Patents

Literature

95results about How to "Solve thermal expansion and contraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polymer electrothermal film

ActiveCN102932974ASolve the shortcomings of not being resistant to high temperature and not being flame retardantSolve uneven heating temperatureChemical industryOhmic-resistance heatingPolymer scienceHeating temperature

The invention discloses a method for preparing a polymer electrothermal film. The method comprises the following steps: according to the weight percentage of raw materials, weighing 10 to 36 percent of colloidal graphite micro powder, 8 to 33 percent of conductive carbon black micro powder, 0.1 to 15 percent of nano carbon powder, 0.1 to 18 percent of zinc oxide powder, 0.1 to 13 percent of silver powder and 0.1 to 13 percent of magnesium hydroxide powder to prepare conductive composite filling powder; then preparing conductive composite filling glue by utilizing the conductive composite filling powder; preparing a heating thin film and simultaneously preparing insulating composite filling glue; preparing an insulating film by utilizing the insulating composite filling glue; and finally, preparing the polymer electrothermal film. The invention solves the problems of nonuniform heating temperature and high heating efficiency of a conventional electrothermal film. The invention also overcomes the defects of power attenuation, short working service life and the like of the conventional electrothermal film in the using process.

Owner:苏州威泰克斯新材料科技有限公司

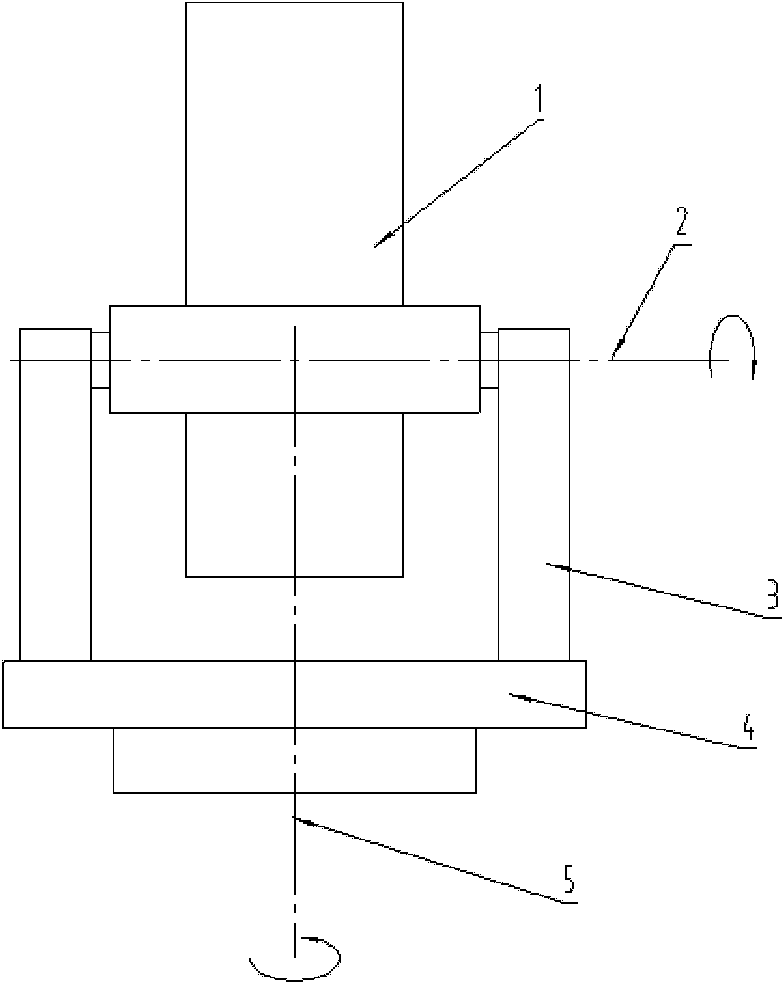

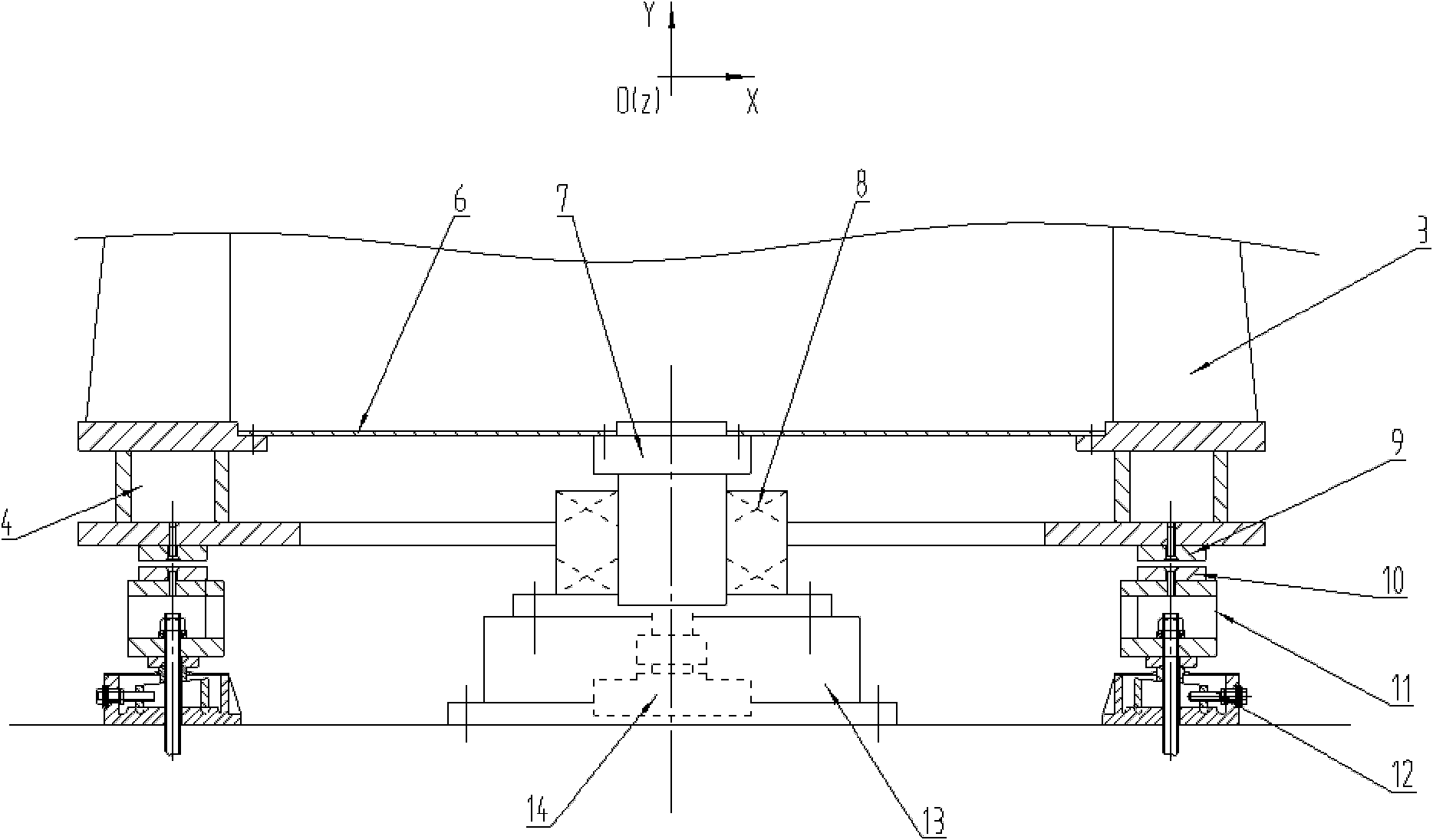

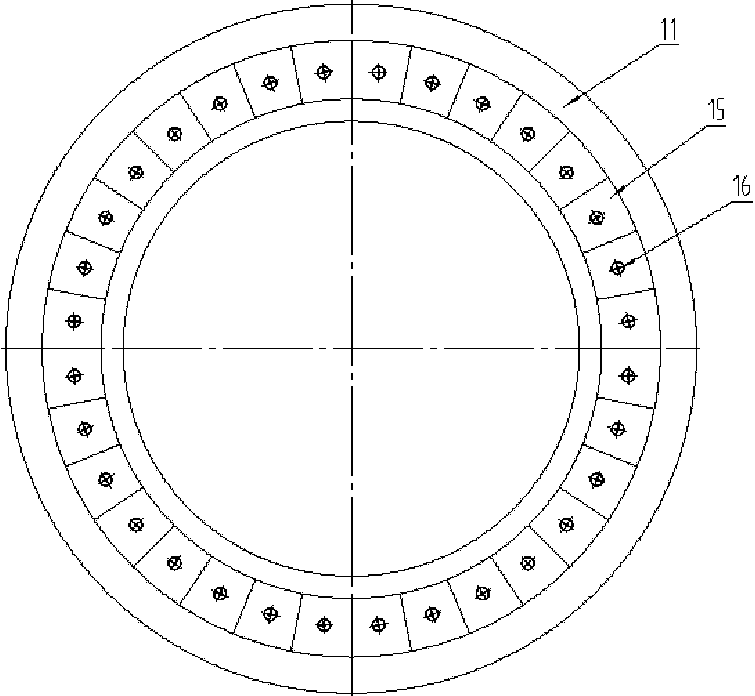

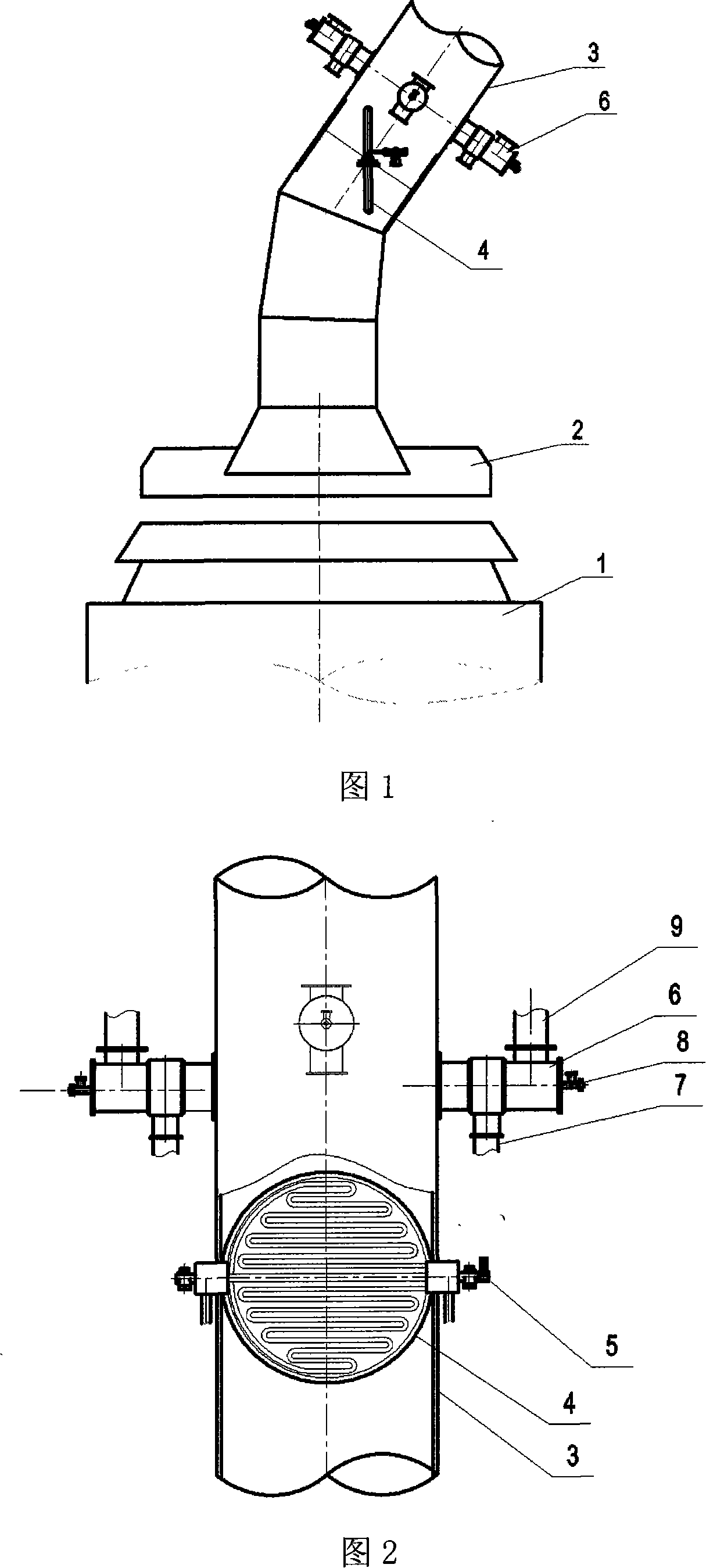

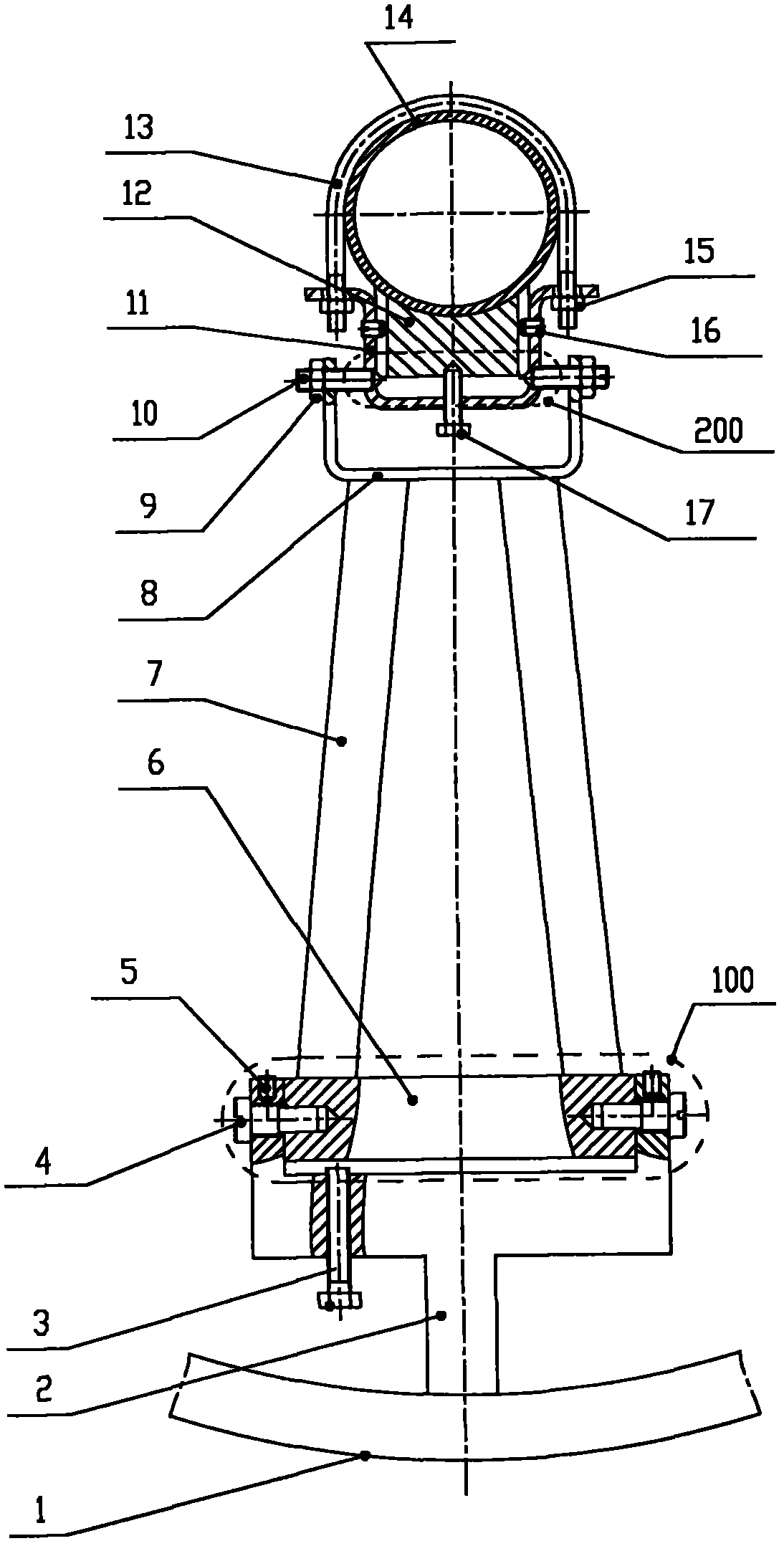

Permanent magnetic suspension support shafting structure suitable for Antarctic astronomical telescope

InactiveCN102162910ASolve lubrication problemsSolve thermal expansion and contractionTelescopesBearingsSouth Pole TelescopeLubrication

A permanent magnetic suspension support shafting structure is characterized in that a radial load bearing and an axial location bearing are arranged on a height shaft; a support shafting structure of an azimuth shaft is arranged between a rotor and a telescope base of an azimuth shaft system; the radial load bearing of the height shaft adopts a permanent magnetic suspension bearing; the permanentmagnetic repulsion force between the moving ring of the bearing and a fixed magnetic plate counteracts the weight of the tube of the telescope; the axial location bearing of the height shaft is located by a Si3N4 ceramic bearing; a non-load location bearing of the azimuth shaft is supported by a Si3N4 ceramic bearing; a load location bearing of the azimuth is supported by a permanent magnetic axial bearing; and the permanent magnetic force generated between the moving magnetic ring and the fixed magnetic ring of the permanent magnetic axial bearing counteracts the weight of the telescope. Thepermanent magnetic suspension support shafting structure solves the problems of mechanical bearing of the Antarctic astronomical telescope, such as bearing lubrication, thermal expansion and contraction, low-speed crawling under heavy loads and the incapability of using the liquid hydrostatic bearing, thereby creating the conditions for high-accuracy tracking and large-diameter development of theAntarctic astronomical telescope.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

Elastic tube-type thermal production casing head

InactiveCN101333917ASolve thermal expansion and contractionAvoid safety hazardsFluid removalSealing/packingButt jointThermal expansion

The invention relates to an elastic pipe type thermal production casing head in the oil well casing connecting piece. The technical proposal includes that a lower flange is butt joint with an upper flange after a hanging steel cylinder is nested in the lower flange; the bottom end of the hanging steel cylinder is provided with a convex rim with contracted diameter; the convex edge is matched with the convex edge with expanded diameter on the periphery of the upper end part of a telescopic pipe; an elastic pipe is threaded through the inner cavity chamber of the hanging steel cylinder and connected between the upper end opening of the telescopic pipe and the upper end opening of the hanging steel cylinder; screw thread connected with the an outer casing is arranged on the lower end pipe wall of the lower flange. The elastic pipe type thermal production casing head well solves the telescopic problem of the telescopic pipe due to the thermal expansion because the elastic pipe additionally arranged in the hanging steel cylinder is connected with the telescopic pipe; thereby, the safety hidden trouble in the current welding fixation mode is solved completely. The elastic pipe type thermal production casing head has the advantages of novel integral structure design, convenient and stable mounting and application, reducing the production cost and ensuring the thermal production to operate safely.

Owner:宿官礼

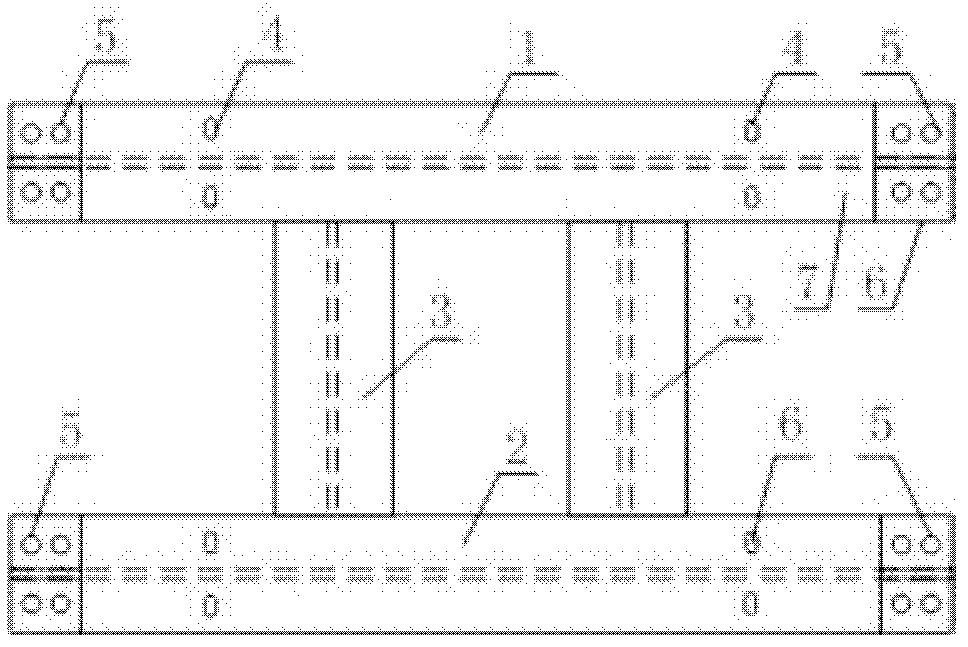

Thermal insulation and sound absorption structure of building external wall

ActiveCN105350680AAchieve securityReach service lifeWallsClimate change adaptationThermal insulationGlue stick

The present invention discloses a thermal insulation and sound absorption structure of a building external wall. The structure comprises a wall body, a rock wool layer is disposed at an inner wall of the wall body while a reflection-type thermal insulating layer is disposed at an outer wall of the wall body, the rock wool layer and the wall body are fixed by building expansion anchors disposed therebetween, a waterproof mortar layer is disposed at the other side of the rock wool layer, the reflection-type thermal insulating layer and the wall body are bonded through a bonding layer, a protective layer is disposed at the other side of the reflection-type thermal insulating layer, the reflection-type thermal insulating layer is composed of aluminum foil plates and elastic glue sticks, the aluminum foil plates are folded to be wave-shaped or zigzag, each top part of the aluminum foil plates is attached with one elastic glue stick so as to form the reflection-type thermal insulating layer, the elastic glue sticks are high-elasticity polyurethane rubber wear-resisting buffering stick pins, and the diameter and length of the elastic glue sticks are defined according to the shape of the aluminum foil plates. Under the condition of meeting strength requirements of the outer wall, the wall body has excellent inflaming-retarding and heat-shielding performance, noises in an outer wall environment are isolated at the same time, and within a certain cost range, the building outer wall can have a special functional performance.

Owner:SHENZHEN MUNICIPAL ENG

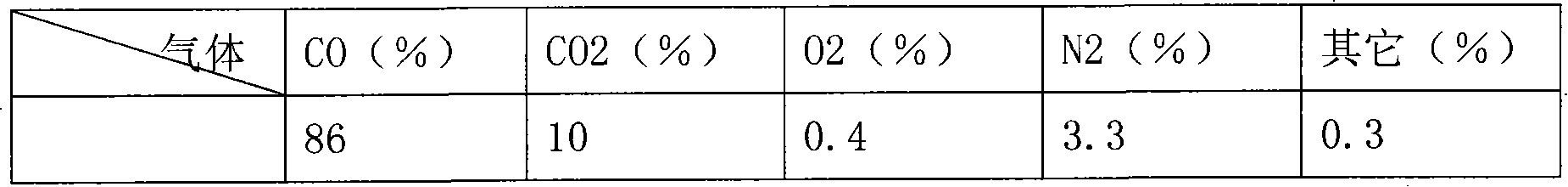

Gas modifying combustion-compensating device for converter evaporation cooling air flue

InactiveCN101117652AEnsure safetyExtended service lifeManufacturing convertersCombustible gas purificationSteelmakingEvaporation

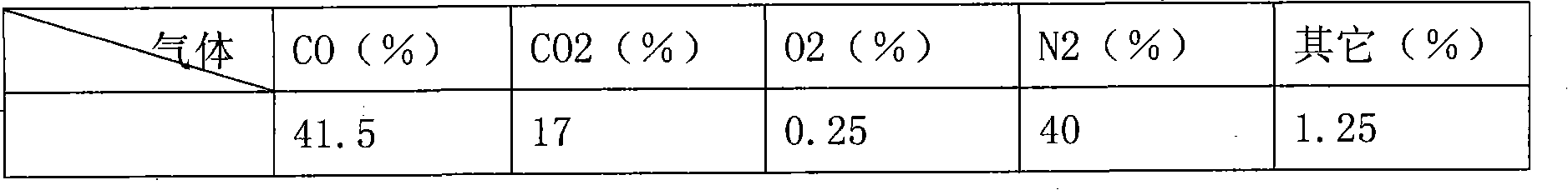

The present invention relates to the field of gas explosion-proof, dry dedusting, and remained energy recovering in a steel-making convertor, and consists of a steel-making convertor boiloff cooling flue, a high temperature rapid valve with a water cooling system, and a coal gas inflamer. The present invention is characterized in that the flue section I behind a movable smoke cover of the steel-making converter is arranged with a high temperature rapid valve with a water cooling system, and a coal gas inflamer is arranged behind the high temperature rapid valve. The high temperature rapid valve opens when oxygen is blown in the steel-making process, the high temperature smoke gas passes through successfully; the high temperature rapid valve closes when oxygen is not blown to prevent the outside air from entering into the boiloff cooling flue. The coal gas inflamer and the high temperature rapid valve cooperate to do quality adjusting on the smoke gas in the boiloff cooling flue, to ensure the high smoke gas continuous production in the boiloff cooling flue, and the heat expansion and cold shrinkage problem caused by the rapid cooling and rapid heating of the boiloff cooling flue caused by the intermitting production of the steel-making convertor can be solved, the service life of the flue can be prolonged, the recovery quantity of the vapor can be increased, the recovery quantity of the coal gas can be increased, and the gas explosion condition can be eliminated.

Owner:昆明阳光基业股份有限公司

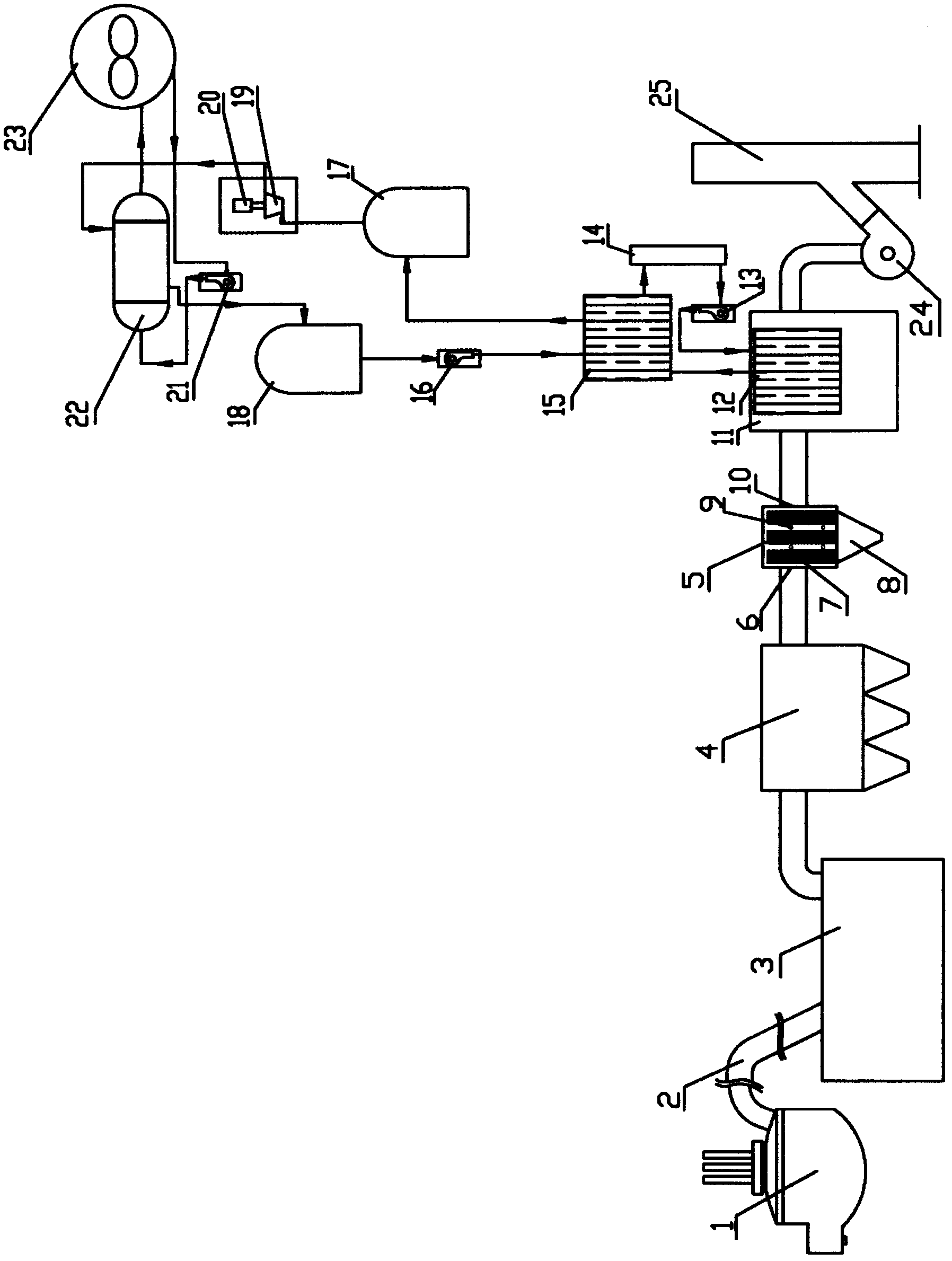

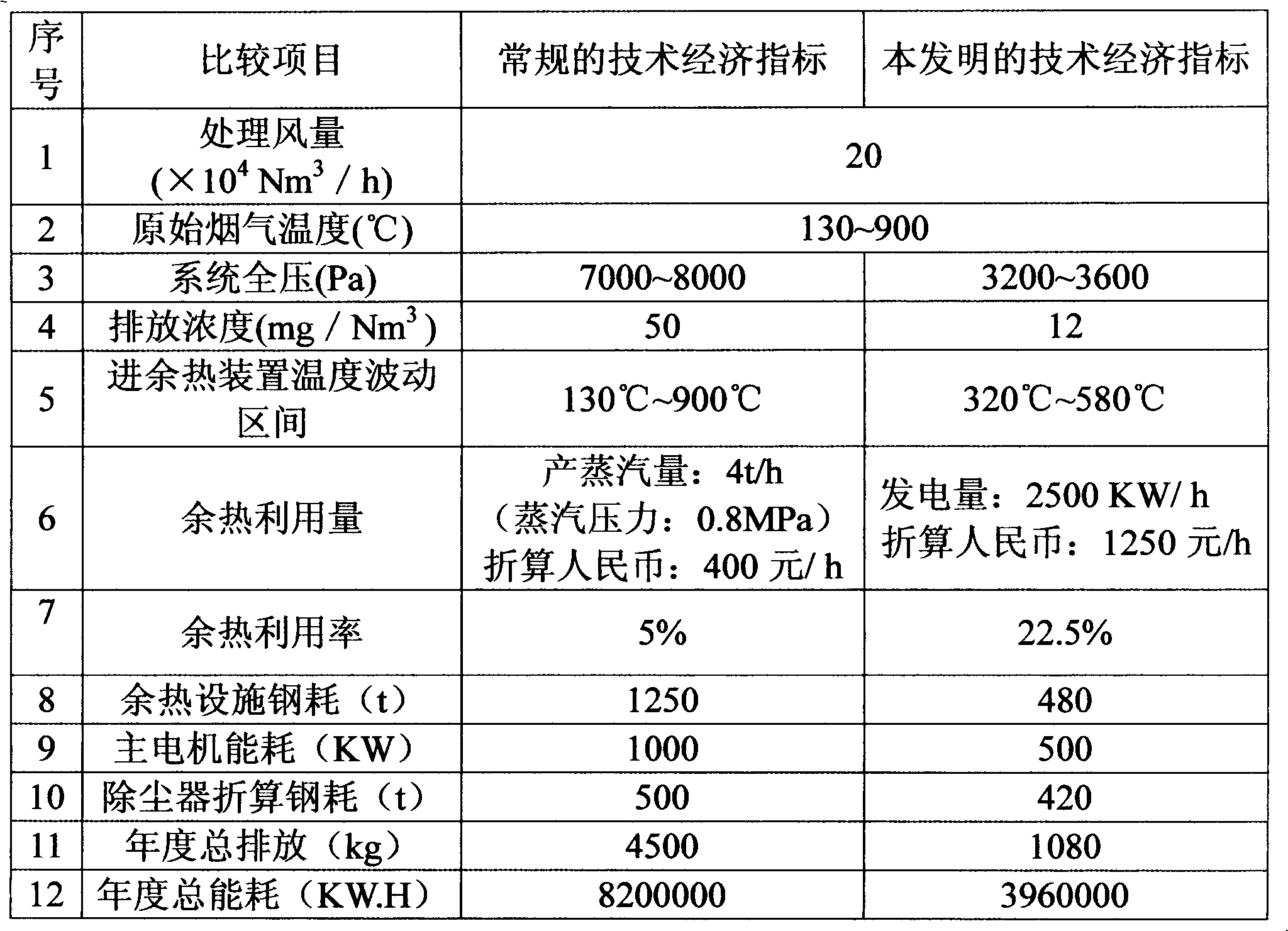

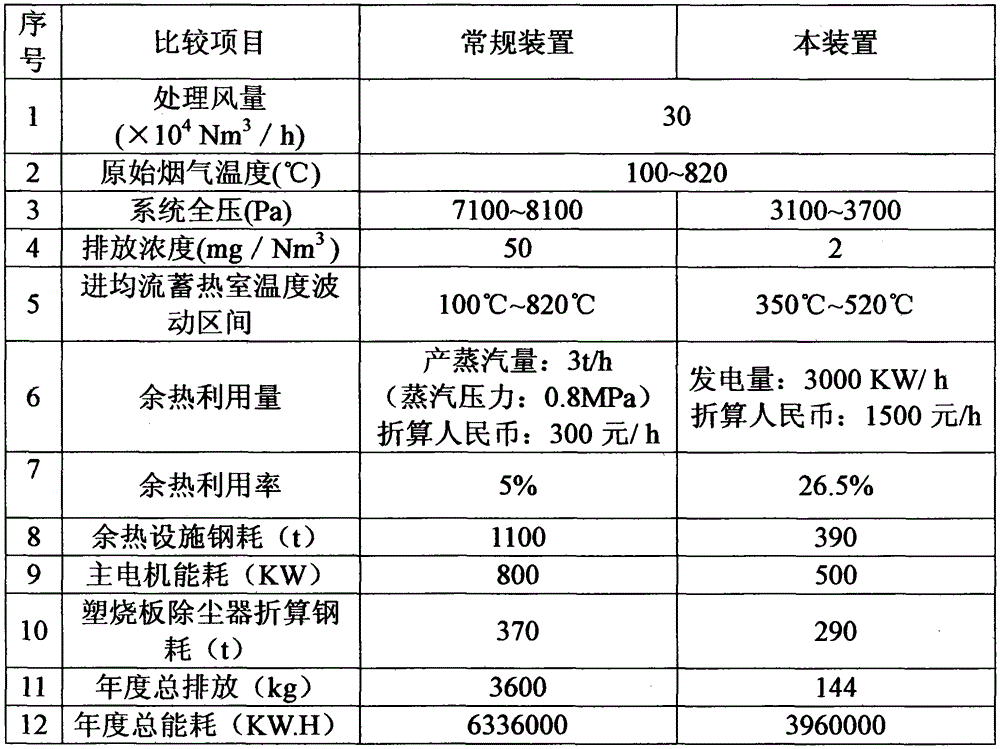

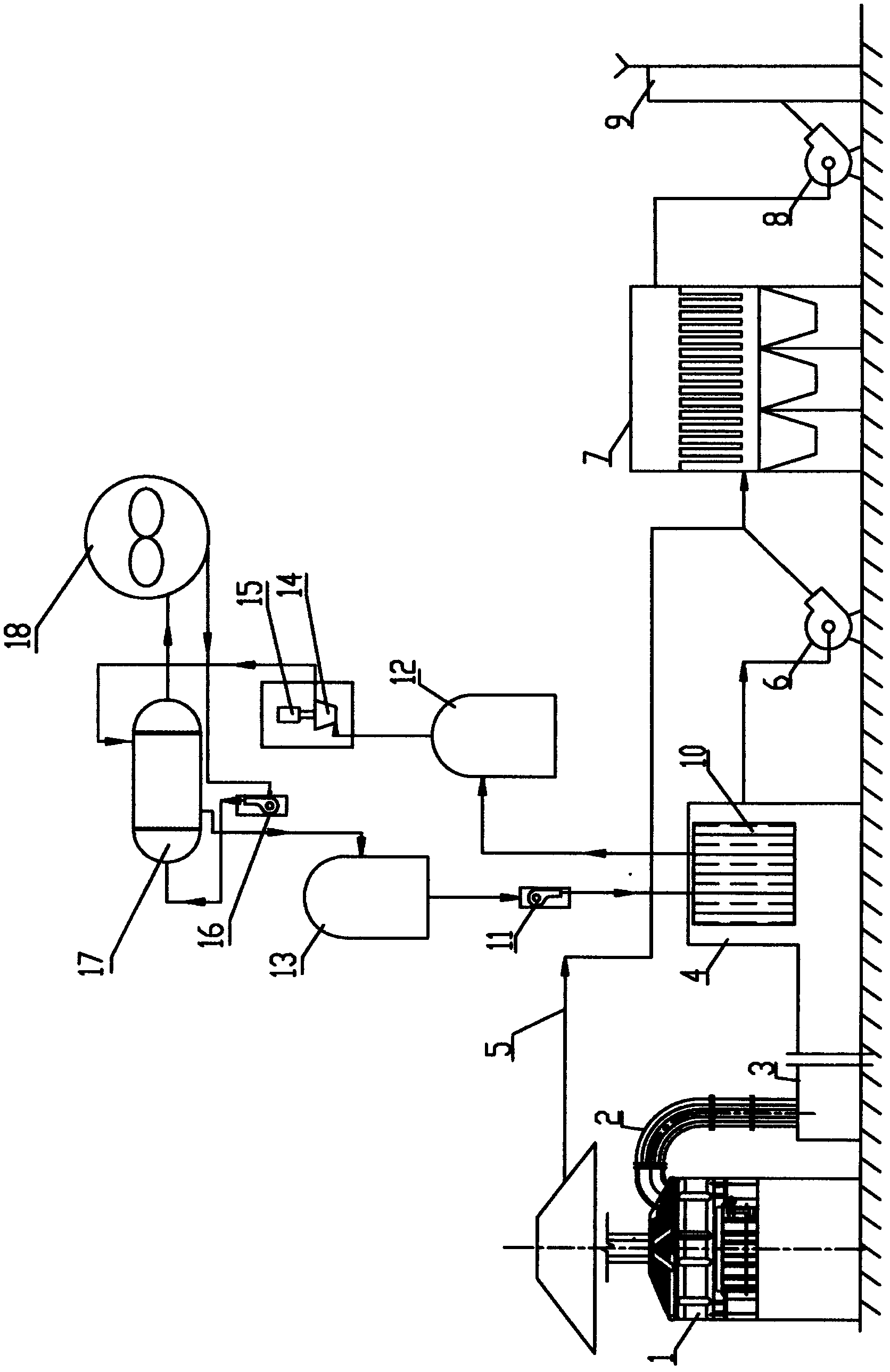

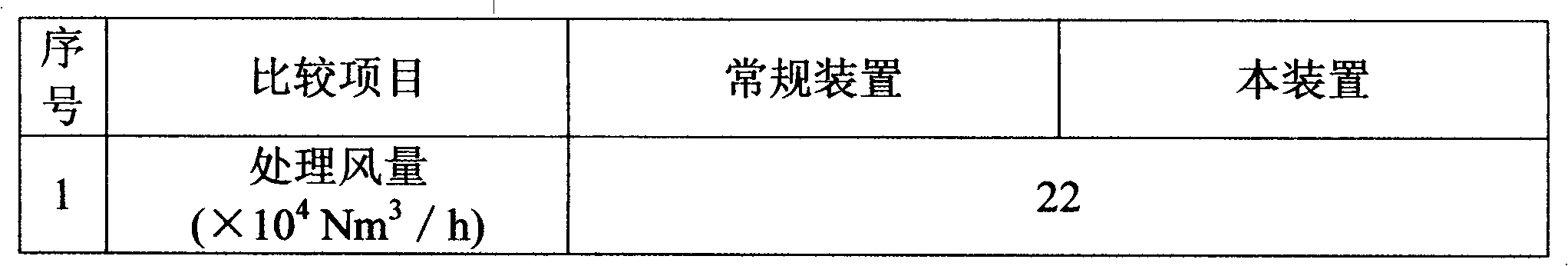

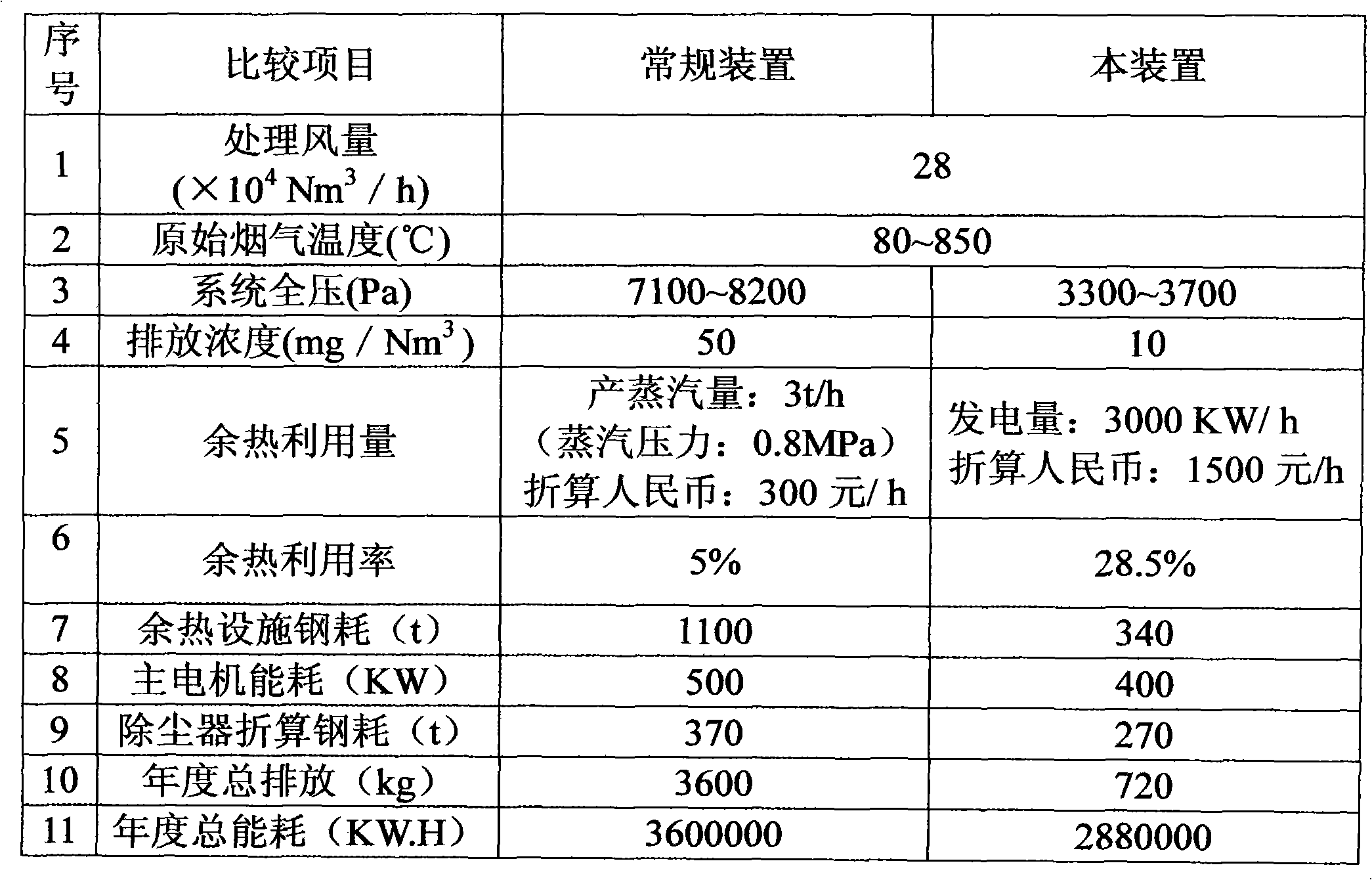

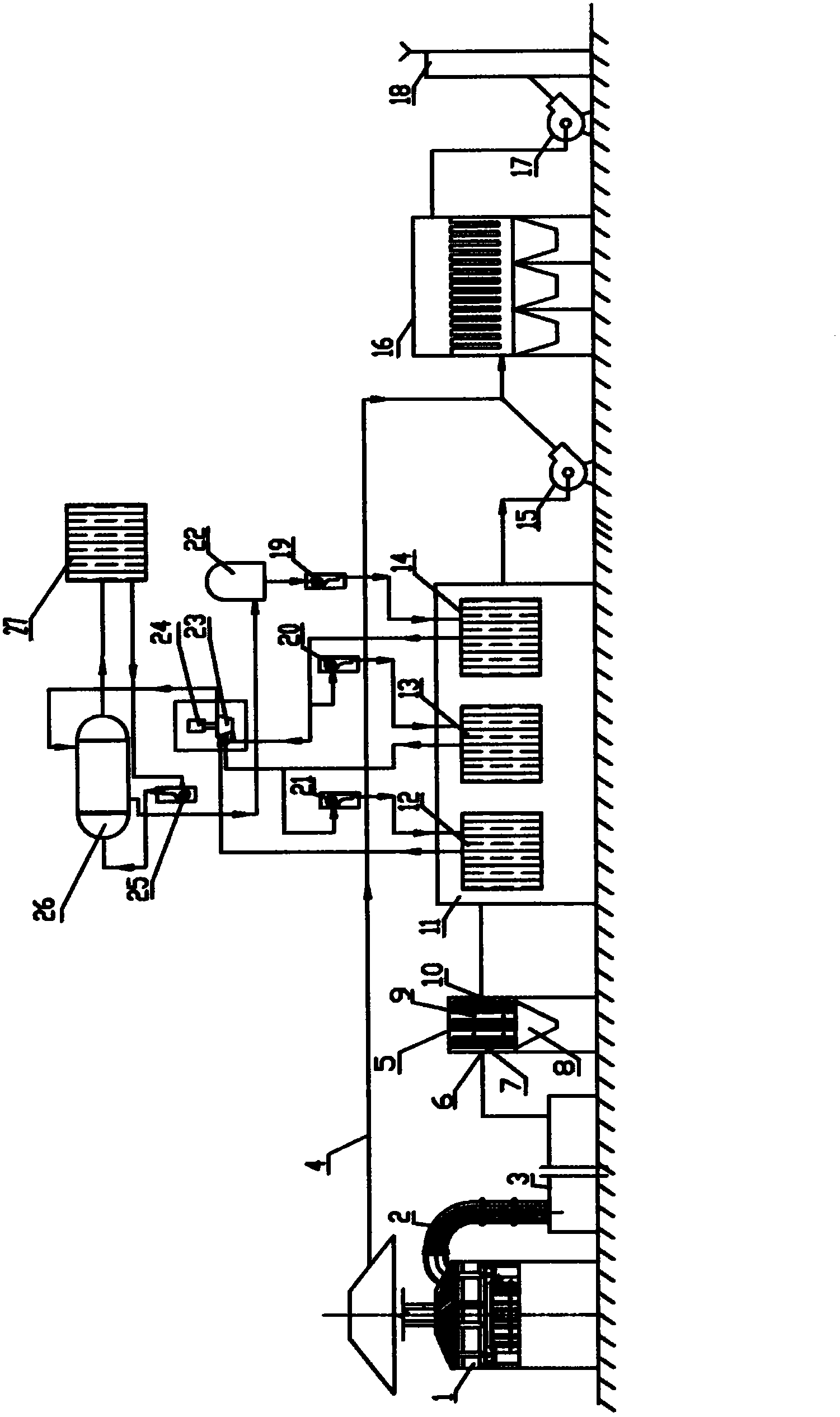

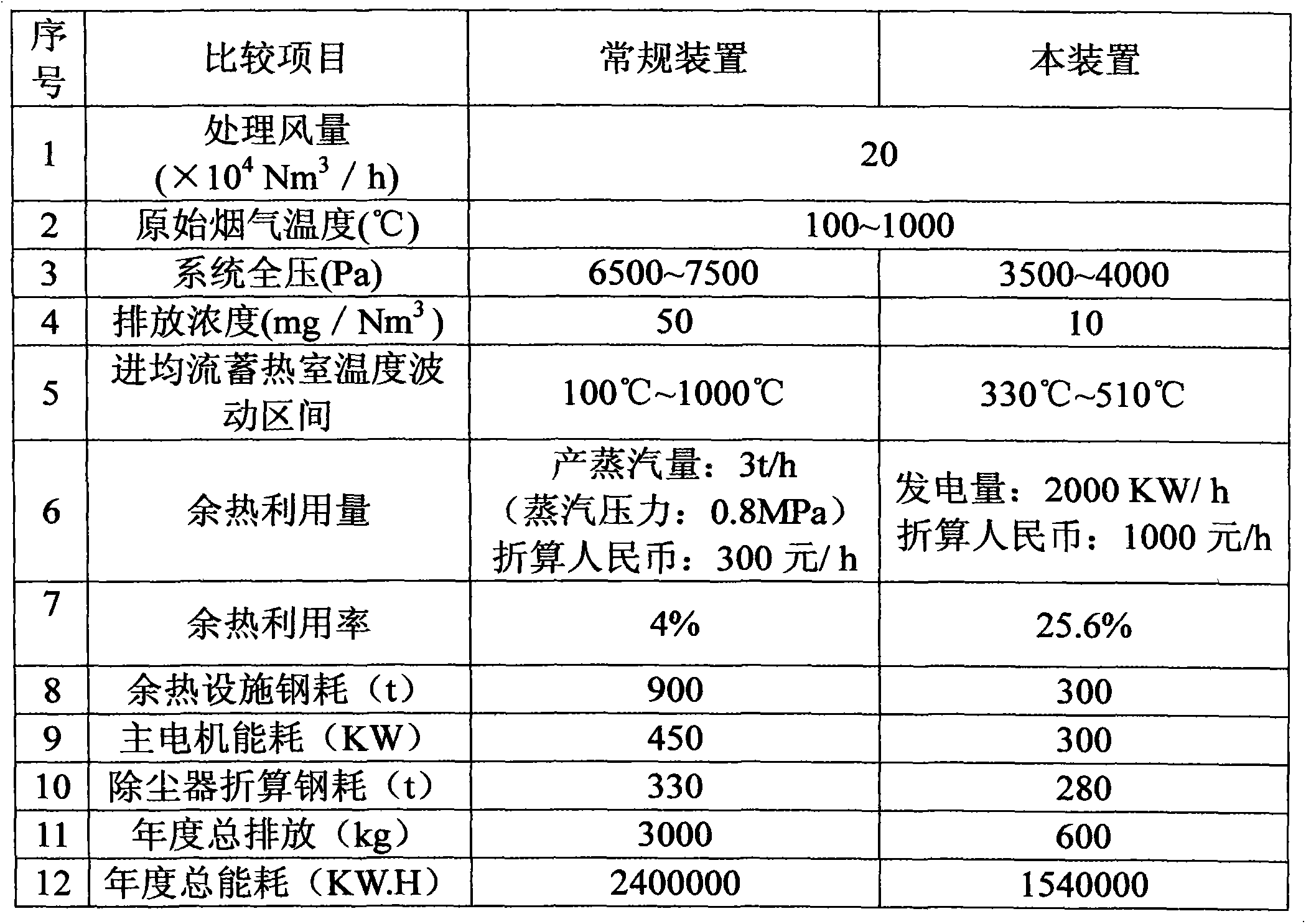

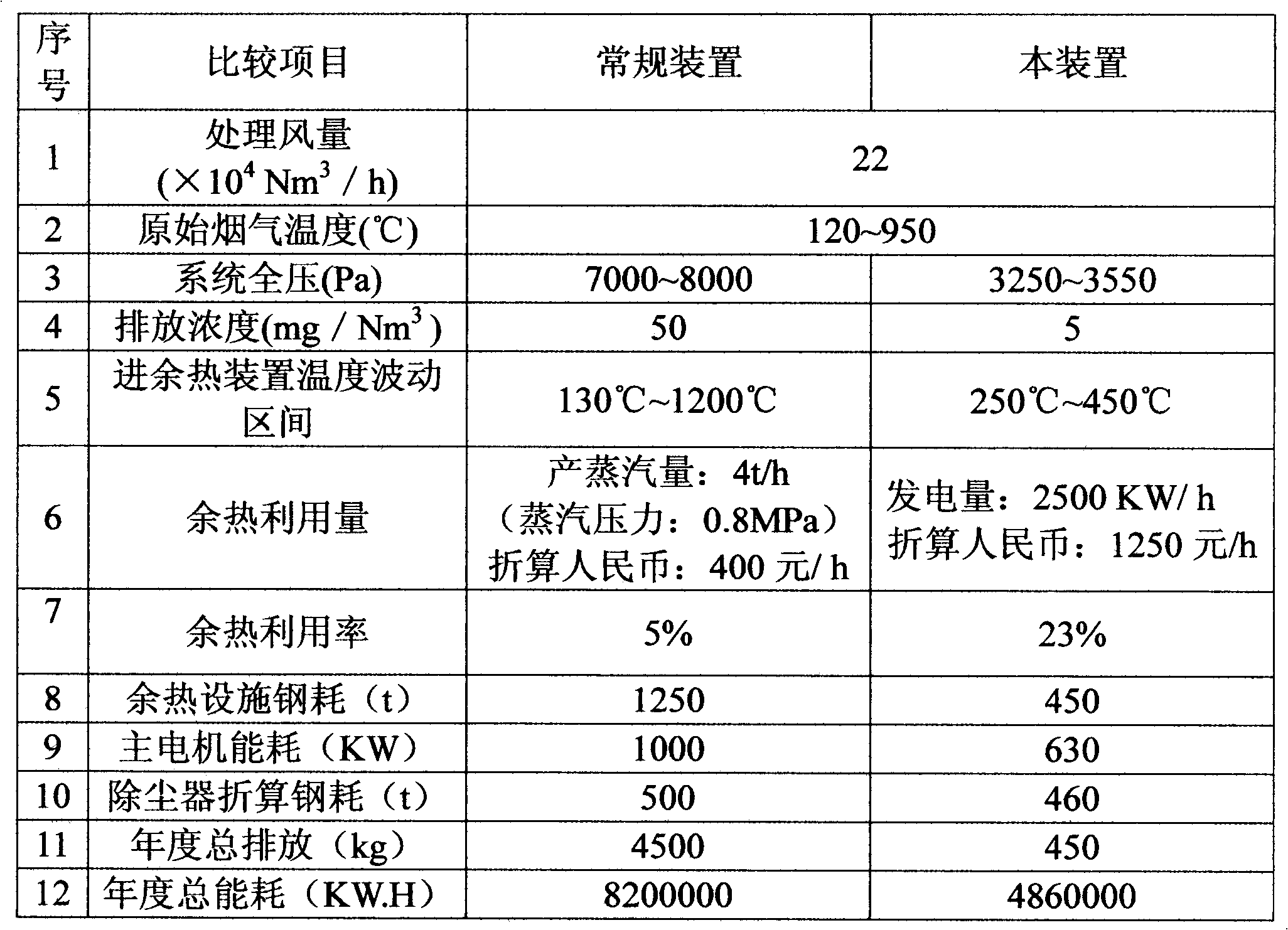

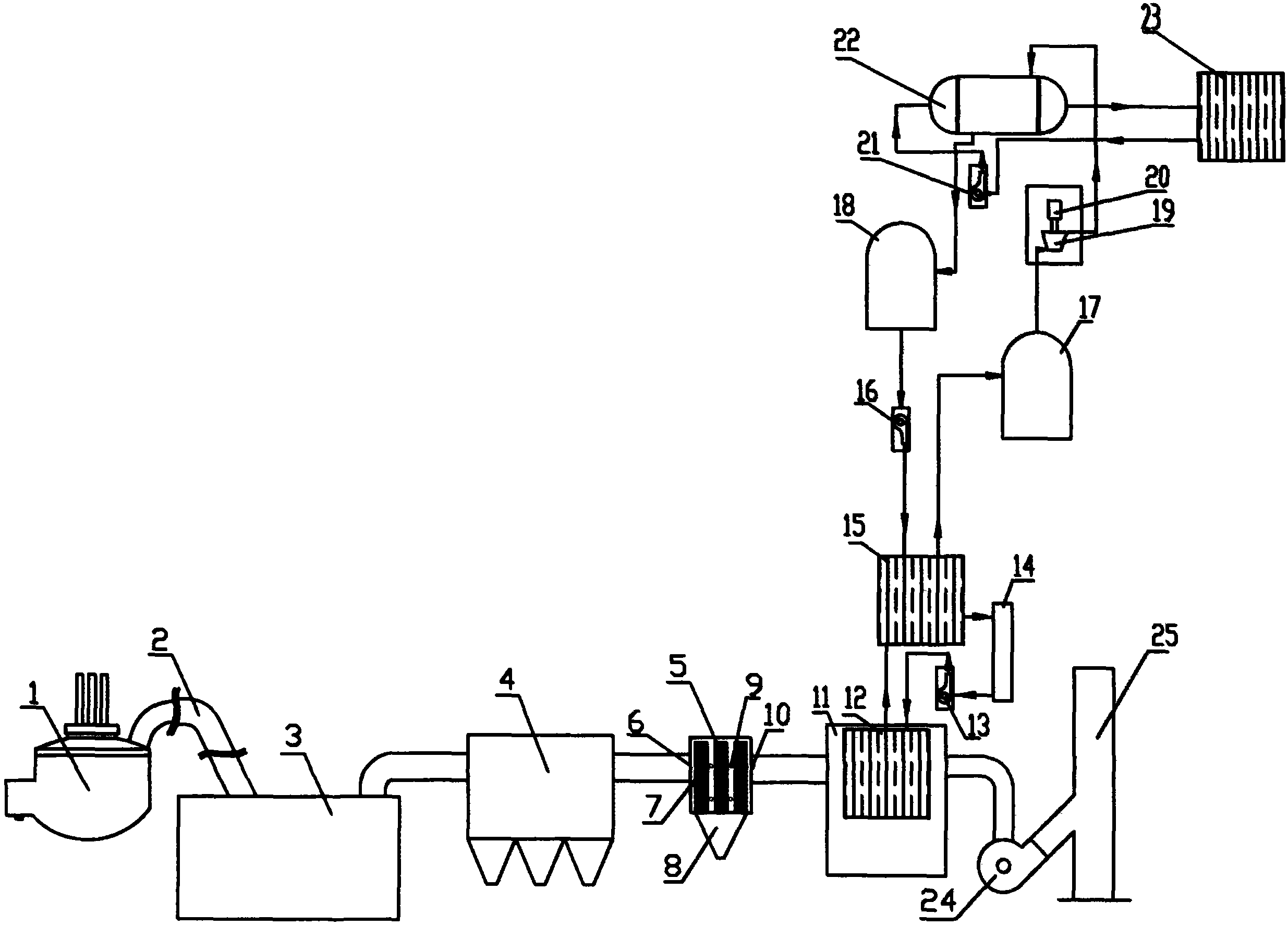

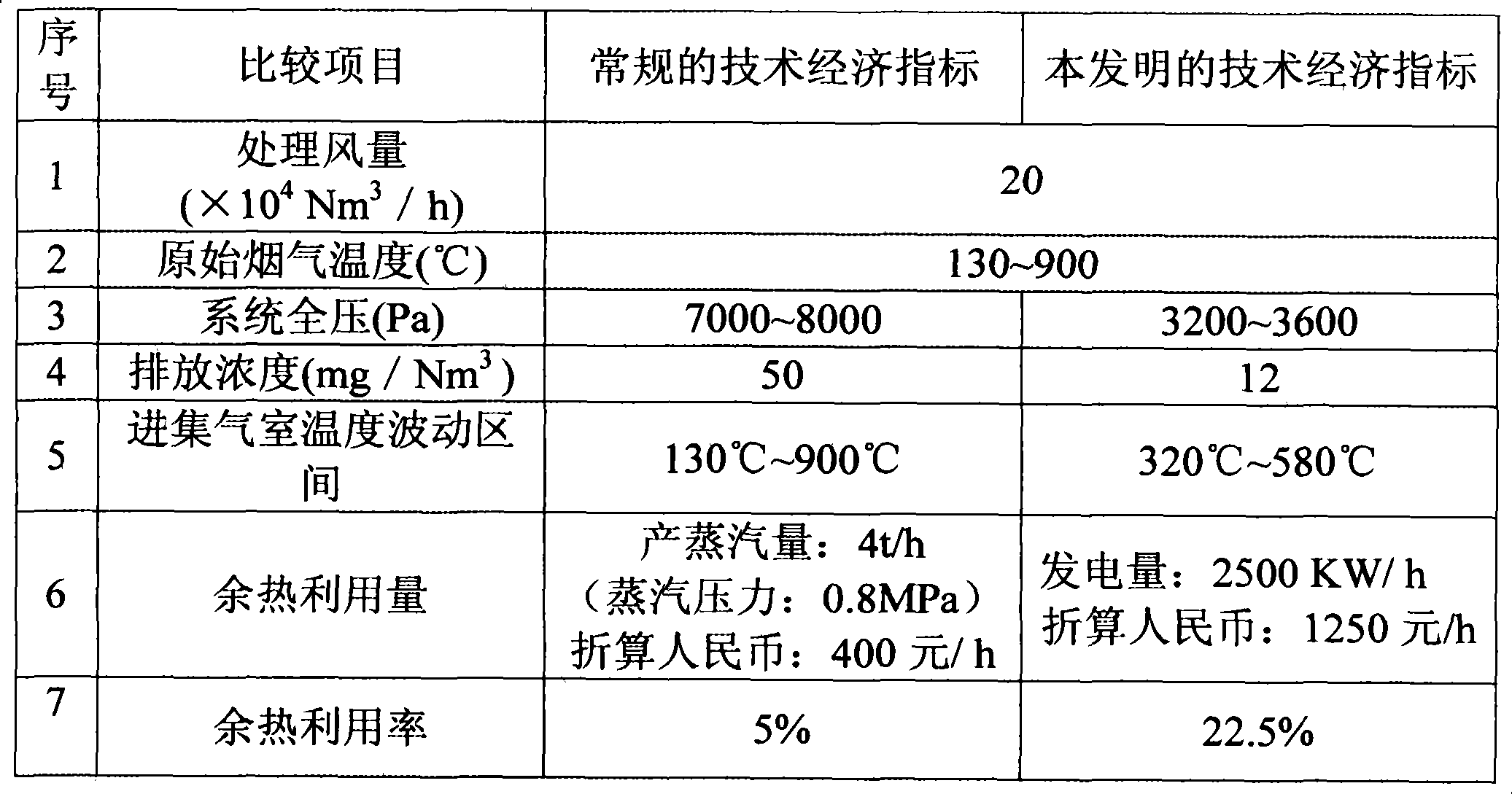

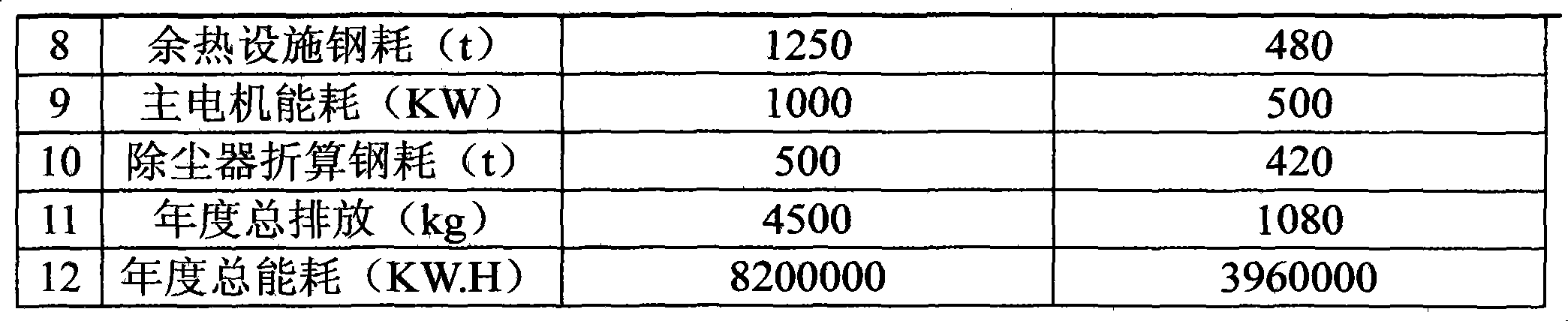

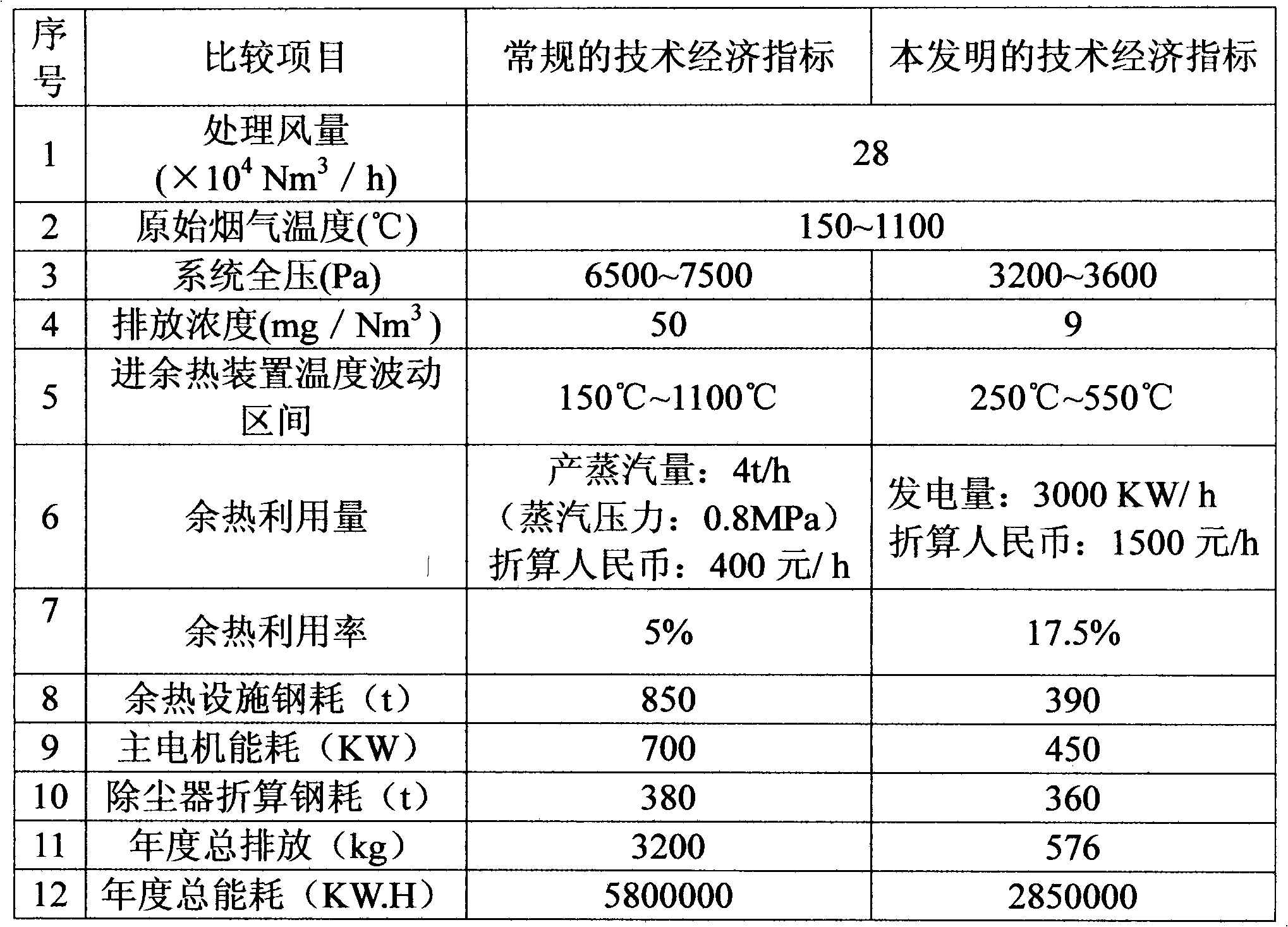

Waste heat utilization and dust removing method for electric furnace flue gas with thermal storage soaking device

InactiveCN103383195AReduce peakLess investmentIncreasing energy efficiencyWaste heat treatmentPeak valueSteam drum

A waste heat utilization and dust removing method for electric furnace flue gas with a thermal storage soaking device is characterized in that flue gas emitted from the interior of an electric furnace enters a settling chamber after being mixed with cold air through a water cooling flue duct, then enters a high-temperature dust remover, the thermal storage soaking device and a gas collection chamber in sequence, emits heat quantity, is pressed into an exhaust pipe through a main air blower, and is emitted into the atmosphere; meanwhile, circulating water enters a heat exchanger to absorb the heat of the flue gas, is converted into steam-water mixture, enters an evaporator, and emits heat quantity; an organic working medium absorbs heat in the evaporator through a working medium pump, is converted into steam, and enters a steam pocket; the working medium steam expands in a steam turbine to apply work, thereby driving a power generator to generate electricity. The method is characterized in that the high-temperature dust remover is a high-temperature resistant C-Cu composite material filter element dust remover; R227ea is adopted as the organic circulating working medium; the thermal storage soaking device is adopted for reducing the fluctuation range and peak value of flue gas; heat energy is converted into high-grade electric energy; the device investment and the operation energy consumption are low.

Owner:无锡市东优环保科技有限公司

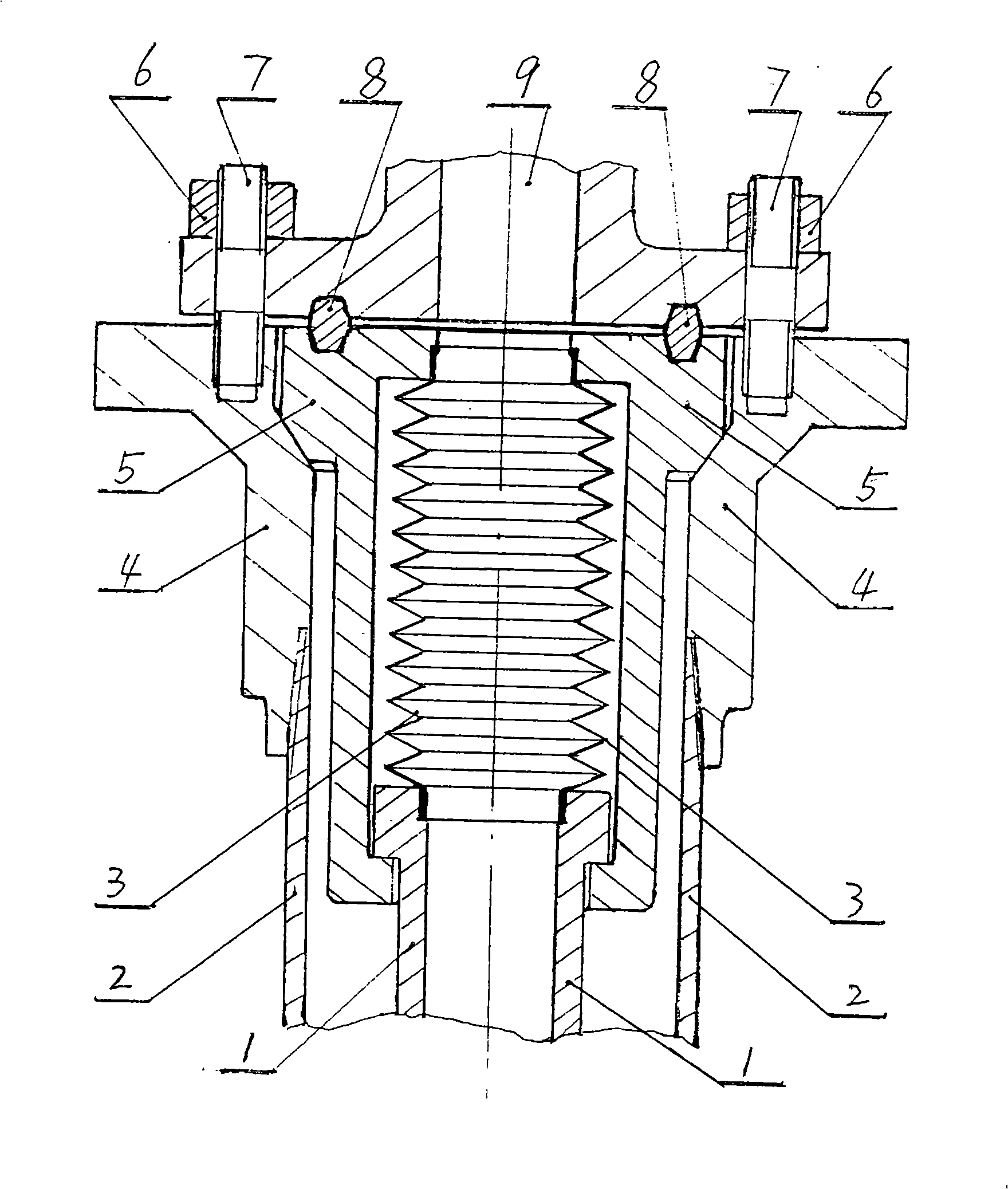

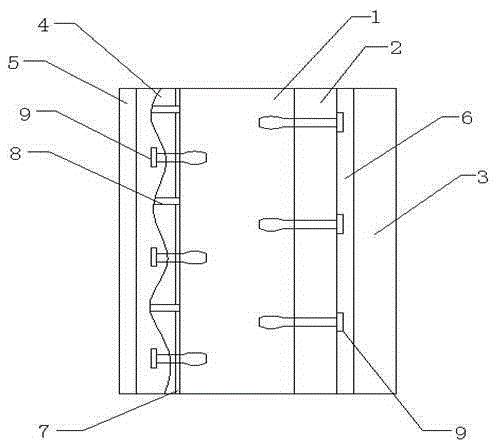

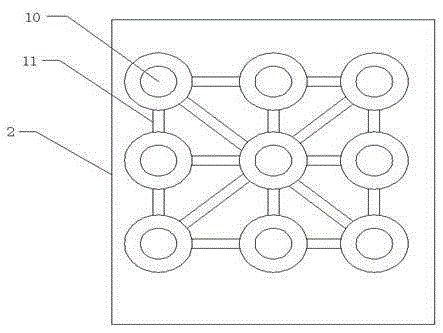

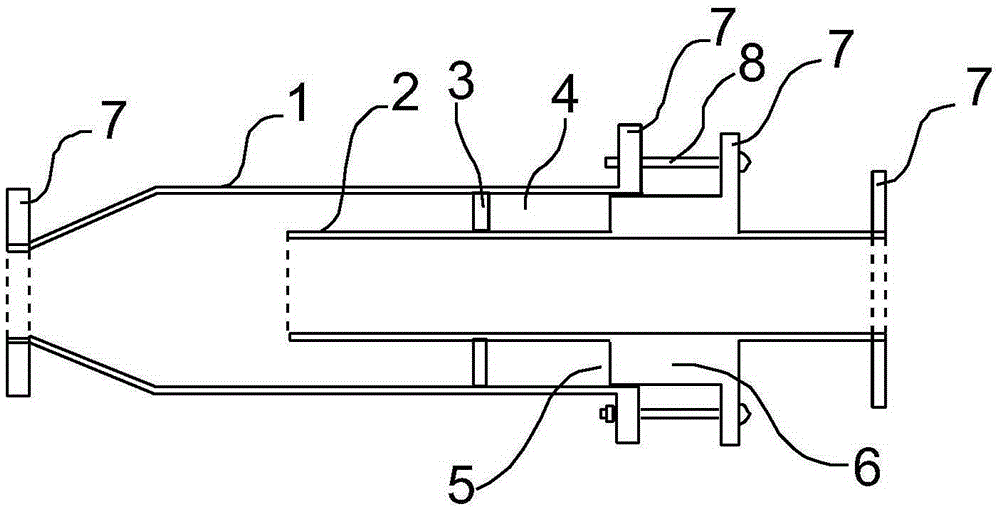

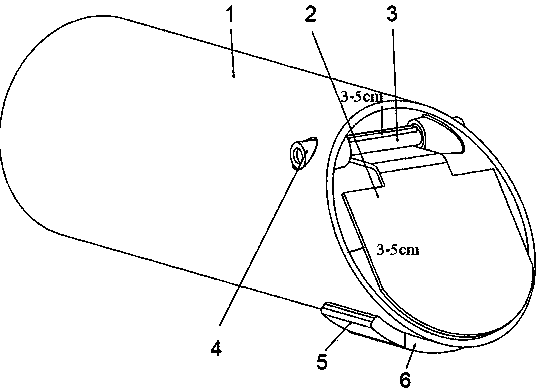

Expansion joint used for high temperature and high pressure pipeline

InactiveCN105257940AReduce weightReduce volumePipeline expansion-compensationAdjustable jointsThermal expansionHigh pressure

The invention discloses an expansion joint used for a high temperature and high pressure pipeline. The expansion joint comprises an inner casing pipe and an outer casing pipe which can axially move relative to each other. The outer wall of the inner casing pipe is limited by a sliding ring arranged on the inner wall of the outer casing pipe. A gap among the inner casing pipe, the outer casing pipe and the sliding ring forms a sealed area, and the sealed area is sealed by filler. An opening in the side, opposite to the sliding ring, of the sealed area is a filler port. A circle of compression boss matched with the filler port in shape and size is arranged on the outer side of the inner casing pipe. The compression boss and the filler port are each provided with a flange perpendicular to the axial direction. The two flanges are connected through a plurality of sliding rods. The sliding rods and the sliding ring limit the relative movement of the inner casing pipe and the outer casing pipe in the axial direction together. The expansion joint has the beneficial effects that 1, the expansion joint is resistant to corrosion, high temperature and low temperature; 2, through the casing pipe type structural design, the expansion joint is light, small in size and convenient to install; 3, the problem that during long-distance pipeline installation, pipelines expand by heat and contract by cold when temperature changes is solved.

Owner:SHANGHAI JINGTENG TECH

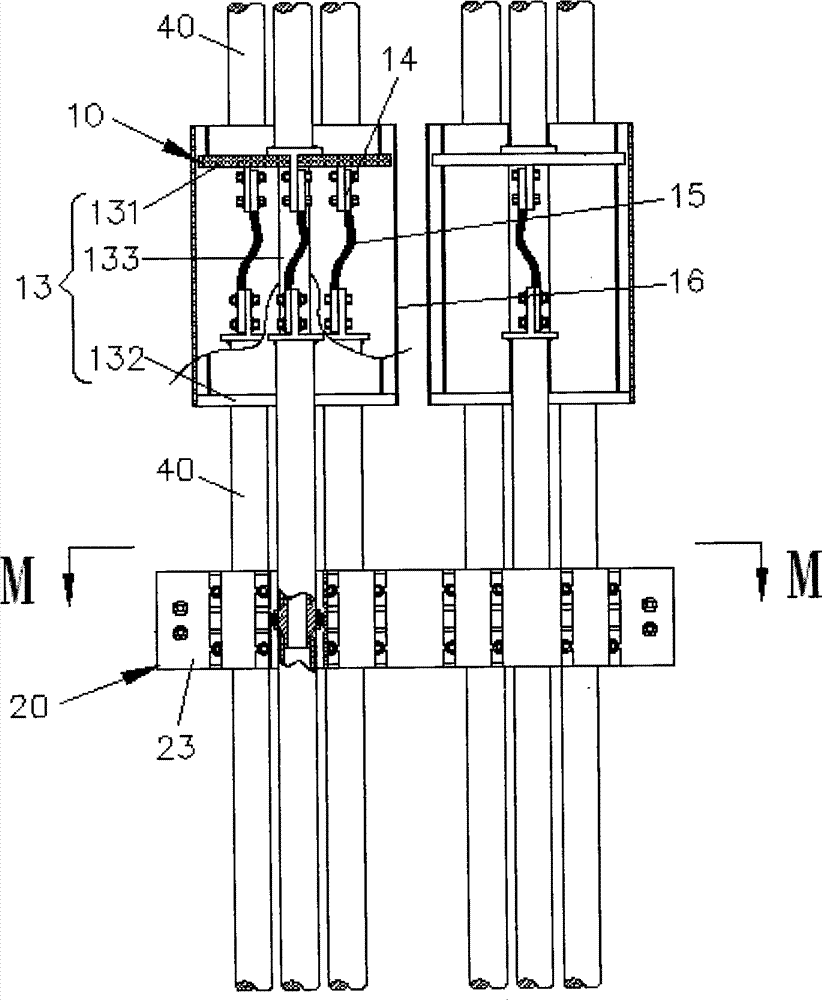

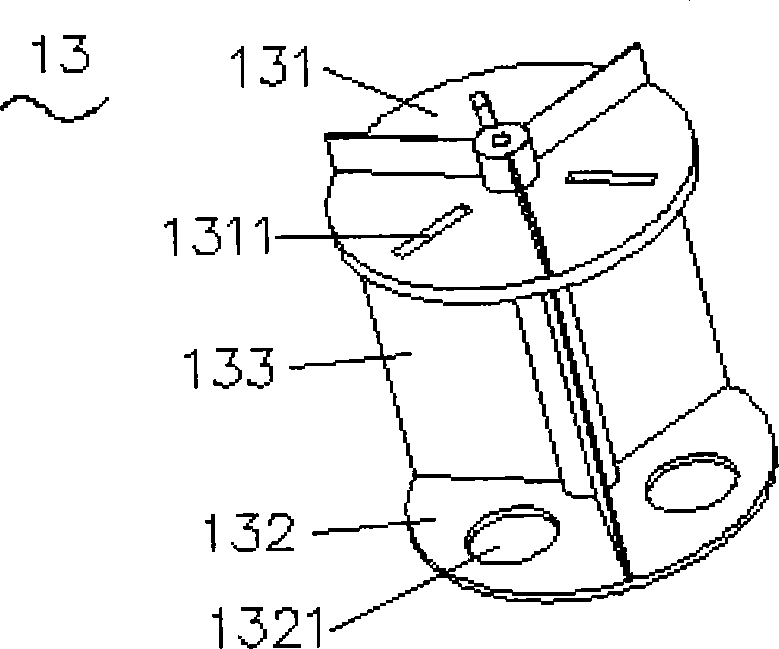

Electric connector

The invention discloses an electric connector which comprises carrier connecting devices and lateral slide support damping devices. Each carrier connecting device comprises first supports, a first damper, a carrier and connecting pieces which are arranged in a wind power tower. Each lateral slide support damping device comprises a plurality of second supports, at least one second damper, a supporting plate, a plurality of clasping pieces and a plurality of slide positioning pieces. The slide positioning pieces are fixed to the outsides of paired insulating tube buses, the clasping pieces are arranged on the outsides of the slide positioning pieces, the slide positioning pieces and the clasping pieces can slide relatively, the clasping pieces are fixed onto the supporting plates, and the second dampers are arranged between the supporting plates and the second supports. The electric connector has the advantages that electric energy can be downwardly transmitted from wind-driven power generators via the carrier connecting devices, and problems of dropping of existing insulating tube buses and damage to outer insulators of the existing insulating tube buses can be solved; the lateral slide support damping devices are flexibly connected with the carrier connecting devices, so that the problem that the existing insulating tube buses are expanded with heat and contracted with cold can be solved.

Owner:TIANJIN WOERFAR ELECTRIC EQUIP

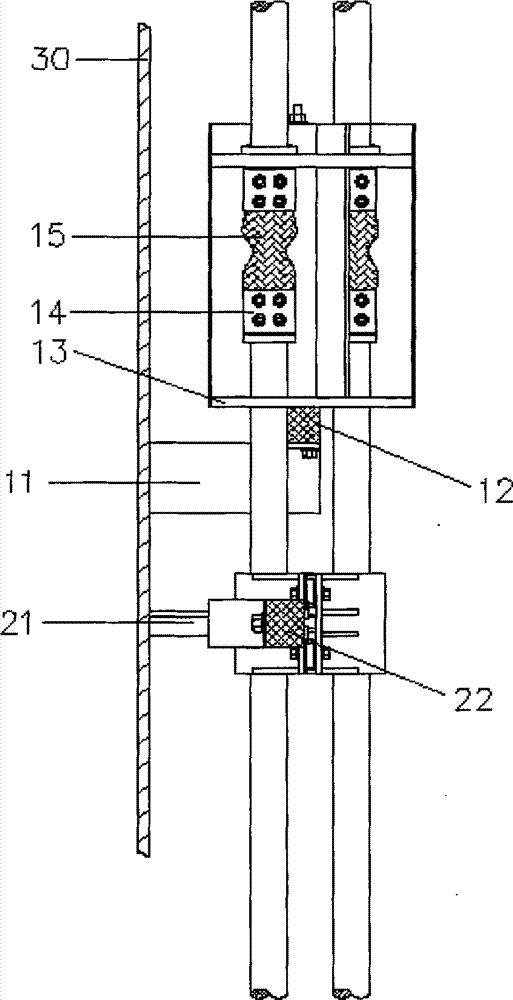

Heat collection pipe adjustable supporting device of solar trough type heat collector

InactiveCN102072582APrecise positioningReduce stressSolar heat devicesSolar thermal energy generationCollector deviceEngineering

The invention discloses a heat collection pipe adjustable supporting device of a solar trough type heat collector. A main support of the trough type heat collector is connected with a supporting fork; a heat collection pipe bracket cross beam is connected with the supporting fork through a bolt pin in the supporting fork and can rotate around the bolt pin to form a first rotational joint; a heat collection pipe bracket upright post is connected with the heat collection pipe bracket cross beam and a U-shaped bracket; a heat collection pipe supporting seat is connected with the U-shaped bracket and can rotate around a transverse adjusting screw to form a second rotational joint; an up-down slide block is arranged in the heat collection pipe supporting seat; the up-down position of the up-down slide block can be adjusted by adjusting a height adjusting bolt; and a heat collection pipe is positioned on the up-down slide block, and can move up and down along with the up-down slide block and move left and right along with the heat collection pipe supporting seat. The device is provided with two rotational joints which can rotate along with the expansion and extraction of the heat collection pipe and realize the accurate positioning of the heat collection pipe, so that the heat collection pipe is positioned on a trough type heat collector focal line all the time when working stably at a high temperature, and a good focusing effect is achieved.

Owner:HIMIN SOLAR

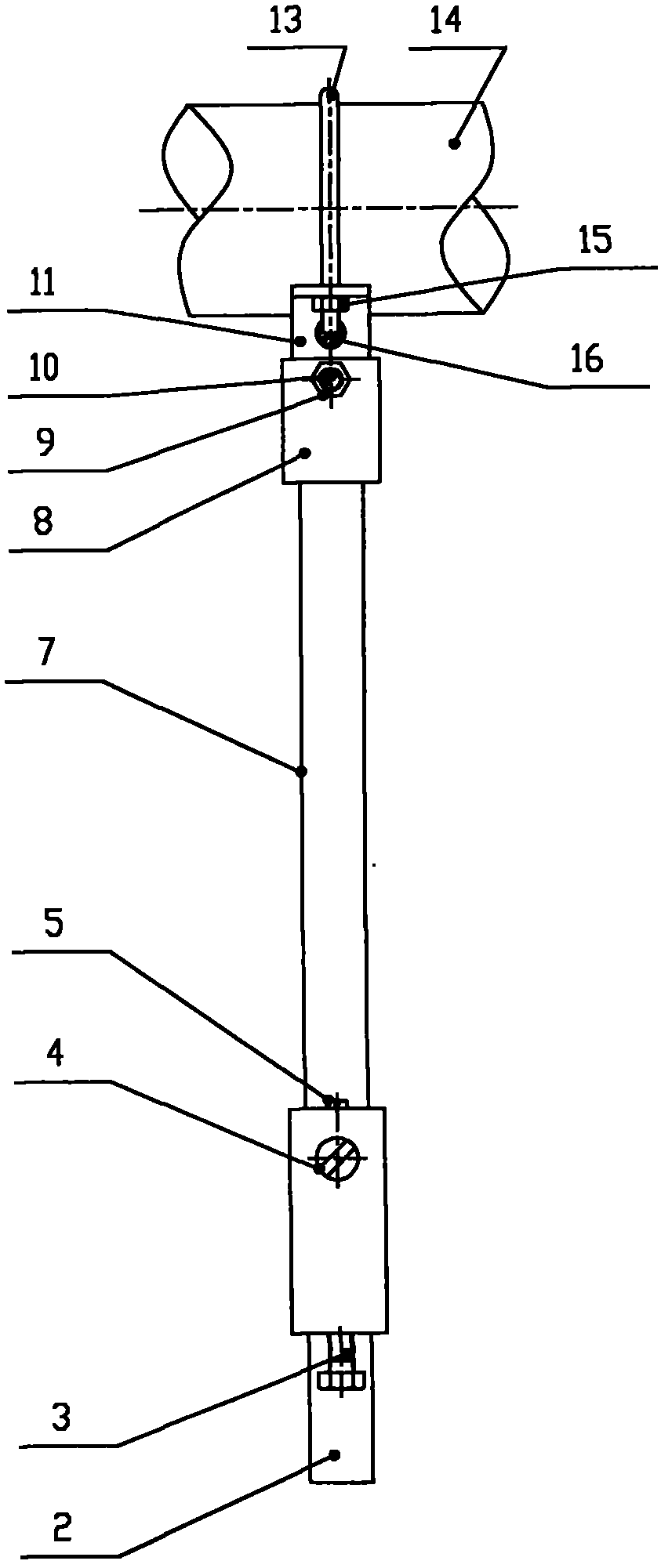

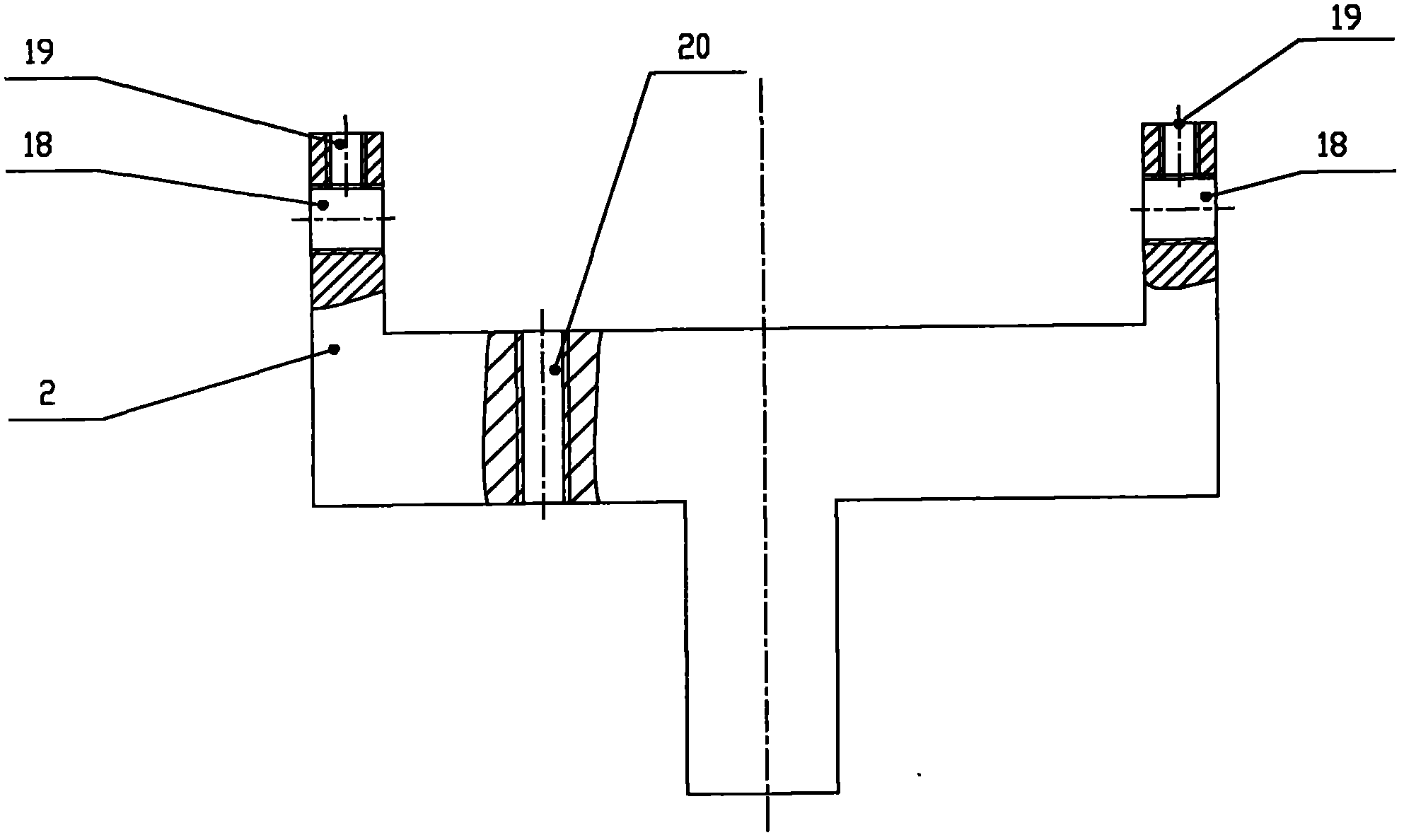

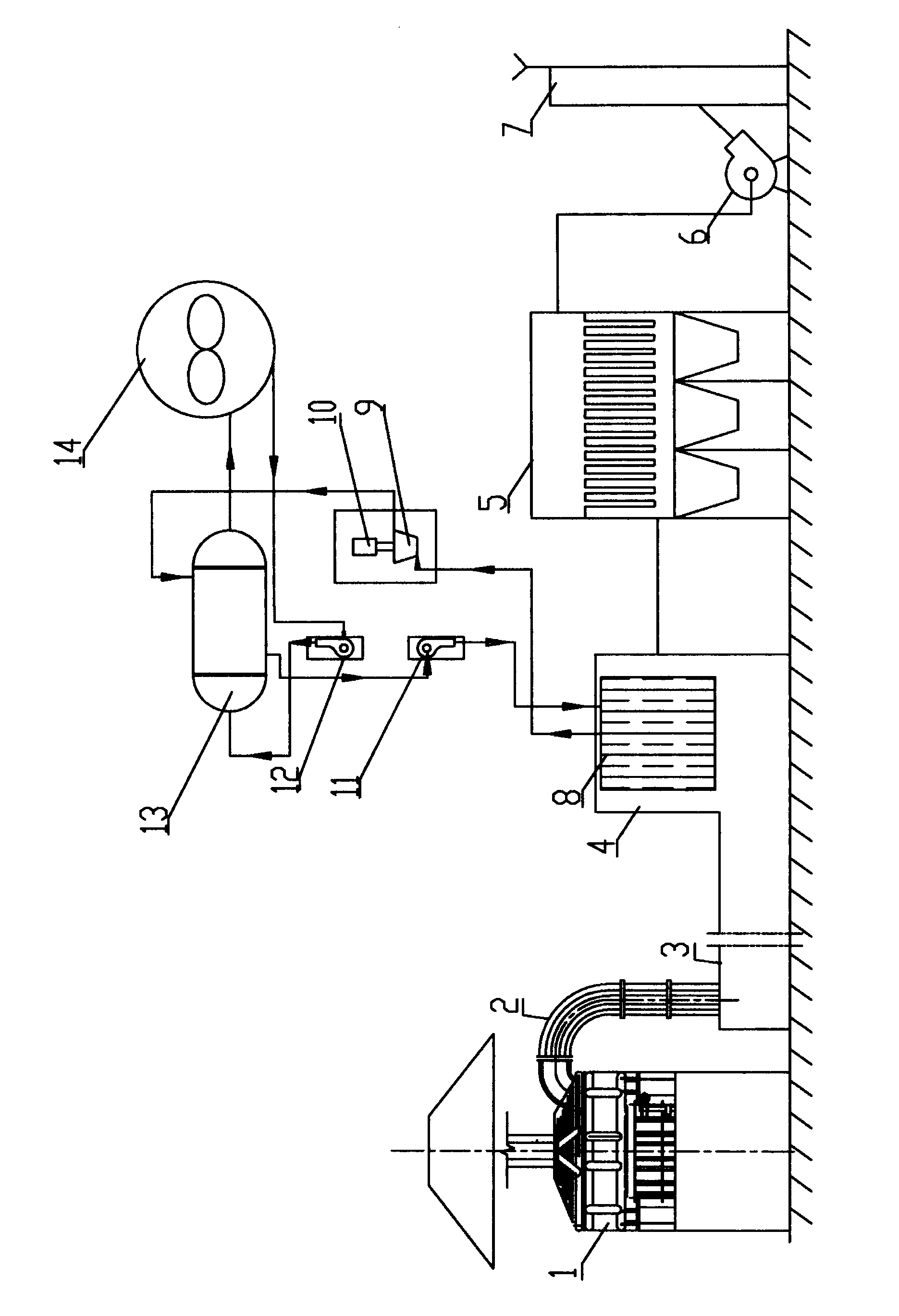

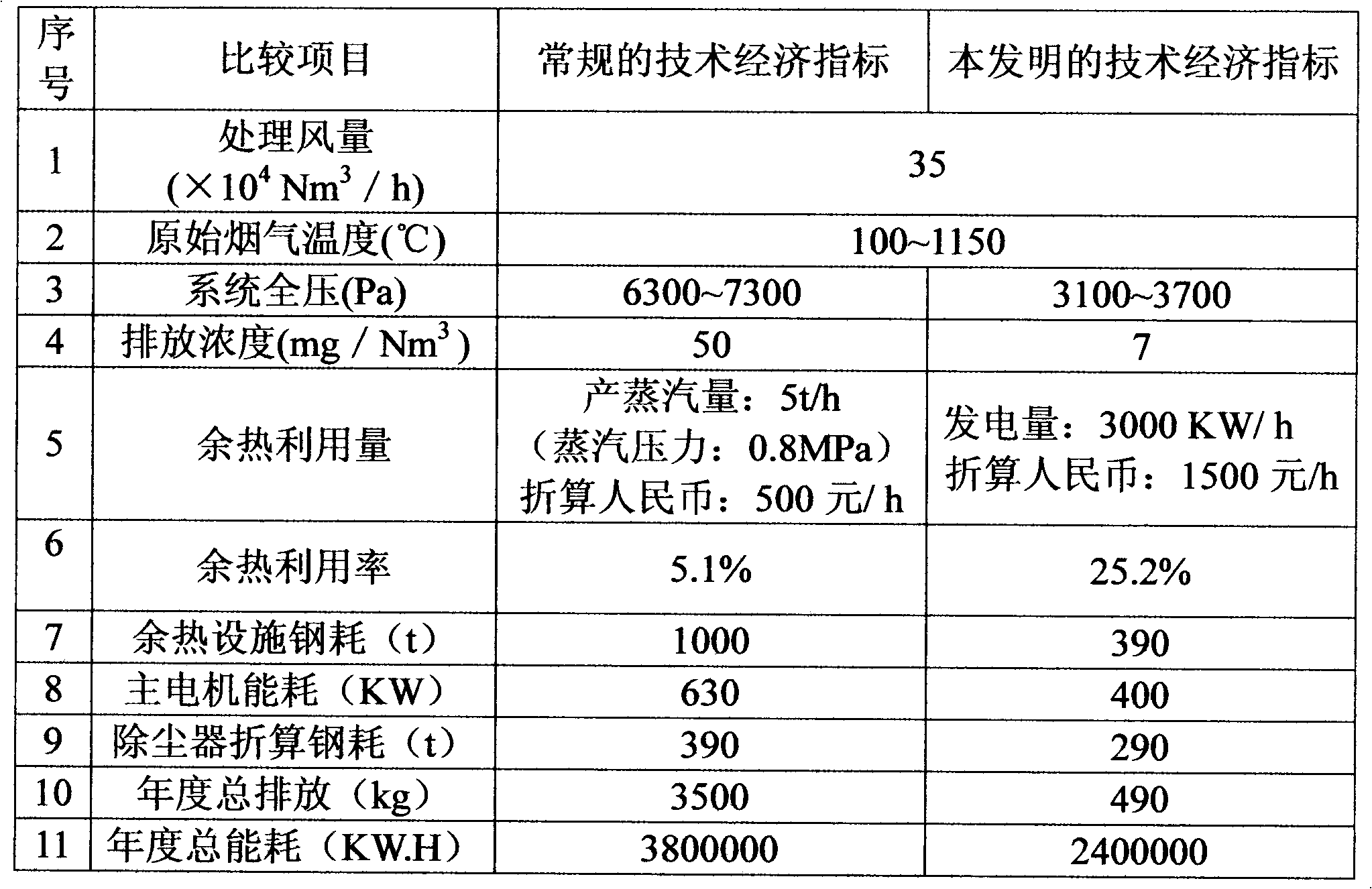

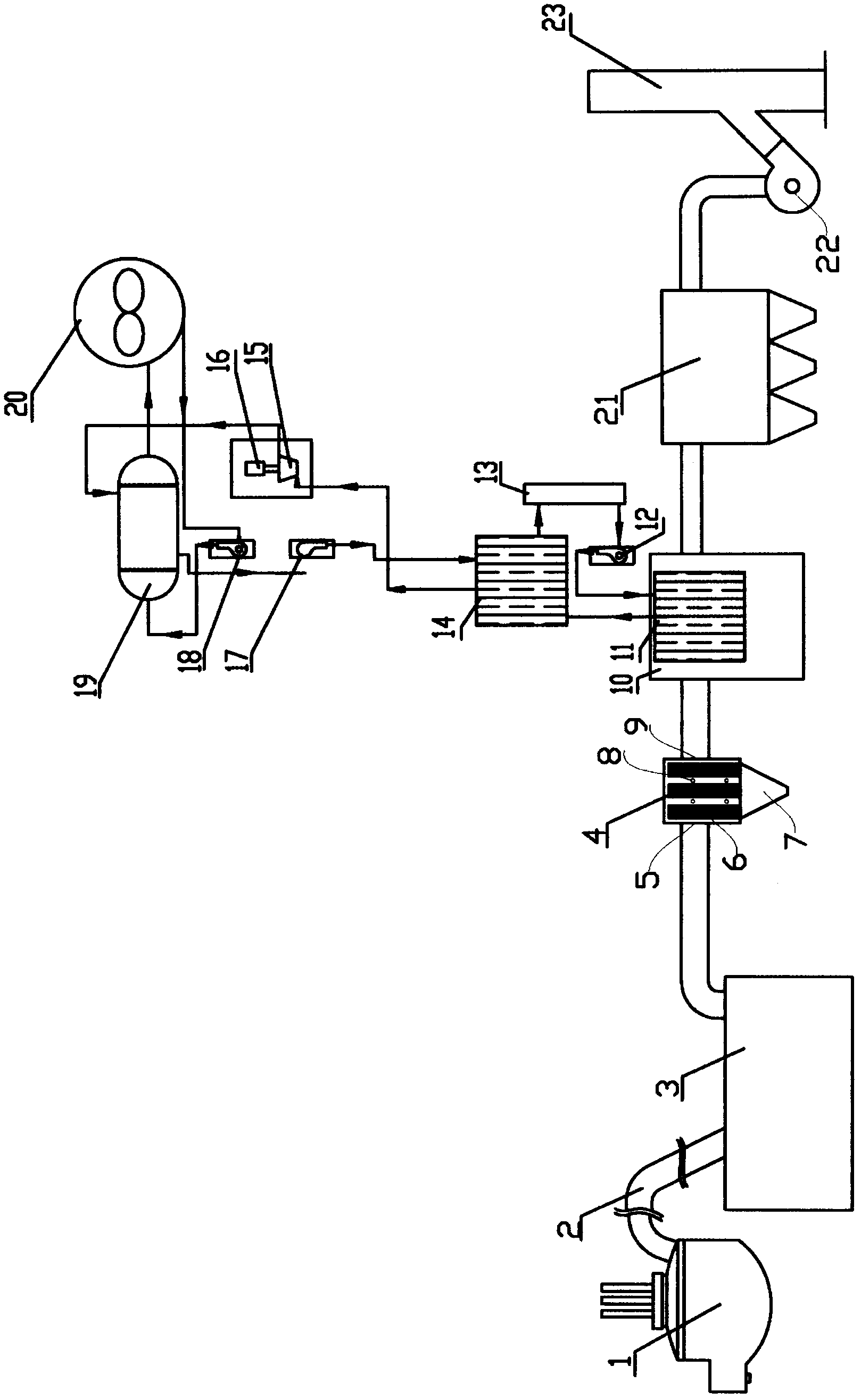

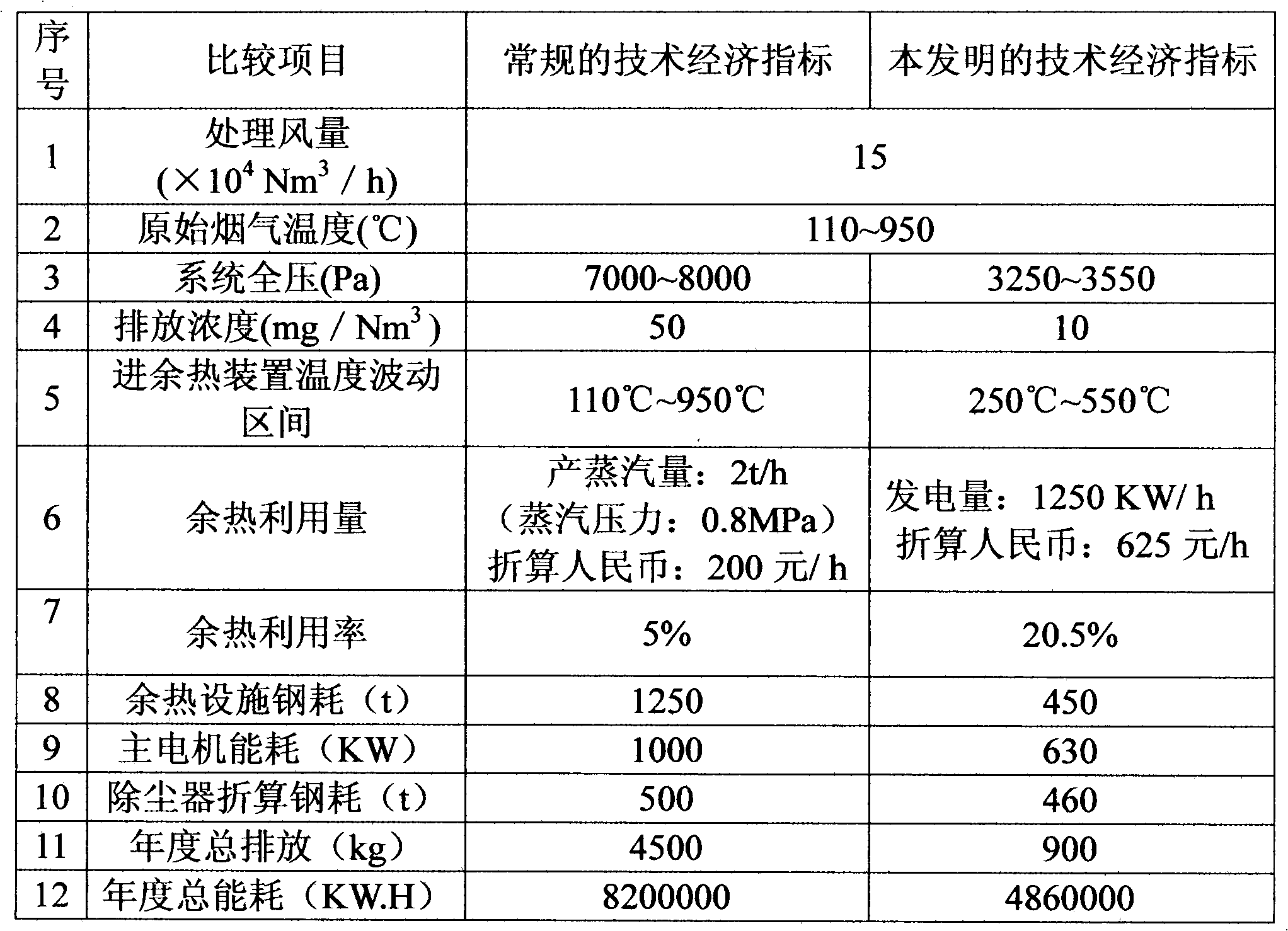

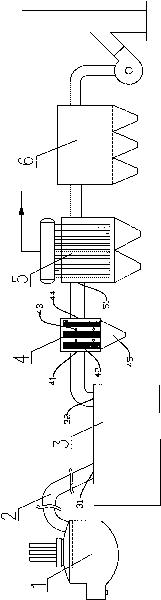

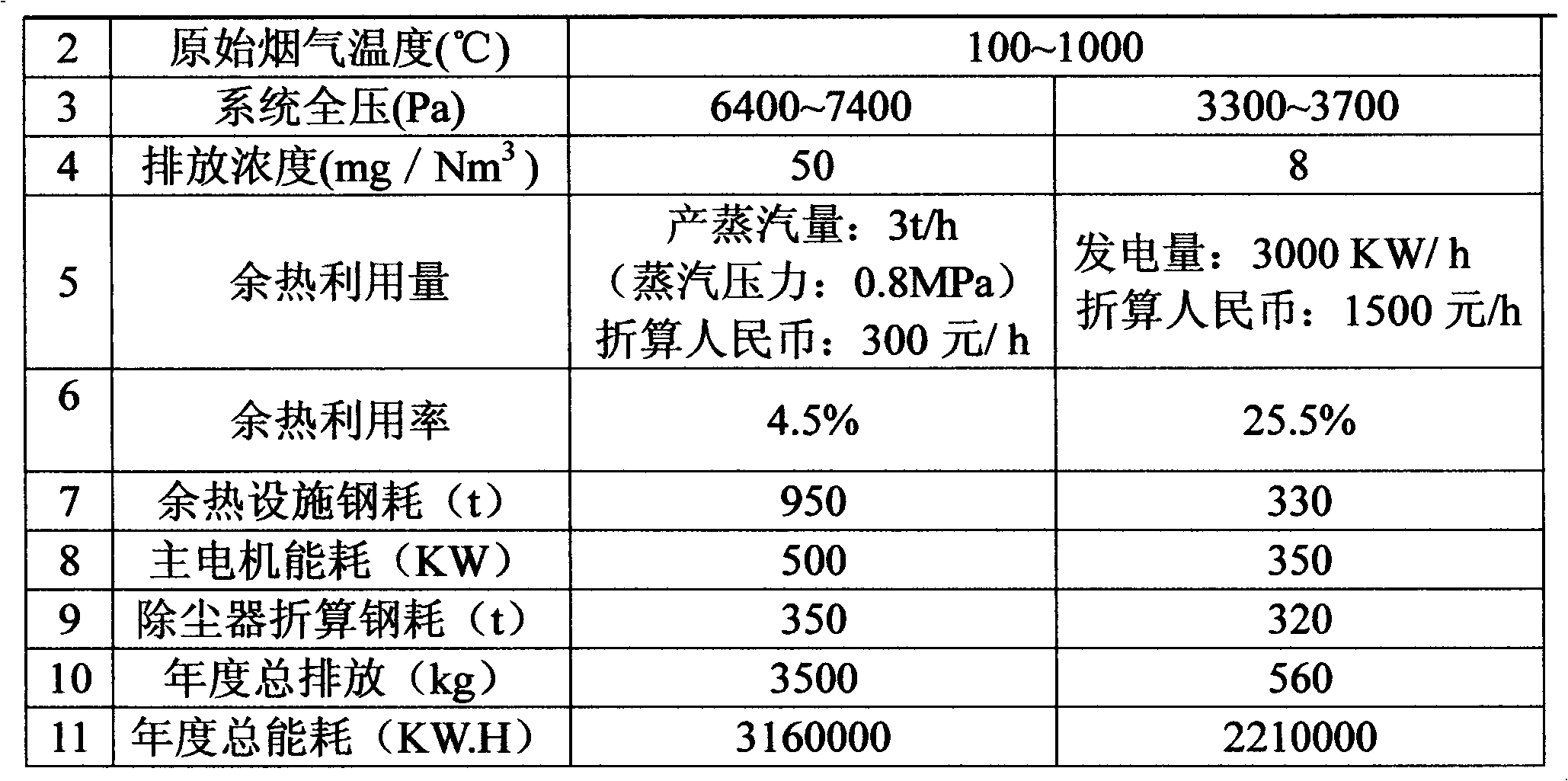

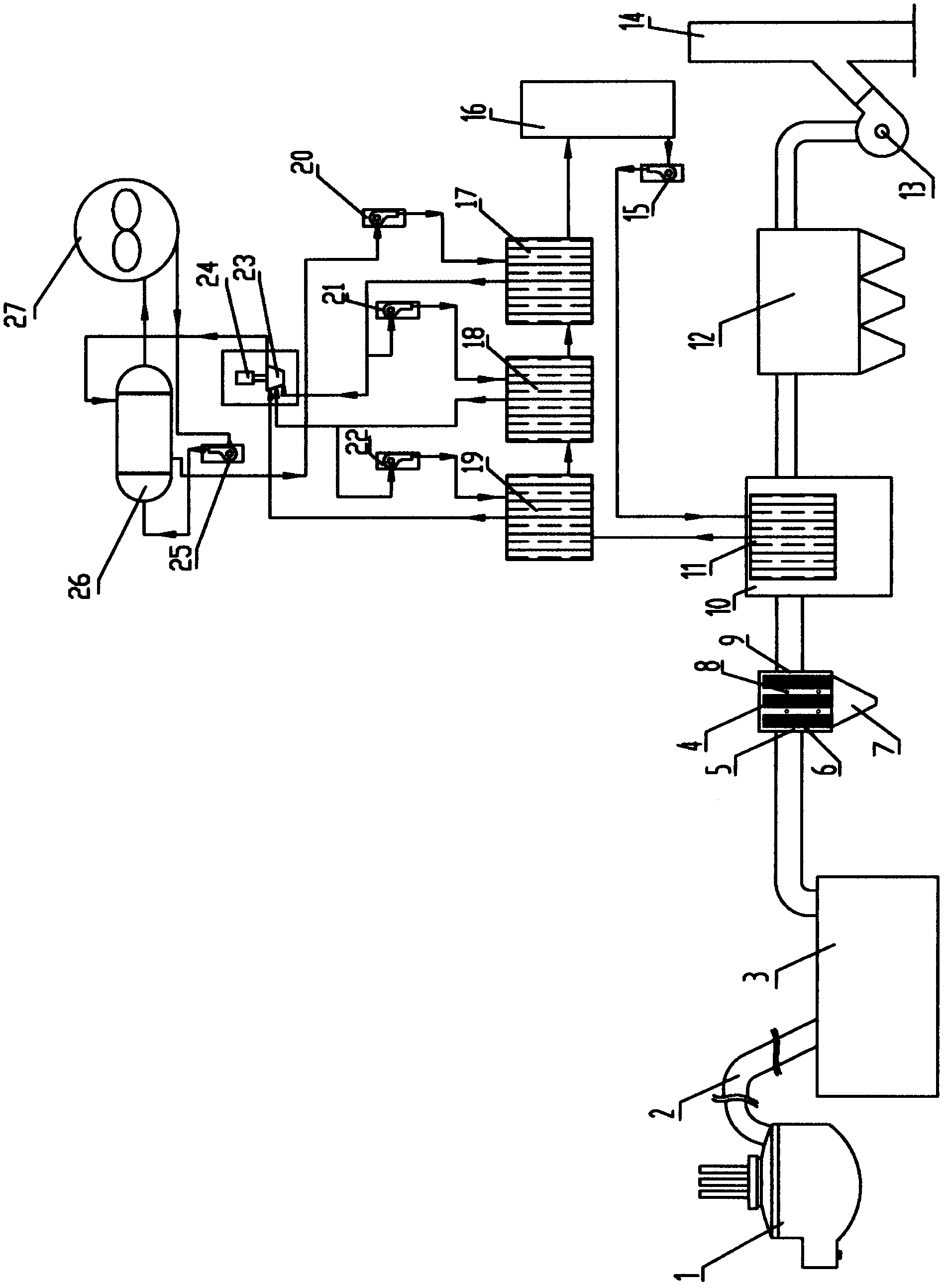

Power generation, energy saving and dedusting method by utilizing heat waste of exhaust gas in electric furnace through organic rankine cycle

InactiveCN103017547ARelief of swells and dipsSolve thermal expansion and contractionIncreasing energy efficiencySteam engine plantsElectric arc furnaceOrganic Rankine cycle

The invention discloses a power generation, energy saving and dedusting method by utilizing heat waste of exhaust gas in an electric furnace through organic rankine cycle, which is characterized in that the exhaust gas in the electric furnace is discharged from a fourth hole, and enters a combustion settling chamber after cold air interfuses the exhaust gas through a water-cooling sliding sleeve; the exhaust gas passing through the combustion settling chamber enters a uniform velocity waste heat exchanger; the exhaust gas discharges heat, enters a bag-type dust collector, and is pressed into an exhaust funnel to be discharged into atmosphere by a main fan after being dedusted; meanwhile, an organic working medium is driven by a working medium pump to absorb the heat in a straight pipe plate heat pipe exchanger to be changed into vapor; and the working medium vapor swells to do work in a steam turbine to drive a generator to generate electricity. The working medium vapor discharged from a low-boiling-point working medium steam turbine is condensed into saturation liquid by a condenser; and the working medium liquid is pressurized by the working medium pump, and is then fed into the straight pipe plate heat pipe exchanger, so as to start a new round of circulation. The power generation, energy saving and dedusting method by utilizing the heat waste of the exhaust gas in the electric furnace through the organic rankine cycle is characterized in that R600 is adopted as a circulating organic working medium. With the adoption of the power generation, energy saving and dedusting method by utilizing the heat waste of the exhaust gas in the electric furnace through the organic rankine cycle, the heat energy in the exhaust gas is recovered to a maximum limit to be transformed into high-grade electric energy. The device is low in investment, low in operation energy consumption and good in environment-protection effect.

Owner:无锡市东优环保科技有限公司

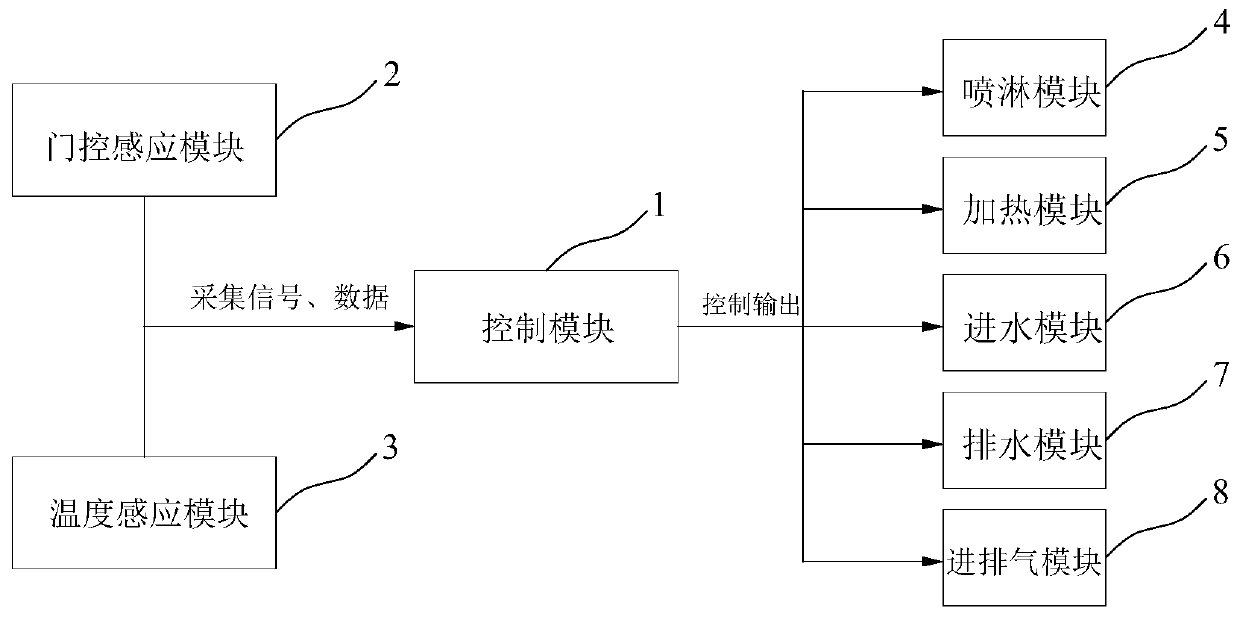

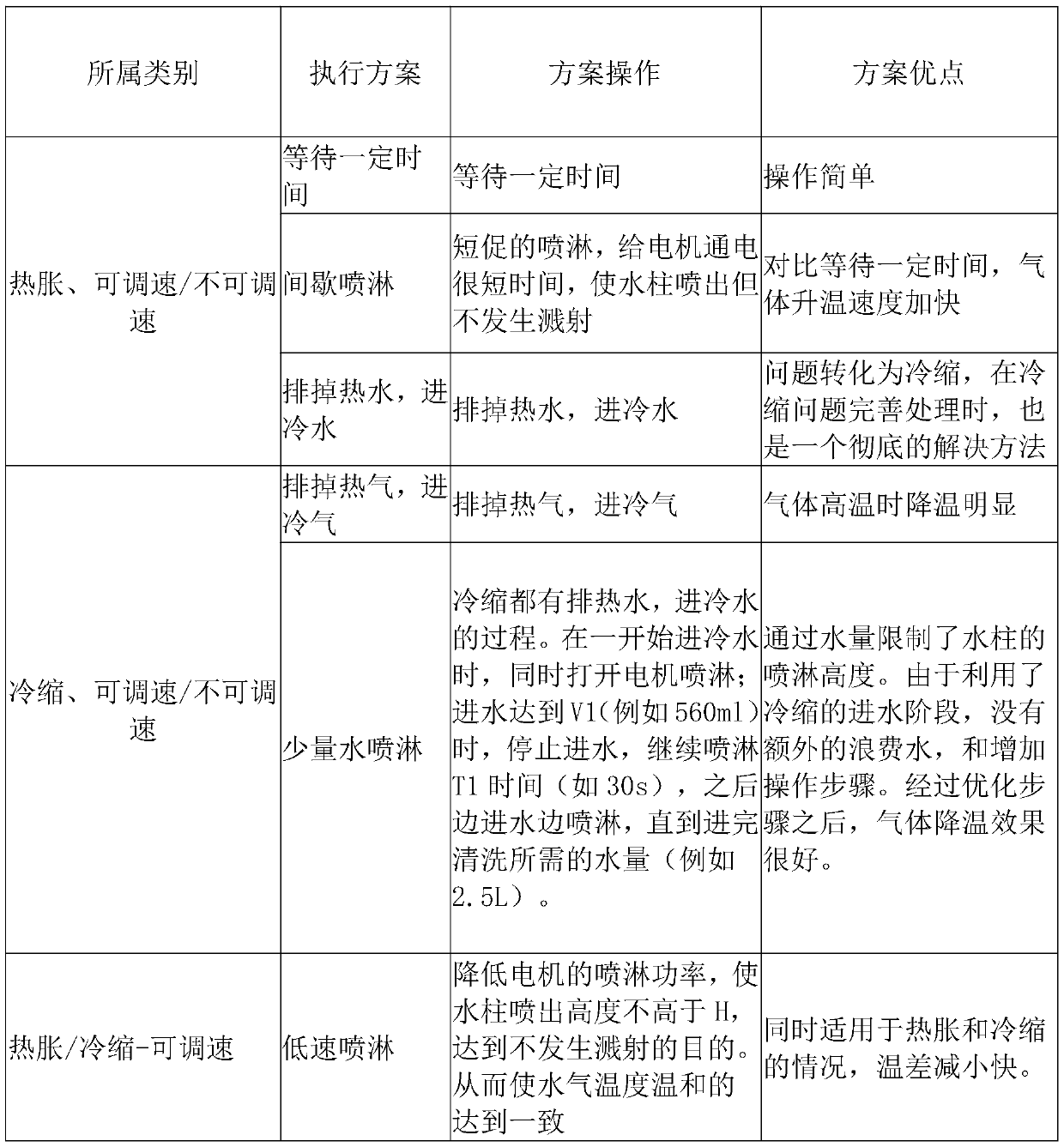

Control method and device for preventing sudden change of gas volume in dishwasher inner cavity

PendingCN111466849APrevent splashAvoid adsorptionTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionThermodynamicsMachine parts

The invention discloses a control method and a control device for preventing sudden change of volume of gas in an inner cavity of a dish washing machine. The method comprises steps of S1, detecting anevent, specifically, a cover opening signal, a water inlet signal and a water outlet signal of the dish washing machine and water temperature and air temperature data in an inner cavity are collected, whether thermal expansion / cold contraction occurs or not is judged according to the cover opening signal, the water inlet signal and the water outlet signal, if thermal expansion / cold contraction does not occur, operation is ended, if thermal expansion / cold contraction occurs, operation continues; S2, judging conditions, whether a thermal expansion type or a cold contraction type occurs is judged; S3, judging conditions, the type of a motor adopted by the dish washing machine is judged, wherein the judging result is an adjustable-speed motor or a non-adjustable-speed motor; and S4, executingthe task, an execution scheme is selected according to the judgment result of the steps S2-S3. The method is advantaged in that loss of dish-washing machine parts caused by thermal expansion and coldcontraction of the inner cavity of the dish washing machine is effectively prevented, and a problem of scalding during uncovering is solved.

Owner:厦门米海智能科技有限公司

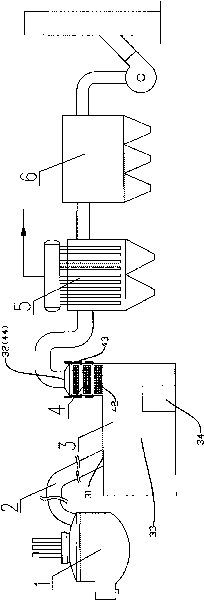

Regenerative submerged arc furnace flue gas waste heat power generation method

InactiveCN103017553ARelief of swells and dipsSolve thermal expansion and contractionIncreasing energy efficiencySteam engine plantsAtmospheric airPeak value

The invention discloses a regenerative submerged arc furnace flue gas waste heat power generation method. The method is characterized by comprising the following steps that flue gases of a submerged arc furnace are exhausted from the furnace, sequentially enter a combustion sedimentation chamber, a heat accumulation temperature equalizing device and a waste heat collection chamber after being mixed with cold air through a water-cooled sliding sleeve, give off heat, enter a bag-type dust collector, and are pressed into an exhaust funnel and exhausted into the atmosphere after being subjected to bag removal; meanwhile, circulating water enters a heat exchanger to absorb the heat of the flue gases to form a steam-water mixture, and the steam-water mixture enters an evaporator, and gives off heat; and an organic working medium absorbs the heat in the evaporator through a working medium pump to form steam, and the working medium steam is expanded to apply work in a steam turbine to drive a generator to generate power. The method is characterized in that R236ea is adopted as the circulating organic working medium. Due to the adoption of the heat accumulation temperature equalizing device, the fluctuation amplitude and a peak value of the flue gases are reduced; and heat energy is converted into high-quality electrical energy, so that a device is low in investment and low in running energy consumption, and has a good environmental protection effect, and influence on the production stability and continuity of the submerged arc furnace is avoided.

Owner:无锡市东优环保科技有限公司

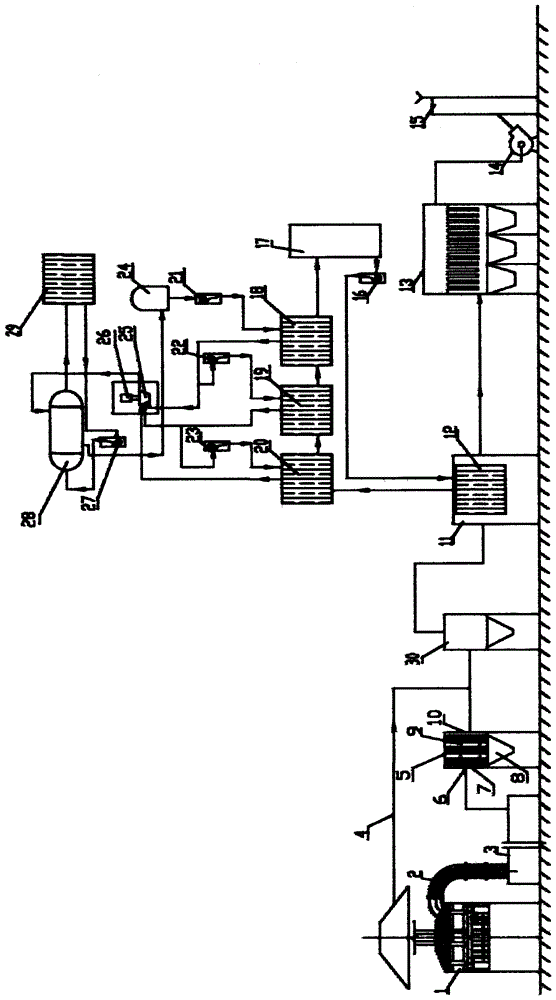

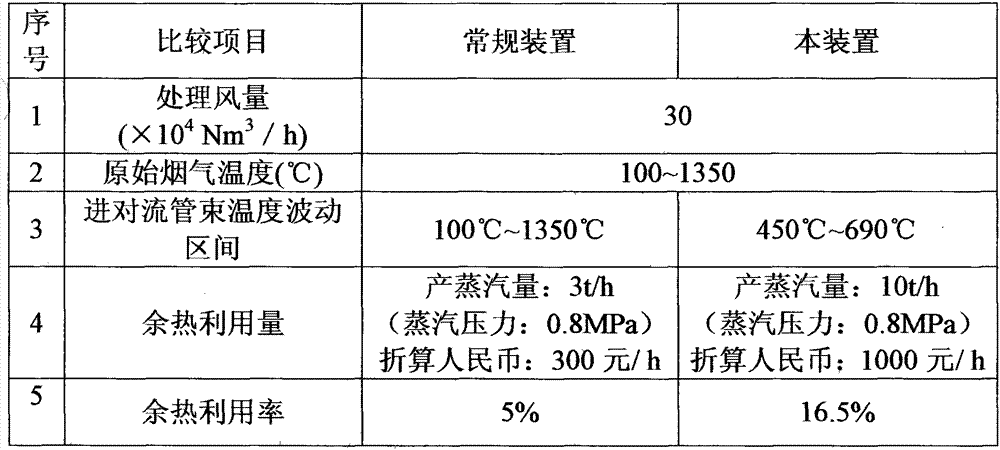

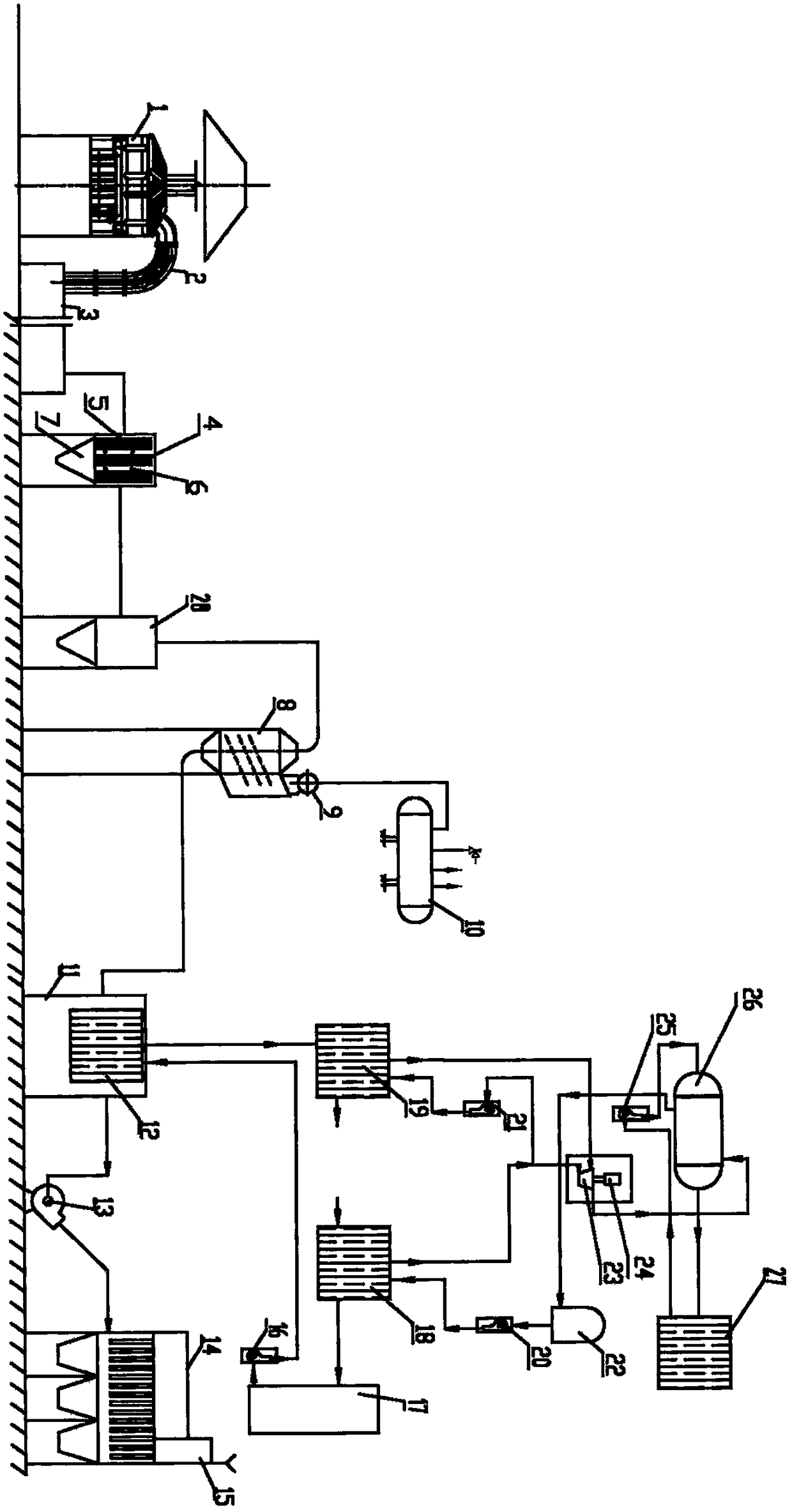

Exhaust gas fume afterheat recovering system with heat-accumulating and temperature-equalizing equipment

InactiveCN101718499AReduce peakLess investmentIncreasing energy efficiencyWaste heat treatmentEngineeringMaximum temperature

The invention relates to an afterheat recovering system, in particular to an exhaust gas fume afterheat recovering system with heat-accumulating and temperature-equalizing equipment, which comprises a settling chamber, the heat-accumulating and temperature-equalizing equipment, an afterheat recovering device and a dust catcher which are sequentially arranged, wherein the heat-accumulating and temperature-equalizing equipment can be independent, can also be integrated with the settling chamber to form a heat-accumulating, temperature-equalizing and settling chamber, and can also be integrated with the afterheat recovering device to form a heat-accumulating, temperature-equalizing and afterheat recovering device. Because of the heat-accumulating and temperature-equalizing equipment, the exhaust gas fume afterheat recovering system of the invention can clip a peak to fill a trough of a gas fume temperature, decrease the maximum temperature of gas fume, reduce a fluctuation amplitude of the gas fume temperature and release drastic rising and dropping of the gas fume temperature, thereby reducing investment of an afterheat system or a gas fume cooling device, improving the stability of the afterheat system and safely allocating various heat exchangers.

Owner:无锡市东方环境工程设计研究所

Utilizing method for flue gas waste heat of electric furnace

InactiveCN105318733AReduce the maximum temperatureReduce volatilityEnergy industryIncreasing energy efficiencyElectric arc furnaceAtmospheric air

The invention discloses a utilizing method for flue gas waste heat of an electric furnace. The utilizing method is characterized in that flue gas in the electric furnace is exhausted from a fourth hole, and is mixed into cold air through a water-cooled sliding sleeve; flue gas enters into a precipitating chamber and a heat storage thermostat; the flue gas from the heat storage thermostat and flue gas from an external exhaust pipeline connected to the upper part of the electric furnace are mixed and jointly enter into a homogeneous flow regenerative chamber; the flue gas from the homogeneous flow regenerative chamber enters into a sinter board dust catcher; dedusted flue gas is pressed into an exhaust funnel through a main air blower and is exhausted into the atmosphere; meanwhile, circulating water absorbs the heat of the flue gas from a heat exchanger and forms a steam-water mixture which enters into an evaporator to release the heat; organic working medium liquid absorbs the heat of the steam-water mixture and is changed into working medium steam; the working medium steam expands in an organic turbine with a stem supplementing port to do work, and drives a power generator to generate electricity. The utilizing method is also characterized in that R717 is adopted as a cyclic organic working medium. By adopting the method disclosed by the invention, heat energy in the flue gas can be recovered to the maximum extent and is directly converted into high-grade electric energy, and a good environment-friendly effect is realized.

Owner:无锡市东优环保科技有限公司

Magnetic control acoustics valve

ActiveCN103437860ASolve thermal expansion and contractionHas a damping effectSilencing apparatusMachines/enginesSteel woolEngineering

The invention relates to a noise reduction device, in particular to a magnetic control acoustics valve. The magnetic control acoustics valve comprises a valve block, a rotating shaft, a steel wool lining, an exhaust pipe, a magnet and a magnet protection cover, wherein automobile exhaust waste gas enters from the inlet of the exhaust pipe; magnetic force to the valve block by the magnet and the self weight of the valve block are overcome, and the valve block is blown to open; when the revolving speed of an engine is increased, the exhaust flow rate is increased, and the opening degree of the valve block is bigger; meanwhile, because the distance between the valve block and the magnet is bigger and bigger, the magnetic force is smaller; correspondingly, the counter-acting force of exhaust is lowered; therefore, exhaust back pressure is lowered. Compared with the traditional acoustics passive valve, the magnetic control acoustics valve has the characteristics of simple structure, easiness in manufacture and installation, low cost and low back pressure during high revolving speed, and low-frequency noise can be controlled.

Owner:JIANGSU UNIV

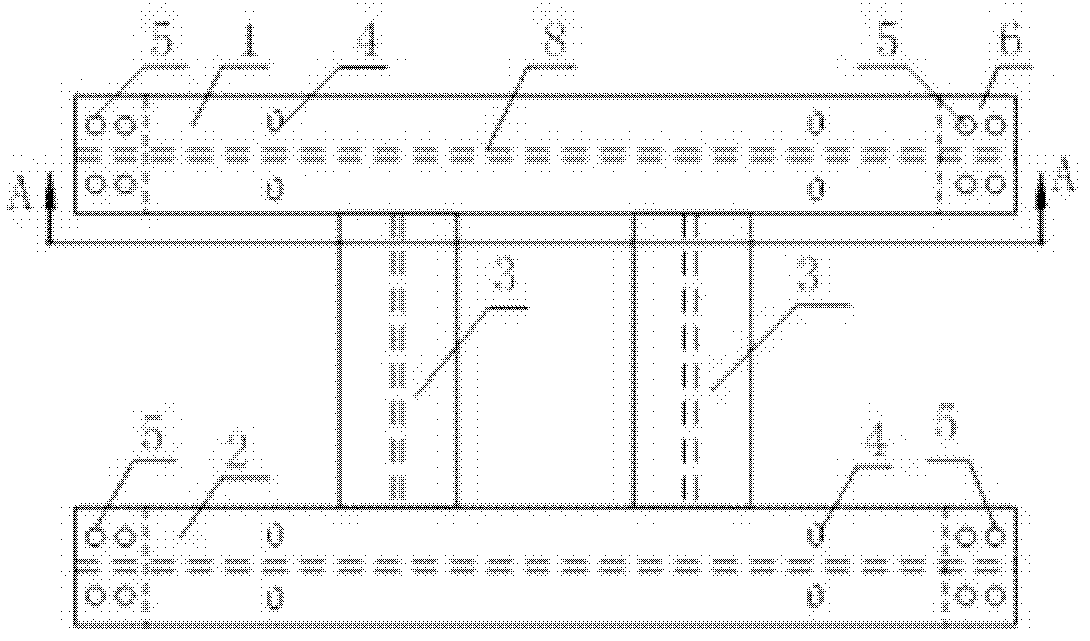

Sleeper for track skeleton and method for manufacturing sleeper

InactiveCN102605685ASolve thermal expansion and contractionReduce manufacturing costBallastwayLow speedThermal expansion

The invention relates to a sleeper for a track skeleton and a method for manufacturing the sleeper, in particular to a sleeper for medium-low speed magnetic-levitation train rails, and in particular to a sleeper for supporting a track skeleton joint on a magnetic-levitation rail, wherein the track skeleton joint has large heat-expansion and cold-contraction quantity. The sleeper comprises a front H-shaped steel sleeper, a rear H-shaped steel sleeper or a square steel tube sleeper and 1-4 middle H-shaped or square steel tubes by means of welding. The sleeper has the advantages of simple structure, simple manufacturing process, convenience in installation and low manufacturing cost, and effectively solves the problem that connection between track skeletons in a special section or an arc section needs the track skeleton joint with the larger heat-expansion and cold-contraction quantity.

Owner:莱芜美澳冶金科技有限公司

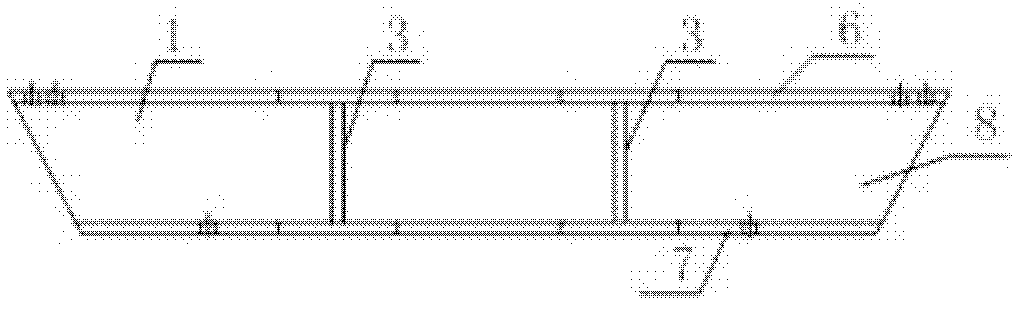

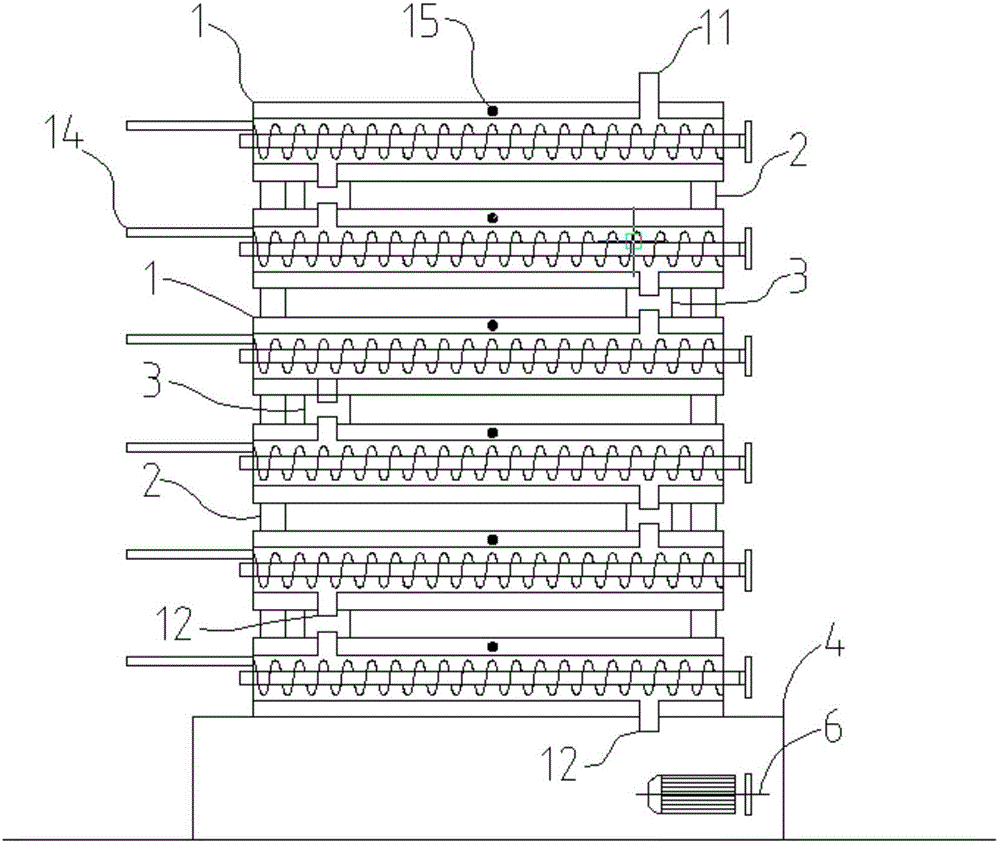

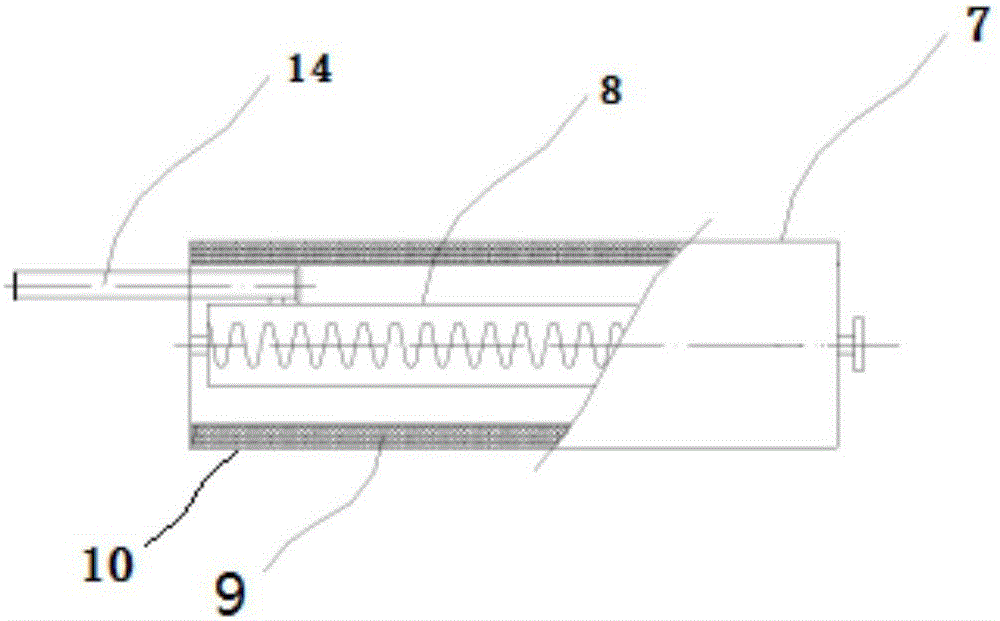

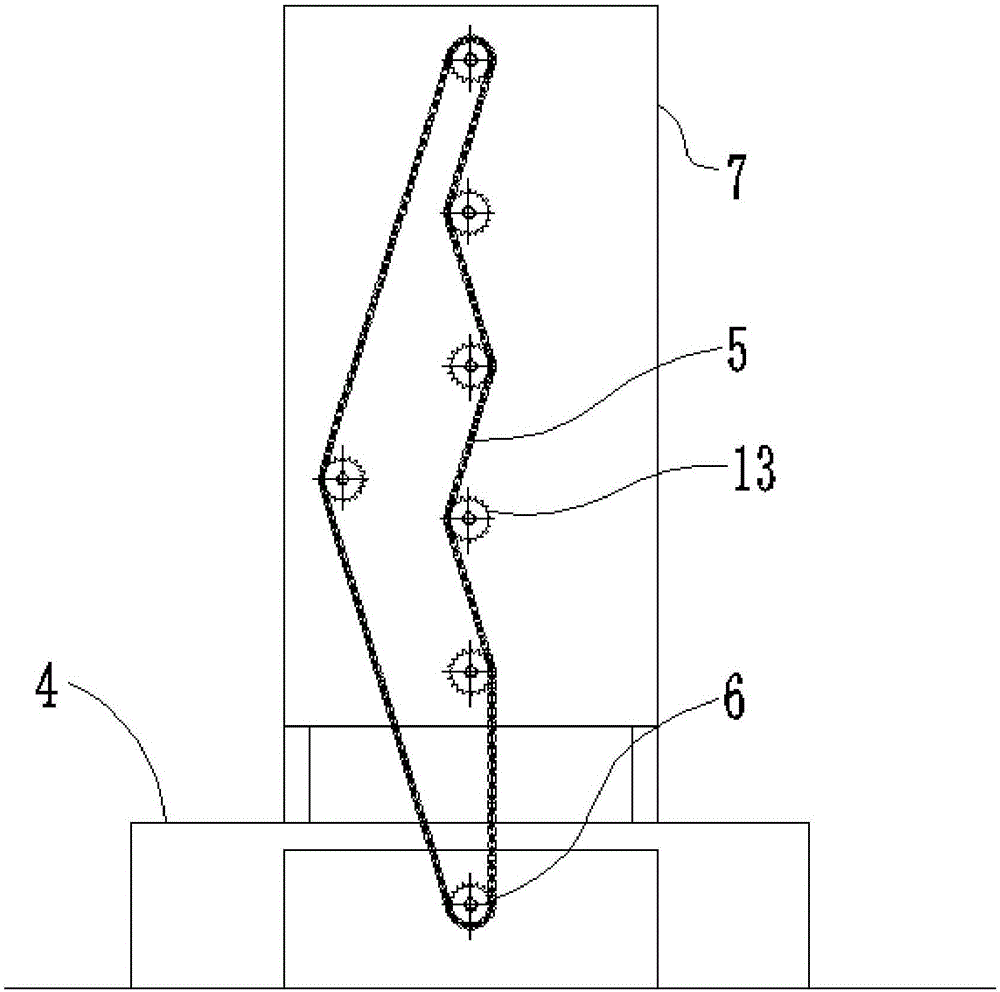

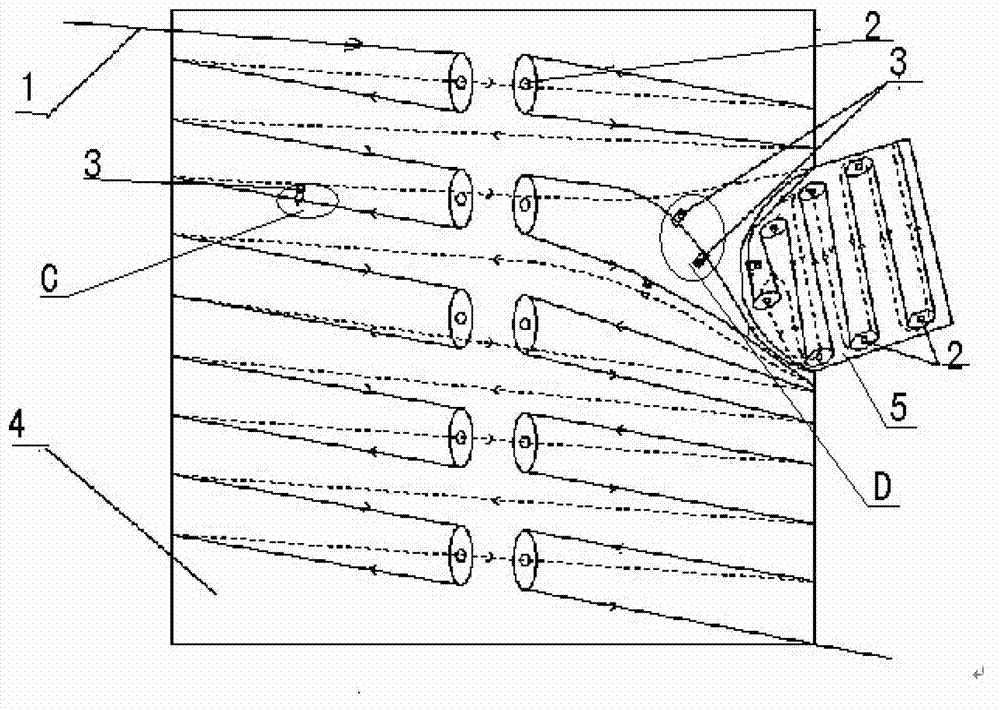

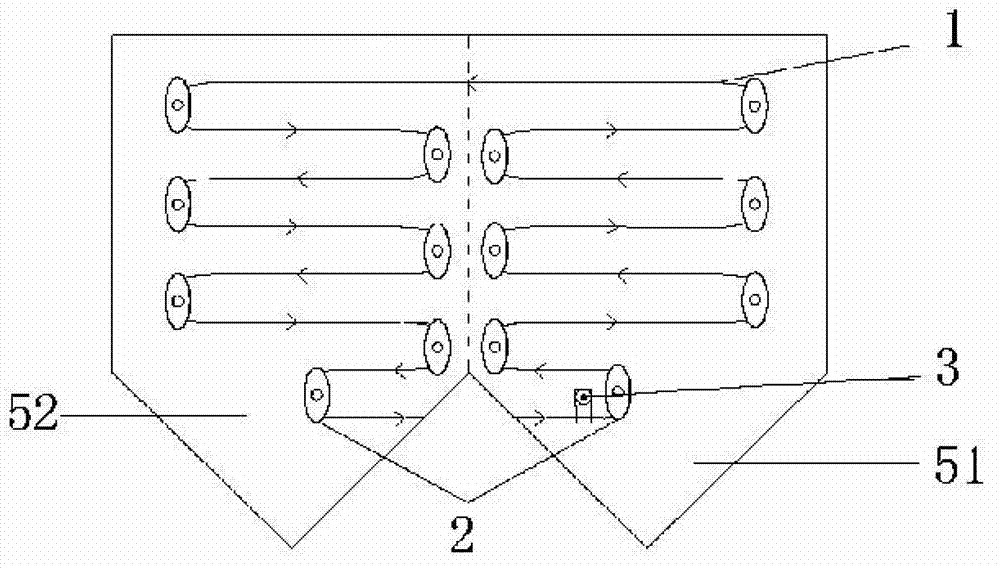

Powder activated carbon modular combination type regenerative furnace

InactiveCN106732490ARandom combinationReasonable division of modulesCombustible gas purificationFilter regenerationModular compositionActivated carbon

The invention discloses a powder activated carbon modular combination type regenerative furnace. The powder activated carbon modular combination type regenerative furnace comprises a plurality of monomer regenerative furnaces, supporting blocks, material falling pipes, base and a motor; each monomer regenerative furnace can realize heating and conveying of a material; the monomer regenerative furnaces are stacked from top to bottom; every two monomer regenerative furnaces are separated from each other by using the supporting blocks and the material falling pipes to form an arch-shaped material feeding trough; the material feeding trough is integrally mounted on the base; spiral conveyors are arranged in the monomer regenerative furnaces and are driven to rotate through the motor, so that the vertically adjacent two spiral feeding conveyors are opposite in material feeding directions; therefore, powder activated carbon forms a flow state in the modular combination type regenerative furnace. The powder activated carbon modular combination type regenerative furnace is a converter, which is good in energy saving effect, low in cost, convenient to convey, long in overall life, high in reliability, convenient to replace, high in maintainability, good in modular structure division and strong in monomer regenerative furnace arbitrary combinability and can regenerate activated carbon continuously in large batches.

Owner:HUBEI JUNJI WATER TREATMENT

Integrated waste heat generating and dust removing method utilizing flue gas from interior and exterior of electric furnace

InactiveCN103383199ARelief of swells and dipsGuaranteed uptimeIncreasing energy efficiencySteam engine plantsDust controlSteam drum

An integrated waste heat generating and dust removing method utilizing flue gas from the interior and the exterior of an electric furnace is characterized in that flue gas from the interior of the electric furnace is discharged through a fourth hole, is mixed with cold draft through a water-cooling sliding sleeve to burn carbon monoxide and then enters a settling chamber; flue gas getting out of the settling chamber enters a thermal storage uniform-temperature chamber and is cooled to about 100 DEG C, the cooled flue gas comes out of a booster to be mixed with flue gas getting out of an external discharge pipeline connected above a metallurgical furnace and enters a dust remover together, and the flue gas is pressed into an exhaust pipe to be discharged into the atmosphere; a low-boiling-point working medium absorbs heat of a flue gas waste heat carrier in an evaporator to become saturated steam, the saturated steam enters a steam pocket, and expands and acts in a steam turbine to drive a three-phase generator to generate power; R290 is a circulatory organic working medium. The steam pocket can be adopted to filter supersaturated moisture and impurities in a gas source to ensure stable running of the steam turbine, and the integrated organic Rankine waste heat generating and dust removing method can be adopted to reclaim heat energy in flue gas to the utmost extent and converts the heat energy into high-grade electric energy to achieve the purposes of energy saving and environmental protection.

Owner:无锡市东优环保科技有限公司

Waste heat power generation and dust removal integrated method for flue gas exhausted from metallurgical furnace

InactiveCN103383198ARelief of swells and dipsGuaranteed uptimeIncreasing energy efficiencySteam engine plantsForming gasSteam drum

A waste heat power generation and dust removal integrated method for flue gas exhausted from a metallurgical furnace is characterized in that flue gas in the metallurgical furnace is exhausted through a fourth hole and mixed with cold air through a water-cooling sliding sleeve; after carbon monoxide gas is burnt out, the flue gas enters a settling chamber; the high-temperature flue gas from the settling chamber enters a heat exchange chamber and gives off heat; the cooled flue gas from a booster fan is mixed with flue gas from an external exhaust pipe connected with the upper part of the metallurgical furnace, and then the mixed flue gas enters a dust remover; after dust removal, the mixed flue gas is pressed into an exhaust funnel by a main air blower to be exhausted to the atmosphere. Circulating water is used for absorbing the heat of flue gas through a heat exchanger to form gas-water mixture; the gas-water mixture enters an evaporator and gives off heat. A low-boiling point organic working medium is used for absorbing the heat of the gas-water mixture to become saturated vapor; the saturated vapor enters a vapor pocket and does work in a steam turbine so as to drive a three-phase generator to generate electricity. R123 is adopted as the cycle organic working medium. According to the waste heat power generation and dust removal integrated method, the adopted steam pocket can remove supersaturated moisture and impurities in the flue gas by filtration; heat energy in the flue gas can be converted into high-grade electric energy to the utmost extent.

Owner:无锡市东优环保科技有限公司

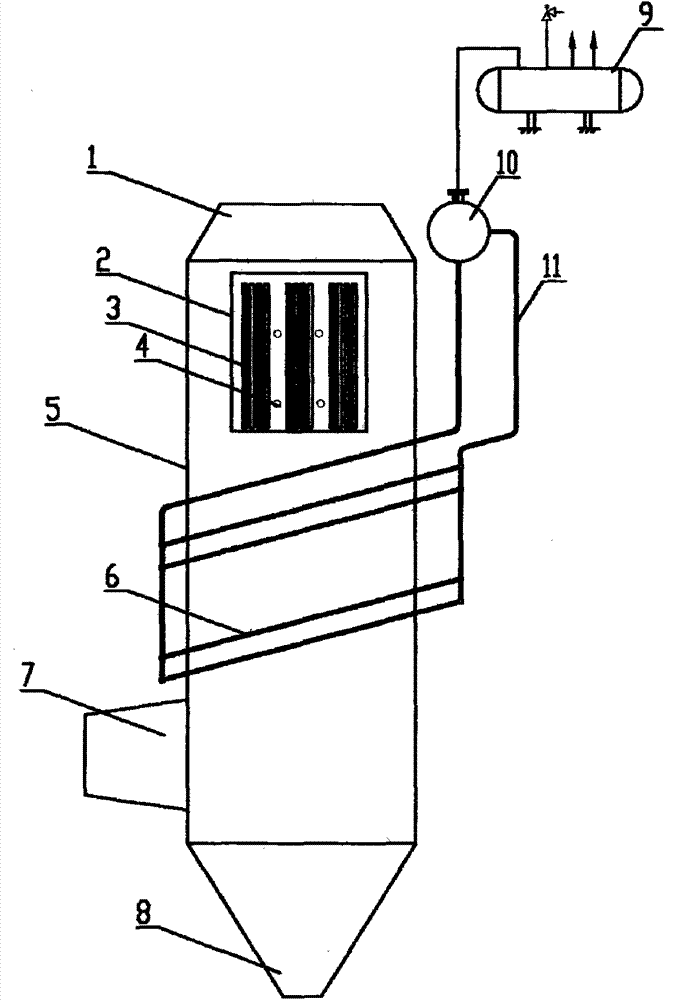

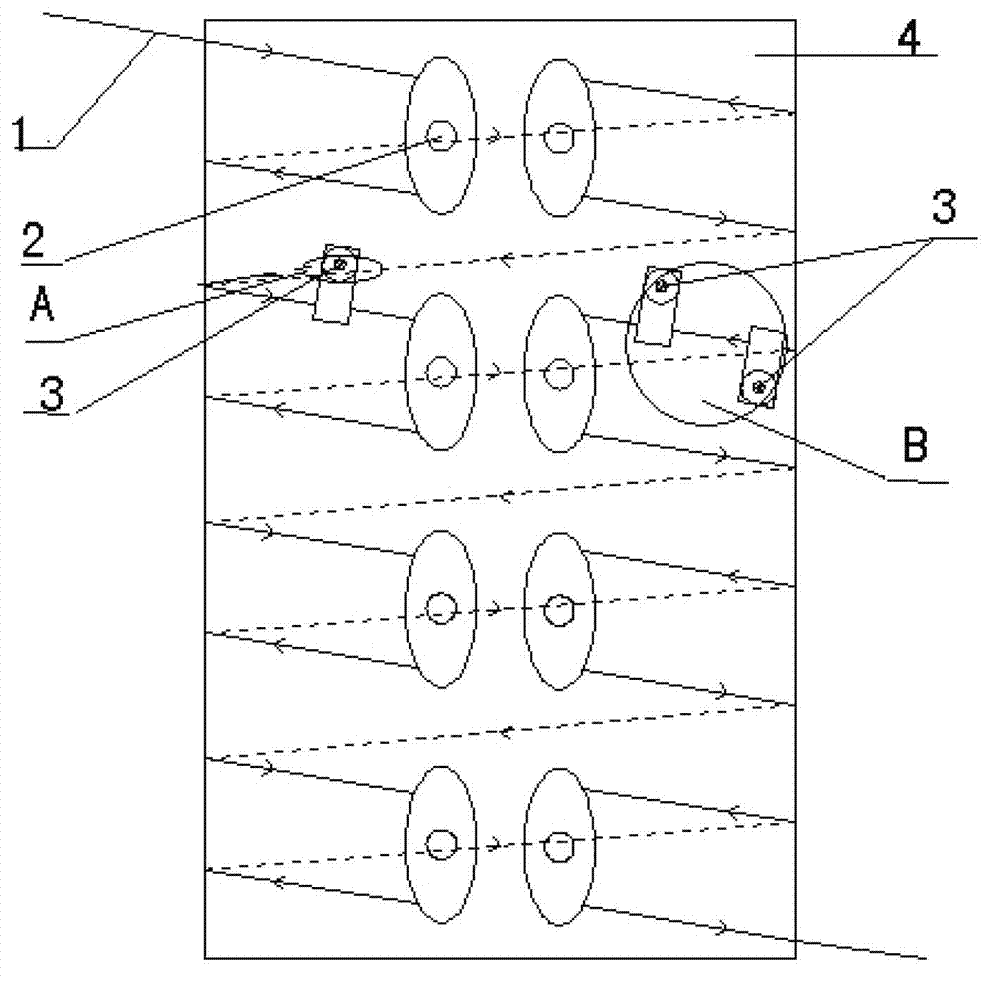

Convection-bank heat exchange set for flue gas waste heat recovery

InactiveCN104729306AReduce the temperatureReduce peakEnergy industryIncreasing energy efficiencyCarbon compositesShock wave

A convection-bank heat exchange set for flue gas waste heat recovery comprises a flue gas inlet, a heat-accumulating temperature homogenizer, a flue gas passage, a convection pipe bank, a flue gas outlet, an ash hopper, a circulation pipe, a steam drum and a steam accumulator. The convection-bank heat exchange set is characterized in that the top of the flue gas passage is provided with the flue gas inlet, the outside of the bottom of the flue gas passage is provided with the flue gas outlet, the bottom of the flue gas passage is provided with the ash hopper, the convection pipe bank is disposed in the flue gas passage and is connected with the steam drum through the circulation pipe, the steam drum is connected with the steam accumulator through a pipe, the steam drum is disposed on the top of the outside of the flue gas passage, the heat-accumulating temperature homogenizer is disposed at the upper end of the convection pipe bank within the flue gas passage and comprises carbon-carbon composite accumulating members and a shock wave ash-remover, and the shock wave ash-remover is disposed among the carbon-carbon composite accumulating members segment by segment. The convection-bank heat exchange set has the advantages that heat in the flue gas can be recovered to the maximum extent, investment on waste heat utilization equipment is lower and the waste heat utilization equipment is more stable.

Owner:JIANGSU HONGHUA HEAVY IND

Fixed device and furnace body temperature measuring optical cable wiring method

InactiveCN103090992ASolve the problem of thermal expansion and contractionExtended service lifeThermometers using physical/chemical changesBody temperature measureEngineering

The invention belongs to the technical field of a distributed type sensing temperature measuring, and particularly relates to a fixed device and a furnace body temperature measuring optical cable wiring method. Wiring is conducted on a furnace body with a connection pipe, two columns of first nuts are welded on the surface of a main body of the furnace body, corresponding arc-shaped spring pieces of two columns of first fixed device are respectively arranged relatively, an optical cable is begun winding from a first fixed device of a first of a first column of a wiring starting point place and wound on a first fixed device of a first of a second column in a reversed mode, and the optical cable is repeatedly wound until winding on the wiring terminal point place. Tabletting discs of the first fixed devices are pressed on each arc-shaped spring piece, the first nuts are respectively used to fasten the first fixed devices, and the second fixed devices are utilized to fix concave-convex uneven place of the furnace body. When wiring of the optical cable is conducted, the problem that the optical cable is expanded with heat and contracted with cold is solved by installing of the first fixed devices, and one optical cable can be adopted to conduct wiring from start to finish. The problem of measuring precision of the connection place of the main body and the connection pipe and the concave-convex uneven place of the furnace body is solved by installing of the second fixed devices.

Owner:WUHAN NORTHERN OPTOELECTRONICS

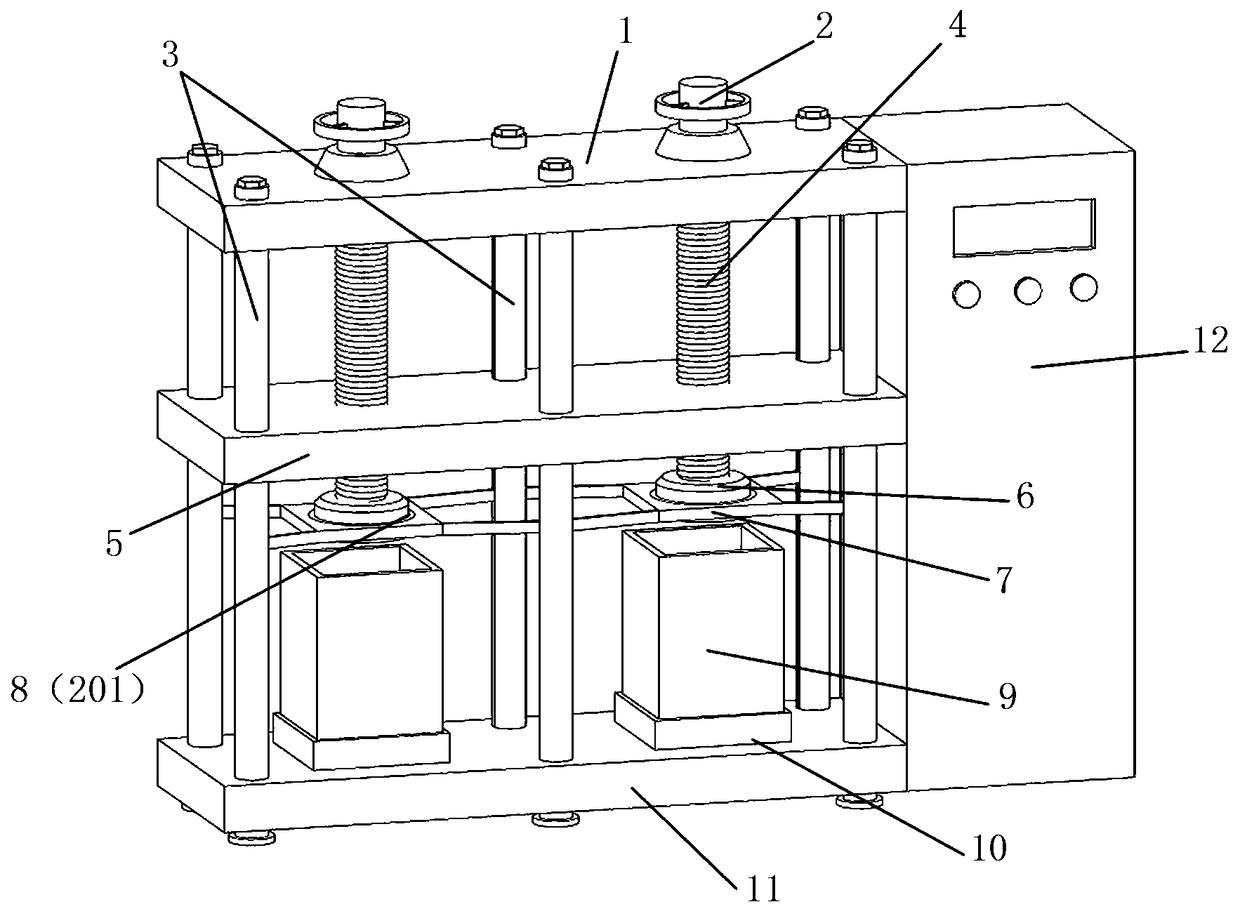

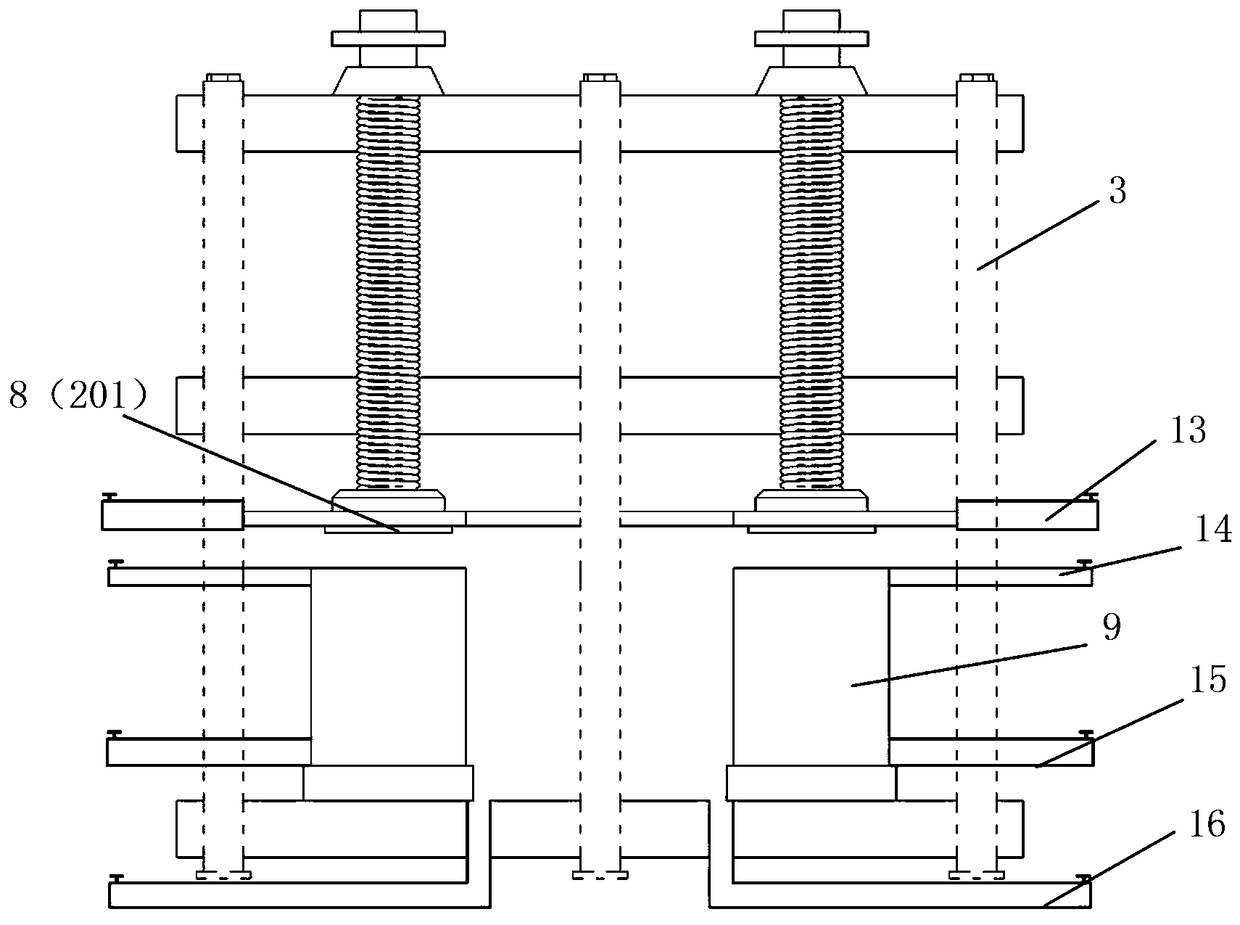

Concrete testing device for loading and freeze-thawing coupling effect

PendingCN109374420ASimple principleEasy to useMaterial strength using tensile/compressive forcesFixed frameFreezing thawing

The invention relates to the technical field of concrete test and in particular relates to a concrete testing device for a loading and freeze-thawing coupling effect. The concrete testing device comprises a fixed frame, an isolating plate, a bottom pedestal, a plurality of fixing rods and two or more trapezoidal screw rods; the plurality of fixing rods are uniformly distributed on the fixed frame,the isolating plate and the bottom pedestal and vertically pass through the fixed frame, the isolating plate and the bottom pedestal; the trapezoidal screw rods vertically pass through the fixed frame and the isolating plate and are equidistantly distributed; the trapezoidal screw rod at the upper end of the fixed frame is provided with a runner; the trapezoidal screw rod located between the isolating plate and the bottom pedestal is provided with a connecting plate; the corresponding bottom pedestal located below the connecting plate is provided with a concrete test piece box; and a testingcavity is provided with a freeze-thawing liquid inlet valve and a freeze-thawing liquid outlet valve. The concrete testing device is simple and clear in theory, convenient to use, capable of continuously applying a load under a freeze-thawing environment, also capable of testing the compressive strength of a concrete test piece subjected to freeze-thawing cycle and free of moving a concrete material.

Owner:NANCHANG UNIV

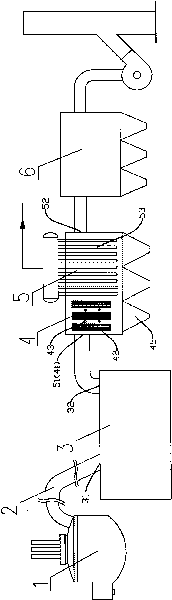

Method for power generation by utilizing flue gas waste heat of semi-sealed electric furnace

InactiveCN104075580AReduce volatilityRelief of swells and dipsIncreasing energy efficiencySteam engine plantsElectric generatorEvaporator

A method for power generation by utilizing flue gas waste heat of a semi-sealed electric furnace is characterized in that flue gas in the semi-sealed electric furnace is discharged out of a fourth hole, is mixed into cold air through a water-cooling sliding sleeve, enters a settling chamber, enters a heat storage temperature uniformizing device and enters a flow uniformizing heat storage chamber, the flue gas cooled is discharged out of a booster fan to be mixed with flue gas discharged out of a discharging pipeline connected above the semi-sealed electric furnace to enter a deduster together, the flue gas is pressed into an exhaust drum after being dedusted and is discharged into the atmosphere; meanwhile, organic working medium liquid absorbs heat of a flue gas waste heat carrier in a low-pressure stage evaporator, a medium-pressure stage evaporator and a high-pressure stage evaporator and becomes working medium steam, and the working medium steam does work by expansion in an organic turbine with a steam supplementing port and drives a generator to generate electricity. The method is characterized in that R600a is adopted to serve as a circulating organic working medium. According to the method, thermal energy in the flue gas can be recycled to the largest extent to be directly converted into high-grade electric energy, thermal efficiency according to the method is improved by 30-35% compared with single stage evaporation Rankine cycle, and the environmental protection effect is good.

Owner:无锡市东优环保科技有限公司

Power generation energy-saving and dedusting method by using multi-level organic Rankine waste heat of smoke in iron alloy furnace

InactiveCN103134330AReduce the temperatureReduce peakIncreasing energy efficiencySteam engine plantsAtmospheric airRecuperator

A power generation energy-saving and dedusting method by using multi-level organic Rankine waste heat of smoke in an iron alloy furnace is characterized in that the iron alloy furnace smoke is discharged from the interior of a furnace, the cold air is mixed with the smoke through a water cooling smoke duct, after carbon monoxide gas is burnt, and the iron alloy furnace smoke enters into a burning setting chamber and enters into a heat storage temperature-balancing device. After being affected by the heat storing and temperature balancing actions of a cast iron material heat accumulator, the high temperature smoke enters into a waste heat collection chamber to complete heat exchange, the temperature of the smoke is lowered to 120 DEG C, after being dedusted, the smoke is pressed into an exhaust funnel by a main air blower to be discharged into air. Meanwhile, the circulating water is driven by a water pump of a heat exchanger and enters into the heat exchanger arranged in the waste heat collection chamber to absorb the heat of the smoke, and steam-water-mixture is formed. Organic working medium liquid absorbs the heat of the steam-water-mixture, does expansion work in a multi-level organic turbine and drives an electric generator to generate electricity. R236ea is adopted as the circulating organic working medium. The power generation energy-saving and dedusting method by using the multi-level organic Rankine waste heat of the smoke in the iron alloy furnace has the advantages that a 'peak clipping and valley filling' function is achieved, the fluctuation range of the temperature is reduced, the heat energy in the smoke can be recycled to the maximum extent and be converted into high-quality electric energy, and a good environment protection effect is achieved.

Owner:无锡市东优环保科技有限公司

Flue gas residual heat utilizing method for copper smelting furnace through dust remover with exhaust funnel

InactiveCN108088265ADoes not affect stabilityDoes not affect continuityIncreasing energy efficiencyWaste heat treatmentShock waveLarge particle

The invention discloses a flue gas residual heat utilizing method for a copper smelting furnace through a dust remover with an exhaust funnel. The flue gas residual heat utilizing method is characterized in that flue gas of the copper smelting furnace is exhausted from the furnace, passes through a water cooling flue to be mixed with cold air and enters a burning settling chamber after carbon monoxide gas is combusted, the function of the burning settling chamber is that the flow speed of the flue gas is reduced to enable large-particle dust carried in the flue gas to be settled and cold air to be properly mixed, carbon monoxide gas is burnt out finally, flue gas exhausted from the burning settling chamber enters a heat storage temperature equaling device, and the heat storage temperatureequaling device comprises a carbon-silicon composite material heat storage body, a shock wave ash removing device and an ash bucket. The dust remover is provided with the exhaust funnel, clean gas isdirectly exhausted from a gas purifying bin of the dust remover, exhaust funnel steel consumption and civil engineering investment are reduced, the system occupied area is greatly reduced, the primaryinvestment cost of a dust removal system is reduced, the on-way resistance loss and local resistance loss of gas flow in redundant pipelines are reduced, finally, operation electricity consumption can be finally reduced, and the purpose of reducing the operation cost of the dust removal system is achieved.

Owner:无锡市东优环保科技有限公司

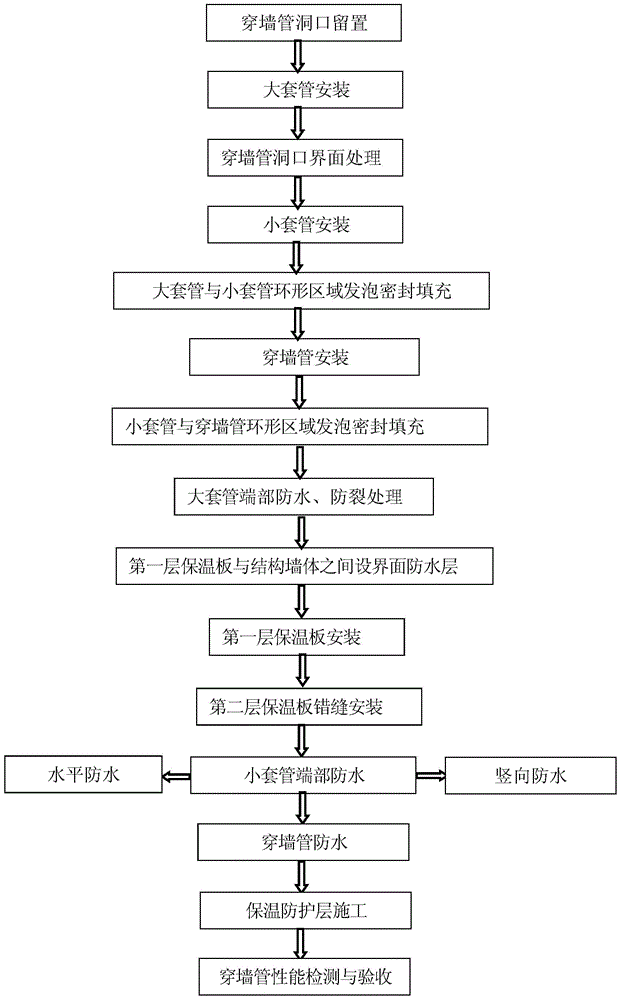

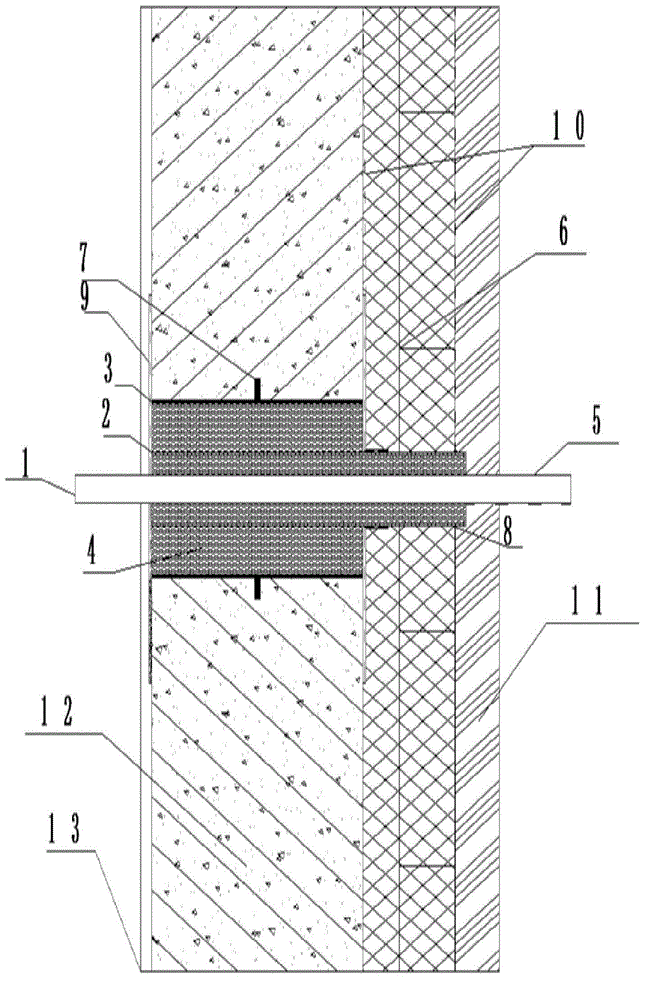

Passive house wall bushing waterproof air tightness structure construction method

ActiveCN104831925AAvoid formingSolve thermal expansion and contractionPipesBuilding material handlingArchitectural engineeringStructural engineering

The invention discloses a passive house wall bushing waterproof air tightness structure construction method, which comprises steps of: preservation of a wall bushing opening, mounting of a large bushing with an annular water stop ring, treatment of an interface of the preserved opening, mounting of a small bushing, foaming sealing filling of an annular region, mounting of the wall bushing, foaming sealing filling of a small annular region, waterproof and crack-proof treatment at the end part of the large bushing, water resistance of a first-layer insulation board and a structure wall body interface, mounting of the first-layer insulation board, staggered mounting of a second-layer insulation board, water resistance (horizontal) at the end part of the small bushing, water resistance (vertical) at the end part of the small bushing, water resistance of the wall bushing, construction of an insulation protection layer, and detection and verification of performance of the wall bushing. Measures of double-bushing protection, double-layer annular foaming sealing filling isolation, double-layer sealing treatment, double-layer staggered insulation energy conservation, four waterproof treatment and two crack-proof treatment are adopted, and integrated function requirements of passive building wall bushing protection, insulation energy conservation, air tightness and water resistance can be realized.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

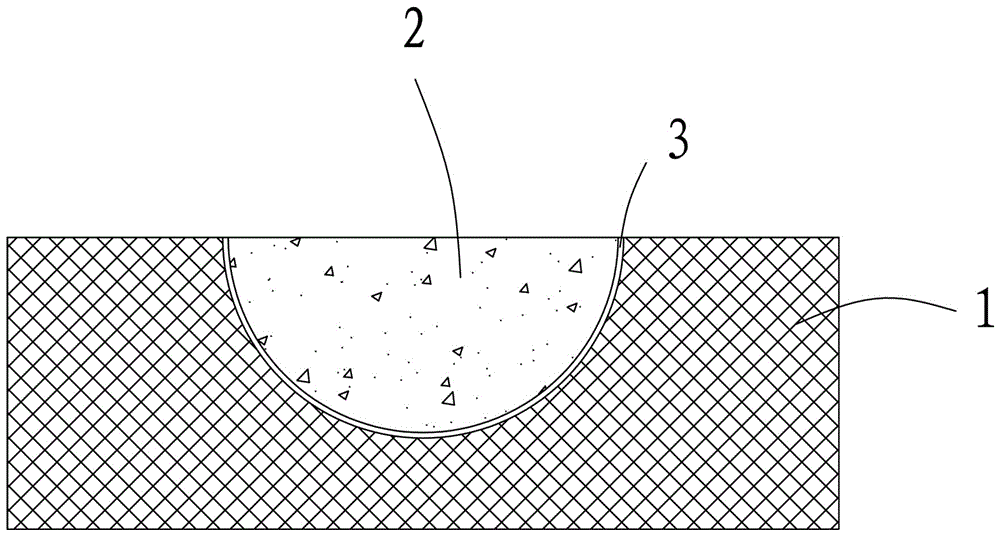

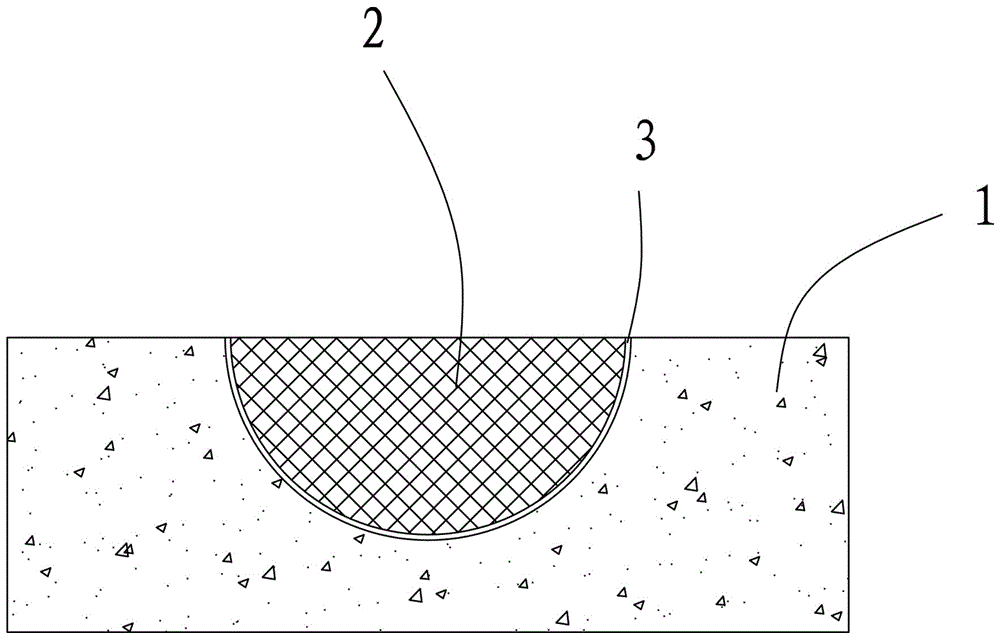

Production process of wood and stone composite floor

InactiveCN107574996AImproves strength and stabilityImprove overall durabilityMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesShape StoneSolid wood

The invention discloses a production process of a wood and stone composite floor. The production process comprises the following steps that A, materials of a solid wood flooring body are prepared, anarc-shaped groove is molded in the surface of the solid wood flooring body, and an arc-shaped batten is dug out for standby application; B, materials of a stone flooring body are prepared, an arc-shaped groove is molded in the surface of the stone flooring body, and an arc-shaped stone stripe is dug out for standby application; C, the arc-shaped batten is embedded into the arc-shaped groove in thesurface of the stone flooring body, and an adhesive layer is arranged at the combining position of the arc-shaped batten and the arc-shaped groove; D, polishing is carried out to obtain the finishedwood and stone composite floor; E, the arc-shaped stone stripe is embedded into the arc-shaped groove in the surface of the solid wood flooring body, and an adhesive layer is arranged at the combiningposition of the arc-shaped stone stripe and the arc-shaped groove; F, polishing is carried out to obtain the finished wood and stone composite floor; and G, the surface of the floor is coated with awaterproof anti-corrosion aldehyde removing gel.

Owner:陈雪珍

Flue gas waste heat power-generation energy-conservation and dust-removal method for electric furnace with liquid storage tank

InactiveCN103836987ALess investmentReduce dust contentIncreasing energy efficiencySteam engine plantsElectric arc furnaceLiquid storage tank

Provided is a flue gas waste heat power-generation energy-conservation and dust-removal method for an electric furnace with a liquid storage tank. The method is characterized in that flue gas of the electric furnace is exhausted from the inside of the electric furnace, the flue gas is mixed into cold air through a water-cooled flue gas to enter a settling chamber, the flue gas passing the settling chamber enters a high-temperature dust remover which is a filter element dust remover made of high temperature resistance carbon and copper composite materials, and then enters a thermal storage temperature evening device, after thermal storage and temperature evening are carried out on the flue gas, the flue gas enters a collection chamber and emits heat, the flue gas is pressed into an exhaust funnel through a main fan and exhausted to atmosphere, meanwhile, circulating water flows into a heat exchanger and absorbs the heat of the flue gas, a steam-water mixture is formed and enters an evaporator, heat is given off, organic working media absorb the heat in the evaporator through a working medium pump to become steam and enter a steam drum, and the steam does work in a steam turbine in an expansion mode and drives a generator to generate electricity; R227ea is adopted to serve as the circulating organic working media. The working medium liquid storage tank is adopted, so that it is guaranteed that the working medium circulating pump can continuously pressurize, heat energy is converted into high-grade electric energy through organic Rankine cycle waste heat power generation, investment of the device is little, and running energy consumption is low.

Owner:无锡市东优环保科技有限公司

Power generation and dedusting method by utilizing waste heat of high-temperature alternating exhaust gas in electric furnace through organic rankine cycle

InactiveCN103017550ARelief of swells and dipsSolve thermal expansion and contractionIncreasing energy efficiencySteam engine plantsThermal energyElectric arc furnace

The invention discloses a power generation and dedusting method by utilizing waste heat of high-temperature alternating exhaust gas in an electric furnace through organic rankine cycle, which is characterized in that the exhaust gas in the electric furnace is discharged, and enters a combustion settling chamber after cold air interfuses the exhaust gas through a water-cooling sliding sleeve; the exhaust gas passing through the combustion settling chamber enters a heat storage temperature equalizer, and then enters a waste heat exchange chamber after passing through the heat storage temperature equalizer; the exhaust gas discharges the heat, enters a bag-type dust collector, and is pressed into an exhaust funnel to be discharged into atmosphere by a main fan after being dedusted; meanwhile, an organic working medium absorbs the heat through a working medium pump in an evaporimeter to be changed into saturated vapor; and the working medium vapor swells to do work in a steam turbine to drive a generator to generate electricity. The working medium vapor discharged from a low-boiling-point working medium steam turbine is condensed into saturation liquid by a condenser; and the working medium liquid is pressurized by the working medium pump, and enters the evaporimeter to start a new round of circulation. The power generation and dedusting method by utilizing the waste heat of the high-temperature alternating exhaust gas in the electric furnace through the organic rankine cycle is characterized in that R123 is adopted as a circulating organic working medium. With the adoption of the heat storage temperature equalizer, the amplitude and a peak value of fluctuation of the exhaust gas are reduced, the heat energy is transformed into the high-grade electric energy, and the device is low in investment and low in operation energy consumption.

Owner:无锡市东优环保科技有限公司

Wood-stone combined floor board and production process thereof

InactiveCN105926895AImprove stabilityHigh strengthWood mortising machinesFlooringSolid woodThermal expansion

The invention relates to a wood-stone combined floor board combined by solid wood and stone materials and used in geothermal environment and a production process thereof. The wood-stone combined floor board comprises a solid wood floor board body, wherein the surface of the solid wood floor board body is provided with an arc-shaped groove; a stone material floor board is arranged in the arc-shaped groove. The integral cost of the floor board is greatly reduced; the product competitive power is greatly improved; the product has wide market prospects. The problem of heat expansion and cold shrinkage is solved by using the splicing gap between the solid wood and the stone material. The production process is simple; wood working machinery can be used for fast groove forming; the dug materials can be enabled to be completely remained; the finished product rate is high.

Owner:谭宏伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com