Preparation process of perfluoropolyether surfactant and perfluoropolyether surfactant

A surfactant and perfluoropolyether technology, applied in the field of perfluoropolyether surfactants, can solve the problems of high metal ion content, unfavorable industrial production, and easy equipment occurrence, so as to achieve reasonable process, reduce impurities and avoid waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

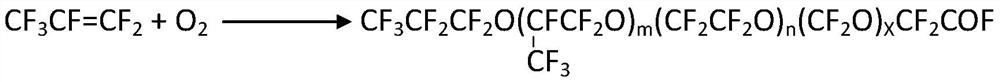

Method used

Image

Examples

Embodiment 1

[0041] Preparation of perfluoropolyether surfactants:

[0042] 1.1 Raw material

[0043] The molar ratio of hexafluoropropylene to chlorotrifluoroethylene is 9:1.

[0044] 1.2 Preparation process

[0045] Concrete preparation steps are:

[0046] (1) Photooxidation

[0047] Place hexafluoropropylene and chlorotrifluoroethylene in a photochemical reactor (volume 10 L), and feed oxygen into the photochemical reactor to carry out photooxidation reaction; continue to add oxygen during the photooxidation reaction, and keep the oxygen excess all the time. And keep the pressure in the photochemical reactor at normal pressure, the wavelength of ultraviolet light used in the photooxidation reaction is 380nm, the power of the light source is 400w; the temperature is -40°C, and the reaction time is 7h;

[0049] After the photooxidation step is completed, the unreacted hexafluoropropylene is collected in a fixed storage tank, and the monomer recovery temper...

Embodiment 2

[0057] Preparation of perfluoropolyether surfactants:

[0058] 2.1 Raw materials

[0059] The molar ratio of hexafluoropropylene to chlorotrifluoroethylene is 1:1.

[0060] 2.2 Preparation process

[0061] Concrete preparation steps are:

[0062] (1) Photooxidation

[0063] Place hexafluoropropylene and chlorotrifluoroethylene in a photochemical reactor (volume 10 L), and feed oxygen into the photochemical reactor to carry out photooxidation reaction; continue to add oxygen during the photooxidation reaction, and keep the oxygen excess all the time. And keep the pressure in the photochemical reactor at 0.05MPa, the wavelength of ultraviolet light used in the photooxidation reaction is 400nm, the power of the light source is 200w; the temperature is -70°C, and the reaction time is 10h;

[0064] (2) Monomer recovery

[0065] After the photooxidation step is completed, the unreacted hexafluoropropylene is collected in a fixed storage tank, and the monomer recovery temperatur...

Embodiment 3

[0073] Preparation of perfluoropolyether surfactants:

[0074] 3.1 Raw material

[0075] The molar ratio of hexafluoropropylene to chlorotrifluoroethylene is 5:1

[0076] 3.2 Preparation process

[0077] Concrete preparation steps are:

[0078] (1) Photooxidation

[0079] Place hexafluoropropylene and chlorotrifluoroethylene in a photochemical reactor (volume 10 L), and feed oxygen into the photochemical reactor to carry out photooxidation reaction; continue to add oxygen during the photooxidation reaction, and keep the oxygen excess all the time. And keep the pressure in the photochemical reactor at 0MPa, the wavelength of ultraviolet light used in the photooxidation reaction is 200, the power of the light source is 600w; the temperature is -30°C, and the reaction time is 4h;

[0080] (2) Monomer recovery

[0081] After the photooxidation step is completed, the unreacted hexafluoropropylene is collected in a fixed storage tank, and the monomer recovery temperature is 40°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com