Patents

Literature

60results about How to "Reduce the possibility of misalignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

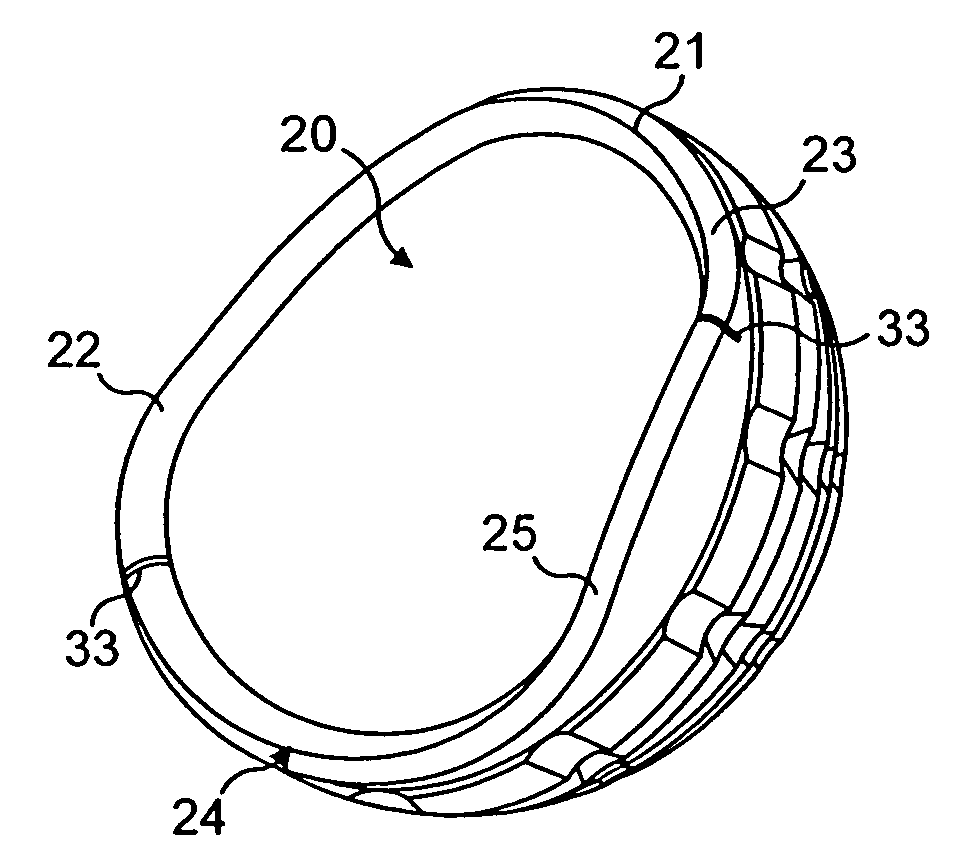

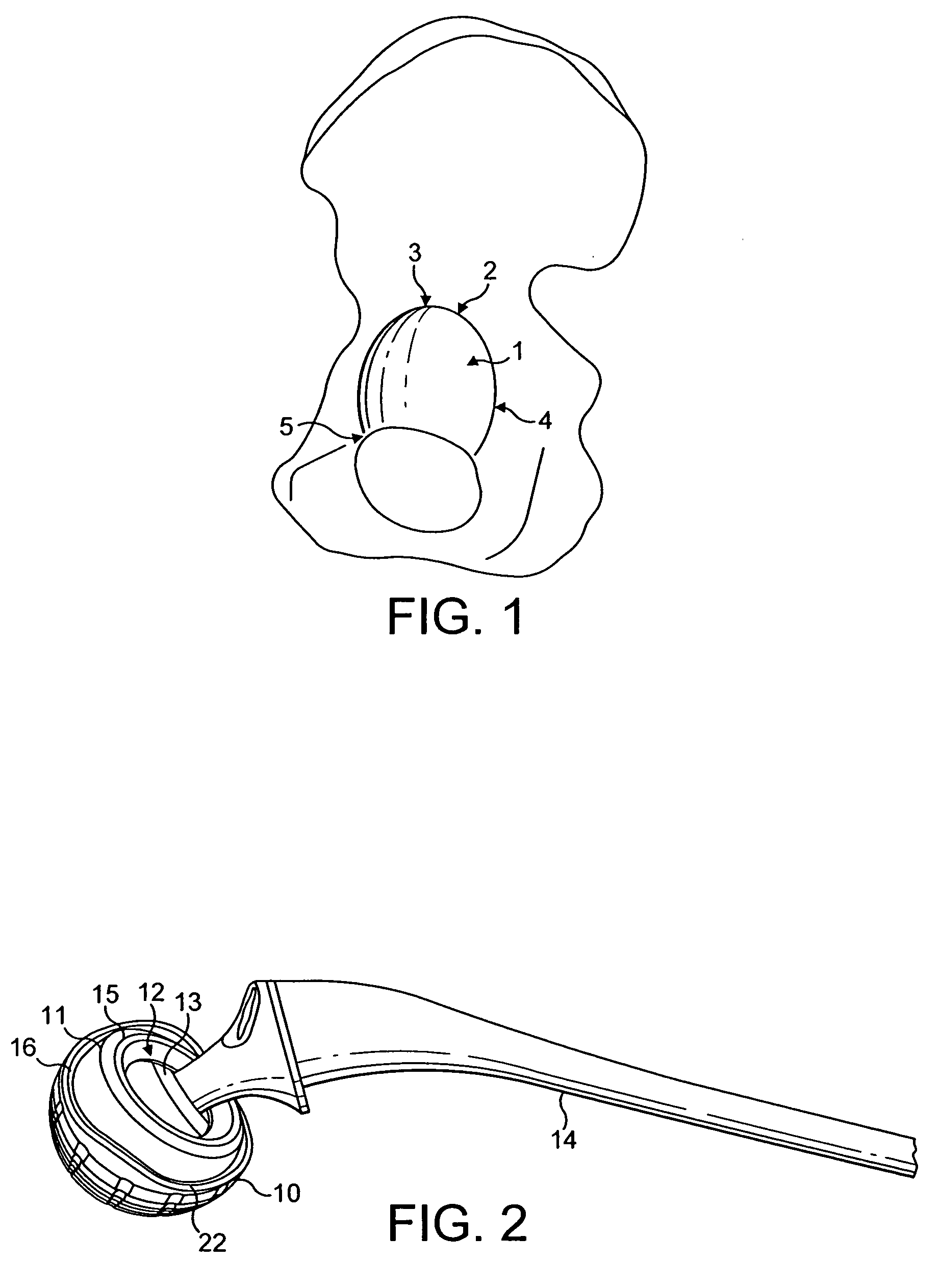

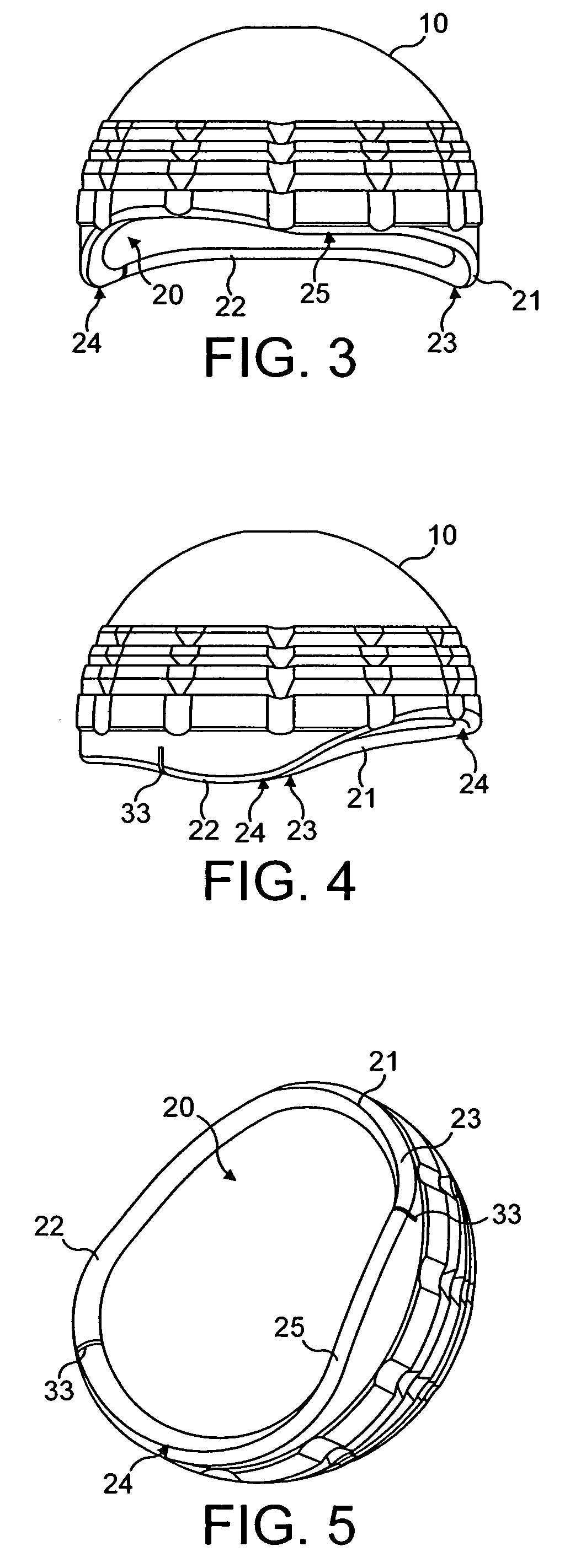

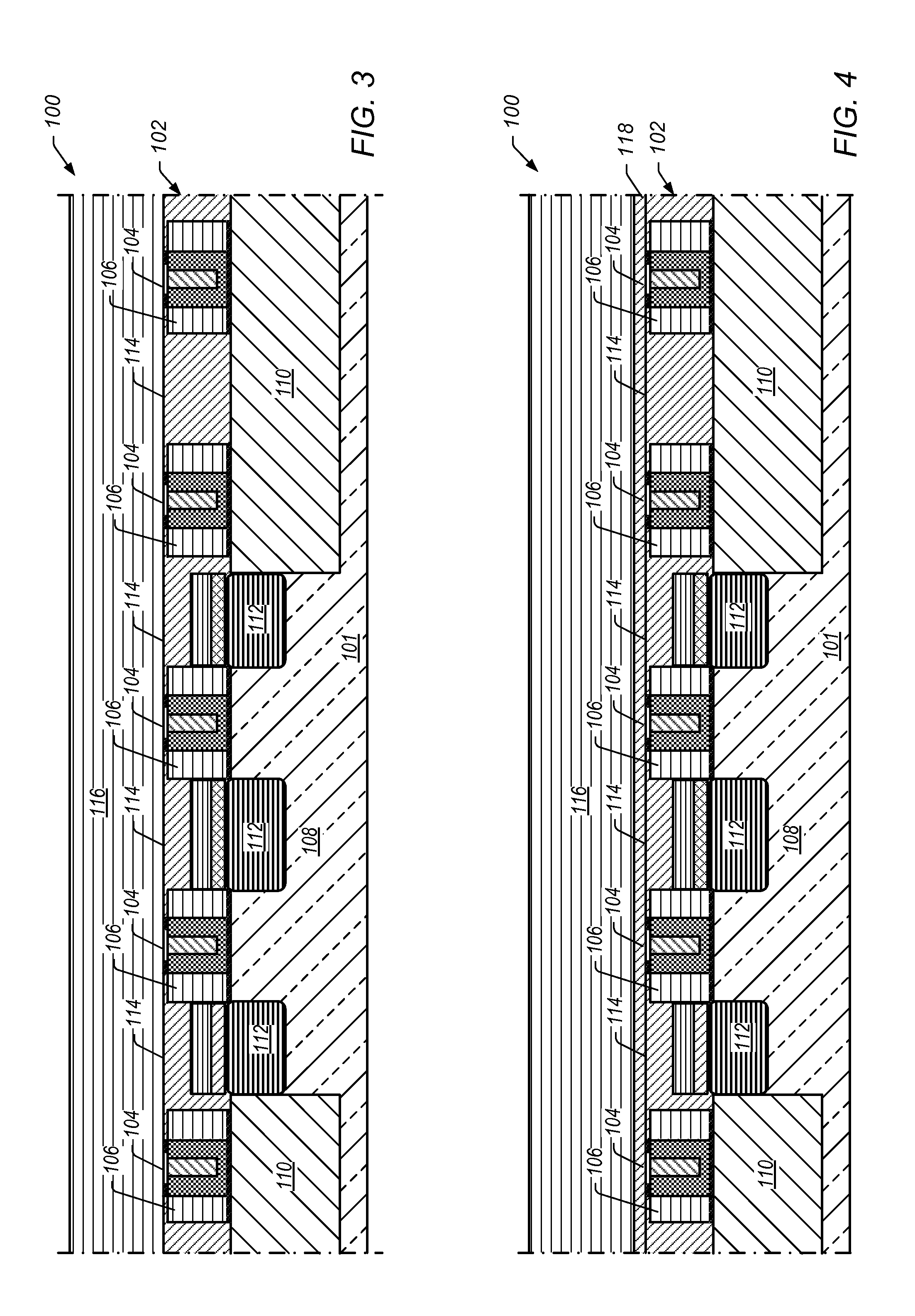

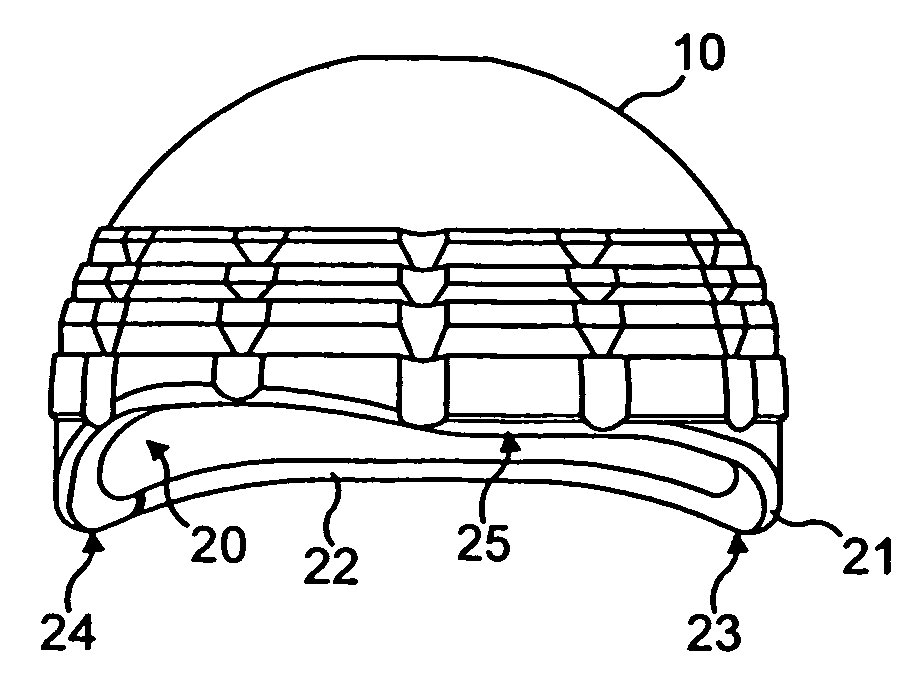

Prosthetic acetabular cup and prosthetic femoral joint incorporating such a cup

ActiveUS20050060040A1Natural angular movementReduce the possibility of misalignmentInternal osteosythesisJoint implantsSpherical bearingProsthesis

An acetabular prosthesis having an outer member for engaging the acetabulum. The outer member has a part-spherical bearing surface terminating in a distal rim. The rim has a contour such that the portion thereof to be located between the ischium and the pubis extends distally further from an equator of the bearing surface than the contour to be implanted between the pubis and the illium and between the ischium and the illium.

Owner:STRYKER EURO OPERATIONS HLDG LLC

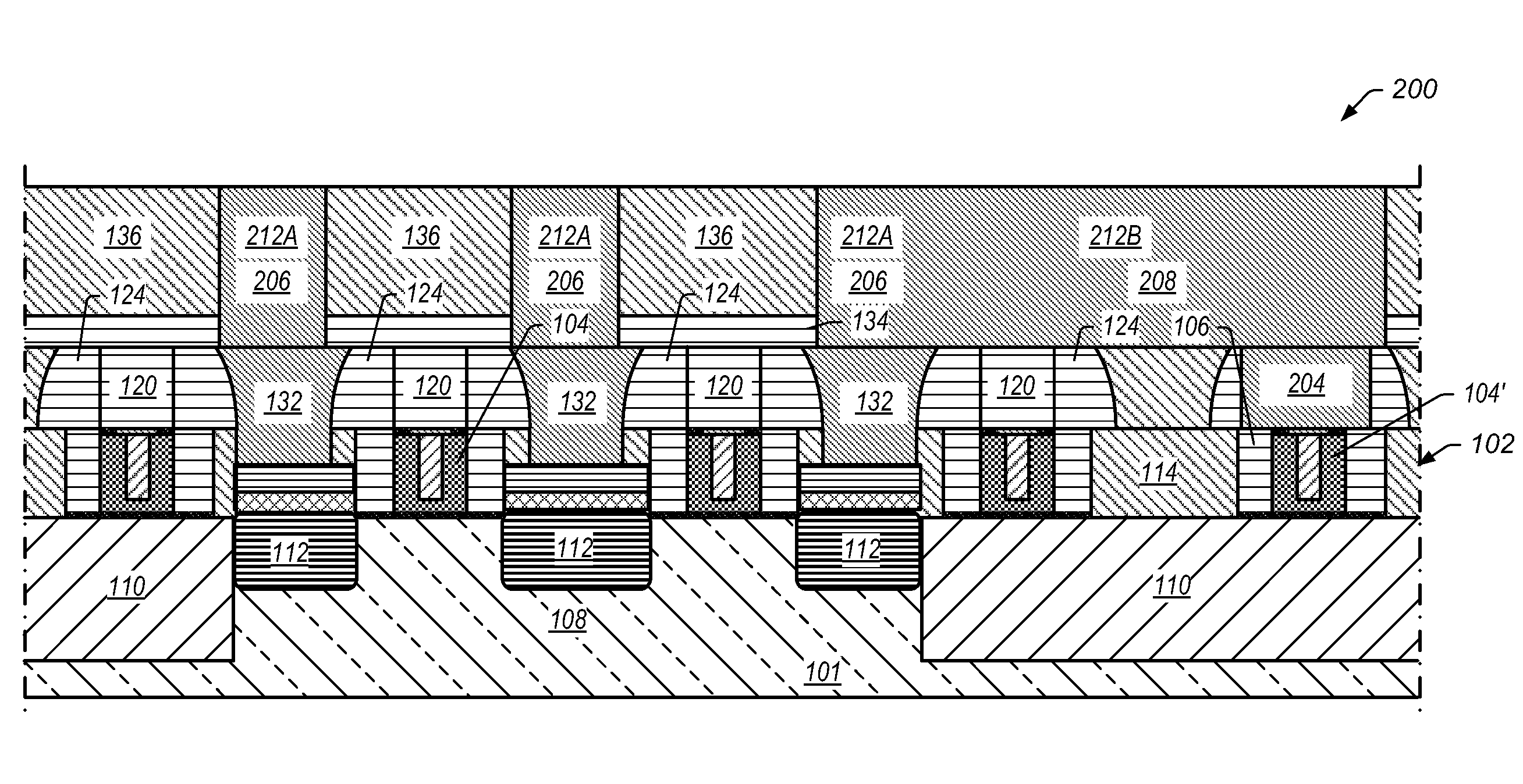

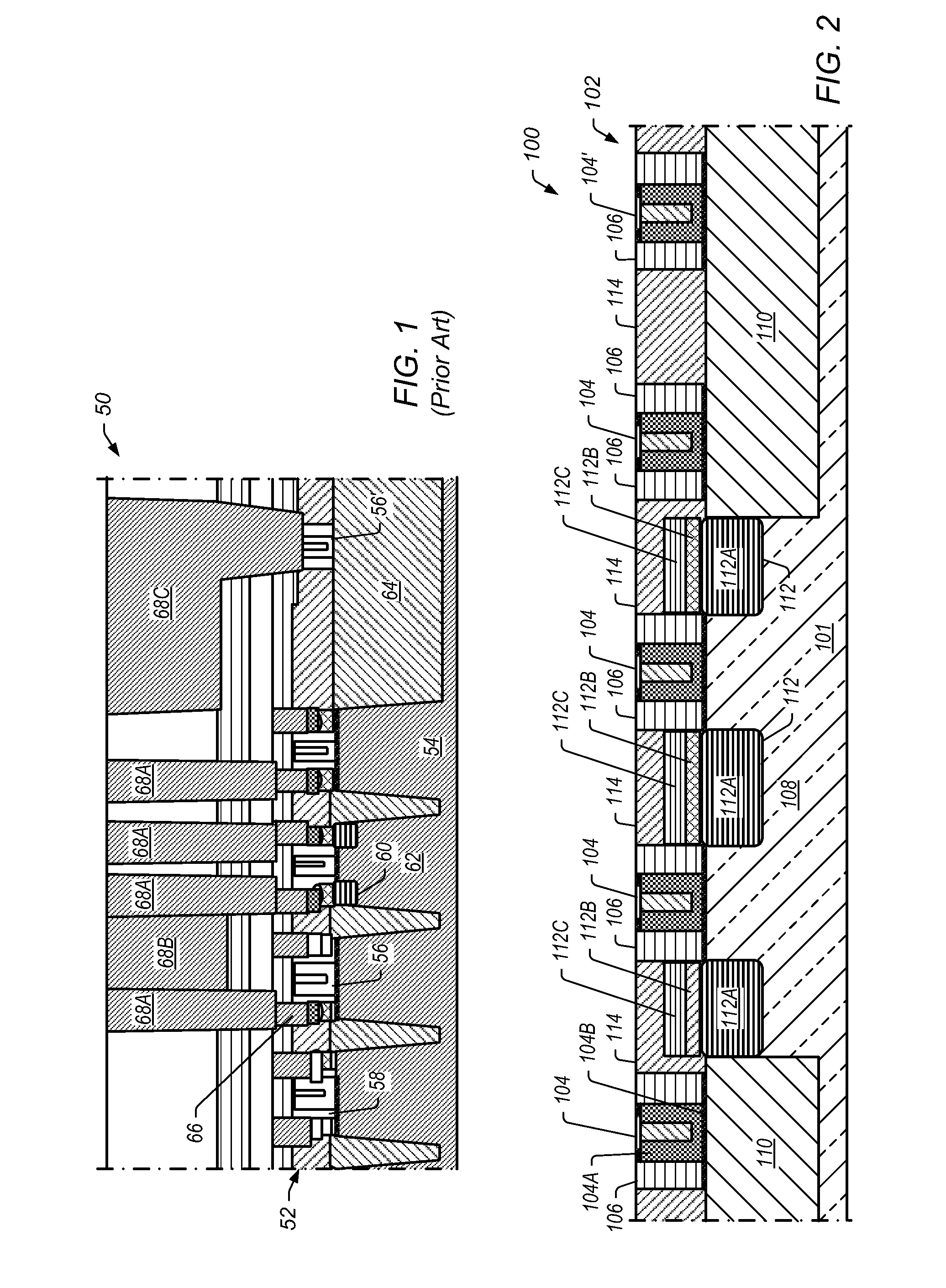

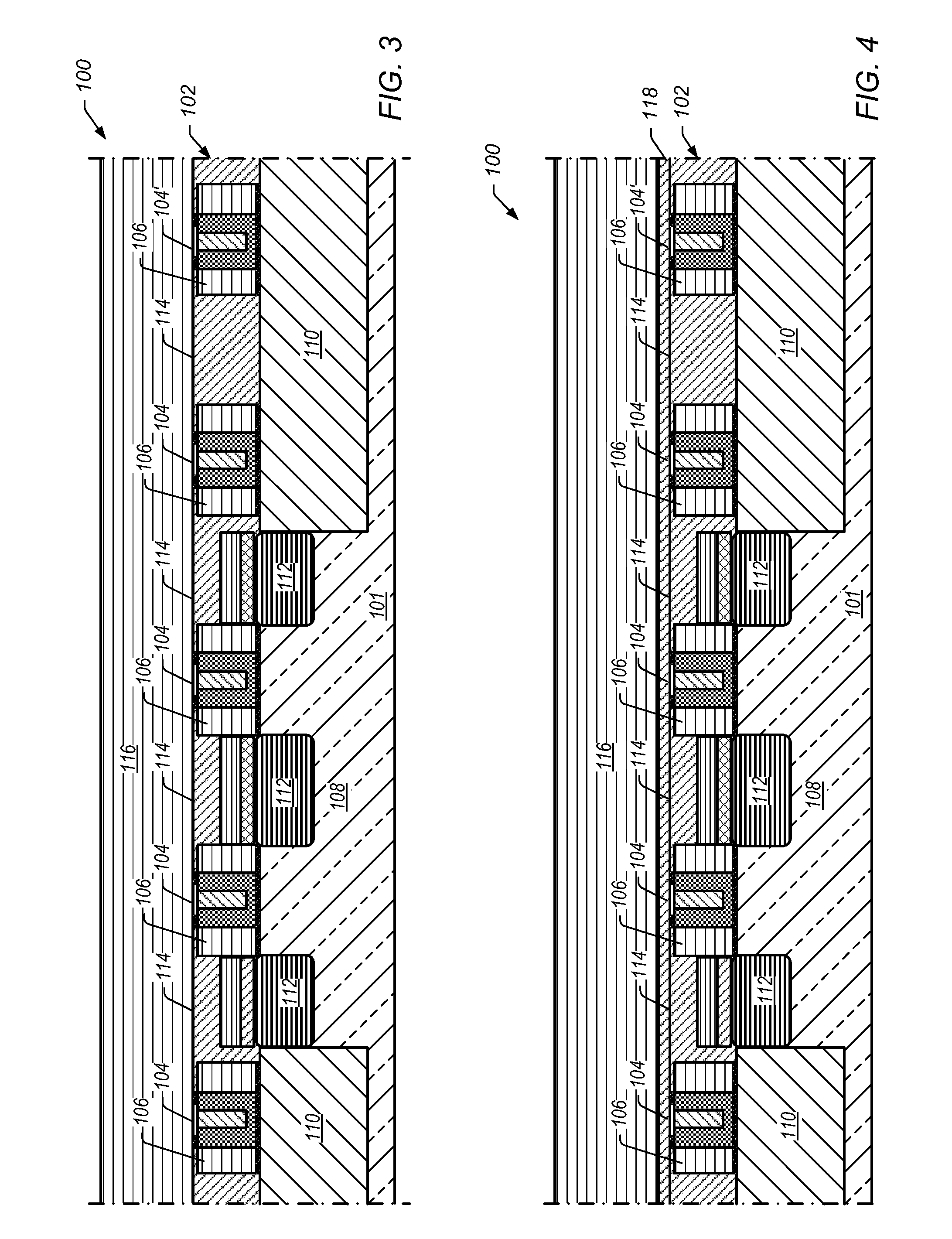

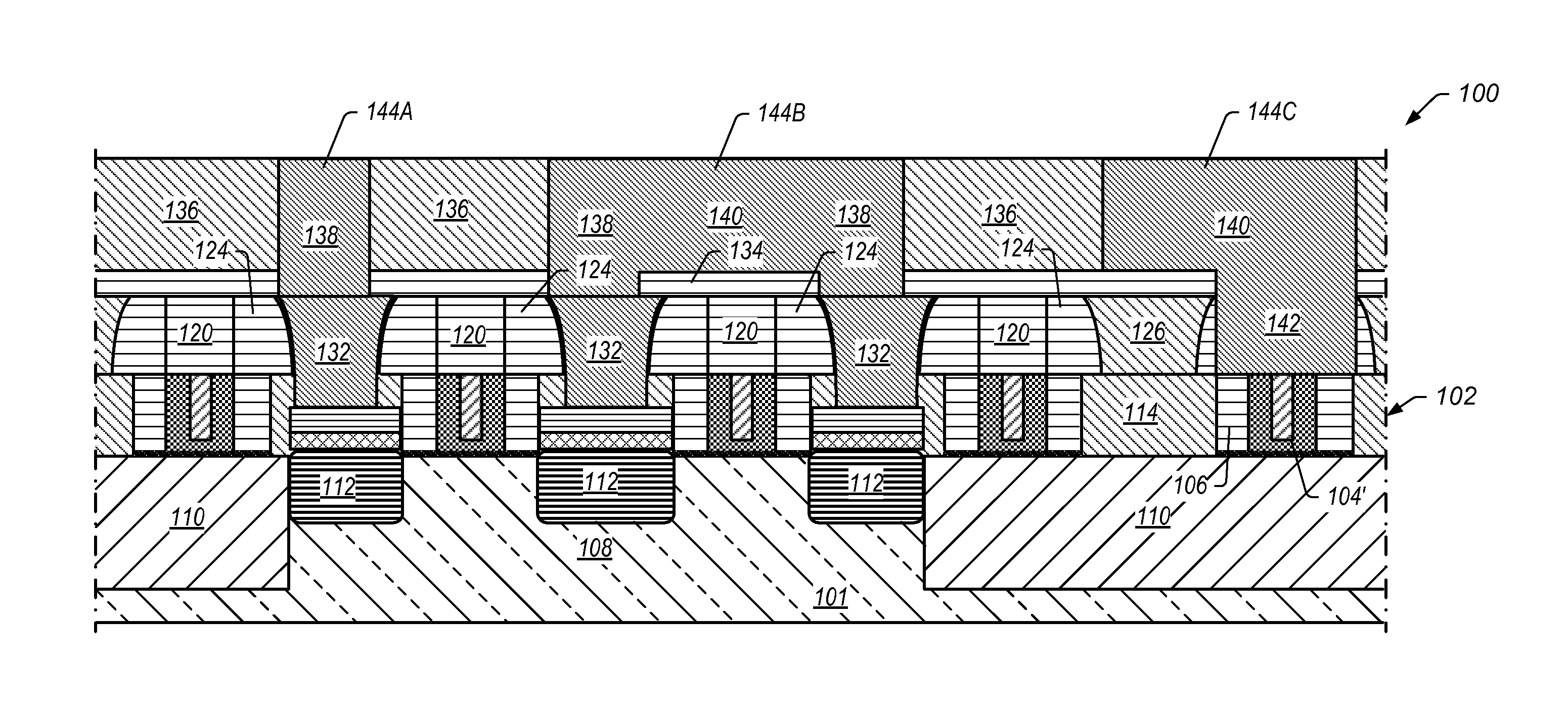

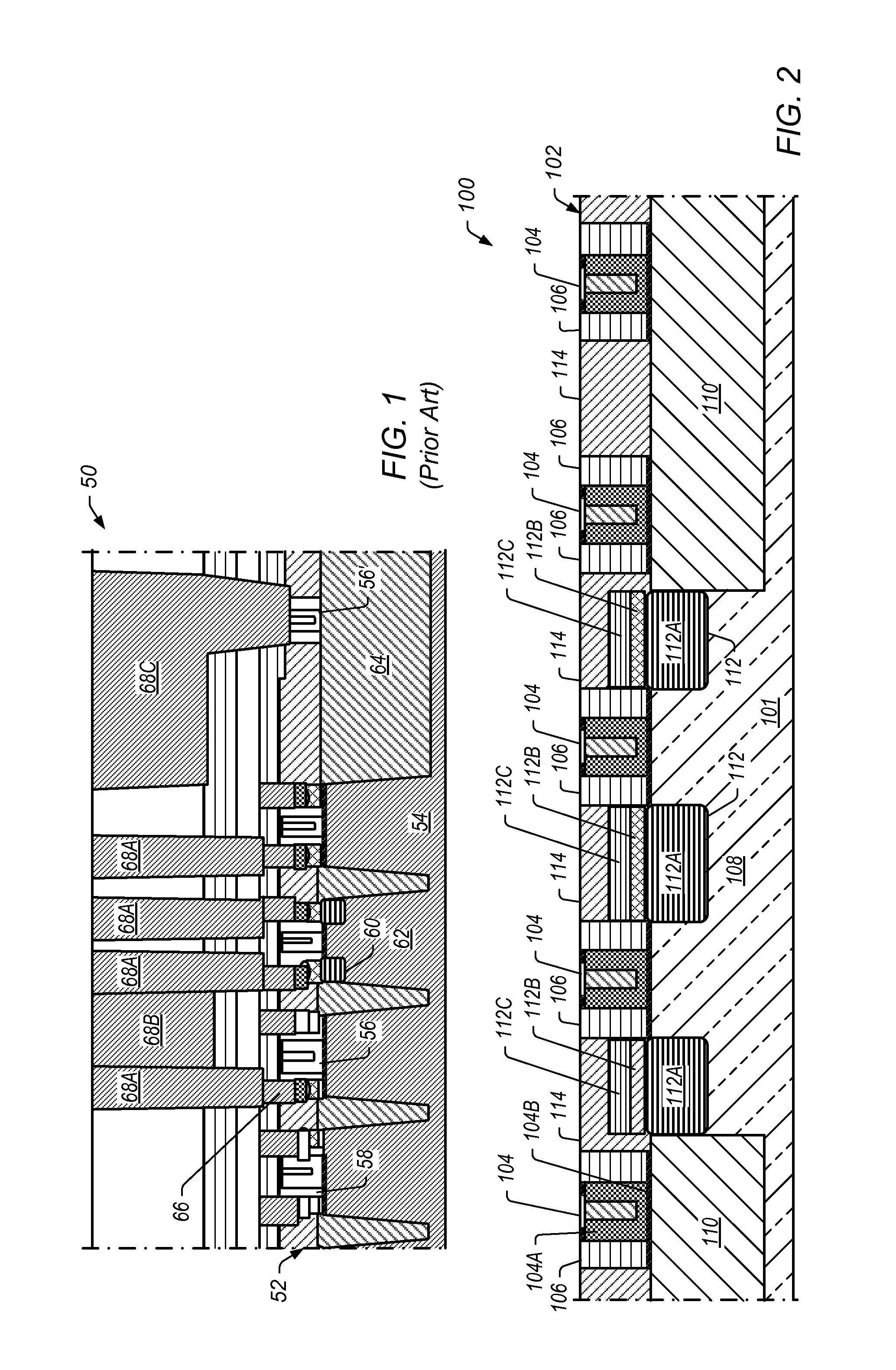

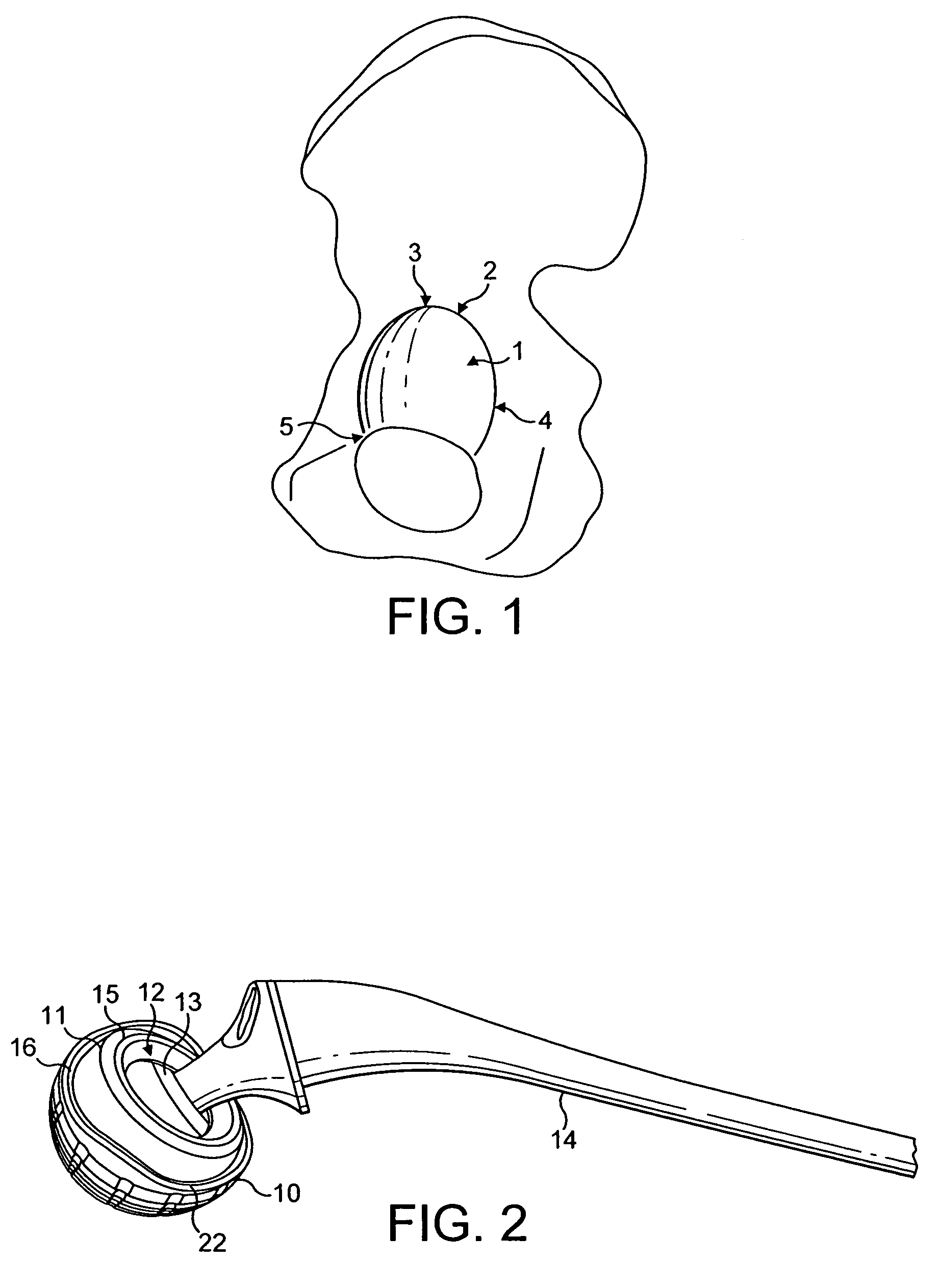

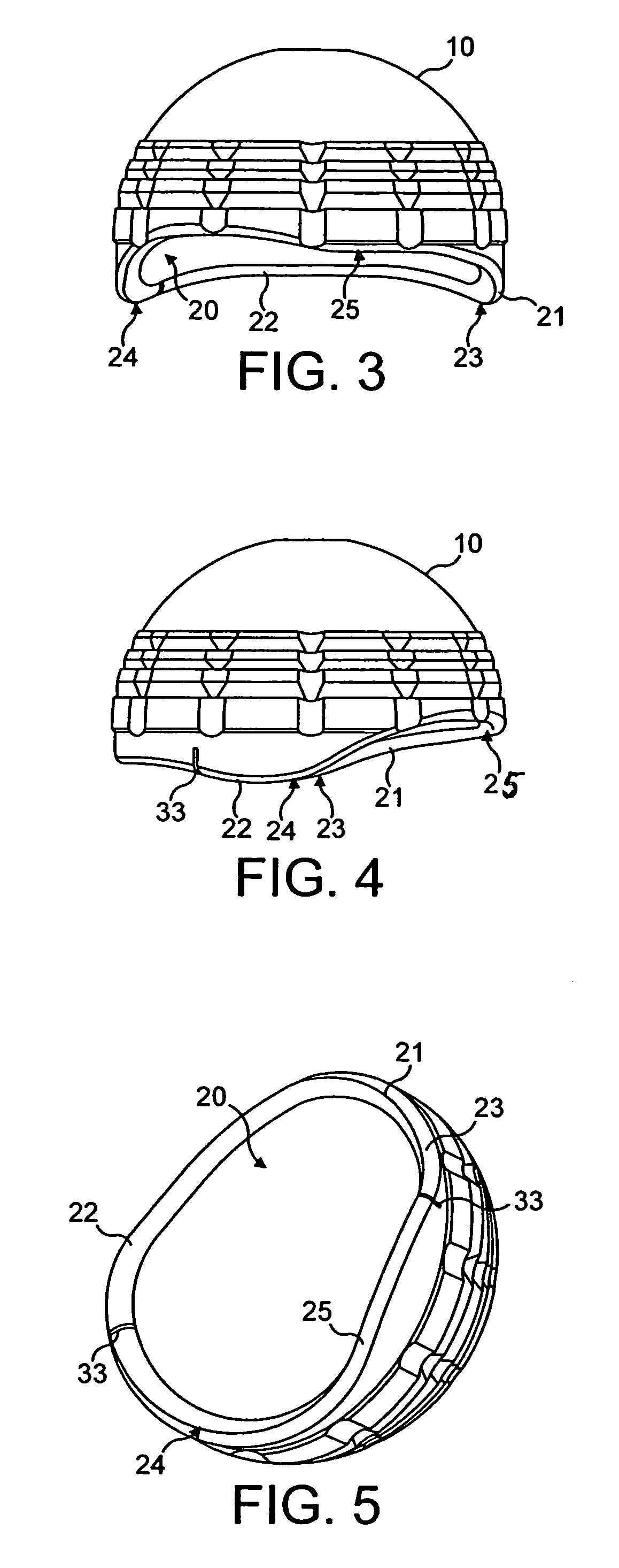

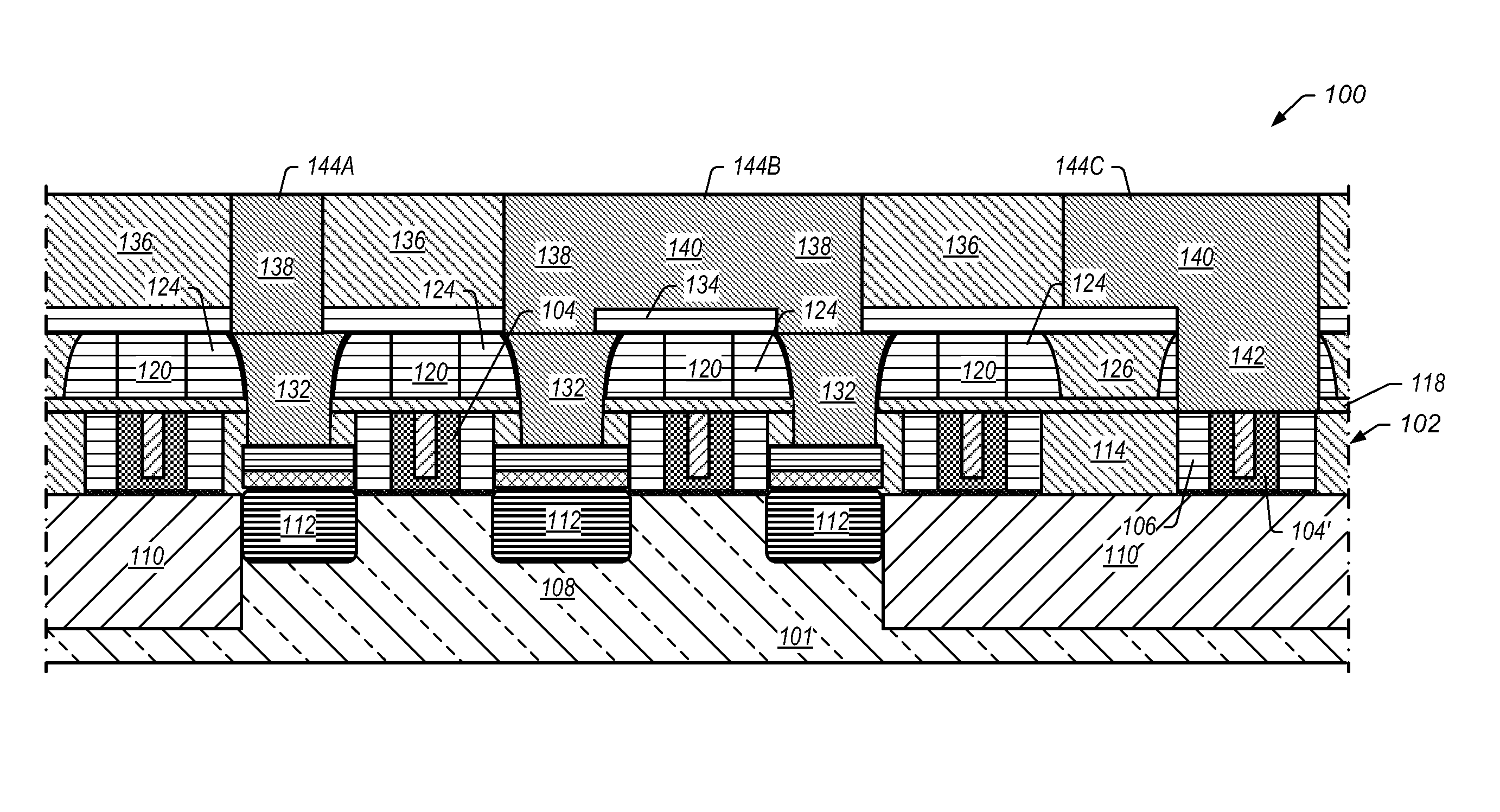

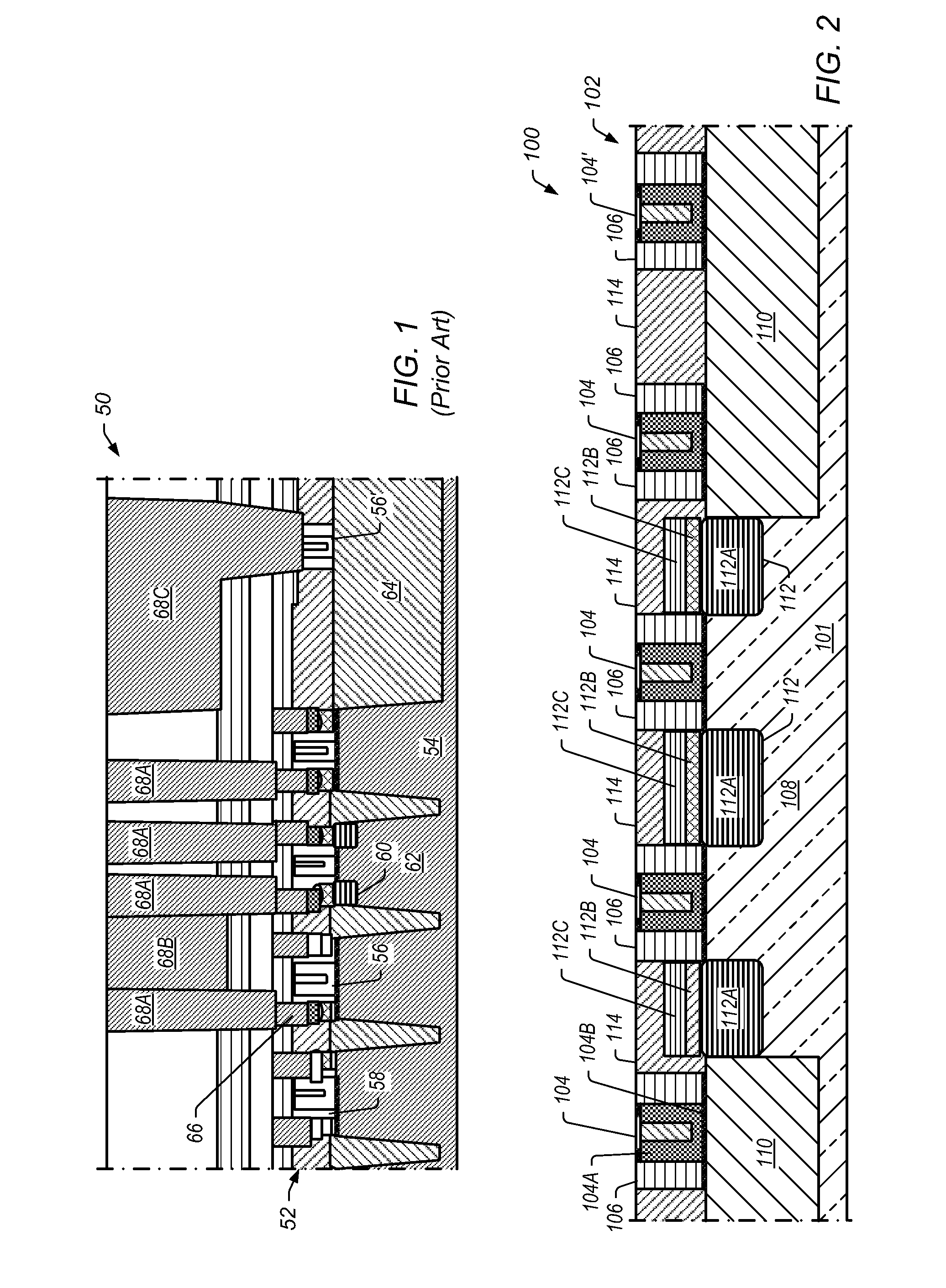

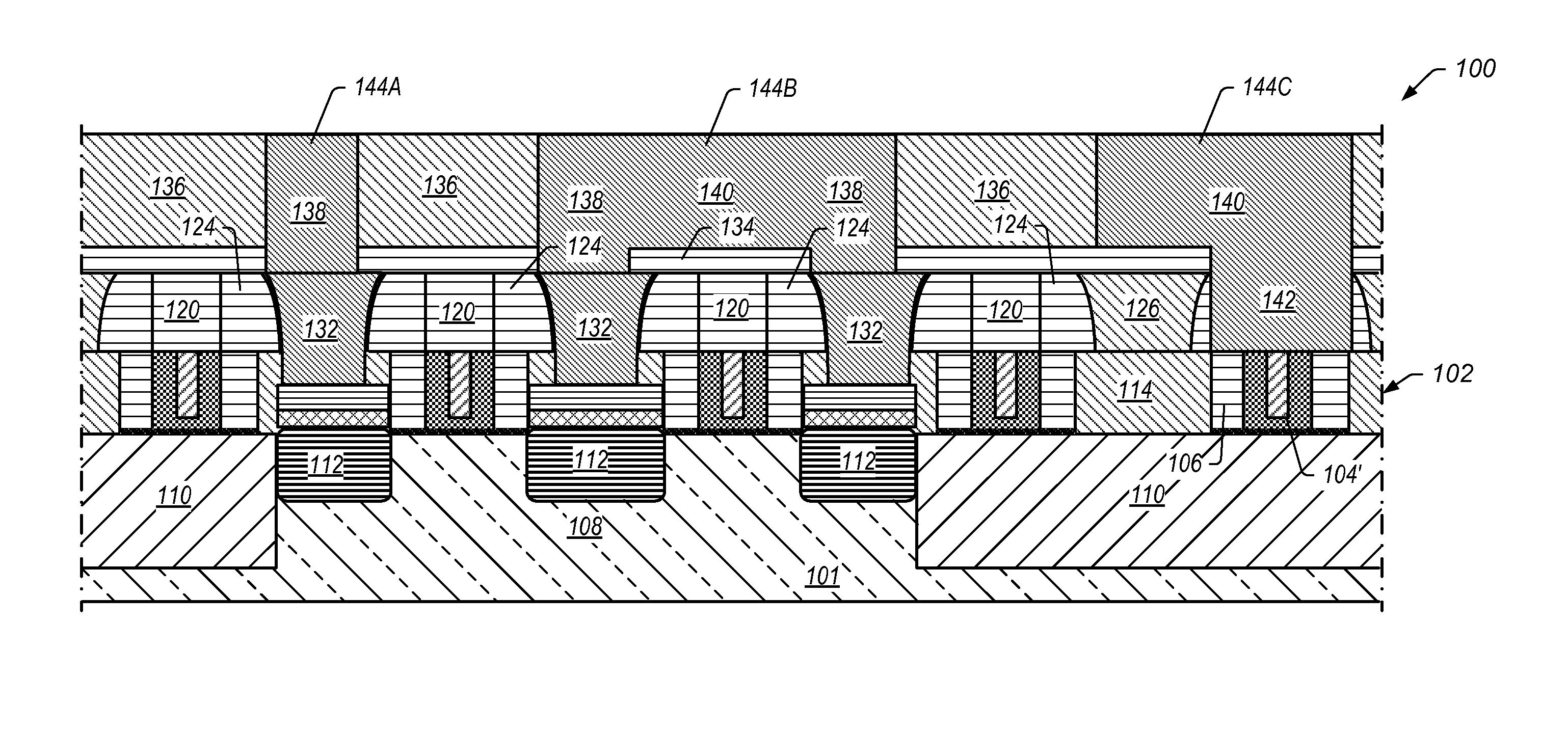

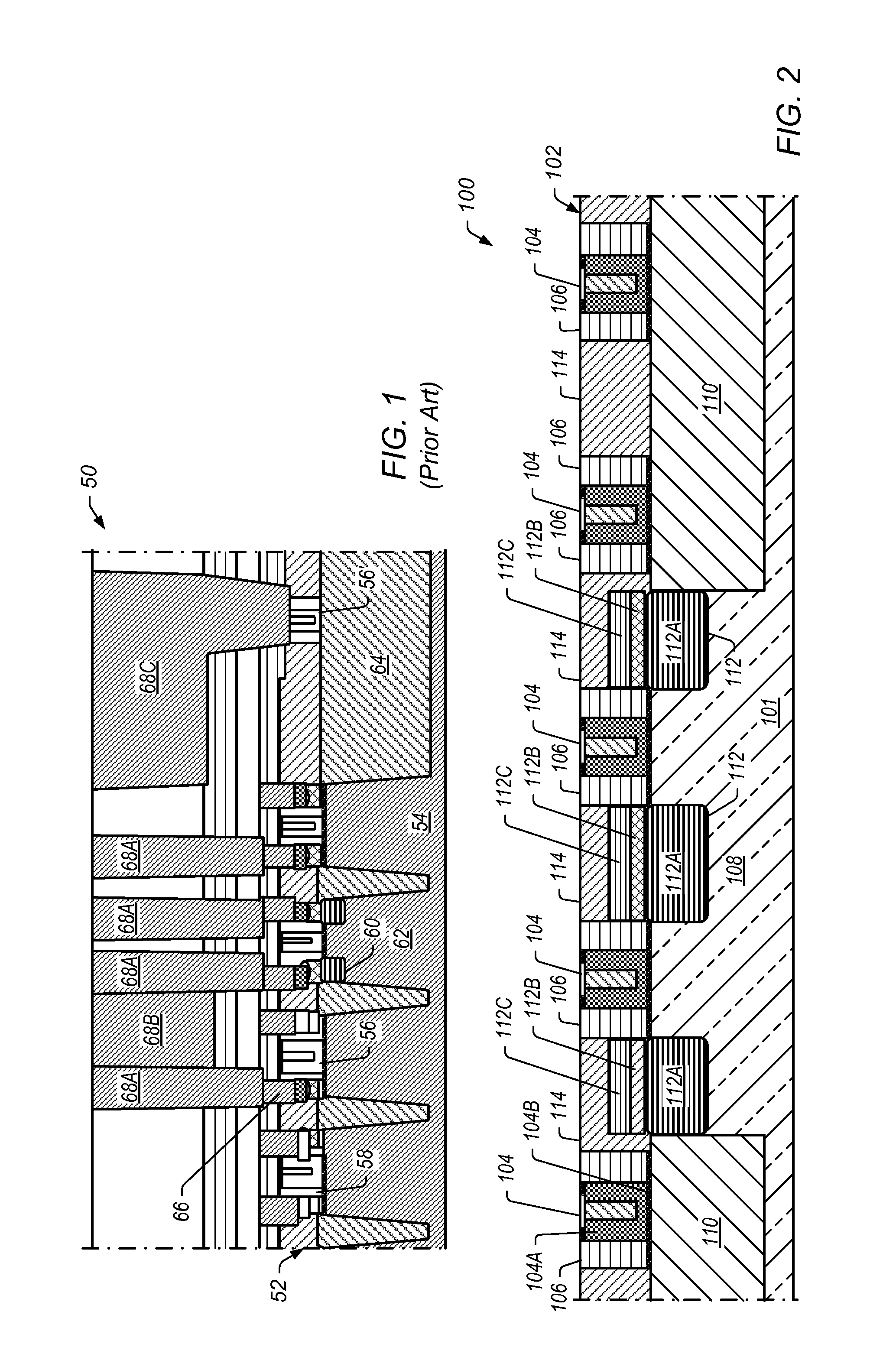

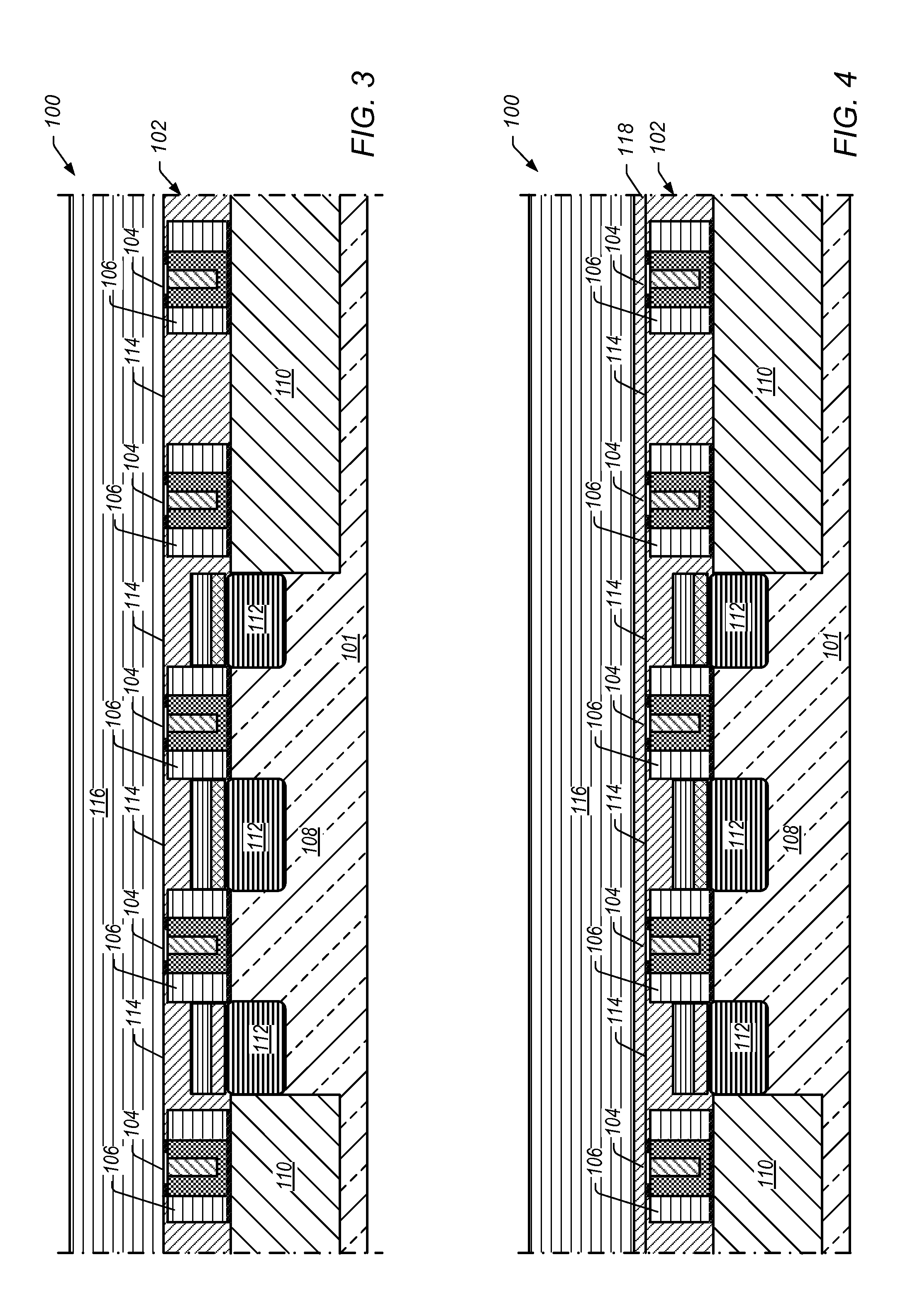

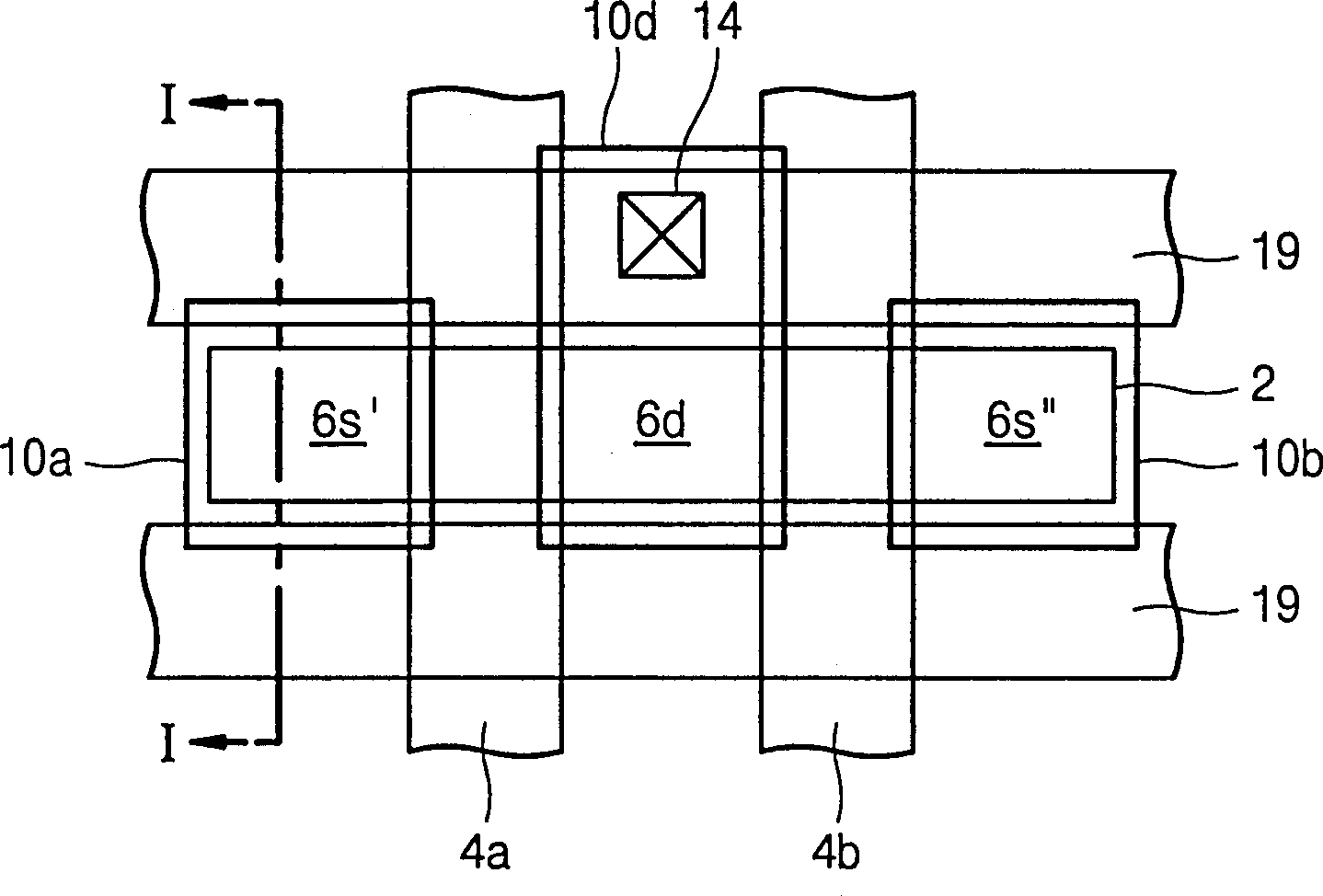

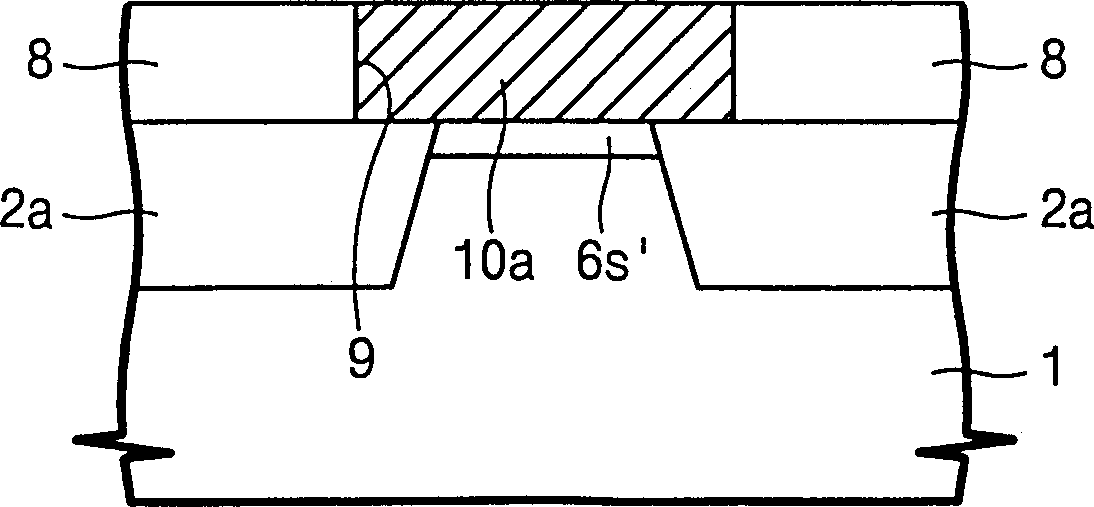

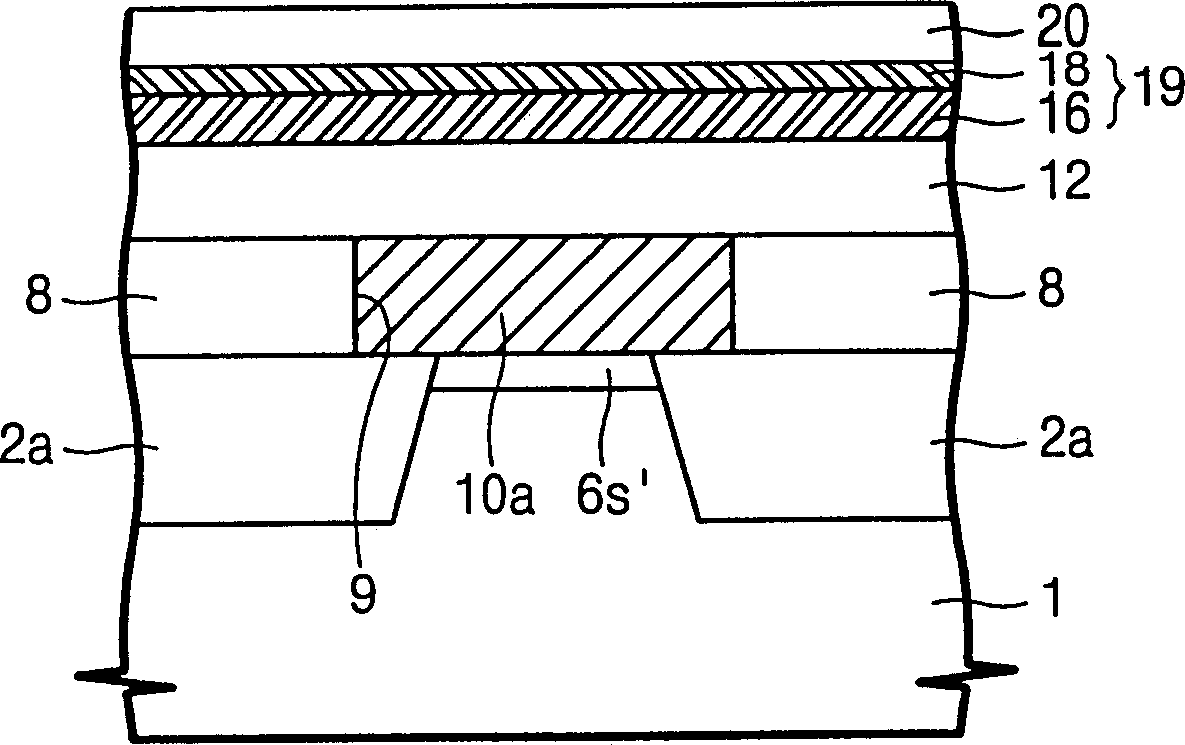

Trench silicide and gate open with local interconnect with replacement gate process

ActiveUS20130119474A1Reduce in quantityImprove production yieldTransistorSemiconductor/solid-state device manufacturingSalicideConductive materials

A semiconductor device fabrication process includes forming insulating mandrels over replacement metal gates on a semiconductor substrate with first gates having sources and drains and at least one second gate being isolated from the first gates. Mandrel spacers are formed around each insulating mandrel. The mandrels and mandrel spacers include the first insulating material. A second insulating layer of the second insulating material is formed over the transistor. One or more first trenches are formed to the sources and drains of the first gates by removing the second insulating material between the insulating mandrels. A second trench is formed to the second gate by removing portions of the first and second insulating materials above the second gate. The first trenches and the second trench are filled with conductive material to form first contacts to the sources and drains of the first gates and a second contact to the second gate.

Owner:ADVANCED MICRO DEVICES INC

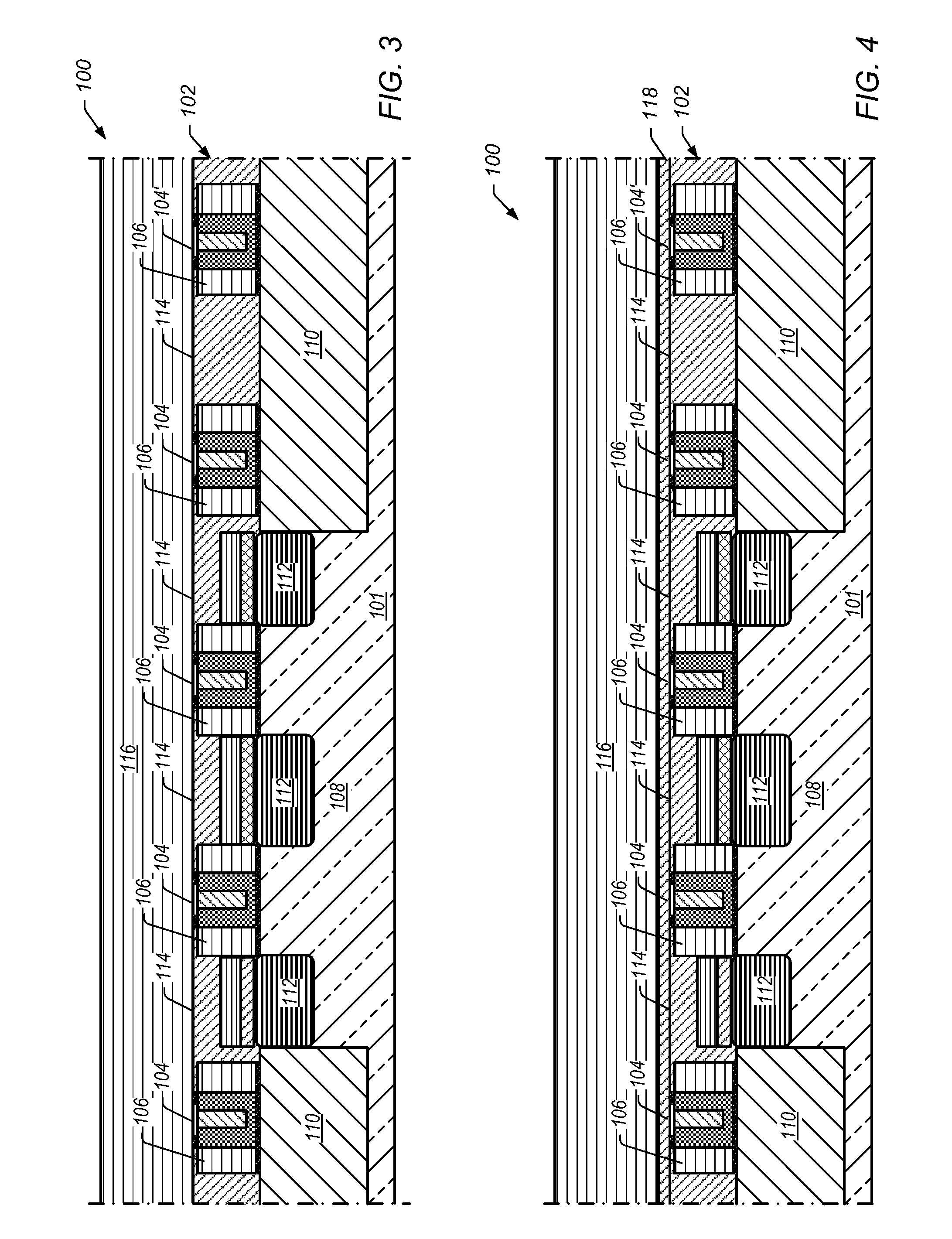

Self-aligned trench contact and local interconnect with replacement gate process

ActiveUS20120313148A1Good manufacturing yieldSimple process flowSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringConductive materials

A semiconductor device fabrication process includes forming insulating mandrels over one or more replacement metal gates on a semiconductor substrate. The mandrels include a first insulating material. Each mandrel has approximately the same width as its underlying gate with each mandrel being at least as wide as its underlying gate. Mandrel spacers are formed around each insulating mandrel. The mandrel spacers include the first insulating material. Each mandrel spacer has a profile that slopes from being wider at the bottom to narrower at the top. A second insulating layer of the second insulating material is formed over the transistor. Trenches to the sources and drains of the gates are formed by removing the second insulating material from portions of the transistor between the mandrels. Trench contacts to the sources and drains of the gates are formed by depositing conductive material in the first trenches.

Owner:ADVANCED MICRO DEVICES INC

Prosthetic acetabular cup and prosthetic femoral joint incorporating such a cup

ActiveUS7833276B2More angular movementReduce the possibility of misalignmentInternal osteosythesisJoint implantsSpherical bearingProsthesis

An acetabular prosthesis having an outer member for engaging the acetabulum. The outer member has a part-spherical bearing surface terminating in a distal rim. The rim has a contour such that the portion thereof to be located between the ischium and the pubis extends distally further from an equator of the bearing surface than the contour to be implanted between the pubis and the illium and between the ischium and the illium.

Owner:STRYKER EURO OPERATIONS HLDG LLC

Trench silicide and gate open with local interconnect with replacement gate process

ActiveUS8716124B2Reduce in quantityReduce the possibility of misalignmentTransistorSemiconductor/solid-state device manufacturingSalicideConductive materials

A semiconductor device fabrication process includes forming insulating mandrels over replacement metal gates on a semiconductor substrate with first gates having sources and drains and at least one second gate being isolated from the first gates. Mandrel spacers are formed around each insulating mandrel. The mandrels and mandrel spacers include the first insulating material. A second insulating layer of the second insulating material is formed over the transistor. One or more first trenches are formed to the sources and drains of the first gates by removing the second insulating material between the insulating mandrels. A second trench is formed to the second gate by removing portions of the first and second insulating materials above the second gate. The first trenches and the second trench are filled with conductive material to form first contacts to the sources and drains of the first gates and a second contact to the second gate.

Owner:ADVANCED MICRO DEVICES INC

Self-aligned trench contact and local interconnect with replacement gate process

ActiveUS8564030B2Reduce in quantityReduce the possibility of misalignmentSemiconductor/solid-state device manufacturingSemiconductor devicesConductive materialsEngineering

A semiconductor device fabrication process includes forming insulating mandrels over one or more replacement metal gates on a semiconductor substrate. The mandrels include a first insulating material. Each mandrel has approximately the same width as its underlying gate with each mandrel being at least as wide as its underlying gate. Mandrel spacers are formed around each insulating mandrel. The mandrel spacers include the first insulating material. Each mandrel spacer has a profile that slopes from being wider at the bottom to narrower at the top. A second insulating layer of the second insulating material is formed over the transistor. Trenches to the sources and drains of the gates are formed by removing the second insulating material from portions of the transistor between the mandrels. Trench contacts to the sources and drains of the gates are formed by depositing conductive material in the first trenches.

Owner:ADVANCED MICRO DEVICES INC

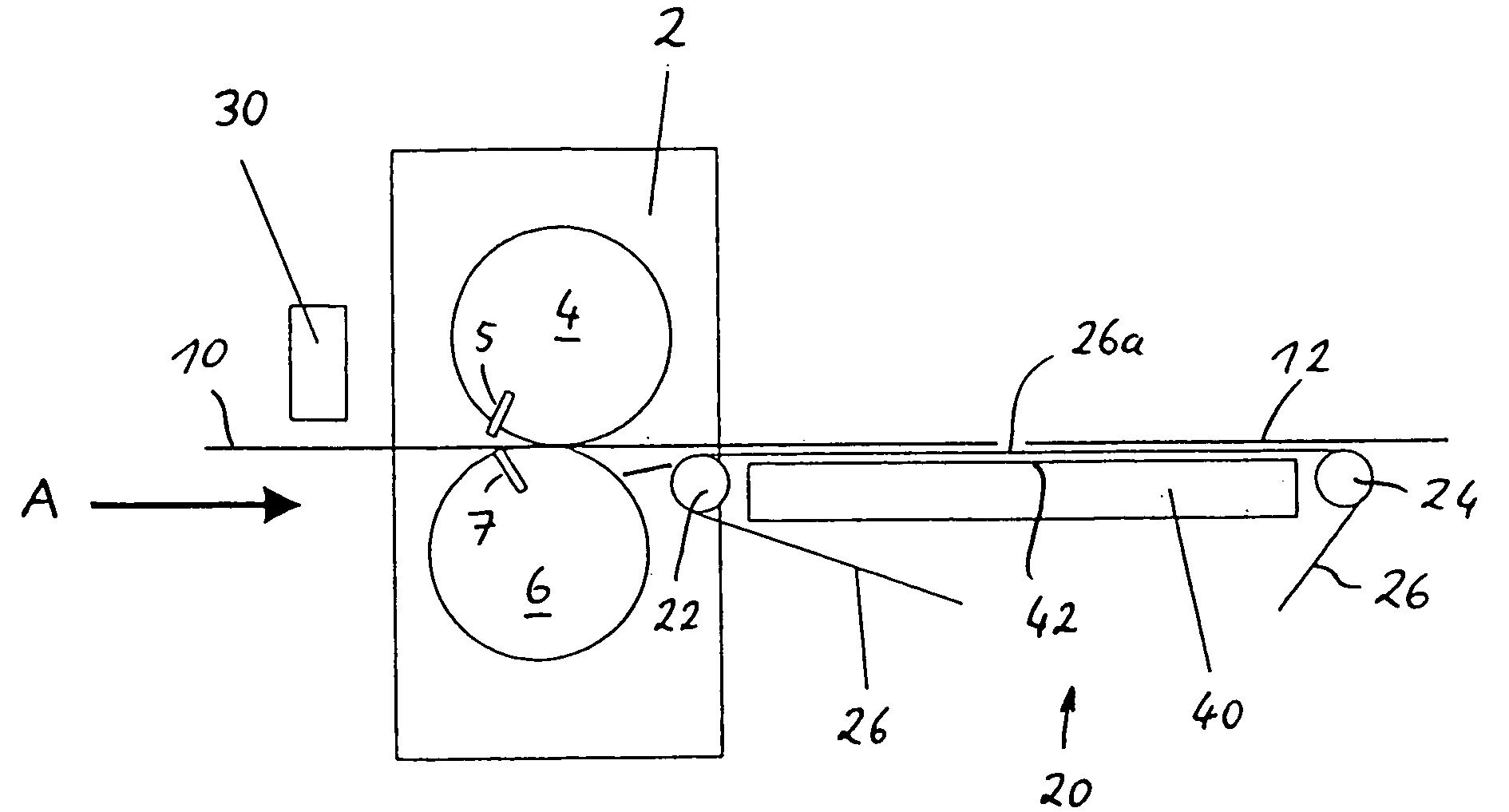

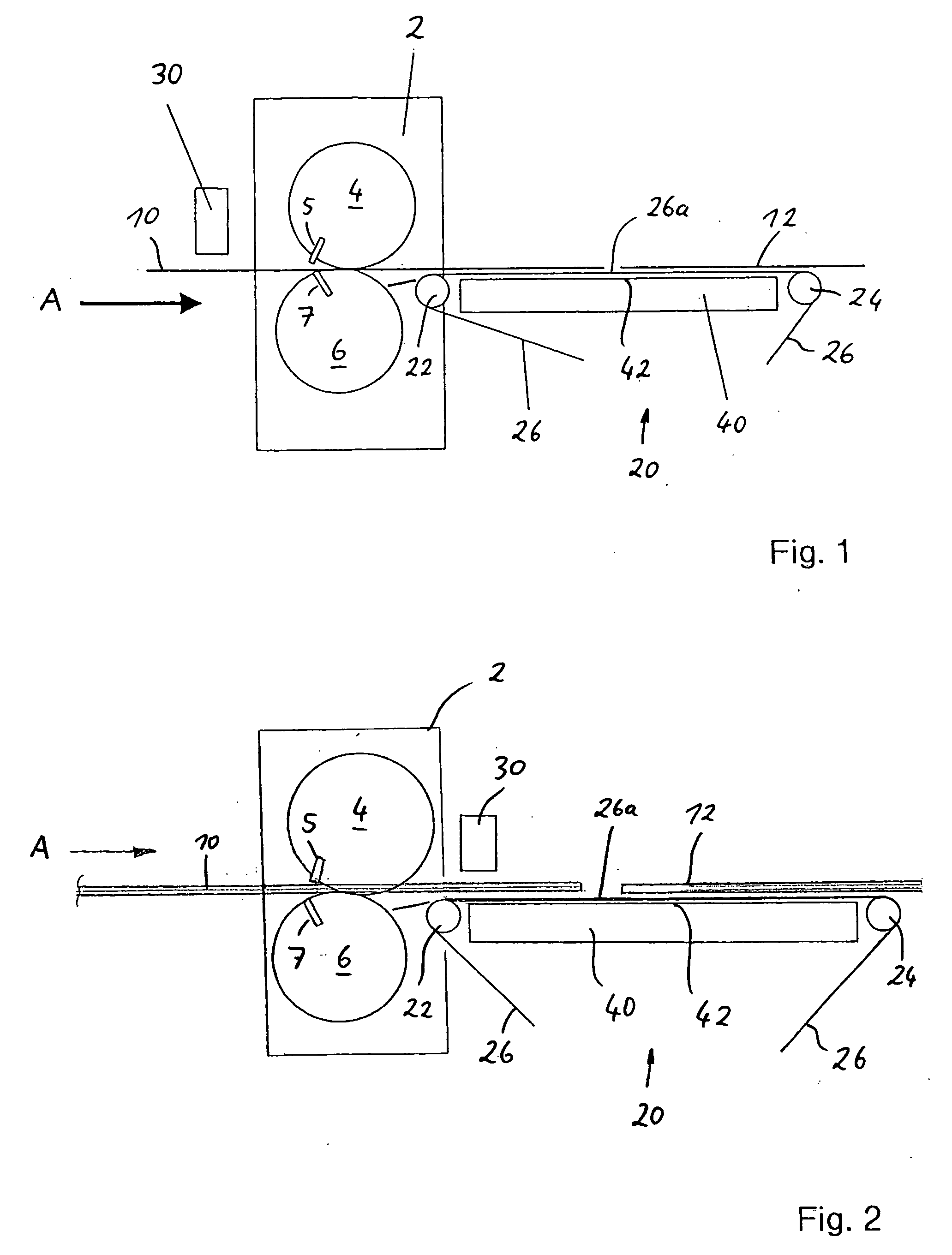

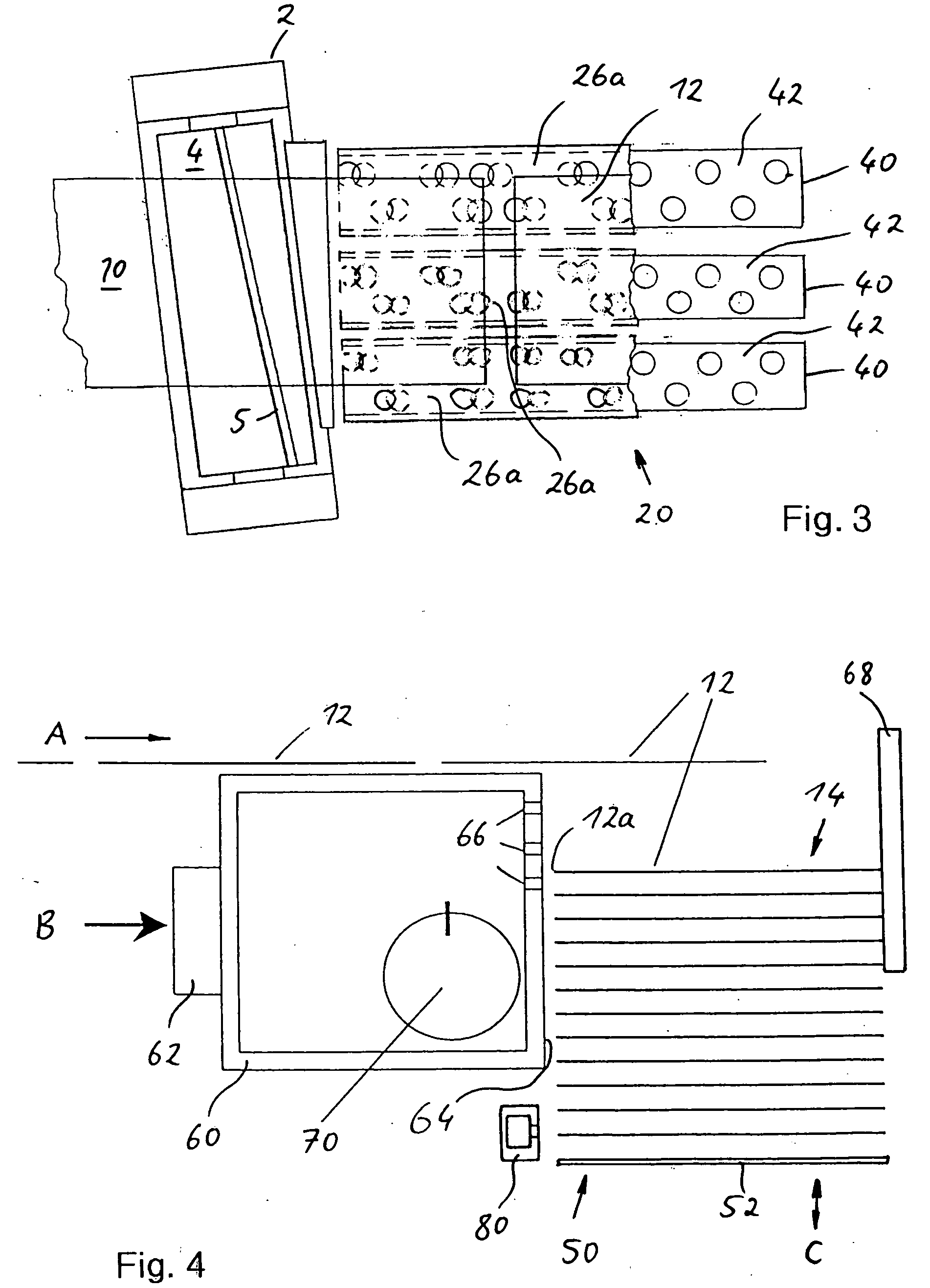

Apparatus for treating elongated multi-layer webs of electrostatically chargeable material

InactiveUS20050077171A1Reduce the possibility of misalignmentPrecise positioningArticle feedersSheet bindingEngineeringMechanical engineering

The invention relates to apparatus for treating a multi-panel or multi-sheet web of paper or similar electrostatically chargeable material. A multi-layer web of such material is advanced toward and through at least one cutter to yield a succession of stacks which are ready for assembly into piles and / or for other processing. The arrangement for moving the web and there-upon the stacks lengthwise includes a first unit up-stream and a second unit downstream of the cutter, and an ionizing unit is installed adjacent the path of the web and stacks, either between the first moving unit and the cutter or between the cutter and the second moving unit. In either event, the ionizing unit is closely adjacent the cutter. If the stacks are to be assembled into a succession of piles downstream of the second moving unit, the apparatus further comprises an electrostatic discharging device in the region of the pile forming station.

Owner:WILL-PEMCO

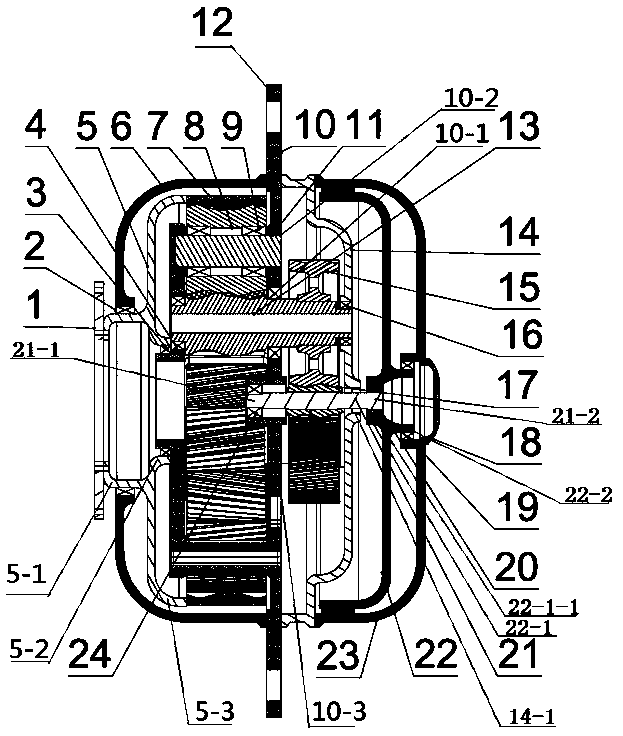

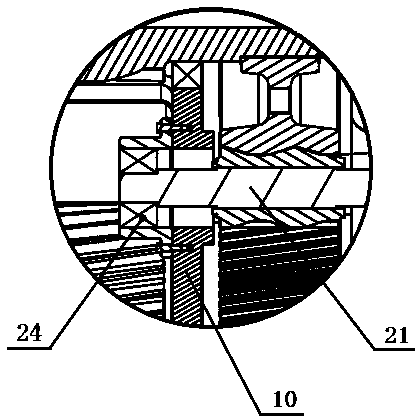

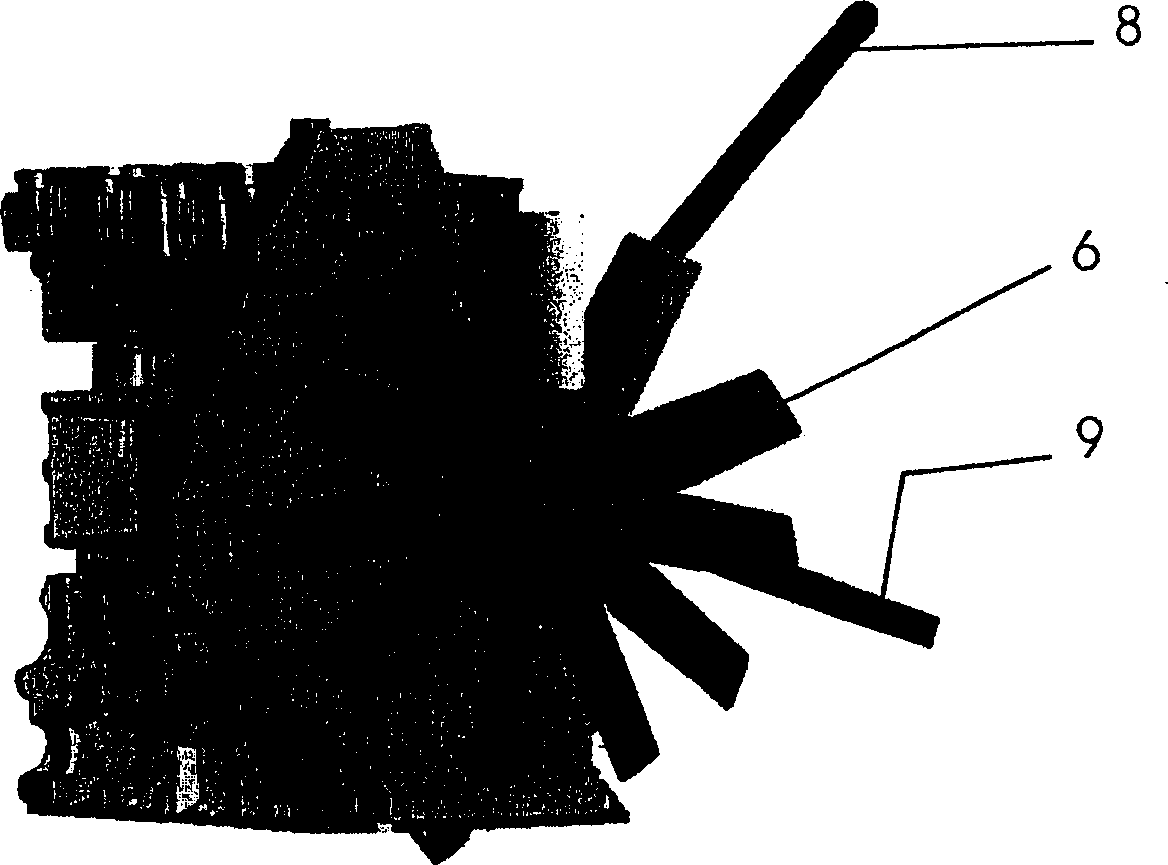

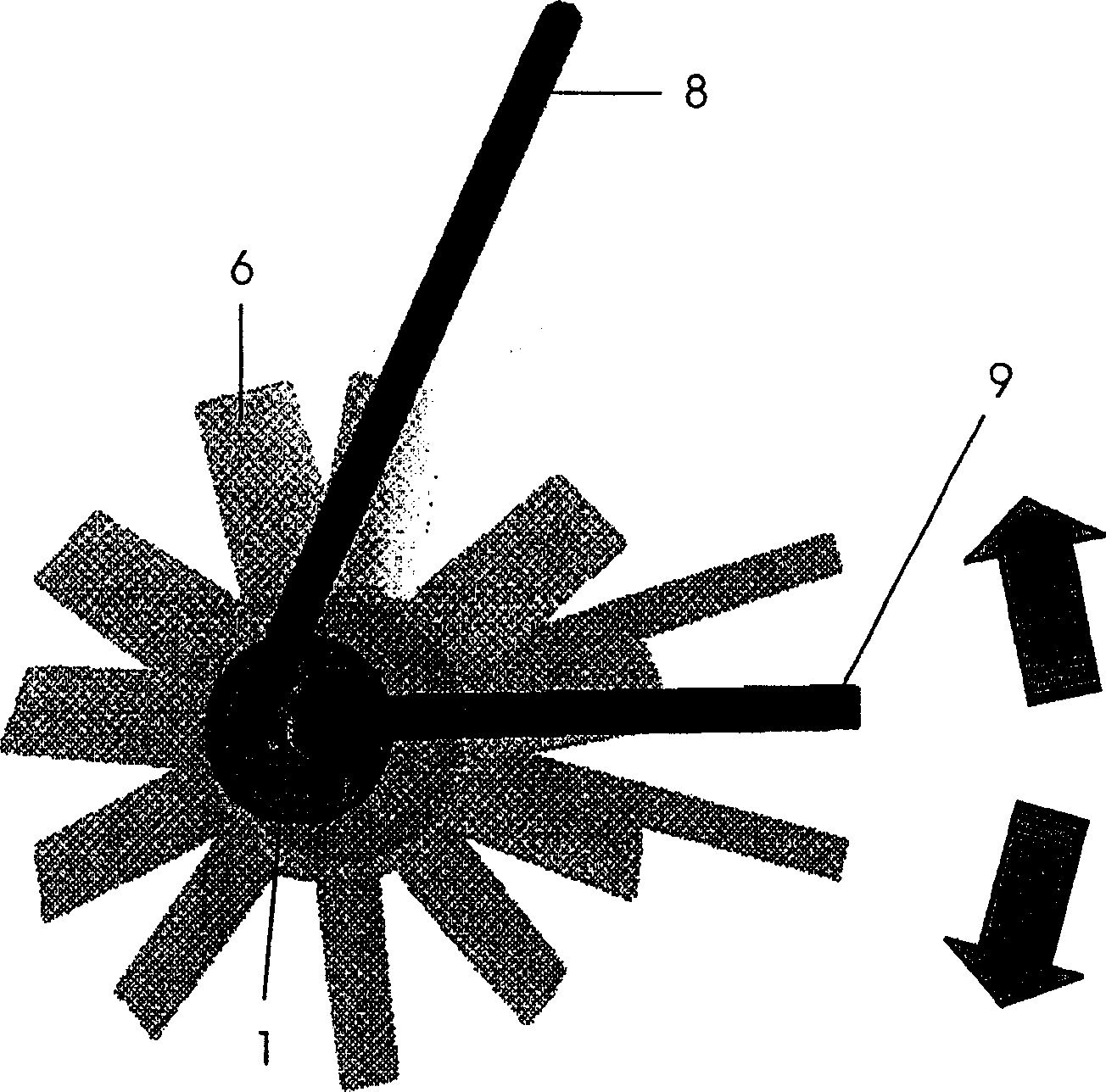

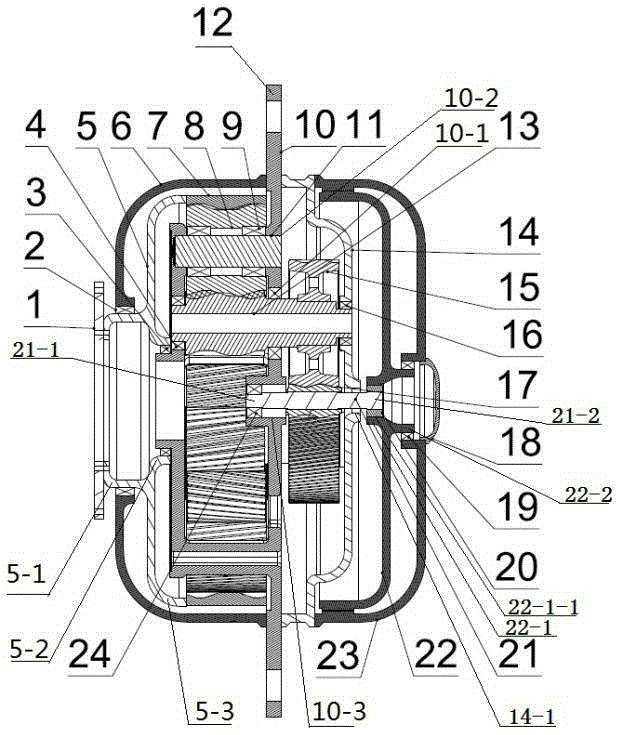

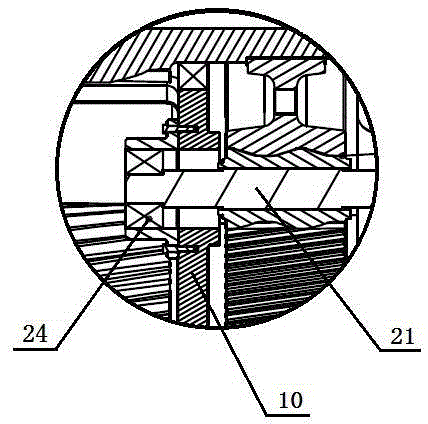

Integrated semi-direct drive wind generator transmission chain and gearbox for same

The invention provides an integrated semi-direct drive wind generator transmission chain and a gearbox for the same. The gearbox comprises a front box body (6), a rear box body (14), a spindle (5) and a planetary carrier (10), a large-diameter portion (5-3) of a downwind end of the spindle is fixedly connected with an inner gear ring (7), the inner gear ring (7) is engaged with at least three idle gears (8) mounted on the planetary carrier (10), the inner gear ring (7), the idle gears (8) and a first planetary gear form a primary fixed shaft transmission pair, a portion of each planetary gear shaft (13) extending out of the planetary carrier (10) is connected with a secondary planetary gear (15), the secondary planetary gear (15) is positioned in a cavity formed by the planetary carrier (10) and the rear box body (14) and engaged with the same sun gear (17), and the secondary planetary gear (15) and the sun gear (17) form a secondary fixed shaft transmission pair. The gearbox has the advantages of integration, light weight, short axial length, convenience in disassembly and assembly and the like.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

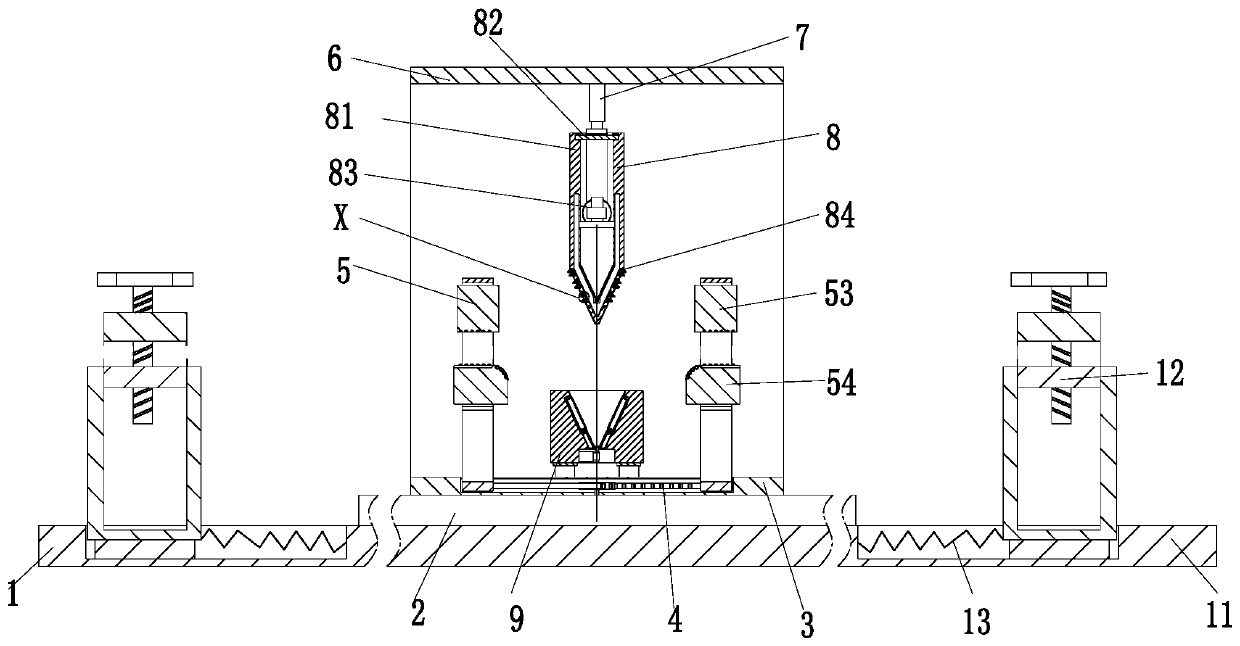

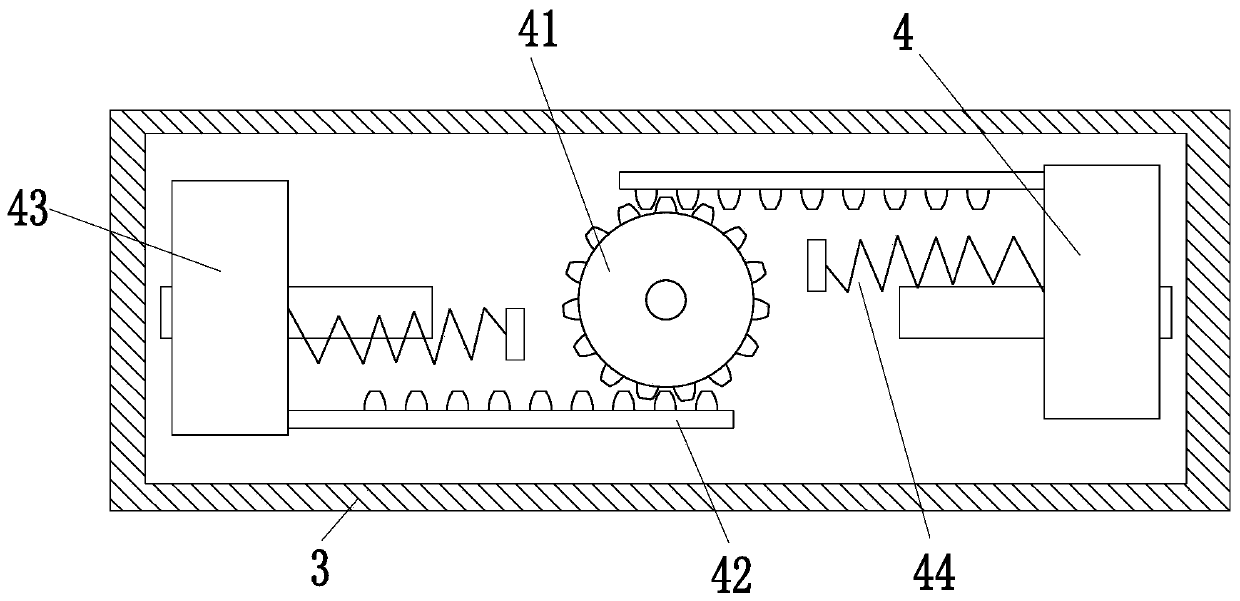

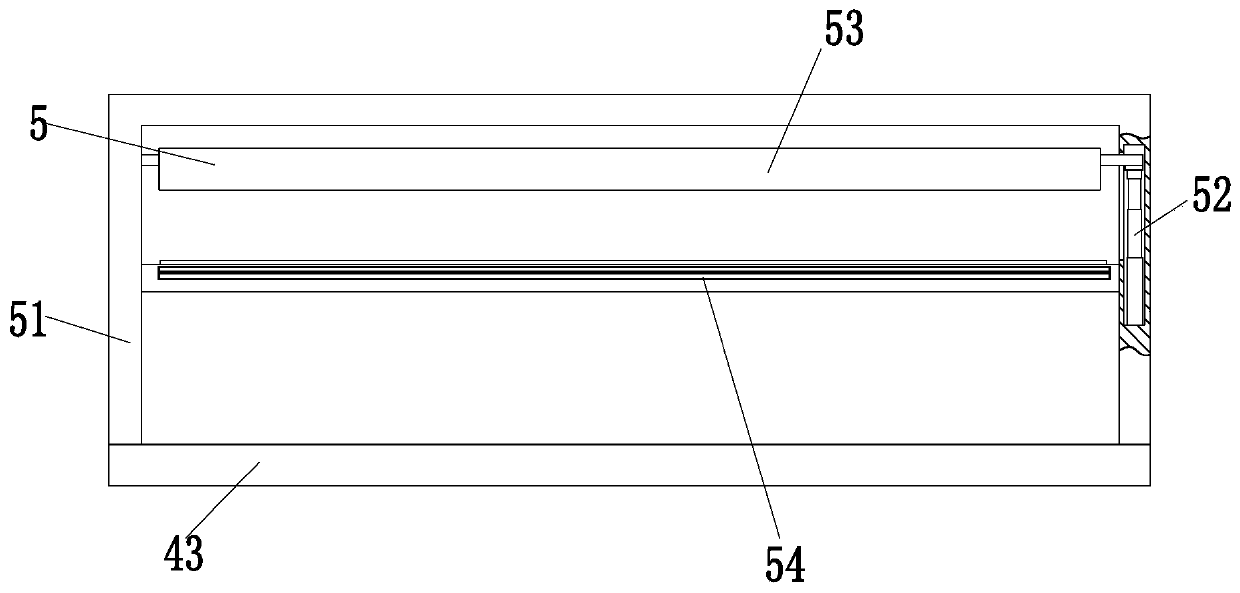

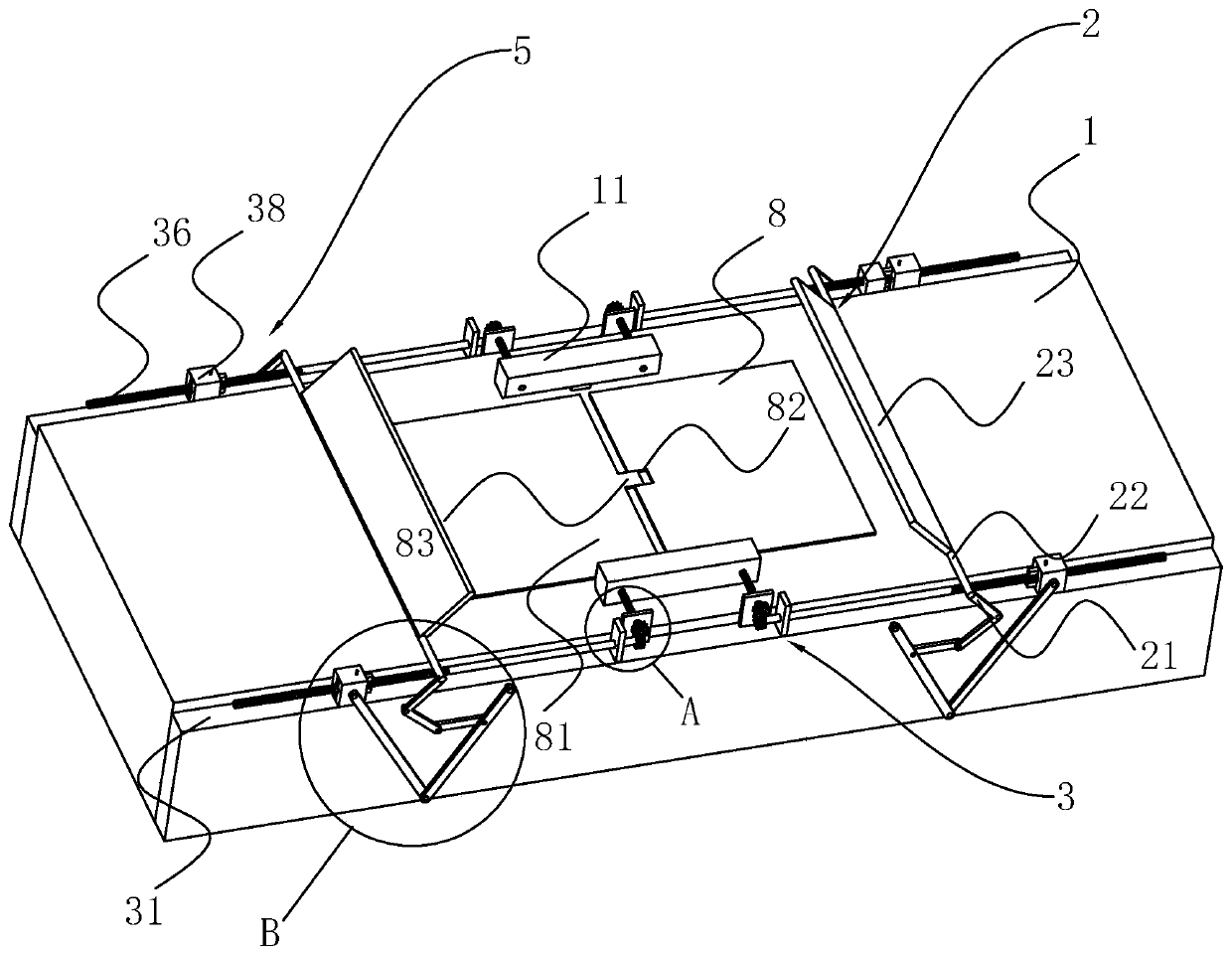

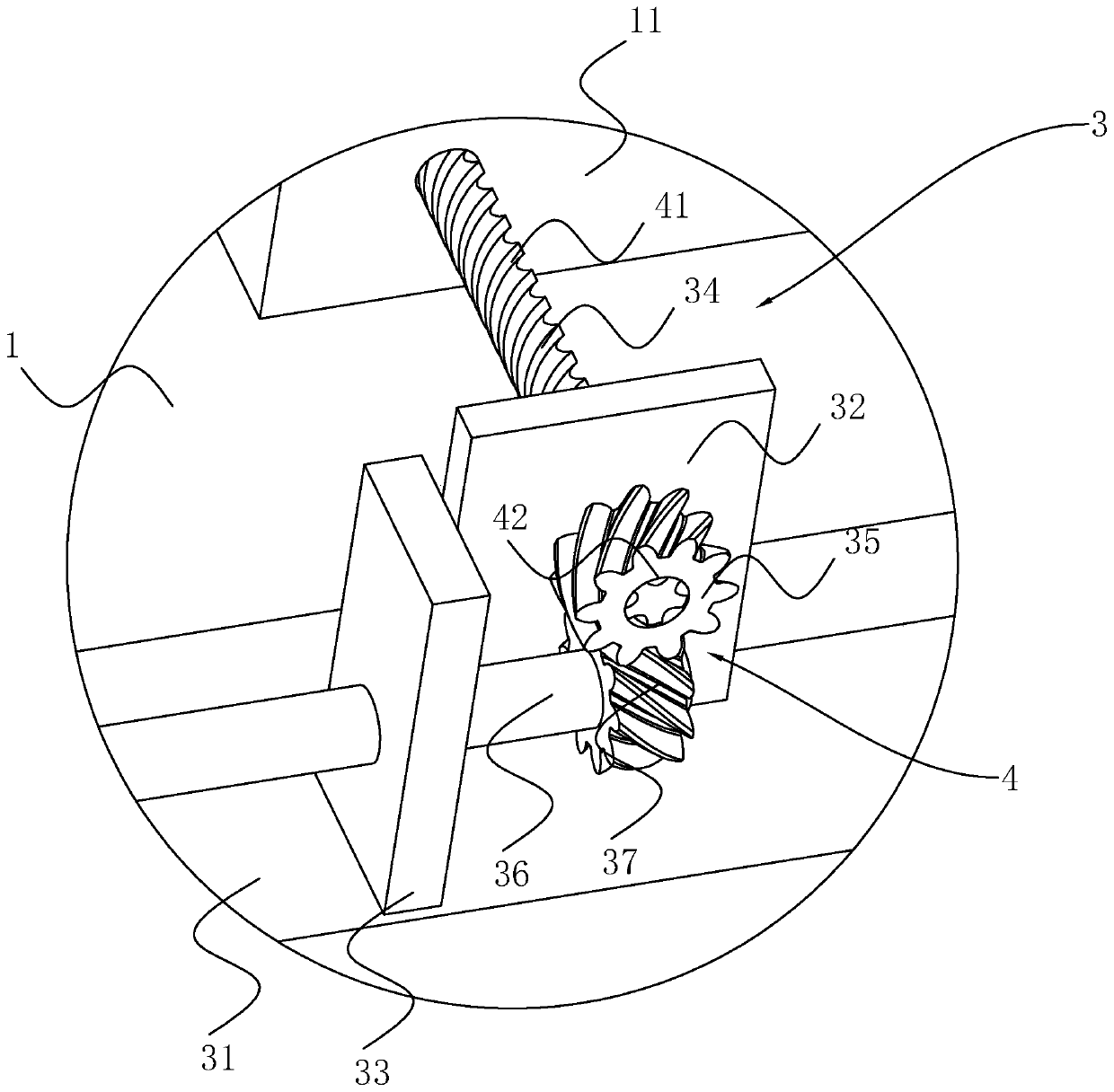

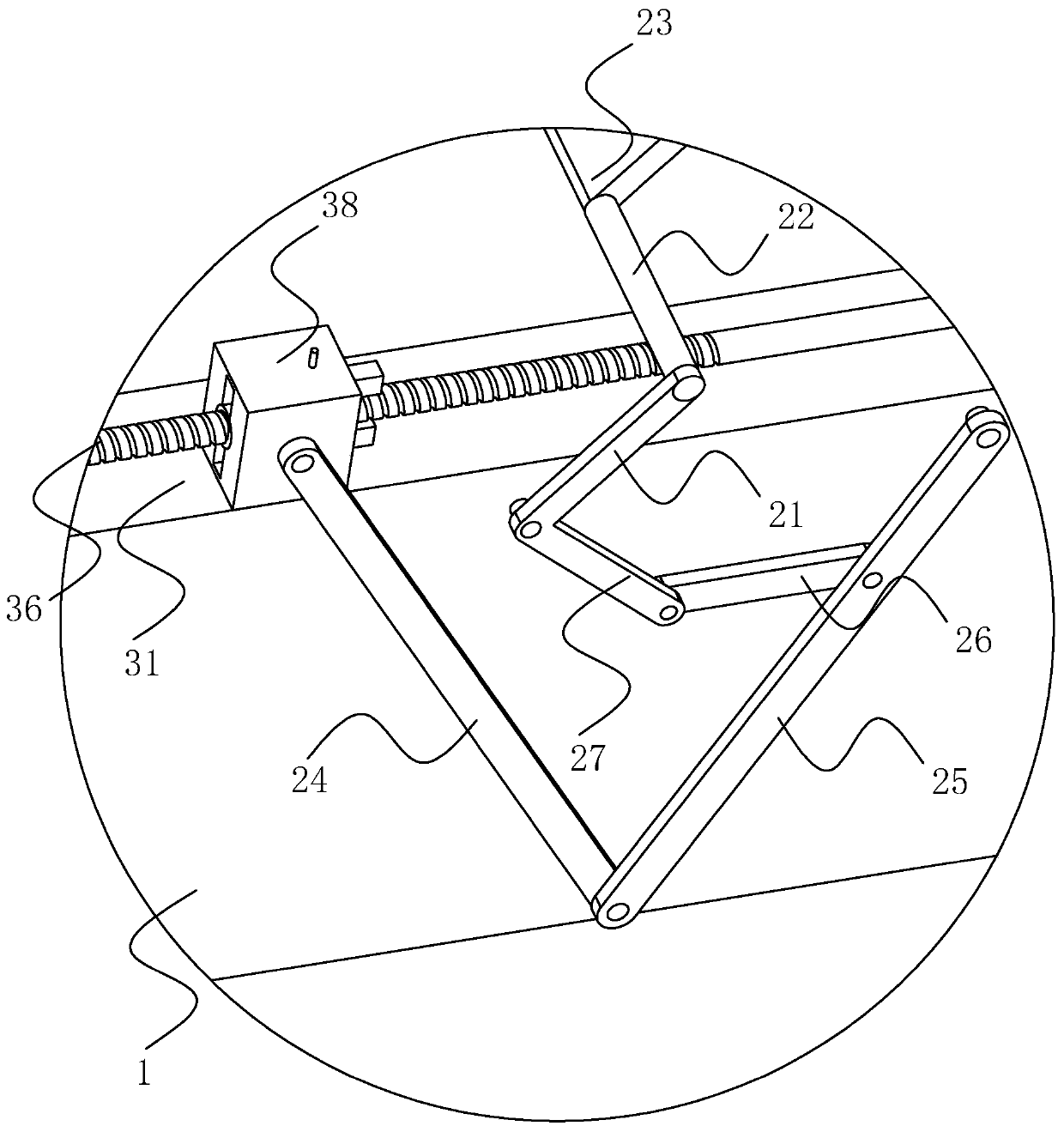

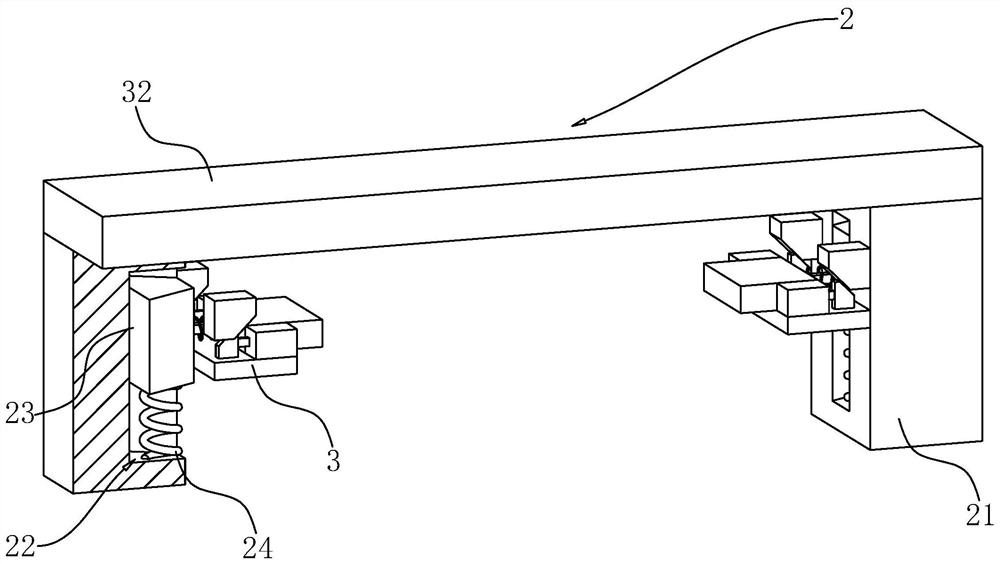

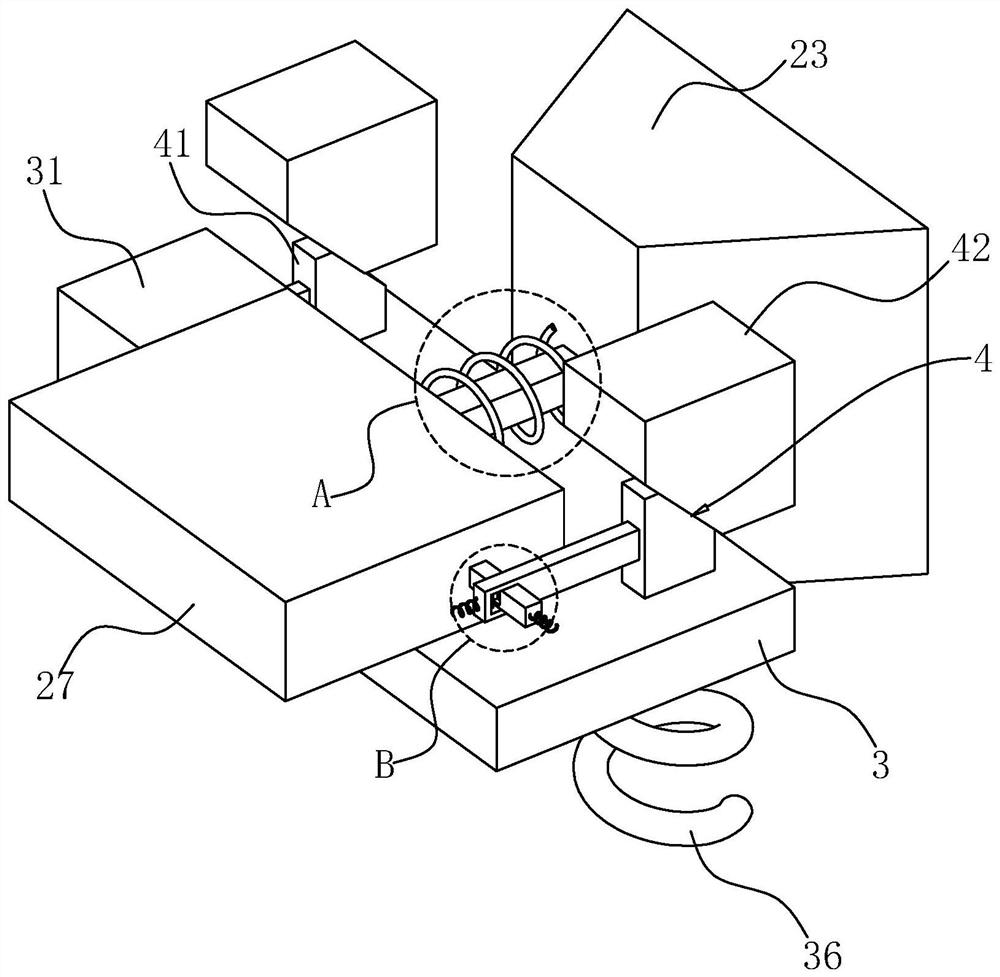

Plastic woven bag edgefold shaping machine and method

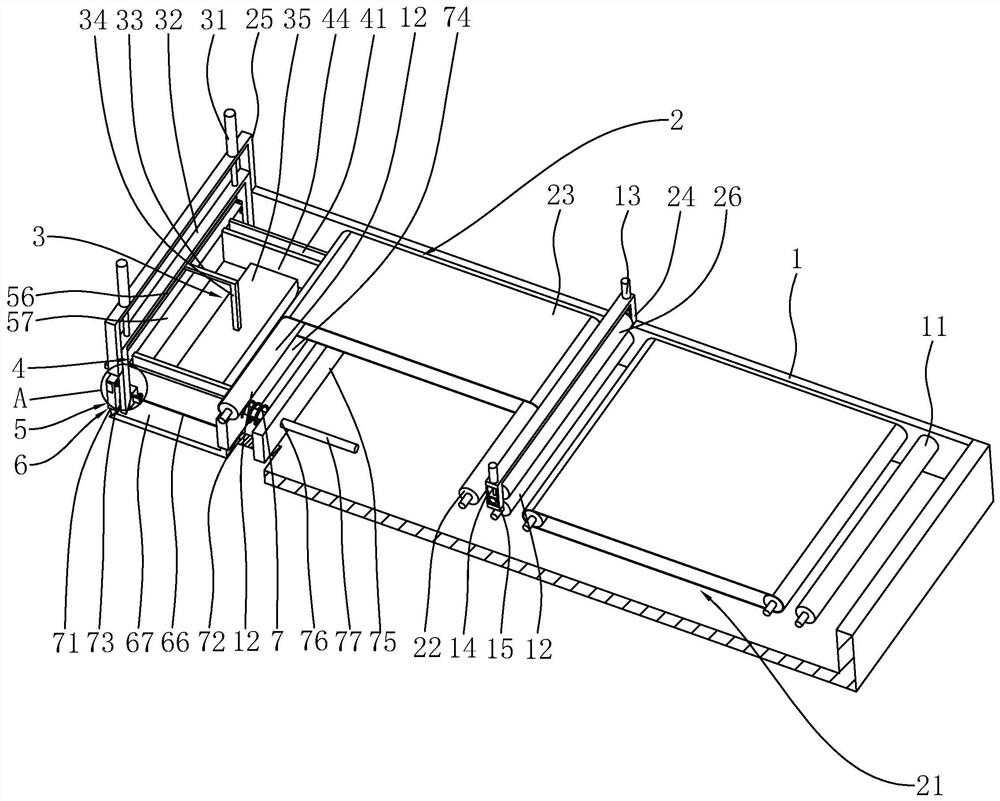

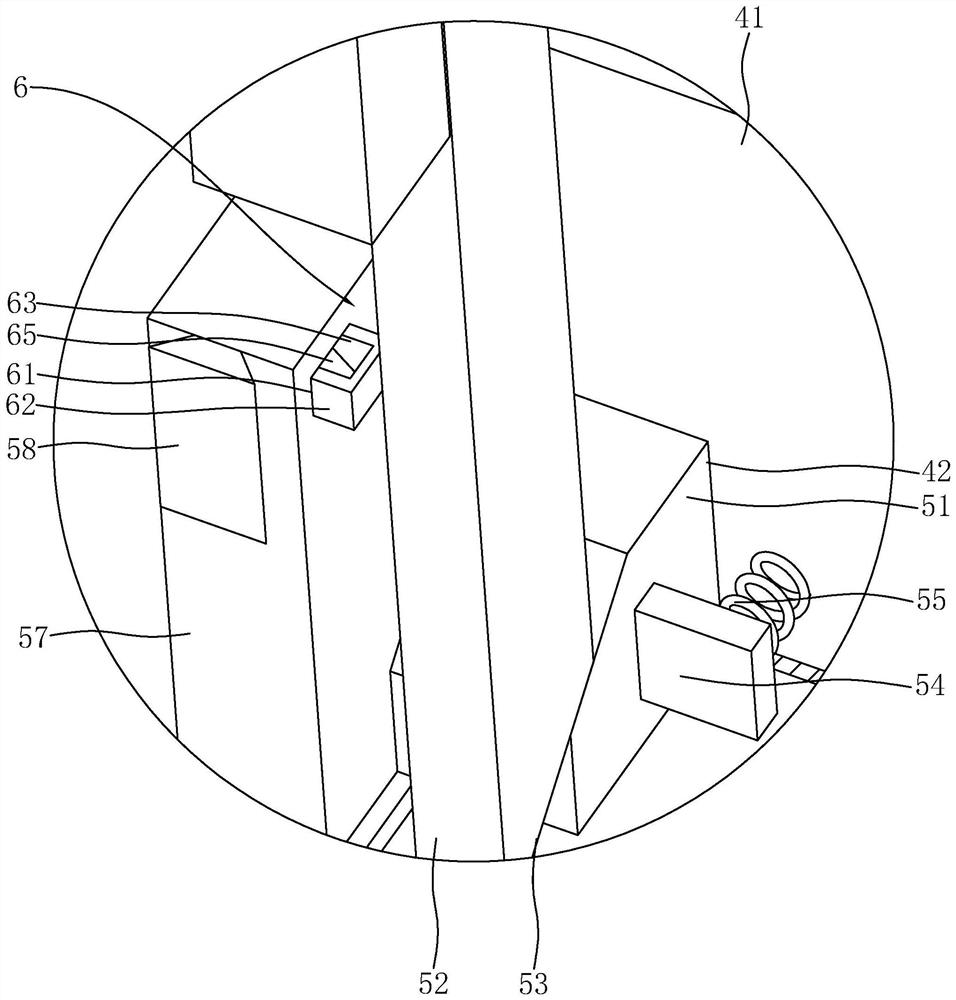

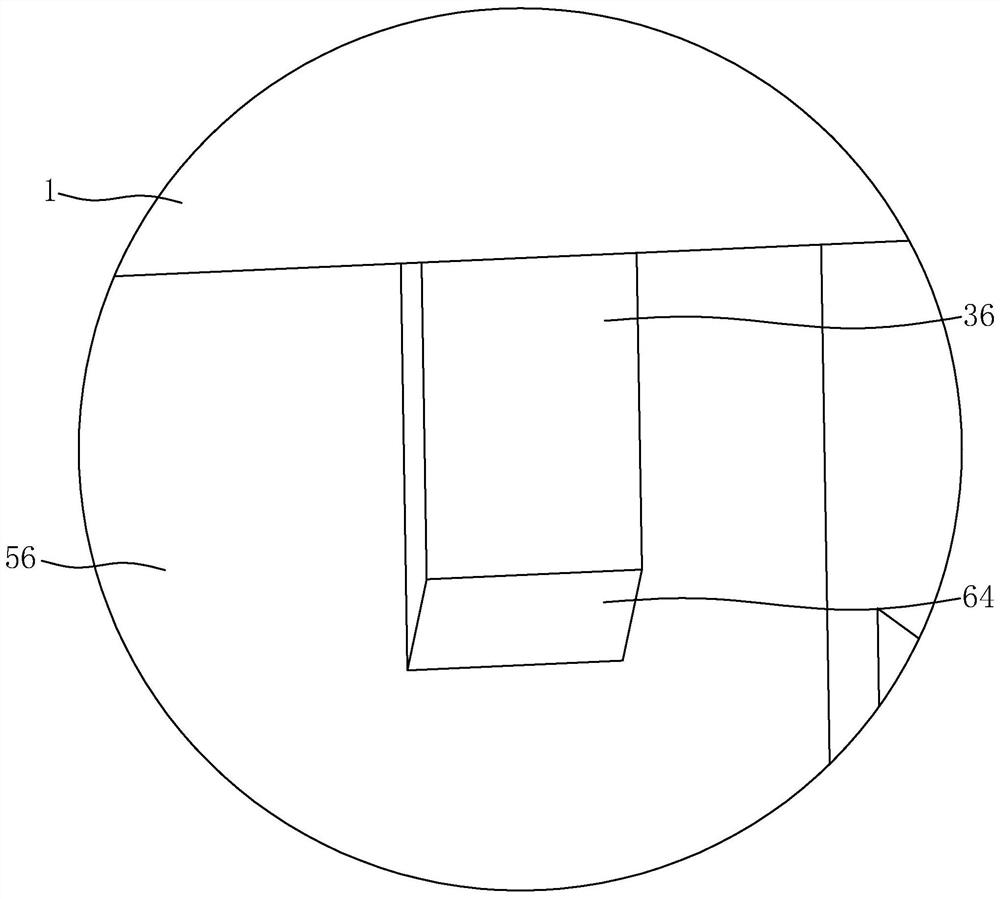

InactiveCN110497653AReduces accidental creasingImprove hemming effectBag making operationsPaper-makingEngineeringPortal frame

The invention relates to a plastic woven bag edgefold shaping machine and a method. The machine comprises a clamping base, a working electric sliding block, a displacement frame, a synchronizing device, two positioning clamps, a portal frame, a driving cylinder, a pressing device and a mark ironing device. The working electric sliding block is mounted on the clamping base. The displacement frame is arranged on the working electric sliding block. The synchronizing device is mounted in the middle of the displacement frame. The two positioning clamps are mounted at the left and right ends of thesynchronizing device. The mark ironing device is mounted in the middle of the displacement frame. The portal frame is mounted on the displacement frame. The upper end of the portal frame is connectedwith the pressing device through the driving cylinder. By means of the plastic woven bag edgefold shaping machine and the method, the problems that an existing edgefold machine commonly adopts rigid pressing for woven fabric, two pressing dies are adopted for pressing the woven fabric repeatedly, clear folding marks can only be obtained through repeated pressing since the woven fabric is flexiblefabric, and the edgefold shaping effect is poor can be solved.

Owner:台州市伟鸿家居用品有限公司

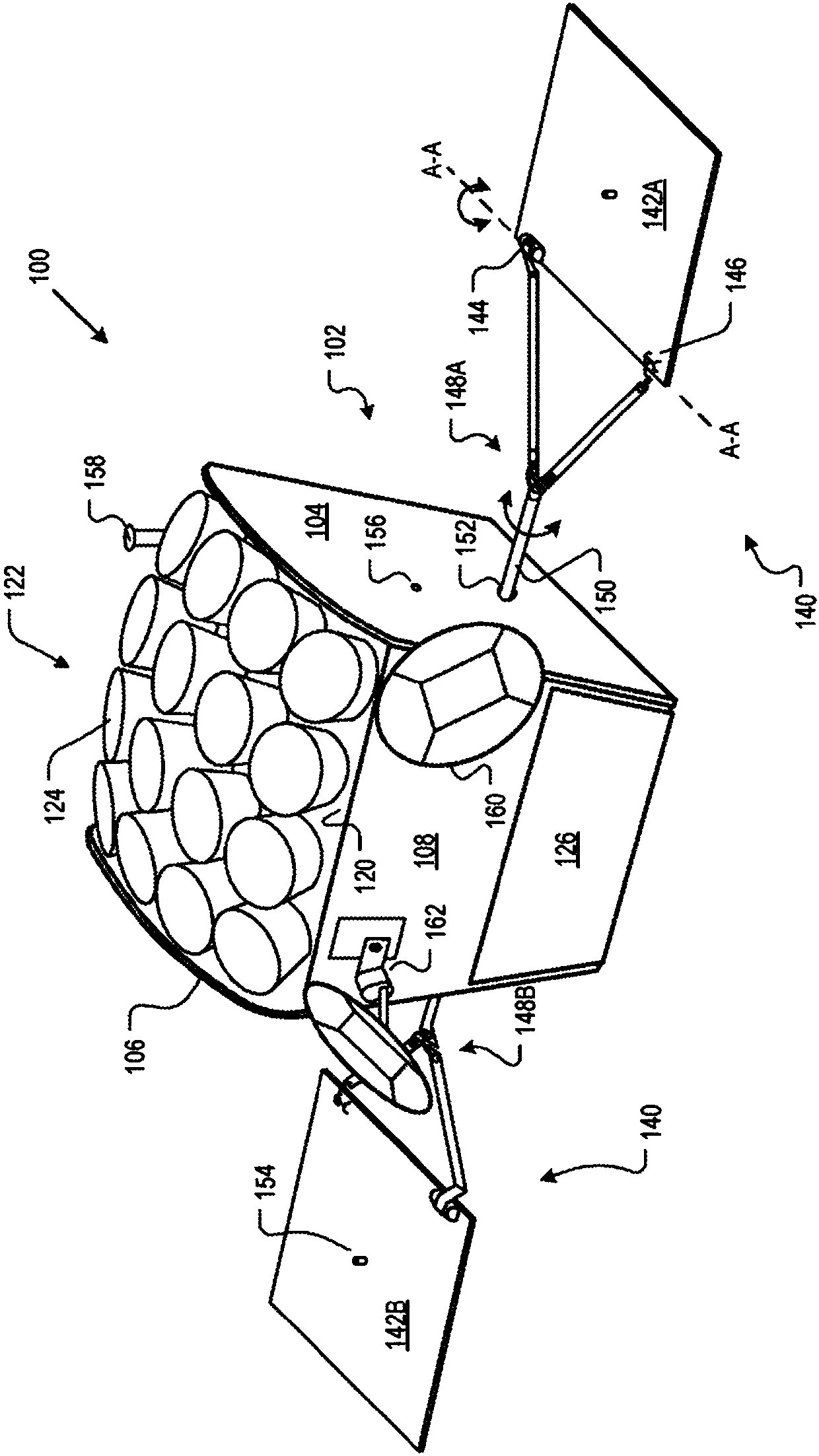

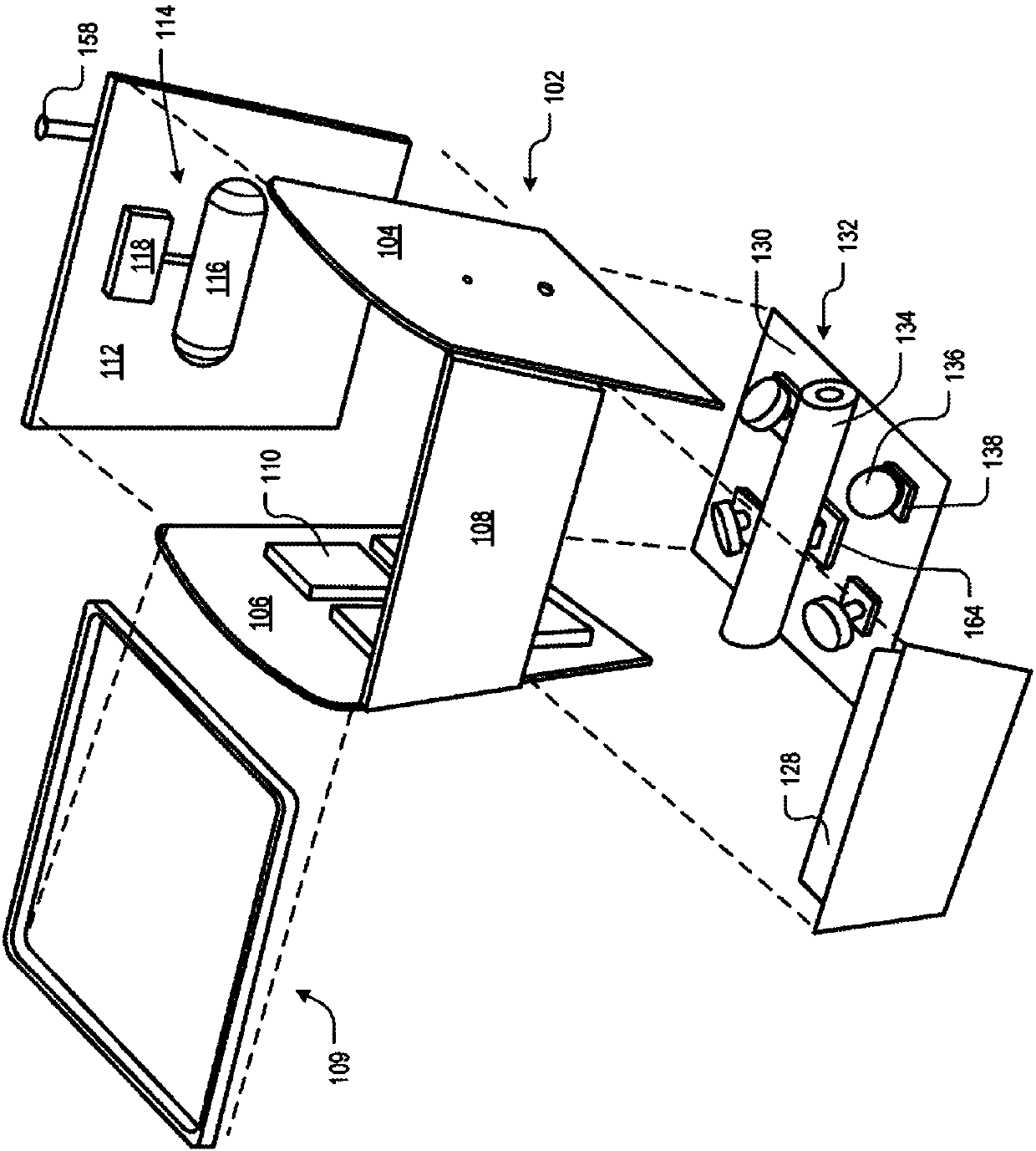

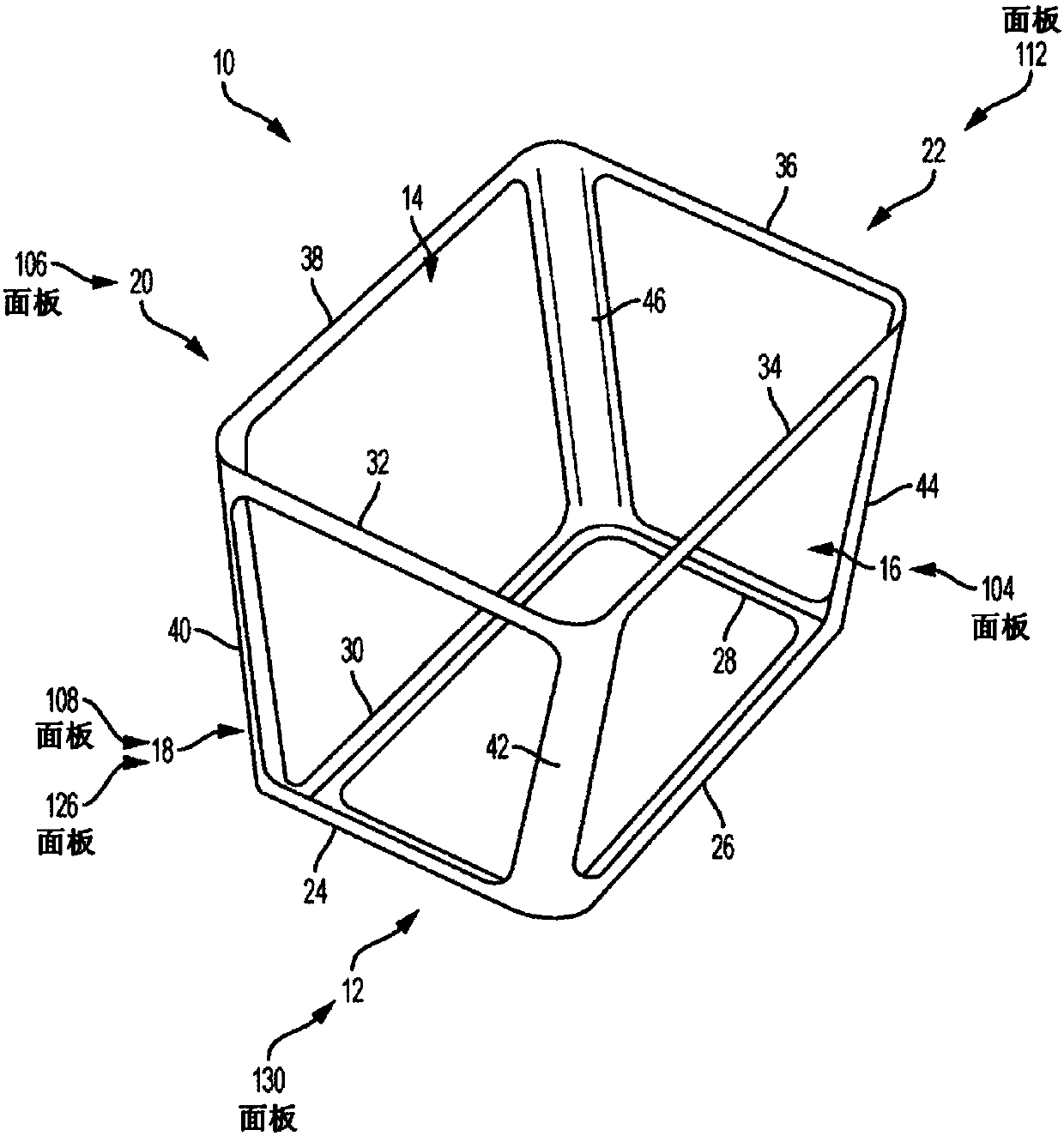

Satellite frame and method of making a satellite

InactiveCN107848634ALow costReduce the possibility of misalignmentCosmonautic propulsion system apparatusArtificial satellitesEngineeringSatellite

A satellite frame includes a one-piece integrated body defining a plurality of sides for attaching satellite components thereto. Use of the single integrated satellite body minimizes the amount of fasteners and alignment equipment and processes. Use of the single piece frame also allows for the maximum possible specific stiffness by greatly reducing the number of connections and structural interfaces.

Owner:WORLDVU SATELLITES

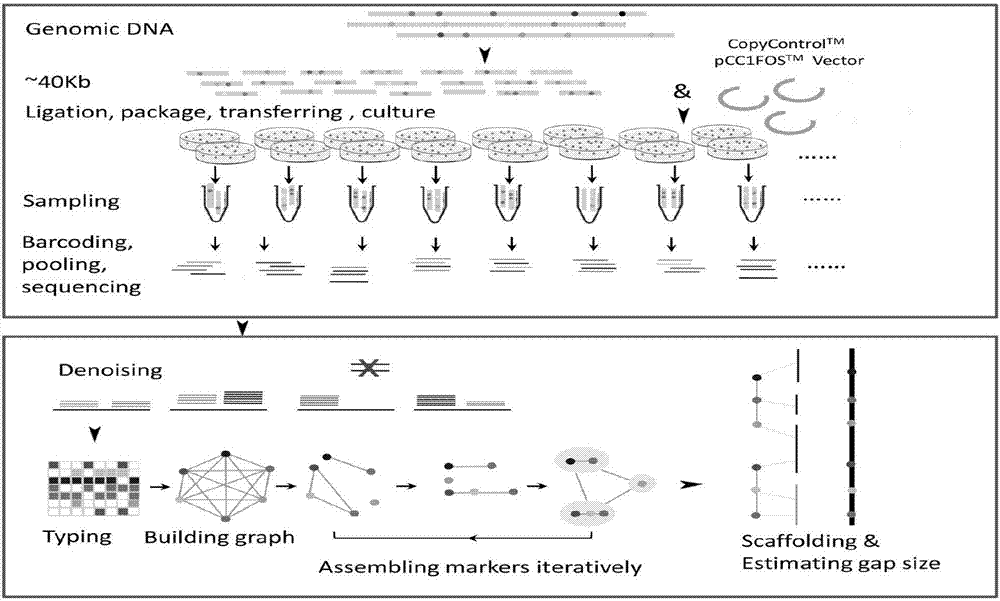

Auxiliary genome assembly method based on artificial meiosis

ActiveCN107058298AReduce the possibilityEliminate restriction enzyme digestion PCR clone decoding methodDNA preparationHigh densityAccessory genome

The invention discloses an auxiliary genome assembly method based on artificial meiosis. A genome in a form of clone library is equally divided so as to establish random artificial meiosis samples, and the random artificial samples are treated through Hpall transmethylase and FspEi methyl-modified dependent-type incision enzyme to form and analyze typing markers with high densities; and then sorting information of the typing markers is obtained; therefore, further assembly of scaffold or direct cascade assembly of Pacbio sequencing reads are achieved. Based on an assembly strategy of artificial meiosis, the auxiliary genome assembly method has the advantages of being easy in experiment operation, short in period, low in cost and capable of splicing the genome with high coverage and accuracy, and owns a wide application prospect in species with relatively complicated and highly heterozygous genomes.

Owner:OCEAN UNIV OF CHINA

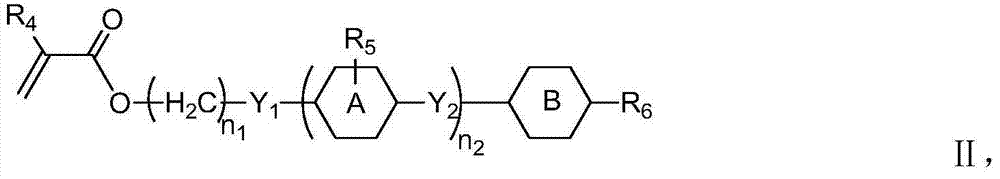

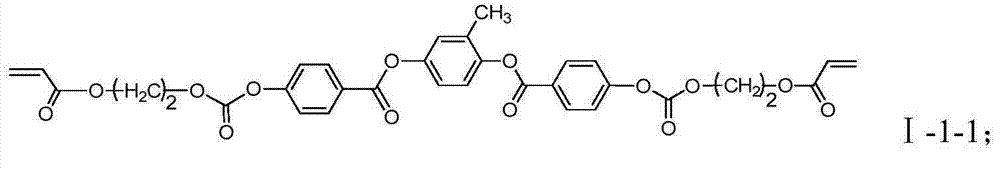

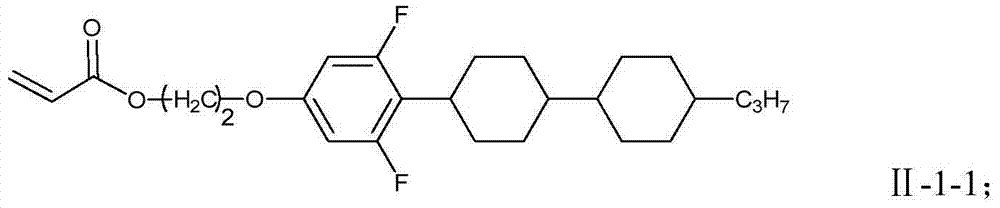

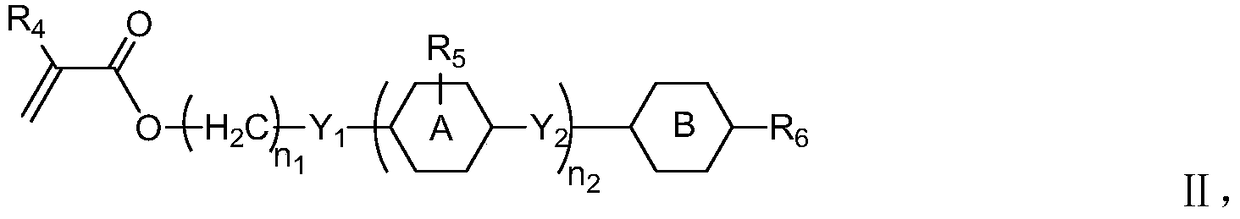

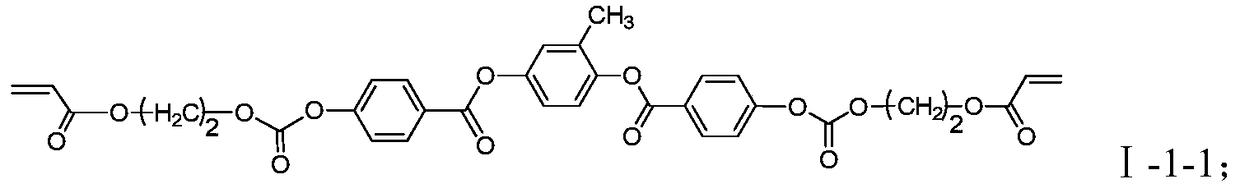

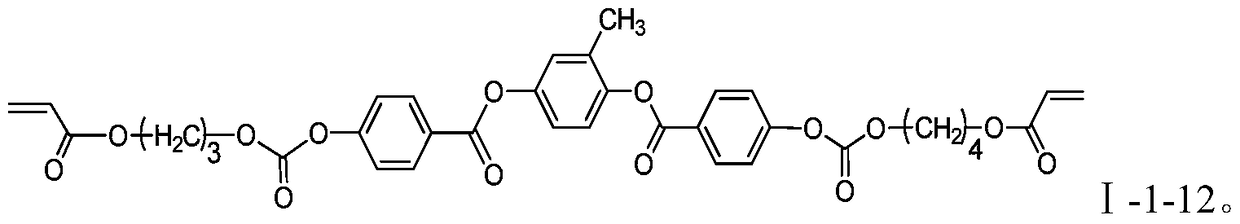

Polymeric liquid crystal composition and application thereof

ActiveCN105441089AImprove matchReduce the possibility of misalignmentLiquid crystal compositionsOptical elementsCrystallographyRefractive index

The present invention provides a polymeric liquid crystal composition. The polymeric liquid crystal composition is low in melting point and long in supercooling time. Meanwhile, the value of the refractive index n<o> of the polymeric liquid crystal composition is between 1.495 and 1.502, and the value of the birefringence index [delta]n is between 0.145 and 0.180. The present invention also provides application of the polymeric liquid crystal composition in the aspect of naked eye 3D display.

Owner:JIANGSU HECHENG ADVANCED MATERIALS

Back face welding method and welding table for aluminum curtain wall plates

ActiveCN111112905AReduce the likelihood of damagePrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesWall plateWelding process

The invention discloses a back face welding method and a welding table for aluminum curtain wall plates, and relates to the technical field of back face welding. According to the key points of the technical scheme, the back face welding method comprises the following steps that a to-be-welded first aluminum curtain wall plate is taken to be provided with a square inserting groove, a second aluminum curtain wall plate is taken, and a square inserting block is fixed; the front faces of the two aluminum curtain wall plates are downwards placed on a base, and the square inserting block and the square inserting groove are connected in an inserted mode; and welding is conducted from the back face joint of the two aluminum curtain wall plates. The welding table comprises the base, two abutting pieces and two sets of pressing devices; each set of pressing device comprises two supporting rods and two pressing plates; and a driving mechanism for driving the supporting rods to rotate is arrangedbetween each supporting rod and the corresponding abutting piece. According to the back face welding method and the welding table for the aluminum curtain wall plates, the problem that a coating is damaged by the high temperature during welding is solved, and possibility that the coating of the wall plates is damaged by the high temperature during welding is reduced. In addition, the welding tablehas the advantage that the aluminum curtain wall plates are fixed in the welding process.

Owner:江苏诺米新材料科技有限公司

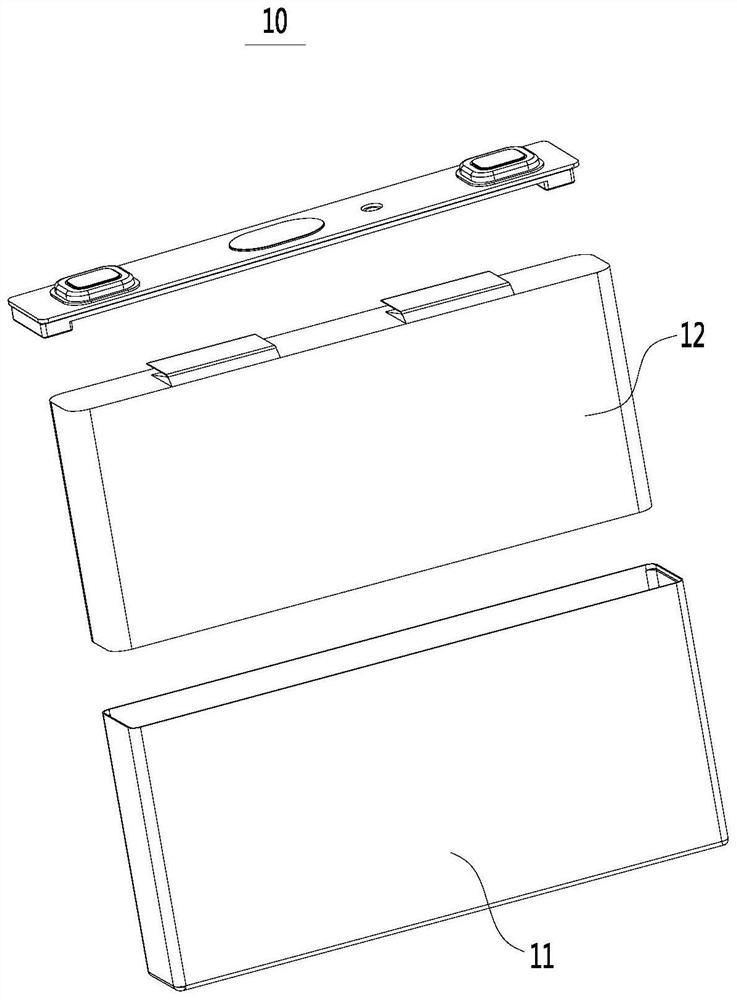

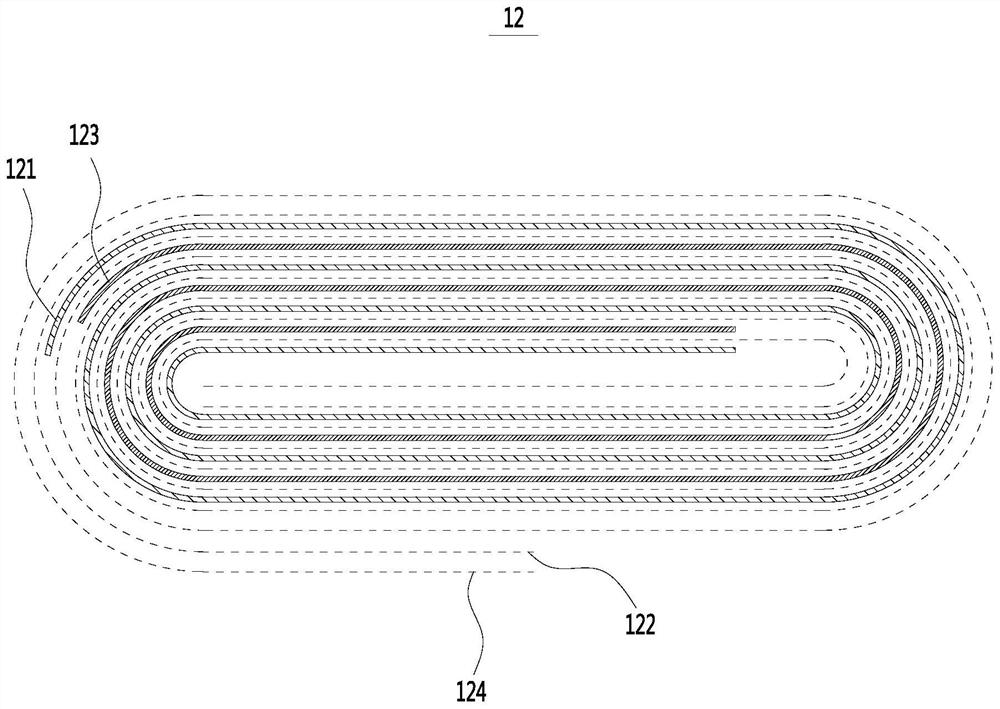

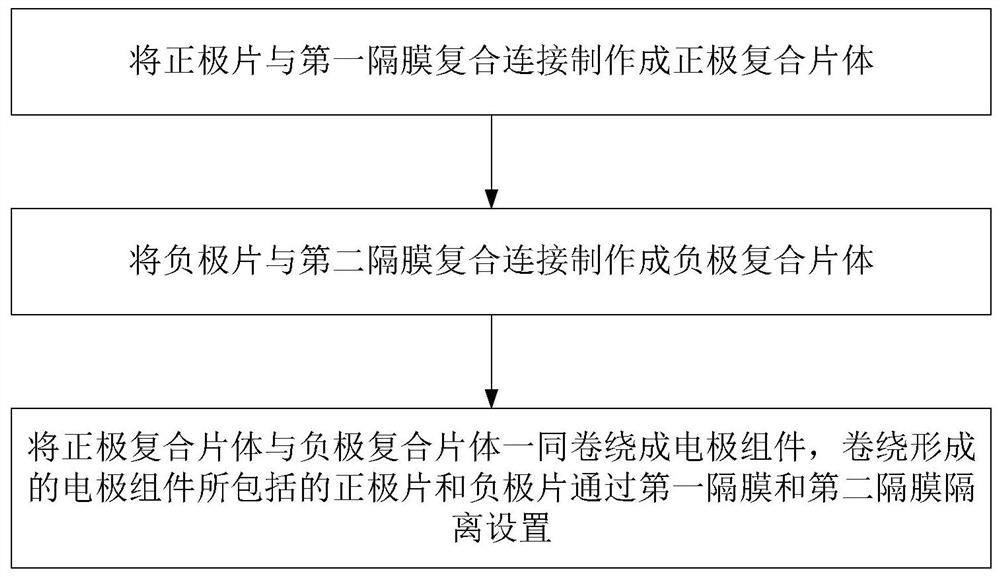

Method and apparatus for manufacturing electrode assembly of secondary battery

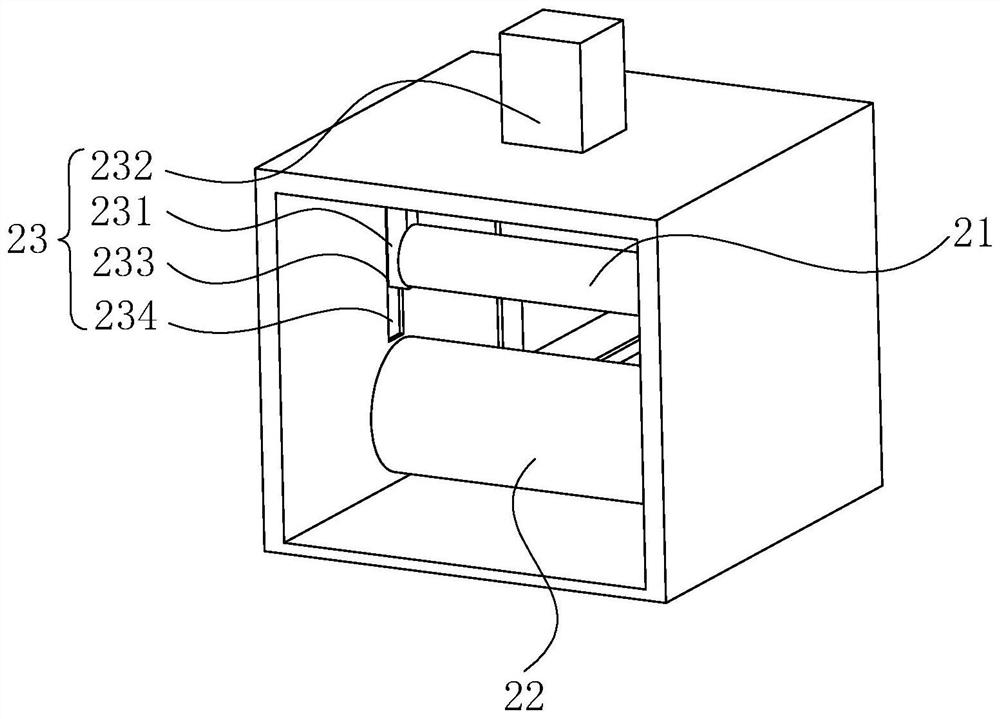

PendingCN112310461AReduce the possibility of misalignmentReduces chance of misalignmentAssembling battery machinesFinal product manufactureElectrical batteryEngineering

The present invention relates to a method and apparatus for manufacturing an electrode assembly of a secondary battery. The embodiment of the invention provides a method for manufacturing an electrodeassembly of a secondary battery. The method comprises the following steps that: a positive plate and a first diaphragm are compositely connected to manufacture a positive composite plate body; a negative plate and a second diaphragm are compositely connected to manufacture a negative composite plate body; the positive electrode composite plate body and the negative electrode composite plate bodyare wound together to form an electrode assembly, the positive plate and the negative plate are isolated through the first diaphragm and the second diaphragm. According to the method for manufacturingthe electrode assembly of the secondary battery, the yield of the electrode assembly can be improved, the structure of winding equipment is simplified, and the winding working efficiency is improved.

Owner:CONTEMPORARY AMPEREX TECH CO

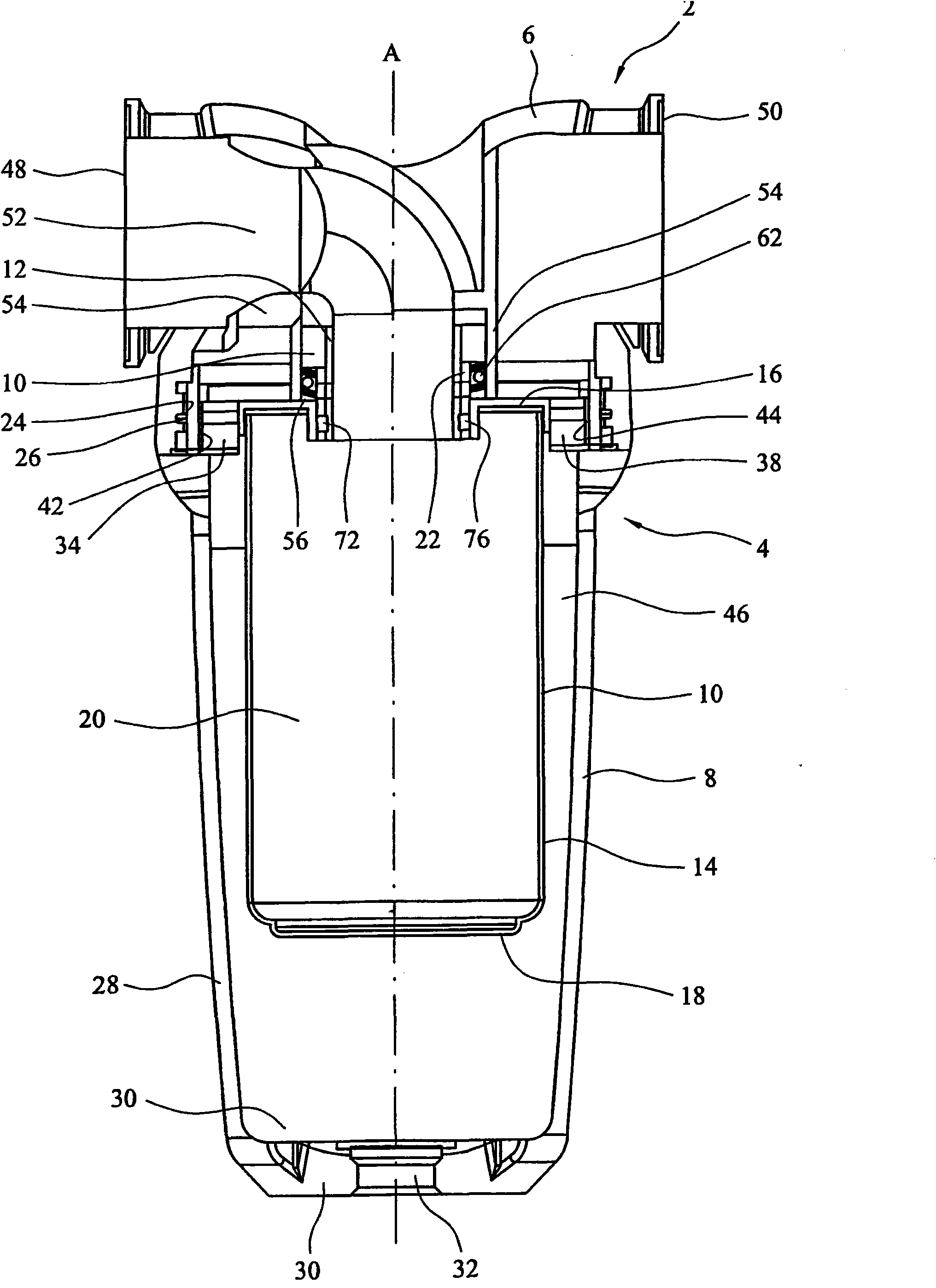

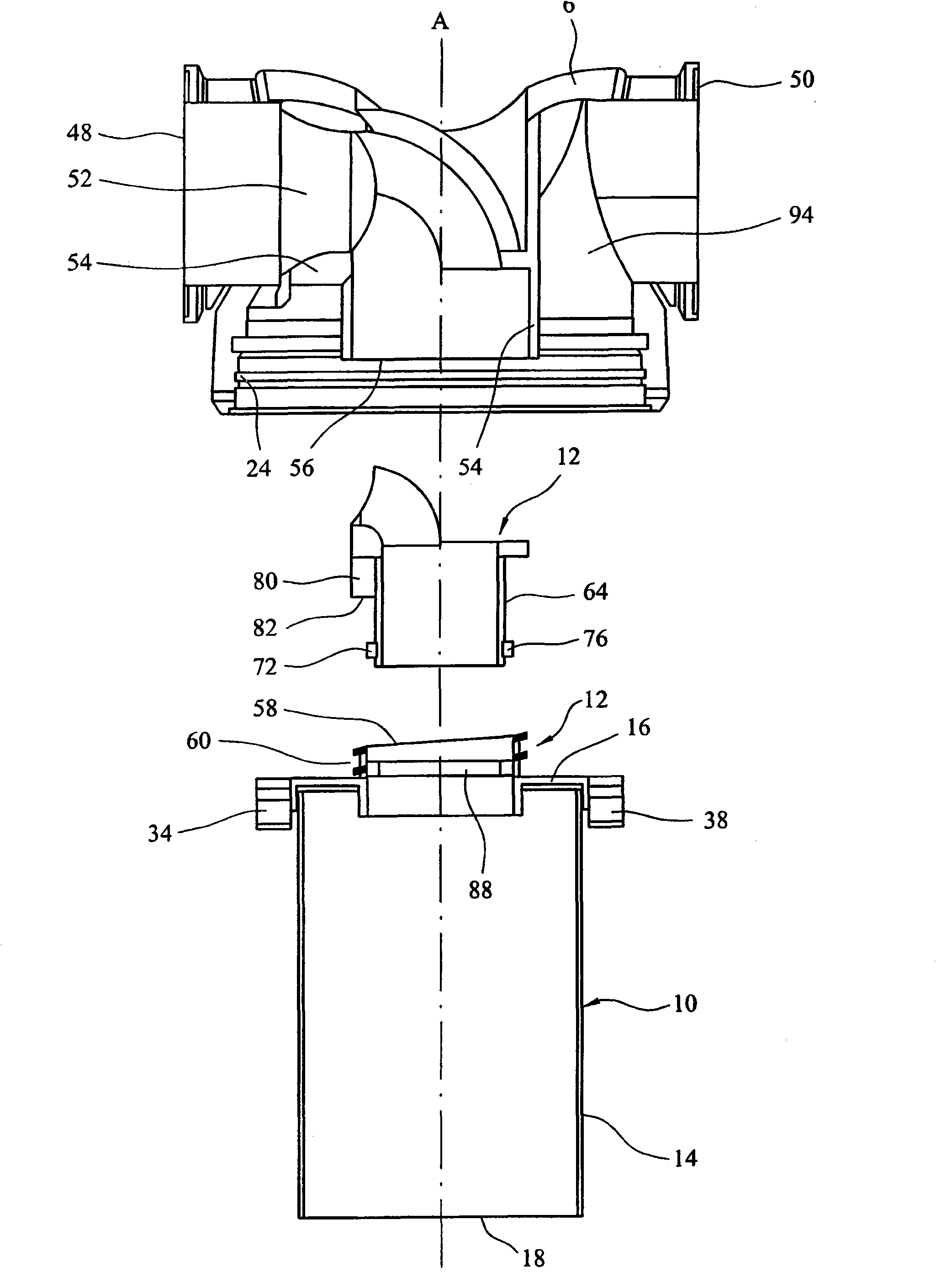

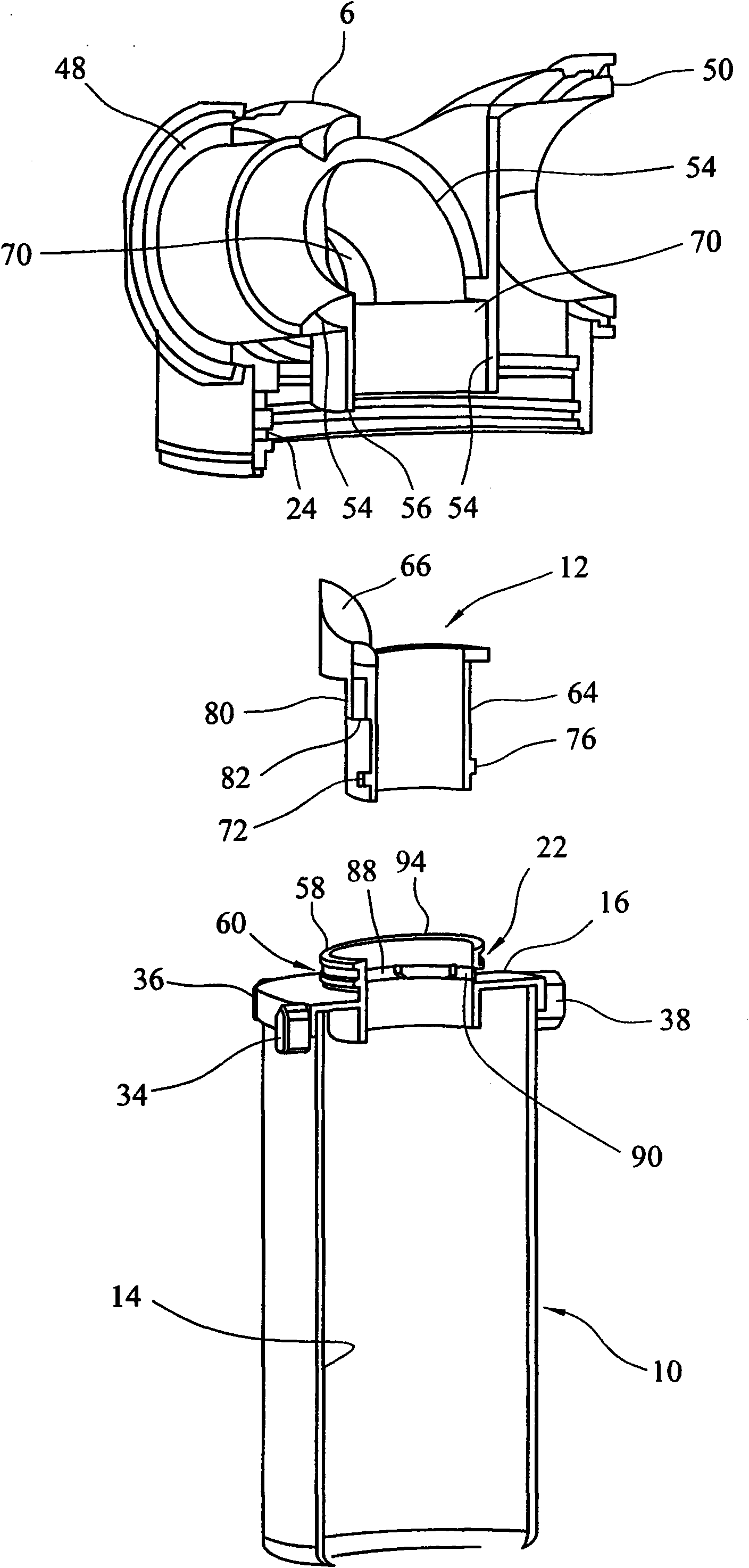

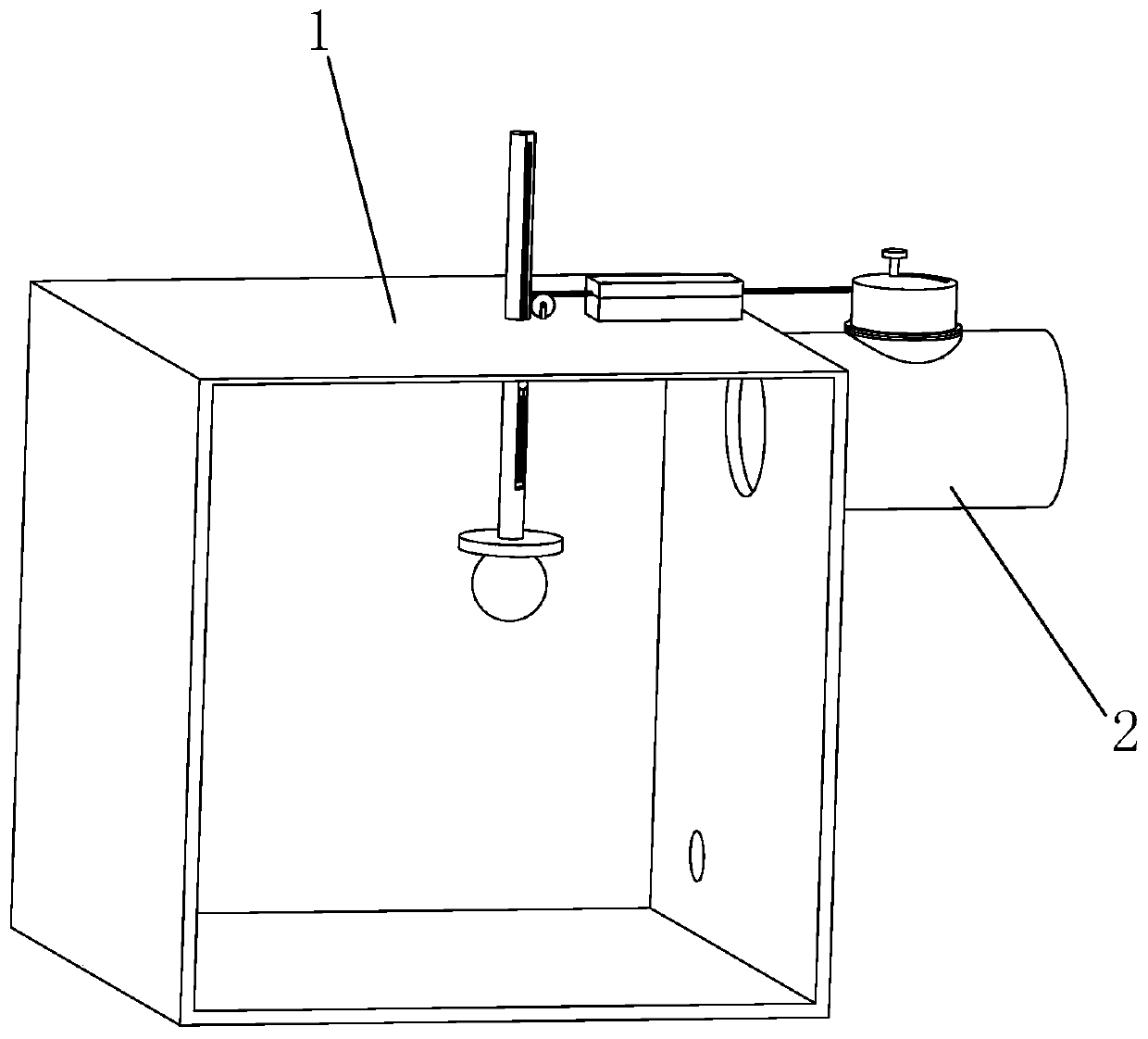

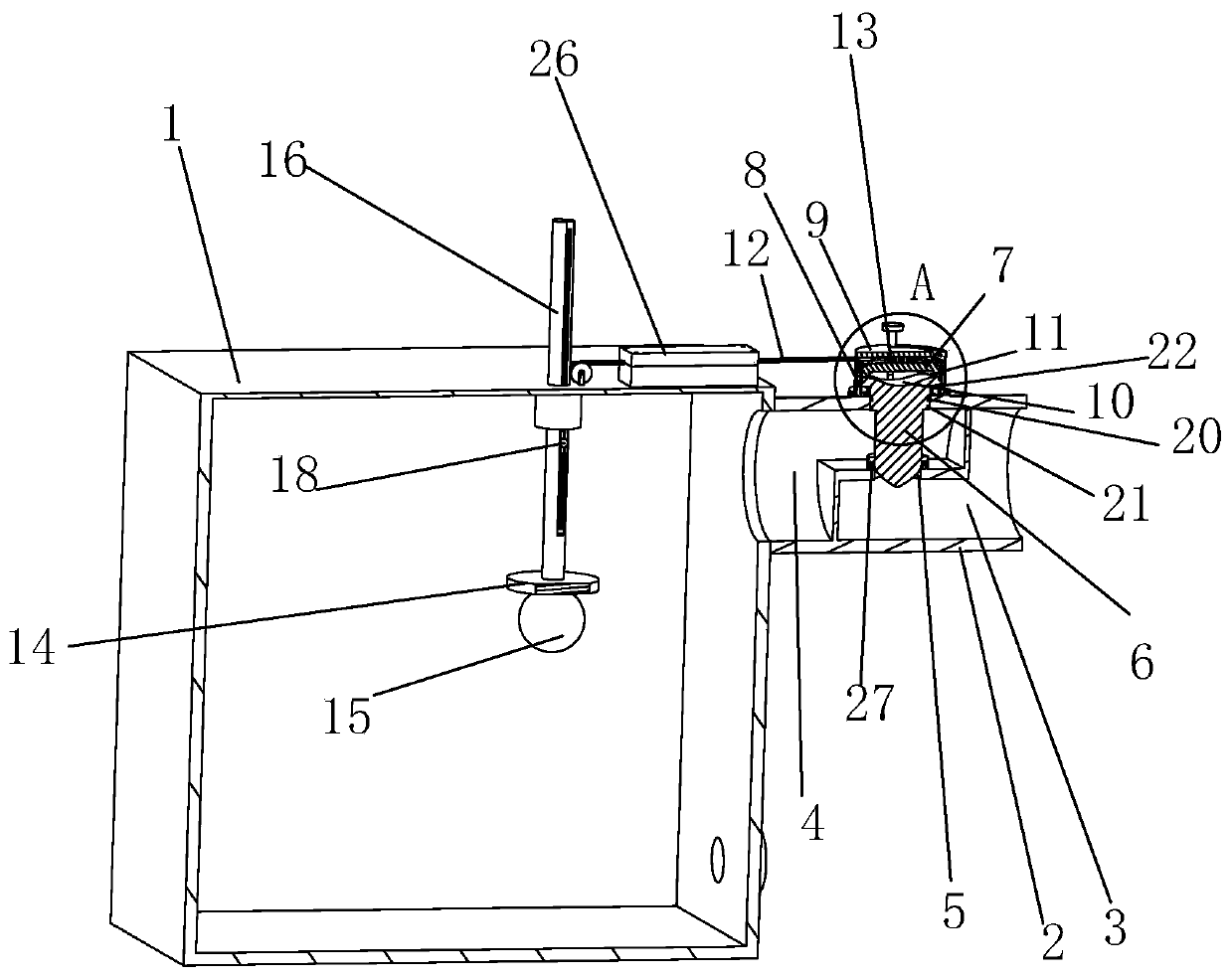

Filter assembly

ActiveCN101772369AReduce the possibility of misalignmentAligned properlyDispersed particle filtrationMembrane filtersRelative motionMechanical engineering

A filter assembly for removing material entrained in a fluid stream, comprises a housing for a filter element, having a head part and a body part for receiving a filter element, and inlet and outlet ports for the fluid that is to be filtered. The head part and the body part each have engagement formations which enable the head and body parts to be connected to one another and separated by relative rotation about an axis which is coaxial with a head axis and a body axis. Head and body part keying formations can be provided in the form of at least one recess which is provided in a rib on one ofthe head and body parts, and at least one projection which is provided on the other of the head and body parts. The keying formations require alignment of the head and body axes for initial assembly of the head and body parts when the projection is can be received in the recess in the rib so as to restrict relative rotation of the head and body parts, and so that the head and body parts can then to be moved to an assembly position in which the projection has passed through the rib so that the head and body parts can be rotated relative to each other to allow the engagement formations to become engaged to one another.

Owner:PARKER HANNIFIN CORP

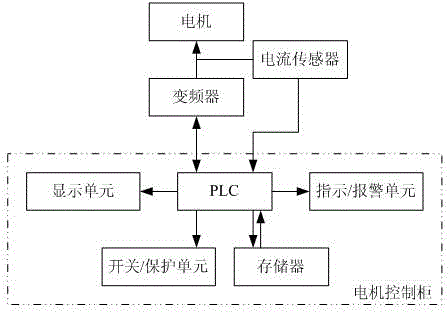

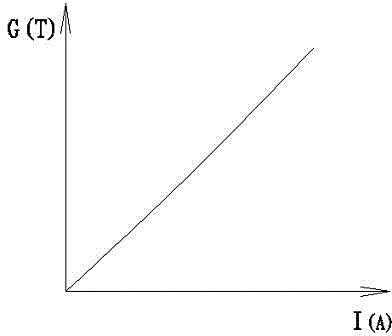

High-torque low-speed permanent magnet synchronous motor hoisting load on-line detection system and detection method

InactiveCN104310220AEasy to collectSimplified throughputSafety gearFrequency changerSynchronous motor

The invention relate to a high-torque low-speed permanent magnet synchronous motor hoisting load on-line detection method and a system. The system comprises a high-torque low-speed magnet synchronous motor, a control device, and a signal collecting device used for acquiring current signals of the motor. The signal collecting device relates to a current sensor used for collecting current inputting signals and / or a frequency converter capable of outputting current outputting signals. According to the online detection method, the current signals of the motor are acquired; the current signals are adopted as sensing signals of the hoisting load, or hoisting load data of the motor can be calculated according to the current signals; a current threshold when the hoisting load is overload is set; and when the collected current signals reach or exceed the set current threshold, the motor is stopped and / or an overload alarm is given. The detection method and the system are simple in structure, and convenient, rapid, accurate and reliable in signal detection, and are particularly suitable for load / hoisting load detection of the high-torque low-speed permanent magnet synchronous motor and a crane gearless hoisting mechanism based on the motor.

Owner:ZHANGSHU ZHISHENG FORGING

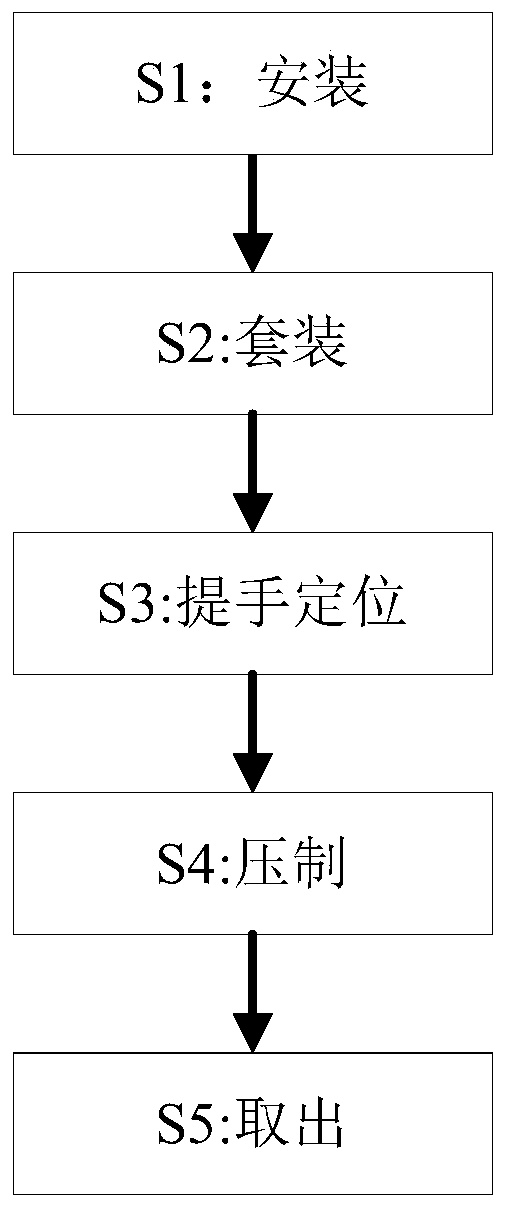

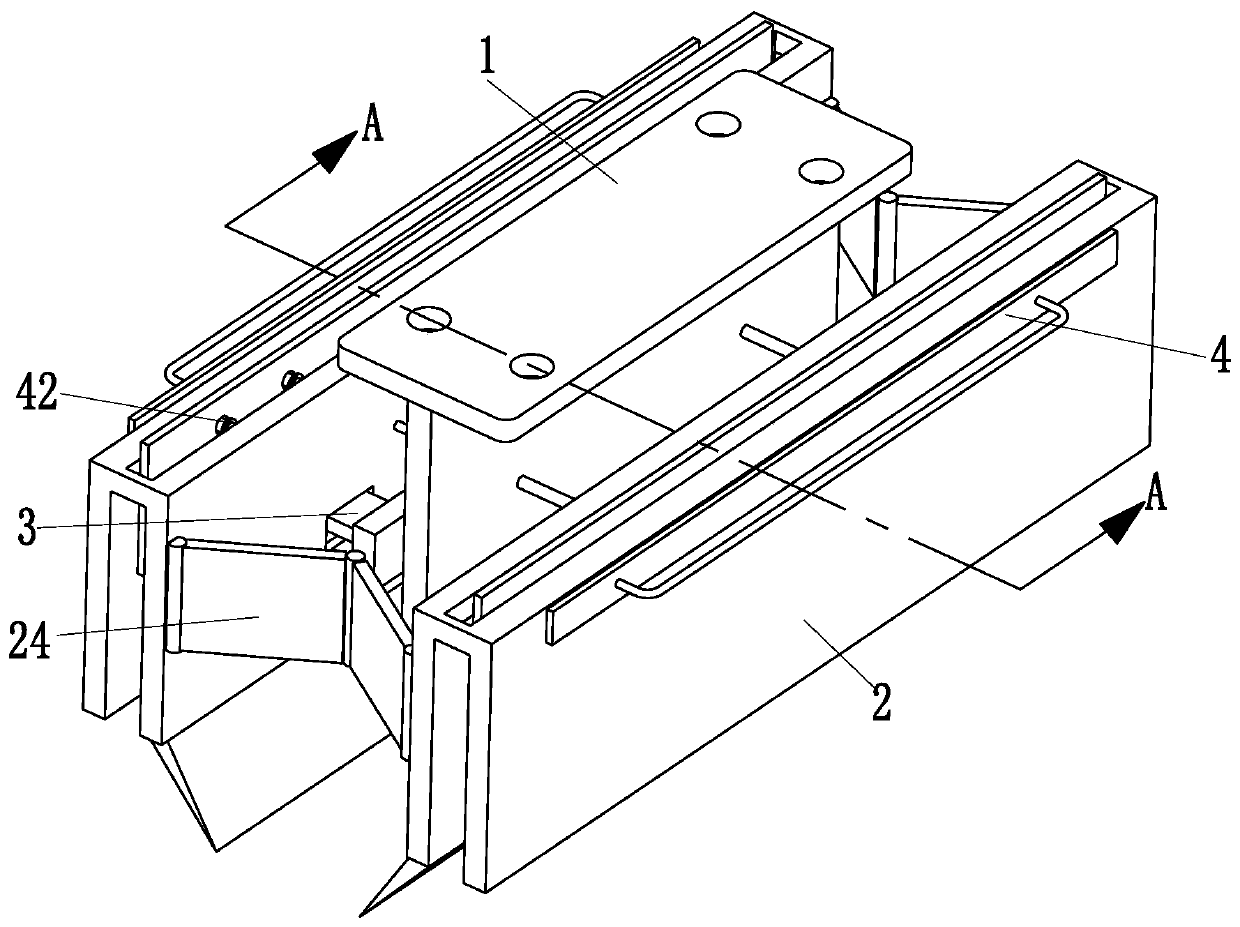

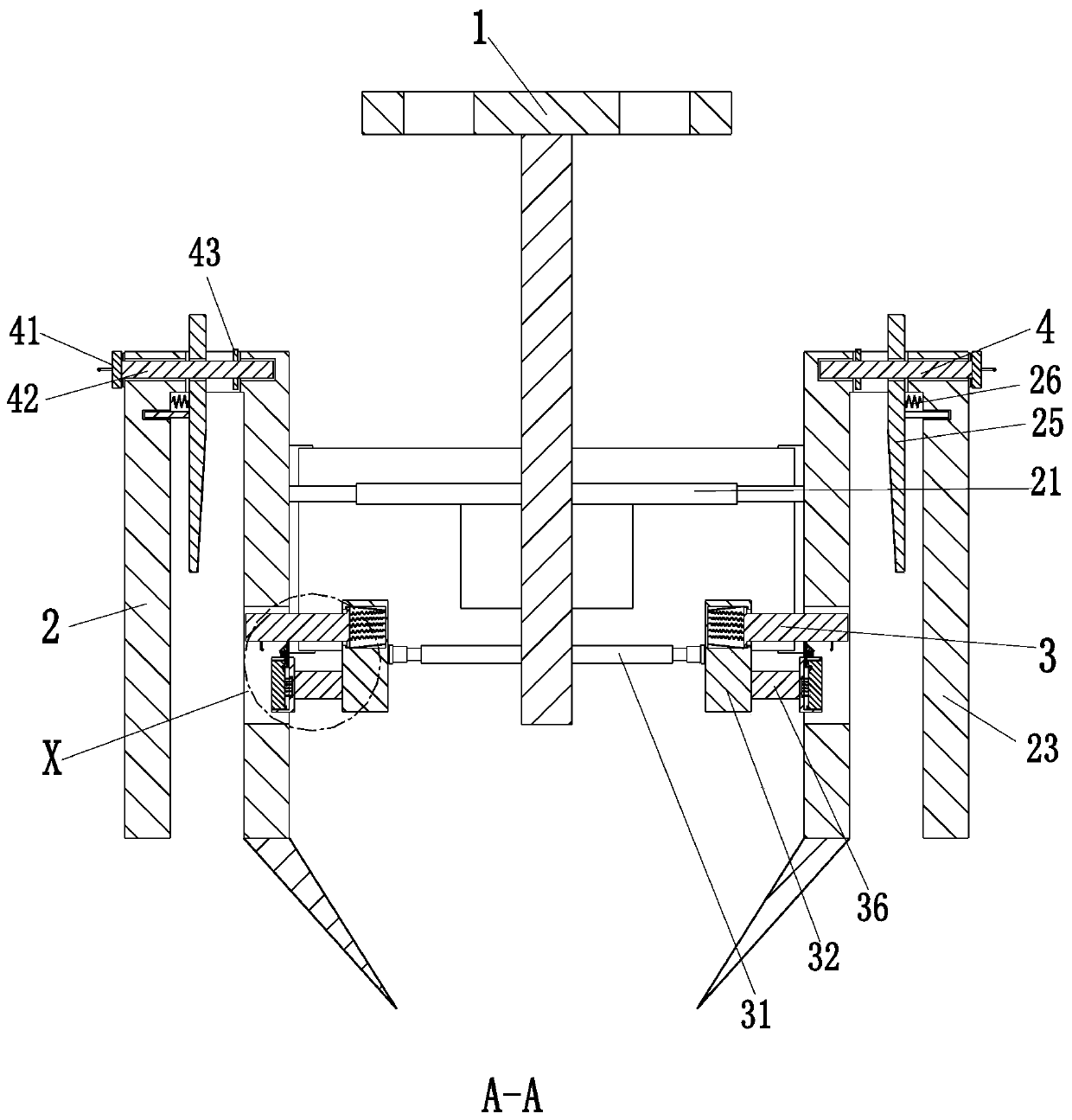

Manufacturing process of non-woven fabric hand bag

ActiveCN111016288AImprove work efficiencyImprove the suppression effectBag making operationsPaper-makingNonwoven fabricMechanical engineering

The invention provides a manufacturing process of a non-woven fabric hand bag. Operation is completed through cooperation of an installation frame, an expansion device, two pressing devices and two handle positioning devices, a problem that the traditional connection mode has many steps and is tedious can be solved, when a lifting handle is adhered to the marking position, manual operation is adopted, problems that the positions of lifting handles of various finished products are slightly different due to small-range dislocation, the lifting handles and a bag body slip due to lubricity of gluesolution during manual pressing, the manual pressing force is not large, and the lifting handles and the bag body possibly fall off in advance before the glue solution is solidified are solved.

Owner:山东绿恒无纺布制品有限公司

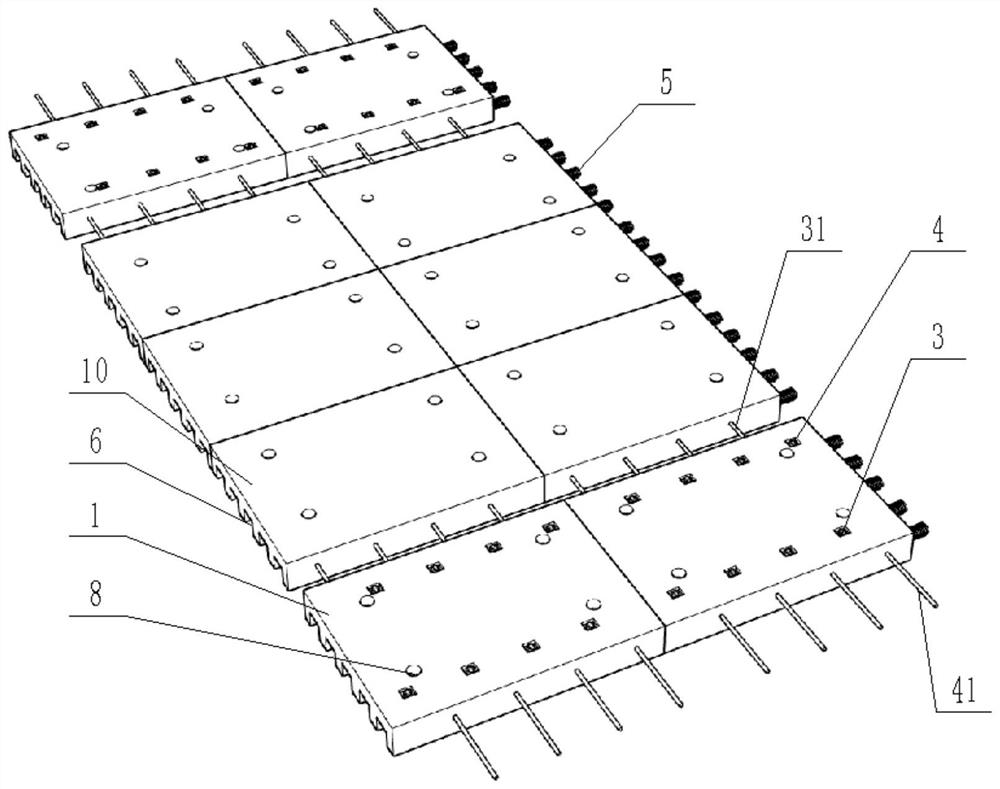

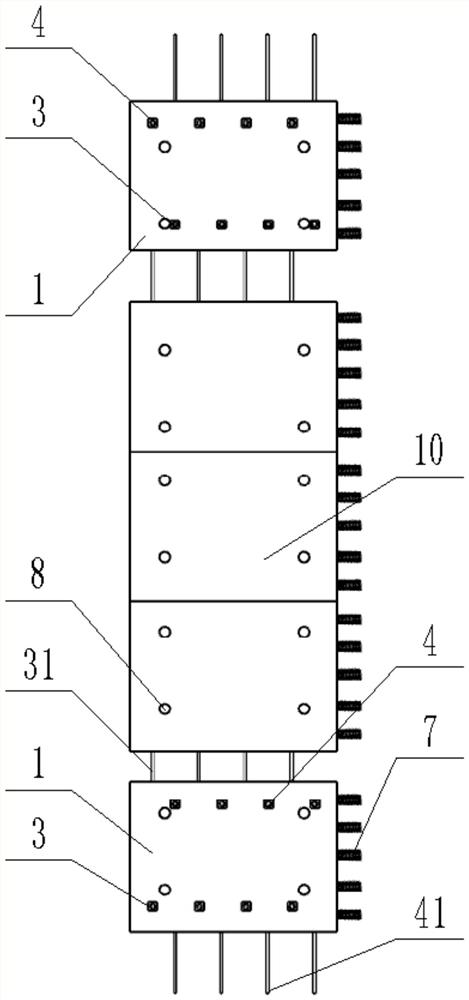

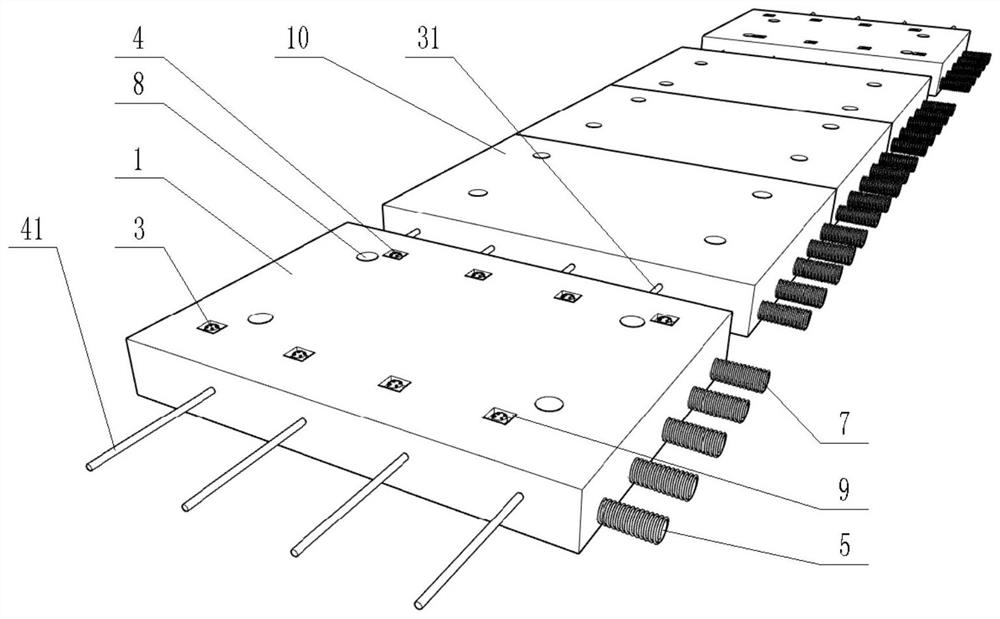

Assembly type cement concrete pavement structure with prestress

ActiveCN113174798AImprove firm performanceEasy to paveSingle unit pavingsPre stressArchitectural engineering

An assembly type cement concrete pavement structure with prestress comprises a first concrete plate and a concrete plate assembly which are connected in sequence, the first concrete plate and the concrete plate assembly are arranged in a spaced mode, and a plurality of prestress hole channels are formed in the first concrete plate and the concrete plate assembly; a plurality of first anchorage devices and a plurality of second anchorage devices are fixedly connected to the top ends of the first concrete slabs respectively and located at the two sides of the first concrete slabs respectively, first steel bars are arranged between the first anchorage devices and the second anchorage devices on the adjacent first concrete slabs, and the two ends of the first steel bars are fixedly connected with the first anchorage devices and the second anchorage devices respectively. and second reinforcing steel bars are arranged between the second anchorage devices and the first anchorage devices on the other adjacent first concrete plate. The step of applying prestress by tensioning the steel bars can be omitted, the construction efficiency is improved, meanwhile, the connection relation between the two adjacent prefabricated road plates is improved, and the possibility that the two adjacent prefabricated road plates are dislocated is reduced.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

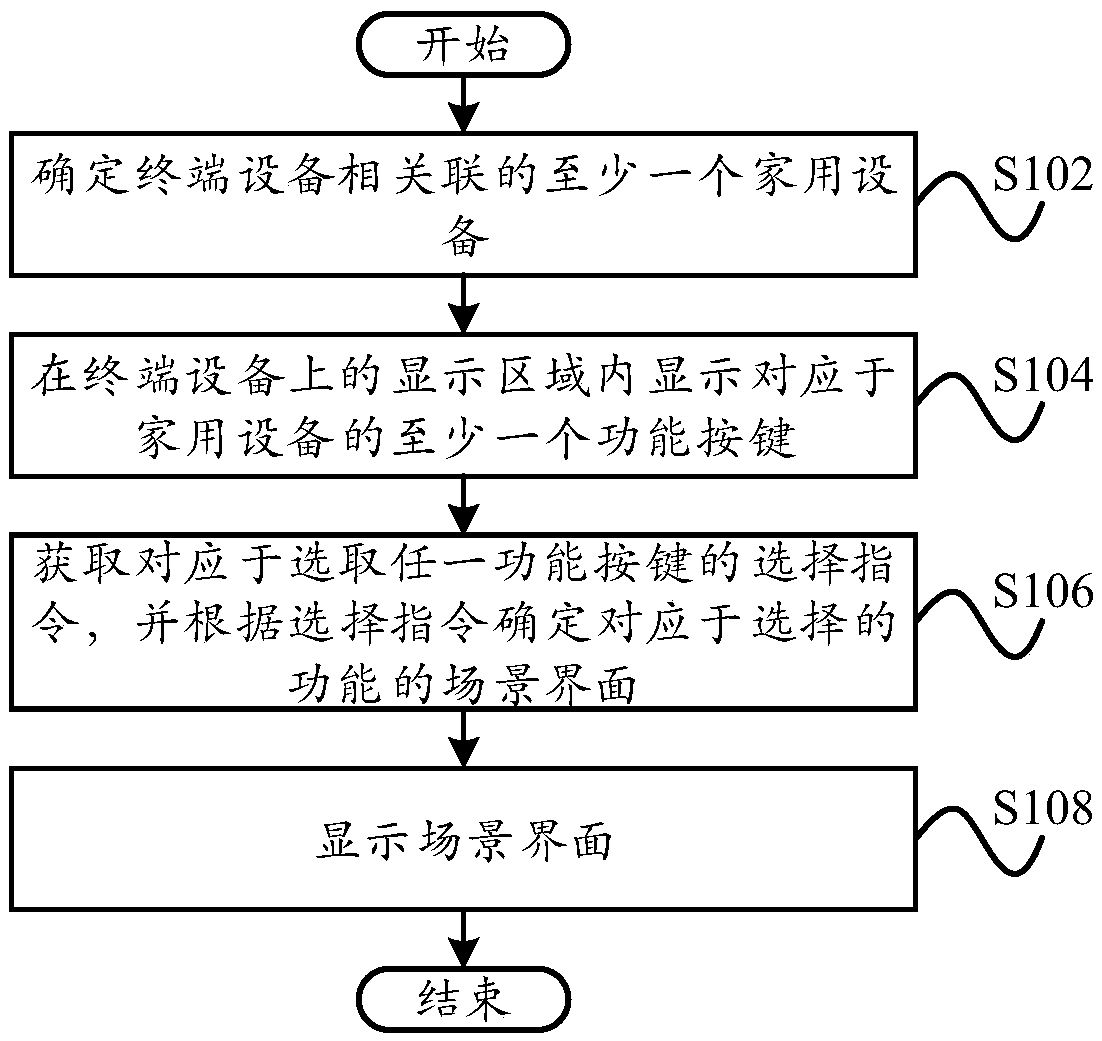

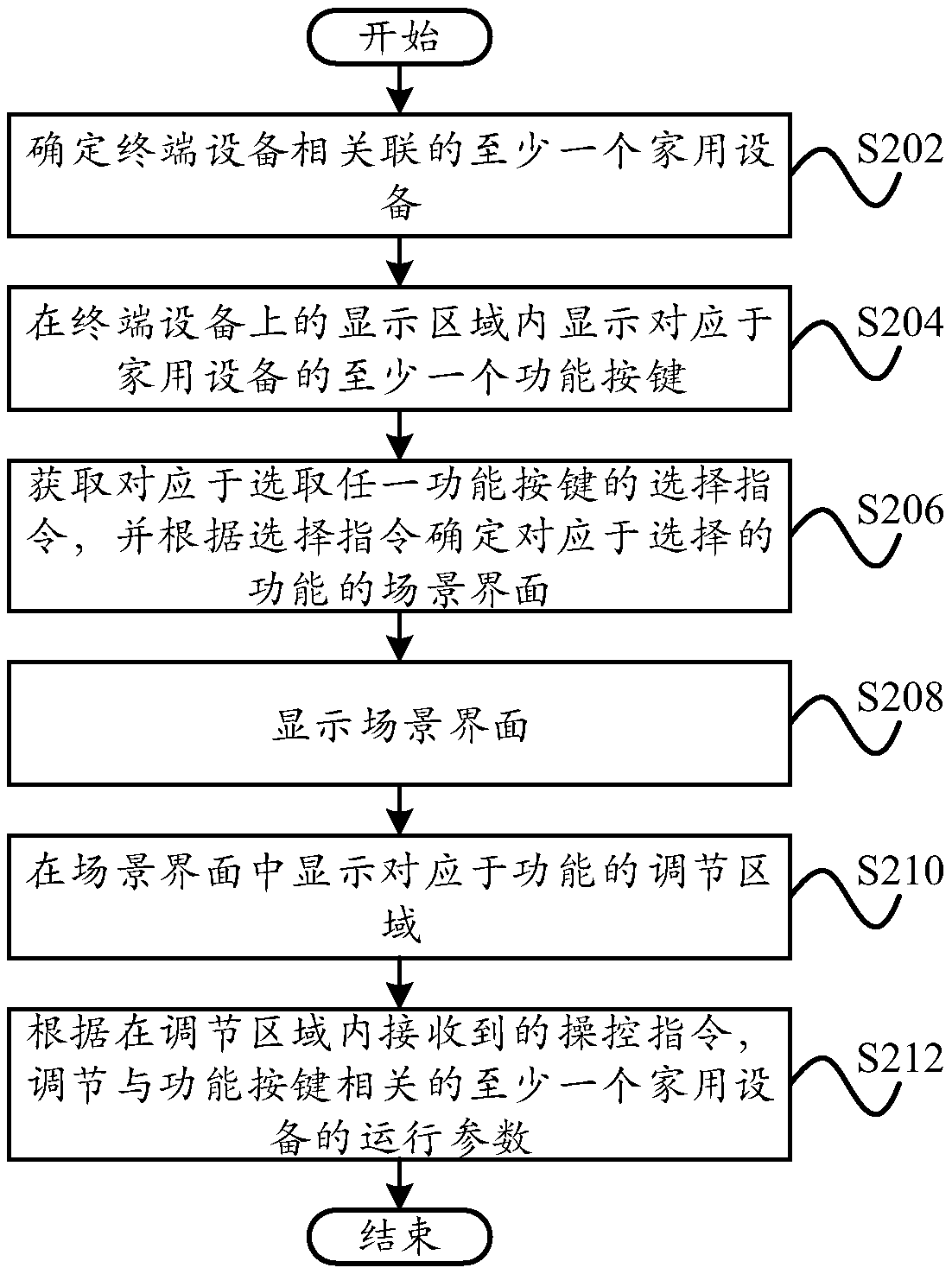

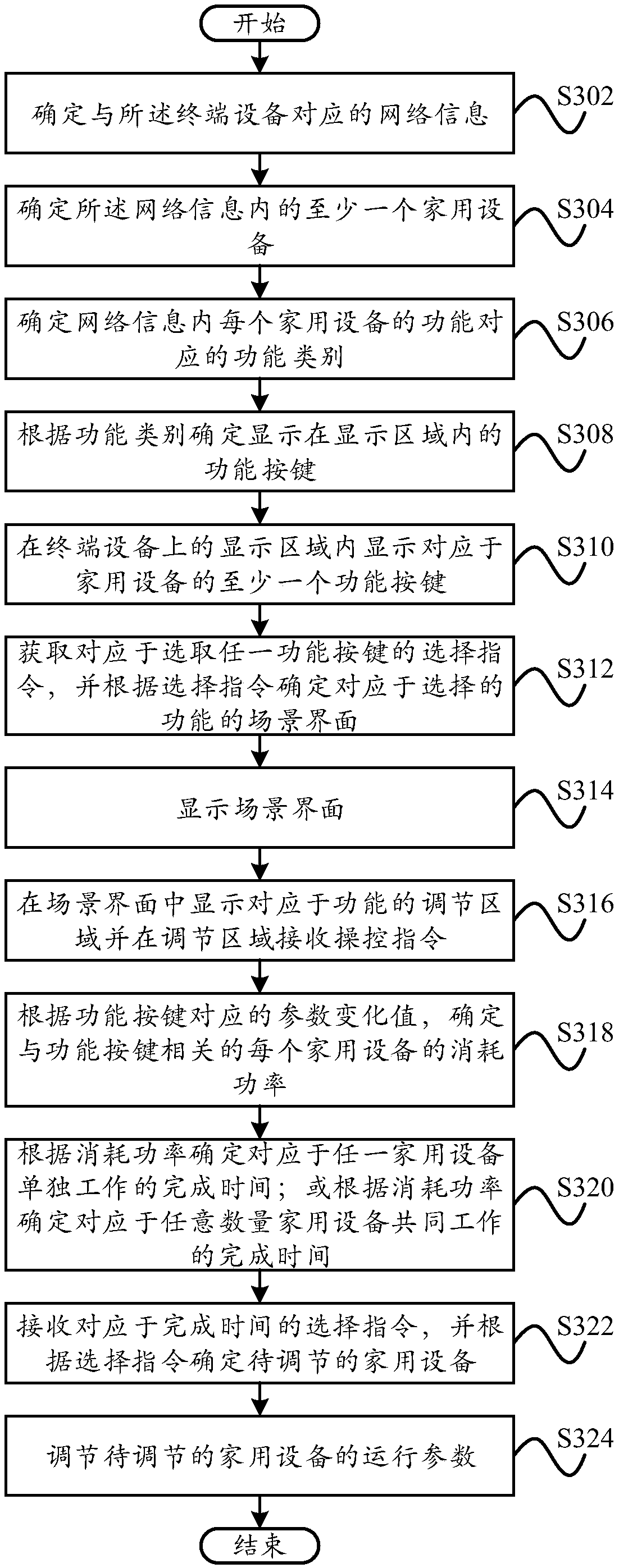

Interface display method, terminal equipment and computer readable memory medium

ActiveCN108880956AGood visualizationEasy to adjustData switching by path configurationSubstation equipmentTerminal equipmentComputer engineering

The invention discloses an interface display method, terminal equipment and a computer readable memory medium. The display method applied to the terminal equipment comprises the steps of determining at least one piece of household equipment associated with the terminal equipment; displaying at least one function key corresponding to the household equipment in a display area on the terminal equipment; obtaining a selection instruction for correspondingly selecting any function key, and determining a scene interface corresponding to a selected function according to the selection instruction; anddisplaying the scene interface. The problem that in the prior art, the scene interfaces and the selected function are not in one-to-one correspondence is solved, a visual effect is relatively good, auser can determine the selected function according to a scene, and the user has the feeling of immersive.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

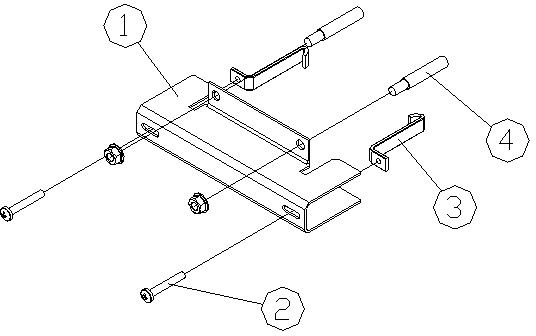

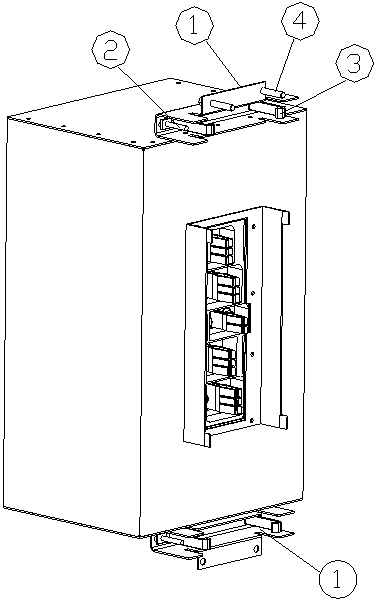

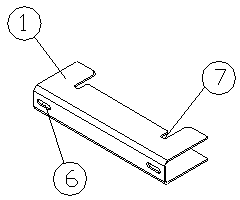

Novel plugging box fixation member

The invention discloses a novel plugging box fixation member. The novel plugging box fixation member comprises casing fixation seats, long bolts, casing fixation hooks and lead-in cylinders, wherein the cross section of each casing fixation seat is horizontally-n-shaped, the side surface of each casing fixation seat is symmetrically provided with long waist-shaped holes, the upper surface and the lower surface of each casing fixation seat are each symmetrically provided with two grooves, a guide plate is arranged between the two grooves in any one surface of each casing fixation seat, and the guide plate is symmetrically provided with lead-in holes; and one end portion of each casing fixation hook is provided with a through hole, the casing fixation hooks pass through the long waist-shaped holes through the long bolts, the through holes are fixed in the casing fixation seats, and the lead-in cylinders are fixed in the lead-in holes of the casing fixation seats. According to the invention, the casing fixation seats can protect the casing fixation hooks, prevents the casing fixation hooks from bumps, the grooves in the casing fixation seats also have a positioning effect, the possibility of deviated plugging of a plugging box is reduced, and the lead-in cylinders can provide accurate positioning for the plugging box; and at the same time, the casing fixation hooks employ S-shaped structures, the plugging box is enabled to be fixed more firmly and not slide down due to a dead weight, and thus safe operation is guaranteed.

Owner:江苏向荣电气有限公司

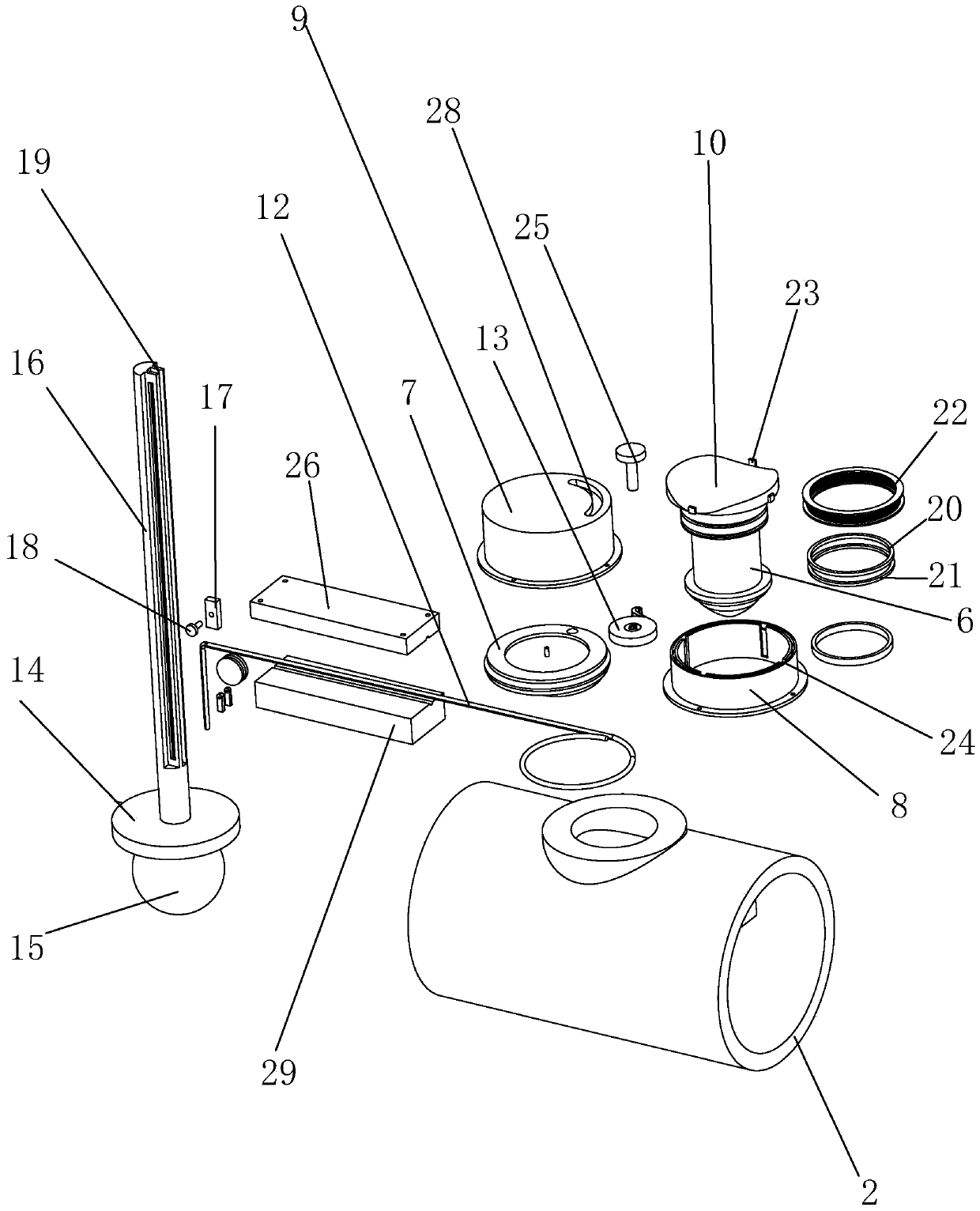

Automatic flow control valve

ActiveCN110594481AControl flowReduce the difficulty of operationOperating means/releasing devices for valvesWater flowEngineering

The invention discloses an automatic flow control valve which is fixedly connected with a water tank. The automatic flow control valve comprises a valve body, a valve element, a driving assembly and awater level control assembly, wherein the valve body is provided with a first space and a second space which communicate with each other through a first through hole: the valve element is arranged vertical to the first through hole and used for controlling the working state of the first through hole; the driving assembly is used for controlling the working state of the valve element; and the water level control assembly controls the working state of the driving assembly through the water level. According to the automatic flow control valve, the working states of the valve element and the first through hole are controlled by matching the driving assembly with the water level control assembly, thereby reducing the operation difficulty and realizing high regulation and control precision; thedescending height of the valve element is controlled along with the rising of the water level, and the flow rate of water is controlled.

Owner:盐城市圣明斯精密机械有限公司

Pipe piles and open caisson combined construction method

ActiveCN109914454AReduce the possibility of misalignmentIncrease frictionCaissonsFalseworkGeological exploration

The invention discloses a pipe pile and open caisson combined construction method. The method comprises the steps of (1) geological exploration; (2) designing measurement calculation; (3) site leveling; (4) construction of pipe piles; (5) connecting an open caisson casting blade angle and the pipe piles into a whole; (6) sinking combination of an open caisson and the pipe piles; (7) enabling the open caisson in place; (8) construction of an open caisson cushion layer; (9) secondary construction of the open caisson and the pipe piles; (10) secondary pile construction and connection constructionof the open caisson cushion layer. Firstly, the pipe piles are driven into the soil, due to the fact that the pipe piles firstly sink into the ground to be positioned, deviation possibly generated inthe sinking process of the open caisson is reduced, the sinking speed can be controlled, the open caisson can be formed at a time, the time taken for disassembling and reshipping a scaffold and a formwork during sectional manufacturing of the open caisson can be shortened, the working efficiency is improved, and the construction period is shortened; and the pipe piles and the open caisson are poured into a whole and then sink, the mode that the cast-in-place piles are broken while then soil is taken is replaced, the construction difficulty is reduced, resources are effectively saved, and thecost is effectively controlled.

Owner:南京市市政设计研究院有限责任公司

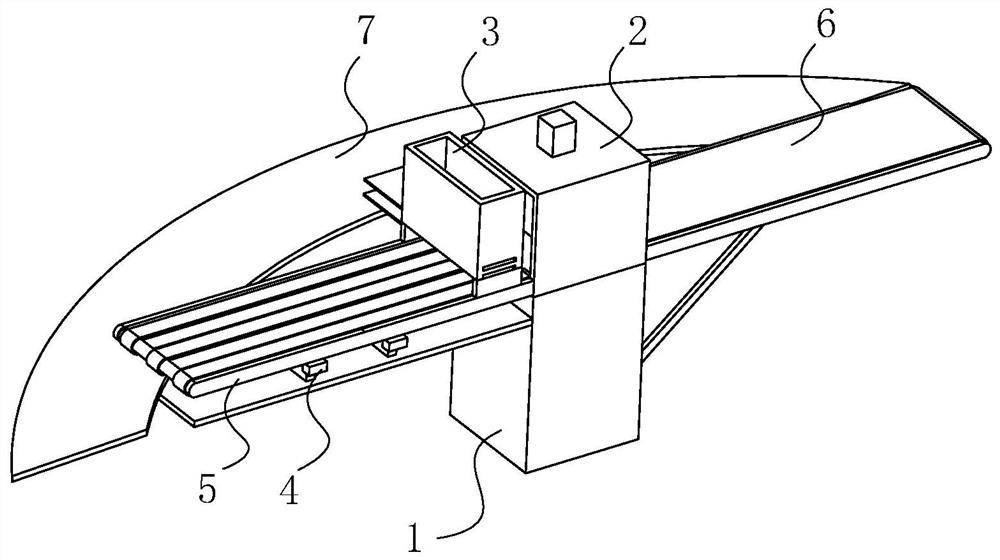

Preparation method of purple rice sandwich toast bread

PendingCN113383809AHave a crisp effectReduce the possibility of misalignmentDough-sheeters/rolling-machines/rolling-pinsPre-baking dough treatmentEngineeringManufacturing engineering

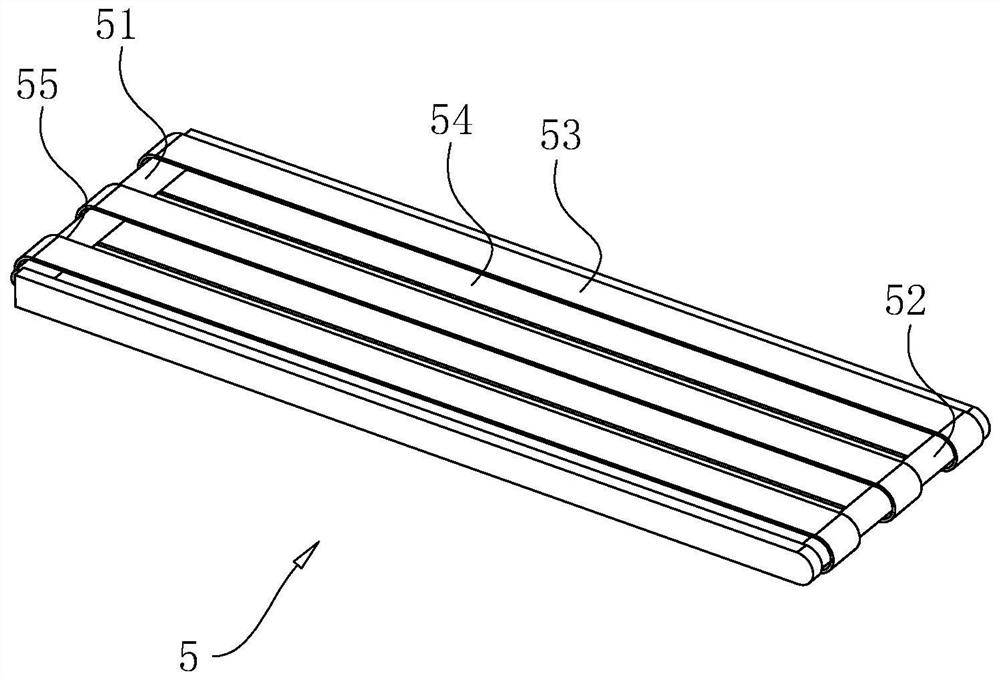

The invention discloses a preparation method of purple rice sandwich toast bread, and belongs to the technical field of food processing. The technical scheme key point of the preparation method comprises the following steps of: S1, preparing materials; S2, kneading dough; S3, freezing; S4, making pastries; S5, forming and fermenting; S6, baking; and S7: slicing and adding fillings. An automatic pastry making machine comprises a frame body, a dough sheet pressing device and an adjusting device, wherein a first conveying piece and a second conveying piece are horizontally arranged on the frame body; one end, which is far away from the dough sheet pressing device, of the first conveying piece communicates with a rotary conveying piece; the other end of the rotary conveying piece communicates with the second conveying piece; the dough sheet pressing device is positioned between the first conveying piece and the second conveying piece; and the adjusting device is positioned in the first conveying piece. The automatic pastry making machine has the effect that manual pastry making does not need to be carried out.

Owner:漳州好名新食品有限公司

Industrial composite paper board and preparing technology thereof

ActiveCN111645369AReduce misalignmentReduce the burden onMechanical working/deformationPaperboardProcess engineering

The invention discloses an industrial composite paper board and a preparing technology thereof, and relates to the technical field of industrial composite paper boards. The preparing technology of theindustrial composite paper board comprises the following steps of conducting feeding; gluing preheated raw paper; press-fitting the glued raw paper; and conducting discharging. The industrial composite paper board comprises three layers of raw paper which are bonded to one another. According to the industrial composite paper board and the preparing technology thereof, the problem that the raw paper is unlikely to get staggered in the press-fitting process is solved, and the possibility that the raw paper is staggered in the press-fitting process is lowered. In addition, the industrial composite paper board has the advantage that side lines are neat.

Owner:武汉荔和纸业有限公司

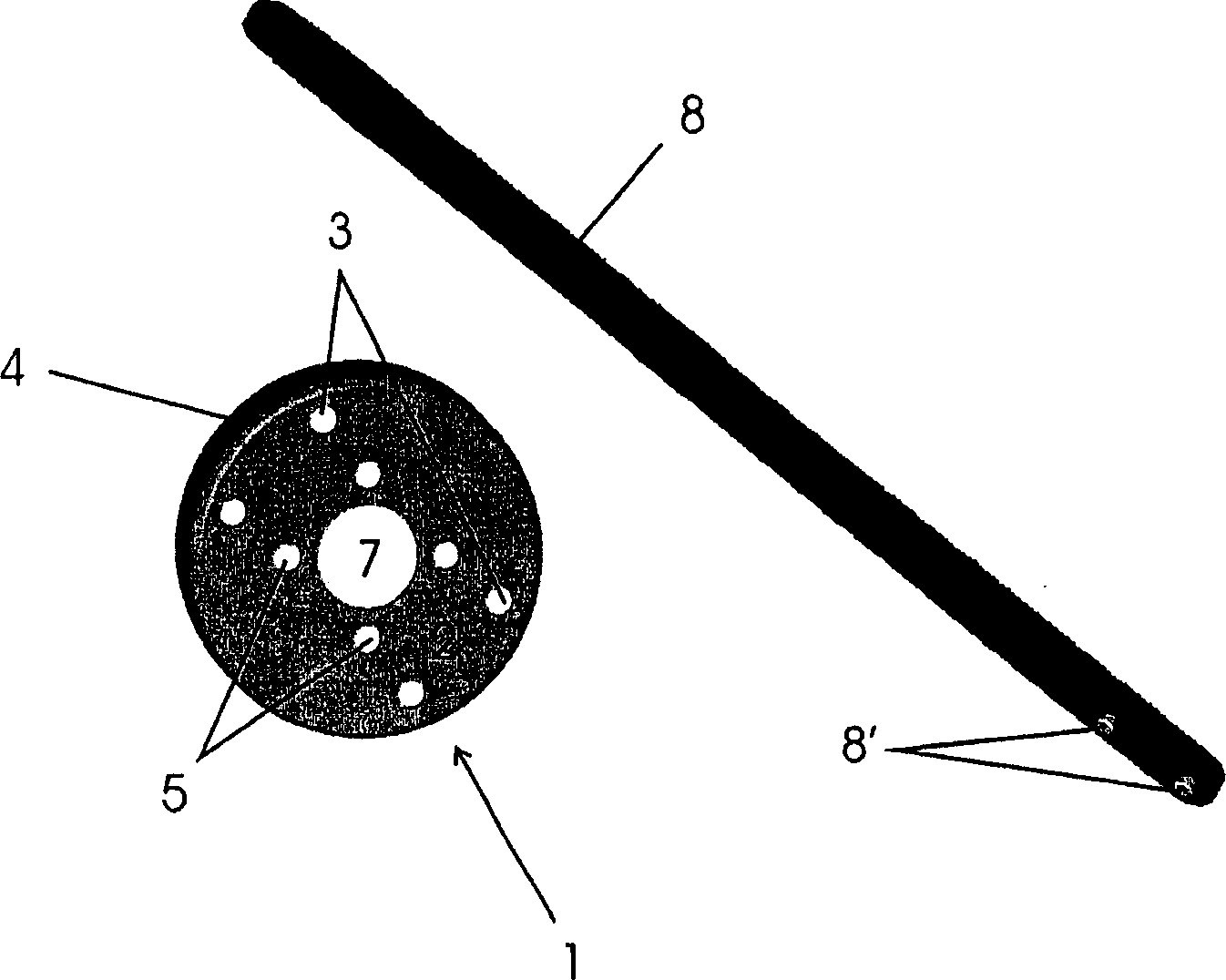

Pulley, particularly for use in internal combustion engines, method for removing a pulley, and, an internal combustion engine

InactiveCN1818426AAvoid damageReduce the possibility of misalignmentPortable liftingMetal-working hand toolsCombustionEngineering

A pulley (1) is described, particularly used for the transmission of circular movements in internal combustion engines, featuring a set of additional orifices (3) to make possible the positioning of a tool (8) for its removal, as well as it also refers to a method to remove pulley (1) by means of a tool (8) with pins or similar projecting elements (8') and an internal combustion engine equipped with the pulley (1).

Owner:INT IND AUTOMOTIVA DA AMERICA DO SUL LTDA (BR)

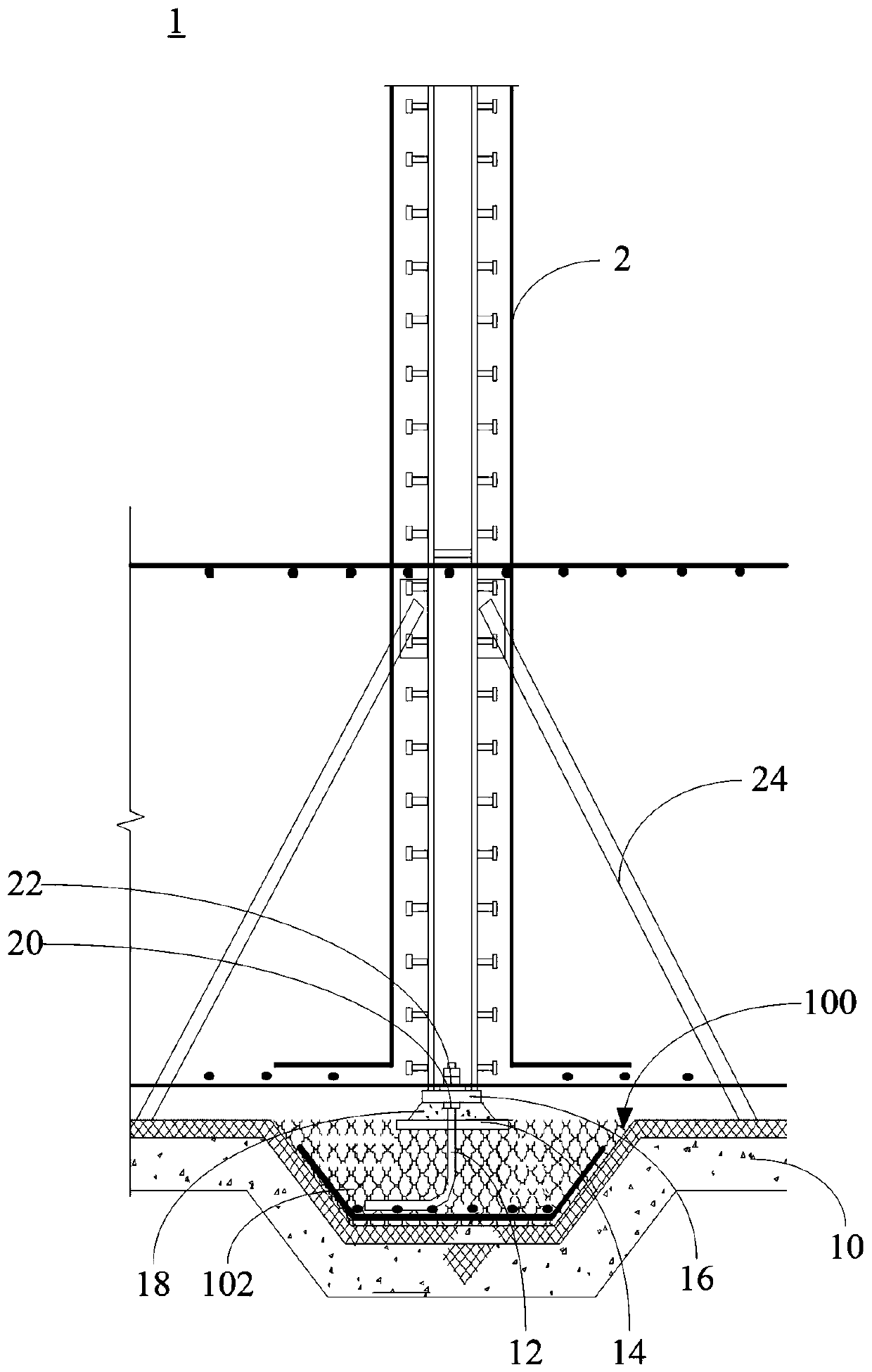

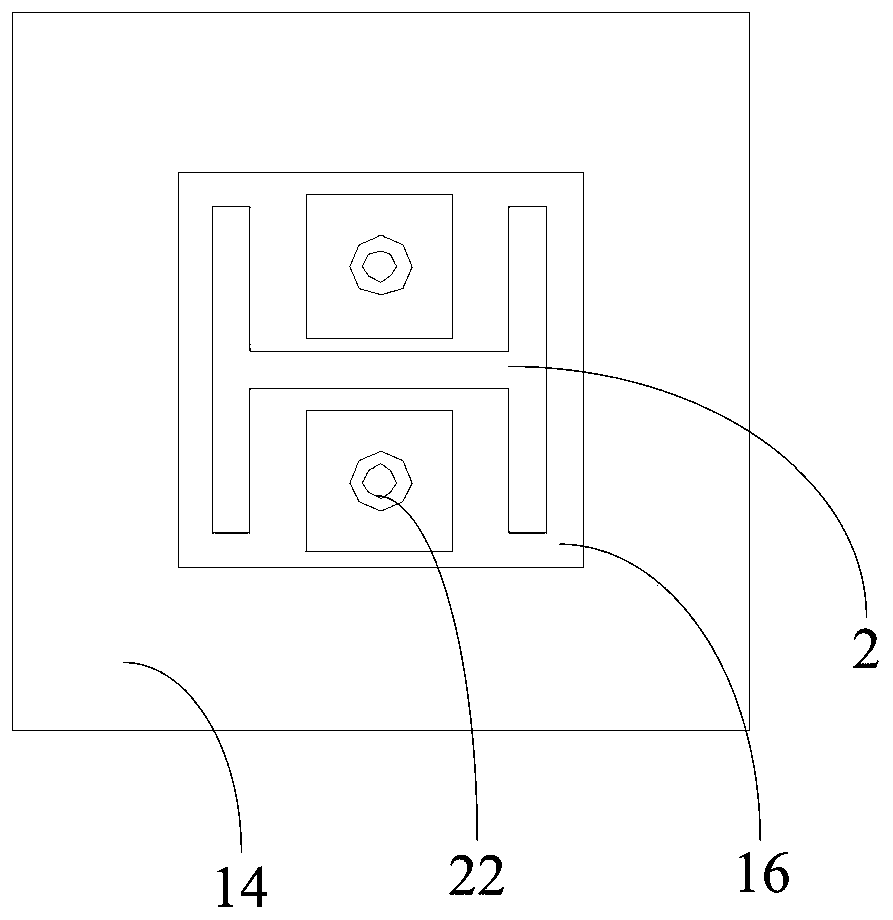

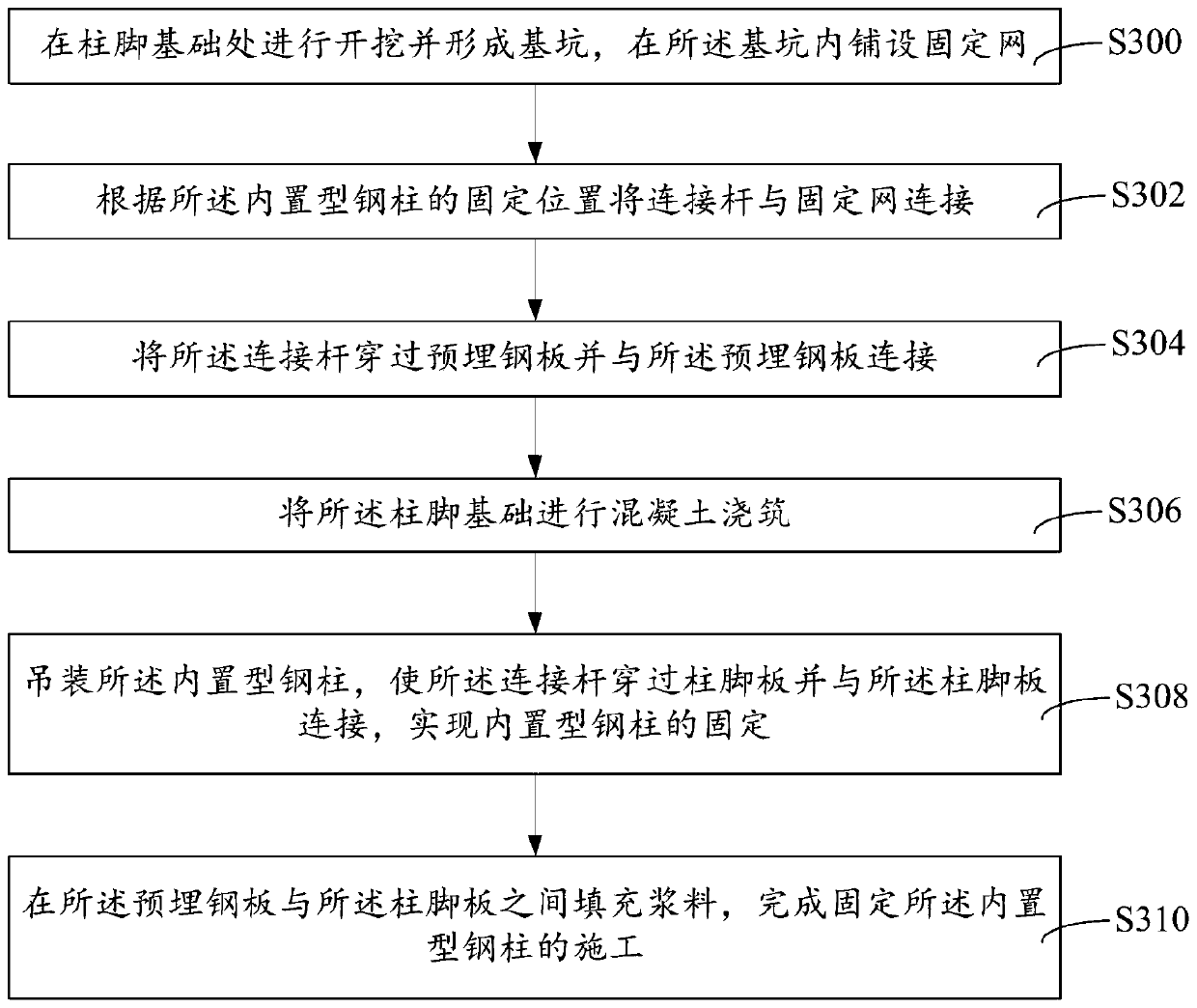

Built-in steel column fixing system and application construction method thereof

PendingCN110847498AAchieve fixationHigh precisionStrutsFoundation engineeringStructural engineeringSlurry

The invention relates to a built-in steel column fixing system and an application construction method thereof. The built-in steel column fixing system includes a column base foundation, a connecting rod, an embedded steel plate and a column base plate. The column base foundation is provided with a foundation pit, and a fixing net is laid in the foundation pit; one end of the connecting rod is connected with the fixing net, and the other end of the connecting rod penetrates through the embedded steel plate and is connected with the embedded steel plate; the column base plate is arranged to be in parallel with the embedded steel plate, the column base plate is provided with a connecting hole, and the connecting rod passes through the connecting hole and is connected with the column base plate after penetrating out of the embedded steel plate; and a slurry layer fills a space between the embedded steel plate and the column base plate. According to the built-in steel column fixing system,by adopting the fixing system, the accuracy of steel column in-position is improved; and the slurry layer directly fills the space between the embedded steel plate and the column base plate, so that the compactness of the embedded steel plate and the column base plate is strengthened, the possibility of steel column deviation is reduced, and the horizontal accuracy is improved. In addition, the application construction method of the built-in steel column fixing system is simple in steps and convenient to operate, thus being suitable for popularization.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

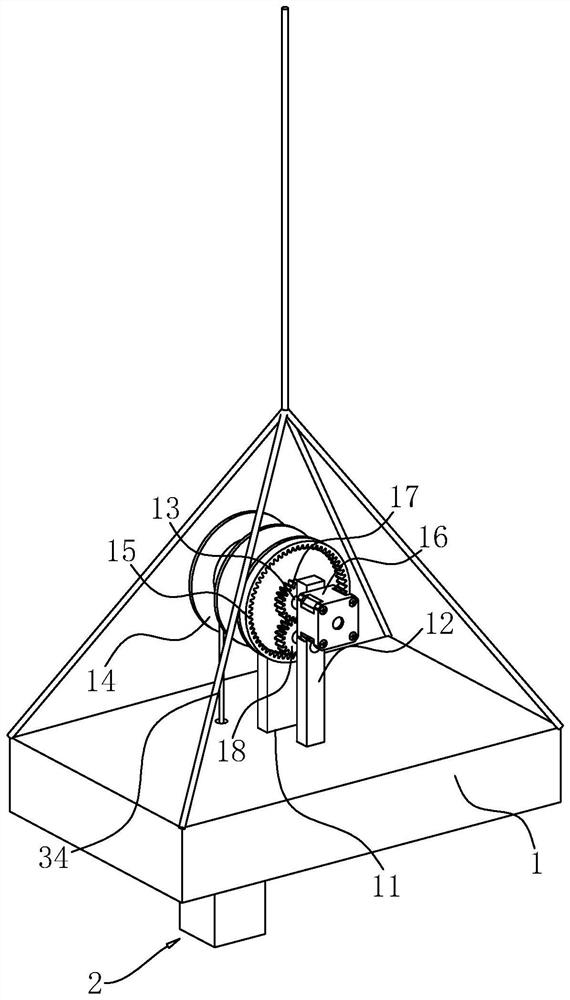

Mounting structure of fabricated building and construction method of fabricated building

ActiveCN113184737AEasy to stop pay-offImprove difficulty in judging heavy objectsWinding mechanismsBuilding material handlingPipe fittingGear wheel

The invention relates to a mounting structure of a fabricated building and a construction method of the fabricated building. The mounting structure of the fabricated building comprises a hoisting platform and a hoisting device, the top of the hoisting platform is connected with a first supporting rod in a sliding manner in the vertical direction, and a second supporting rod is fixed to the top of the hoisting platform. A winding drum and a gear ring are rotationally connected to one side of the first supporting rod and fixedly connected. A first gear engaged with the gear ring is rotationally mounted on one side, close to the first supporting rod, of the second supporting rod. The construction method of the fabricated building comprises the steps that the steel pipe fittings, a main beam and a secondary beam are prefabricated, and a plurality of mounting notches used for being connected with the steel pipe fittings are formed in the main beam and the secondary beam correspondingly; the main beam is hoisted and lifted on the surface of a mounting platform; the steel pipe fittings are hoisted to the main beam, and the steel pipe fittings are fixed in the mounting notches in the main beam correspondingly; and the secondary beam is hoisted to the top ends of the steel pipe fittings, and the steel pipe fittings are fixedly connected with the secondary beam through the mounting notches in the secondary beam. The mounting structure of the fabricated building and construction method of the fabricated building have the effect of conveniently judging whether a heavy object is in contact with the lower platform or not.

Owner:广东铭濠润建工有限公司

Polymeric liquid crystal composition and its application

ActiveCN105441089BImprove matchReduce the possibility of misalignmentLiquid crystal compositionsOptical elementsCrystallographyRefractive index

The present invention provides a polymerizable liquid crystal composition, which has a lower melting point and a longer supercooling time. Meanwhile, the value of the refractive index no of the polymerizable liquid crystal composition is between 1.495-1.502, and the value of the birefringence Δn is between 0.145-0.180. The present invention also provides the application of the polymerizable liquid crystal composition in naked-eye 3D display.

Owner:JIANGSU HECHENG ADVANCED MATERIALS

Integrated semi-direct drive wind turbine drive chain and its gear box

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Method for forming self-aligning contact structure in semiconductor IC device

InactiveCN1151550CReduce parasitic capacitanceImprove reliabilityTransistorSolid-state devicesEngineeringIc devices

Methods of forming integrated circuit devices include the use of preferred self-aligned contact hole fabrication steps. These steps improve process reliability. A plurality of line patterns are formed on a substrate. A capping insulating layer is formed to cover the surface of the line patterns and the surface of the substrate. An upper interlayer insulating layer is formed on the capping insulating layer to fill a gap region between the line patterns. The upper interlayer insulating layer and the capping insulating layer are patterned, so that the first contact hole is formed between the line patterns. By wet-etching the upper interlayer insulating layer selectively, the first contact hole is extended, so that the second contact hole for exposing the capping insulating layer on the sidewall of the line patterns is formed.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com