Satellite frame and method of making a satellite

A frame and satellite technology, applied in the field of satellites, can solve problems such as the difficulty of repairing satellites, reducing the rigidity of the overall structure, the failure rate and the increase of misalignment problems, so as to reduce the possibility of misalignment, quickly integrate design, and improve alignment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

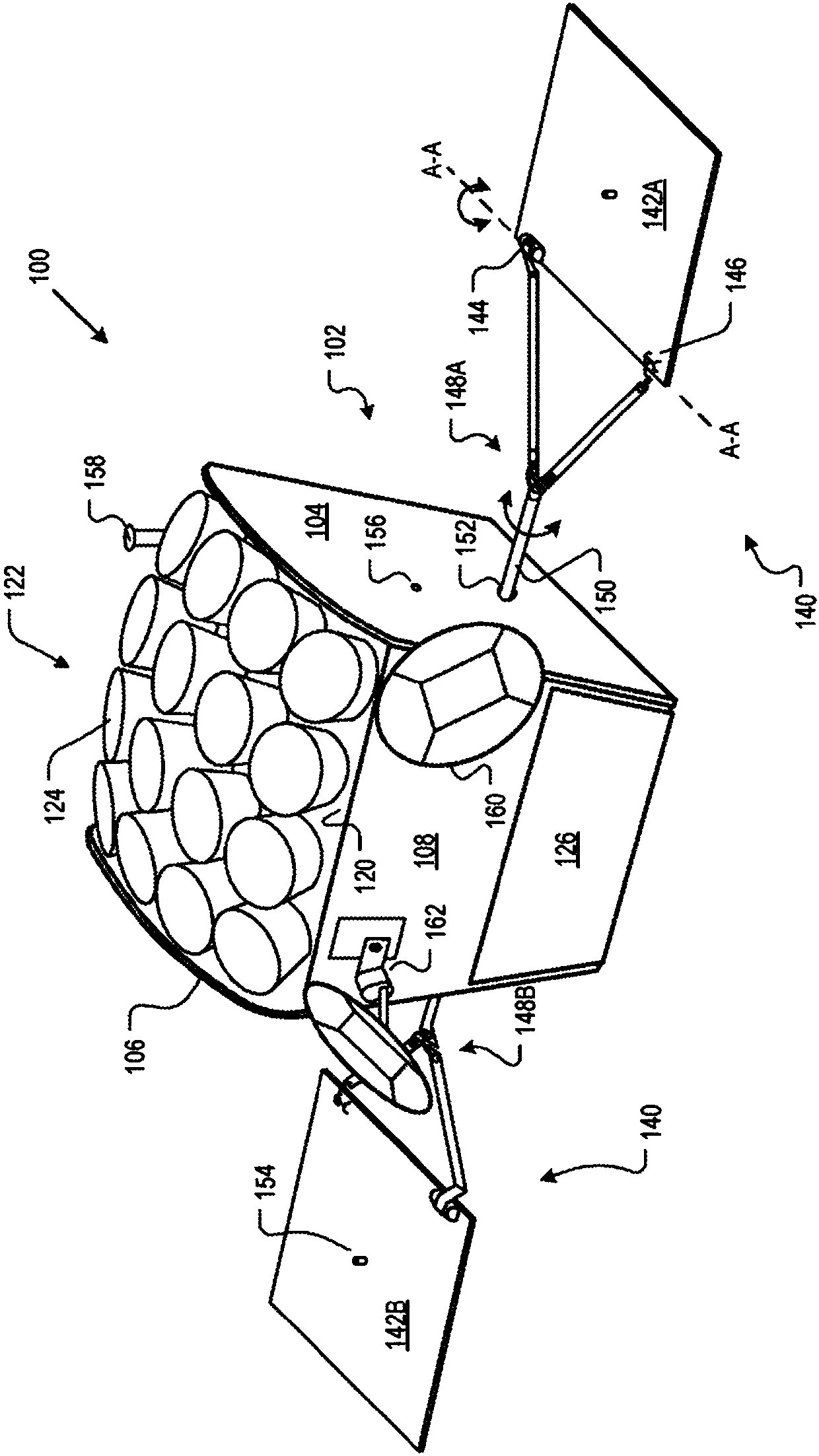

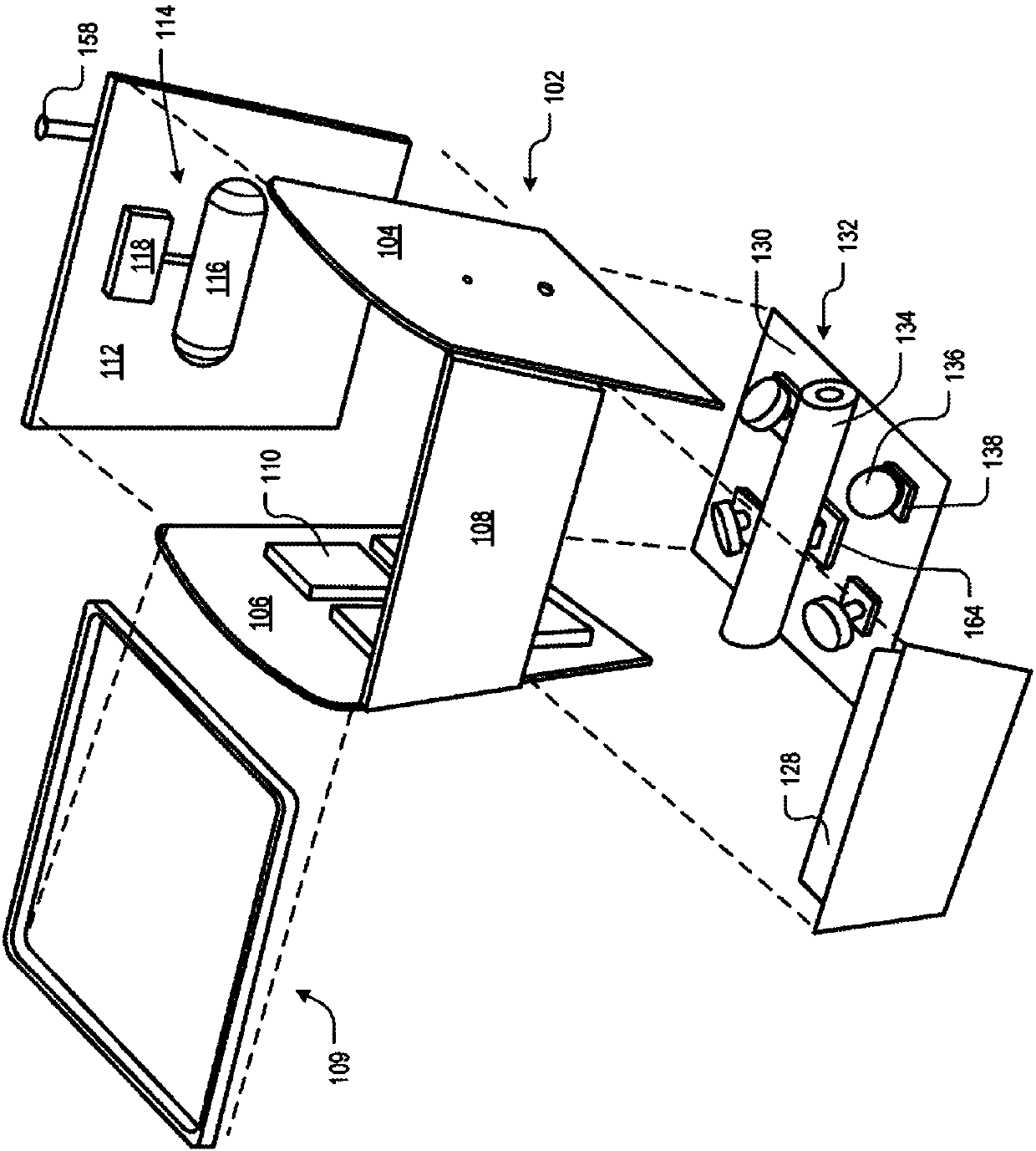

[0014] figure 1 A satellite 100 according to the present teachings is shown. figure 2 An "exploded" view of some salient features of satellite 100 is shown. now refer to figure 1 with figure 2 Both, the satellite 100 includes a unified payload module 102 , a propulsion module 114 , a payload antenna module 122 , a bus assembly module 132 and a solar array system 140 arranged as shown. It should be noted that figure 1 with figure 2 The orientation of the satellite 100 is "inverted" in the sense that, in use, the antenna 124 shown facing "up" will face "down" towards the Earth.

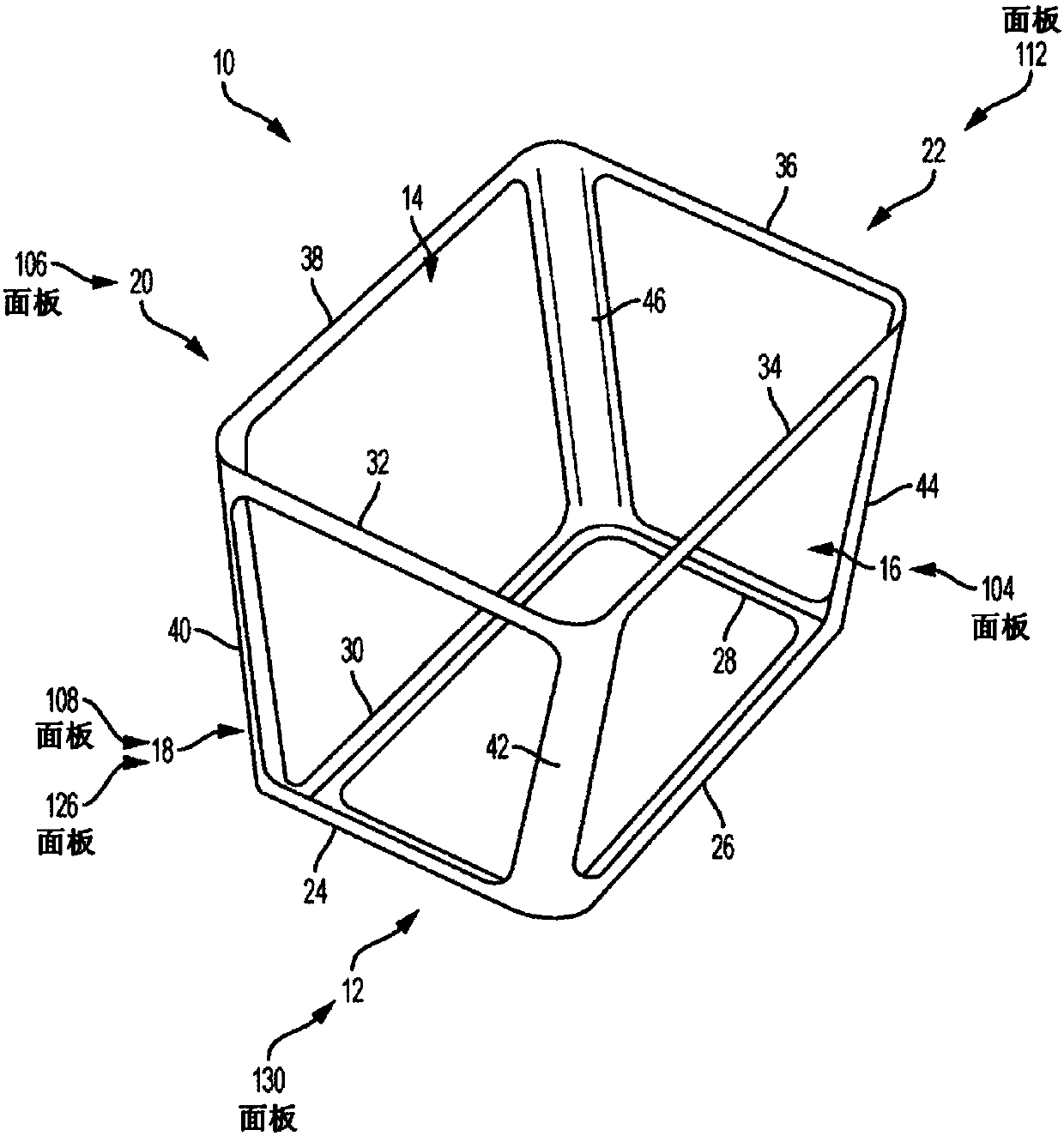

[0015] Unified payload module 102 includes panels 104 , 106 and 108 . In some embodiments, the panels are joined together in known manner using various connectors and the like. Brackets 109 provide structural reinforcement to the connecting panels.

[0016] Panels 104 , 106 , and 108 serve as radiators for radiating heat from satellite 102 , among other functions. In some embodiments, the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com