Powder activated carbon modular combination type regenerative furnace

A technology of powdered activated carbon and regeneration furnace, which is applied in the direction of filter regeneration, combustible gas purification, combustible gas purification/transformation, etc. It can solve the problems of inconvenient transportation, poor maintainability, low reliability, etc., and achieve reasonable module division, Good process flexibility and good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

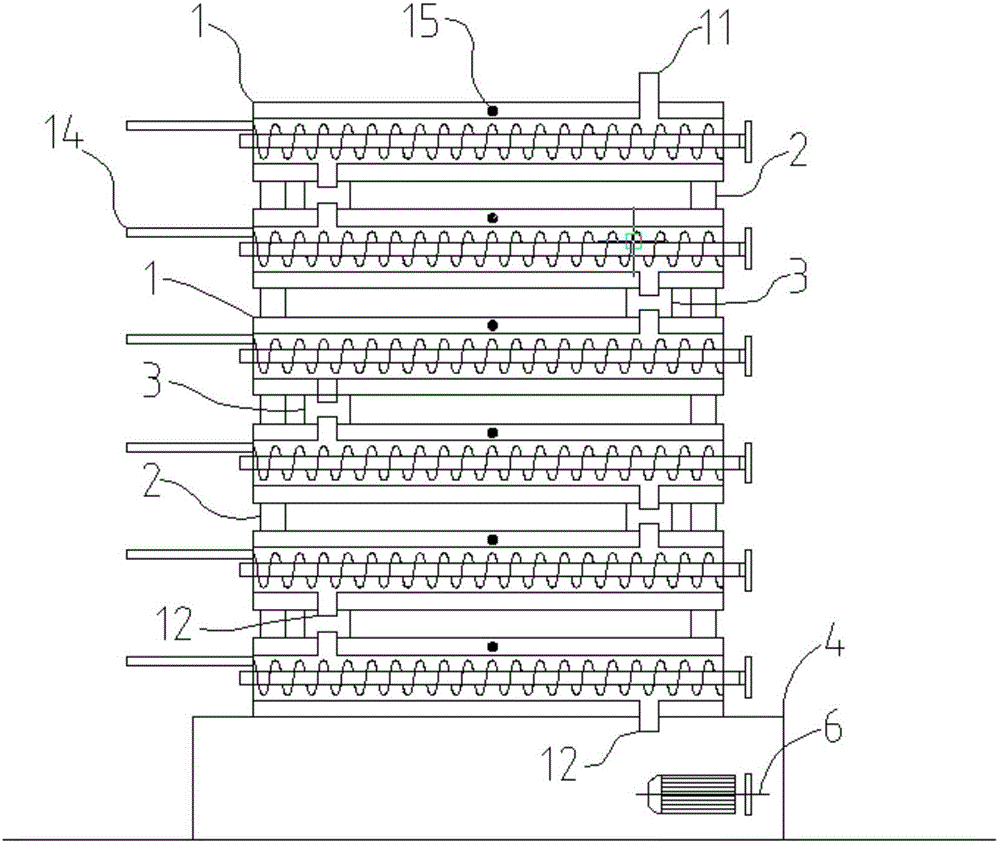

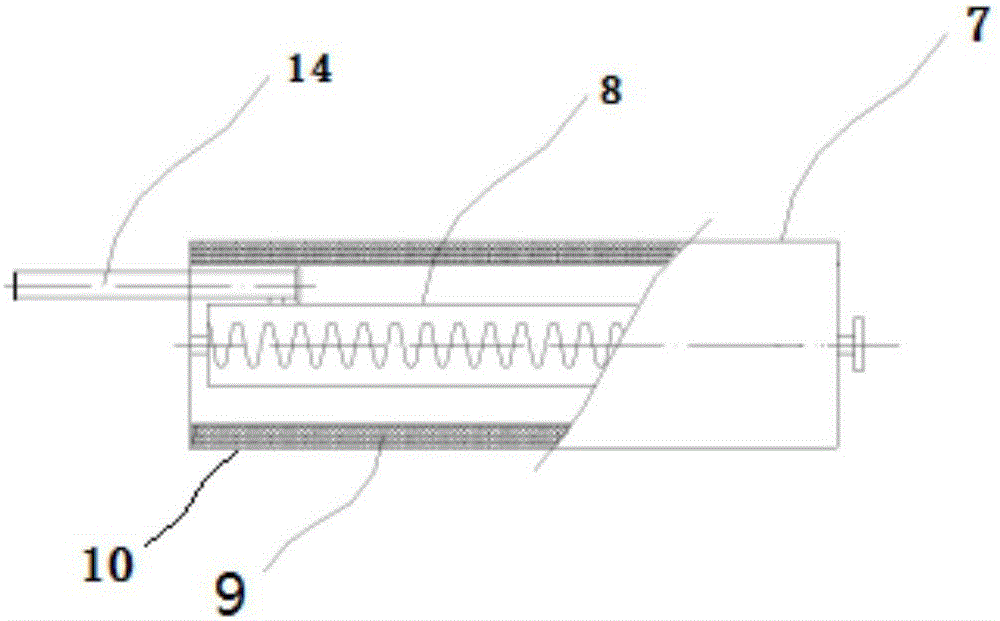

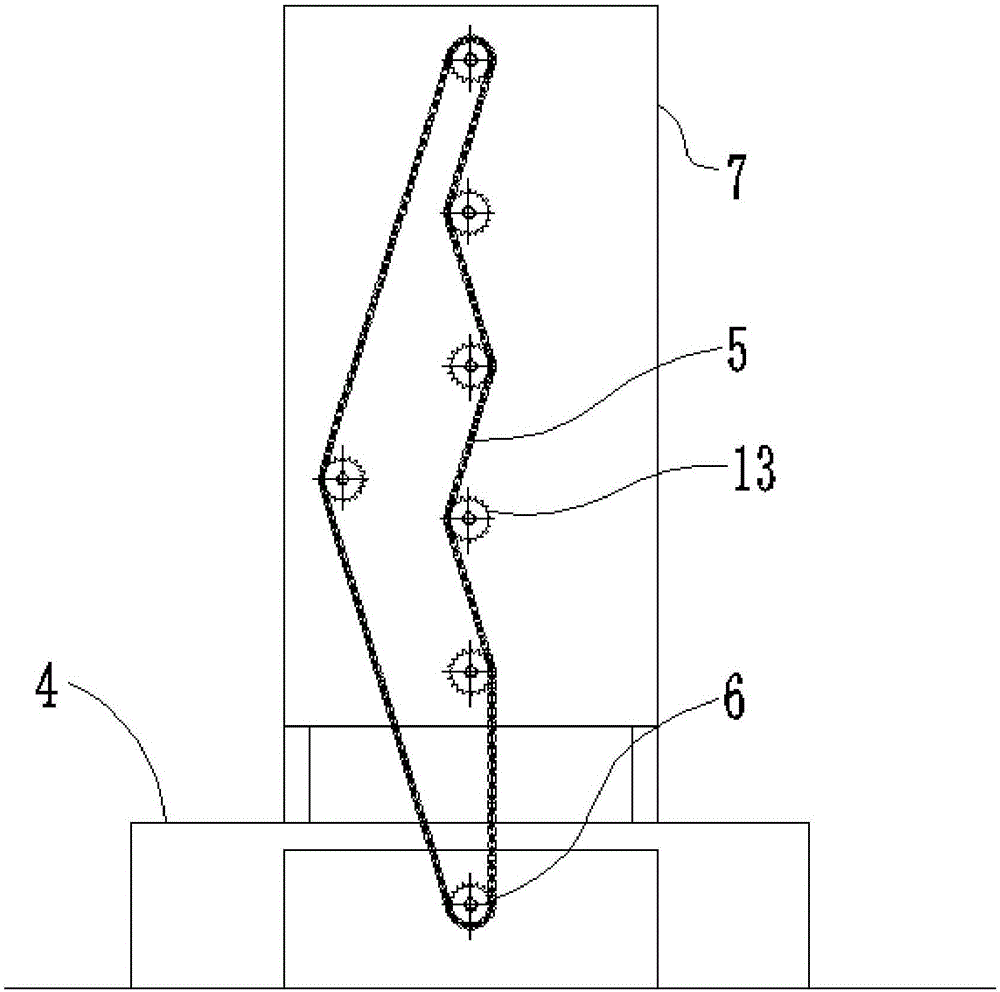

[0027] Example 1: see figure 1 , figure 2 and image 3 , a modular combined converter for regeneration of powdered activated carbon provided by the present invention, including six monomer regeneration furnaces 1, support blocks 2, blanking tubes 3, bases 4, chains 5, motors 6, six monomers The regenerative furnace 1 can realize the heating and transportation of materials; each monomer regenerative furnace 1: includes a furnace body 7, a screw conveyor (single root) 8, a heating resistance wire 9, and a refractory insulation material 10; the upper part of the furnace body 7 is provided with Feed inlet 11 communicates with the inlet of screw conveyor 8; body of furnace 7 bottom is provided with discharge port 12, communicates with the outlet of screw conveyor 8; The heating resistance wire 9 is installed on the refractory heat preservation material 10; the six monomer regeneration furnaces are stacked from top to bottom, separated by the support block 2 and the blanking pipe...

Embodiment 2

[0031] Embodiment 2: A powdered activated carbon modular combined regeneration furnace provided by the present invention includes several monomer regeneration furnaces 1, support blocks 2, blanking pipes 3, bases 4, and motors 6, and each monomer regeneration furnace 1 Both can realize the heating and conveying of materials; several monomer regeneration furnaces 1 are stacked from top to bottom, separated by support blocks 2 and drop pipes 3 in the middle to form arched feeding troughs, and are installed on the base 4 as a whole; The body regeneration furnace 1 is provided with a screw conveyor 8, and the screw conveyor 8 is equipped with a transmission motor 6, which is driven by the motor 6 to rotate, so that the feeding direction of the two adjacent screw conveyors 8 is opposite, so that the powdered activated carbon Formation of the fluid state in the Modular Combined Regeneration Furnace.

[0032] Other parts of Embodiment 2 are the same as Embodiment 1, so they will not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com