Magnetic control acoustics valve

A magnetic control and acoustic technology, applied in mufflers, engine components, machines/engines, etc., to solve problems such as increased fuel consumption, increased exhaust system back pressure, and wasted engine power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

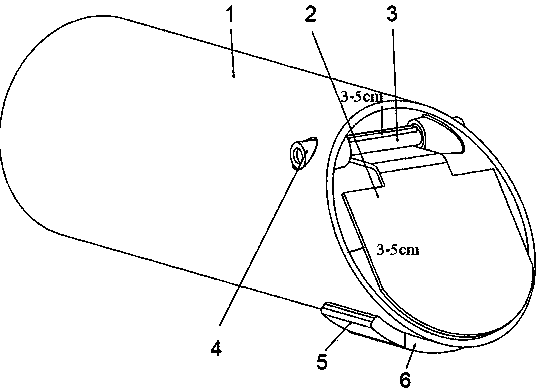

[0017] see figure 1 The magneto-acoustic valve device for exhaust system tailpipe noise control of the present invention comprises an exhaust pipe 1, a valve plate 2, a rotating shaft 3, a steel wool bushing 4, a magnet 5, and a magnet protection cover 6; Holes are opened on the side, the steel wool bushings are respectively fixed in the holes, the rotating shaft is fixed in the steel wool bushings, the valve plate is welded on the rotating shaft, and the magnet is welded directly below the valve plate through the magnet protection cover.

[0018] The working principle of the present invention combines figure 1 described as follows:

[0019] The restoring force required by the valve plate is provided by the magnetic force of the magnet 5 and the gravity of the valve plate 2 itself to replace the function of the spring. At low speed, the torque and power required by the car are relatively low, and the back pressure requirement is also relatively low, but The requirements for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com