Plastic, concrete and fiber composite pipe with reinforcing rib

A fiber composite and reinforcing rib technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor rigidity and temperature resistance, poor corrosion resistance, short life, etc., and reduce thermal expansion and contraction. coefficient, reduce production costs, and improve the effect of pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

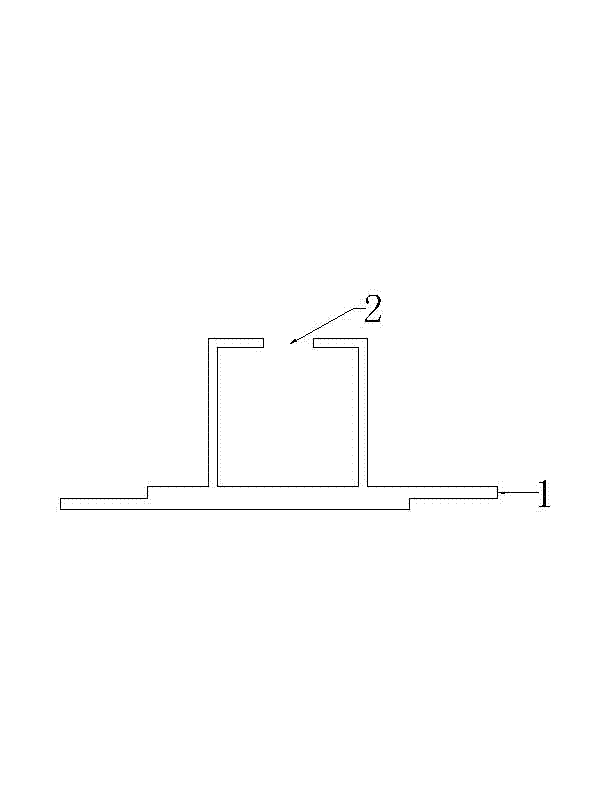

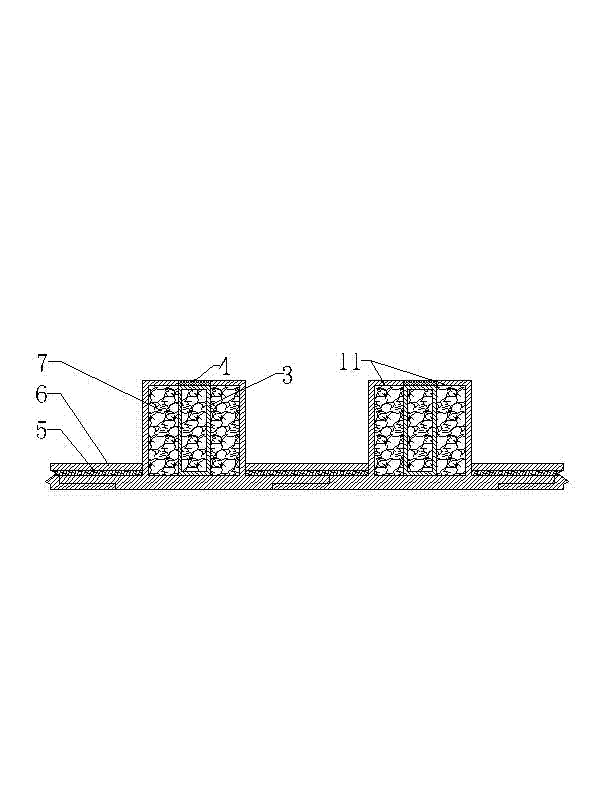

[0020] Embodiment 1: see attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 16 , attached Figure 17 The plastic, concrete and fiber composite pipes with reinforcement described in this embodiment include plastic strips 1 (such as figure 1 As shown), the edges of the plastic strips 1 are overlapped or fused with each other to form a pipe wall. The plastic strip 1 is provided with a slot 2, and the slot 2 is embedded with a reinforcing rib 3; the reinforcing rib 3 in this embodiment is square, A concrete cavity 11 is formed between the outer wall of the reinforcing rib 3 and the inner wall of the slot 2; the central cavity of the concrete cavity 11 and the square reinforcing rib 3 is filled with concrete 7, and the side wall of the reinforcing rib 3 is provided with a connecting hole 10, The connecting hole 10 of the present embodiment is trapezoidal (as Figure 16 As shown), it can also be designed into other geometric shap...

Embodiment 2

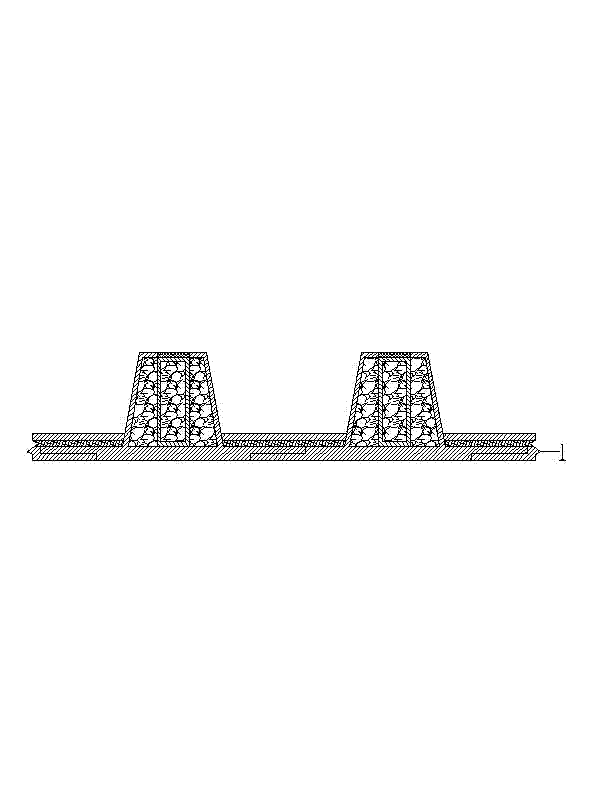

[0030] Embodiment 2: see attached Figure 5 to attach Figure 12 , the difference between this embodiment and embodiment 1 is that the bottom of the card slot 2 is provided with a support rib 8, the two sides of the notch of the card slot 2 extend downwards with a stop 9, the lower end of the reinforcement rib 3 is supported by the support rib 8, and the upper end passes through the stop Bit 9 is fixed. In addition, the fiber layer 5 and the anti-crack layer 6 of this embodiment are extended and coated on the outer wall of the card slot 2 .

Embodiment 3

[0031] Embodiment 3: see attached Figure 13 to attach Figure 15 , the difference between this embodiment and embodiment 1 is that the reinforcing rib 3 is a steel belt, the bottom of the slot 2 is provided with a support rib 8, and the two sides of the slot of the slot 2 extend downward with a stop 9, and the lower end of the steel belt passes through the support rib 8 is clamped and fixed, and the upper end is clamped and fixed by gear position 9. And the outside of the sealing layer 4 is covered with a fiber layer 5 and a crack-proof layer 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com