Modified wood powder, wood plastic composite material and preparation method and application of wood plastic composite material

A wood-plastic composite material and wood powder technology, which is applied in the field of modified wood powder and wood-plastic composite materials, can solve the problems of wood-plastic materials such as insignificant improvement in mechanical properties, insignificant compatibilization effect, poor compatibility, etc., and achieve improvement Effects of bonding ability, life improvement, and water absorption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In view of the defects such as many by-products, low grafting rate and insignificant compatibilizing effect in the current preparation method of wood-plastic material, the present invention provides a modified wood powder, a composite wood-plastic material and its preparation method and application.

[0035] In a preferred embodiment, the present invention prepares the novel wood-plastic composite material process as follows:

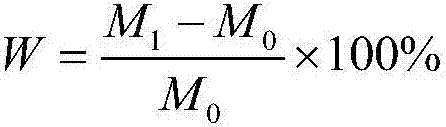

[0036] Put 500g of wood powder into 800ml of NaOH solution with a mass fraction of 15%, and adjust the pH value of the reaction solution to 12; after soaking for 90 minutes, start stirring, heat up to 40-70°C, pass nitrogen to remove the air in the reaction kettle, and then reduce Press until the vacuum degree is -0.1MPa, add metered propylene oxide; adjust the pH value to neutral with glacial acetic acid after the process reaction, filter, wash and filter the lower layer with distilled water at 80°C, and repeat the washing; put the obtained produ...

Embodiment 1

[0057] Put 500g of wood powder into 800ml of NaOH solution with a mass fraction of 15%, and adjust the pH value of the reaction solution to 12; after soaking for 90 minutes, start stirring, heat up to 45°C, pass nitrogen to remove the air in the reaction kettle, and then depressurize To a vacuum of -0.1MPa, add 100g of propylene oxide; after the process reaction, adjust the pH value to neutral with glacial acetic acid, filter, and then wash and filter the lower layer with distilled water at 80°C, and repeat the washing; put the obtained product in a drying oven , dried at 50°C until the quality was constant, and the modified wood powder was obtained.

[0058] Take by weight 70 parts of HDPE, 30 parts of modified wood flour, 0.5 parts of antioxidant, 1 part of anti-ultraviolet agent, 500g in total; wherein, the antioxidant includes 0.25 parts of antioxidant The antioxidant MB of oxygen agent 1035 and 0.25 parts by weight;

[0059] Mix wood powder, HDPE, antioxidant 1035, antio...

Embodiment 2

[0065] Put 500g of wood powder into 800ml of NaOH solution with a mass fraction of 15%, and adjust the pH value of the reaction solution to 12; after soaking for 90 minutes, start stirring, heat up to 45°C, pass nitrogen to remove the air in the reaction kettle, and then depressurize To a vacuum of -0.1MPa, add 100g of propylene oxide; after the process reaction, adjust the pH value to neutral with glacial acetic acid, filter, wash and filter the lower layer with distilled water at 80°C, and repeat the washing; put the obtained product in a drying oven , dried at 50°C to a constant quality to obtain modified wood flour;

[0066] Take by weight 60 parts of HDPE, 40 parts of modified wood powder, 0.5 parts of antioxidant, 1 part of anti-ultraviolet agent, 500g in total; wherein, said antioxidant includes antioxidant 1076 0.25 parts by weight and antioxidant MB0.25 parts by weight;

[0067] Mix wood powder, HDPE, antioxidant 1076, antioxidant MB and anti-ultraviolet agent UVP-36...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com