Flute

A flute and sound tube technology, applied in the field of improvement of traditional flutes, can solve the problems of individual flute sound quality differences, inconvenient mass production, inconsistent outer diameter, inner diameter, and taper, etc., to achieve consistent intonation, strong metallic feeling, and beautiful timbre Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

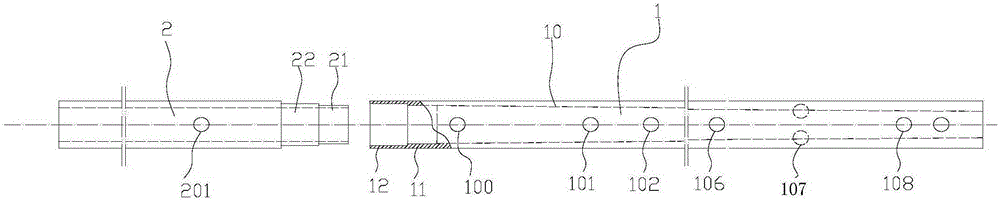

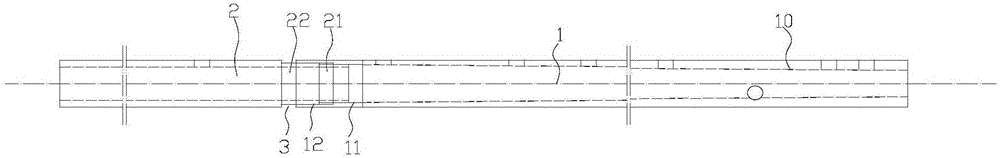

[0018] The present invention as figure 1 , 2 As shown, it includes a copper blowpipe 2 and a copper sound pipe 1, the blowpipe 2 is provided with a blow hole 201, and the sound pipe 1 is sequentially provided with a film hole 101, the first to six sound outlet holes (101, 102 ... 106), the rear sound hole 107 and the tuning hole 108; the blowpipe 2 and the sound pipe 1 are detachably connected through a plug-in structure, the inner surface 10 of the sound pipe is tapered, and the taper is 0.8 / 1000~1.2 / 1000. After several experiments, it is determined that the designed taper ratio is 1 / 1000, and the effect is the best. If the taper ratio is greater than 1.2 / 1000, when the 6 sound holes are arranged, especially the 6th and 5th holes The distance between the holes will increase, which is not conducive to the flexibility of pressing the holes with the fingers. If the taper is less than 0.8 / 1000, the desired tone will not be achieved.

[0019] The plug-in structure includes so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com