Patents

Literature

117results about How to "Solve lubrication problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

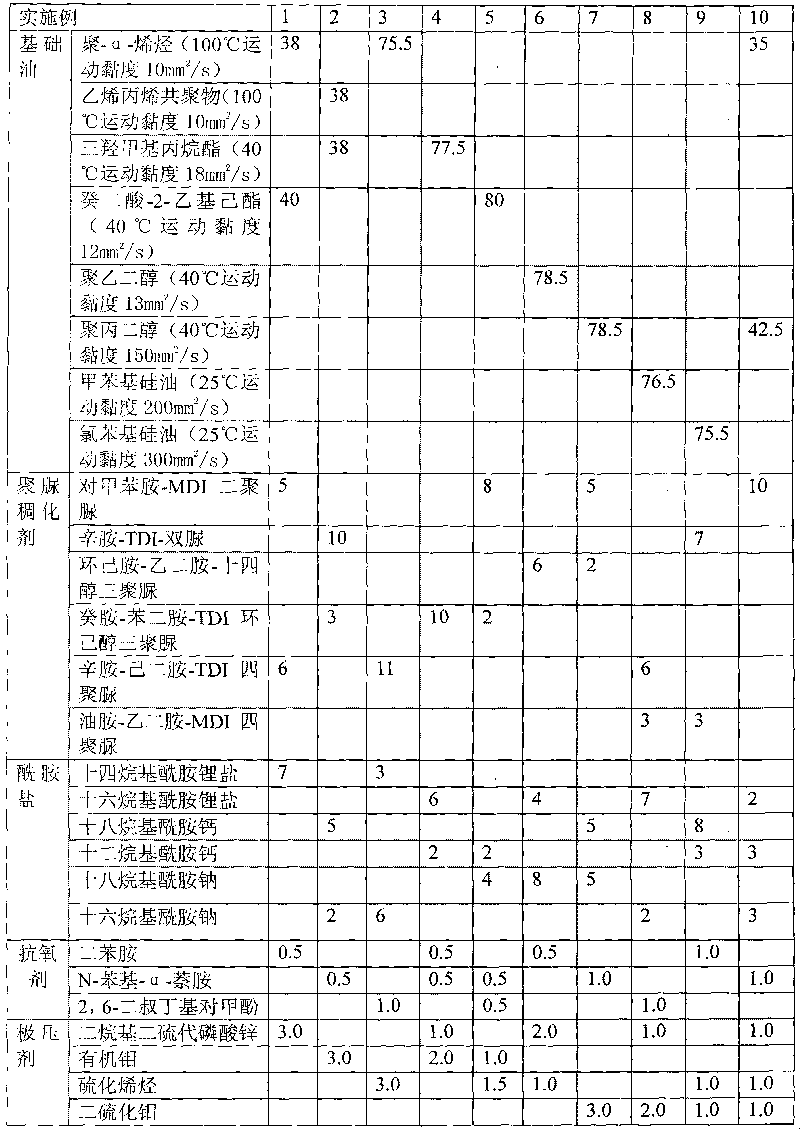

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

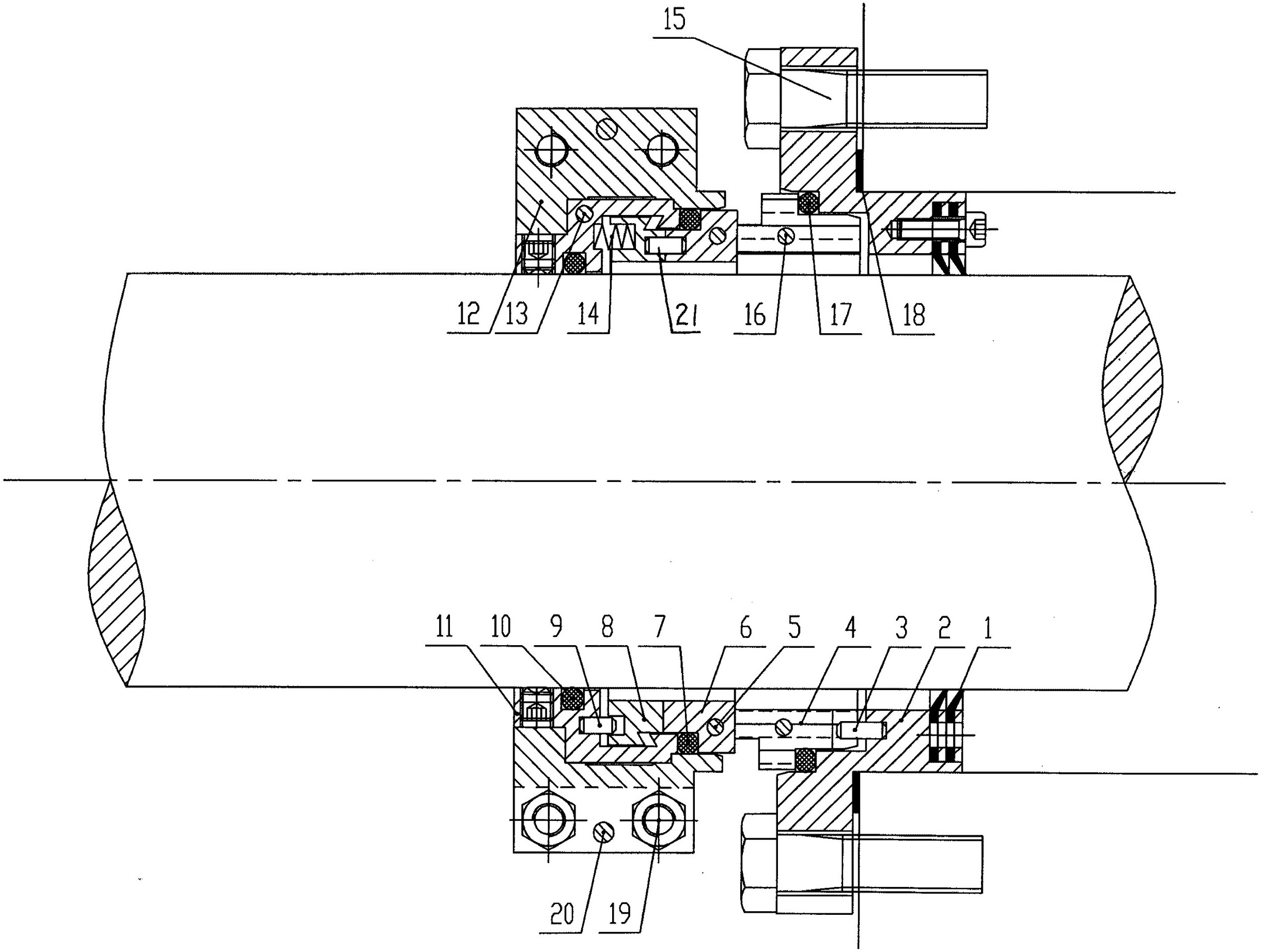

Non-stopping device for lifeboat diesel engine while inversion

InactiveCN101392670ASolve lubrication problemsSolve Exhaust ProblemsMachines/enginesPressure lubrication with lubrication pumpRespiratorLubrication Problem

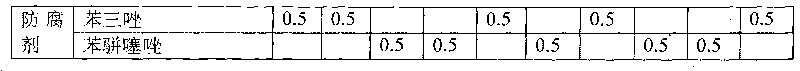

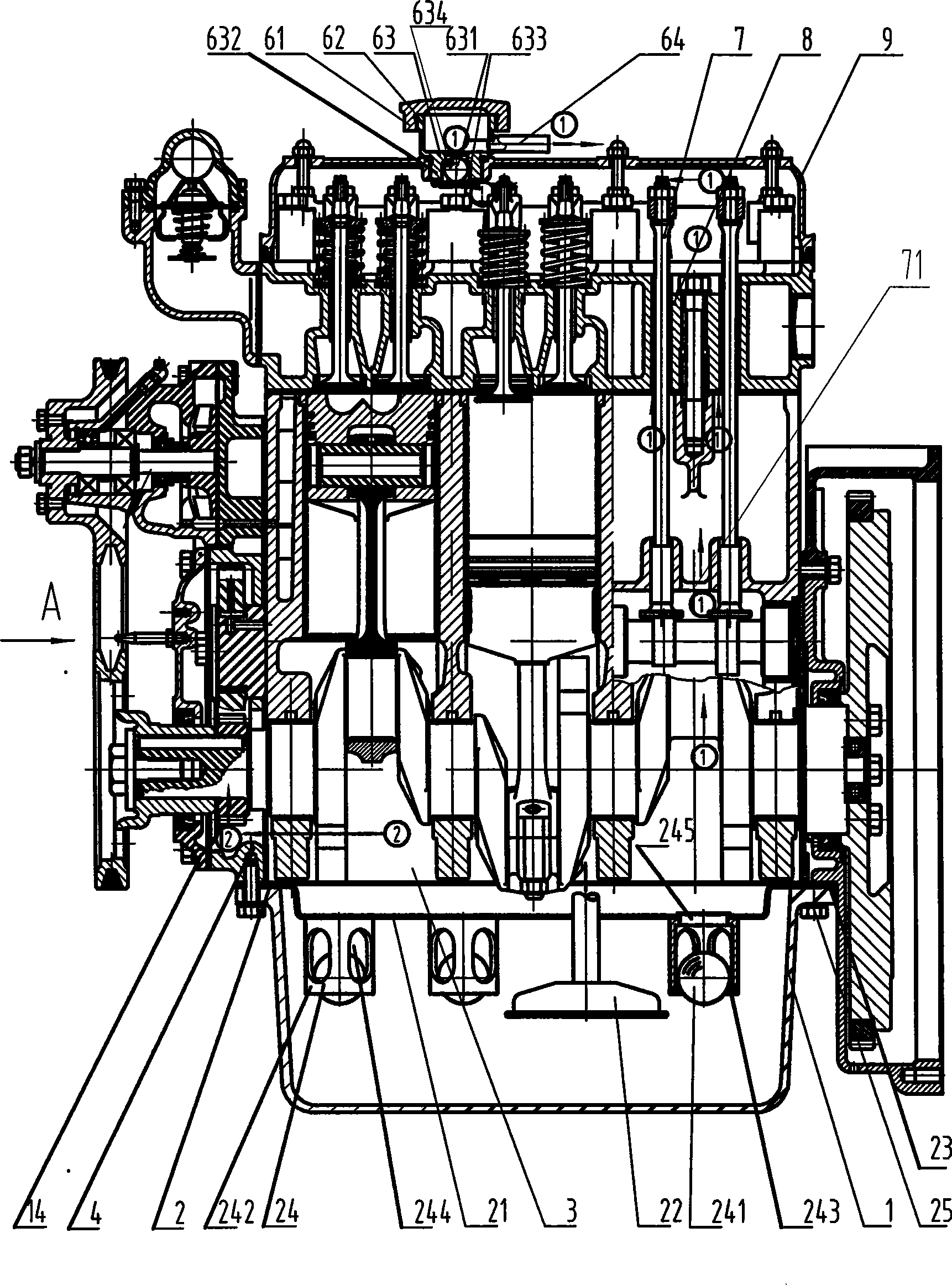

The invention discloses a non-shutdown device for the inversion of a lifeboat diesel engine, which comprises a lubrication system and a respiratory system, wherein the lubrication system comprises an oil suction port of an oil pump and an oil tray arranged at the bottom of a crankcase; and the respiratory system comprises a main respirator holder arranged on a cylinder cover and a main respiration channel which passes through a machine body of the diesel engine. The top of the oil tray is provided with a unidirectional sealing mechanism, a main respirator check valve is arranged in the main respirator holder, a secondary respiration channel is arranged in the machine body of the diesel engine, and an advancer cover is provided with a secondary respirator check valve. The device has a simple structure and low cost, can meet the requirement stipulated in the SOLAS convention, and solve the lubrication problem of a diesel engine system and the air exhaust problem inside the crankcase when the lifeboat diesel engine is in an inverted state.

Owner:JIANGSU UNIV OF SCI & TECH

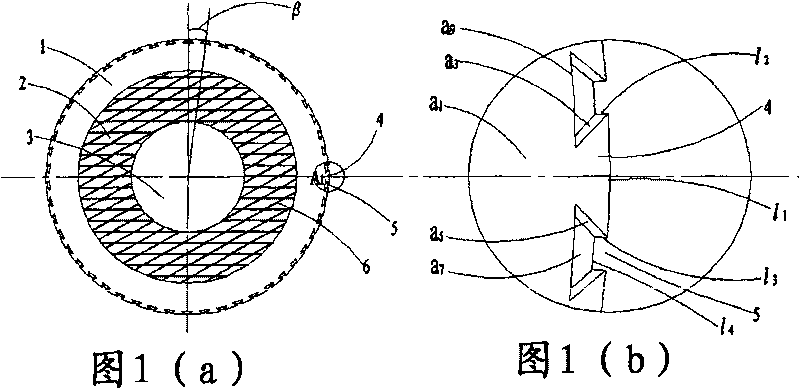

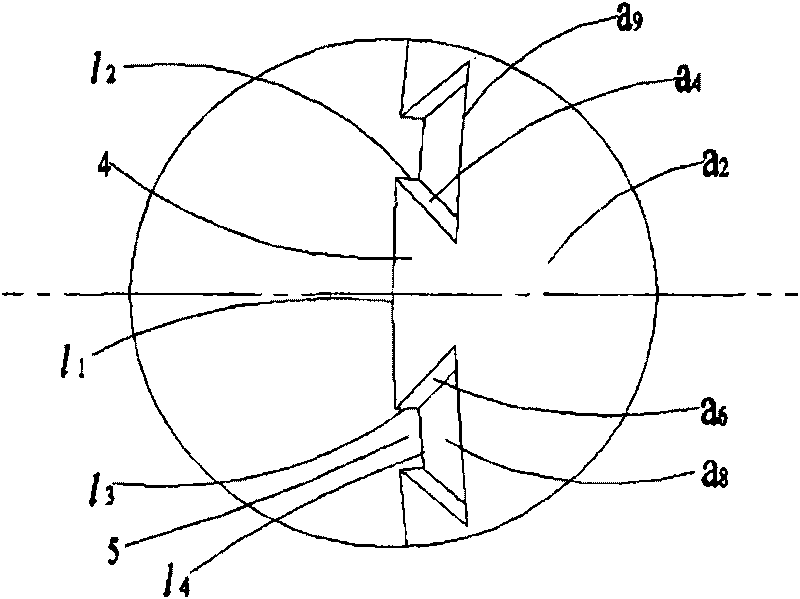

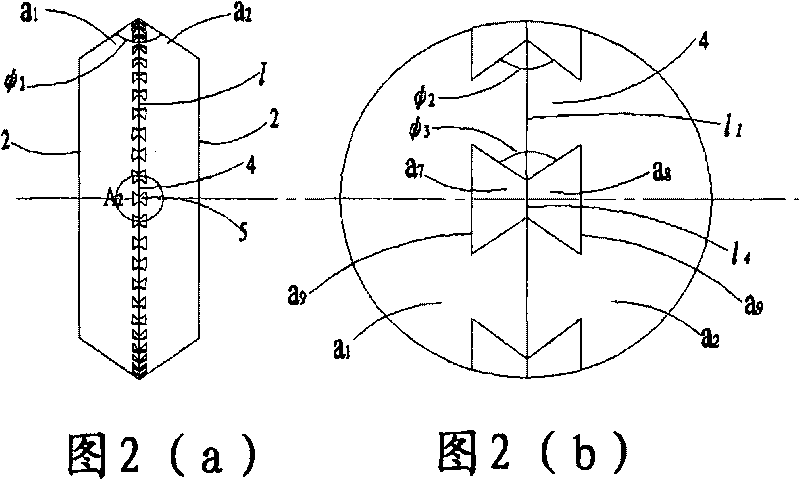

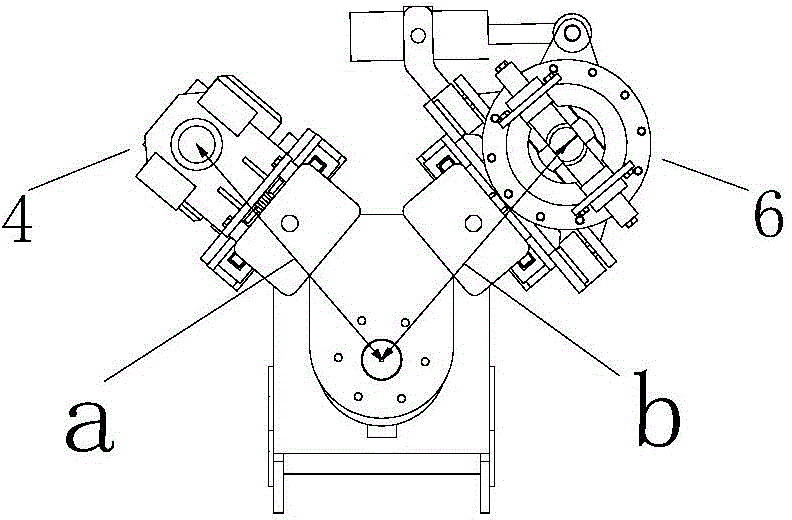

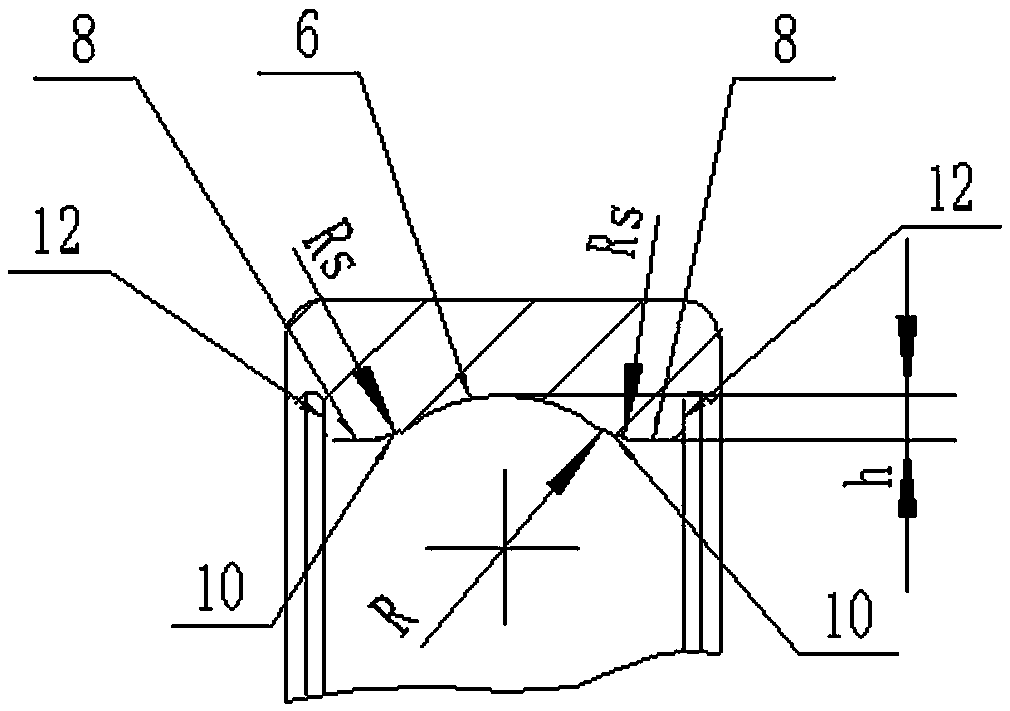

Cutter wheel for cutting brittle material and processing method thereof

InactiveCN101745990ARemoval depthExtended service lifeGlass severing apparatusMetal working apparatusLubrication ProblemLubricant

The invention discloses a cutter wheel for cutting a brittle material and a processing method thereof. The cutter wheel is provided with a V-shaped cutting blade part (1), a disc surface (2) and an axle hole (3), wherein the periphery of the chine line l at the external edge of the V-shaped cutting blade part (1) is provided with cutting blades (4) and recess structures (5), which are alternately-distributed; each cutting blade (4) comprises curved surfaces (Part a1 and Part a2), four side surfaces (a3, a4, a5 and a6) and V-shaped cutting edges (V-shaped cutting edge 1, V-shaped cutting edge 2 and V-shaped cutting edge 3)of which the included angles are respectively psi1, psi2 and psi3; and the disc surface (2) and the axle hole are provided with grid-line grooves (6), and the cutting blades (4), the recess structures (5) and the grid-line grooves (6) are obtained by the processing in a laser scanning mode. The cutter wheel with the new structure can avoid or reduce the condition that the cutter wheel is blocked when the cutter wheel with other structures cuts the material, and can prevent the material from producing radial cracks, thereby prolonging the service life of the cutter wheel and simultaneously obtaining the high-grade cutting sections. Besides, the inner walls of the grid-line grooves (6) are coated with solid lubricant, thereby well solving the lubrication problem.

Owner:孙春雨

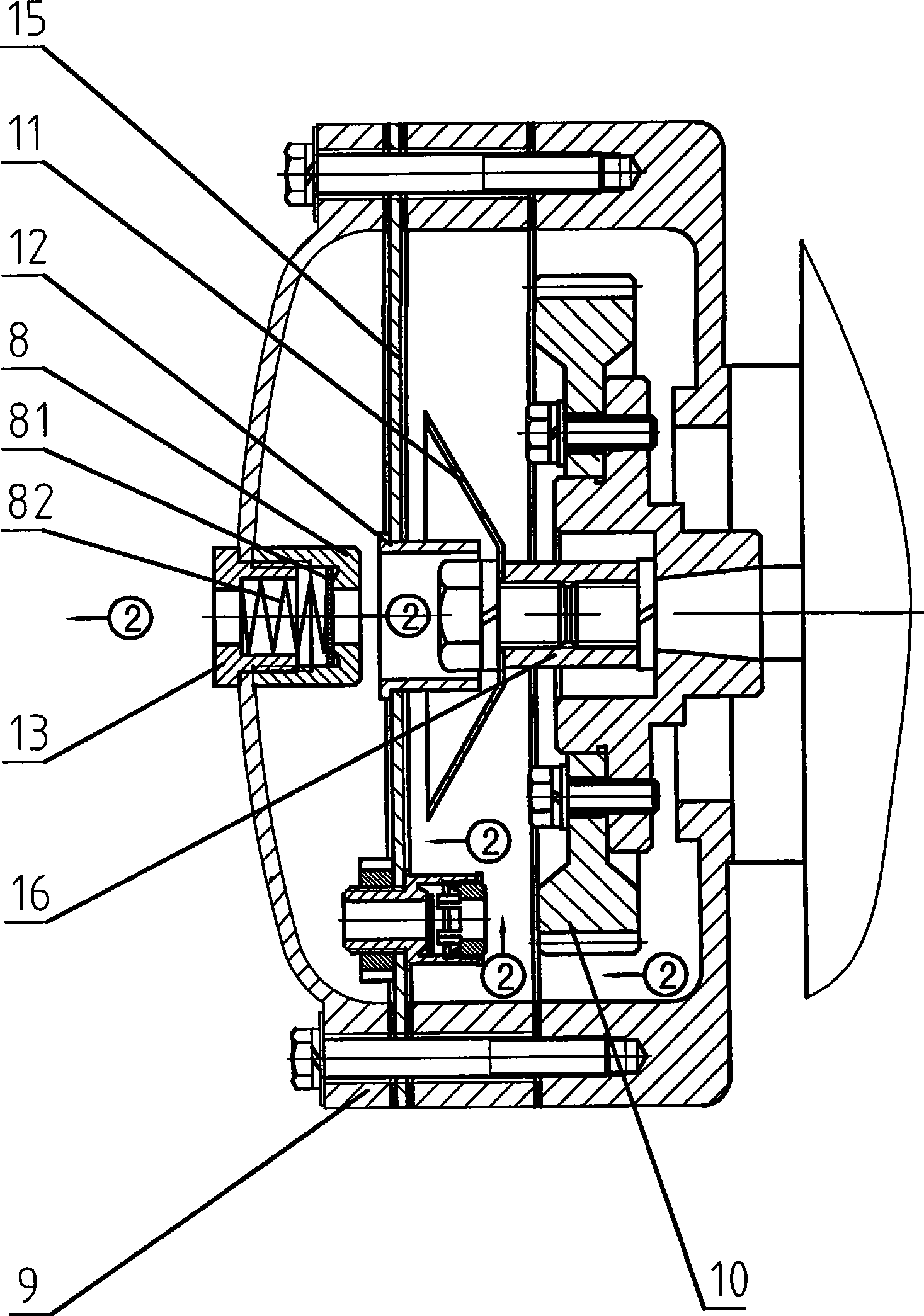

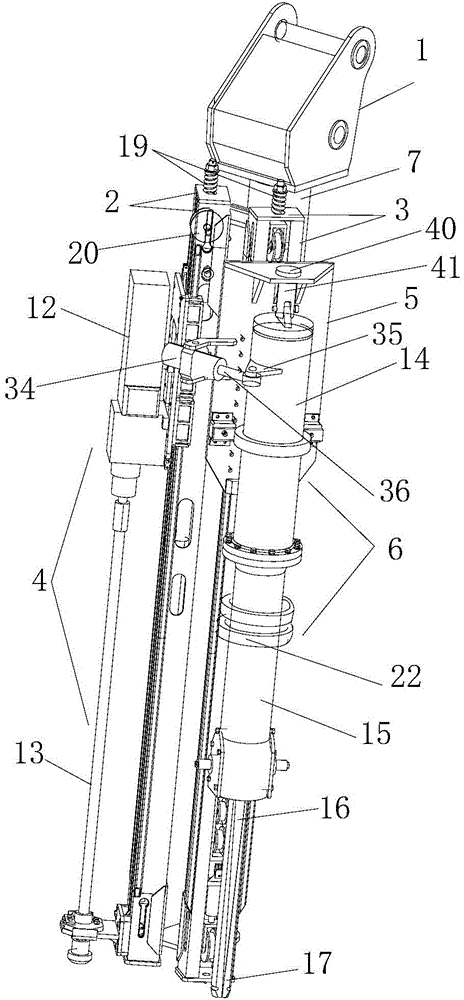

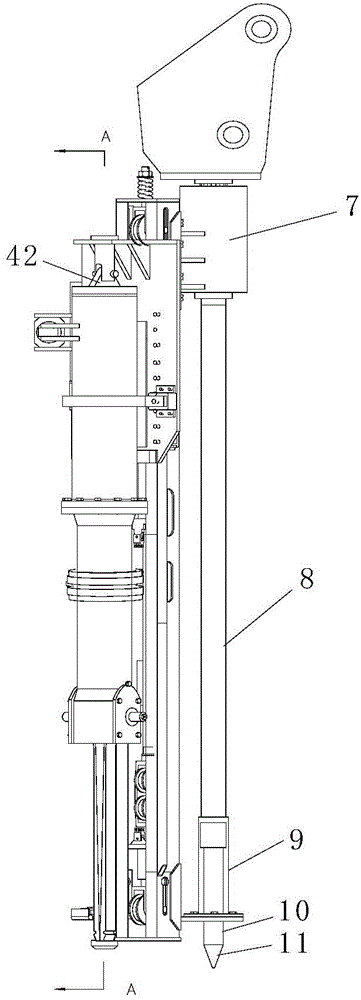

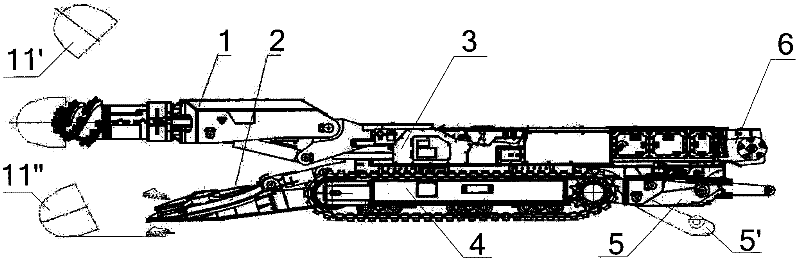

Soundless rock drilling and splitting integrated machine

ActiveCN104612581AExtended service lifeStress reliefDisloding machinesReciprocating drilling machinesDamping functionLubrication

The invention discloses a soundless rock drilling and splitting integrated machine and belongs to the field of rock drilling and splitting devices. The soundless rock drilling and splitting integrated machine comprises a hinged head, a rock drilling slide rail, a splitting slide rail, a rock drilling device arranged in the rock drilling slide rail in a sliding mode and a sliding seat arranged in the rock splitting sliding rail in a sliding mode. A splitting device is fixed to the sliding seat. The soundless rock drilling and splitting integrated machine further comprises a rotating component connected to the hinged head in a rotatable and hung mode. The rock drilling slide rail, the splitting slide rail and the rotating component are fixedly connected. The distance between the center line of a drill bit of the rock drilling device and the central axis of the rotating component is equal to the distance between the center line of a splitting sharp component of the splitting device and the central axis of the rotating component. By the adoption of the soundless rock drilling and splitting integrated machine, a rotating motor or a hydraulic oil cylinder is adopted, the rotation radius equidistance principle is utilized, after rock is drilled, a splitting block of the splitting device is accurately located and fed into a drill hole, accurate locating can still be achieved after the soundless rock drilling and splitting integrated machine is used for a long time, the splitting direction can be flexibly adjusted, and the flexible damping function and the automatic lubrication function are also achieved.

Owner:湖南烈岩科技有限公司

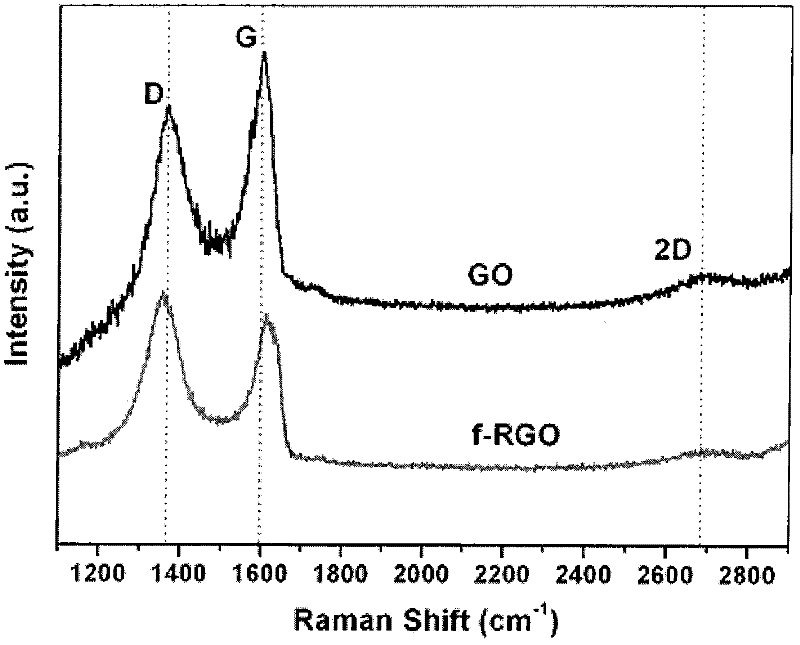

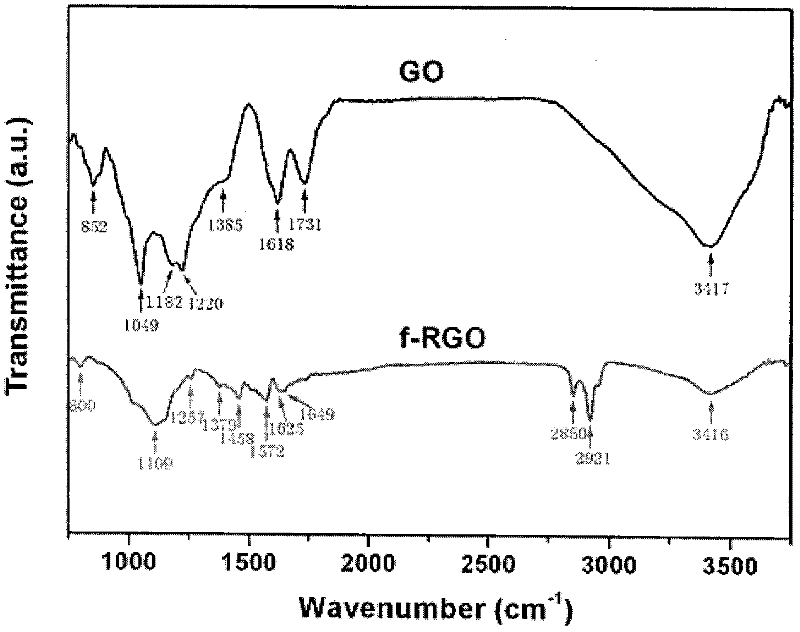

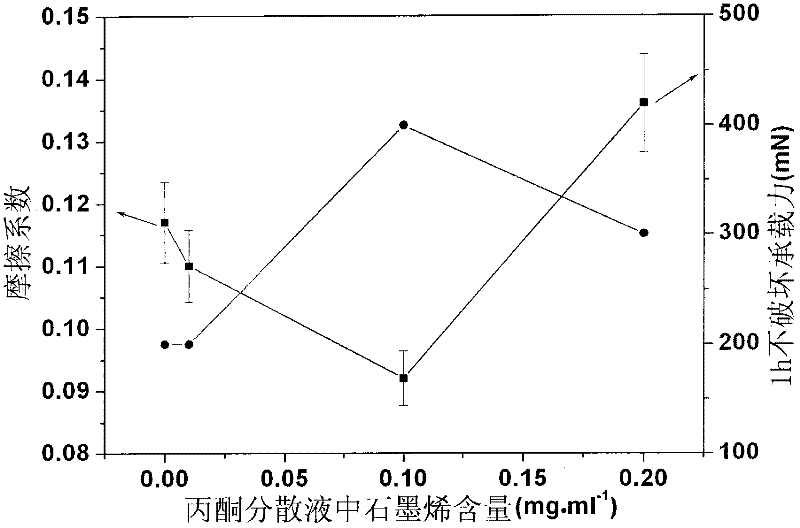

Graphene-containing ionic liquid nanometer composite lubricating membrane

ActiveCN102533406AImprove electrostatic adsorption capacityImprove bindingAdditivesTetrafluoroborateAcetone

The invention discloses a graphene-containing ionic liquid nanometer composite lubricating membrane. The graphene-containing ionic liquid nanometer composite lubricating membrane is prepared by the steps of carrying out non-covalent functionalization treatment to graphene through 1-butyl-3-methylimidazolium chloride ionic liquid so as to disperse the obtained graphene in water and an organic solvent stably, mixing and dispersing graphene and 1-octyl-3-methylimidazolium hexafluorophosphate ionic liquid in acetone, and preparing the graphene-containing ionic liquid nanometer composite lubricating membrane from the dispersion liquid through a static absorption manner finally. The nanometer composite lubricating membrane both has high micro-friction bearing capacity of the graphene and low micrometer / nanometer friction coefficient of the ionic liquid, and can be used for solving lubricating problems of micro-components such as MEMS (Micro-electromechanical System) and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

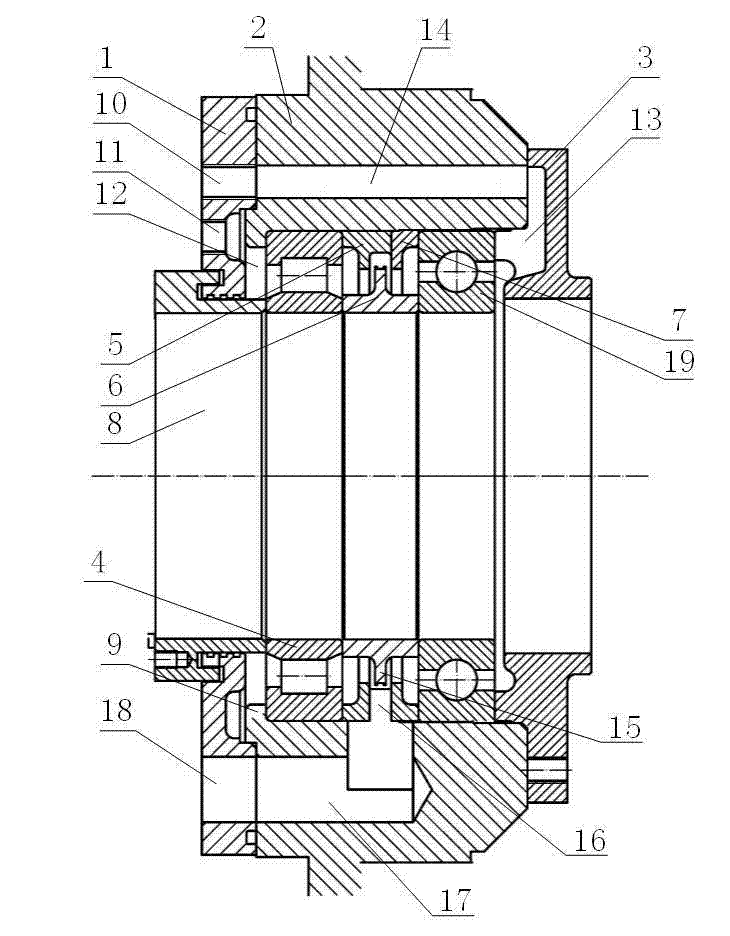

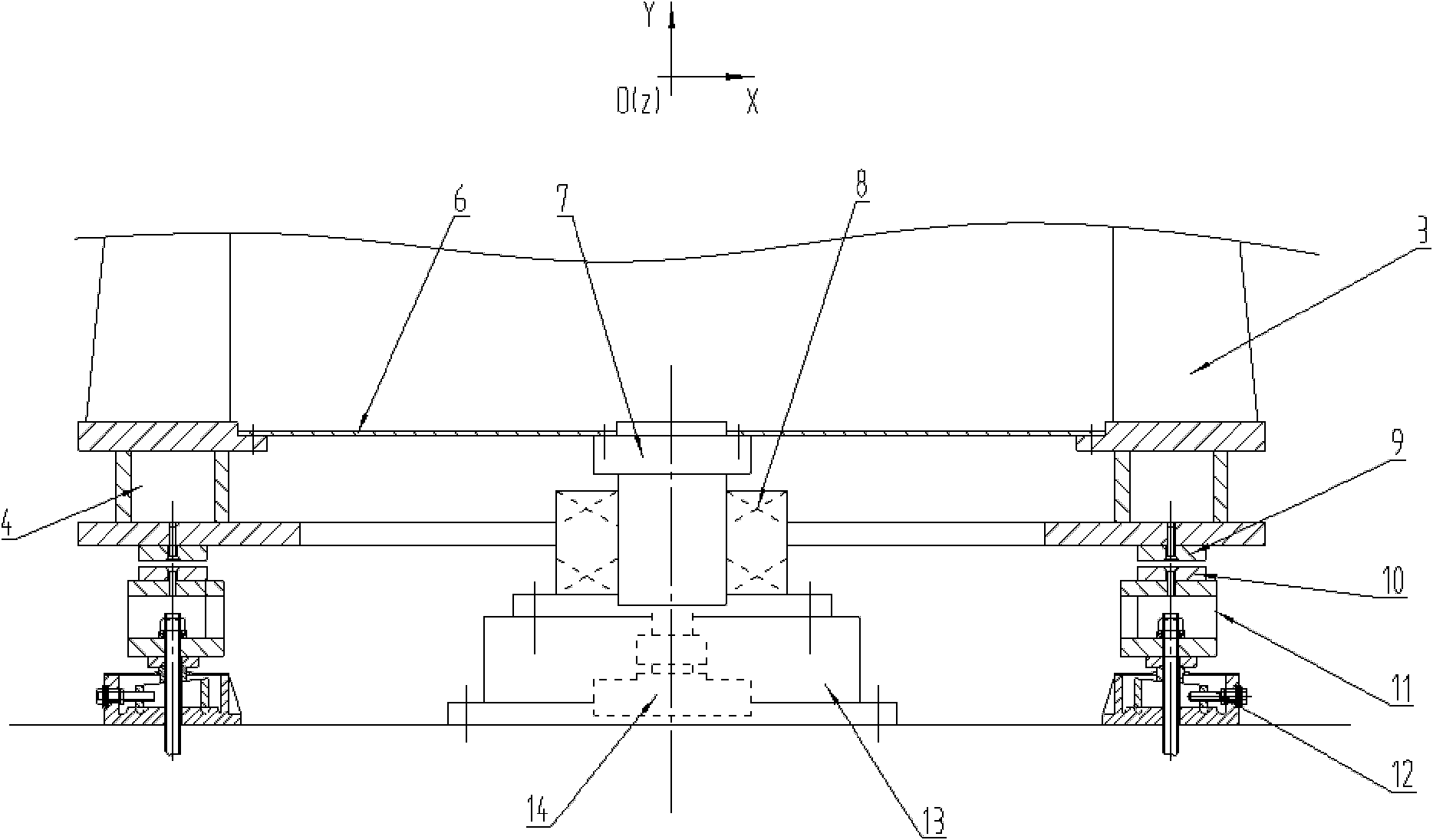

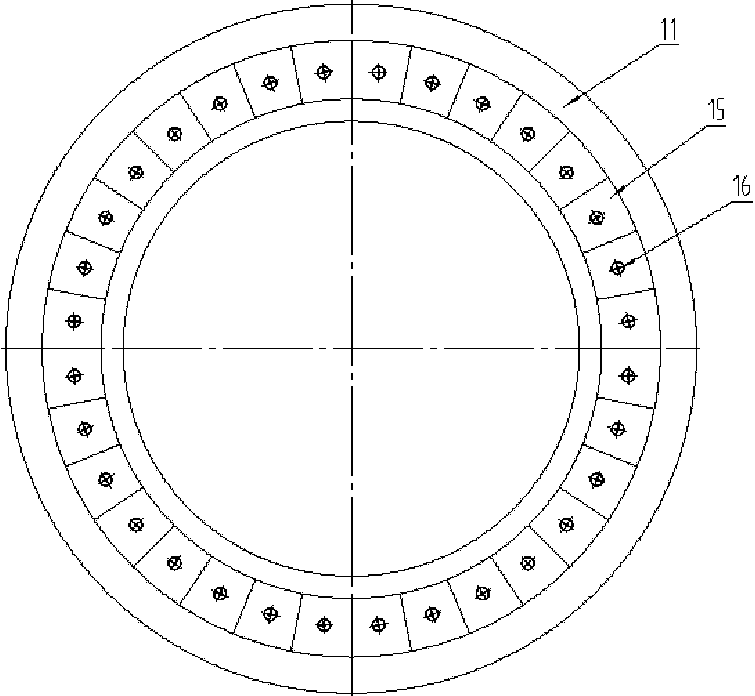

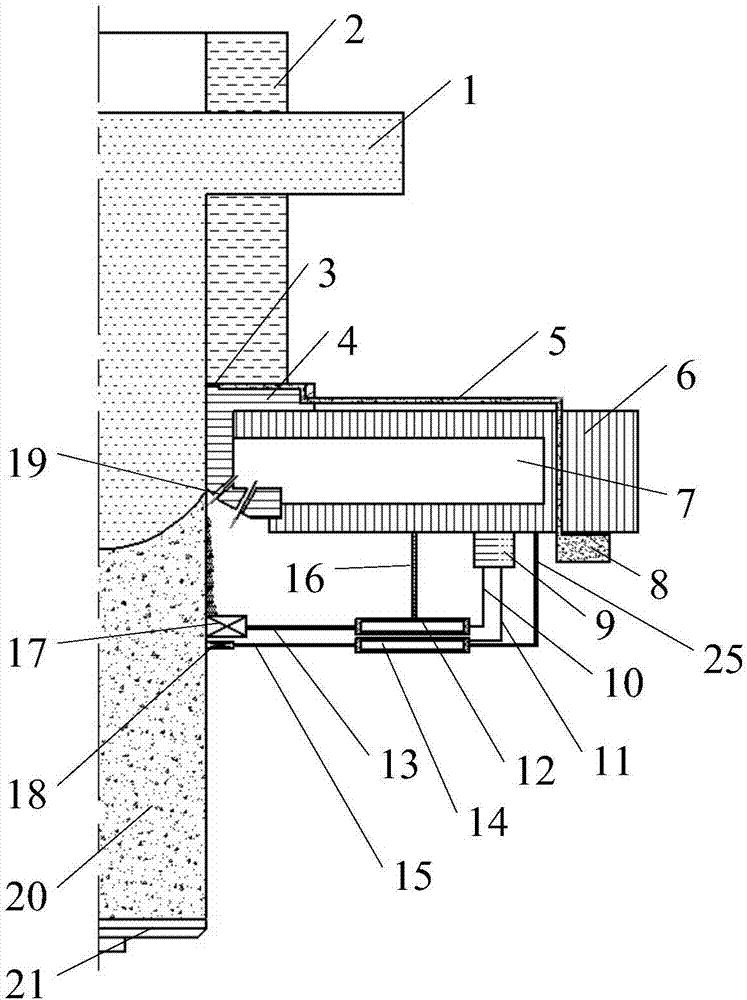

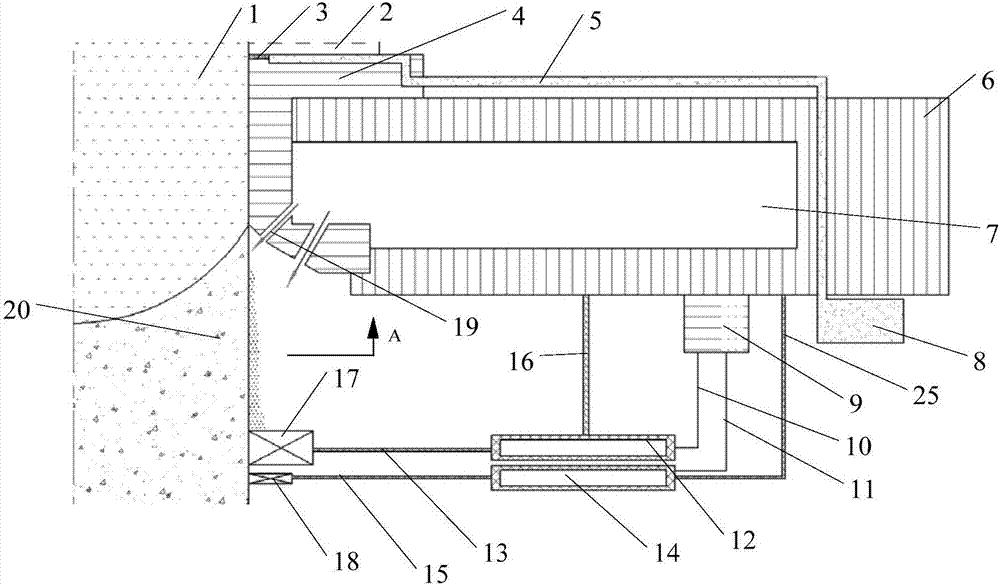

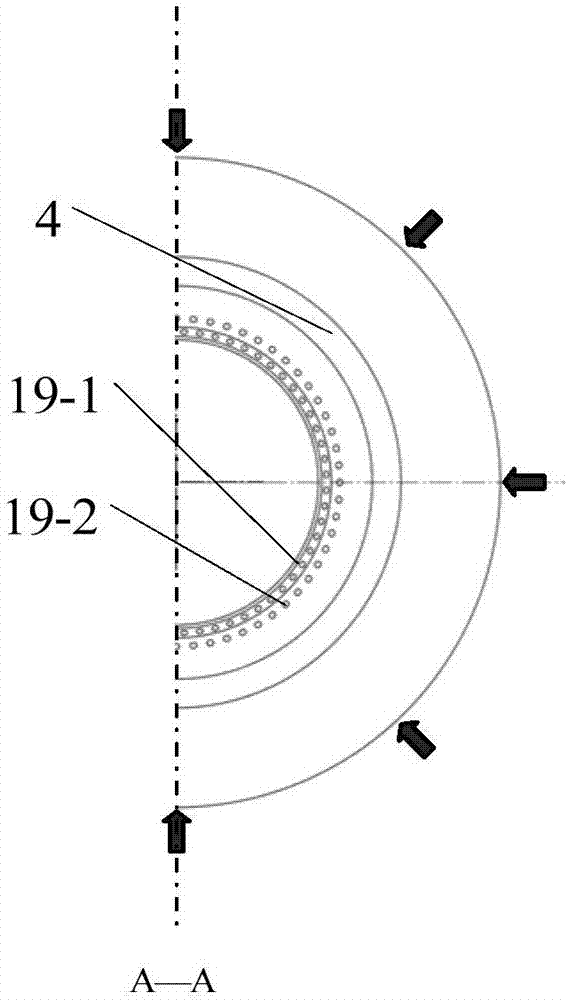

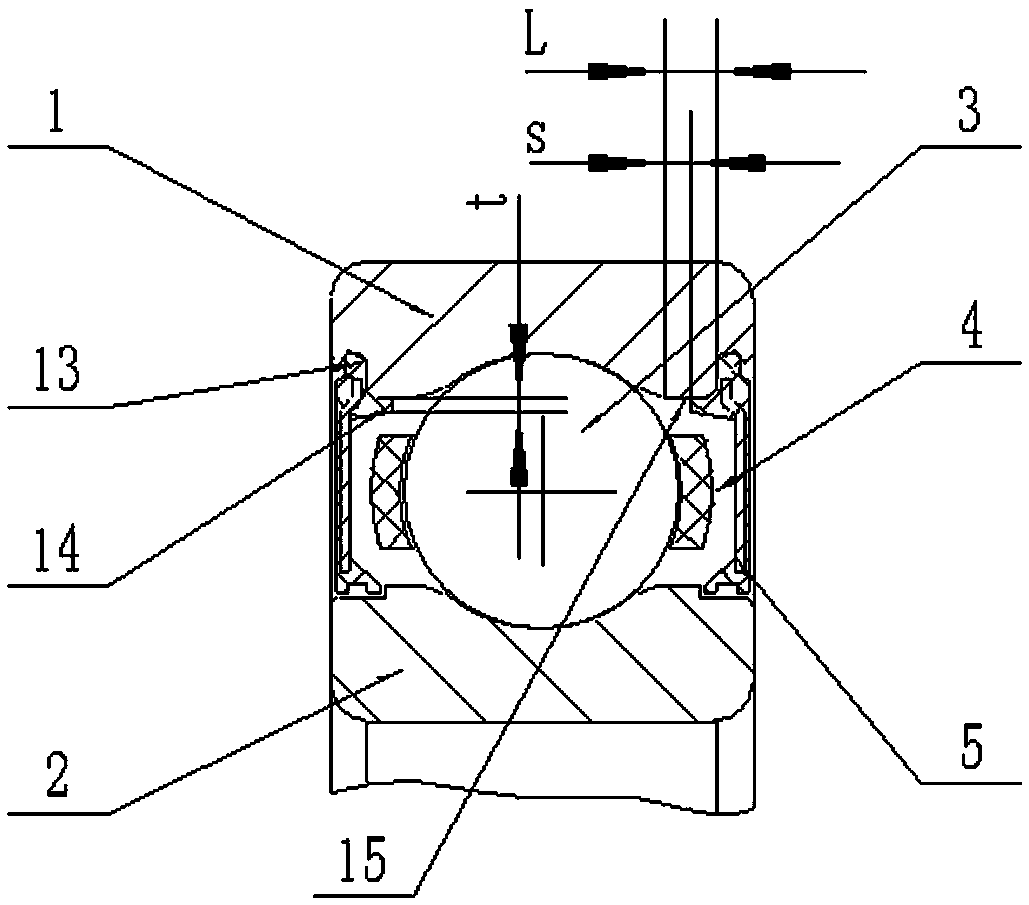

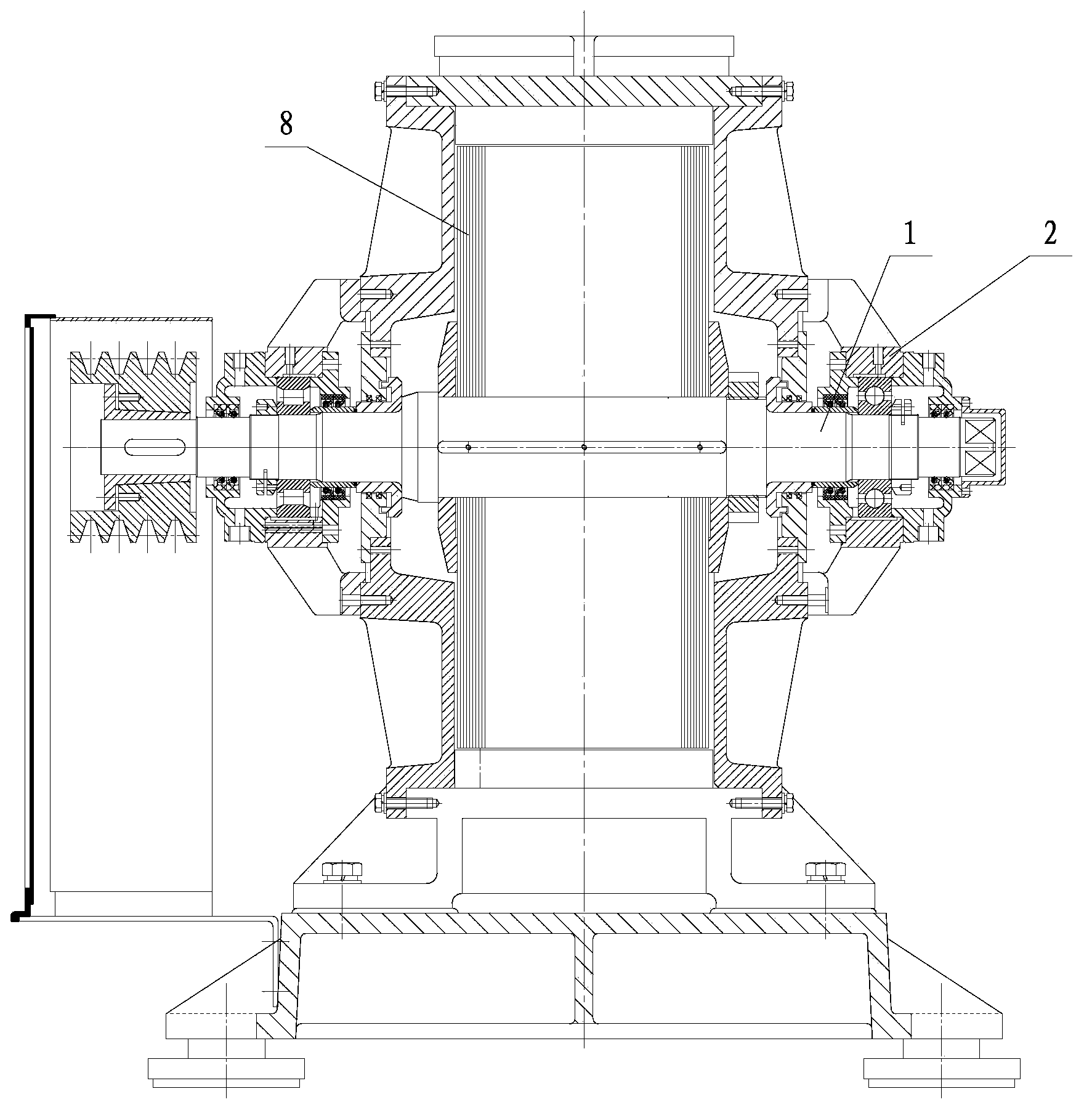

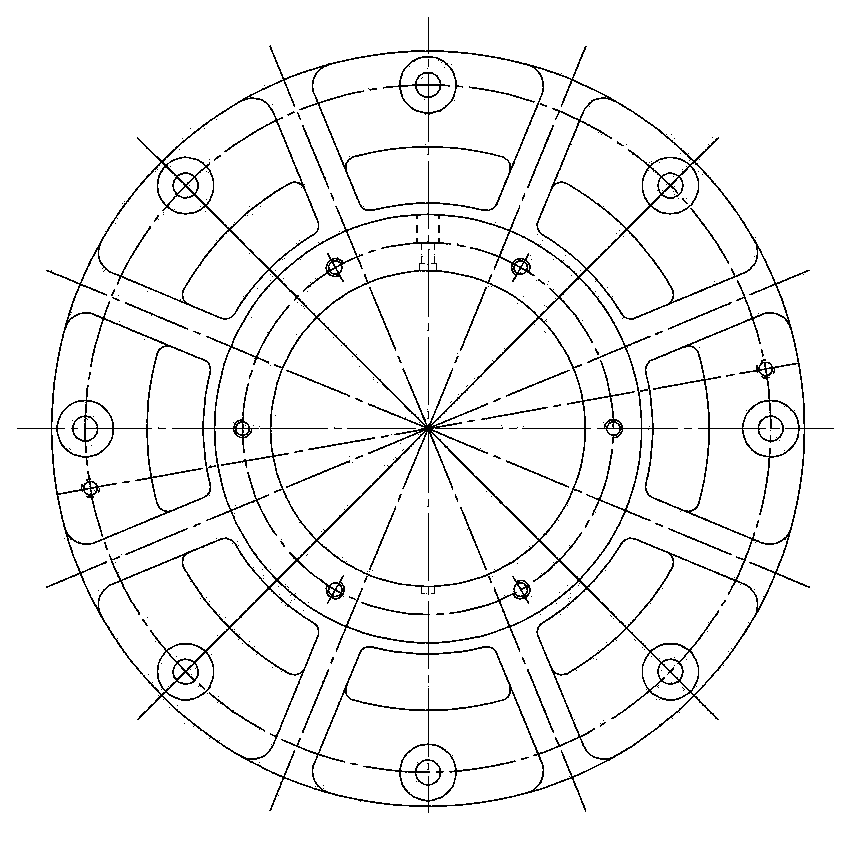

Wind driven generator bearing lubricating structure

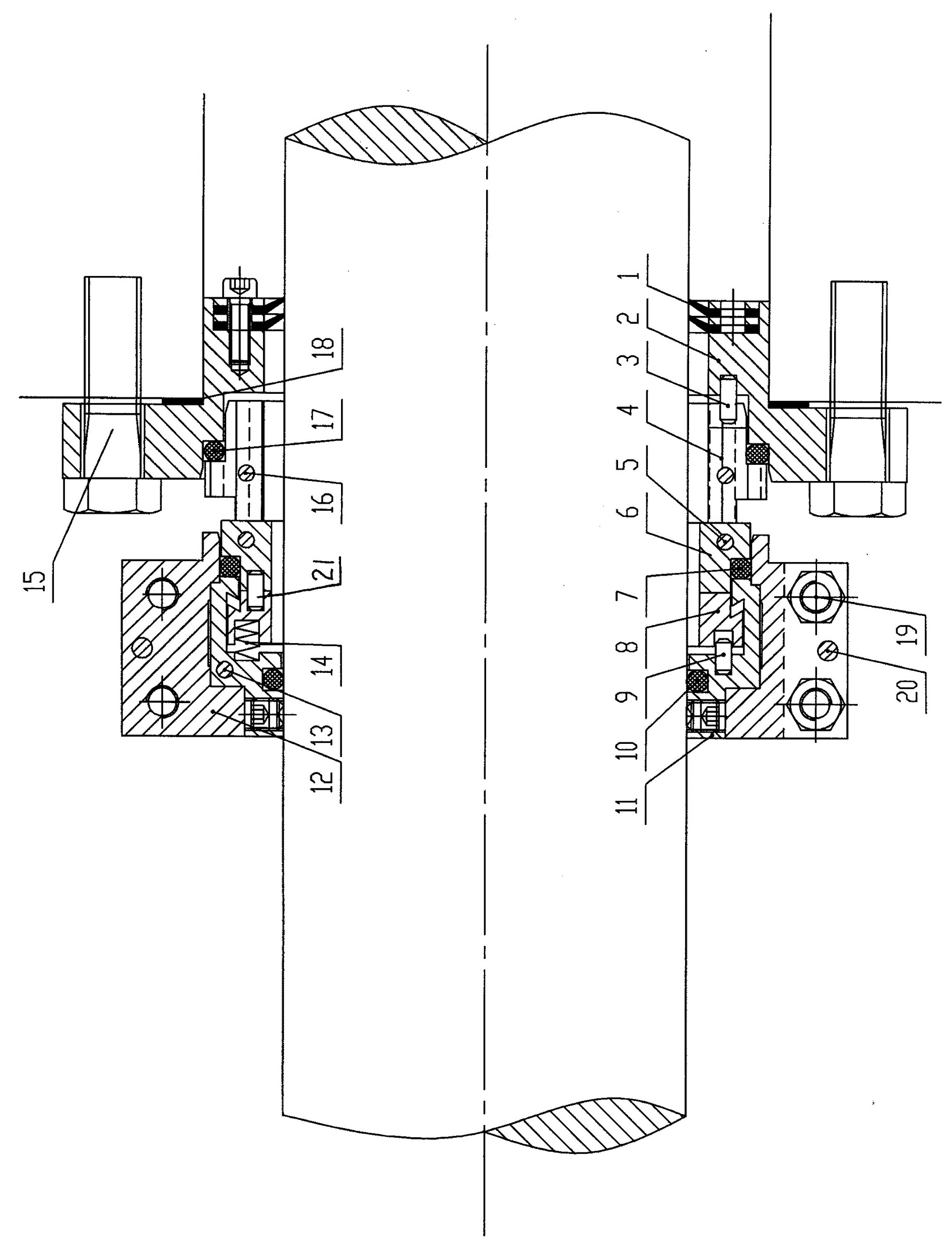

InactiveCN103398106AReasonable lubrication structureEfficient dischargeEngine lubricationBearing unit rigid supportWind drivenElectric generator

The invention discloses a wind driven generator bearing lubricating structure which comprises a left baffle (1), a main body (2) and a right baffle (3), wherein the main body (2) is internally provided with a bearing A (4), a left oil retainer (5), an oil slinger (6), a right oil retainer (7) and a bearing B (19); the left baffle (1) is provided with an oil inlet A (10) and an oil inlet B (11), the oil inlet B (11) is communicated with a cavity A (12), an oil inlet channel (14) is communicated with the oil inlet (10) and a cavity B (13), the bottom of the left oil retainer (5) is provided with a notch (16) communicated with the internal space of a right groove, and an oil discharge channel (18) communicates the notch (16) with an oil discharge hole (17). The wind driven generator bearing lubricating structure has the beneficial effects that two bearings are lubricated simultaneously, so that each bearing is lubricated by new grease; a reasonable oil shedding structure is designed, and waste oil is discharged from the same oil discharge hole; the oil retainer and the oil slinger enable an oil chamber to store proper quantity of grease.

Owner:DONGFANG ELECTRIC CORPLESHAN NEW ENERGY EQUIP

Starting motor carbon brush for vehicle engine and making method of the same

InactiveCN102447206AHigh strengthSolve lubrication problemsRotary current collectorElectric motor startersLubricationAdhesive

The invention relates to a starting motor carbon brush for a vehicle engine and a making method of the same. The starting motor carbon brush for the vehicle engine is characterized in that the starting motor carbon brush for the vehicle engine comprises the following components: a mixed graphite powder, a copper powder, molybdenum disulfide and cerium oxide, wherein the mixed graphite powder comprises the following components in percentage by weight: graphite powder, epoxy resin and phenolic resin. The making method of the same comprises the following steps that the phenolic resin and alcohol which have a same amount are firstly mixed for 15 minutes; the epoxy resin is added into the mixing phenolic resin and mixed with the phenolic resin together for 15 minutes so as to make composite resin; the mixed composite resin is mixed with the graphite powder at the temperature of 90 DEG C so as to make the mixed graphite powder; the copper powder, the molybdenum disulfide and the cerium oxide are added into the mixed graphite powder in a mode of dry powder; and the copper powder, the molybdenum disulfide, the cerium oxide and the mixed graphite powder are pressed to make the starting motor carbon brush for the vehicle engine after being mixed in a dry type mixer. The starting motor carbon brush for the vehicle engine has the advantages that with the selection of epoxy phenolic composite resion as an adhesive, the strength of the carbon brush is strengthened; with the molybdenum disulfide as a lubricant, the problem of lubrication at the starting instant is solved; and with the cerium oxide as a grinding agent, the electrical property of a motor keeps a stable level.

Owner:温州东南碳制品有限公司

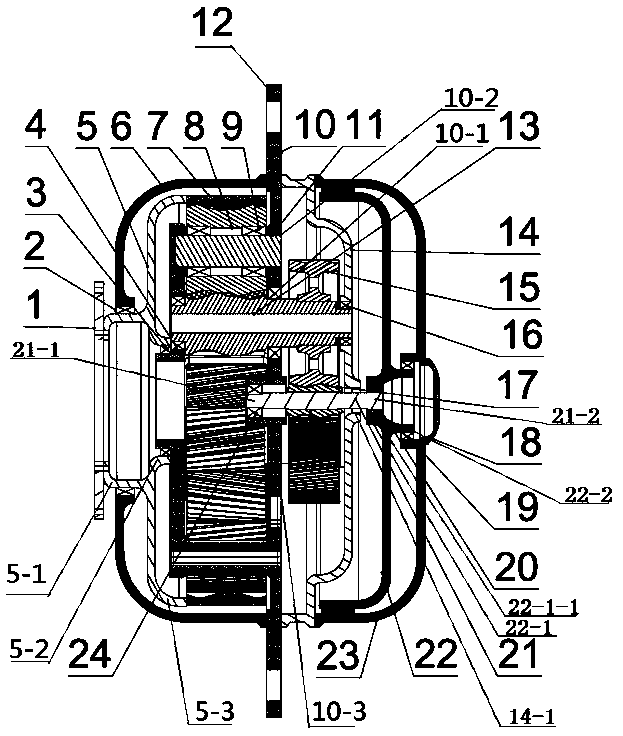

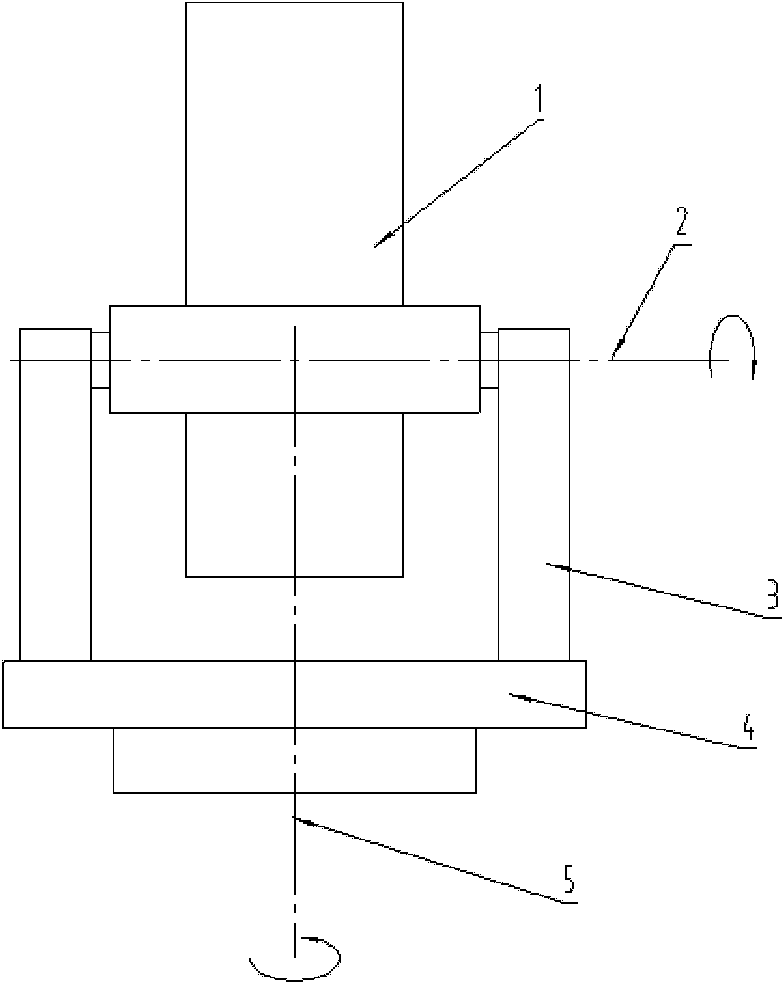

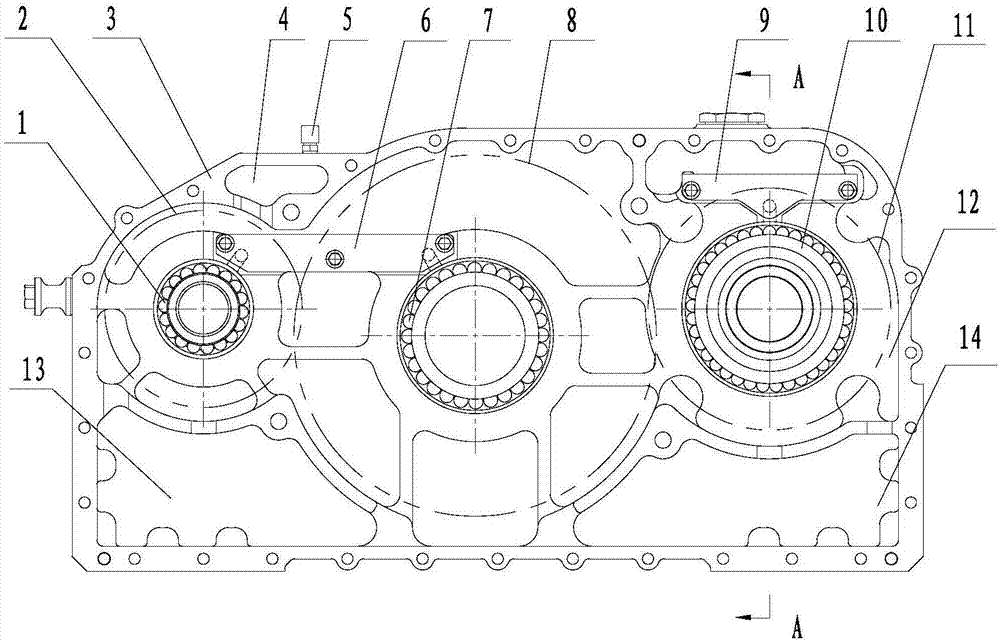

Integrated semi-direct drive wind generator transmission chain and gearbox for same

The invention provides an integrated semi-direct drive wind generator transmission chain and a gearbox for the same. The gearbox comprises a front box body (6), a rear box body (14), a spindle (5) and a planetary carrier (10), a large-diameter portion (5-3) of a downwind end of the spindle is fixedly connected with an inner gear ring (7), the inner gear ring (7) is engaged with at least three idle gears (8) mounted on the planetary carrier (10), the inner gear ring (7), the idle gears (8) and a first planetary gear form a primary fixed shaft transmission pair, a portion of each planetary gear shaft (13) extending out of the planetary carrier (10) is connected with a secondary planetary gear (15), the secondary planetary gear (15) is positioned in a cavity formed by the planetary carrier (10) and the rear box body (14) and engaged with the same sun gear (17), and the secondary planetary gear (15) and the sun gear (17) form a secondary fixed shaft transmission pair. The gearbox has the advantages of integration, light weight, short axial length, convenience in disassembly and assembly and the like.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Permanent magnetic suspension support shafting structure suitable for Antarctic astronomical telescope

InactiveCN102162910ASolve lubrication problemsSolve thermal expansion and contractionTelescopesBearingsSouth Pole TelescopeLubrication

A permanent magnetic suspension support shafting structure is characterized in that a radial load bearing and an axial location bearing are arranged on a height shaft; a support shafting structure of an azimuth shaft is arranged between a rotor and a telescope base of an azimuth shaft system; the radial load bearing of the height shaft adopts a permanent magnetic suspension bearing; the permanentmagnetic repulsion force between the moving ring of the bearing and a fixed magnetic plate counteracts the weight of the tube of the telescope; the axial location bearing of the height shaft is located by a Si3N4 ceramic bearing; a non-load location bearing of the azimuth shaft is supported by a Si3N4 ceramic bearing; a load location bearing of the azimuth is supported by a permanent magnetic axial bearing; and the permanent magnetic force generated between the moving magnetic ring and the fixed magnetic ring of the permanent magnetic axial bearing counteracts the weight of the telescope. Thepermanent magnetic suspension support shafting structure solves the problems of mechanical bearing of the Antarctic astronomical telescope, such as bearing lubrication, thermal expansion and contraction, low-speed crawling under heavy loads and the incapability of using the liquid hydrostatic bearing, thereby creating the conditions for high-accuracy tracking and large-diameter development of theAntarctic astronomical telescope.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

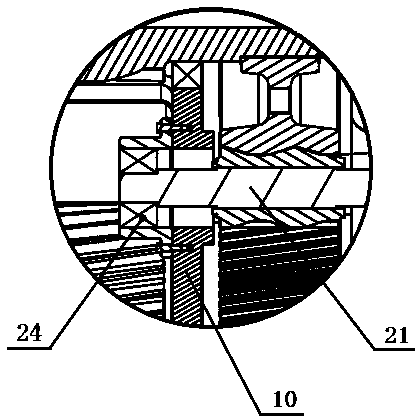

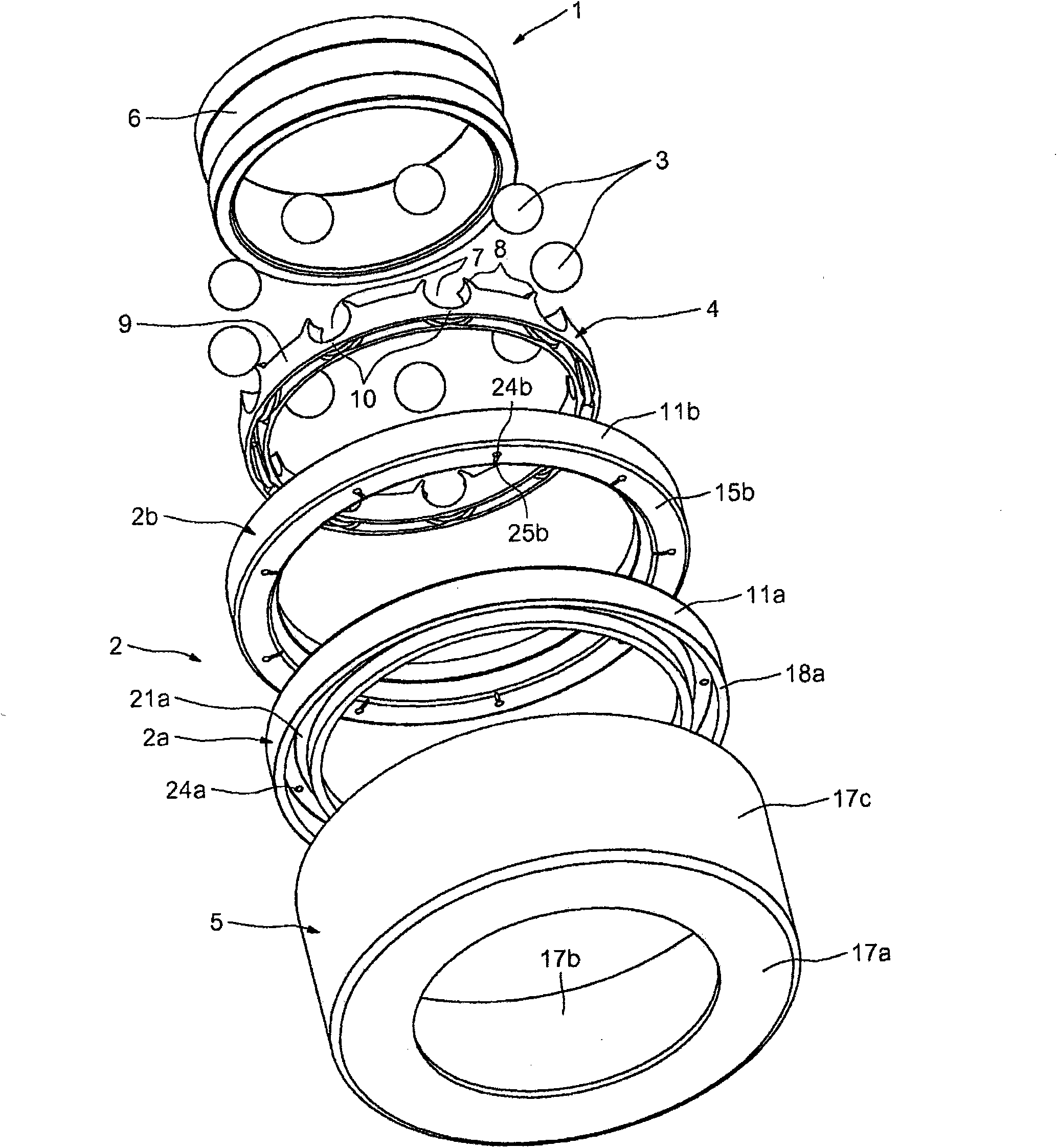

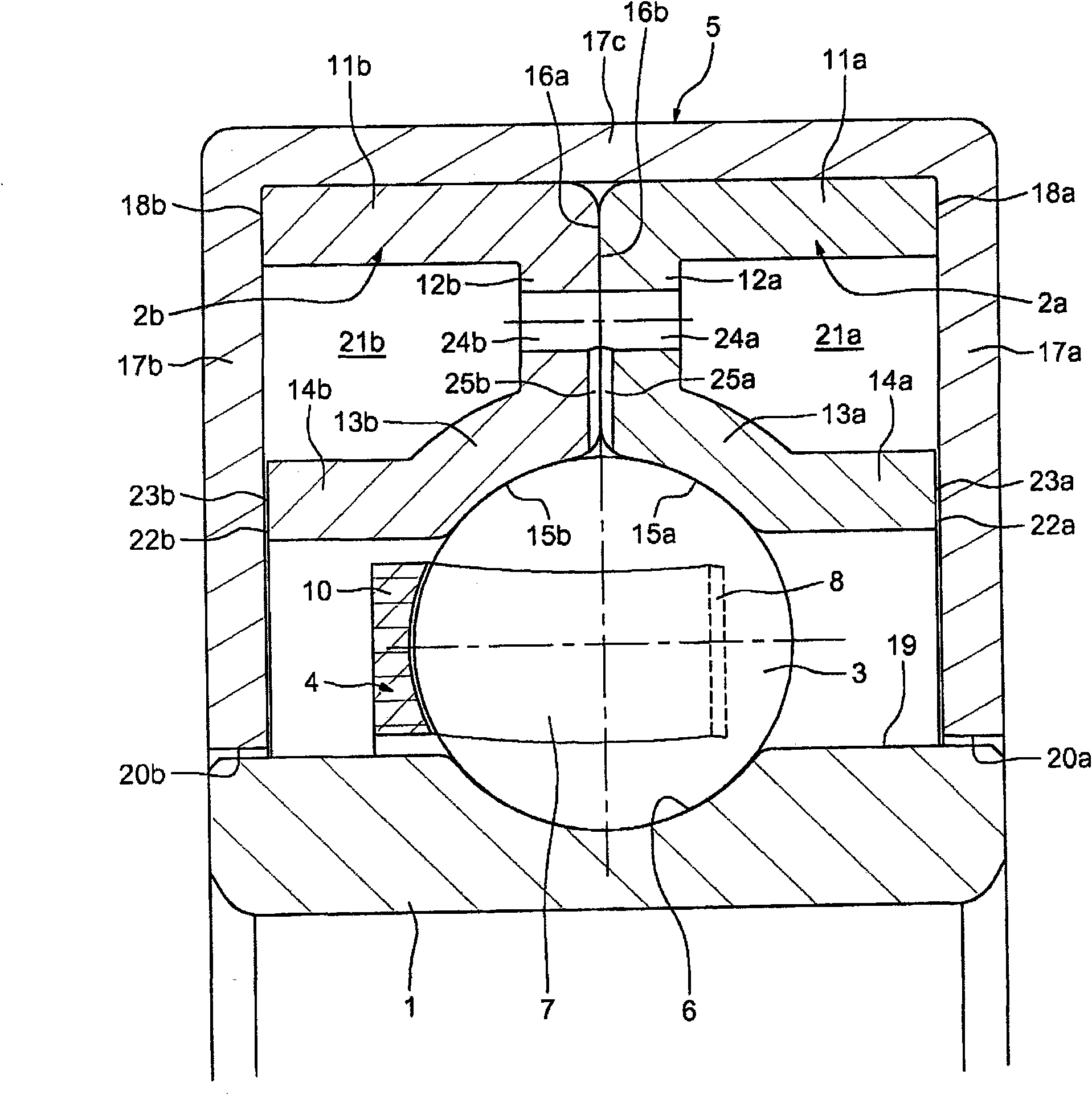

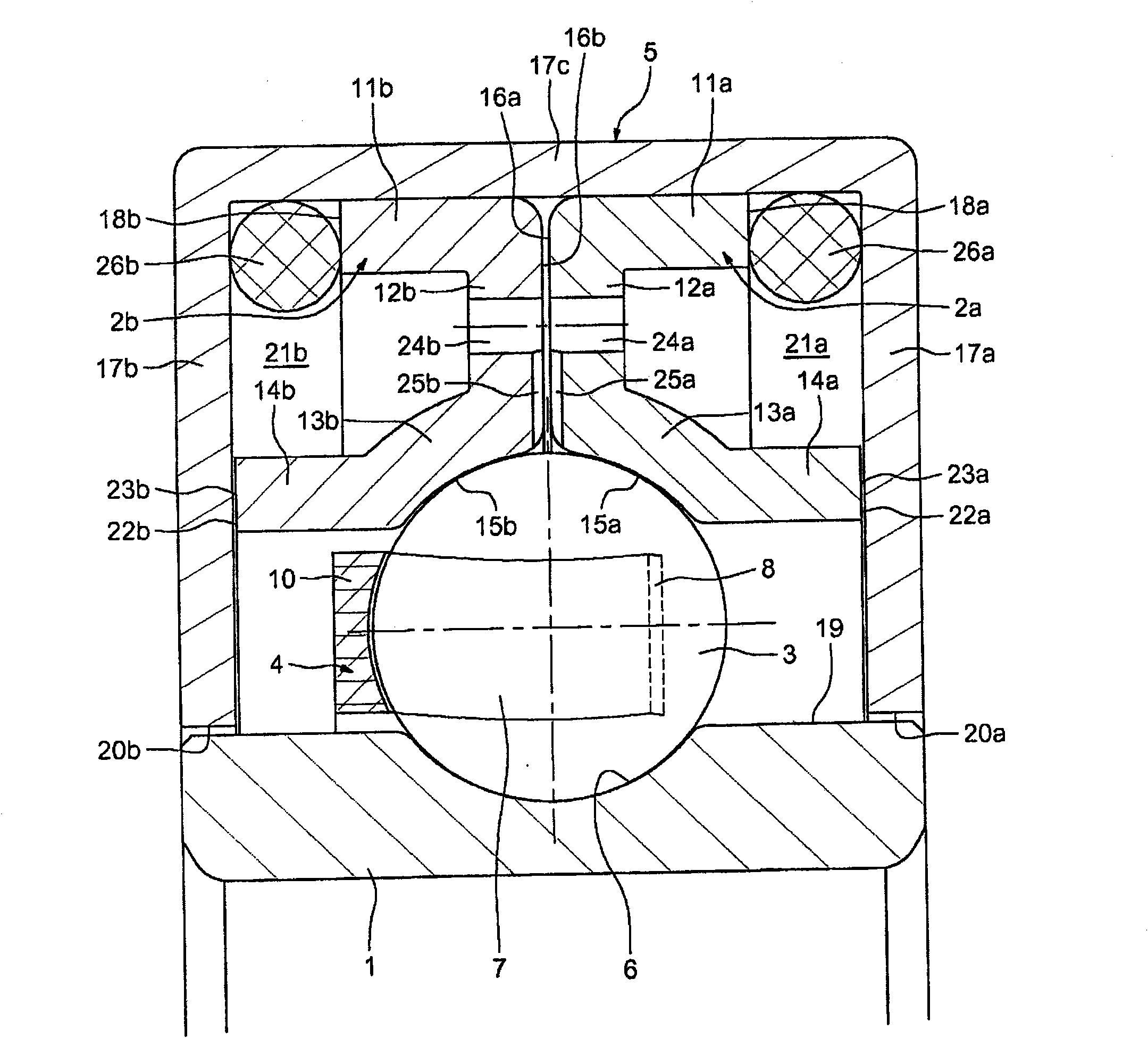

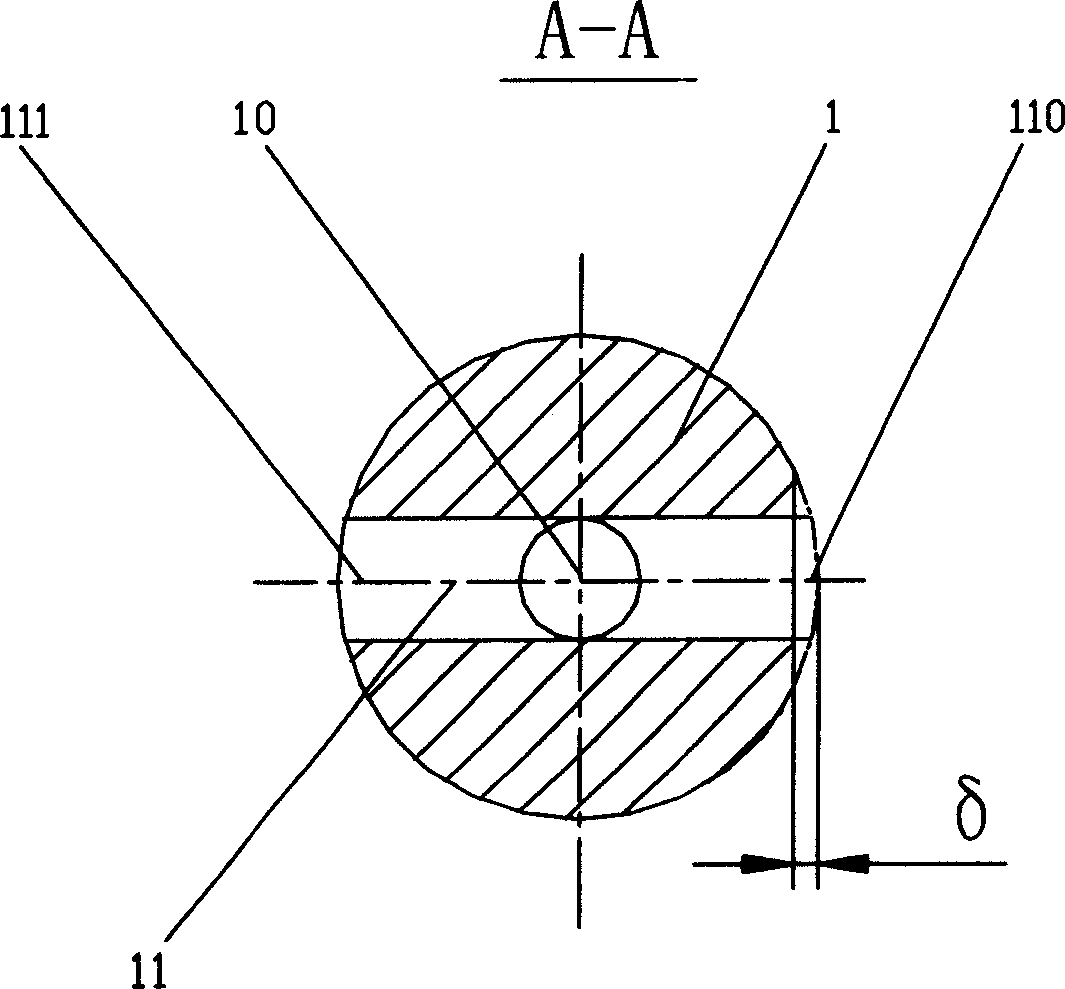

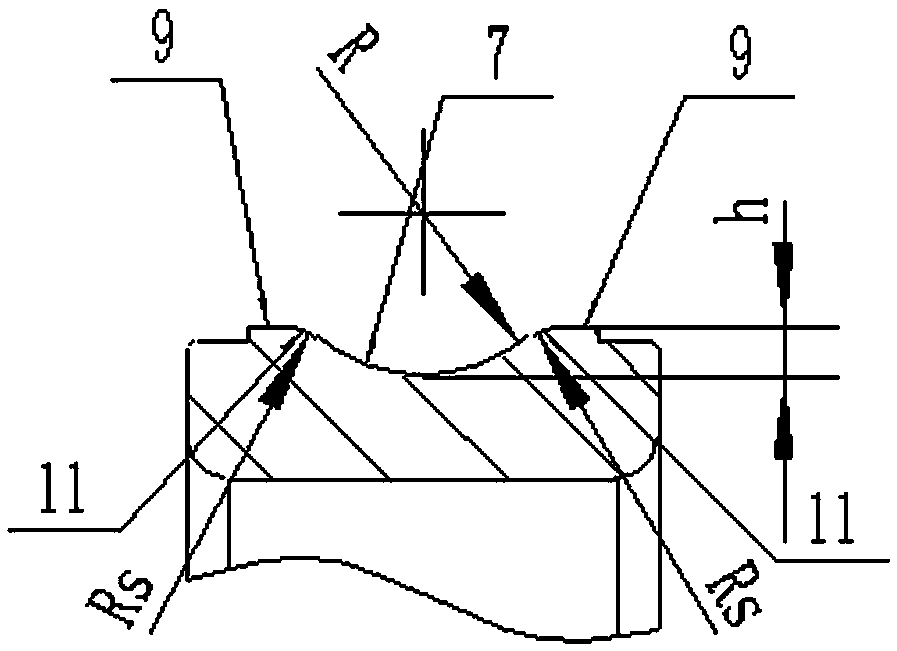

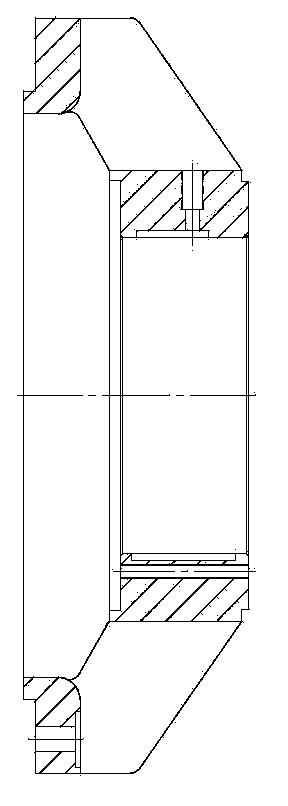

Rolling bearing having internal lubrication

InactiveCN101849115ASolve lubrication problemsEasy to manufactureShaftsBall bearingsRolling-element bearingLubrication

Rolling bearing having an inner ring (1) and an outer ring (2) with a row of rolling elements (3) held by a cage (4) between bearing races provided on the two rings, and an annular housing (5) surrounding one of said rings. Said ring forms with the housing at least one closed space (21a), (21b), inside which a lubricant is located.

Owner:AB SKF

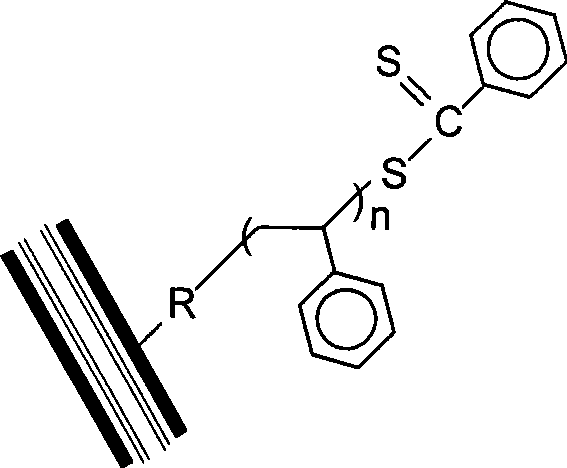

Preparation of multi-arm carbon nano-tube lubricant additive

InactiveCN101469143AGood anti-wear performanceEasy to prepareAdditivesPigment treatment with non-polymer organic compoundsLubricationCarbon nanotube

The invention discloses a method for preparing a multi-arm carbon nanotube lube additive. Through solid load of a chain transfer agent on the surface of a multi-arm carbon nanotube, the method carries out active polymerization on different monomers to obtain functionalized multi-arm carbon nanotubes modified by different polymers. The preparation process is simple and easy to operate; the prepared multi-arm carbon nanotube lube additive has good thermal stability and mechanical stability, and can greatly improve dispersion of the carbon nanotube in lube. The lube additive utilizes the rigid carbon nanotube as a nuclear structure and plays a role in bearing; long-chain macromolecule plays a role in abrasion reduction due to the flexibility and viscoelasticity of the macromolecule and realizes the conversion from sliding friction to rolling friction microscopically; therefore, the lube additive shows excellent abrasion resistance and is expected to solve the problem of lubrication of a mechanical material.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

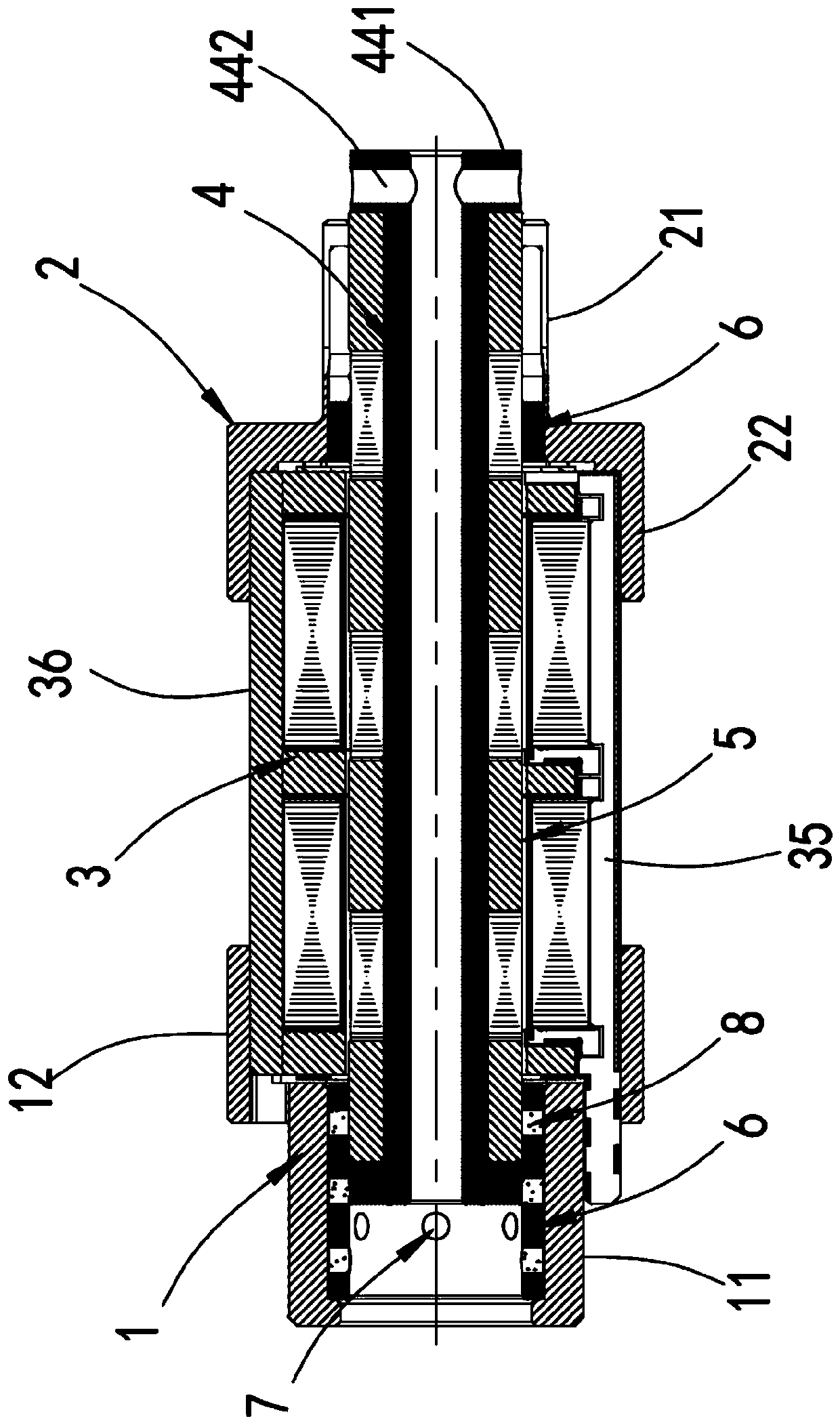

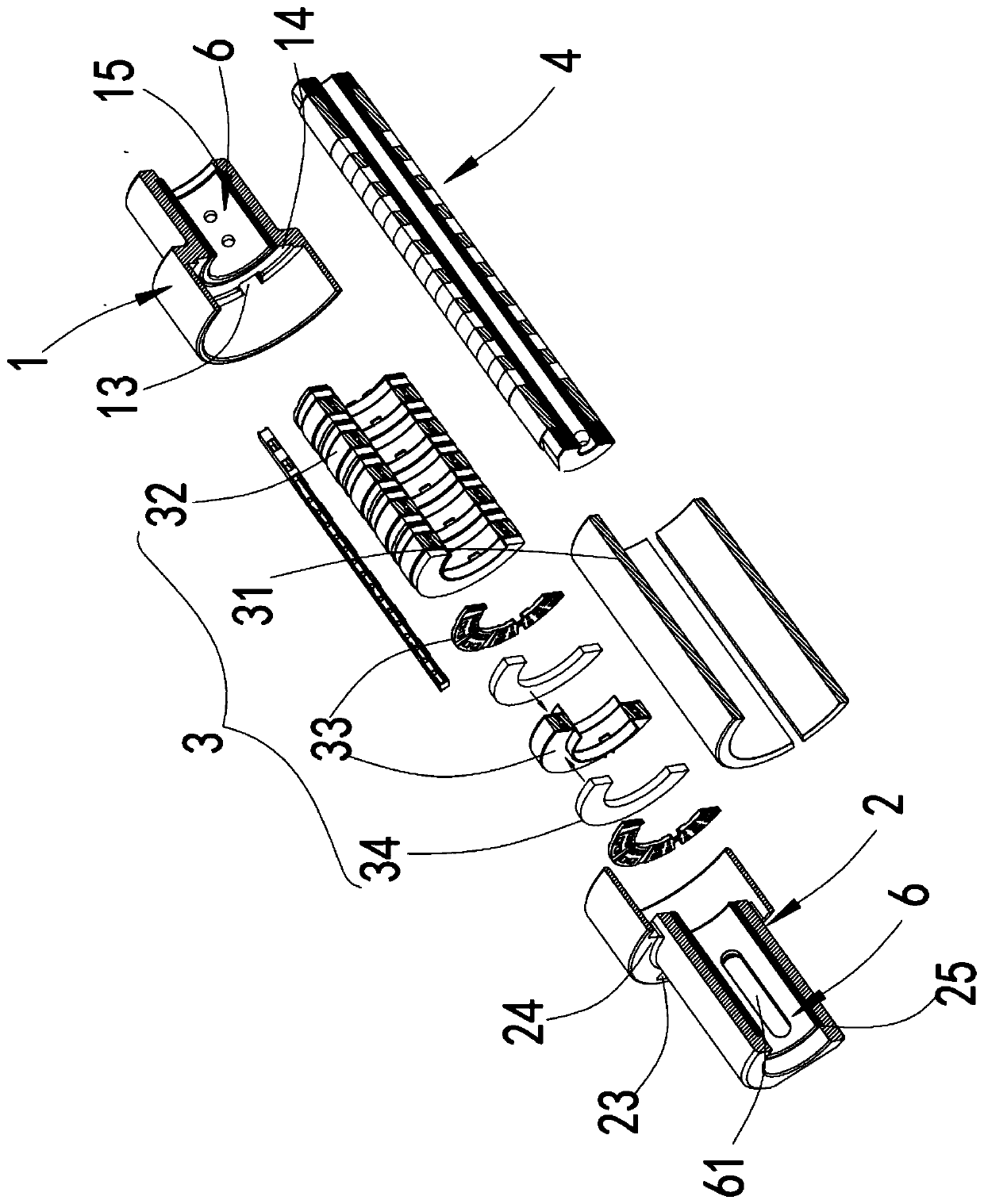

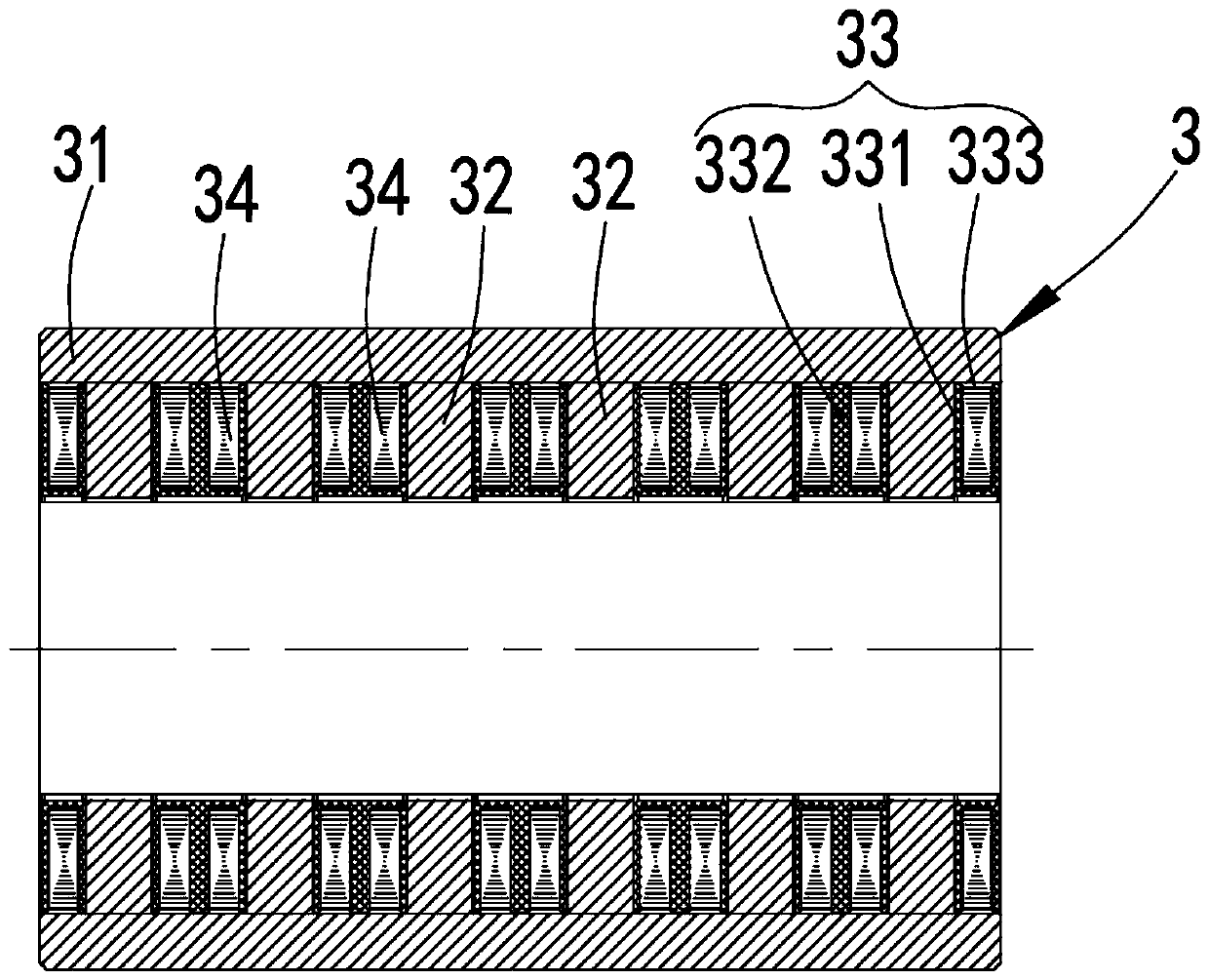

Linear power machine and power tool

PendingCN111371279AShorten the dimensional chainHigh precisionReciprocating/oscillating/vibrating magnetic circuit partsWindings insulation shape/form/constructionElectric machineControl engineering

The invention discloses a linear power machine and a power tool. The linear power machine enables the stator component to be installed on the first end and the second end. The mover component is guided and supported by the first end and the second end. No extra guide rail or guide structure is needed to be matched with the mover component. The whole structure is simplified, the size chain of the motor is reduced, the problem that the rotor component and the stator component are damaged by collision due to tolerance is avoided, the requirement for the precision of the components is lowered accordingly, the manufacturing difficulty is lowered, the precision of the motor is improved, and under the condition of the same size, the driving force of the scheme is larger, and the effect is better.Meanwhile, the stator component is partially exposed, heat exchange with external air can be effectively carried out through the exposed area of the stator component to achieve heat dissipation, andthe heat dissipation efficiency is improved.

Owner:苏州品匠机电技术有限公司

Low-noise motor and electric brush combination

InactiveCN103972758AHigh strengthSolve lubrication problemsRotary current collectorLow noiseElectrolysis

The invention belongs to the technical field of electric brushes or carbon brushes for motors, and relates to a low-noise motor and electric brush combination. The low-noise motor and electric brush combination comprises, by weight, 50-90% of colloidal graphite powder, 5-50% of electrolytic copper powder, 2-4% of molybdenum disulfide and 1-5% of tin powder. The colloidal graphite powder comprises 70-90% of graphite powder and 10-30% of solid phenolic resin. The low-noise motor and electric brush combination has the advantages that the phenolic resin is used as a binder, so that the strength of a carbon brush can be improved; an electric brush can be effectively lubricated by the aid of the molybdenum disulfide, properties such as pressure resistance, abrasion resistance, high-temperature resistance and chemical corrosion resistance of the electric brush can be improved, and multiple effects can be realized by the aid of the molybdenum sulfide; the conductivity and the lubrication property of the electric brush can be improved by the tin powder, and double effects can be realized by the aid of the tin powder; the graphite powder, the tin powder and the electrolyte copper powder are high in purity and are applicable to manufacturing electric brushes for fan heaters of automobiles or similar motors.

Owner:TAIZHOU HAOZE CARBON PROD

Split type solid dust mechanical seal system

ActiveCN102011865AImprove the working environment of employeesSimple structureEngine sealsEngineeringLip seal

The invention discloses a split type solid dust mechanical seal system. The inner side of a pressure cover center hole is provided with a multi-layer lip sealing ring, a rotating shaft in the pressure cover center hole is sleeved with a sealing static ring, a rotating shaft at the outer side of the static ring is sequentially sleeved with a rotating ring, a transmission seat and a fixing ring seat which are connected respectively through pins and rotate synchronously, the fixing ring seat and the rotating shaft are fixedly connected together, the inner peripheral wall of the fixing ring seat is provided with an O-shaped sealing ring being in contact with the rotating shaft; an annular groove is arranged in the fixing ring seat, the transmission seat is matched and sleeved in the annular groove, an O-shaped sealing is arranged between the inner end face of the fixing ring seat and an annular stop shoulder at the outer peripheral wall of the rotating ring, and the fixing ring seat and the rotating ring are matched and sleeved in a fixing pressure cover; and the fixing ring seat, the transmission seat, the rotating ring, the static ring and the fixing pressure cover are formed by twohalf bodies respectively, a lubricating grease wear-reducing structure is arranged on the end face of the static ring which is in contact with the rotating ring, and a compensation spring is arrangedbetween the transmission seat and the fixing ring seat.

Owner:新疆乌苏市北方新科有限公司

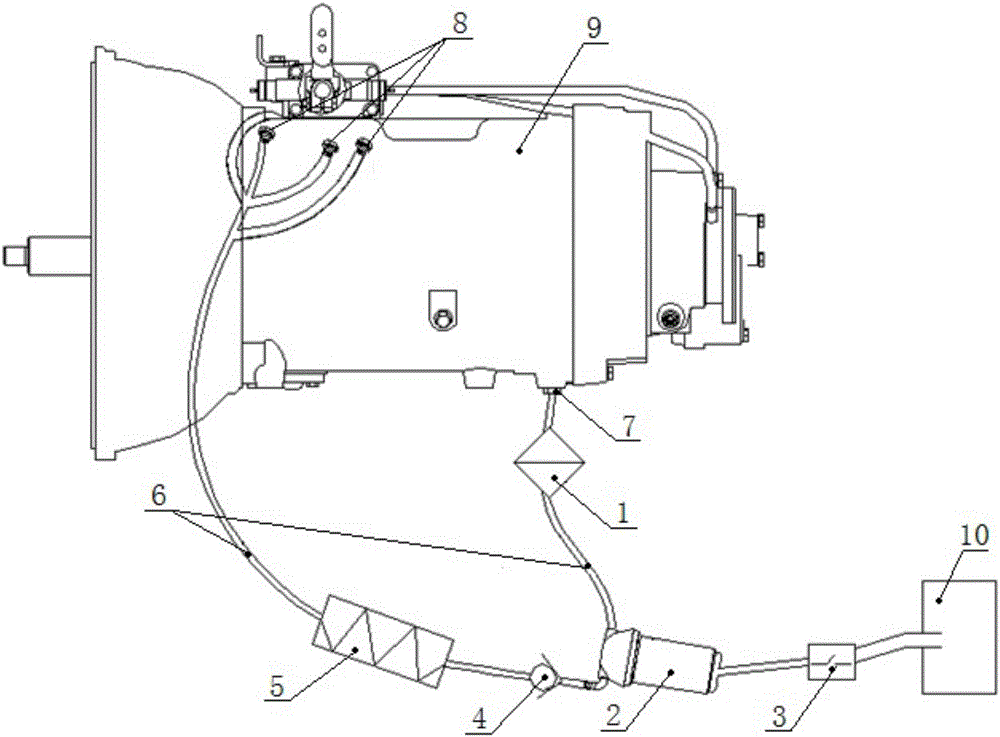

Oil way system for aerodynamic engine

ActiveCN103452619ASolve lubrication problemsLubrication of auxillariesMachines/enginesPiston ringEngineering

The invention relates to a lubricating system for engines, particularly to an oil way system for an aerodynamic engine. The oil way system comprises pressure lubrication, splash lubrication, a pipeline, two magnet suction filters and two strainers which are stacked together, wherein the pressure lubrication is adopted on a crankshaft diameter of the engine, a connecting rod shaft diameter, a cam shaft diameter, a cam shaft thrust flange, a timing gear, a rocker arm shaft and the like; the splash lubrication is adopted on a piston, a piston ring, a piston pin, a cylinder wall, a valve, a tappet, a cam and the like; the pipeline is used for lubricating an air controller. According to the oil way system, only one pipeline is added to lubricate the controller, so that the inner space of the engine is saved.

Owner:周登荣 +1

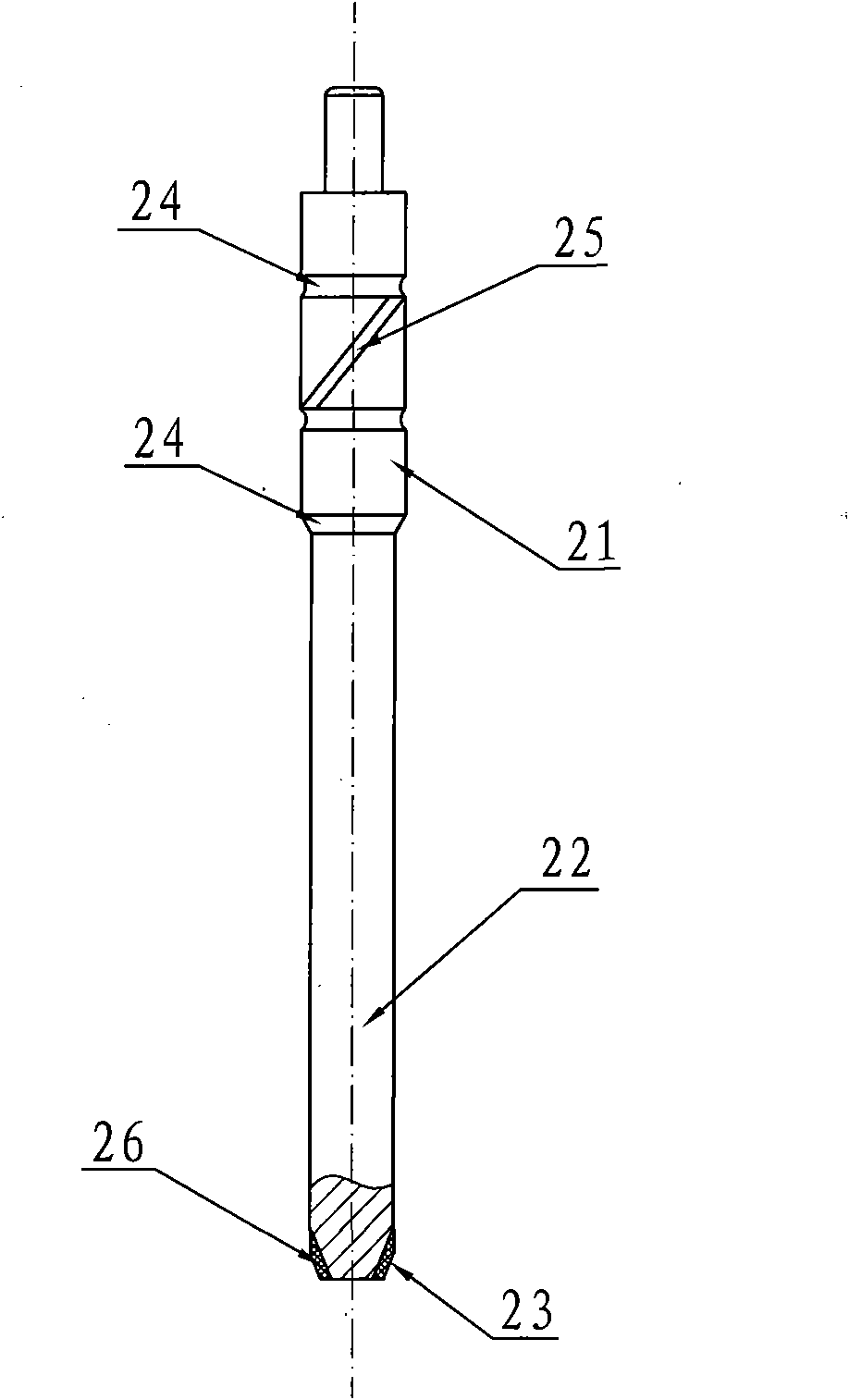

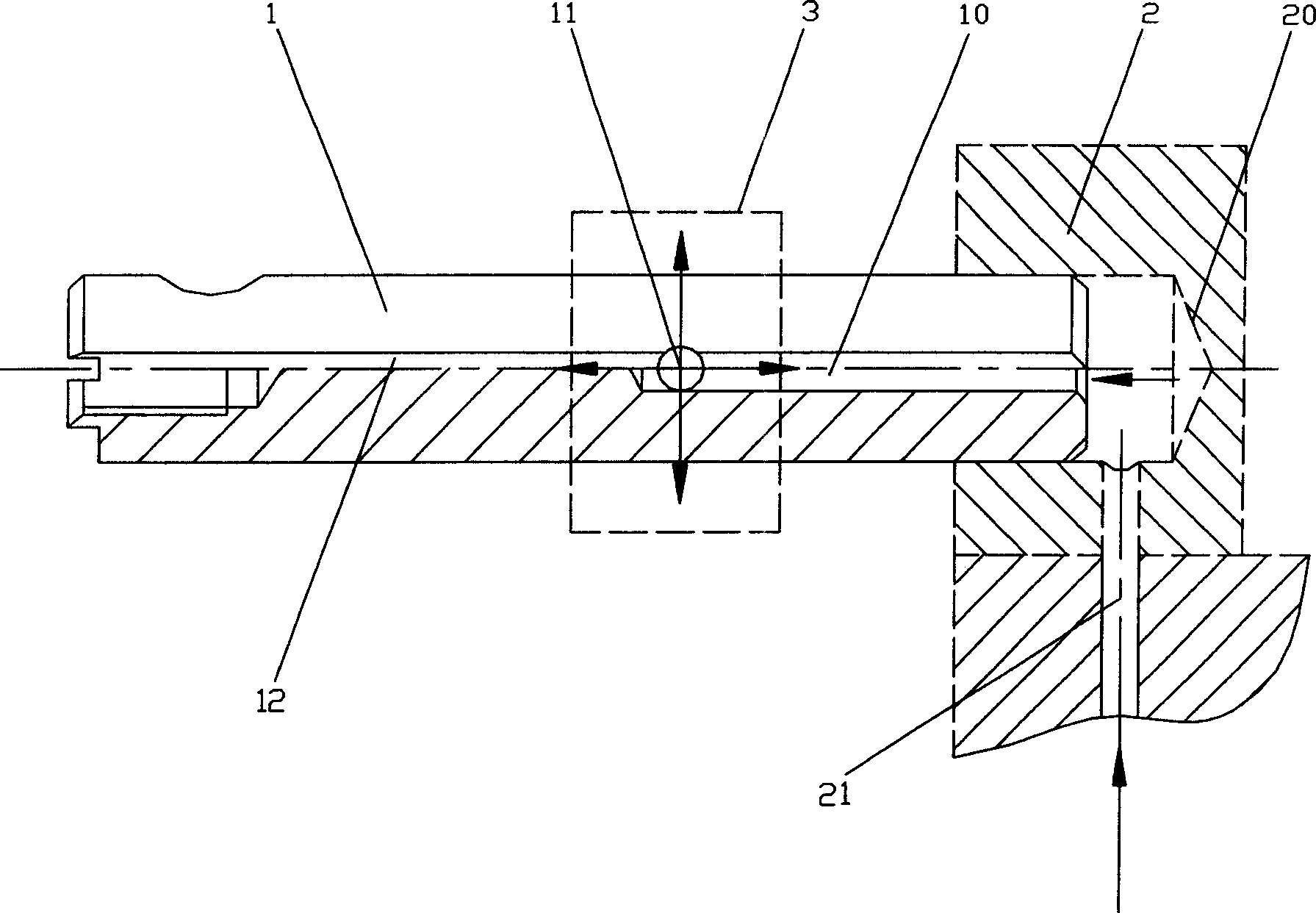

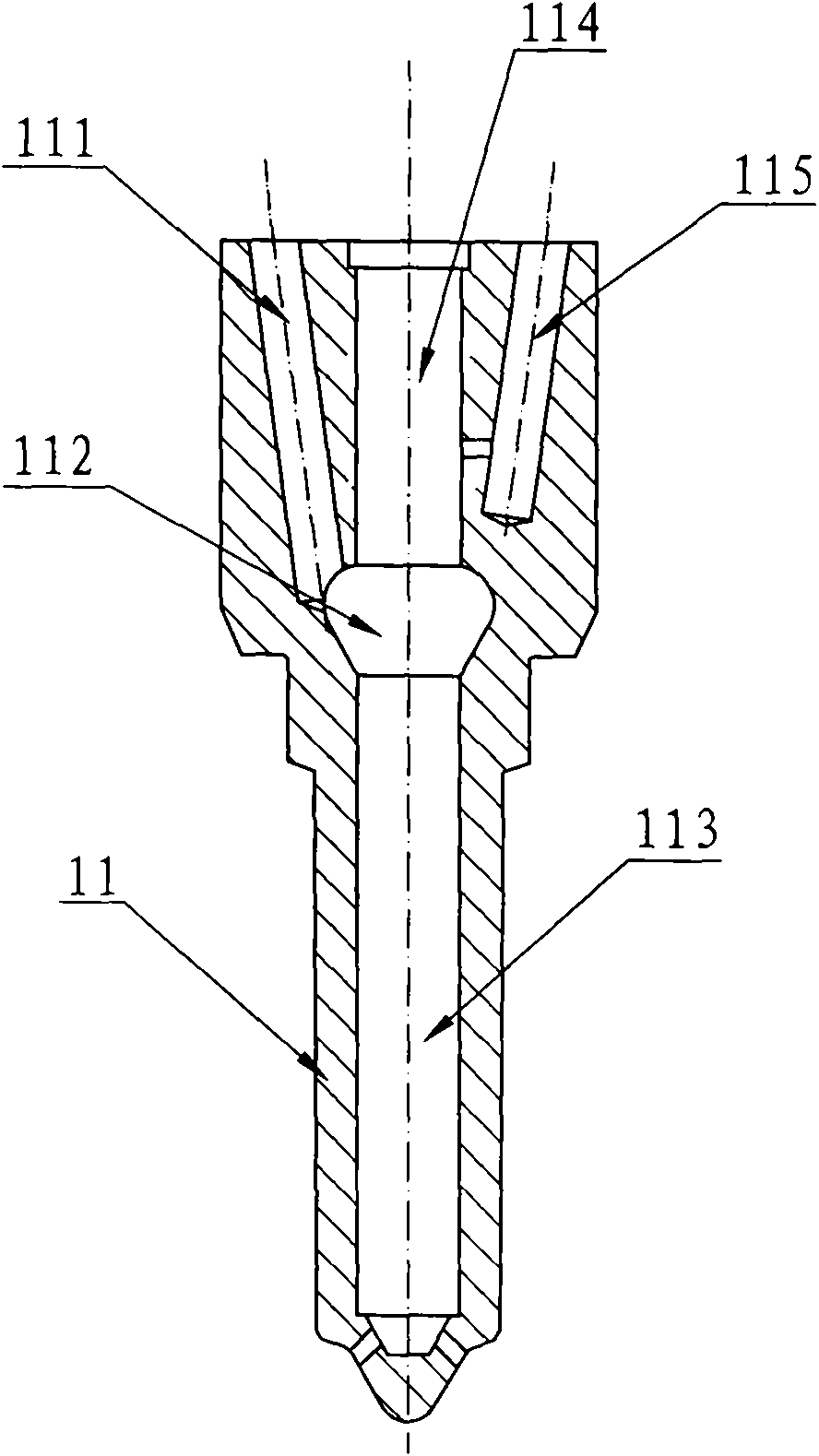

Diesel injector coupler applied to multiple fuels

InactiveCN101985912AIncrease axial lengthMake sure to formLubrication of auxillariesFuel injection apparatusDiesel injectorProcessing cost

The invention discloses a diesel injector coupler applied to multiple fuels. A needle valve body is provided with a fuel passage, a fuel accommodating cavity, a needle valve guide hole, a needle bar hole, a sealed inner conical surface, an oil jet hole and a lubricating oil passage, wherein the oil jet hole is formed on the sealed inner conical surface; the fuel passage is communicated with the fuel accommodating cavity; the lubricating oil passage is communicated with the needle valve guide hole; a guide section is sleeved in the needle valve guide hole on the needle valve body; a conical surface sealing bar is positioned in the needle bar hole; the sealed outer conical surface of a needle valve is matched with the sealed inner conical surface of the needle valve body; the guide section of the needle valve is provided with a lubrication groove; and when the needle valve is positioned at a limit position, the lubrication groove is communicated with the lubricating oil passage. The lubrication groove is formed on the guide section of the needle valve so as to increase the axial length of the lubrication groove between the needle valve and the needle valve body, reduce the processing cost and prevent the needle valve and the needle valve body from being blocked due to lubrication lack; and an abrasion-resistant coating is arranged on the sealed outer conical surface of the needle valve so as to prolong the sealing life between the needle valve and the needle valve body and prevent the fuel liquid from leaking.

Owner:CHANGZHOU YITONG FUEL EJECTOR MFG

External lubrication device for transmission and method

InactiveCN106641216AMeet lubrication and cooling needsExtended service lifeGear lubrication/coolingLubrication ProblemSpray nozzle

The invention discloses an external lubrication device for a transmission and a method. An external lubrication system is added on the basis of an existing transmission lubrication system. The external lubrication device comprises an external lubrication pump and an angle switch. The external lubrication pump is used as a power source of the external lubrication system. The angle switch is used as a control element. When a vehicle reaches the set slope value in the operation process, the external lubrication pump starts by itself, and normally-engaged gears, the third-gear gear and the fourth-gear gear of the transmission are spattered and lubricated through spray nozzles. When the gradient is smaller than the set value, the angle switch is turned off, and the transmission is lubricated through an internal lubrication system of the transmission. The external lubrication device is simple in structure, convenient to operate, high in reliability, capable of effectively solving the lubrication problem under the condition that a wide-body mining vehicle climbs a slope in a heavy-loaded manner, and capable of prolonging the service life of the transmission.

Owner:SINO TRUK JINAN POWER

Special continuous casting crystallizer protection slag for bloom type easy-cutting steel and preparation method thereof as well as bloom type easy-cutting steel continuous casting method

The invention relates to the technical field of steelmaking, and provides a special continuous casting crystallizer protection slag for bloom type easy-cutting steel. The protection slag comprises thefollowing components of, by weight, 27%-32% of CaO, 40%-43% of SiO2, 1%-4% of MgO, 3.5%-6% of Al2O3, 1%-4% of Na2O, 0.77%-4% of F-, 0.19%-1% of Li2O, 0.25%-1.47% of B2O3 and 8%-14% of C. The protection slag can solve the problems that the molten steel surface is prone to generate large slag strips, and the surface of a casting blank is not smooth in the continuous casting process of the easy-cutting steel. The invention further provides a method for preparing the protection slag by taking wollastonite, carbon-free soot, glass powder, fluorite, clinker, white alkali, carbon black, amorphous graphite, clay, lithium carbonate, borax, calcite, magnesia and bauxite as raw materials. The invention further provides a bloom type easy-cutting steel continuous casting method using the protection slag in the continuous casting process. The casting blank prepared by using the method is good in quality.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

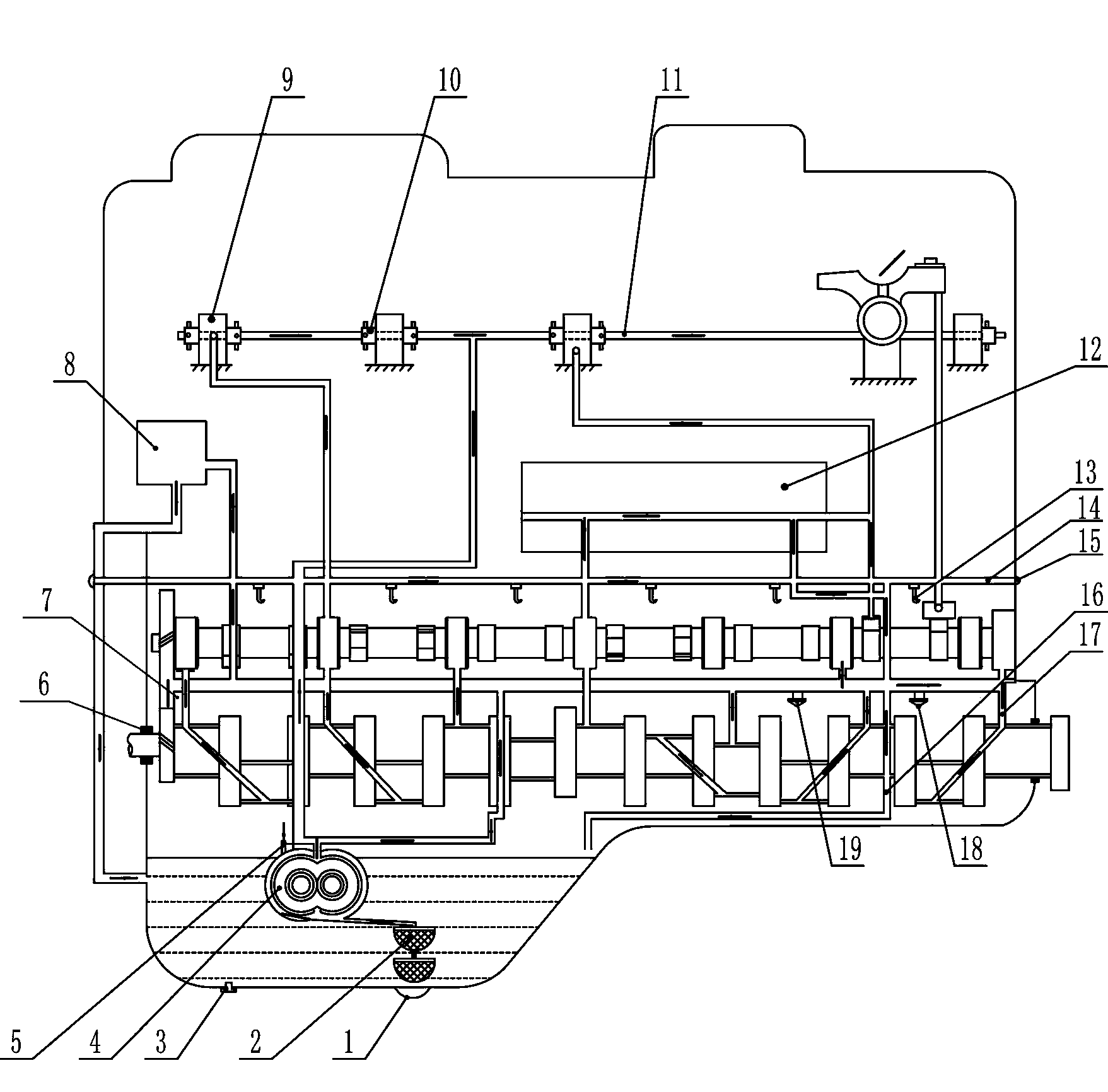

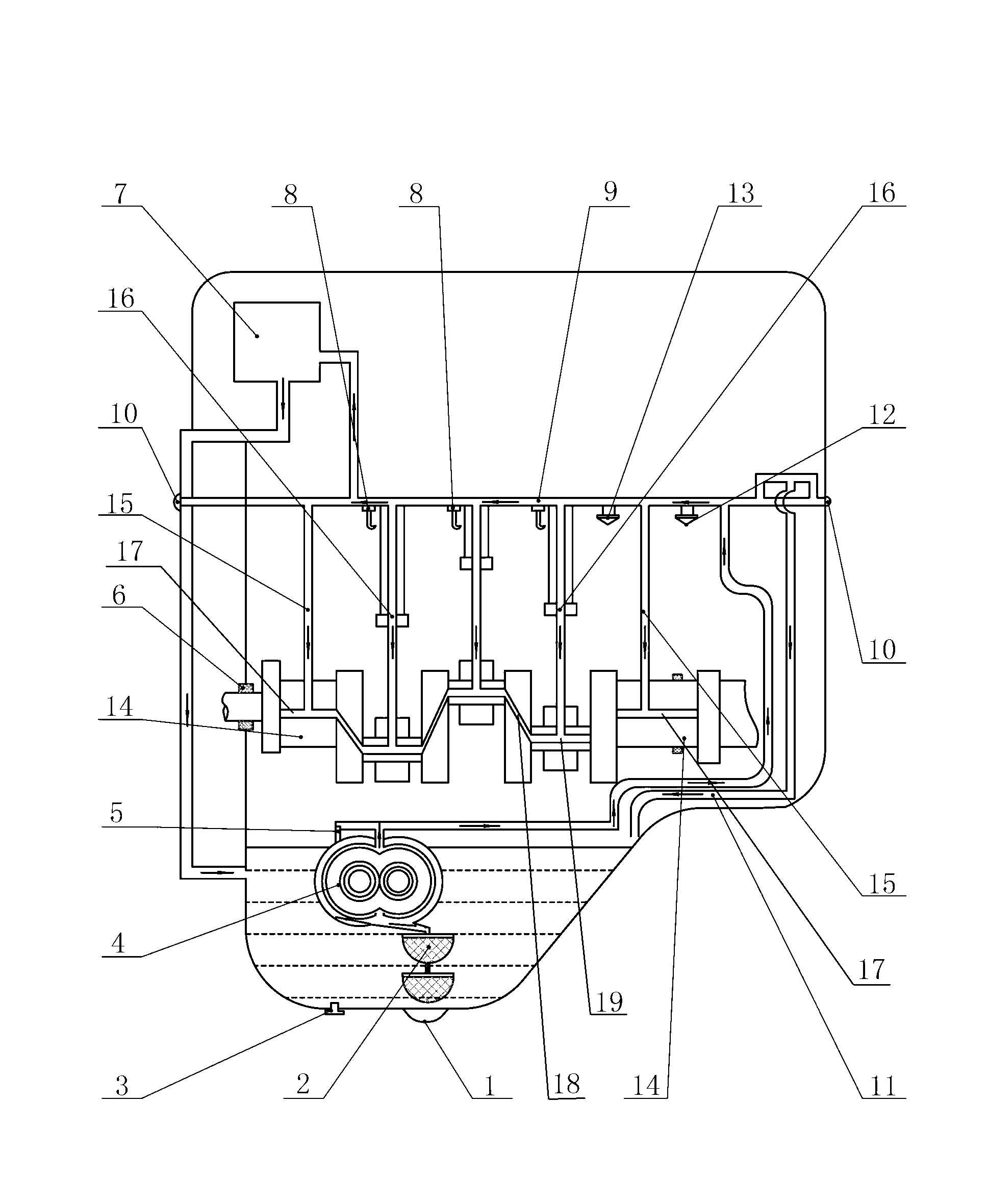

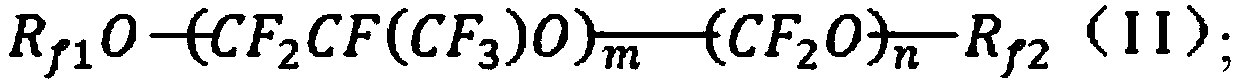

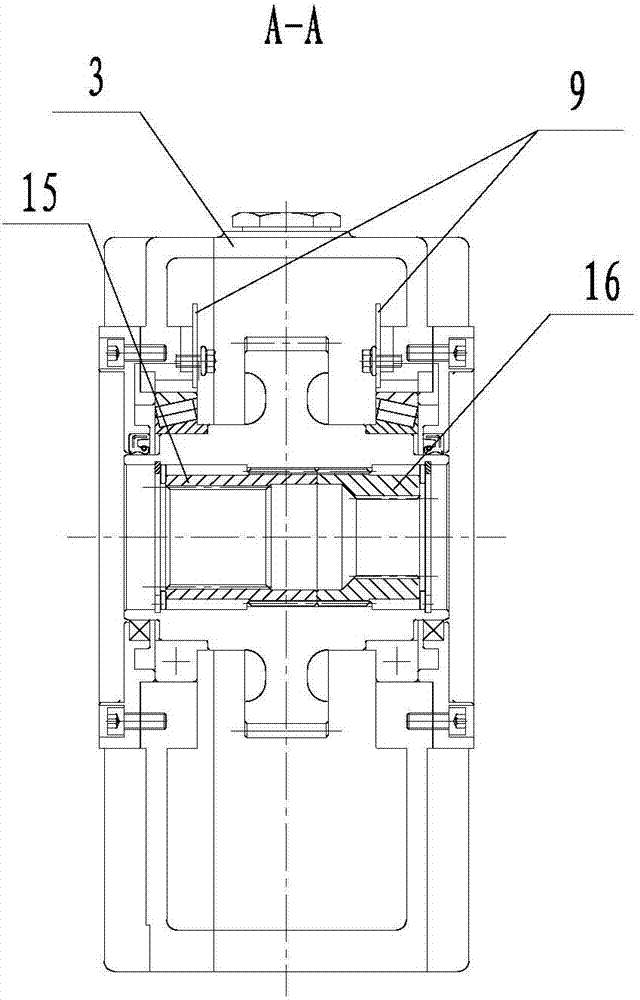

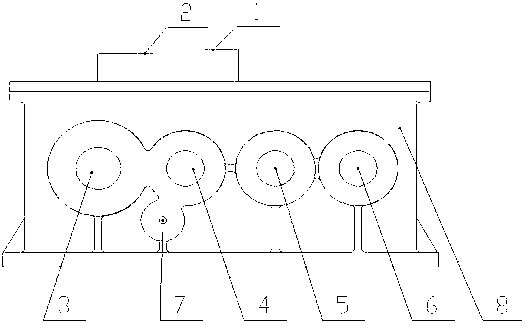

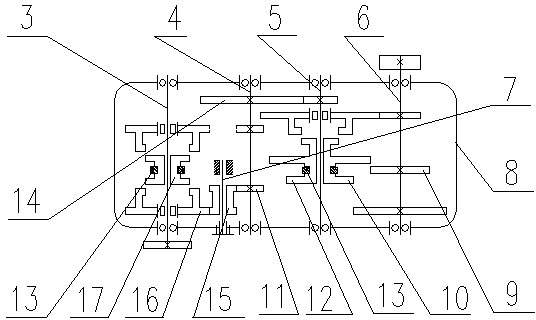

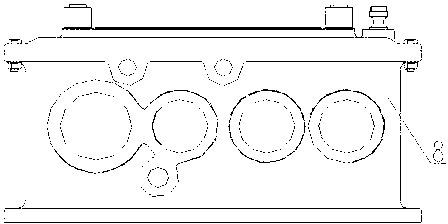

Lubricating oil path system of multi-cylinder aerodynamic engine

InactiveCN103206280AReasonable layoutImprove the lubrication effectDrip or splash lubricationMachines/enginesAir compressorImpurity

The invention discloses a lubricating oil path system of a multi-cylinder aerodynamic engine. The lubricating oil path system comprises a magnet suction filter (1), a suction filter (2), an oil pump (4), a relief valve (5), an air compressor (7), a main oil path (9), an oil return pipe (11), a journal lubricating oil path (15) and a connection rod lubricating oil path (16). The air compressor (7) in the lubricating oil path system is connected with the oil return pipe (11) in communication mode, and the other path is connected with the main oil path (9) in communication mode. Further, lubricating oil in an oil base casing is filtered to remove impurities through the suction filter (2) and the magnet suction filter (1). The lubricating oil path system of the multi-cylinder aerodynamic engine is reasonable in layout and good in lubricating effect.

Owner:LUCKSKY HLDG GRP

High-speed semicontinuous casting device and method of aluminum alloy cast ingot

The invention discloses a high-speed semicontinuous casting device of an aluminum alloy cast ingot, and belongs to the technical field of aluminum alloy casting. The device comprises a hot top, a crystallizer inner sleeve, a crystallizer outer sleeve, a cooling water cavity and a dummy bar head. A secondary cooling water cut-off device is arranged below the crystallizer inner sleeve, and a grease metering valve is arranged at an inlet of each oil conveying pipe below the crystallizer outer sleeve. A method comprises the steps that aluminum alloy melt is cast for semicontinuous casting, and lubricating oil is conveyed; (2) the semicontinuous casting speed is controlled to range from 200 mm / min to 400 mm / min, secondary cooling water is sprayed to the surface of the cast ingot, and the conveying amount of the lubricating oil is increased along with the casting speed; (3) the surface temperature of the cast ingot is detected; (4) the secondary cooling water cut-off device is controlled according to the surface temperature of the cast ingot; and (5) operation of the step (4) is repeated till casting is completed. According to the device and the method, the casting speed is greatly increased, the surface quality of the cast ingot is improved, the cast ingot has no casting defect, and the microstructure is uniform.

Owner:NORTHEASTERN UNIV

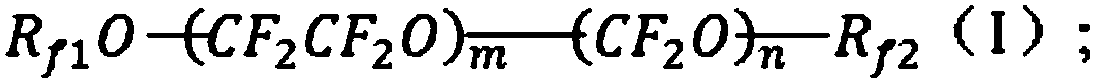

Perfluoropolyether lubricant and preparation method thereof

InactiveCN107653037ASolve lubrication problemsDoes not affect the colorLubricant compositionPerfluoropolyetherSolvent

The invention provides a perfluoropolyether lubricant and a preparation method thereof. The perfluoropolyether lubricant comprises, by weight, 2-15% of perfluoropolyether oil and 80-98% of a fluorine-containing solvent. The perfluoropolyether lubricant has the advantages of very simple formula, low cost, and easiness in industrial production; and the lubricant contains no solid lubricant components, so the lubricant is very suitable for lubricating the micro-electromechanical system.

Owner:CHINA PETROLEUM & CHEM CORP

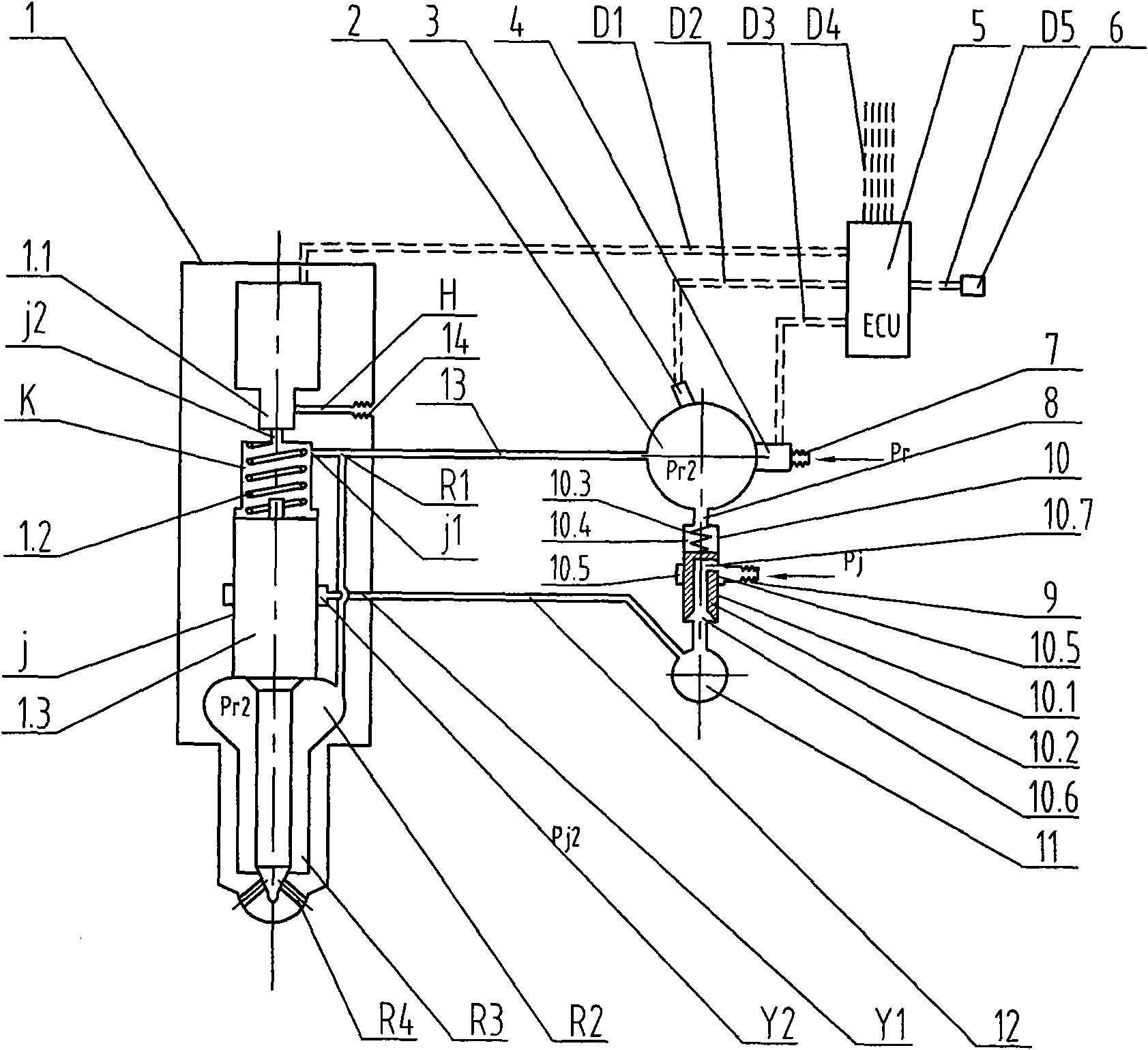

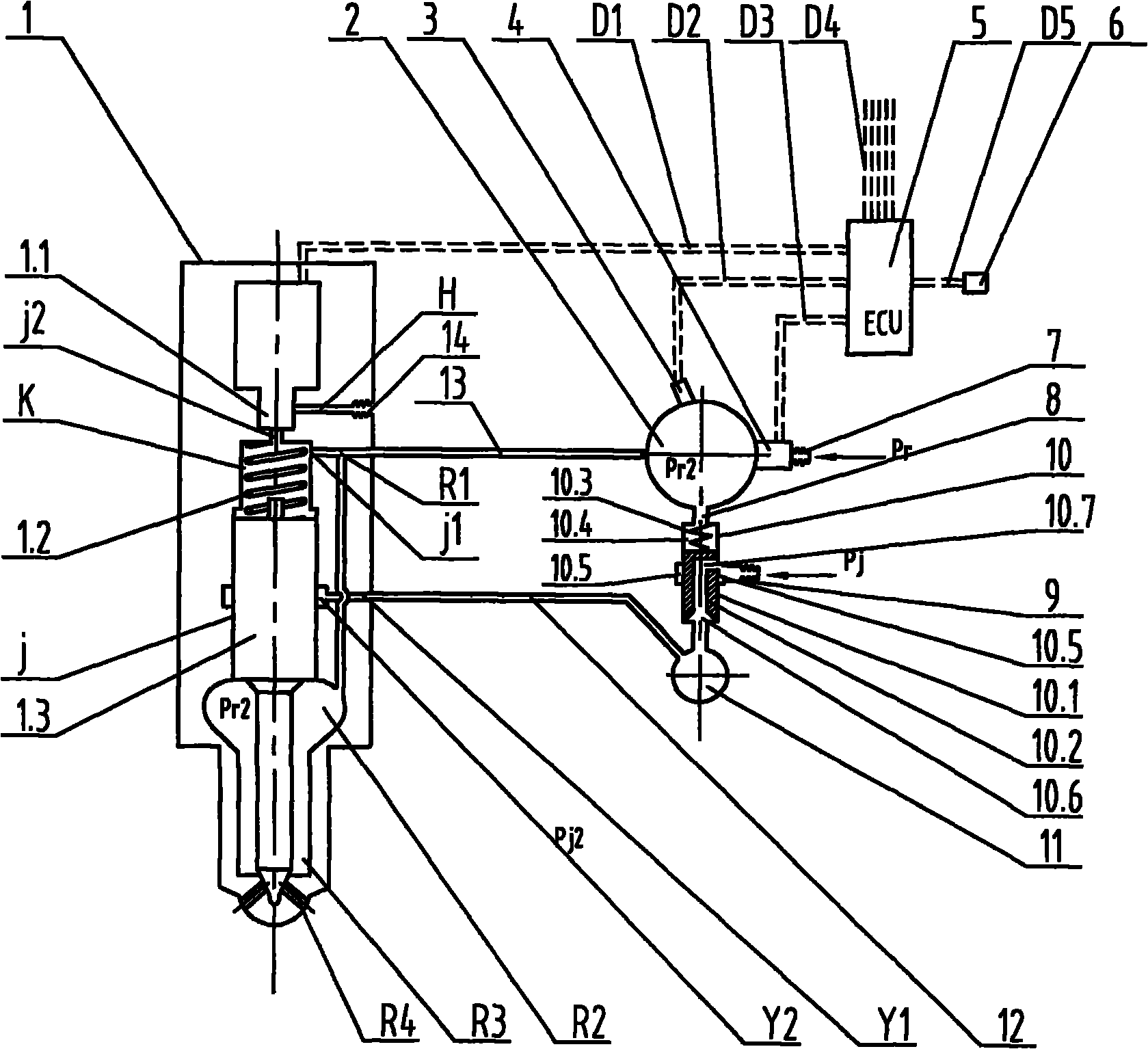

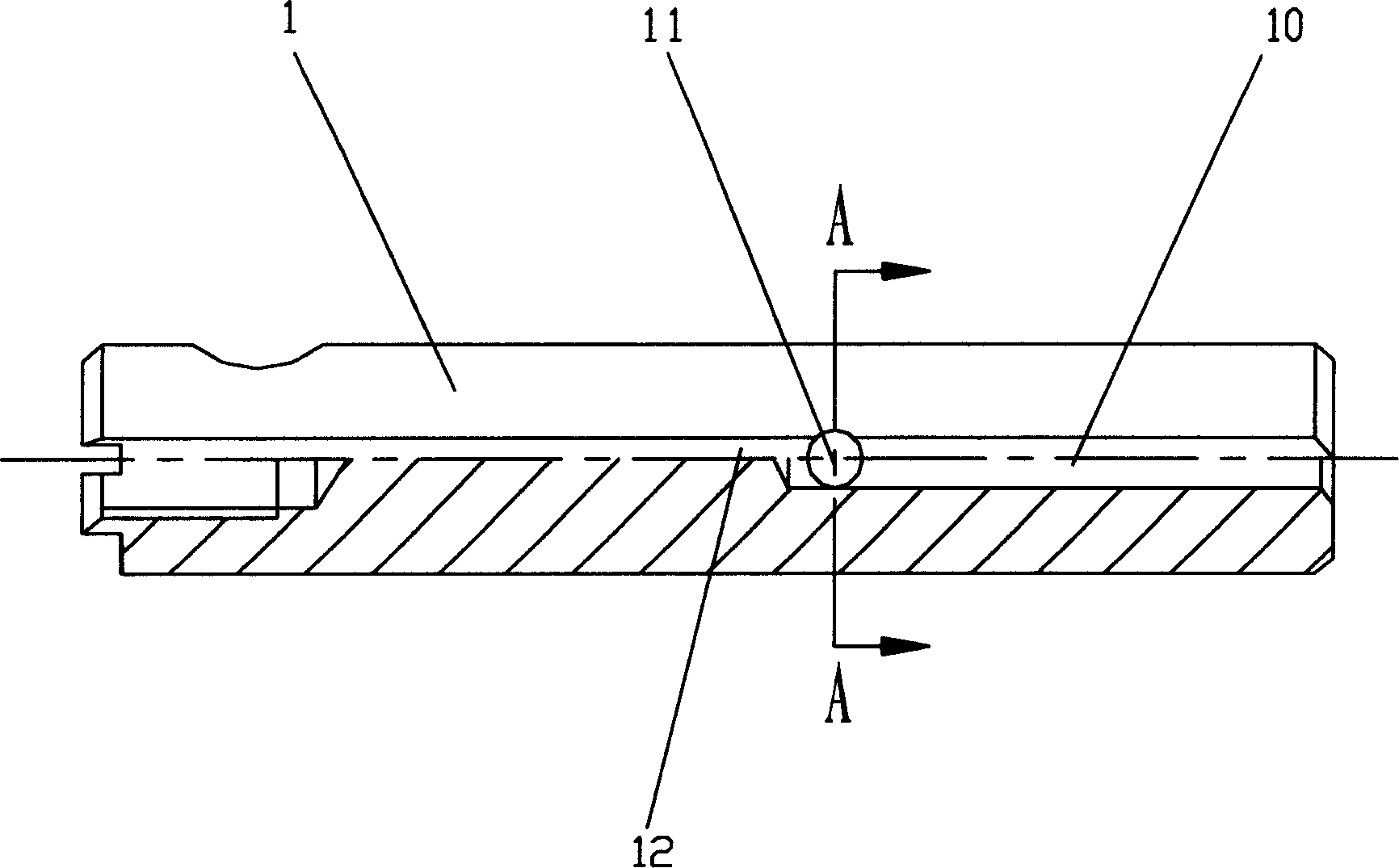

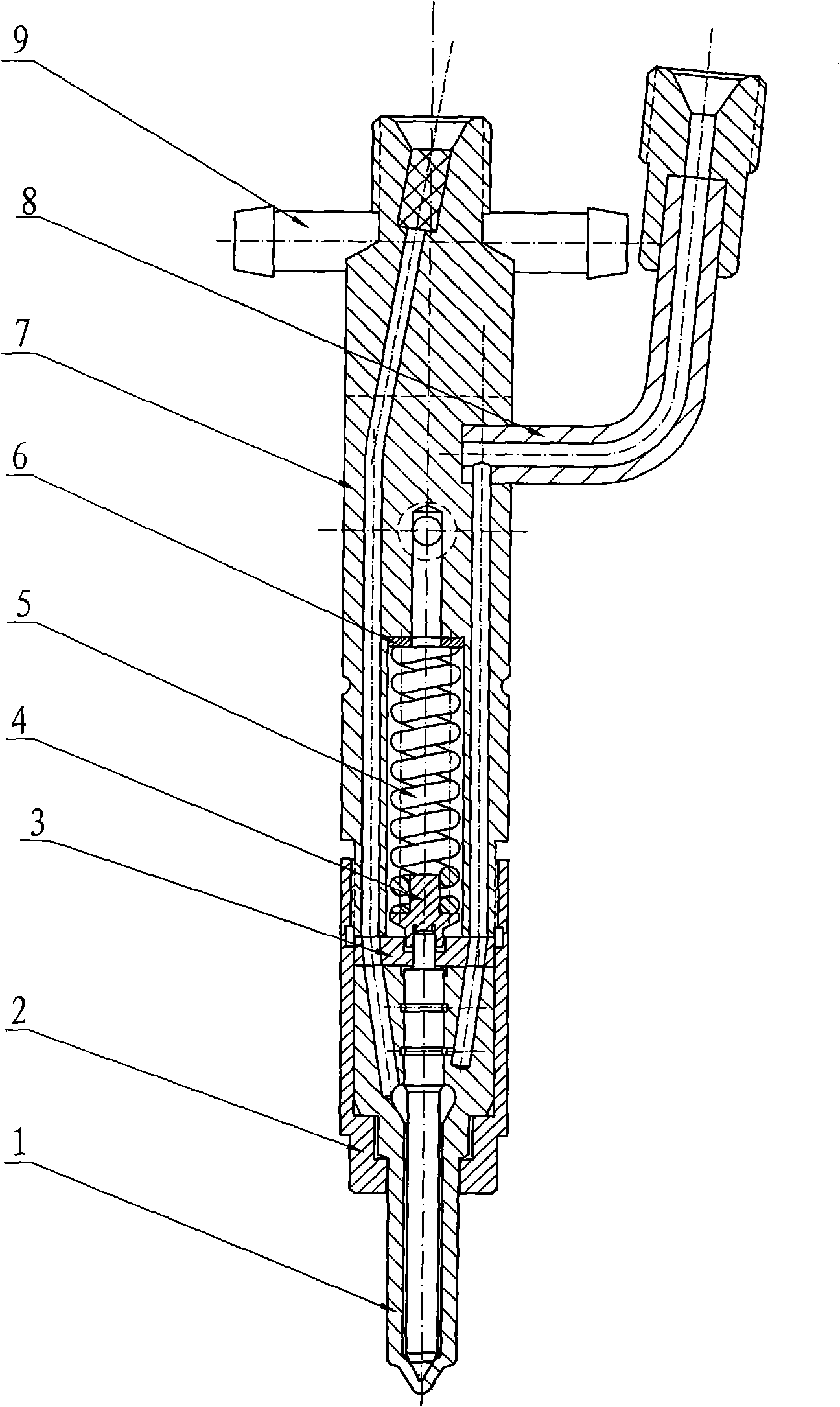

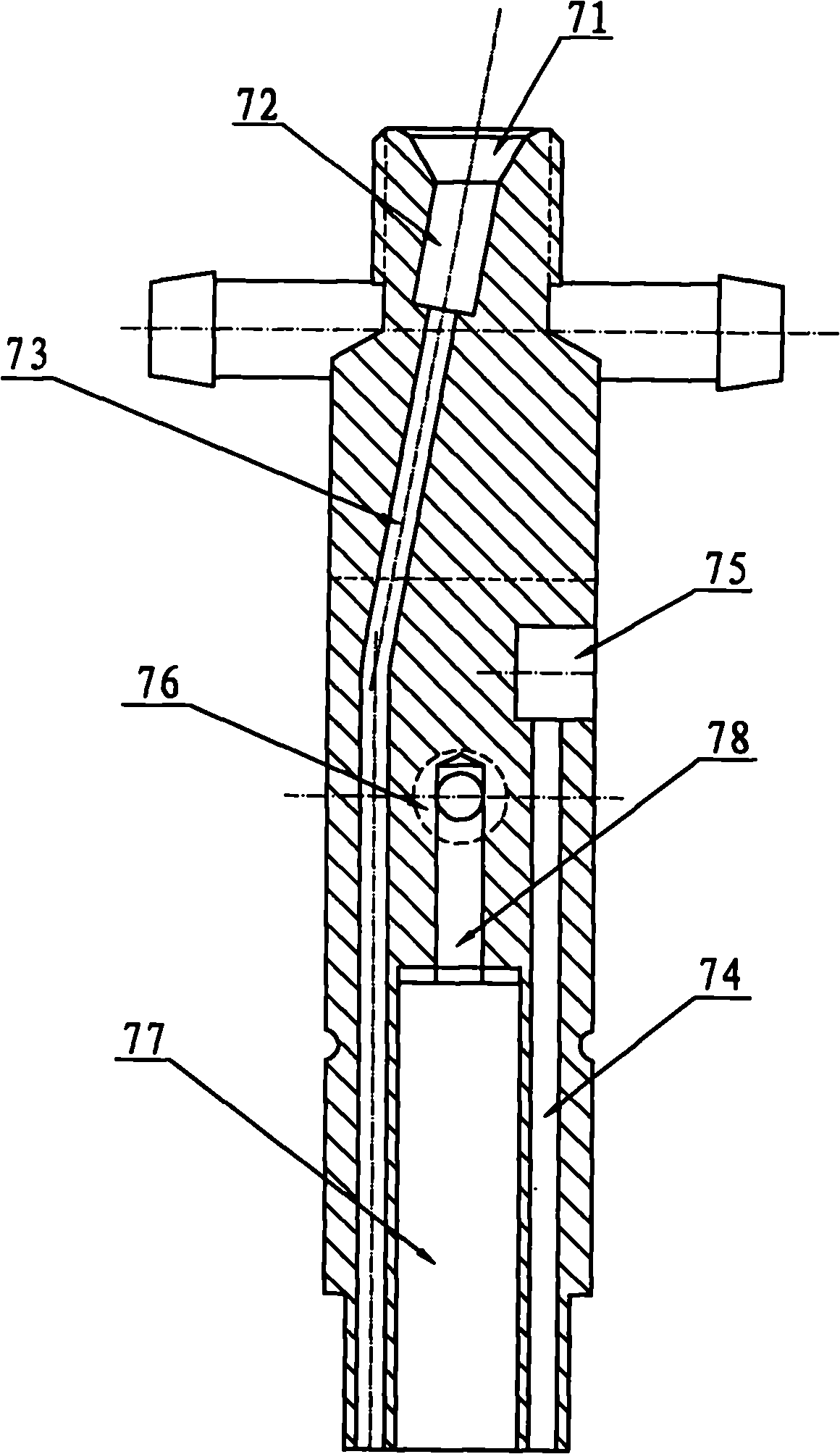

Electronic control high-pressure common rail fuel injecting device

InactiveCN101975130AAvoid wear and failureHigh working reliabilityElectrical controlFuel injection apparatusLubricationElectronic control unit

The invention discloses an electronic control high-pressure common rail fuel injecting device comprising an electronic control high-pressure common rail fuel injector, a high-pressure common rail, an electronic control unit (ECU), a fuel selector switch, a differential pressure control valve and a high-pressure lubricating oil rail. By using the selector switch and selecting and starting various fuel subprograms stored in the ECU by switching a signal input circuit of the fuel programs, the device solves the problems of the switching of various fuels for the electronic control high-pressure common rail fuel injector to combust and the matching and lubrication of a slidably-matched circular hole surface of the electronic control high-pressure common rail fuel injector and a needle valve; and the ECU controls the frequency of an electronic control two-way valve to be higher than 1KHz. The invention avoids the wear and the failure of the needle valve, improves the work reliability, can combust various fuels with different components, not only can accurately control the optimal start fuel injection time and pulse width of various fuels, but also can control the speed of the fuel and allow a diesel engine to obtain the minimum fuel consumption rate and emission pollution.

Owner:郑国璋

Air valve swinging arm shaft with oil pressure unloading plane

ActiveCN1648421AIncrease flow rateSolve lubrication problemsValve arrangementsMachines/enginesRocker armOil pressure

The rockshaft with oil pressure unloading plane has one axial oil path along the central axis and one radial oil path along the rockshaft, the axial oil path is connected to the radial oil path, and the outer surface of the rockshaft has one oil pressure unloading plane through the said radial oil path port. Therefore, the present invention solves the problem of lubricating the air valve rock arm and the rockshaft, the oil pressure unloading plane can raise lubricant oil flow speed to reach the aim of lowering the temperature of air valve rock arm and rockshaft.

Owner:CHONGQING ZONGSHEN ENGINE MFG

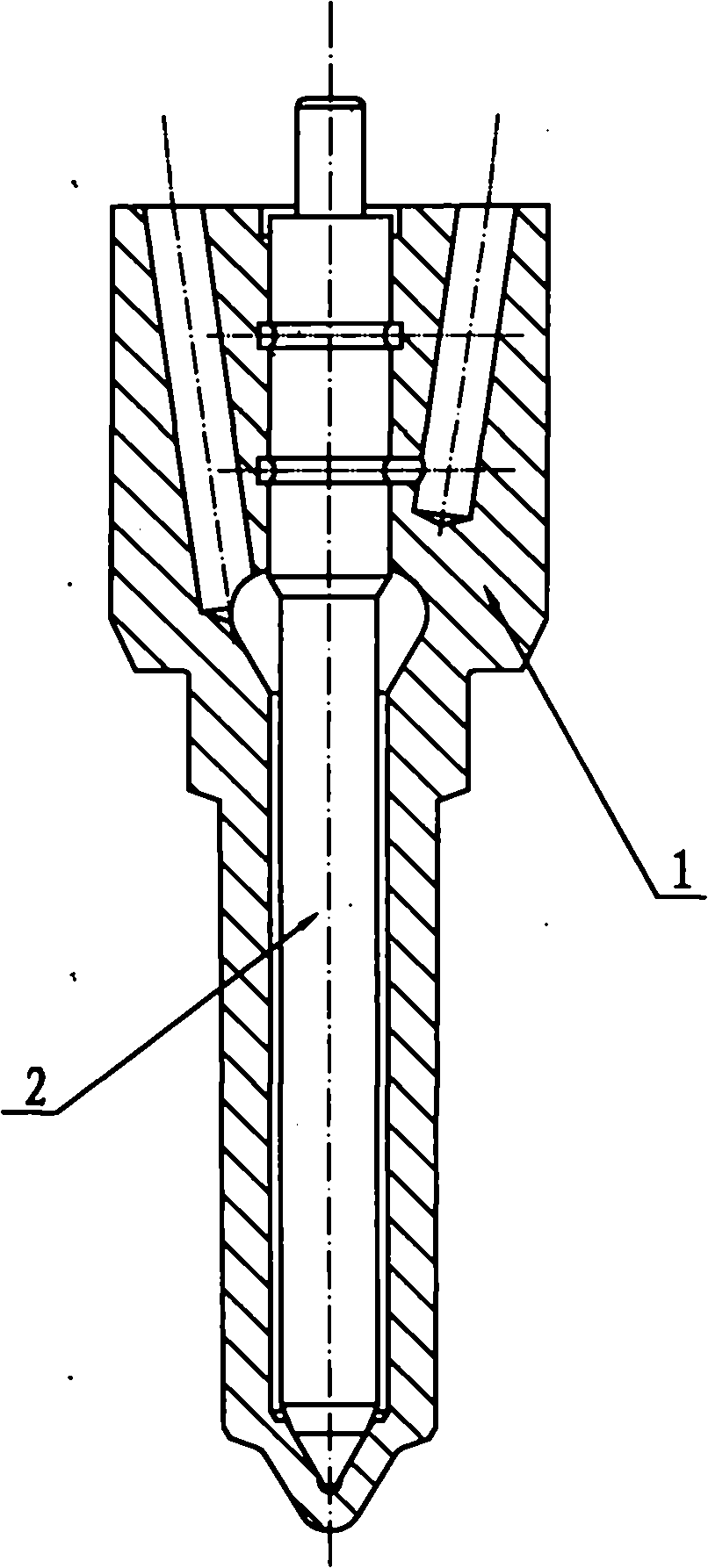

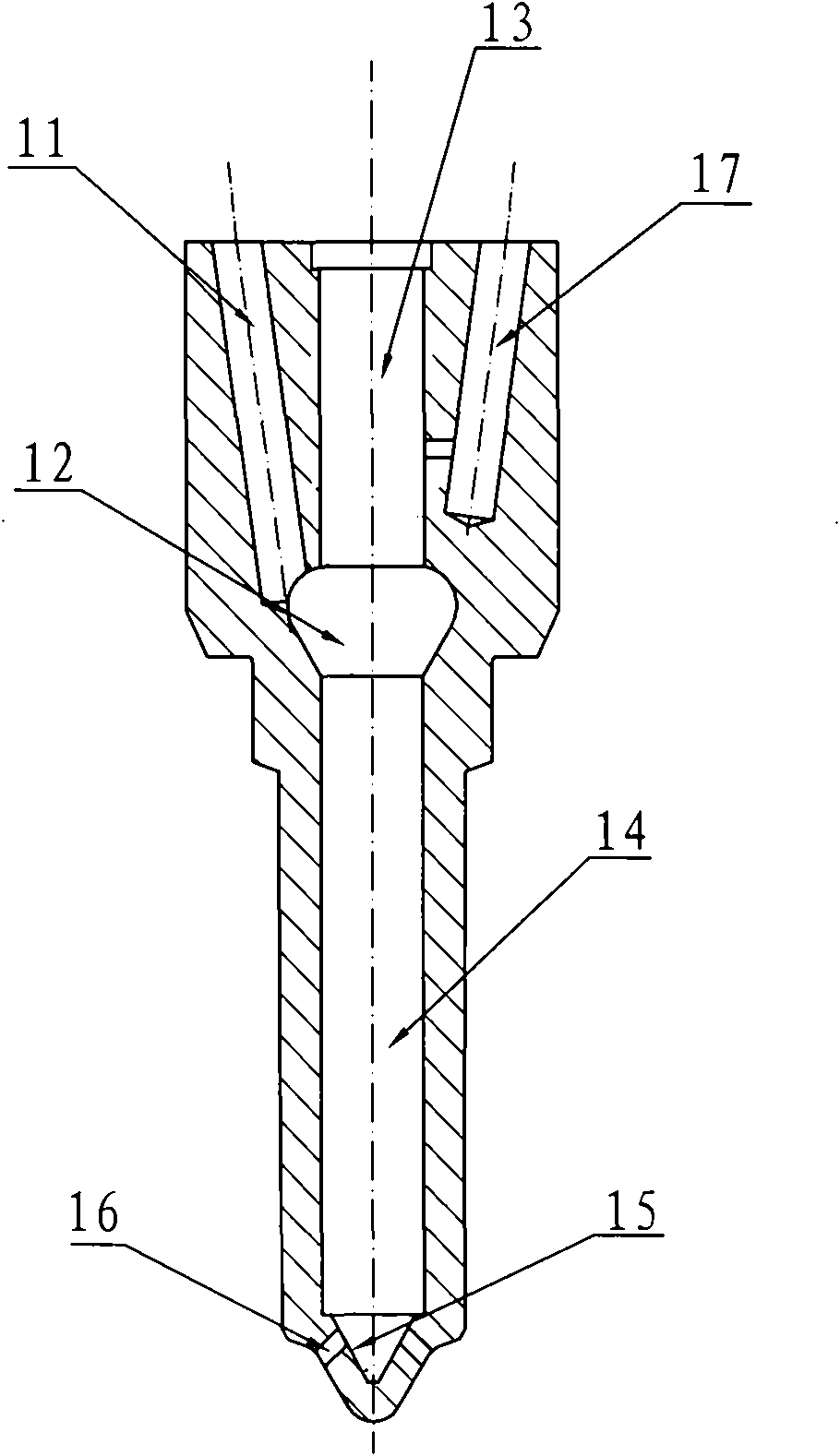

Diesel injector suitable for various fuels

InactiveCN101985911ASolve lubrication problemsPrevent bite phenomenonFuel injection apparatusMachines/enginesMultifuelDiesel injector

The invention relates to a diesel injector suitable for various fuels. The diesel injector comprises an injector couple, a couple fixing nut, a transition plate, a needle valve top seat, a spring, a pressure adjustment plate and an injector body, wherein the injector body, the transition plate and the needle valve body are provided with liquid fuel channels and lubricating oil channels; the lubricating oil channels are used to provide lubricating oil for the needle valve and the guide fitting surface of the needle valve body; by arranging the transition plate, the processing difficulties of the fuel channels and the lubricating oil channels are improved and the integral structure becomes more compact; as an oil-storing groove is arranged on the guide section of the needle valve, the axial length of the oil-storing groove between the needle valve and the needle valve body is increased, the lubrication effect of the two parts is optimized, the processing technology of forced lubrication is simplified and the processing cost is reduced; the oil-storing groove is suitable for the injection of organic fuels such as dimethyl ether, methanol and ethanol; the blocking phenomenon between the needle valve and the needle valve body can not be caused by the lack of lubricating oil; and the diesel injector has the same appearance and mounting dimension of the existing P-type injector, thus the diesel injector is more beneficial for popularization.

Owner:CHANGZHOU YITONG FUEL EJECTOR MFG

High-speed deep groove ball bearing

ActiveCN108361275AImprove high-speed lubrication performanceOvercome stress concentrationBall bearingsBearing componentsBurning outLubrication

The invention provides a high-speed deep groove ball bearing belonging to deep groove ball bearings. The high-speed deep groove ball bearing is a deep groove ball bearing for supporting high-speed drive motor rotors in industrial engineering and transportation. According to the technical scheme, the value of the radiuses R of channel arcs / the diameter Dw of a steel ball ranges from 0.53 to 0.56, the two ends of connecting arcs are tangent to channels and flanges, a vertical line at the inner end of a sealing ring peripheral protrusion penetrates a retainer, and the protrusion is in seal fit with the outer-ring flange to form a groove. The technical problems that quantitative research on internal dimensions in existing bearing design is lacked, so that lubrication of rotary supporting bearings of existing drive motor high-speed rotary rotors fails, energy consumption is improved, and then the bearings are burnt out are solved.

Owner:蚌埠市昊德汽车轴承有限责任公司

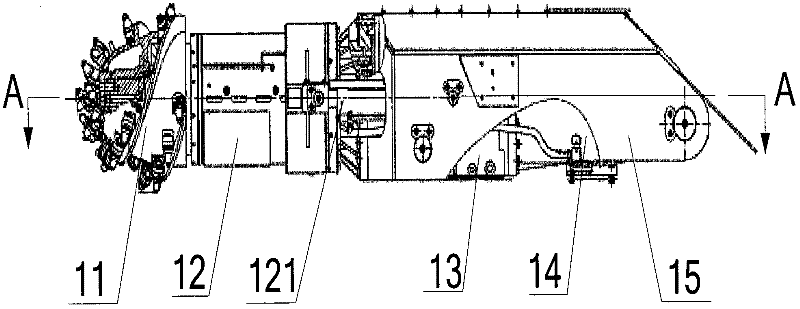

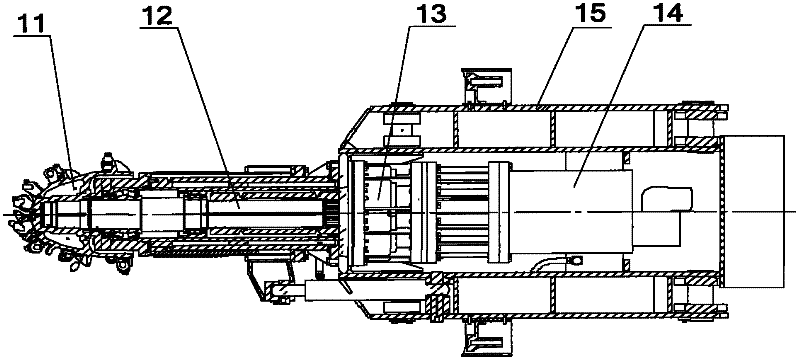

Power variable speed roadheader

InactiveCN102268991AImprove productivity and safetySolve lubrication problemsGear lubrication/coolingDriving meansLubrication ProblemCoal

The invention provides a power speed change heading machine. The power speed change heading machine comprises a cutting part, a shovel plate part, a machine body part, walking parts, a supporting part and a transport part. The cutting part is installed in the upper front part of the machine body part. The shovel plate part is installed in the lower front part of the machine body part. The supporting part is installed in the rear of the machine body part. The walking parts are installed respectively in the lower parts of two sides of the machine body part. The transport part is installed in the machine body part. The cutting part comprises a cutting head, a telescoping part, a power variable-speed motor, a cutting motor and an attachment bracket. The power speed change heading machine can realize power shift transmission without machine halt at anytime according to coal rock hardness change, maximize production efficiency and safety, solve lubrication problems of the power variable-speed motor when the power variable-speed motor swings in the cutting part of the power speed change heading machine and specially swings vertically, and realize an instant speed change function without machine halt.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

Power takeoff gearbox casing in direct connection with hydraulic pump, and power takeoff gearbox

InactiveCN106969133AAvoid excessive churningReduce stirring oil heatGearboxesGear lubrication/coolingBreatherGear wheel

The invention discloses a power take-off gearbox casing and a power take-off gearbox directly connected to a hydraulic pump, which solve the problems of excessive oil stirring and high oil temperature of the gears in the prior art, and solve the problems caused by the excessive stirring of the gears. It solves the problem of heat dissipation caused by oil and solves the problem of lubrication of multiple bearings. The scheme is as follows: a power take-off gearbox casing directly connected to a hydraulic pump comprises that the power take-off gearbox casing is sequentially divided into a ventilation cavity, a main cavity, a first oil storage cavity and a second oil storage cavity through inner ribs, Oil passages are respectively provided between the main cavity and the two oil storage cavities, the ventilation cavity is isolated from the main cavity, and a first oil collecting pool is arranged above the position between the first bearing and the second bearing in the main cavity, and the third A second oil collecting pool is arranged above the bearing.

Owner:泰安航天特种车有限公司

Integral gearbox of road roller

InactiveCN102797802AReduce volumeIncrease chance of bindingGear lubrication/coolingToothed gearingsDrive shaftGear wheel

Owner:洛阳信全源机械设备有限公司

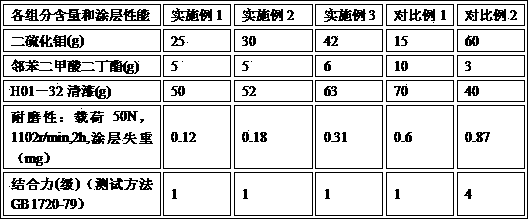

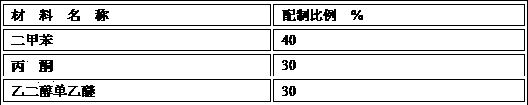

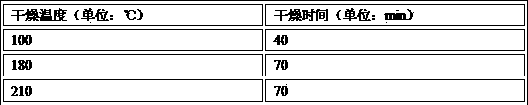

Dry film lubricant coating composition and preparing method thereof

ActiveCN103421412AGood lubricityReduce coefficient of frictionAdditivesEpoxy resin coatingsDi n butyl phthalateOrganosilicon

The invention provides dry film lubricant coating composition and a preparing method of the dry film lubricant coating composition. The dry film lubricant coating composition has a good lubricating property, high abrasive resistance and strong binding force and can meet the requirements for being used for coating of the surface of a transportation assembly with the rotating speed of up to 10000 RPM. According to the technical scheme, the dry film lubricant coating composition comprises, by weight, H01-32 varnish 43%-53%, molybdenum disulfide 23%-33%, dibutyl phthalate 4%-6% and organosilicon coating diluents X-13 13%-24%, wherein the grain diameter of the molybdenum disulfide is smaller than 2 microns. The preparing method of the dry film lubricant coating composition comprises the following steps: roasting the molybdenum disulfide at 300+ / -10 DEG C for 3-4 hours, adding the molybdenum disulfide into a steel drum loaded with the diluents X-13 after the molybdenum disulfide is processed and cooled, mixing well, shocking the mixture in an ultrasonic cleaner loaded with water for 5-10 minutes, then adding the dibutyl phthalate and the H01-32 varnish into the organosilicon coating diluents X-13, mixing well, shocking the mixture in the ultrasonic cleaner, and finally adding the solution into a roller ball grinder loaded with stainless steel beads to be made into the pasty coating composition.

Owner:PLA NO 5719 FACTORY

Water-cooled bearing seat of fine crusher

InactiveCN104047964ASolve lubrication problemsAvoid overall overheatingGrain treatmentsBearing coolingEngineeringCrusher

The invention relates to a bearing seat, and in particular relates to a water-cooled bearing seat of a fine crusher; the water-cooled bearing seat comprises a bearing seat body and a bearing seat end cover, wherein the bearing seat body of the bearing seat is respectively provided with a water jacket and a lubrication oil hole, the bearing seat end cover is provided with a water inlet interface and a water outlet interface which are communicated with the water jacket; the water jacket is an annular water jacket, a plurality of openings are evenly and circumferentially distributed on an end face of an outer side of the bearing seat body, the plurality of openings are respectively communicated with the water jacket, any two of the openings are respectively communicated with the water inlet interface and the water outlet interface, the lubrication oil hole is arranged along the radial direction of the bearing seat body, and the axial center line of the lubrication oil hole is perpendicular to the axial center line of the bearing seat. The water-cooled bearing seat is designed into a water-cooled bearing seat with a water jacket structure, a strong lubrication structure of bearing seats in the prior art can be maintained, and the problems of bearing lubrication and bearing overheating both can be solved.

Owner:DANDONG TIANHE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com