Composite board and production process thereof

A composite board and production process technology, applied in the direction of layered products, adhesive types, metal layered products, etc., can solve the problems of easy deformation and mildew, easy thermal expansion and contraction, poor fire resistance, etc. Effects of pollution, reduction of thermal expansion and contraction coefficient, and improvement of fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

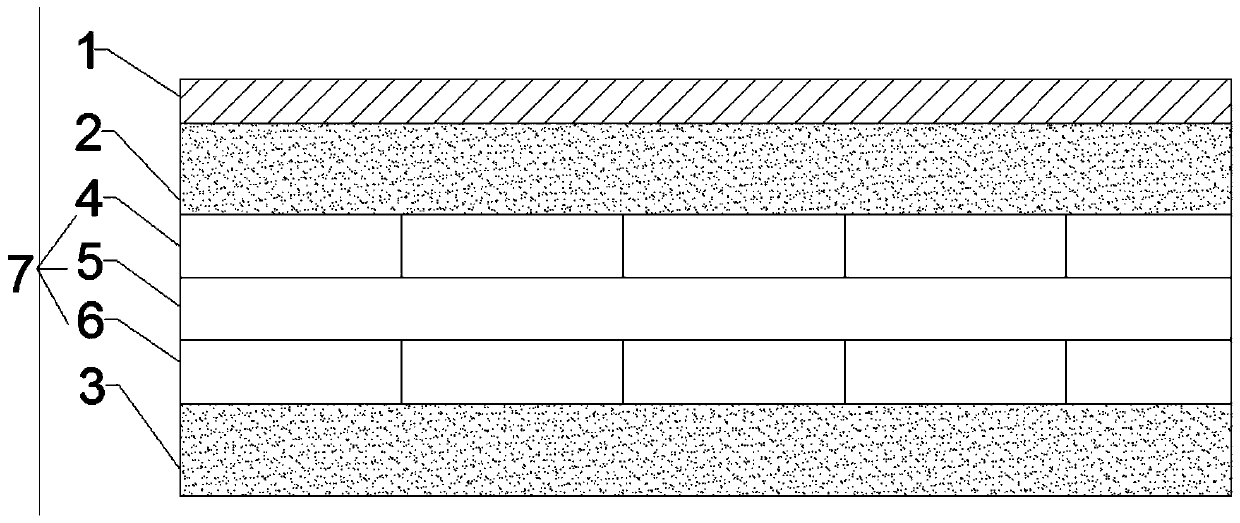

[0030] The embodiment of the present invention provides a composite board, the specific structure is as figure 1 As shown, the sprayed layer 1 is included. A first alloy layer 2 is provided under the sprayed layer 1, a substrate layer 7 is provided under the first alloy layer 2, and a second alloy layer 3 is provided under the substrate layer 7. By providing the sprayed layer 1, the manufacturing cost is low, the surface strength and the wear resistance coefficient are improved, and the transparency and three-dimensional sense of the sheet can be strengthened. By arranging the first alloy layer 2, its wear resistance is greatly improved, it is fireproof, moisture-proof, corrosion-resistant, has a stable structure and is not easily deformed, and prolongs the service life of the product. By providing the second alloy layer 3, the product structure is more stable, the coefficient of thermal expansion and contraction is reduced, and the probability of cracking and deformation is gr...

Embodiment 2

[0032] This embodiment is a preferred embodiment of the present invention, and the specific structure is as follows figure 1 As shown, it discloses the following improvements on the basis of Embodiment 1. The thickness of the first alloy layer 2 is 0.5mm, and the substrate is a three-layer wood board. The three-layer wood board includes an upper board 4 and a middle layer arranged from top to bottom. The board 5 and the lower board 6, the upper board 5 includes a plurality of upper substrates arranged in a crisscross pattern on the same plane, and the lower board includes a plurality of lower boards arranged in a crisscross pattern on the same plane. The thickness of the three-layer wood board is 10.5mm. By setting the thickness of the first alloy layer 2, it is avoided that the thickness is too low and the sheet strength is insufficient, or the thickness is too thick, which makes it more difficult to flatten the sheet. By arranging multiple upper boards 4 and multiple lower b...

Embodiment 3

[0034] This embodiment is a preferred embodiment of the present invention, and the specific structure is as follows figure 1 As shown, it discloses the following improvements on the basis of Embodiment 1. The thickness of the first alloy layer 2 is 1.5 mm, the substrate is a three-layer wood board, and the thickness of the three-layer wood board is 13.5 mm. The three-layer wood board includes The upper board 4, the middle board 5 and the lower board 6 are arranged in sequence from the bottom. The upper board 5 includes a plurality of upper substrates arranged in a crisscross pattern on the same plane, and the lower board includes a plurality of boards arranged in a crisscross pattern on the same plane. Of multiple lower substrates. By arranging multiple upper boards 4 and multiple lower boards 6 to form a criss-cross structure between the three-layer wood boards, the stability of the three-layer wood boards can be improved, avoiding excessively long boards from breaking, and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com