Convection-bank heat exchange set for flue gas waste heat recovery

A convection tube bundle and flue gas technology, applied in the field of convection tube bundle heat exchange equipment and waste heat utilization equipment, can solve problems such as large horse-drawn trolleys and low steam output, and achieve thermal expansion and contraction, investment reduction, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

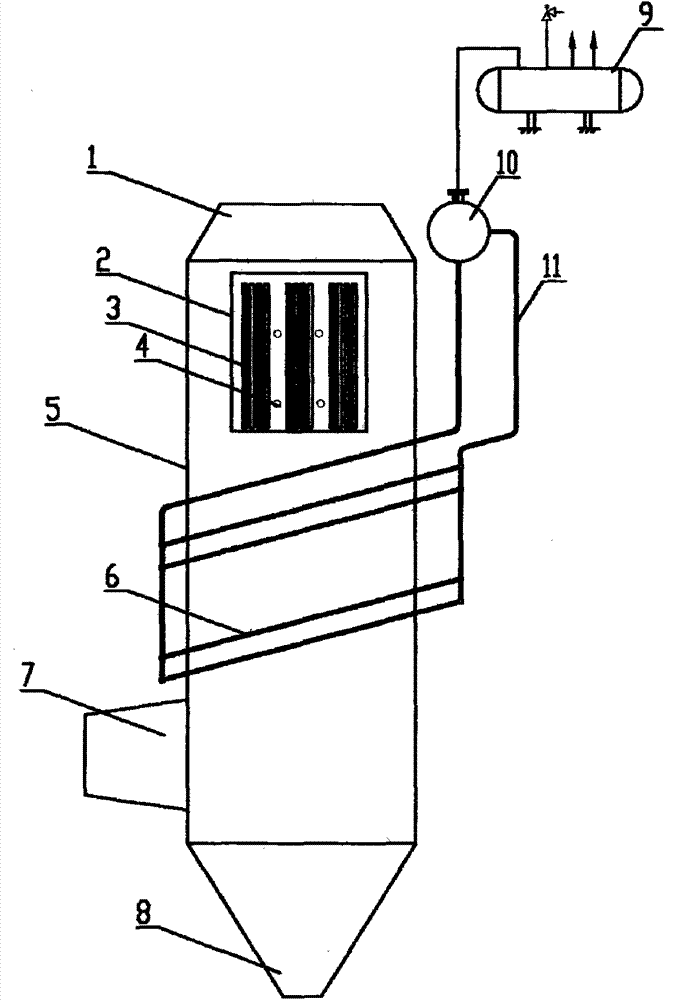

[0013] The present invention will be further described below in conjunction with the drawings.

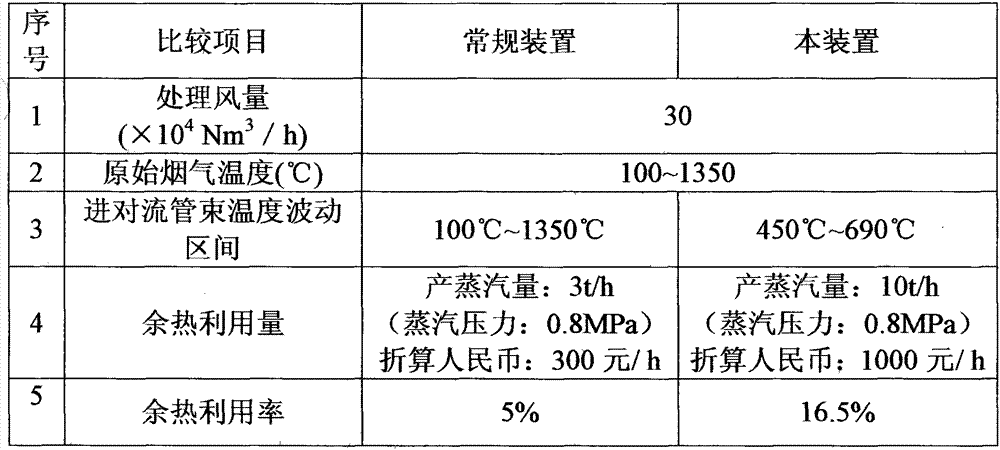

[0014] In the present invention, a convection tube bundle heat exchange device for recovery of flue gas waste heat includes flue gas inlet 1, heat storage homogenizer 2, flue gas passage 5, convection tube bundle 6, flue gas outlet 7, ash hopper 8. Circulation pipeline 11, steam drum 10, steam accumulator 9, characterized in that: the top of the flue gas channel 5 is provided with a flue gas inlet 1, and the bottom of the flue gas channel 5 is provided with a flue gas outlet 7 and a flue gas channel 5 An ash hopper 8 is provided at the bottom, a convection tube bundle 6 is provided inside the flue gas channel 5, and the convection tube bundle 6 is connected to a steam drum 10 through a circulation pipe 11, and the steam drum 10 is connected to a steam accumulator 9 through a pipe. The steam drum 10 is provided with At the top of the outer side of the flue gas channel 5, the heat stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com