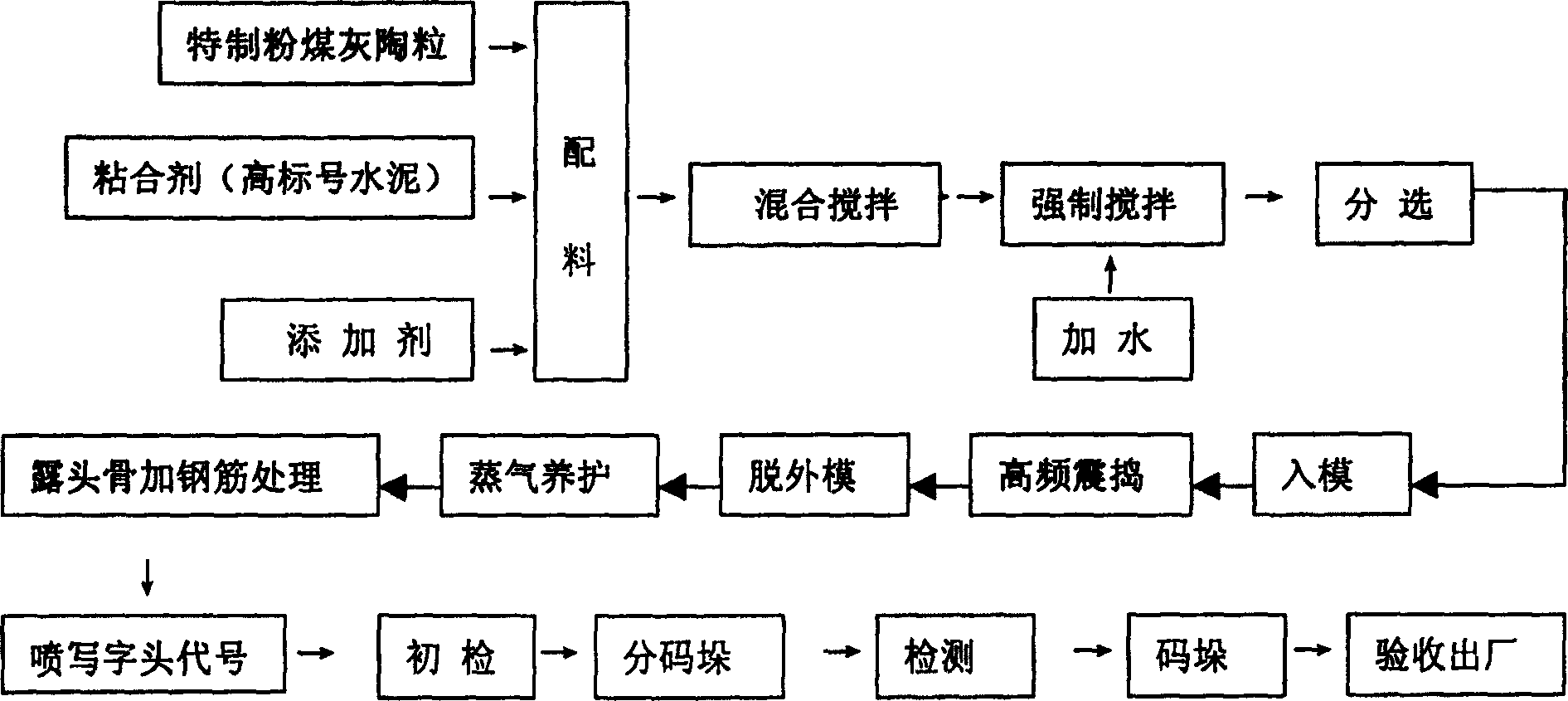

Railway sleeper and its preparing method

InactiveCN1183054CPhysicochemically stableReduce loadSolid waste managementBallastwaySteel barUltimate tensile strength

The present invention aims at providing railway sleeper with light weight, high corrosion resistance, high damping and silencing effect, high strength and low cost. The technological scheme is that flyash haydite, pot sand, adhesive, additive and water are produced into the railway sleeper through mixing, depositing into mold with steel bar net, high frequency tamping, extruding to setting, demolding and steam curing. The sleeper is light weight, only weighing 1 / 3 to 1 / 2 of common concrete one, high in fireproof temperature, corrosion resistant, friction resistant and ageing resistant, and may be used to replace sleeper of timber and sandstone concrete.

Owner:杨普安

Ka-band parabolic antenna heat treatment method

ActiveCN104882678AReduce the impact of accuracyImprove rigidityFurnace typesHeat treatment furnacesSalt waterThermal expansion

The invention discloses a Ka-band parabolic antenna heat treatment method. The method comprises a step of moulding a steel plate into a parabolic steel plate with a die; a step of placing the die with the parabolic steel plate in salt water for heat treatment; and a step of opening the die subjected to the heat treatment and locking the die for laminating the parabolic steel plate. The method provided by the invention is good; and when the bad weather changes, the thermal expansion coefficient of the antenna steel material becomes extremely small, so that the design directionality, the high focusing radiation and the low interference of the antenna are ensured.

Owner:深圳市华讯方舟光电技术有限公司 +1

Anti-freezing concrete pole with high collision resistance

ActiveCN114000760AImprove structural strengthImprove crash resistanceClimate change adaptationCable installations in underground tubesEngineeringRebar

The invention provides a high-collision-resistance anti-freezing concrete pole, and relates to the technical field of power supply and transmission. The anti-freezing concrete pole comprises connecting pieces, wherein the connecting pieces are divided into upper connecting pieces and lower connecting pieces, the upper connecting pieces are connected to the top ends of main steel bars, the lower connecting pieces are connected to the bottom ends of the main steel bars, and the top side of one upper connecting piece is connected with the bottom side of the other lower connecting piece; a steel bar frame connected to the outer sides of the main steel bars; and foam strips, wherein the number of the foam strips is six, and the upper ends and the lower ends of the foam strips are connected with the upper connecting pieces and the lower connecting pieces correspondingly. The self weight of the concrete pole is reduced through the foam strips, meanwhile, the concrete pole is subjected to anti-freezing and heat preservation, the thermal expansion and cold contraction coefficient of the concrete pole is reduced, and the concrete pole is prevented from cracking. The problems that a traditional concrete electric pole is poor in anti-freezing performance, after being used for a period of time, the concrete electric pole is prone to being affected by heat expansion and cold contraction of the outside air temperature, many cracks are generated, and the anti-collision strength of the concrete electric pole is affected are solved.

Owner:浙江双新预构件有限公司

Novel engine valve

The invention provides a novel engine valve. The novel engine valve comprises the following components in percentage by weight: 40%-45% of graphite fibers of which the content of carbon is above 97%, 50%-55% of engineering plastic or resin, 2.8%-3.2% of rare earth and 1.8%-2.2% of a curing agent. The preparation method comprises the following steps of placing the engineering plastic or resin, the curing agent and rare earth into a stirring container, blowing the chopped graphite fibers into the stirring container filled with engineering plastic or resin, the curing agent and rare earth by virtue of a blower and uniformly stirring, after the materials are uniformly stirred, pouring the uniformly stirred materials into a die, carrying out injection molding, calcining, graphitizing, turning off a power supply, cooling to room temperature, taking out the molded part and then carrying out finish machining and heat treatment to obtain the engine valve. Since the valve provided by the invention has small thermal-expansion and cold-contraction coefficient, the valve clearance cannot be changed and thus the service life of the composite material valve is prolonged.

Owner:RONGCHENG COMPOSITE MATERIALS

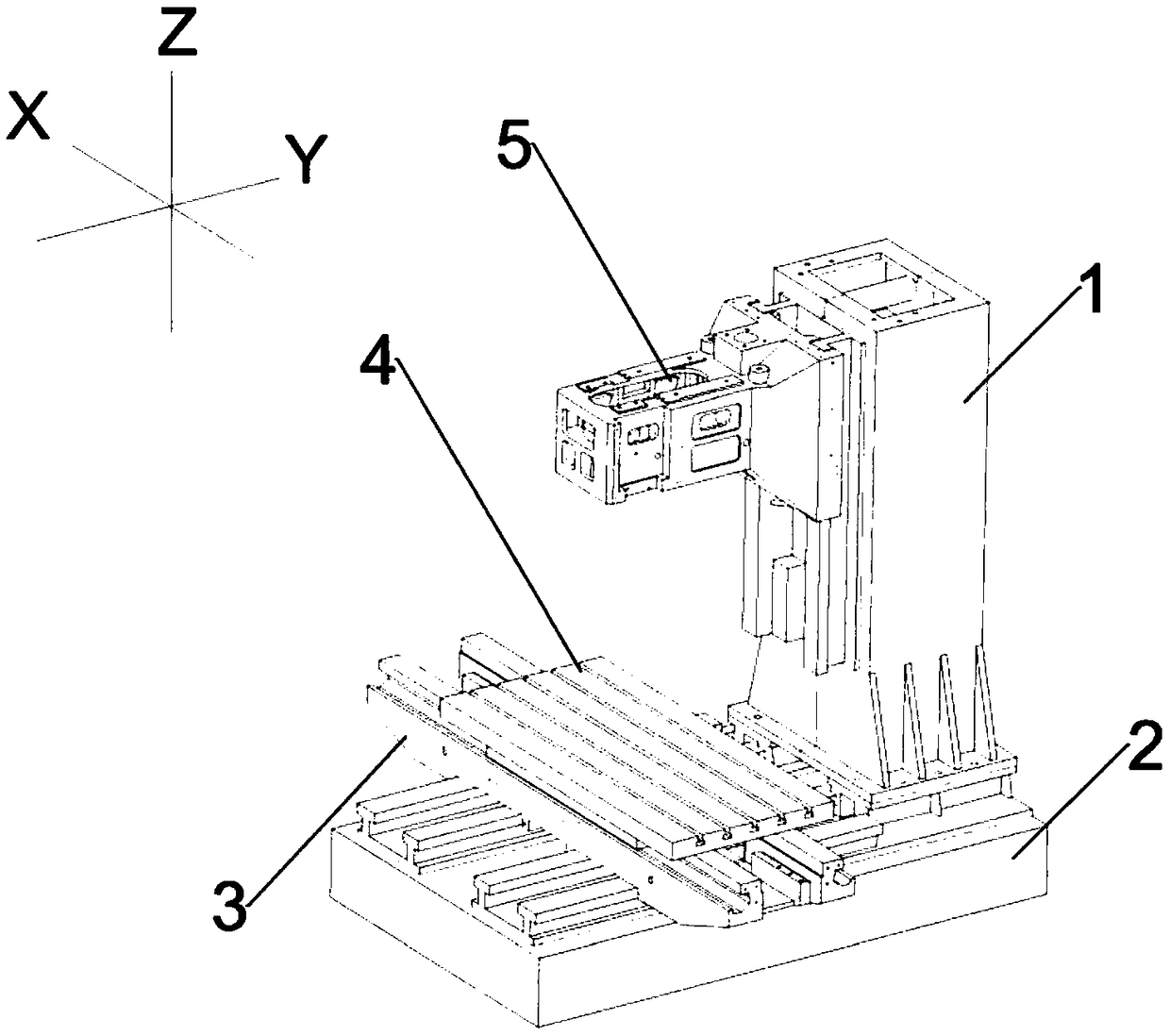

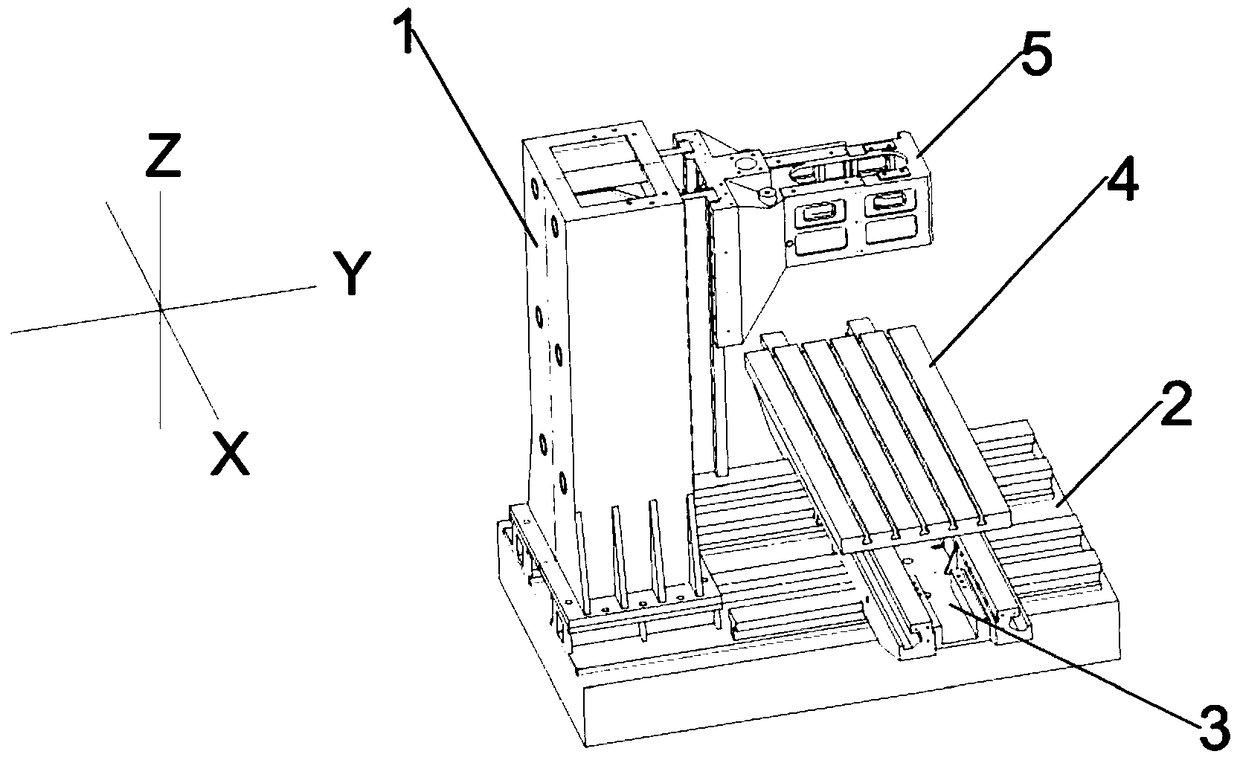

Bed of vertical machine tool and vertical machine tool with bed

PendingCN109014974AWith degree of flexibilityImprove economyLarge fixed membersEngineeringMachine tool

The invention relates to a bed of a vertical machine tool and the vertical machine tool with the bed. The bed comprises a bed top wall and a bed side wall arranged along the outer periphery of the bedtop wall, and the bed top wall and the bed side wall are perpendicular to each other. The bed is characterized in that a space formed by the bed top wall and the bed side wall is internally providedwith bed supporting tubes and bed supporting plates which are welded to the bed. The bed of the vertical machine tool has ideal rigidity and precision.

Owner:CHINA ACADEMY OF MACHINERY SCIENCE & TECHNOLOGY +1

engine valve

The invention provides a novel engine valve. The novel engine valve comprises the following components in percentage by weight: 40%-45% of graphite fibers of which the content of carbon is above 97%, 50%-55% of engineering plastic or resin, 2.8%-3.2% of rare earth and 1.8%-2.2% of a curing agent. The preparation method comprises the following steps of placing the engineering plastic or resin, the curing agent and rare earth into a stirring container, blowing the chopped graphite fibers into the stirring container filled with engineering plastic or resin, the curing agent and rare earth by virtue of a blower and uniformly stirring, after the materials are uniformly stirred, pouring the uniformly stirred materials into a die, carrying out injection molding, calcining, graphitizing, turning off a power supply, cooling to room temperature, taking out the molded part and then carrying out finish machining and heat treatment to obtain the engine valve. Since the valve provided by the invention has small thermal-expansion and cold-contraction coefficient, the valve clearance cannot be changed and thus the service life of the composite material valve is prolonged.

Owner:RONGCHENG COMPOSITE MATERIALS

Anti-crack exterior wall putty powder

The invention discloses an anti-crack exterior wall putty powder, which is mainly composed of the following raw materials in parts by weight: heavy calcium carbonate powder 600-700; gray calcium powder 30-70; white cement 260-320; hydroxypropyl Methylcellulose 3.5‑5.5; wood fiber 0.6‑1.5. The crack-resistant exterior wall putty powder of the present invention not only has strong water resistance and cohesiveness, but also has the advantages of high and low temperature resistance, crack resistance, etc., and solves the problem of poor weather resistance of the existing exterior wall putty powder. question.

Owner:CHONGQING TAIRUI NEW BUILDING MATERIALS

Plastic, concrete and fiber composite pipe with reinforcing rib

Owner:娄底市朝阳塑胶有限公司

Composite board and production process thereof

InactiveCN111559136AStable product structureSmall thermal expansion and contraction coefficientLaminationLamination apparatusManufacturing engineeringSpray coating

The invention discloses a composite board and a production process thereof, belonging to the technical field of boards, the composite board comprises a spray coating layer, wherein a first alloy layeris arranged below the spray coating layer, a substrate layer is arranged at the lower part of the first alloy layer, and a second alloy layer is arranged at the lower part of the substrate layer. Byarranging the spray coating layer, manufacturing cost is low, surface layer strength and an abrasion resistance coefficient are improved, and the transparency and the stereoscopic impression of the composite board can be enhanced. By arranging the second alloy layer, a product structure is more stable, the coefficient of thermal expansion and cold contraction is reduced, the probability of cracking deformation is greatly reduced, and the product can be applied to decoration and laying of northern floor heating rooms.

Owner:蒙阴圣尼亚家居科技有限公司

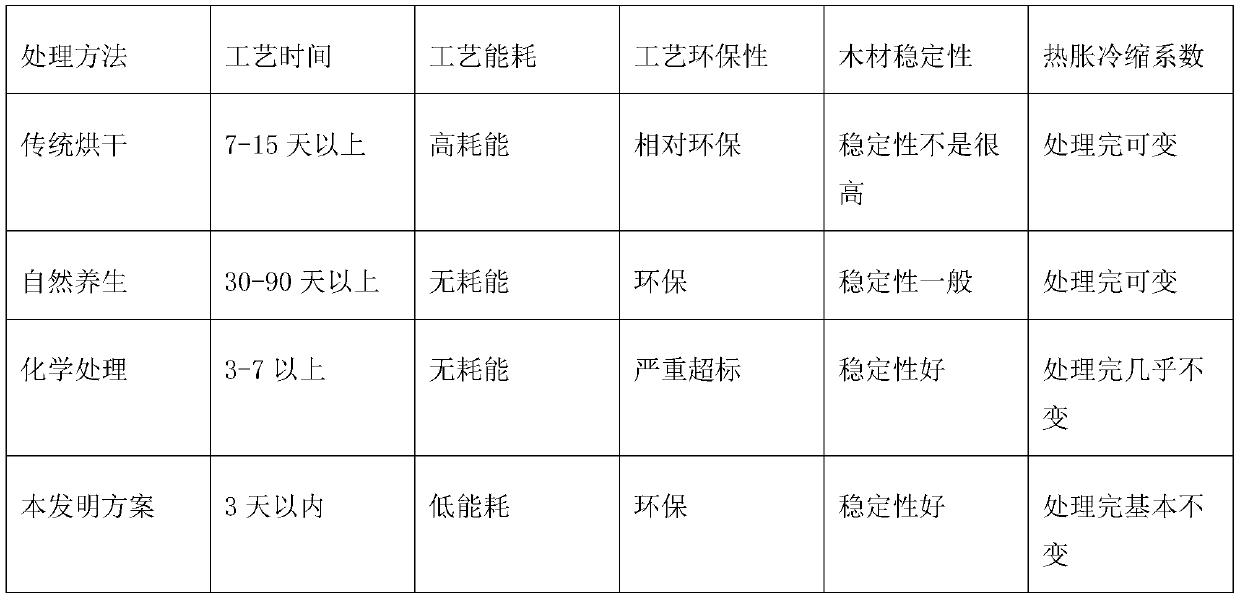

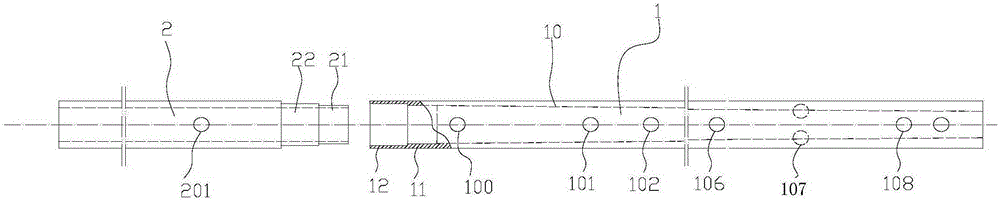

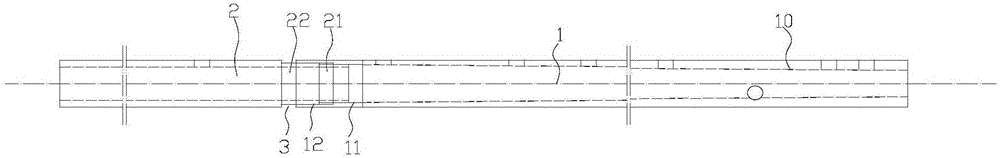

Treatment method for controlling heat expansion and cold contraction coefficient of wood

InactiveCN110238924AReduce hydroxylImprove stabilityWood treatment detailsThermal wood treatmentProduction lineRoom temperature

The invention discloses a treatment method for controlling a heat expansion and cold contraction coefficient of wood. The method comprises the following steps: S1, stacking the wood according to a principle of first heavy and then light, first thick and then thin, and placing spacers between adjacent woods; S2, putting the stacked wood into a closed wood stabilizing apparatus, wherein a temperature in the wood stabilizing apparatus is set to 190 DEG C-215 DEG C, and closing the whole circulatory system after keeping for about 2-3 h; S3, closing the whole circulatory system when a temperature and a water content in the wood stabilizing apparatus are kept standards and unchanged, naturally cooling the wood for 24 h to normal temperature in the stabilizing apparatus, and then opening the treated wood; and S4, putting the wood subjected to stabilizing treatment into a production line for waiting for production. The treatment method can reduce hydroxyl groups in the wood by 95%-99% or more, reduces the thermal expansion and cold contraction coefficient of the wood, and greatly improves stability and a service life of wood products.

Owner:黄新波

Flute

InactiveCN106469549ASmall thermal expansion and contraction coefficientGood pitchWind musical instrumentsFluteEngineering

The invention relates to a flute. The invention belongs to an ethic group music instrument to play through the whistling from a player's mouth. And more particularly, the invention provides improvements to a traditional flute. The flute of the invention is free of the influence of the change in temperature and humidity. Irrespective of the location and the season of the year, the flute can be played effectively without compromising its tones. The flute comprises a copper made blowpipe and a copper made tone pipe. The blowpipe is provided with blowholes. The tone pipe is provided with the following elements in succession: diaphragm holes, a first sound making hole, a second sound making hole, a third sound making hole, a fourth sound making hole, a fifth sound making hole, a sixth sound making hole, a back tone hole and a tone regulating hole. The blowpipe and the tone pipe are detachably connected through a plugging structure; the inner surface of the tone pipe is of a conical structure whose conical degree ranges from 0.8 / 1000 to 1.2 / 1000. In comparison with a traditional flute, the flute of the invention is made from pure brass materials and can never be torn apart so as to enable people to play permanently. With the flute, a good stage performing effect can be achieved; it can also be collected by flute fans for collection purpose as well.

Owner:张倚明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com