Treatment method for controlling heat expansion and cold contraction coefficient of wood

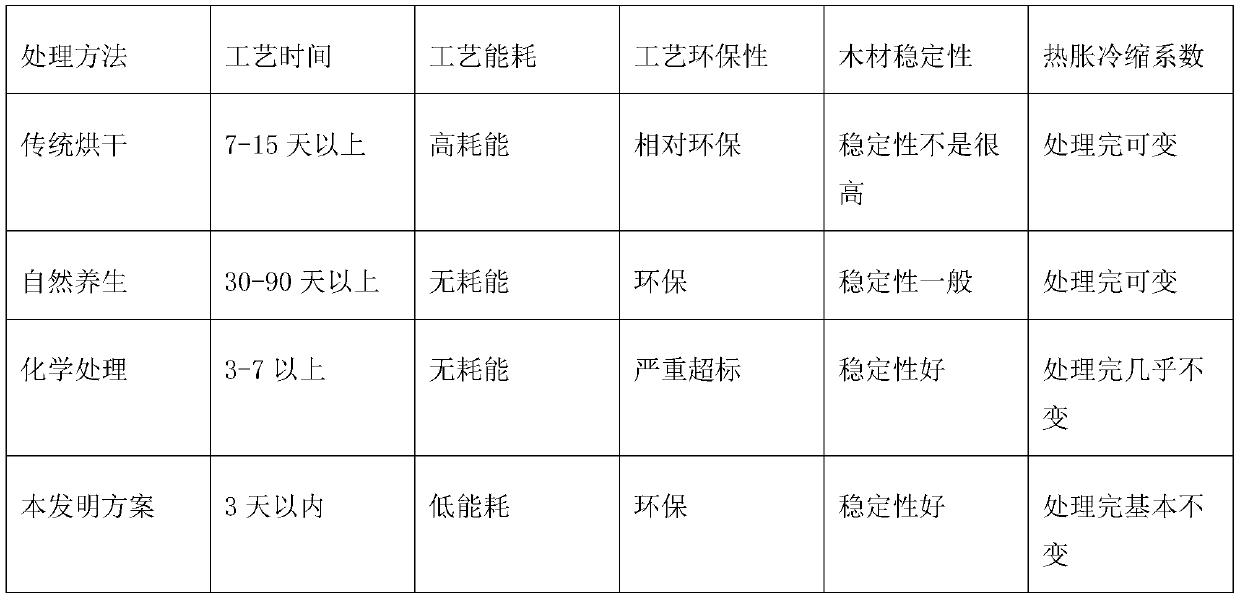

A processing method, a technology of thermal expansion and contraction, which is applied in the direction of wood heat treatment, wood treatment, wood treatment details, etc., can solve problems such as easy cracking and deformation, achieve enhanced stability, reduce the proportion of cracking and deformation, improve stability and stability. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] A method for processing the coefficient of thermal expansion and contraction of blood sandalwood wood includes the following steps:

[0015] S1. Stack the blood sandalwood woods according to the principle of first heavy and then light, thick first and then thin. Place 1cm×4cm spacers between adjacent blood sandalwood woods to form a reasonable gap between each blood sandalwood wood, which is convenient Uniform heating and air circulation;

[0016] S2. Put the stacked wood into a closed wood stabilization device. The temperature in the wood stabilization device is set to 200°C. It is heated by hot water steam circulation heating method. The temperature in the kiln is quickly raised by high temperature steam, and the temperature in the kiln is quickly sealed with high temperature steam. Live all parts of the wood, and then heat it to about 200℃ through the electric heating tube on the wall of the container, and use continuous high temperature and high pressure steam to kill al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com