Integrated semi-direct drive wind generator transmission chain and gearbox for same

A wind turbine and drive chain technology, which is applied to wind turbine components, wind engines, wind power generation, etc., can solve the problems of high-power wind turbines, short axial length, and small installation space, and achieve simple structure and high efficiency. Effects of performance, lifetime, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

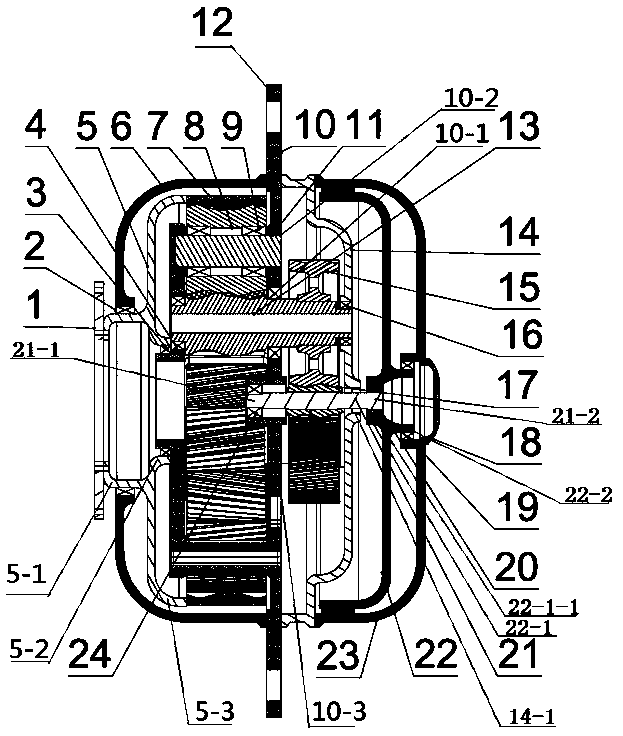

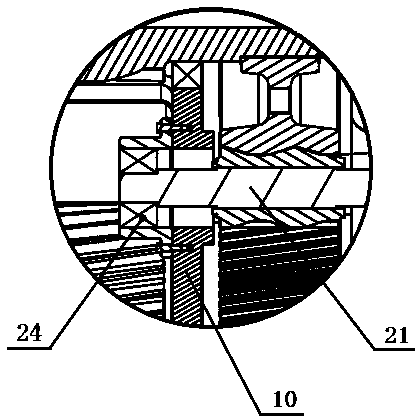

[0043] An integrated semi-direct drive wind power generator transmission chain of this embodiment, such as figure 1 As shown, there are a front box body 6, a rear box body 14, a main shaft 5, and a planet carrier 10. The planet carrier 10 is arranged between the front box body 6 and the rear box body 14. The planet carrier 10 is provided with a front box body 6 And the torsion arm 12 outside the rear box 14; the main shaft 5 includes the main shaft upwind end 5-1, the main shaft downwind end small diameter part 5-2 and the main shaft downwind end large diameter part 5-3;

[0044] The upwind end 5-1 of the main shaft is supported on the inner hole of the front case 6 through the upwind bearing 2 of the main shaft; the small diameter part 5-2 of the downwind end of the main shaft is supported on the planet carrier 10 through the downwind bearing 3 of the main shaft; the downwind direction of the main shaft The end large diameter portion 5-3 is fixedly connected with the inner gear r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com