Patents

Literature

101results about How to "Improve hemming effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

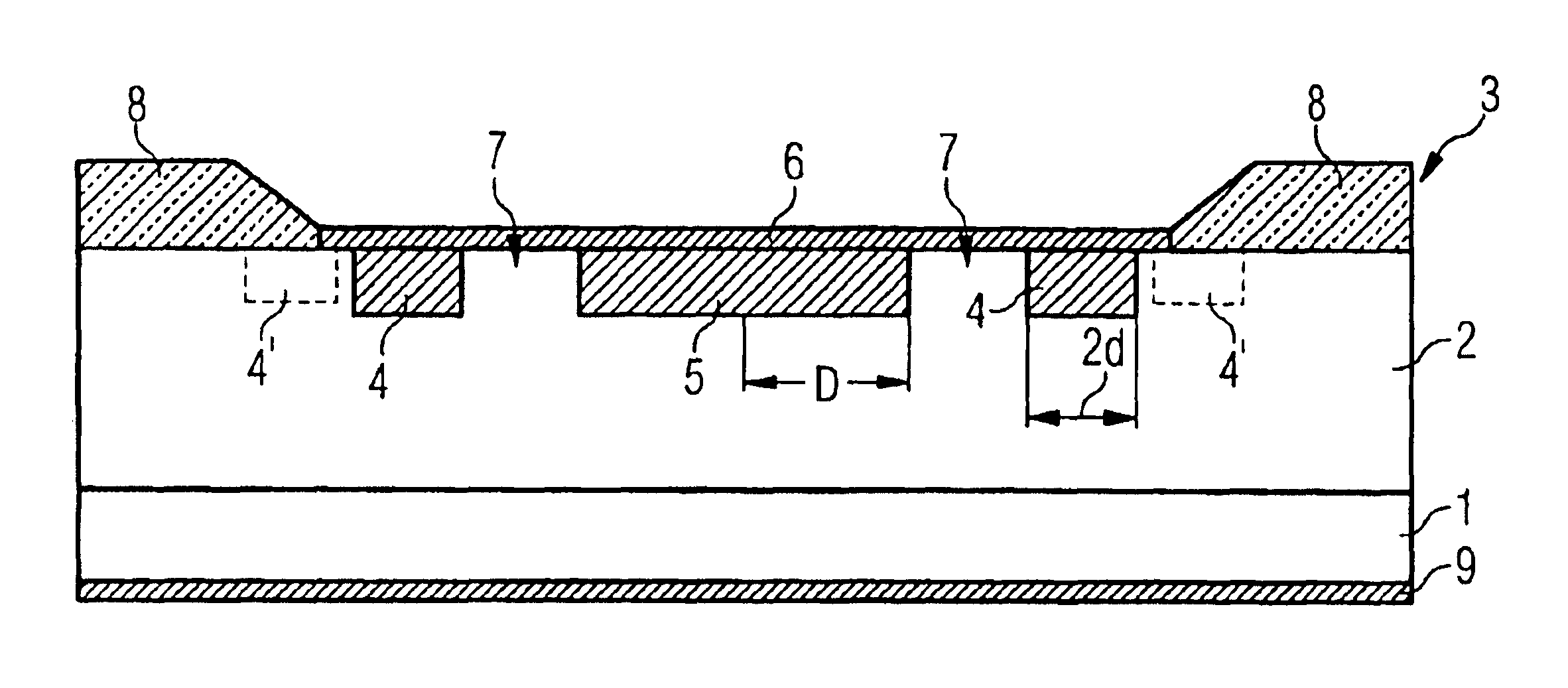

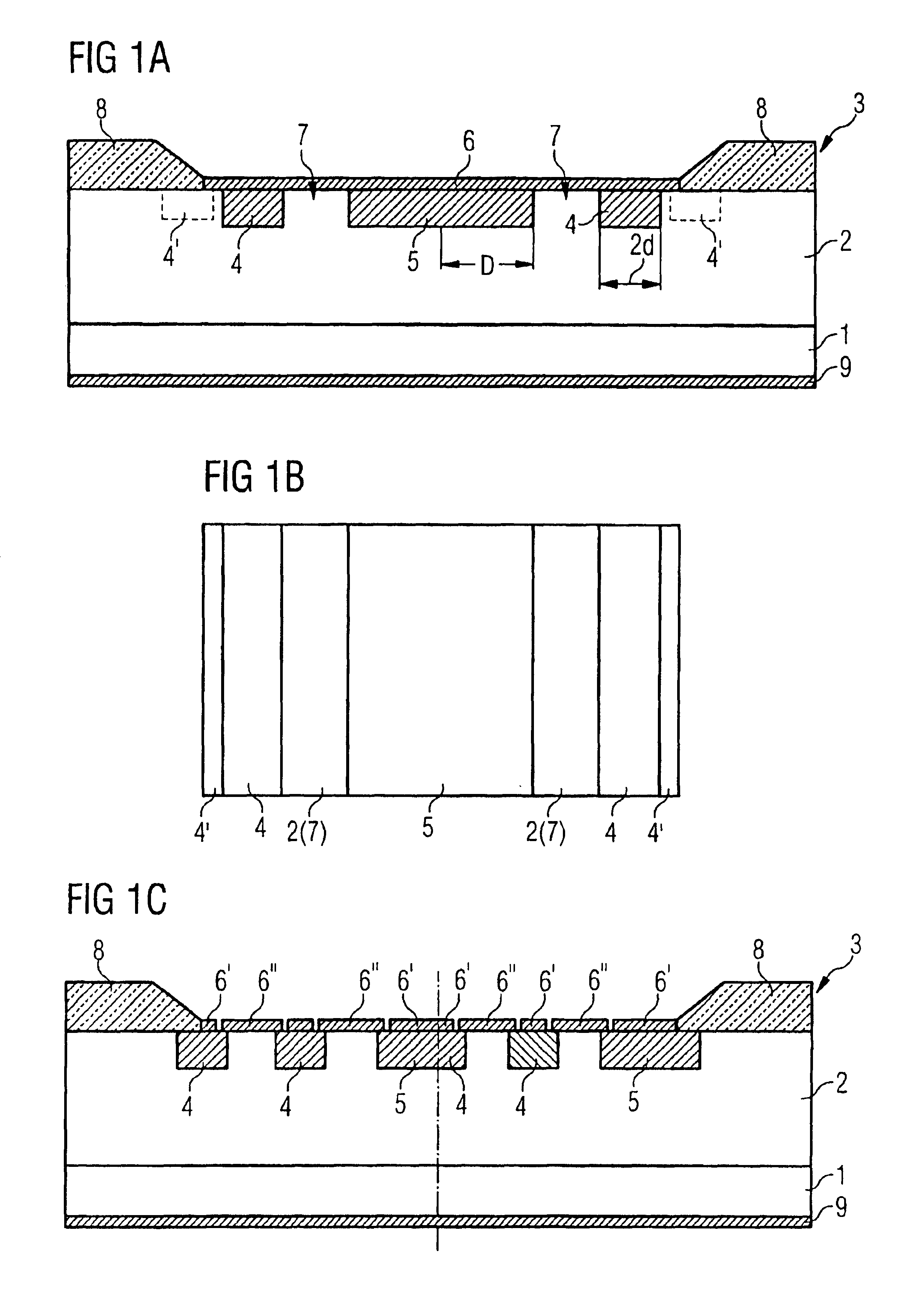

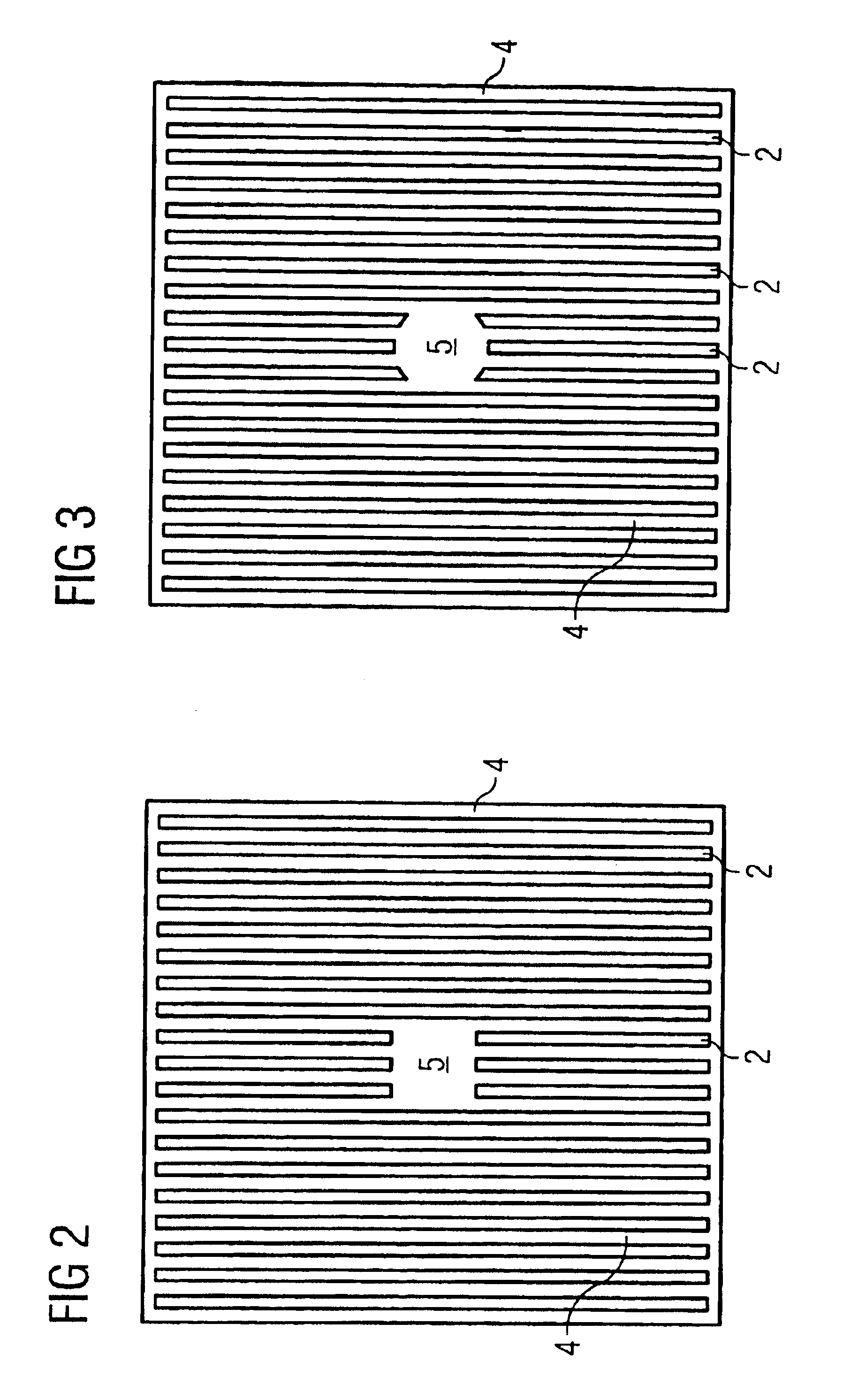

Schottky diode having overcurrent protection and low reverse current

ActiveUS6861723B2Good resistance to overcurrentsLower forward voltageTransistorReverse currentEngineering

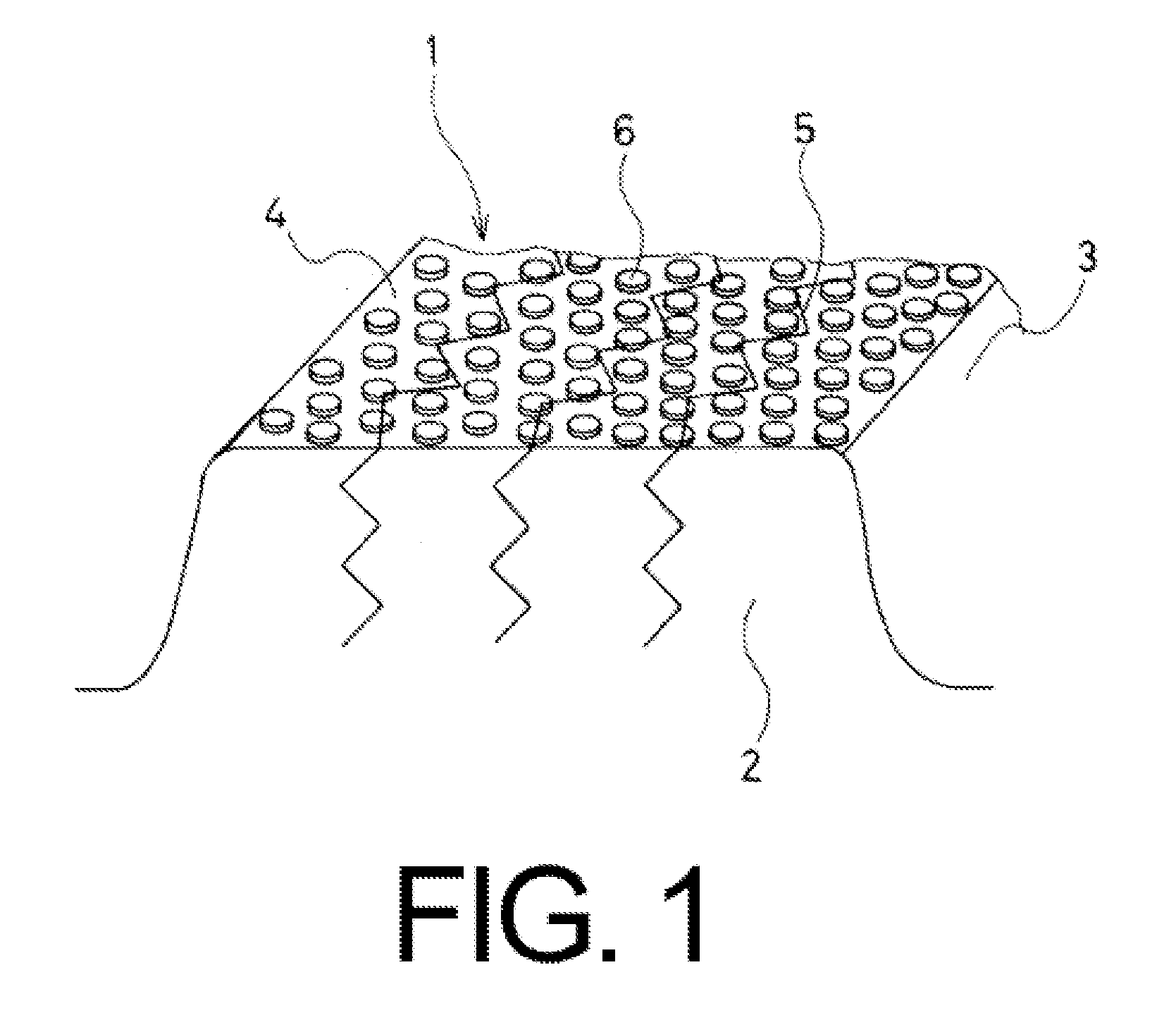

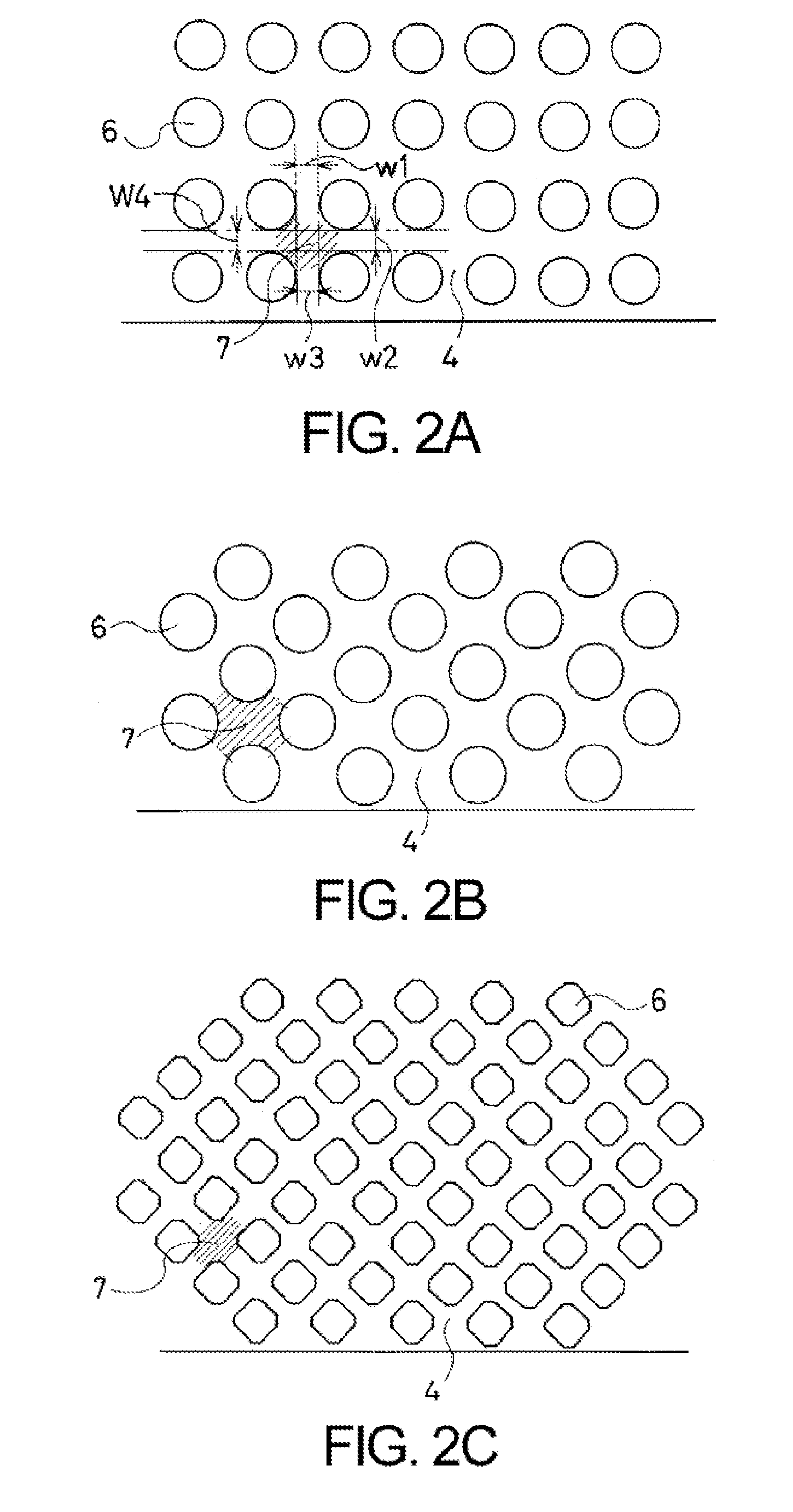

The invention relates to a Schottky diode in which p-doped regions (4, 5) are incorporated in the Schottky contact area. At least one (5) of these regions (4, 5) has a greater minimum extent, in order to initiate a starting current.

Owner:INFINEON TECH AG

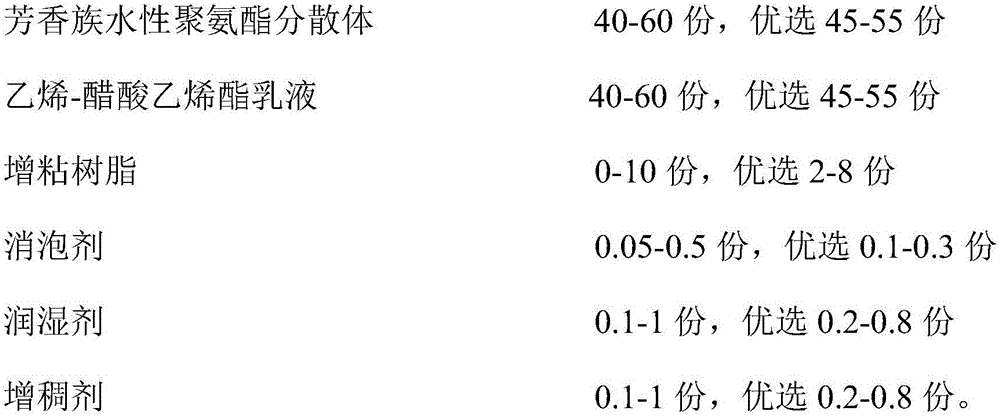

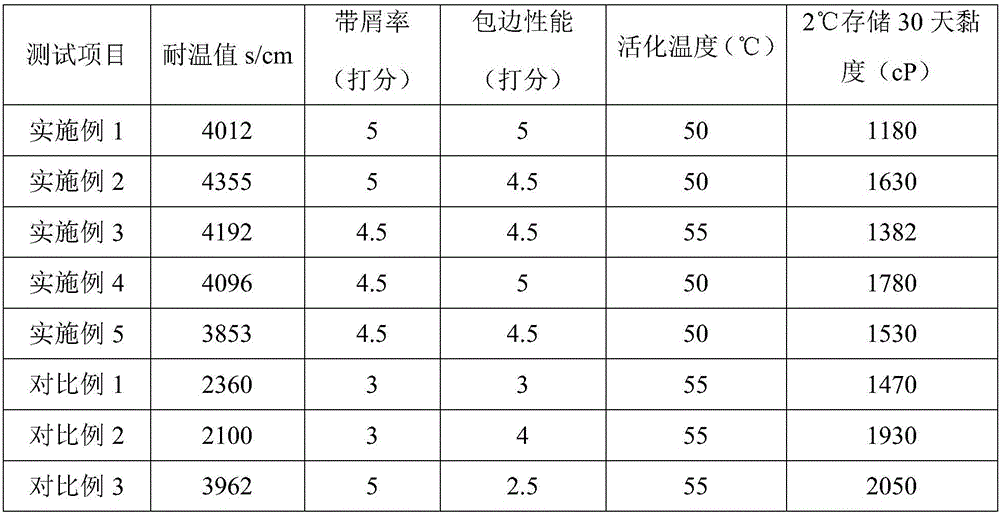

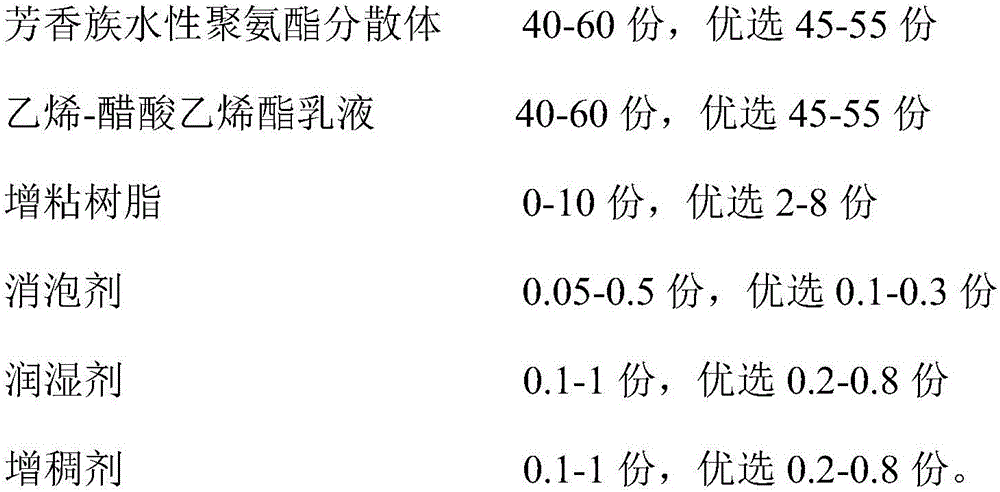

Waterborne vacuum plastic-absorbing glue and preparing method thereof

ActiveCN106590506AReduce the risk of slagSimple preparation stepsPolyureas/polyurethane adhesivesPolymer scienceCarvacryl acetate

The invention discloses a waterborne plastic-absorbing glue and a preparing method thereof. The waterborne plastic-absorbing glue is prepared from, by weight, 40-60 parts of aromatic aqueous polyurethane dispersion, 40-60 parts of ethylene-vinyl acetate emulsion, 0-10 parts of tackifying resin, 0.05-0.5 part of antifoaming agent, 0.1-1 part of wetting agent, and 0.1-1 part of thickening agent. The plastic-absorbing glue has excellent heat-resistant performance, pickup rate, bordure performance, low-temperature viscosity stability, and low activation temperature. The preparing method comprises the steps of adding aqueous polyurethane dispersion and ethylene-vinyl acetate emulsion into a high-speed dispersing kettle, then adding the tackifying resin, wetting agent, and antifoaming agent in sequence under a stirring condition, and finally adding the thickening agent to adjust the mixture into suitable viscosity to obtain the waterborne vacuum plastic-absorbing glue. According to the waterborne plastic-absorbing glue and the preparing method thereof, it is not necessary to adjust the pH of the ethylene-vinyl acetate emulsion in advance, and thus preparation procedures of traditional plastic-absorbing glue are simplified, and deslagging risks in the preparing process are lowered.

Owner:WANHUA CHEM GRP CO LTD

Carton folding device with size adjusting function

InactiveCN106881906ARealize the function of foldingEven by forceBox making operationsPaper-makingCartonEngineering

The invention relates to a size-adjustable carton hemming device. The pressing device includes a pressing plate, which is connected with a positioning plate, and a positioning hole is arranged on the pressing plate, and a pressing long plate and a pressing plate are fixed in the positioning hole. Pressing down the short plate, the pressing down long plate and the pressing down short plate both include a pressing down fixing plate, the two ends of the pressing down fixing plate are connected to the extension block through the extension plate, the pressing device includes a supporting plate, and the outer periphery of the supporting plate is sequentially provided with a second A pallet frame and a second pallet frame, the second pallet frame is provided with an adjustment plate on the outer periphery, and a push plate is provided on the adjustment plate, and the adjustment plate includes an adjustment plate fixing block, and the two ends of the adjustment plate fixing block are connected and adjusted by an extension plate The plate extension plate, the push plate includes a push plate fixing block, the two ends of the push plate fixing block are connected to the push plate extension plate through the extension plate, the positioning plate, the pressing plate, the adjustment plate, the push plate, the supporting plate, the first supporting plate Both the frame and the second pallet frame are connected to the cylinder through the piston rod, which is a size-adjustable carton hemming device that can meet the hemming of cartons of various sizes.

Owner:天津市腾旭工贸有限公司

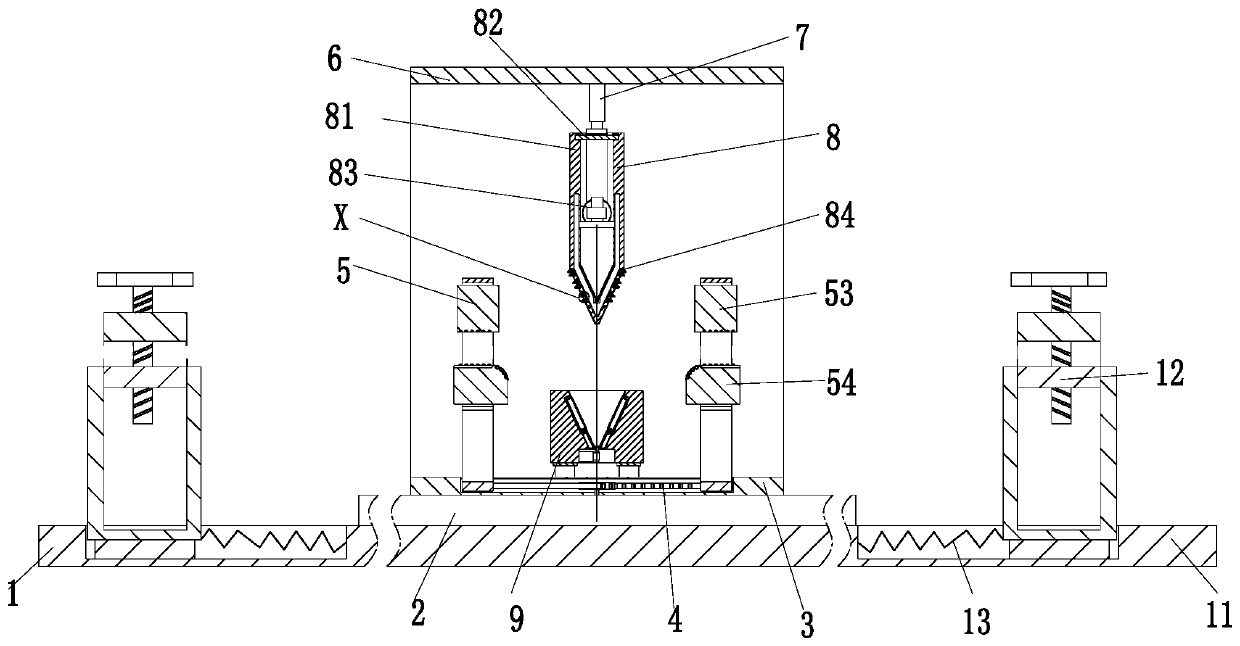

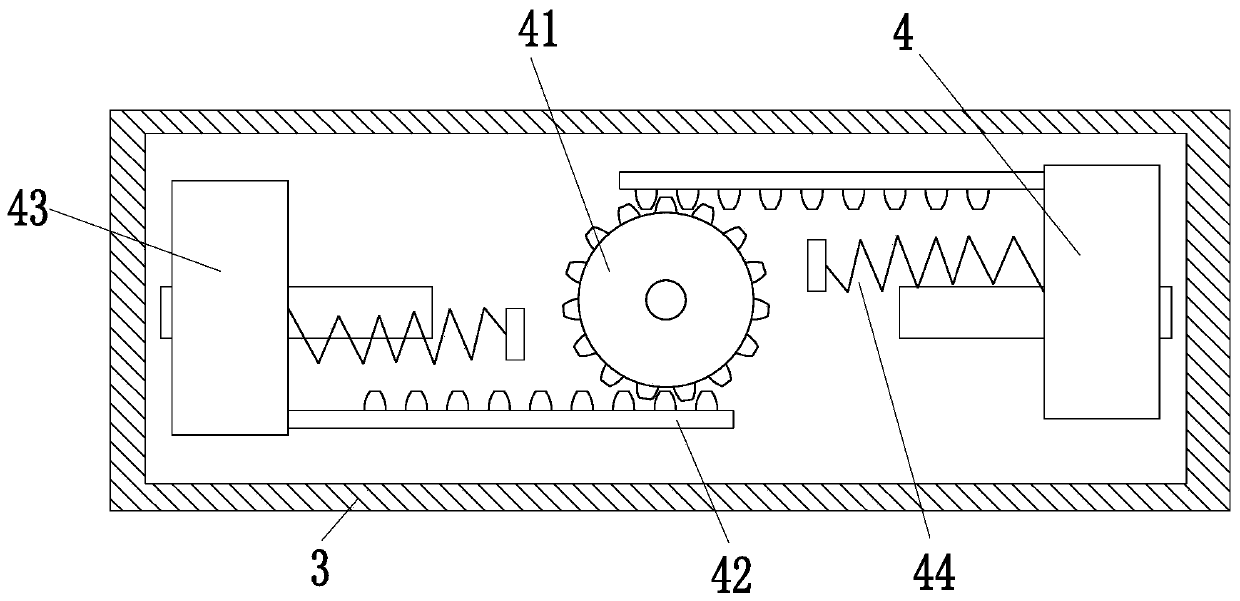

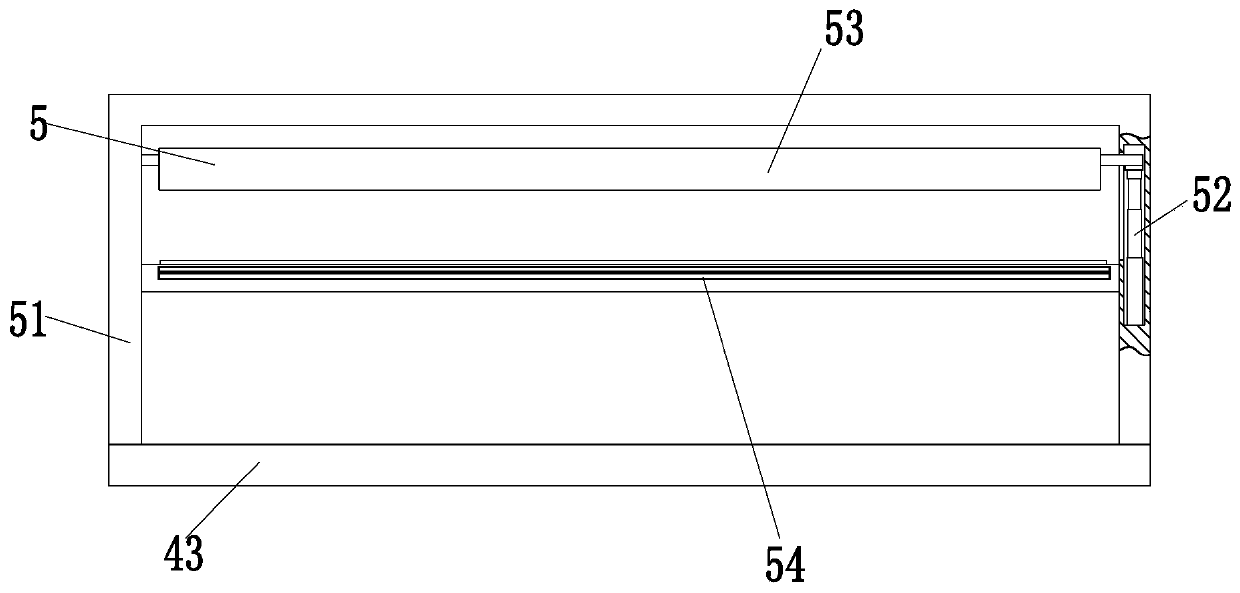

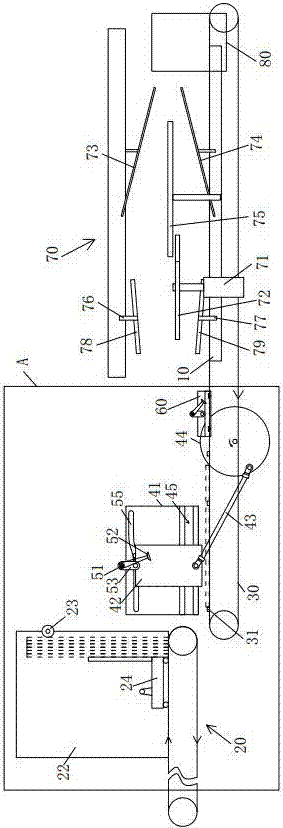

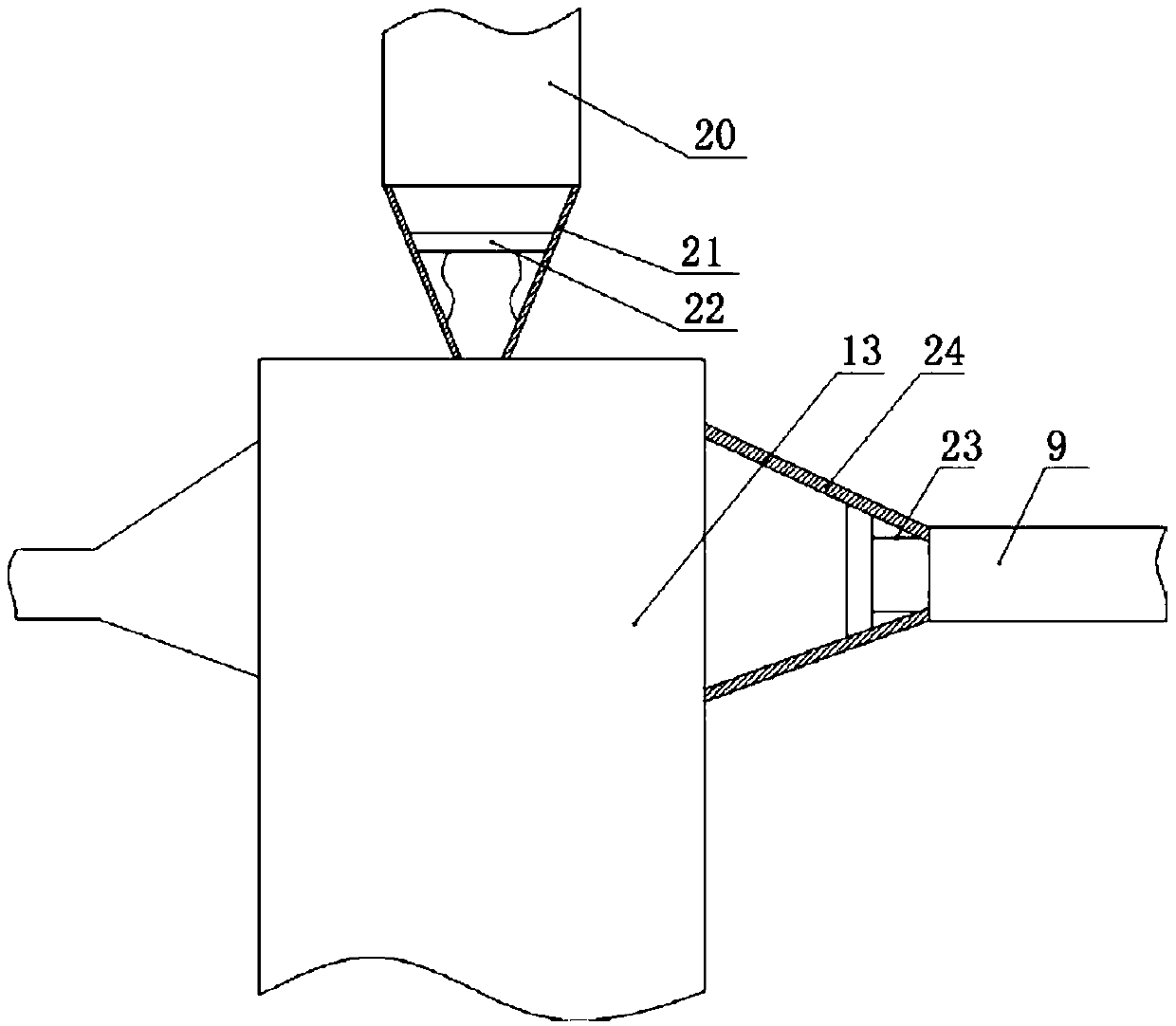

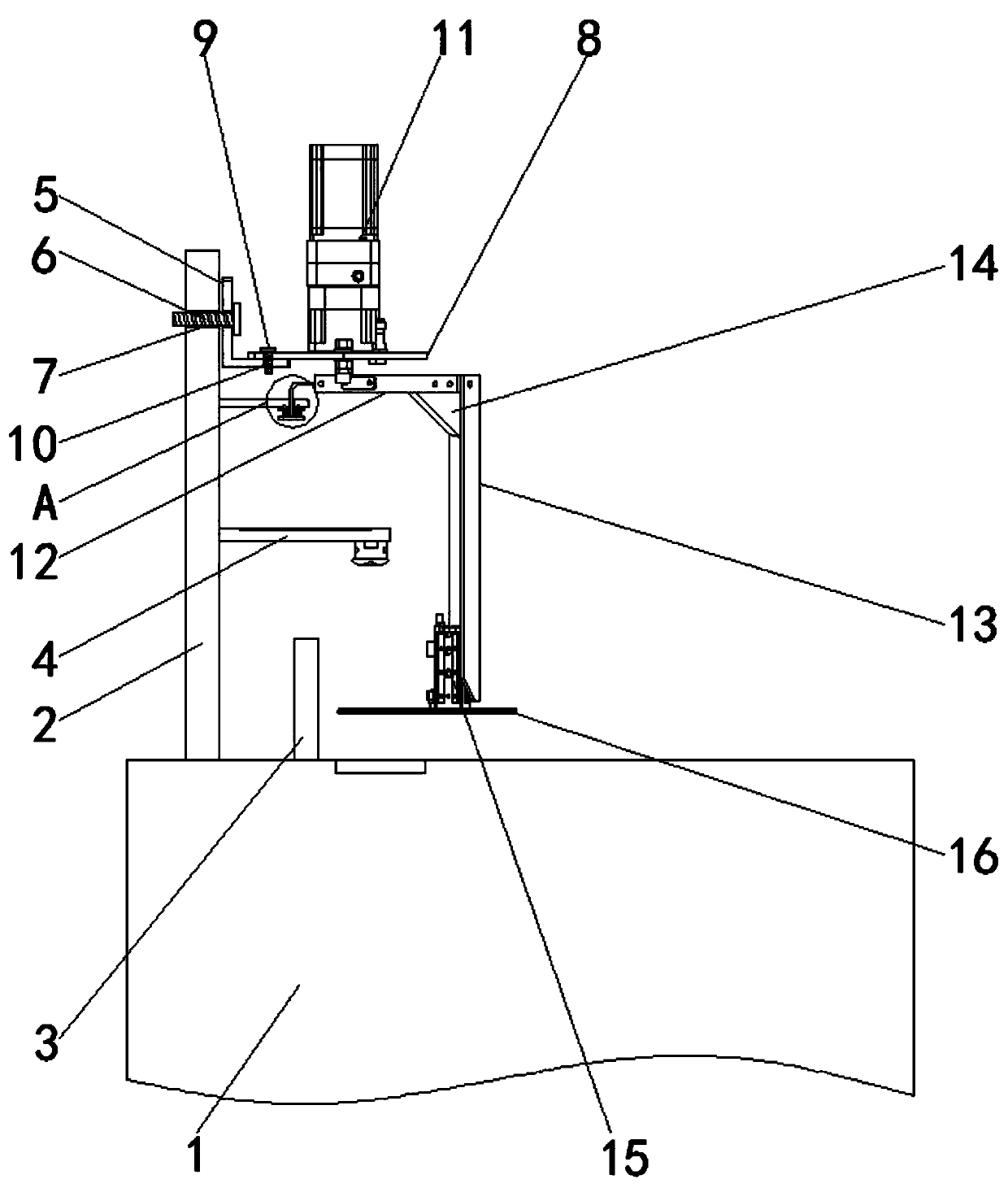

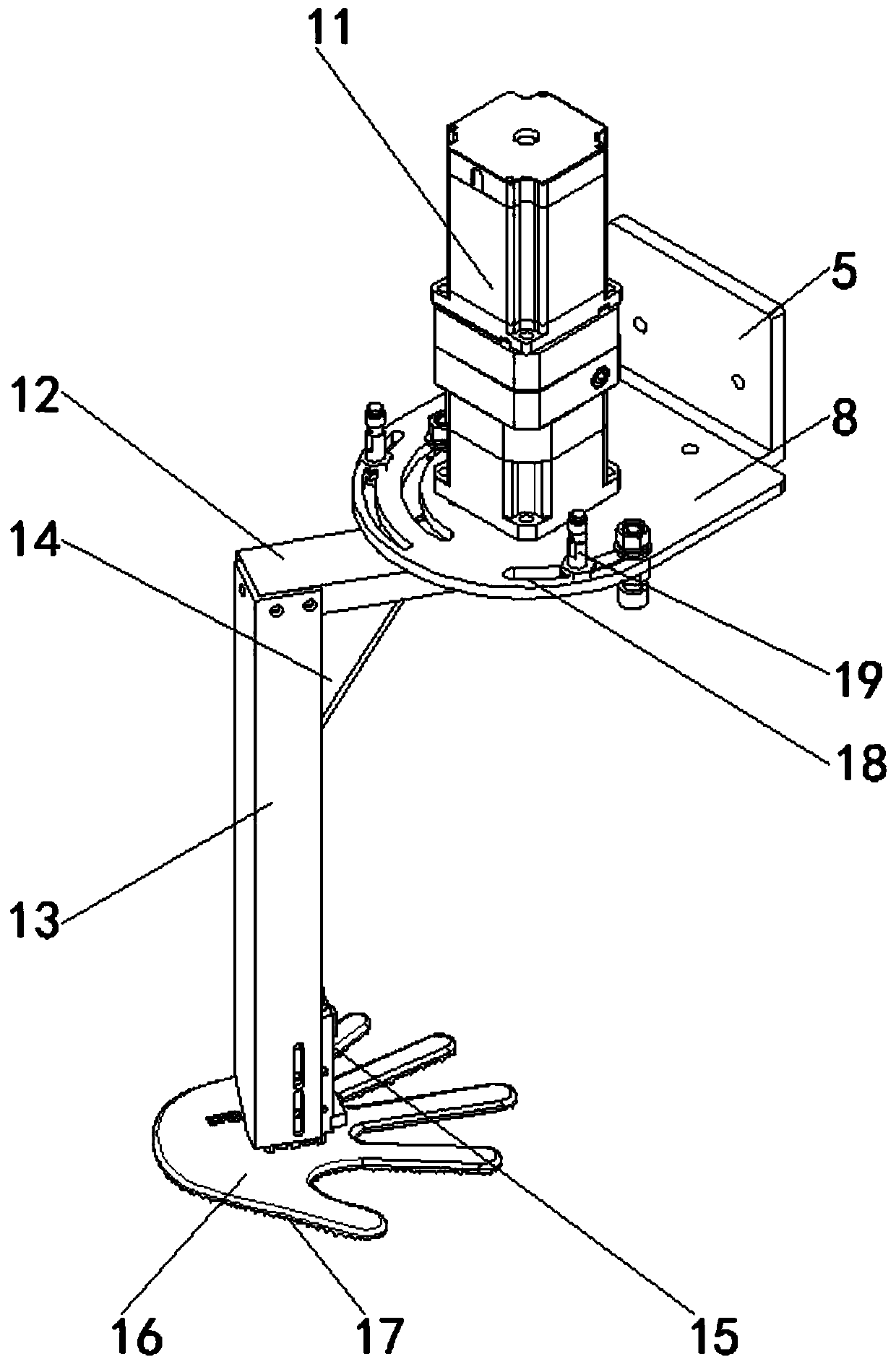

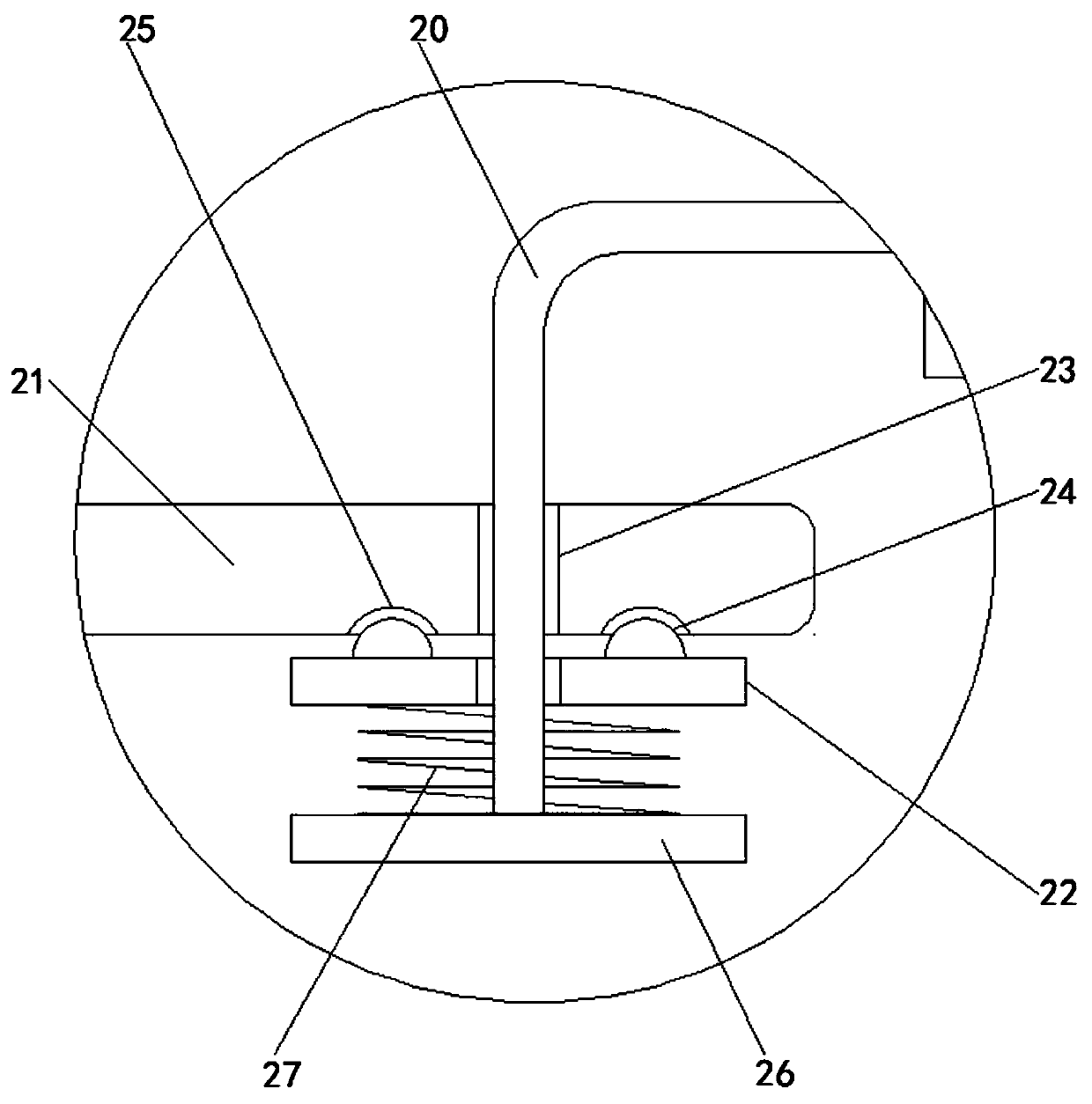

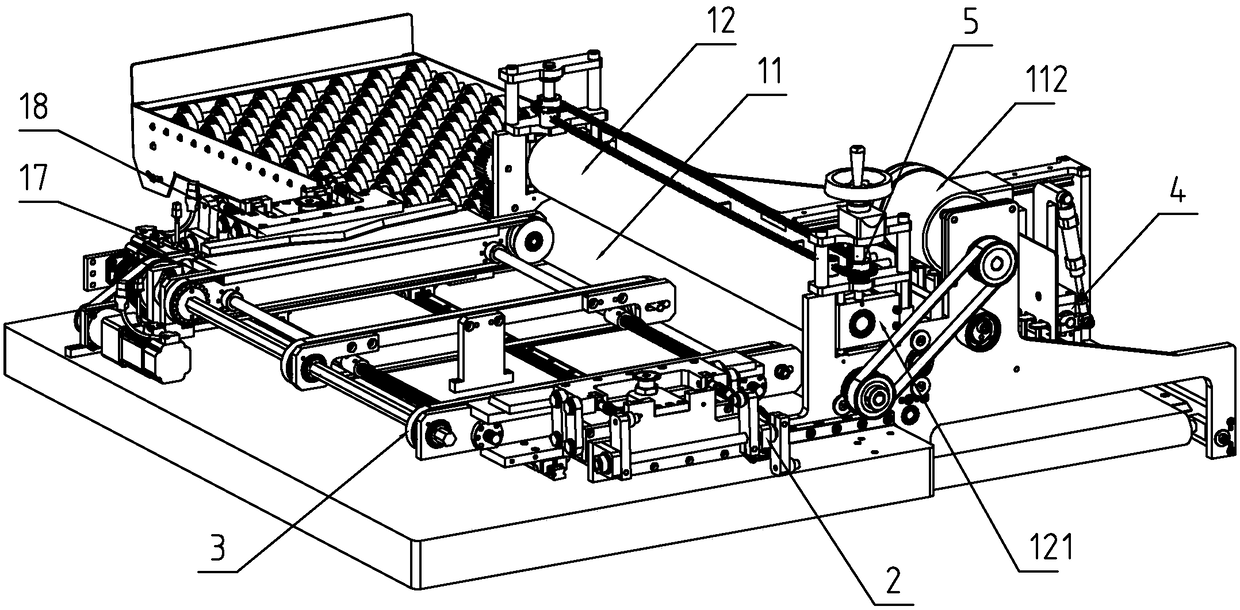

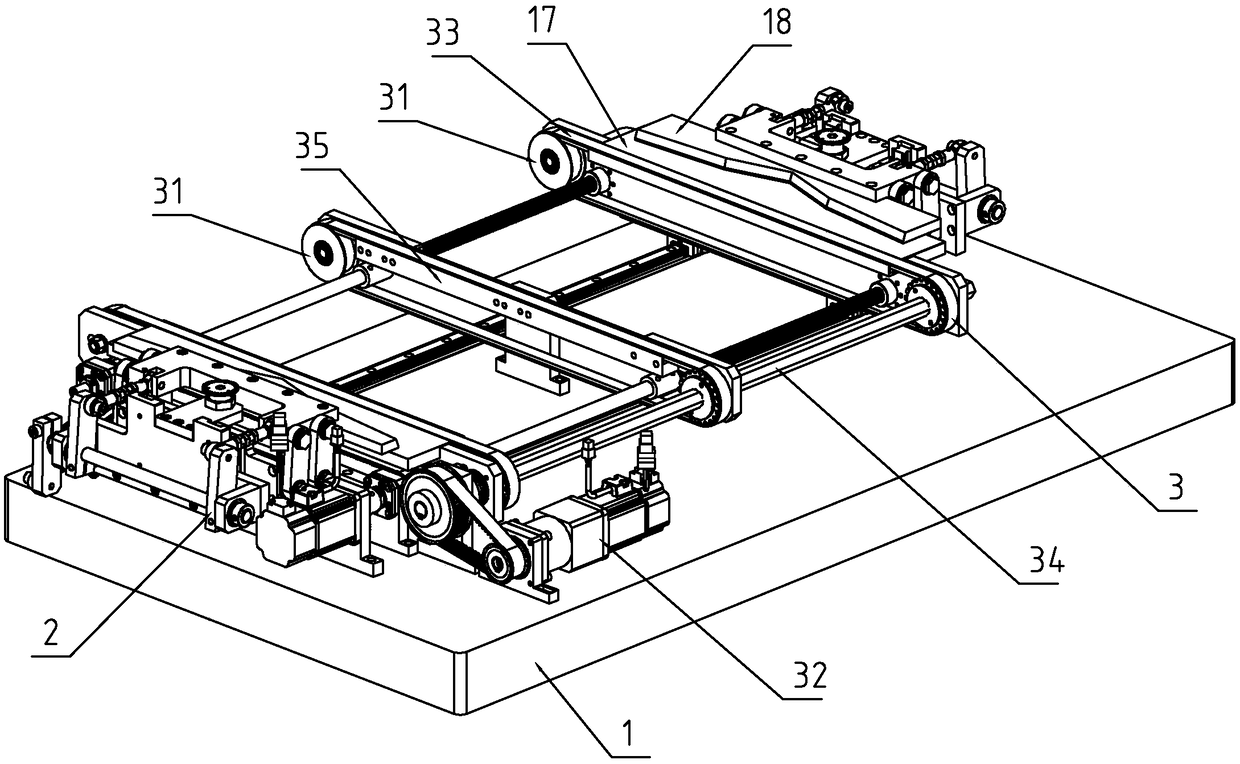

Plastic woven bag edgefold shaping machine and method

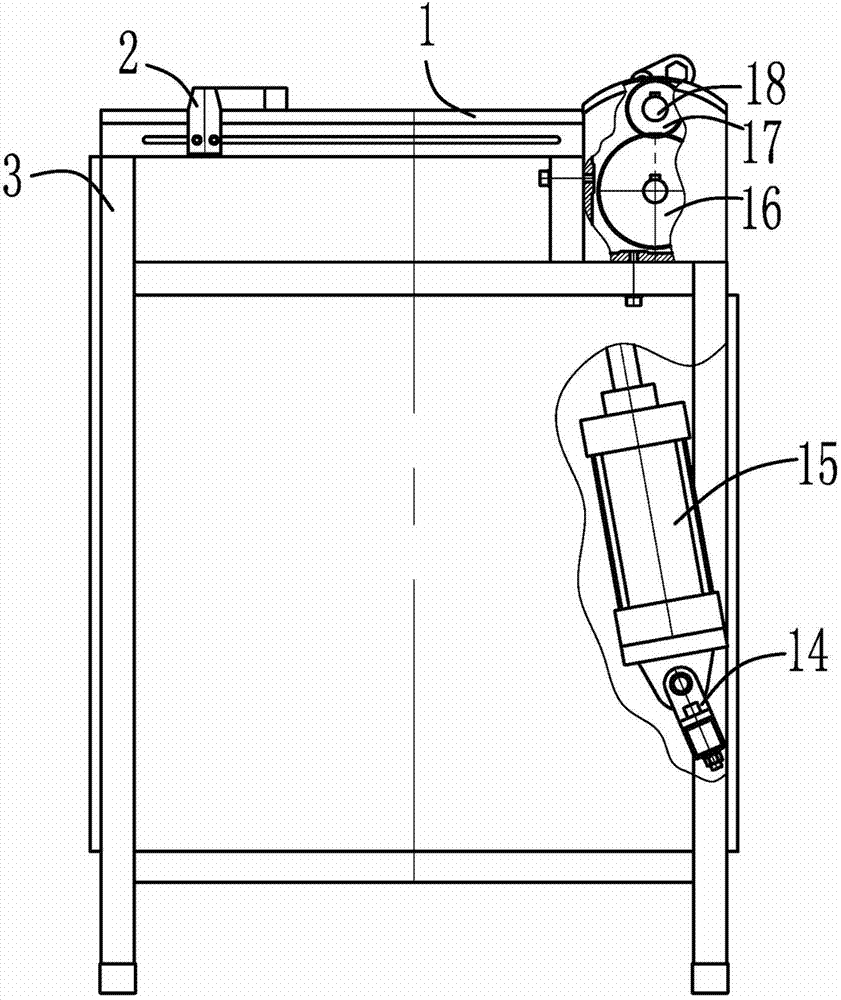

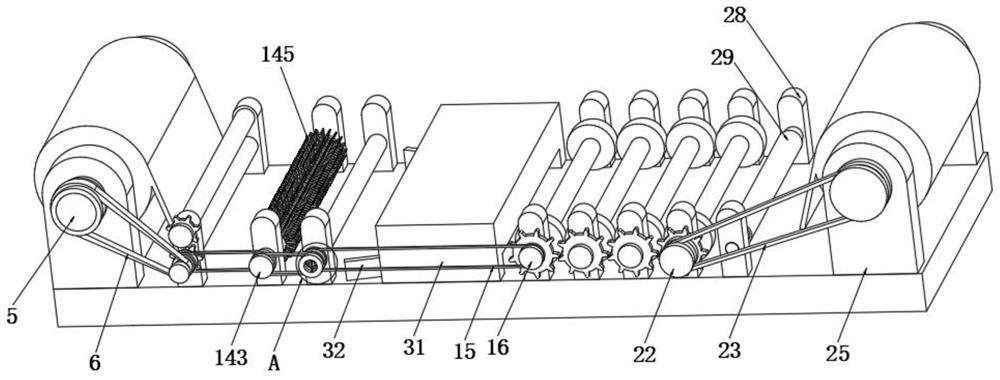

InactiveCN110497653AReduces accidental creasingImprove hemming effectBag making operationsPaper-makingEngineeringPortal frame

The invention relates to a plastic woven bag edgefold shaping machine and a method. The machine comprises a clamping base, a working electric sliding block, a displacement frame, a synchronizing device, two positioning clamps, a portal frame, a driving cylinder, a pressing device and a mark ironing device. The working electric sliding block is mounted on the clamping base. The displacement frame is arranged on the working electric sliding block. The synchronizing device is mounted in the middle of the displacement frame. The two positioning clamps are mounted at the left and right ends of thesynchronizing device. The mark ironing device is mounted in the middle of the displacement frame. The portal frame is mounted on the displacement frame. The upper end of the portal frame is connectedwith the pressing device through the driving cylinder. By means of the plastic woven bag edgefold shaping machine and the method, the problems that an existing edgefold machine commonly adopts rigid pressing for woven fabric, two pressing dies are adopted for pressing the woven fabric repeatedly, clear folding marks can only be obtained through repeated pressing since the woven fabric is flexiblefabric, and the edgefold shaping effect is poor can be solved.

Owner:台州市伟鸿家居用品有限公司

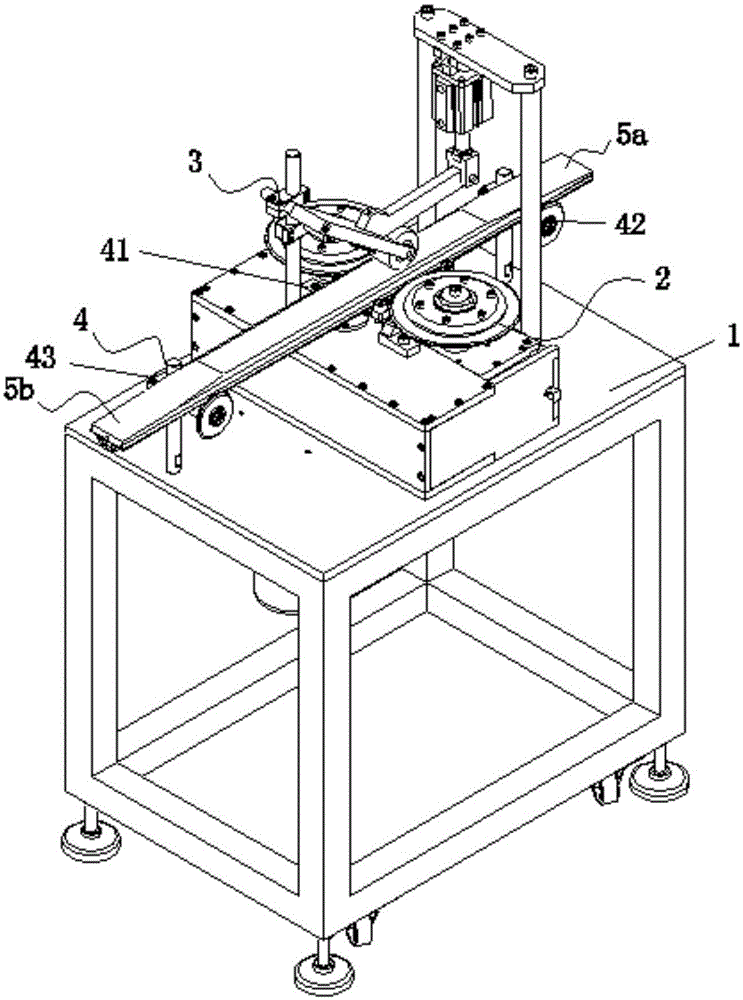

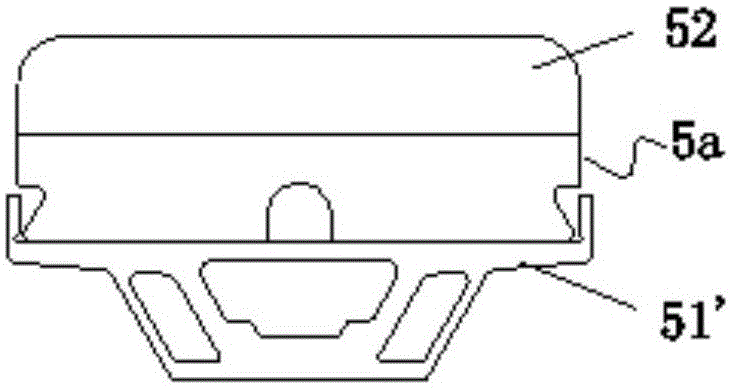

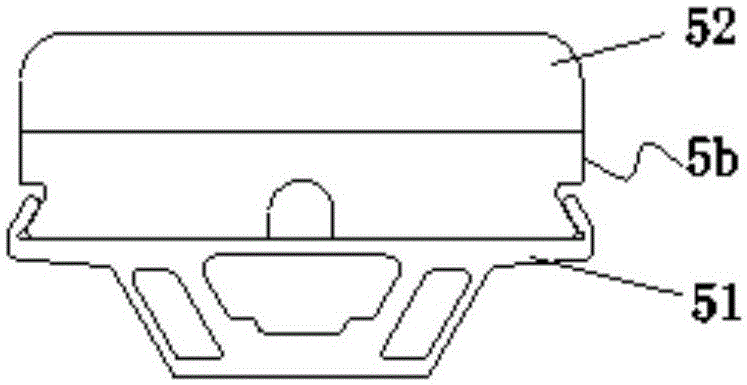

Flanging machine for carbon contact strip carriers

ActiveCN106466693AHigh degree of automationEasy to bendMetal-working feeding devicesPositioning devicesFlangingAutomation

The invention discloses a flanging machine for carbon contact strip carriers. The flanging machine comprises a working table on which a flanging working station is arranged and the following components mounted on the working table: a support device which is used for supporting the bottom of a carbon contact strip; a material pressing device which begins pressing after the head of the carbon contact strip on the support device reaches the flanging working station so that the carbon contact strip is pressed from the head of the carbon contact strip; and a flanging conveying device which applies opposite extrusion force on the two side edges of a carbon contact strip carrier and pushing force for pushing the carbon contact strip to move, enabling each part of the two side edges of the carbon contact strip carrier to be sequentially bent and wrapping the carbon strip. According to the flanging machine, the carbon contact strip carrier can be automatically bent, and the carbon contact strip can be automatically conveyed forwards, so that the automation degree is high, the bending and conveying efficiency is high, the production efficiency is increased, and labor is saved; the flanging machine can carry out bending treatment on carbon contact strips with different widths and is wide in the range of applications; and flanged products are great in consistency and high in quality, power is saved, emission is reduced, and environmental protection is facilitated.

Owner:SUZHOU RUIBEN IND FURNACE

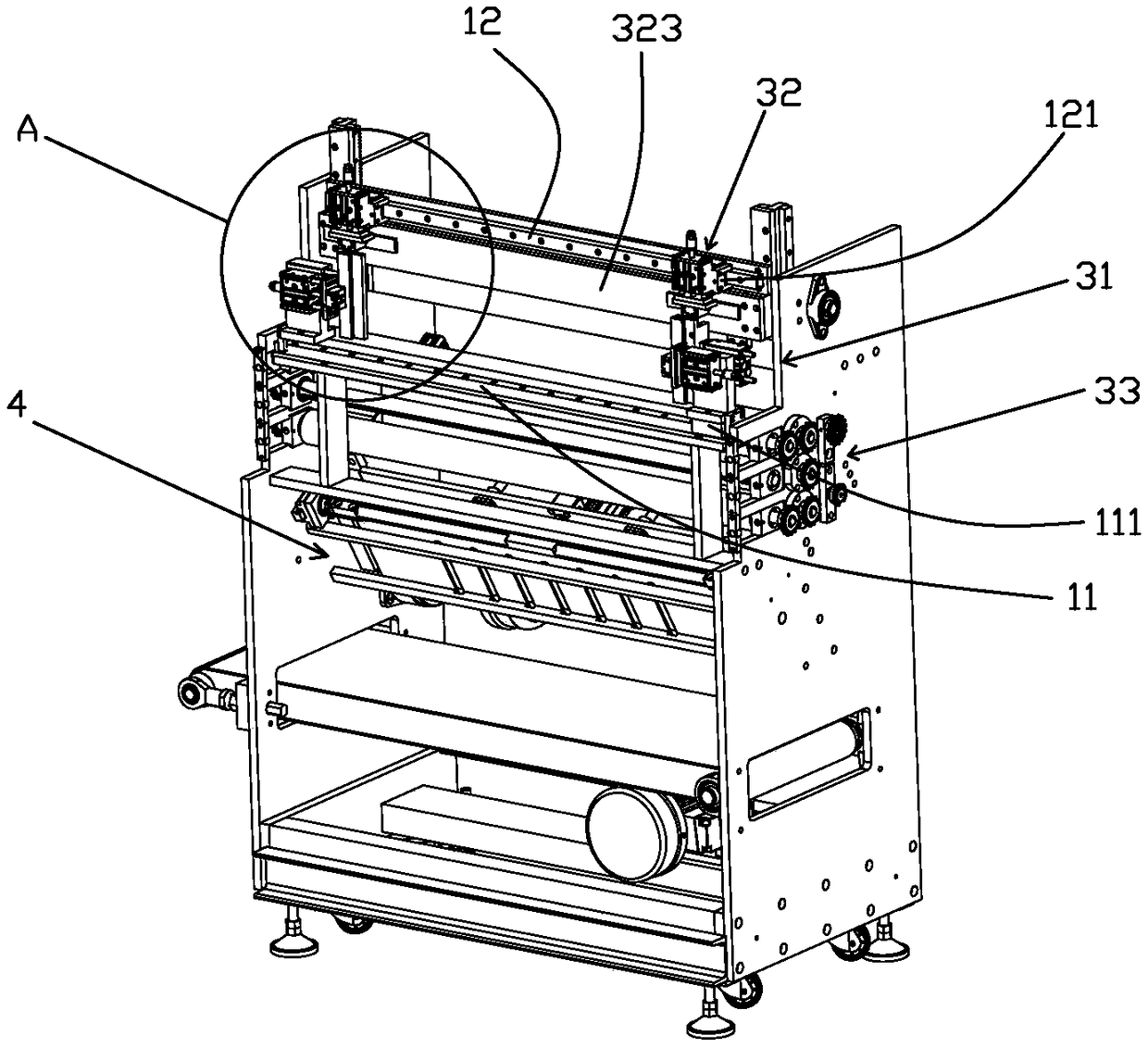

Automatic paperboard covering machine

ActiveCN104163009AAvoid deformationNot easy to cause deformationMechanical working/deformationCardboardPaper tape

An automatic paperboard covering machine is used for covering lateral edges of a paperboard with paper tape. The automatic paperboard covering machine comprises a machine platform support and an edge covering mechanism, wherein the edge covering mechanism is arranged on the machine platform support, the edge covering mechanism comprises an edge covering clamp and a soft edge covering material, the soft edge covering material is made of soft materials, and the soft edge covering material is arranged along the covered edges of the paperboard. One side of the soft edge covering material is fixed to the machine platform support, the other side of the soft edge covering material is fixed to the edge covering clamp, and thus the soft edge covering material is in a tensioned state. The edge covering clamp is hinged to the machine platform support. When the edge covering mechanism carries out edge covering, the paper tape is fed to the soft edge covering material and attached to the soft edge covering material, the edge covering clamp is driven to rotate around a hinged point of the machine platform support, the edge covering clamp drives the soft edge covering material to overturn upwards, the soft edge covering material drives the paper tape to synchronously overturn upwards step by step, and thus the paper tape makes contact with the lateral edge, to be covered, of the paperboard step by step and adheres to the lateral edge.

Owner:深圳市川菱科技有限公司

Automobile door taping machine

InactiveCN103157711ASmooth hemmingReduce noiseShaping toolsMetal-working feeding devicesEngineeringCar door

The invention discloses an automobile door taping machine. A pre-taping module and a taping module of the automobile door taping machine are provided with working faces which are matched with automobile door pre-taping molded surfaces. Two ends of the pre-taping module and two ends of the taping module are provided with rotary shafts respectively. The rotary shafts are arranged on bearing blocks which are arranged at two ends of each edge of a die block. The pre-taping module and the taping module are respectively driven by a first actuating device and a second actuating device and rotate around the rotary shafts of the pre-taping module and the taping module. The pre-taping module and the taping module are arranged in a separating mode and are controlled by independent actuating devices, so that the whole structure is reasonable, dismantling becomes convenient, and mold repairing quantity of the pre-taping module and the taping module is greatly reduced. Due to the fact that a rolling mechanism which guides a clamping device to move up and down and can adjust gaps automatically is arranged on the clamping device, work of the clamping device is stable and reliable, a chattering phenomenon generated when the clamping device works is restrained effectively, and positioning error is reduced.

Owner:戴崇强

Pneumatic tire

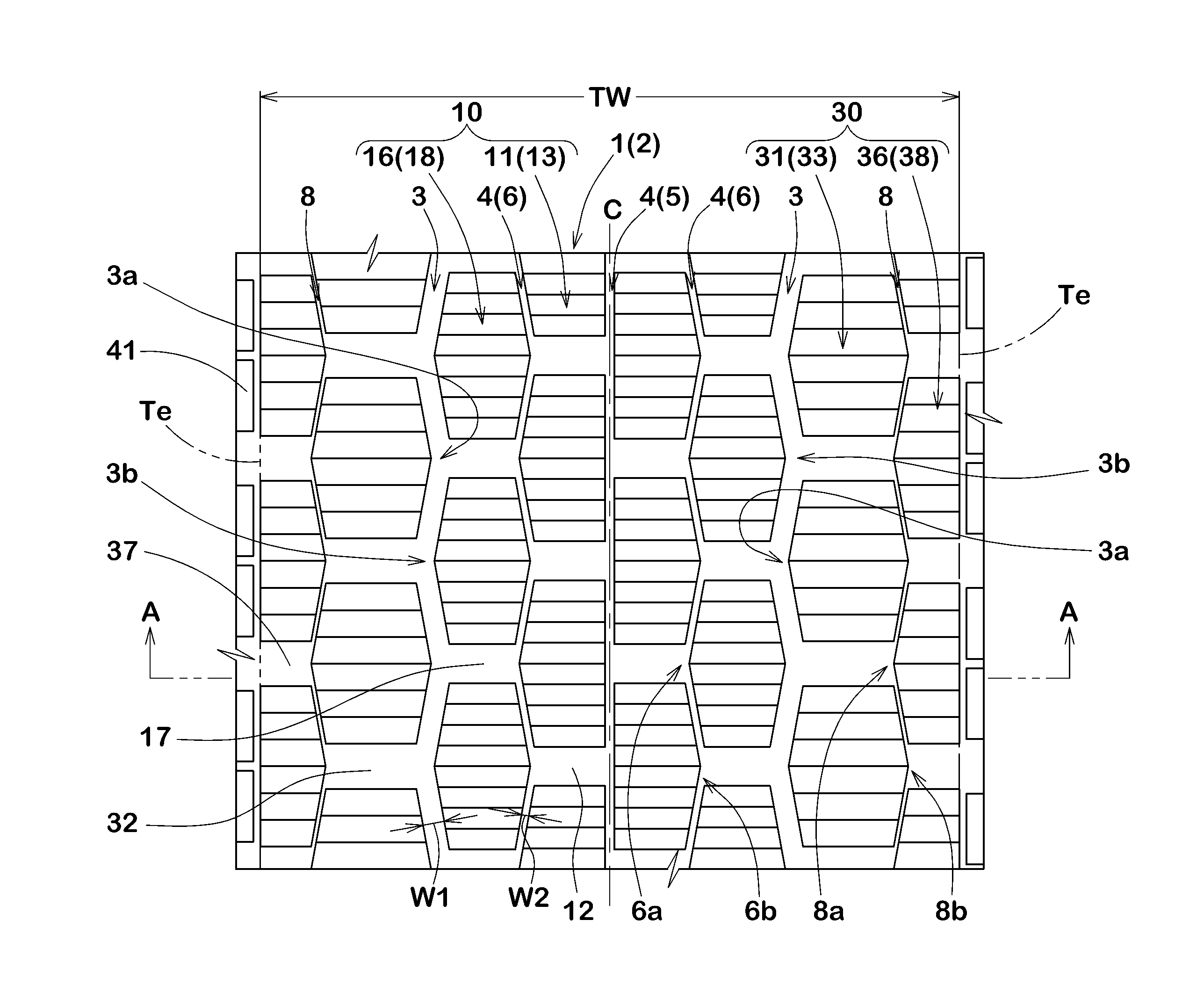

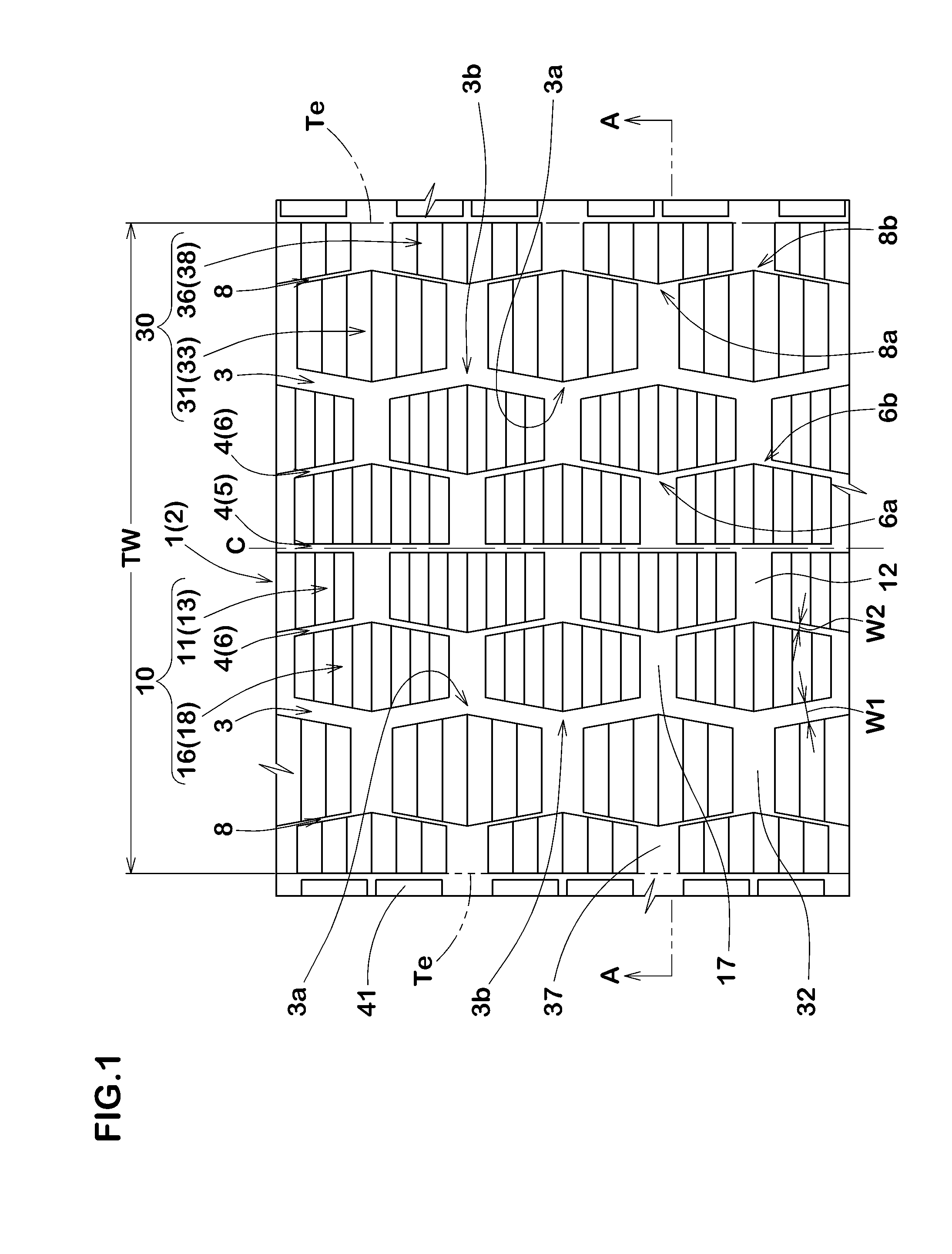

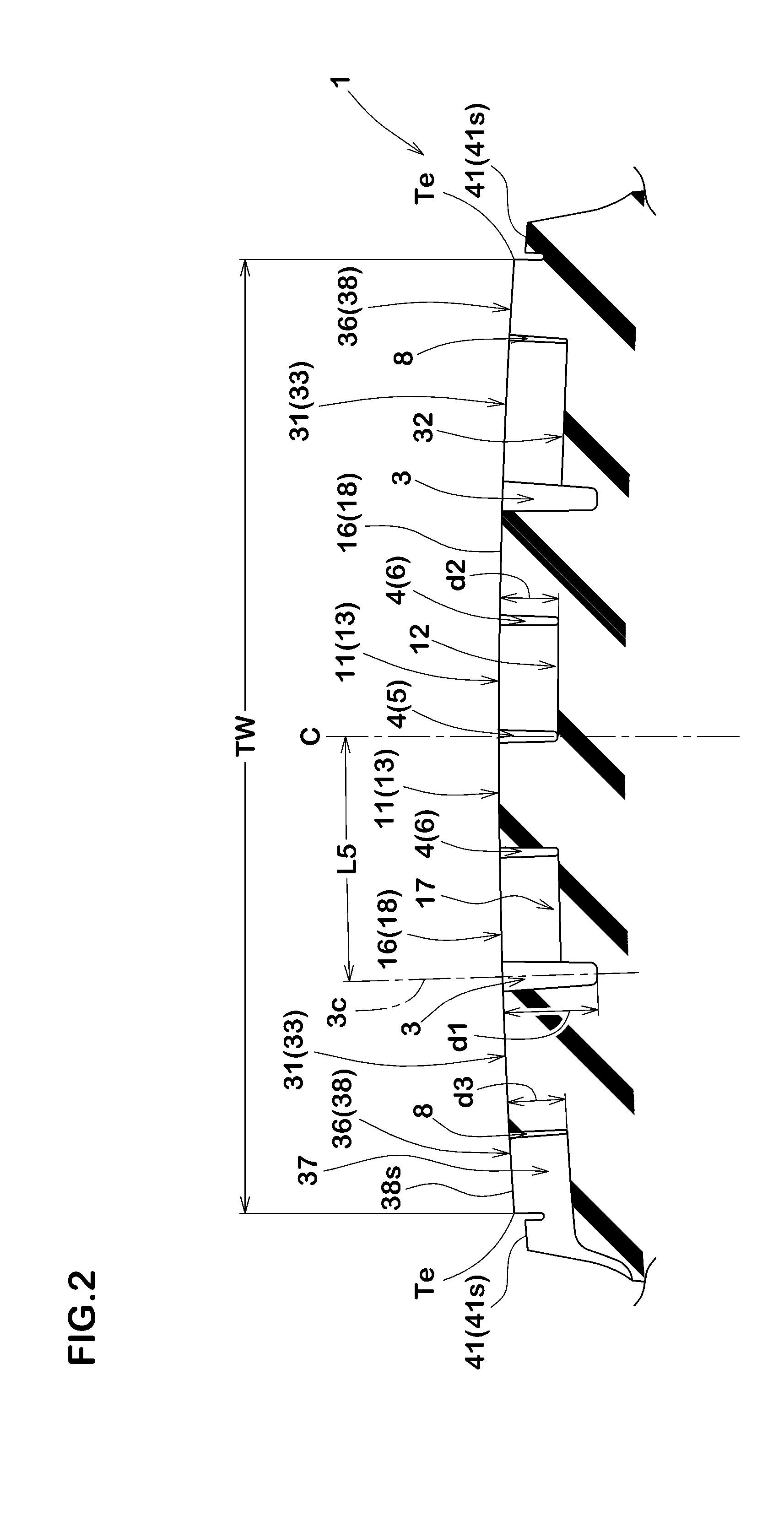

ActiveUS20160243898A1Resistance is maintainedMaintain wear resistanceTyre tread bands/patternsGroove widthEngineering

A pneumatic tire in which a tread part is provided with a pair of central main grooves extending continuously around the circumference of the tire on both sides of a tire equator C, and central thin grooves extending continuously around the circumference of the tire on the tire-axially inner sides of the central main grooves and having less groove width than the central main grooves. The central thin grooves include a linear first central thin groove running along the tire circumference, and zigzagging second central thin grooves. The first central thin groove is provided on the tire-axially inner sides of the second central thin grooves.

Owner:SUMITOMO RUBBER IND LTD

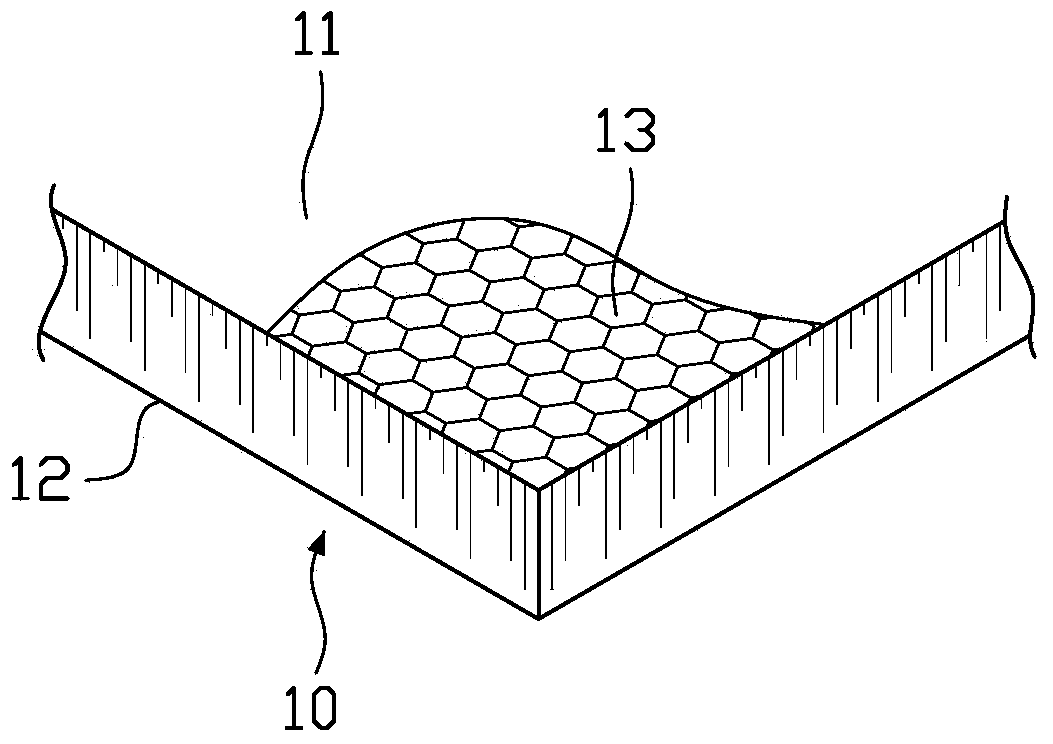

Pneumatic tire

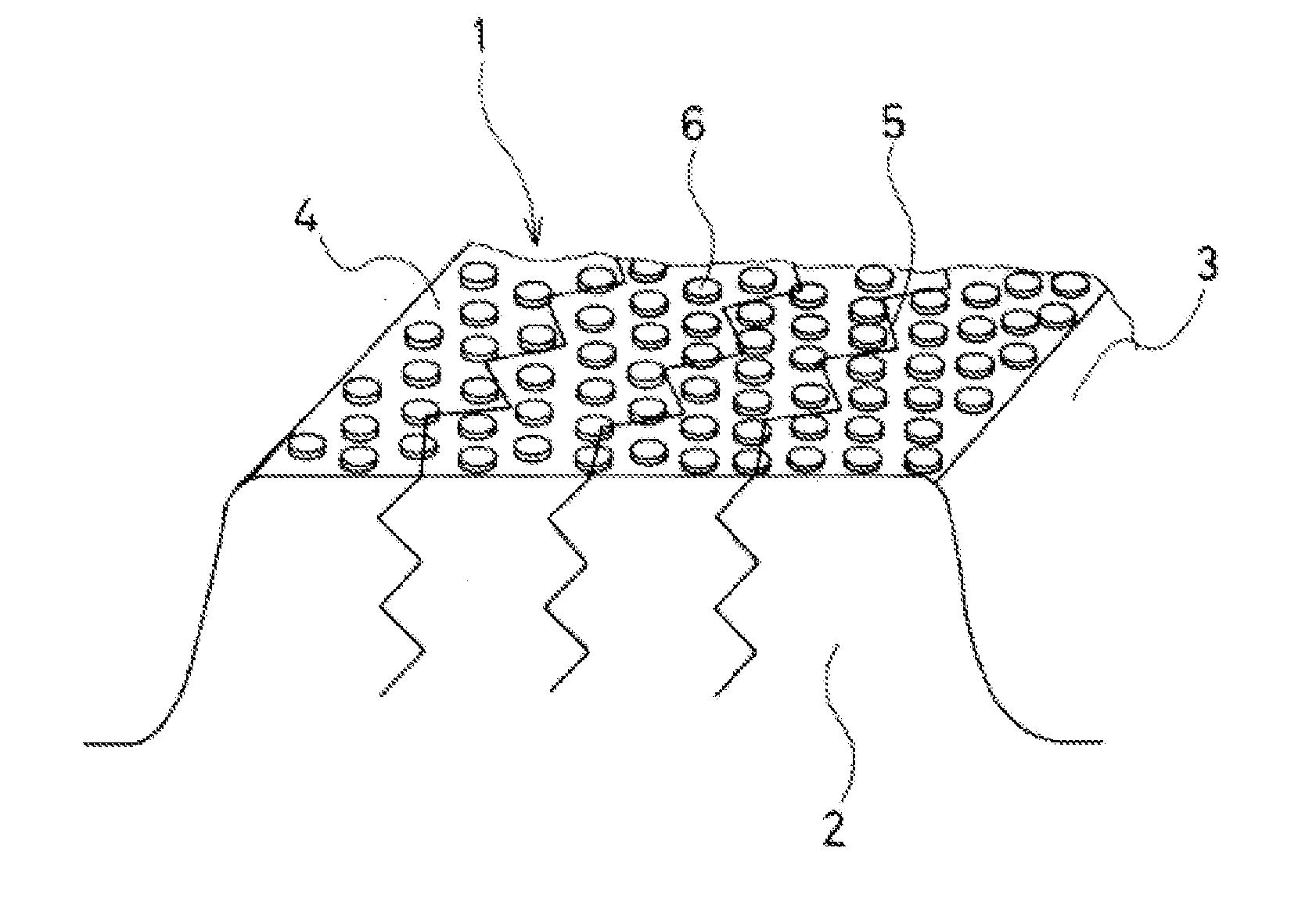

InactiveUS20110220256A1High water pickup effectImprove braking effectTyre tread bands/patternsNon-skid devicesEngineeringSmall hole

A pneumatic tire including, on a tread surface, rib-like land portions partitioned by a plurality of main grooves and / or a plurality of block-like land portions partitioned by lug grooves extending in a tire width direction, wherein sipes or small holes are provided in the land portions, multiple protrusions are disposed having a height that is less than a depth of the sipes or small holes, and the multiple protrusions are disposed so as to form a shape wherein a flow path width increases at a flow path convergence point where flow paths formed in a mesh-like shape between the protrusions converge from at least three directions, and a ratio of an area of the multiple protrusions to an area of a block-like land portion is 0.5 or greater and 0.9 or less.

Owner:YOKOHAMA RUBBER CO LTD

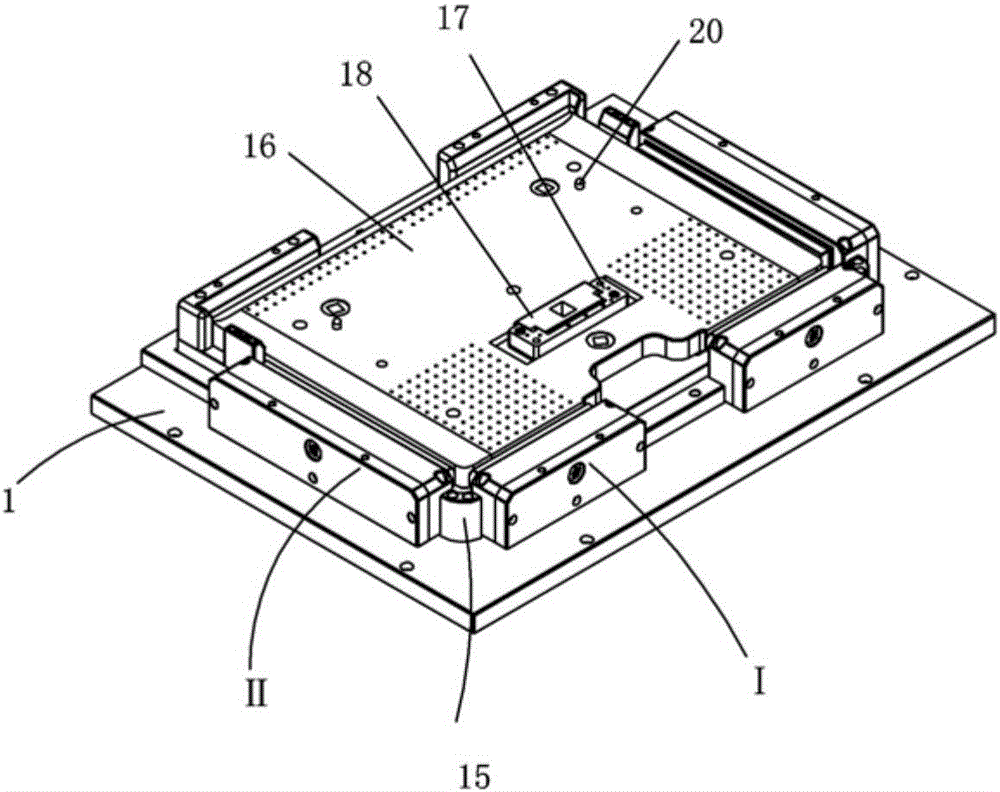

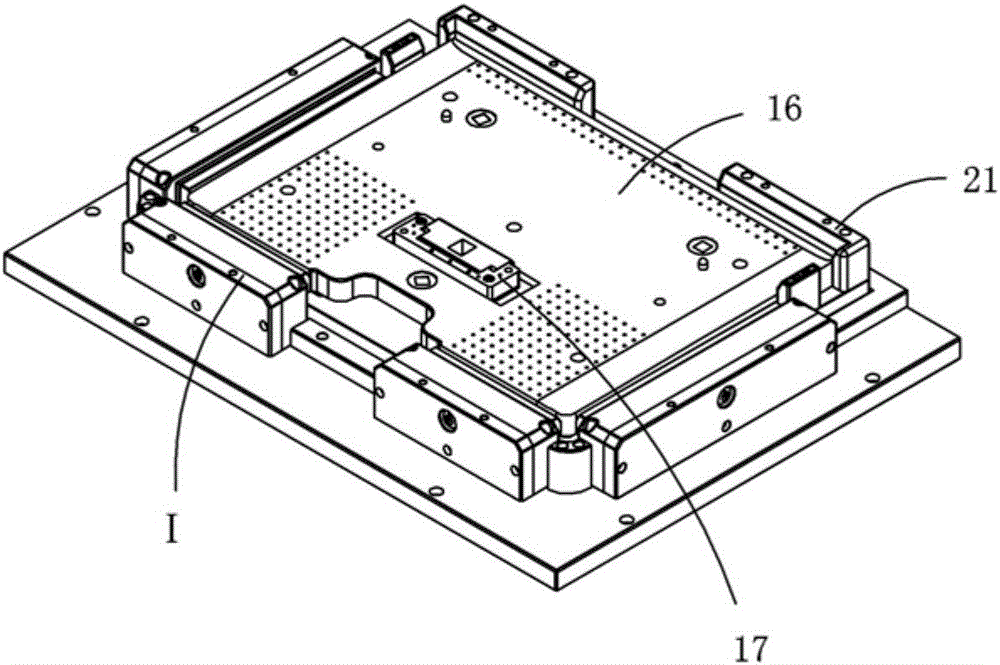

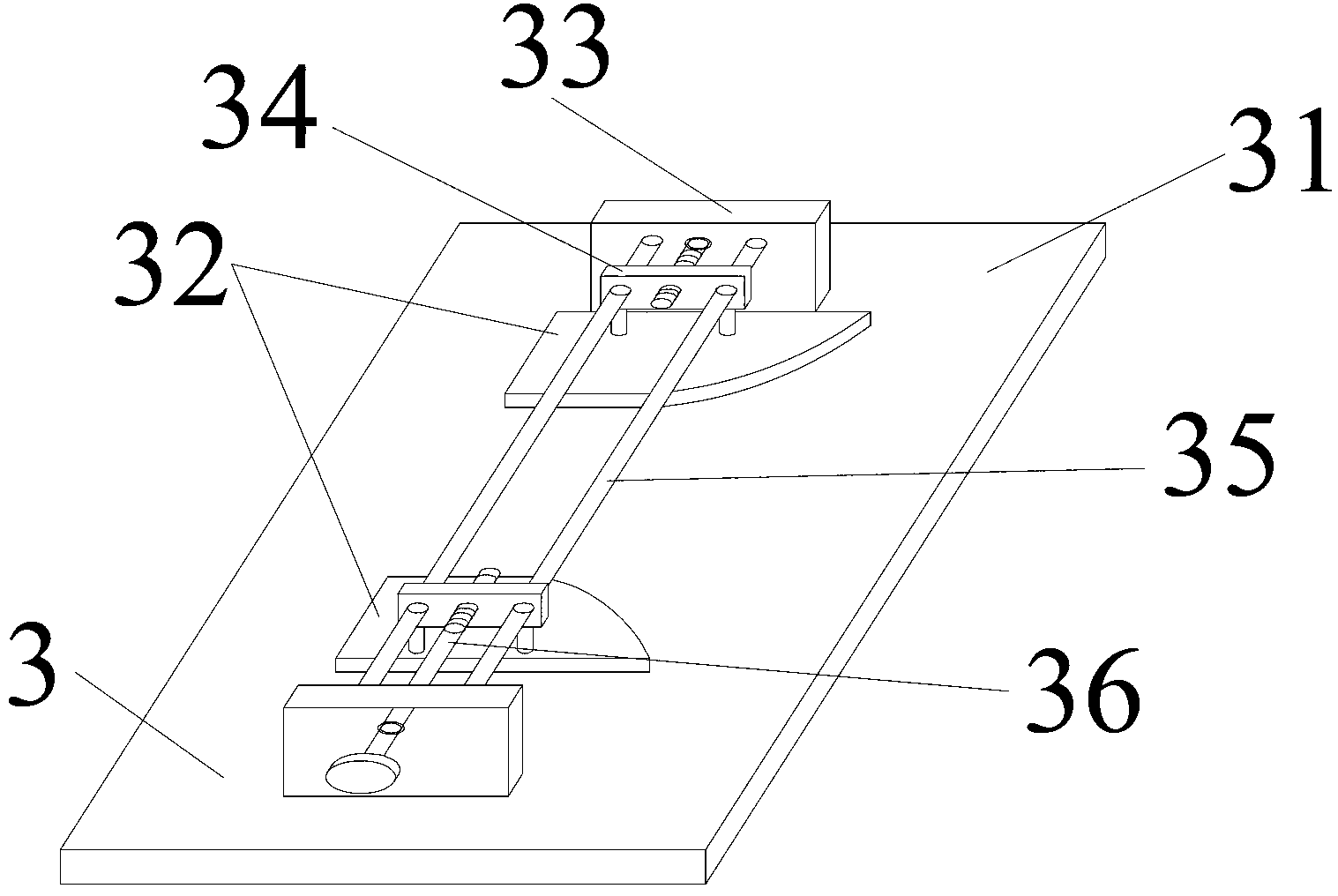

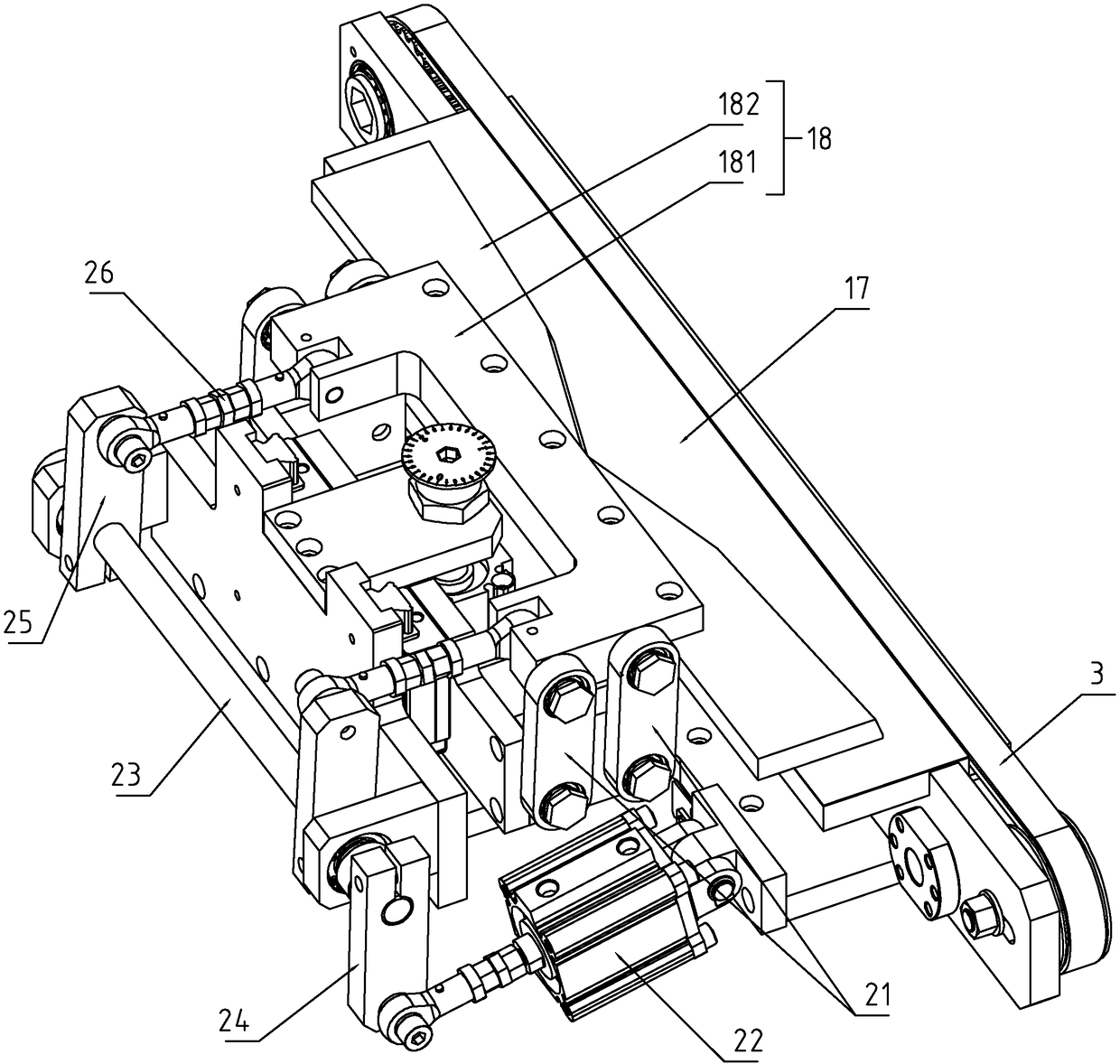

Film pasting and bending mechanism

ActiveCN106003997ASimple structurePracticalLamination ancillary operationsLaminationTectorial membraneEngineering

The invention relates to a film pasting and bending mechanism. The film pasting and bending mechanism is characterized in that a bottom plate is connected with a suction plate seat plate; the bottom plate is provided with a front edge-folding device and a side edge-folding device which are capable of automatically and upwards foldingthe edge of a protection film; the suction plate seat plate is fixedly provided with a vacuum suction plate; a containing groove is formed in the middle part of the vacuum suction plate; a product locating and fixing block is fixedly arranged in the containing groove; the product locating and fixing block is movably connected with a product locating and moving block; air vents which are used for sucking the protection film are also formed in the vacuum suction plate; the suction plate seat plate is connected with locating pins which are used for assisting product location through elastic pieces a; the top ends of the locating pins stretch out from the vacuum suction plate. According to the film pasting and bending mechanism disclosed by the invention, the protection film is arranged on the vacuum suction plate and is located through the locating pins, and the protection film can be sucked by the vacuum suction plate; a back adhesive layer of the protection film can be torn off by hand, aproduct is placed on the protection film, the product can be pressed down through the matching of a pressing machine after locating, the edge of the product leans against the front edge-folding device and the side edge-folding device, the edge of the protection film can be automatically and upwards bent so as to coat the product, and the film pasting effect is good.

Owner:BOZHON PRECISION IND TECH CO LTD

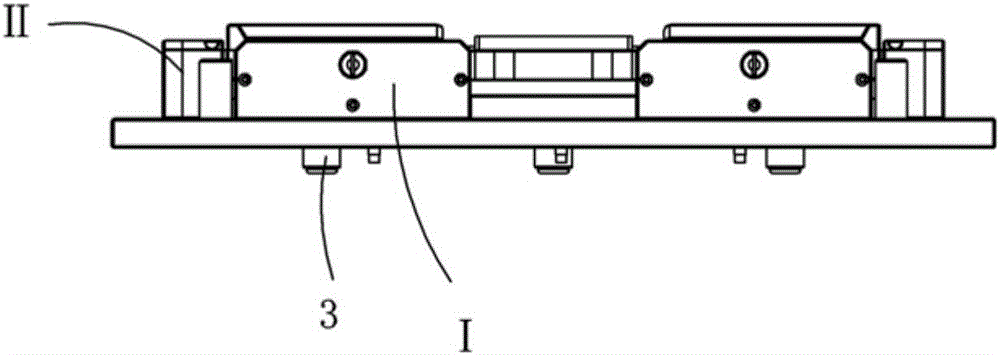

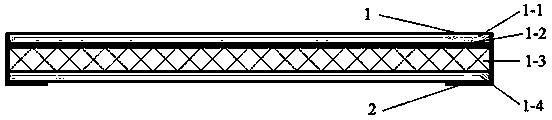

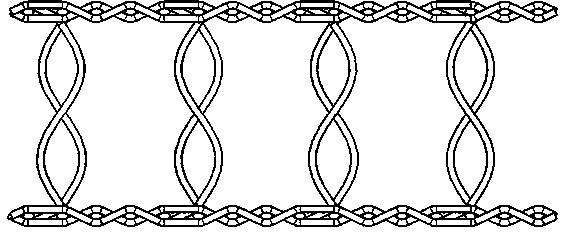

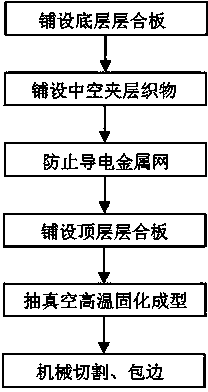

Anti-static floor made of composite materials and provided with hollow interlayer and manufacture method thereof

The invention relates to an anti-static floor made of composite materials and provided with a hollow interlayer and a manufacture method thereof and belongs to the technical field of protection. The anti-static floor comprises a floor main body (1) and a metal covered edge (2). The floor main body (1) is composed of a top layer laminated board (1-1), a conducting layer (1-2), the hollow interlayer (1-3) and a bottom layer laminated board (1-4). The conducting layer (1-2) is formed by coating epoxy resin glue on a conductive metal net in a curing mode. The top layer laminated board (1-1) and the bottom layer laminated board (1-4) are formed by glass fiber cloth and epoxy resin glue in a laminated mode according to a certain paving angle, and the paving sequence is [(0 / 90)(+ / -45) (0 / 90)(+ / -45) (0 / 90)]. The metal covered edge (2) covers the side surfaces on the periphery of the floor main body and contacts the conducting layer (1-2). The anti-static floor is light in structural weight, long in service life and low in cost, and has anti-deformation and anti-static functions.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

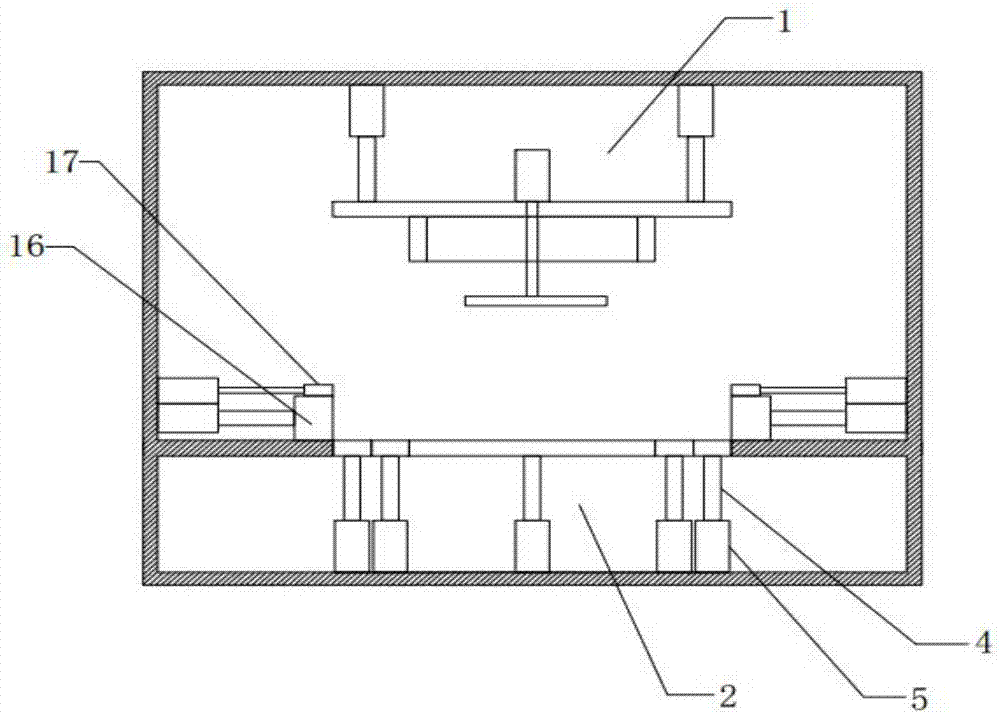

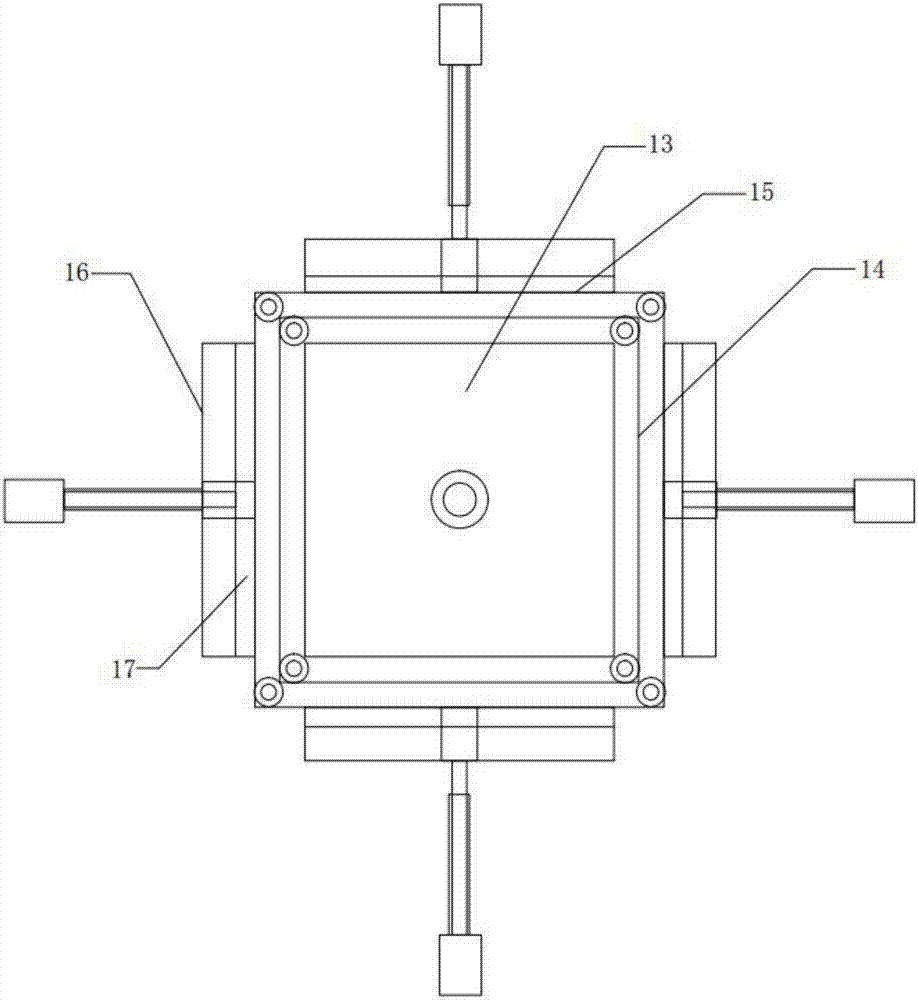

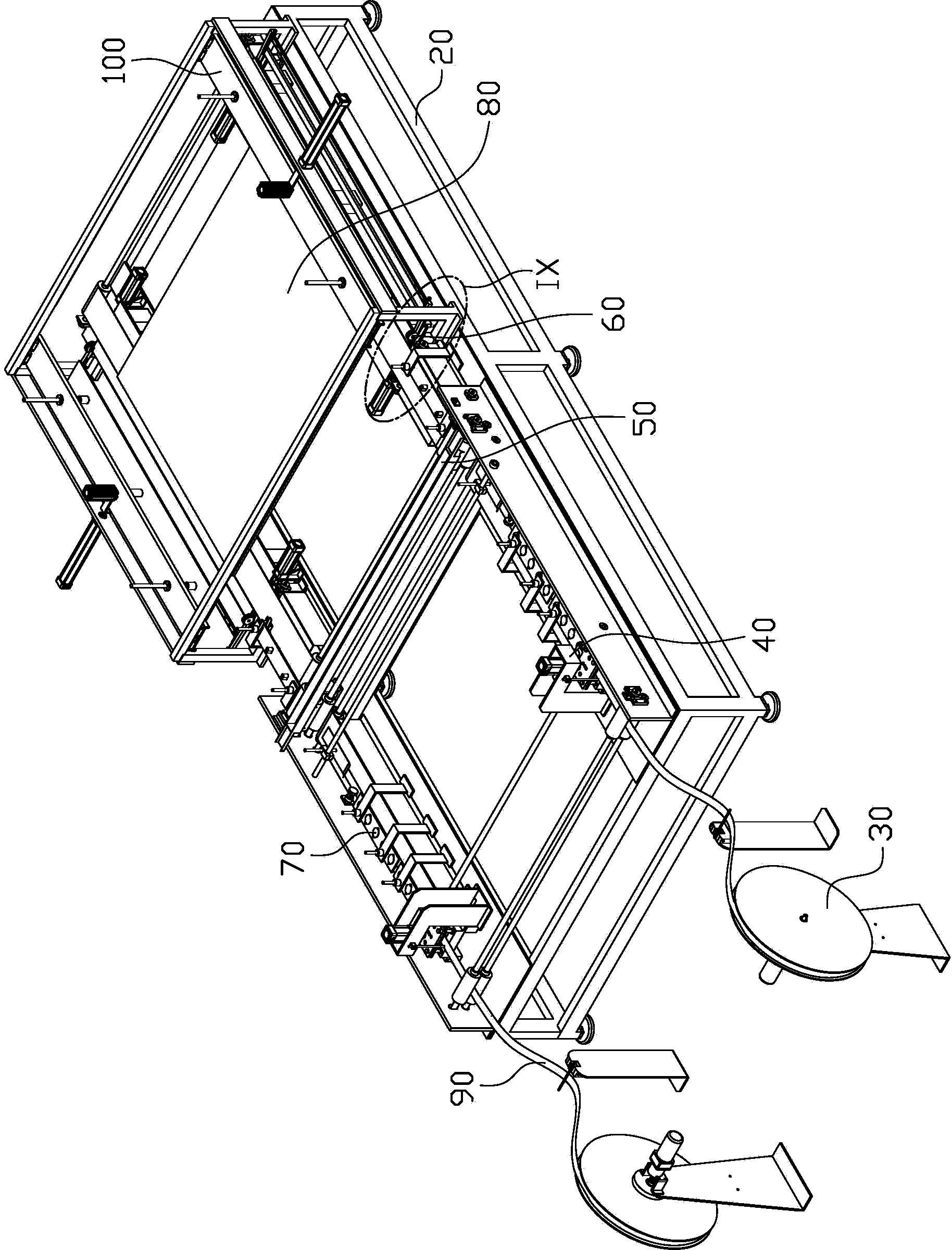

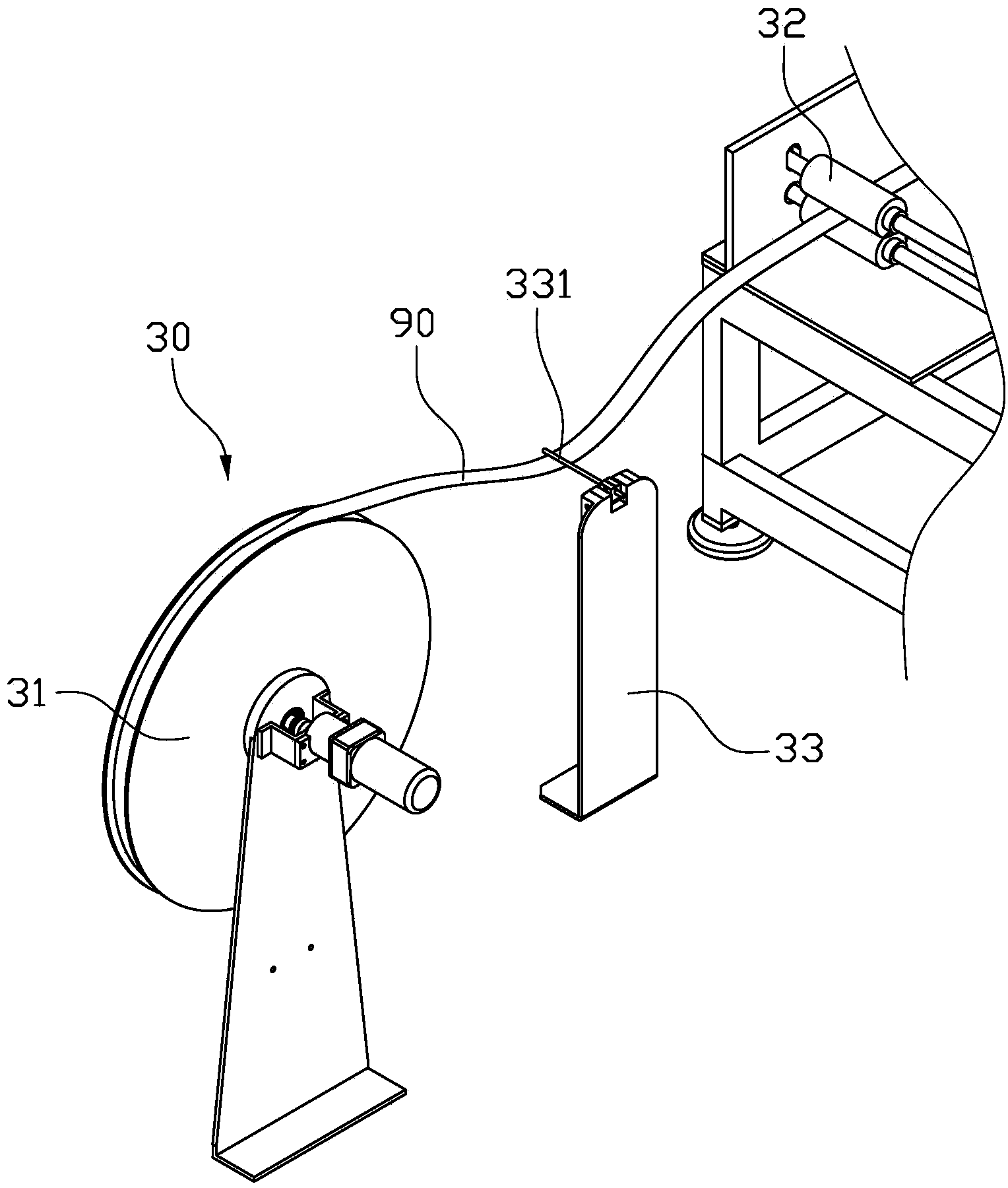

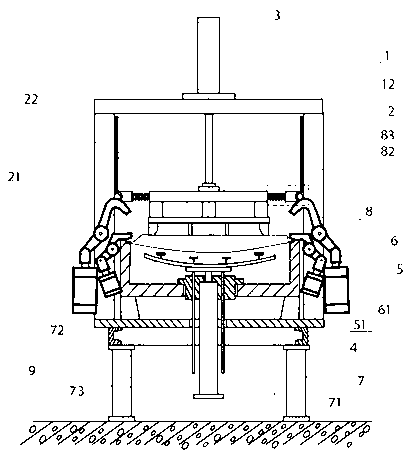

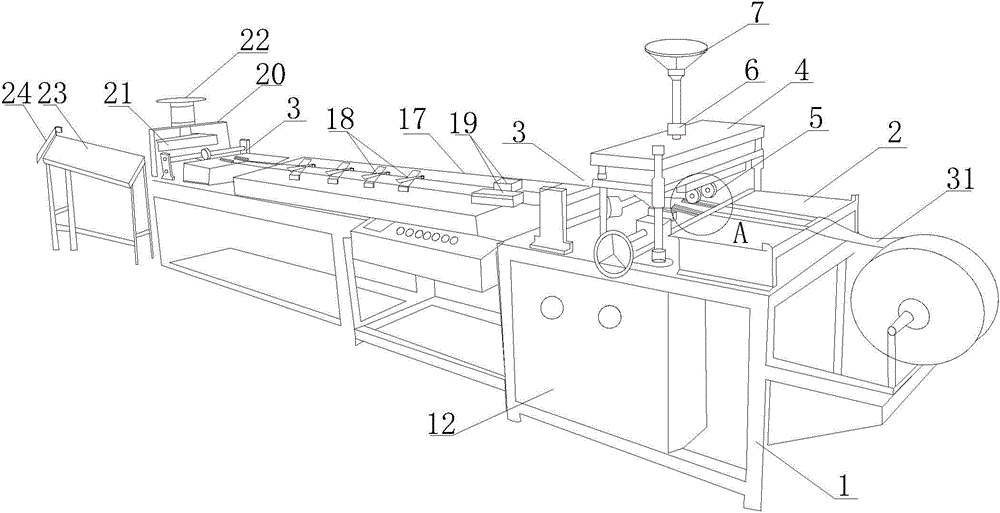

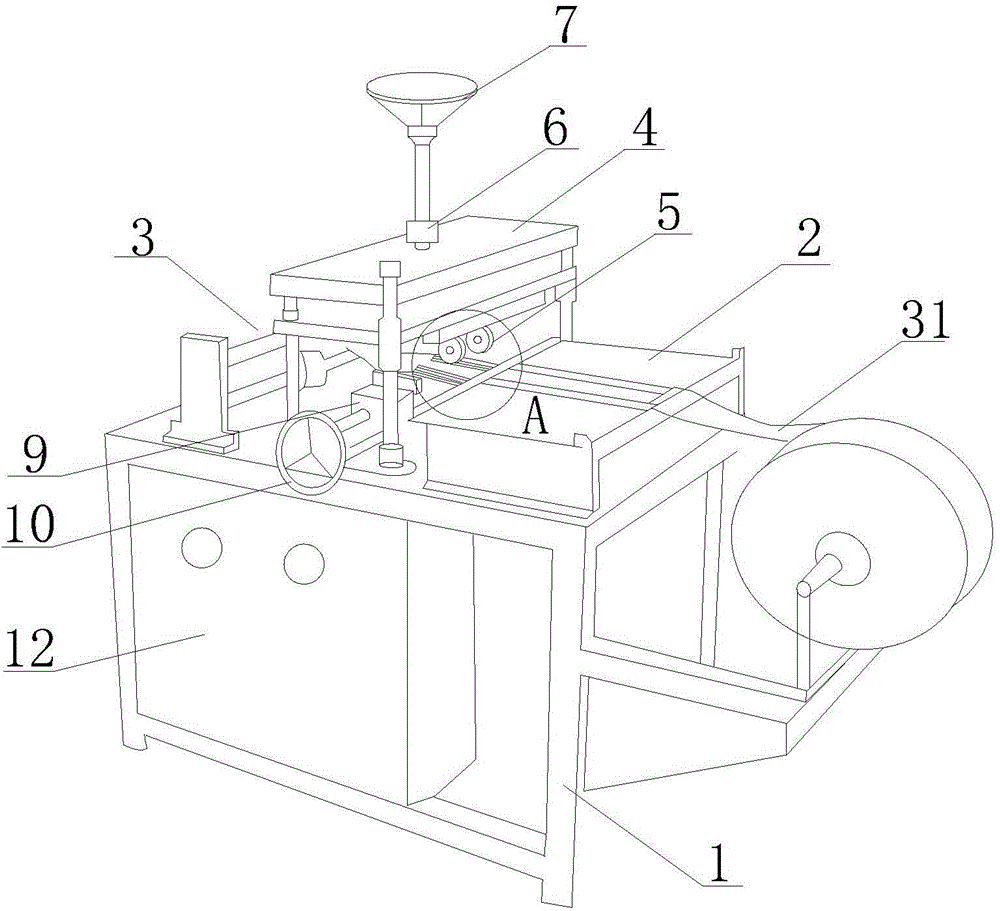

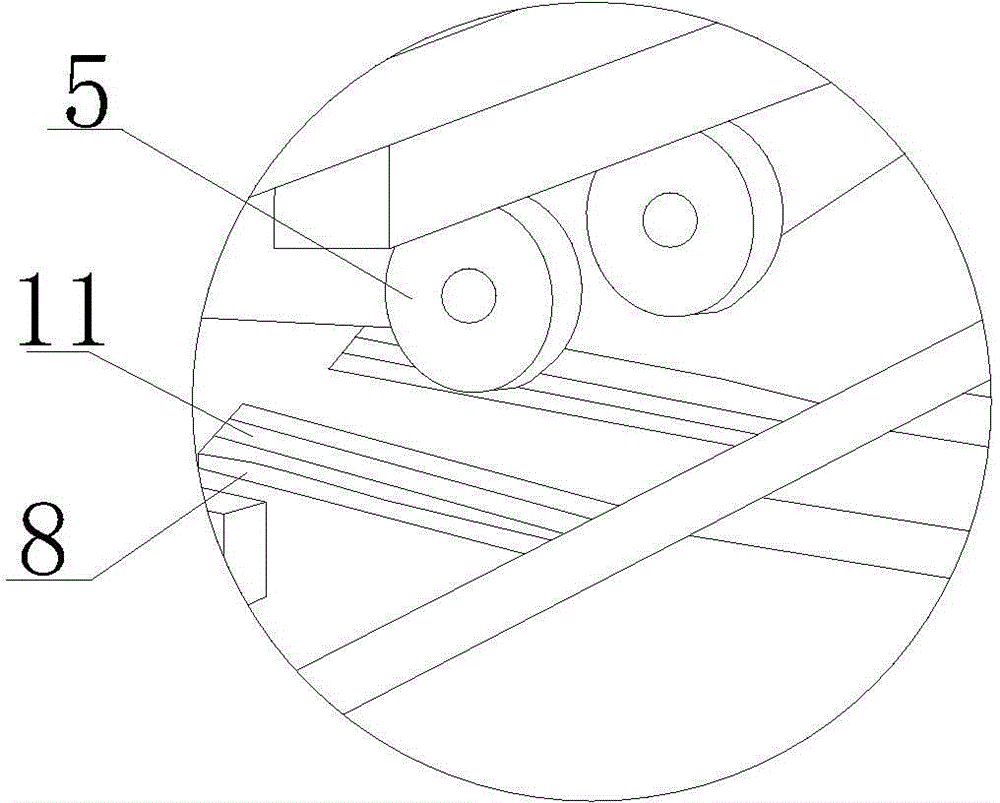

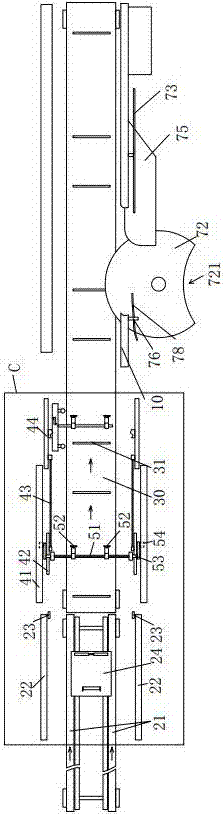

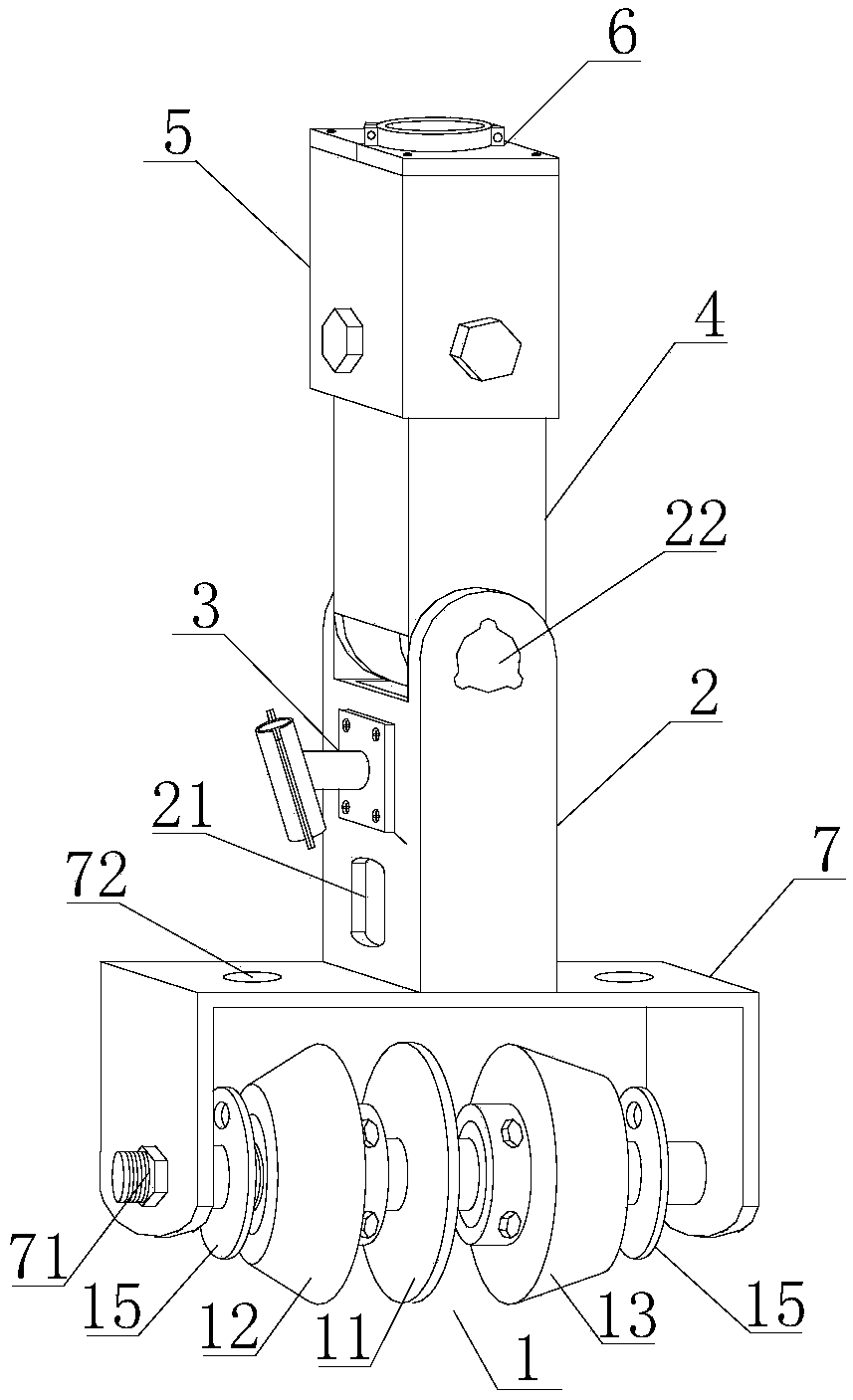

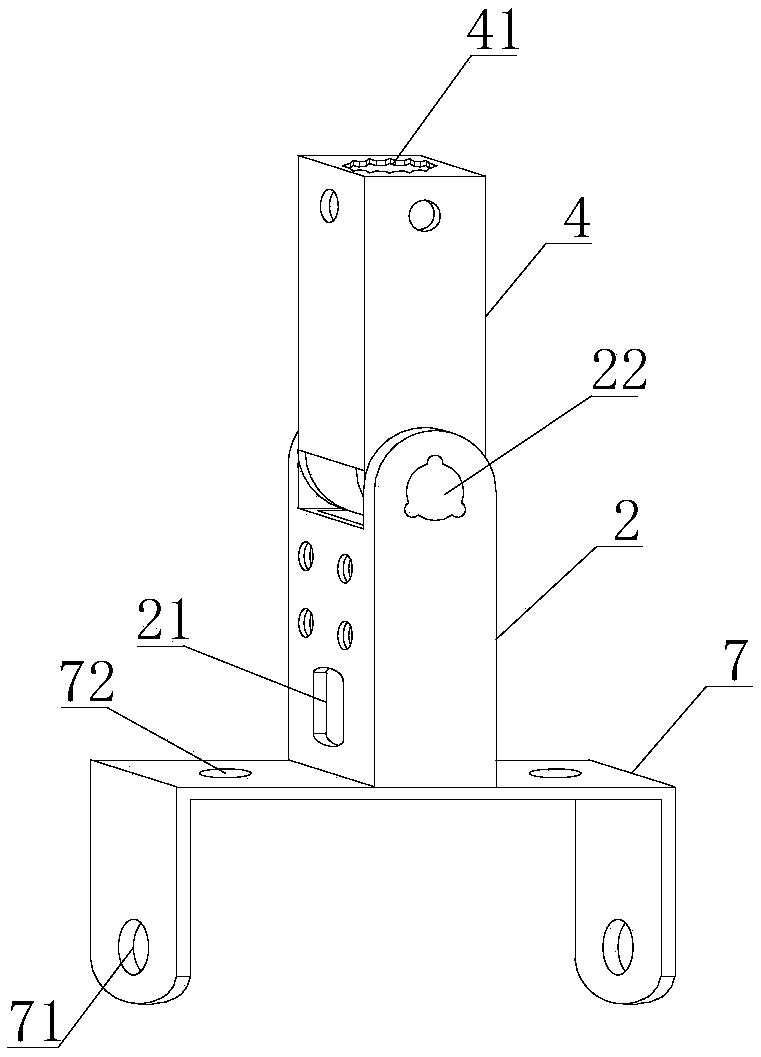

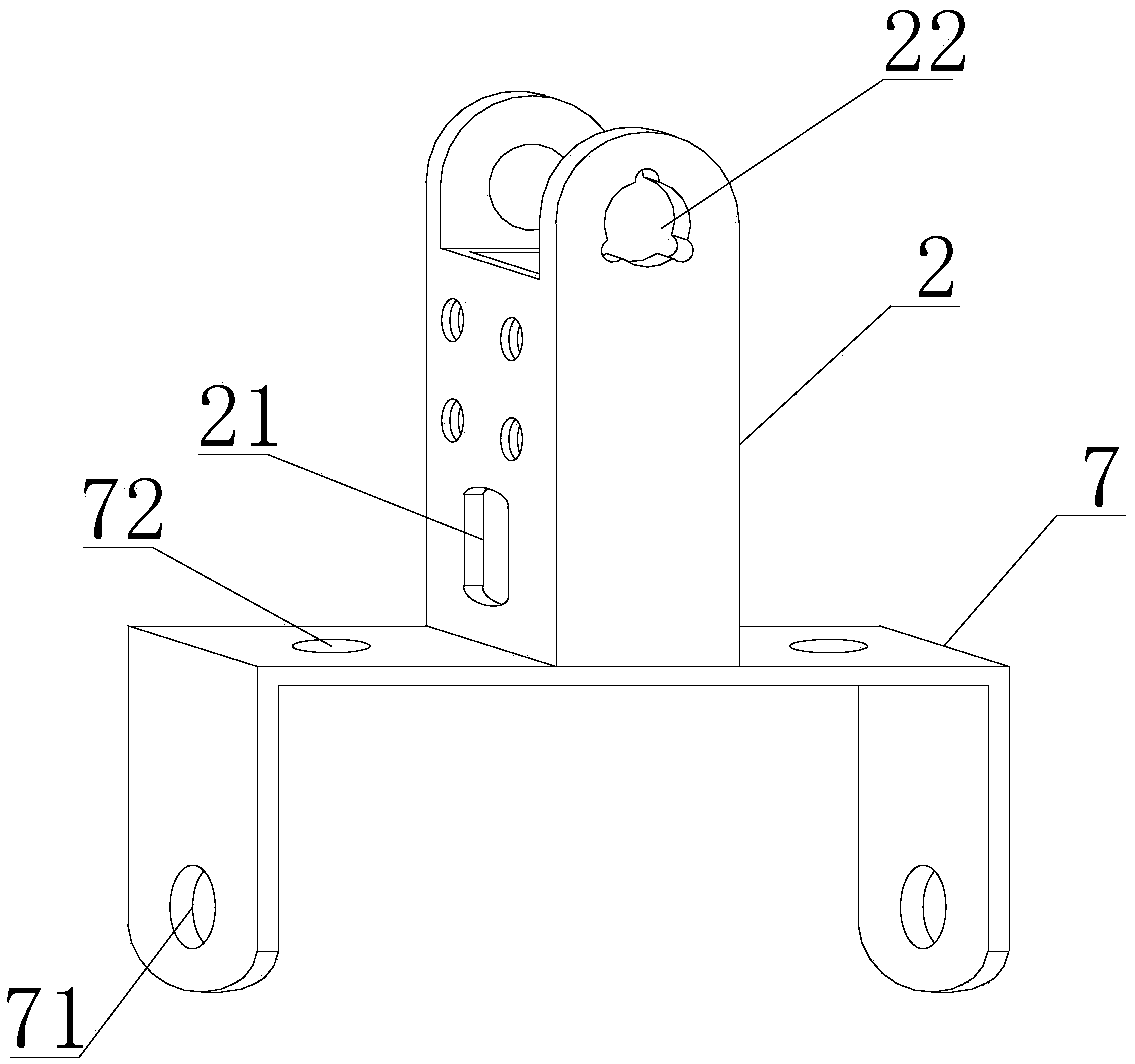

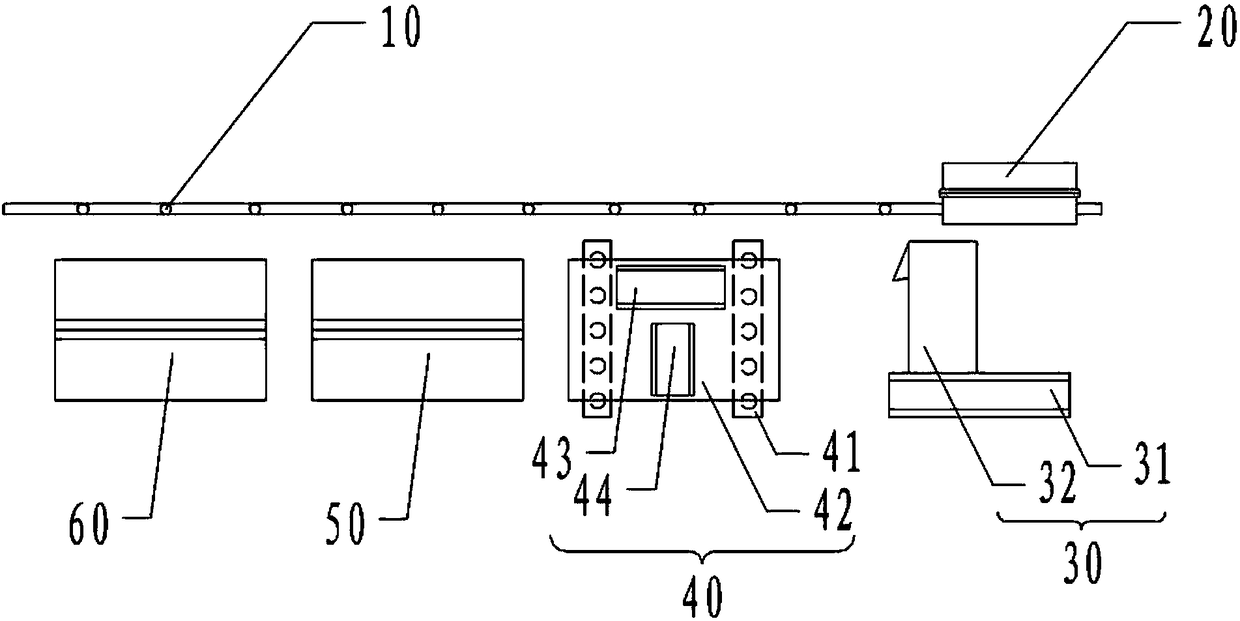

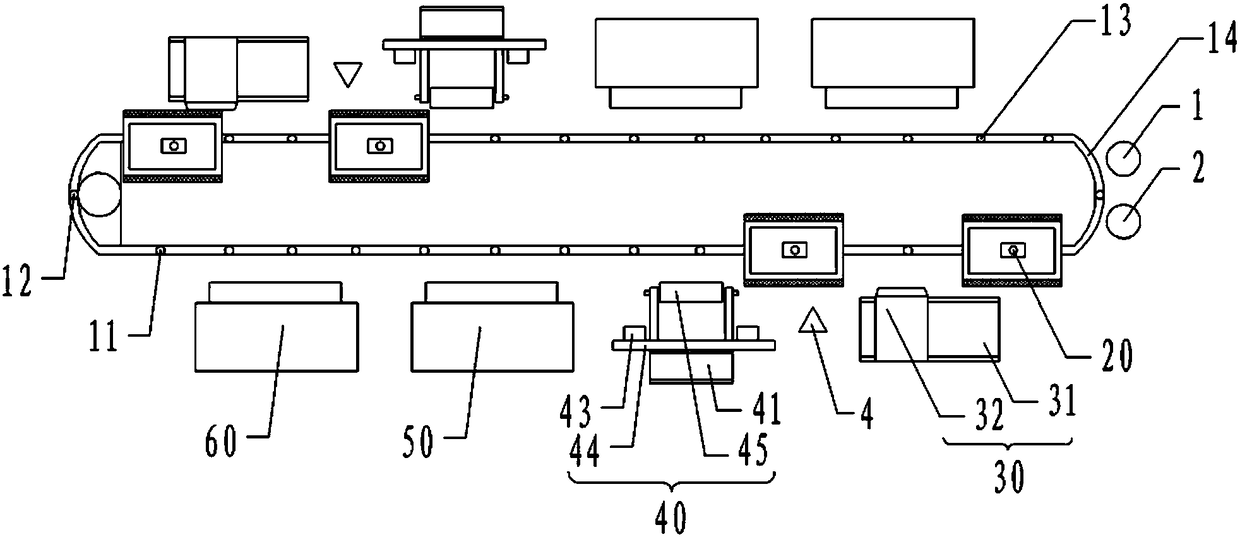

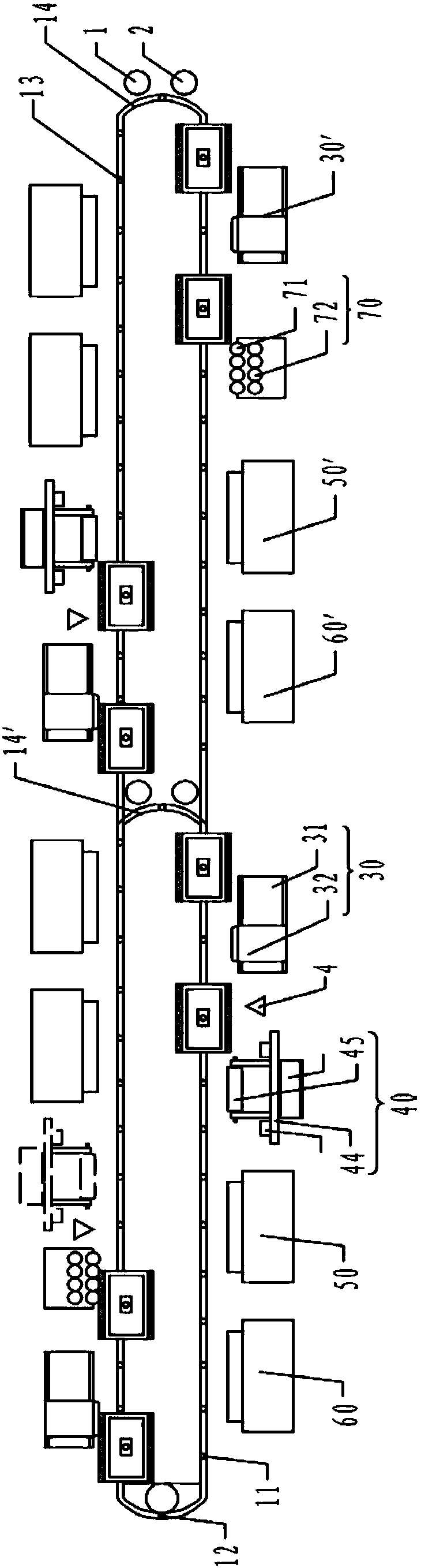

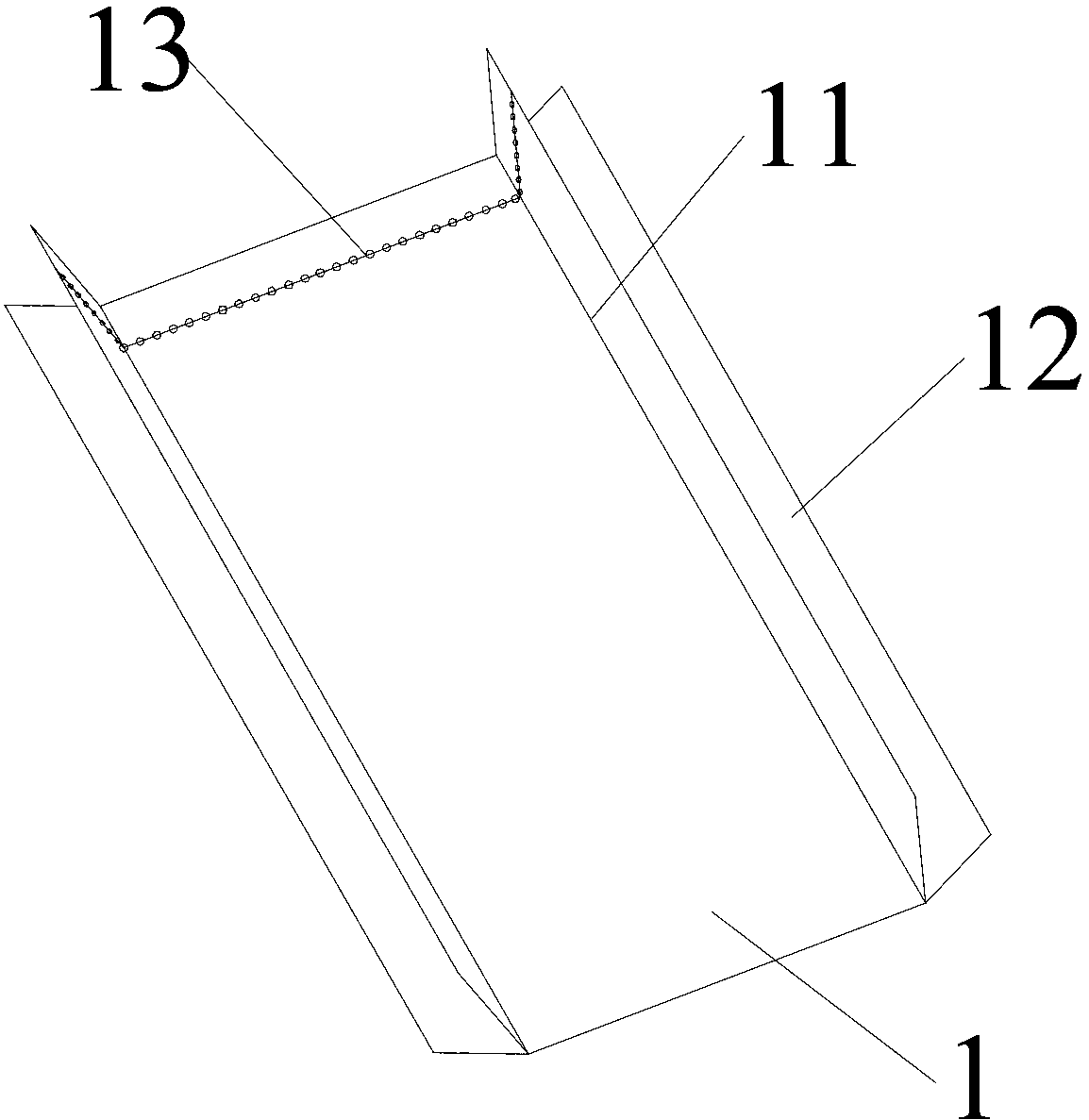

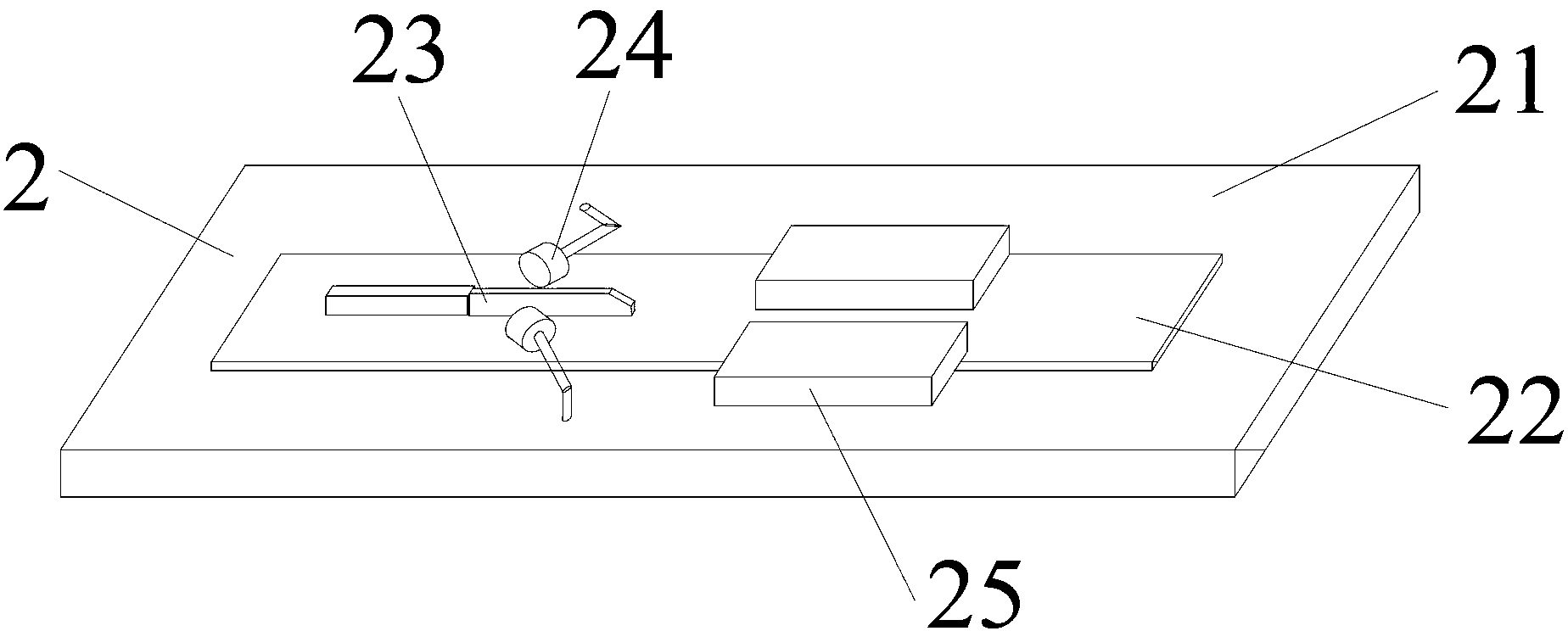

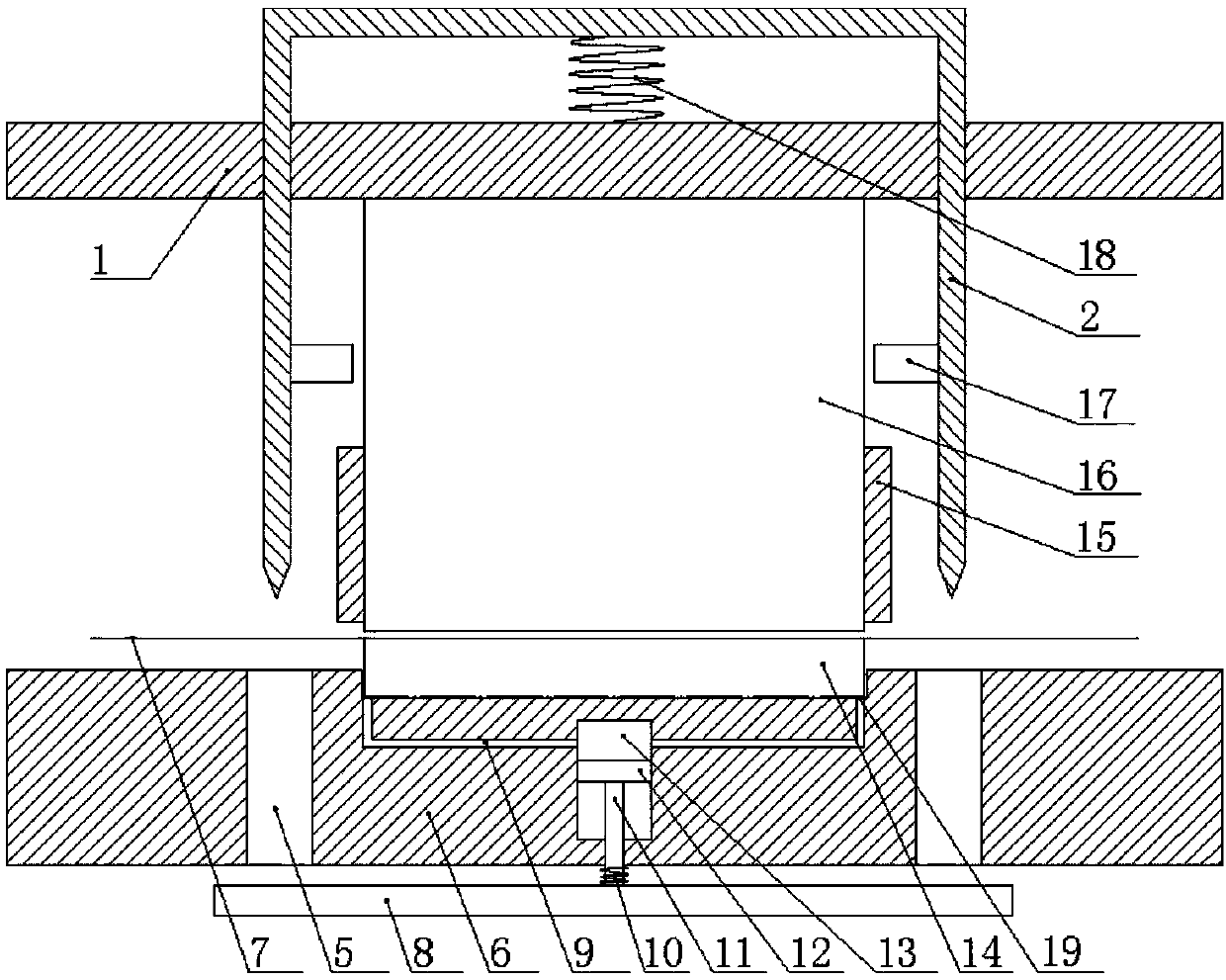

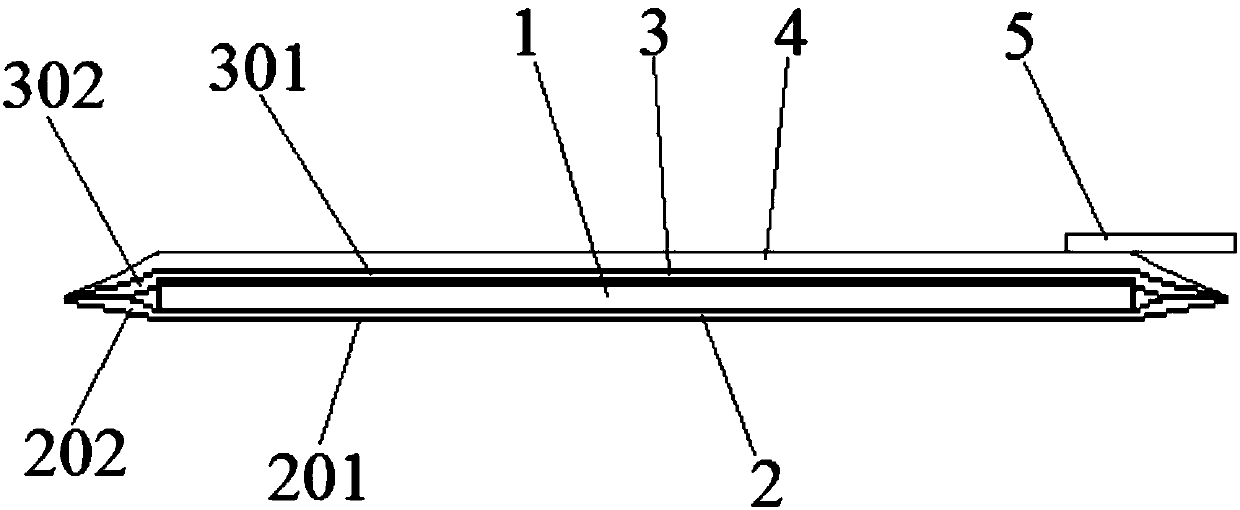

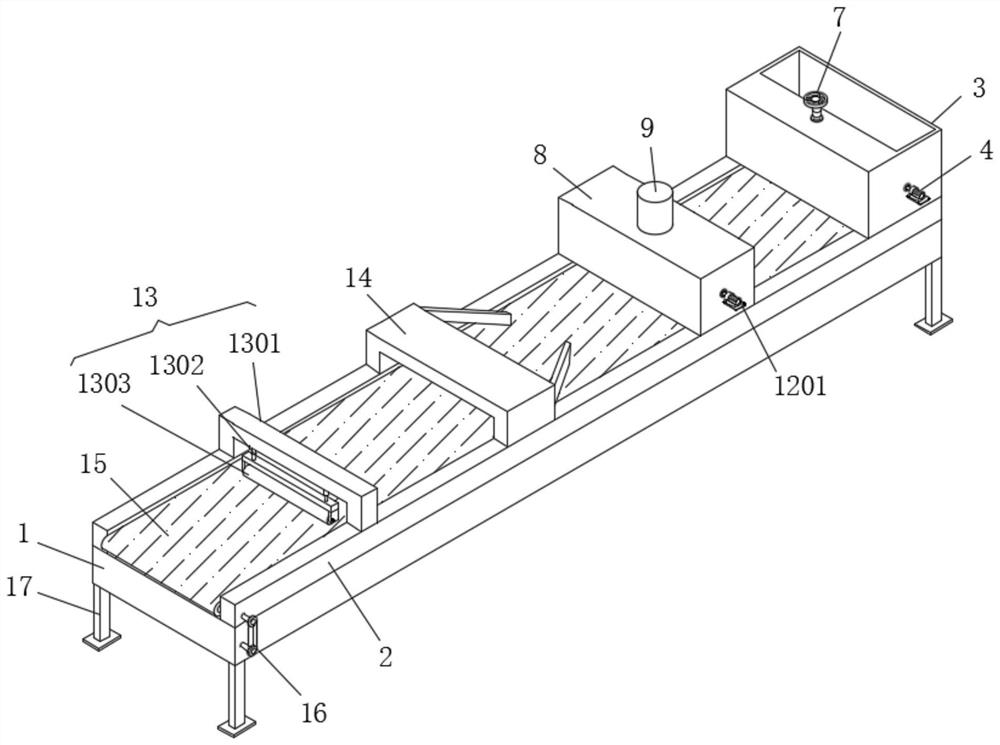

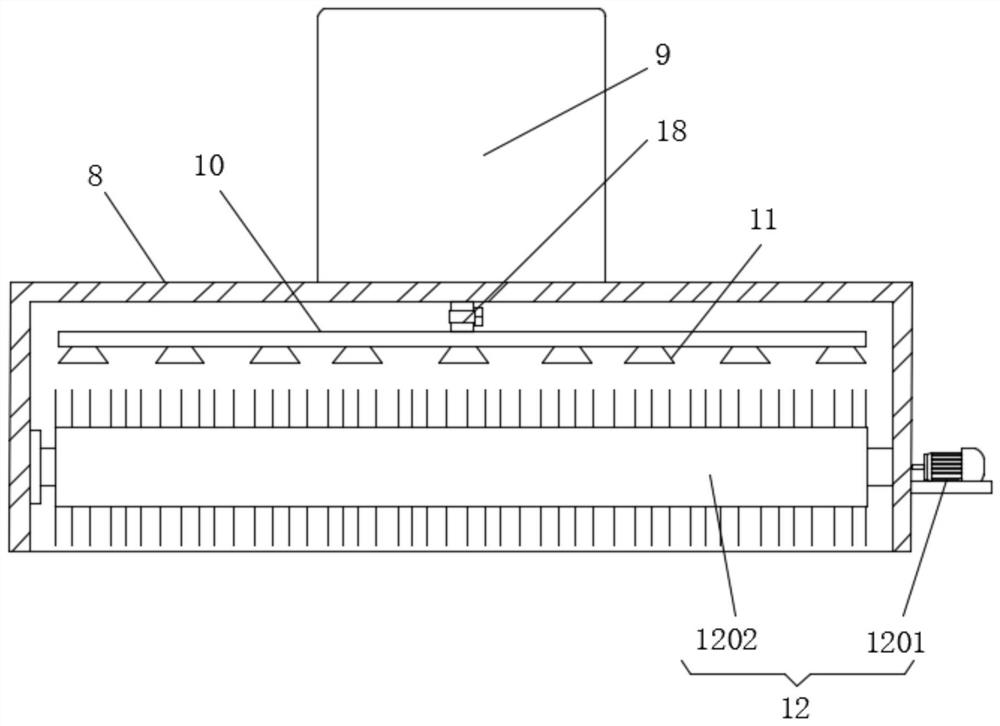

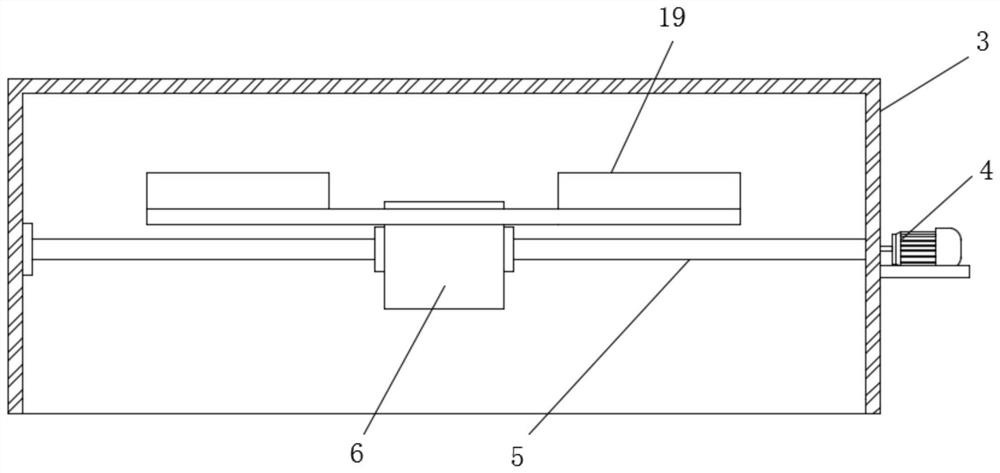

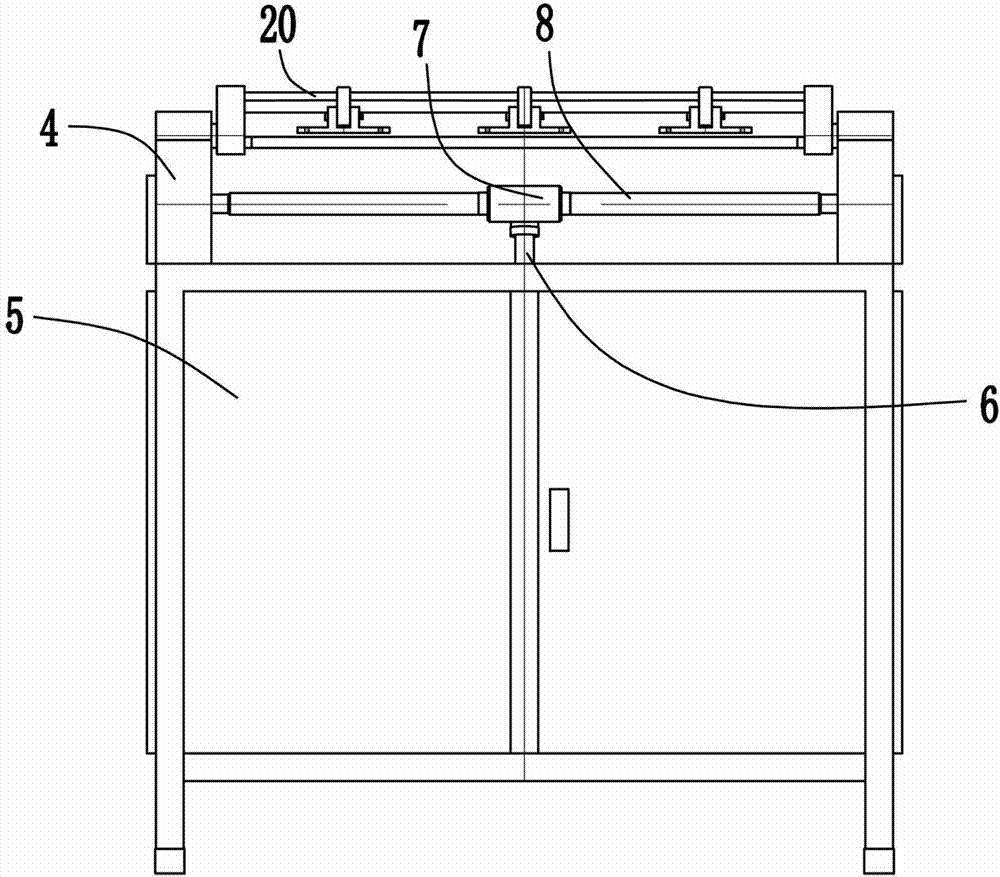

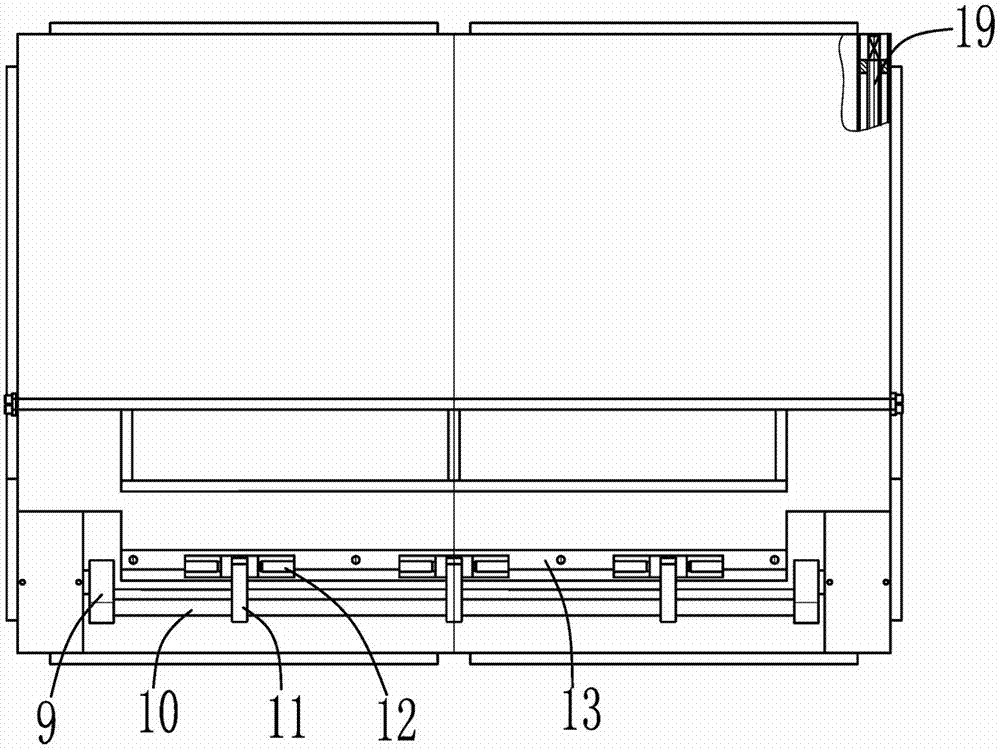

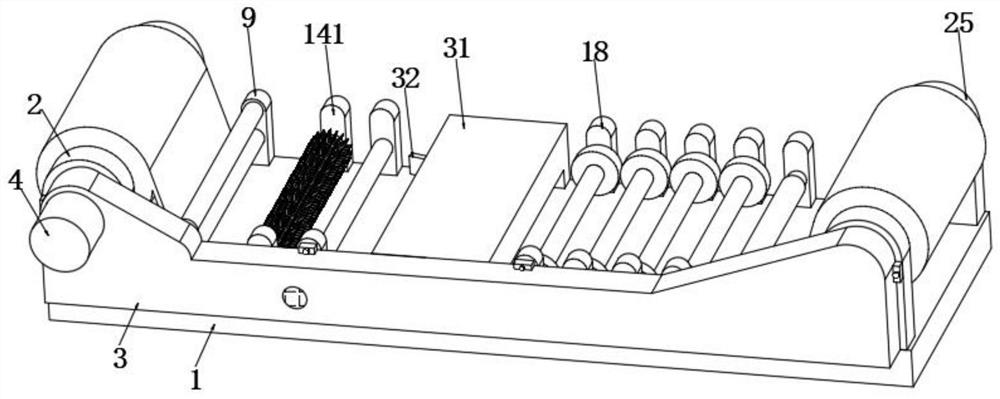

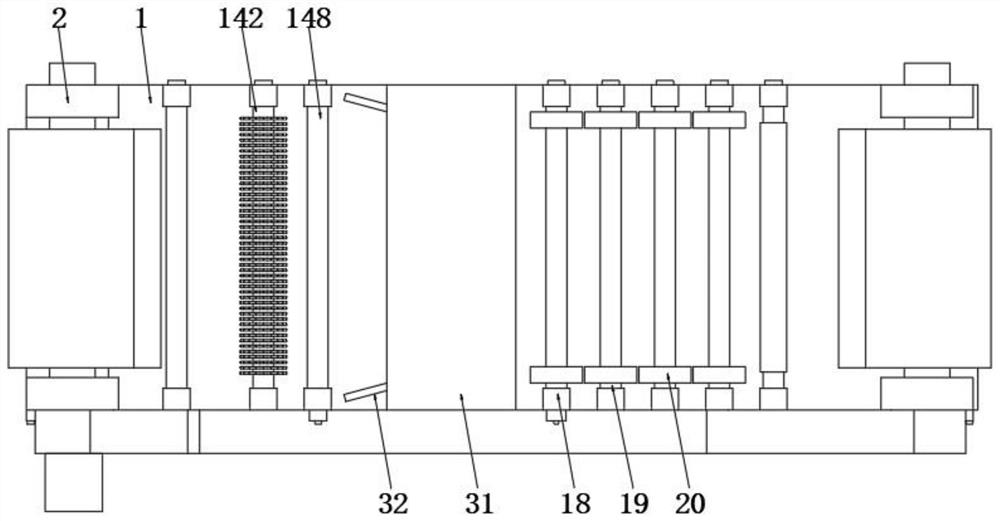

Shaping equipment for bus duct insulation film

ActiveCN105082520AImprove molding efficiencyImprove hemming effectMetal working apparatusEngineeringMechanical engineering

The invention relates to shaping equipment for a bus duct insulation film. The shaping equipment comprises a bracket, a feeding table, a material pulling device and a feeding mechanism, wherein the feeding table is arranged on the bracket; the material pulling device is arranged on one side of the feeding table; the feeding mechanism is arranged on two sides of the material pulling device; an insulation film positioning preheating structure is arranged on the feeding table; an automatic cutting device is arranged on the side far away from the feeding table of the material pulling device. The positioning preheating device of the shaping equipment conducts positioning on the position of a to-be-folded edge of the insulation film through positioning wheels of the positioning mechanism; the positioning wheels are in tight contact with a preheating plate of the preheating structure to enable the position of the to-be-folded edge of the insulation film to be partially heated on the preheating plate; during the further material pulling forming procedure, the folding effect of the insulation film is good; width of a groove of the insulation film can be adjusted freely by adjusting the width between the two positioning wheels and the preheating plate; forming efficiency of the bus duct insulation film is high; the automatic cutting device realizes integration of loading, forming and cutting; under the condition that high forming efficiency is ensured, cutting efficiency is improved.

Owner:NINGBO GELAITE ELECTRICITY VAPOR CREATES

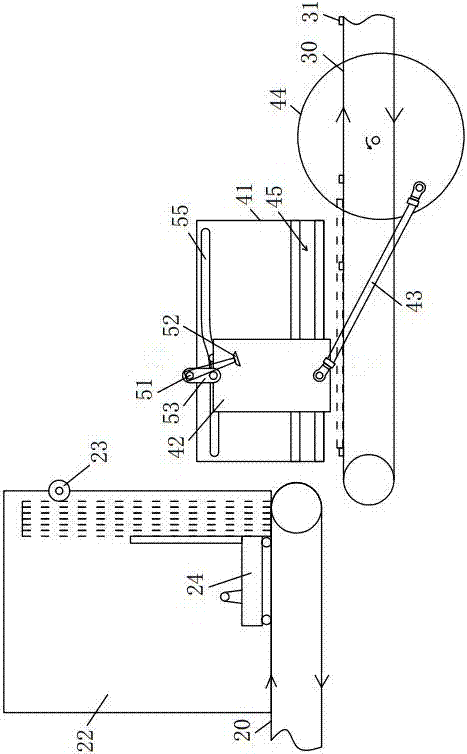

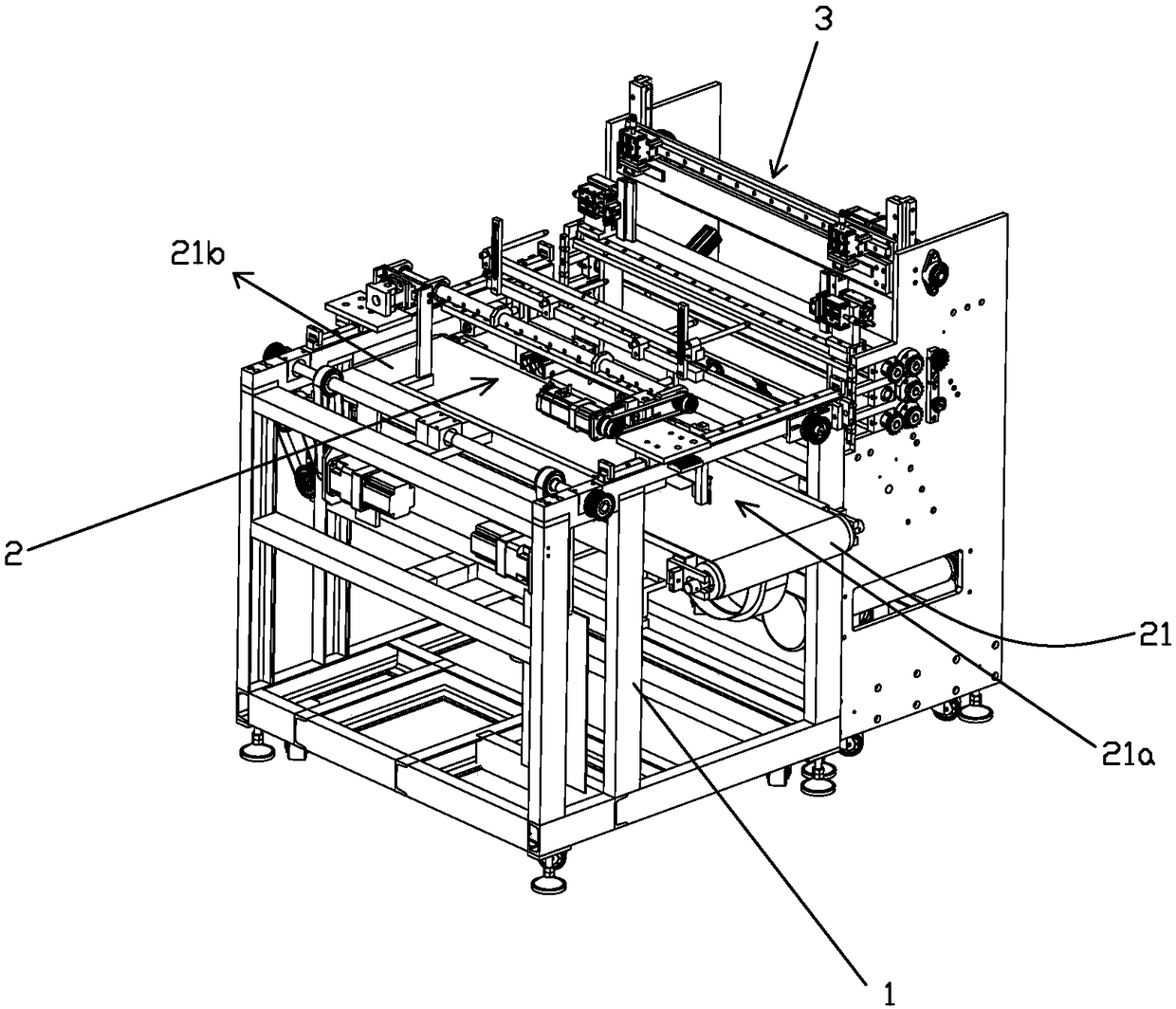

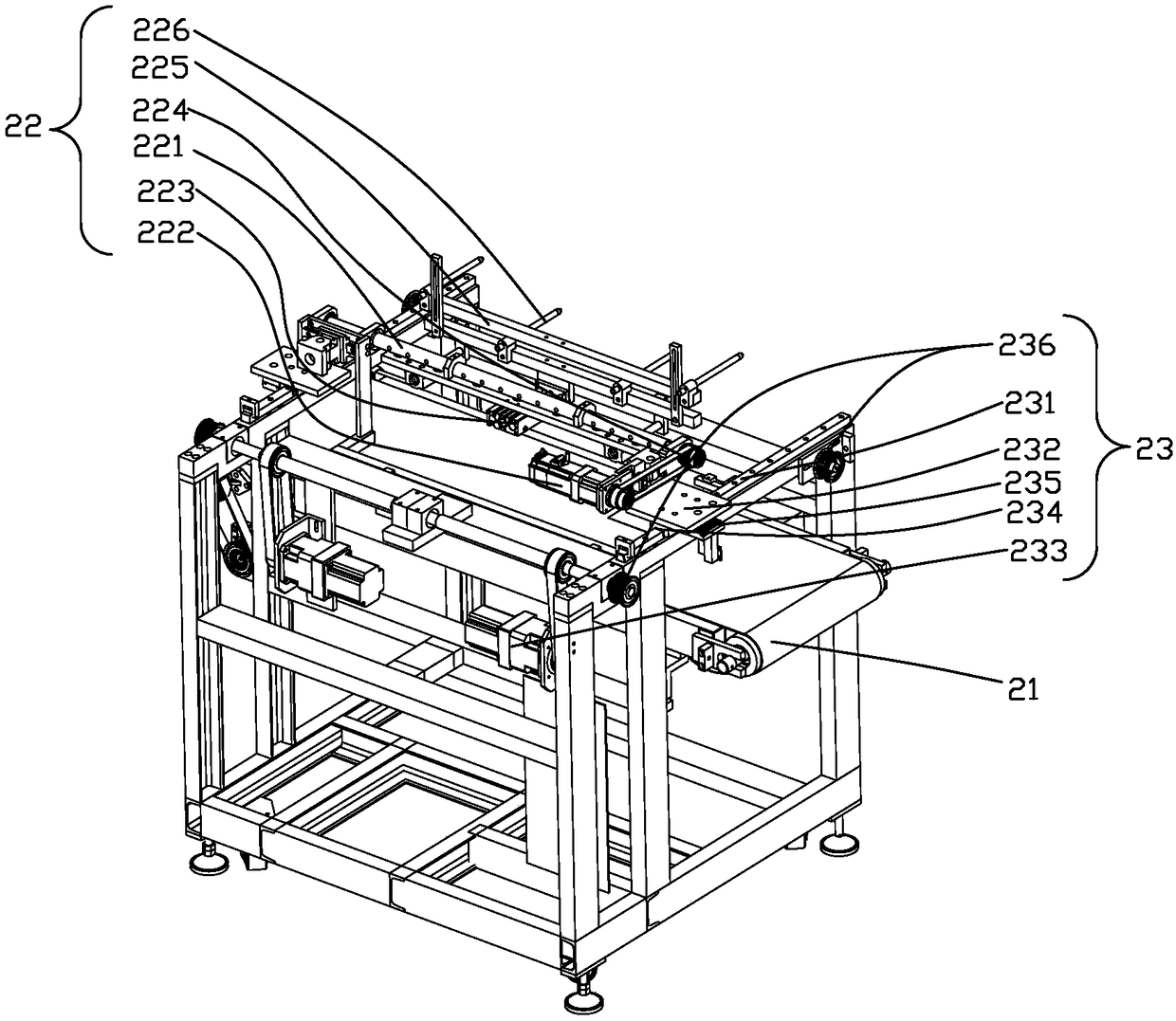

Unfolding, edge folding and carton sealing device for carton forming machine

ActiveCN106956468ACompact structureQuick suction boxBox making operationsPaper-makingMolding machineCarton

The invention relates to an unfolding, edge folding and carton sealing device for a carton forming machine. The unfolding, edge folding and carton sealing device comprises a rack, wherein a feeding mechanism for slowly delivering stacked vertical-state carton plates to the front side is arranged on one side of the rack; a transmission mechanism for horizontally conveying horizontal-state carton plates one by one is arranged on the lower side of an output end of the feeding mechanism; a carton adsorption linkage mechanism for adsorbing the carton plates on the transmission mechanism one by one from the feeding mechanism is arranged on the upper side of an input end of the transmission mechanism; an unfolding mechanism for unfolding the carton plates into a three-dimensional rectangular carton from the horizontal state is arranged on the front side of the carton adsorption linkage mechanism positioned on the transmission mechanism; an edge folding mechanism which is mounted aside the transmission mechanism and is used for making the end part of the three-dimensional rectangular carton complete edge folding is arranged on the front side of the adsorption mechanism positioned on the rack; and a carton sealing mechanism which is used for completing glue sealing after the edge folding of the end part of the carton is also arranged on the front side of the edge folding mechanism. The device has a compact structure and can realize integrated production of unfolding, edge folding and carton sealing of the carton.

Owner:福州广泰机械设备有限公司

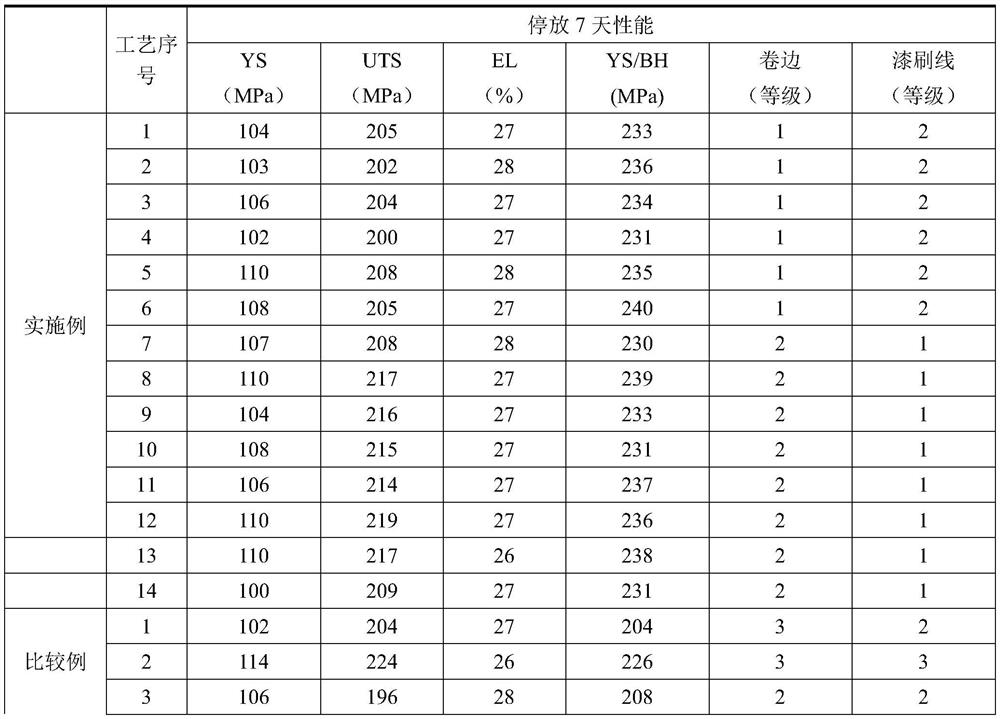

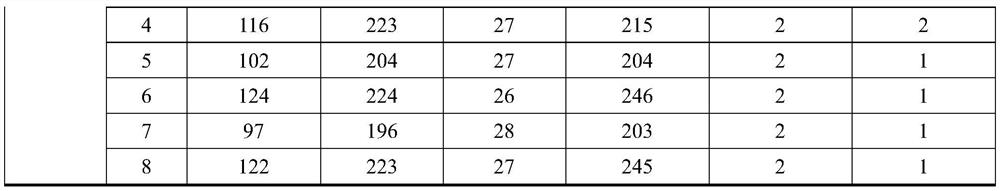

High-strength 6xxx-series aluminum alloy plate for automobile body and preparation method of high-strength 6xxx-series aluminum alloy plate

InactiveCN112195376AFully solid solutionPrevent precipitationFurnace typesHeat treatment furnacesMetallurgyBake hardening

The invention discloses a high-strength 6xxx-series aluminum alloy plate for an automobile body and a preparation method of the high-strength 6xxx-series aluminum alloy plate. The plate comprises thefollowing components in percentages by mass: 0.4wt.%-1.2wt.% of Si, 0.3wt.%-0.8wt.% of Mg, less than or equal to 0.3wt.% of Zn, 0.05wt.%-0.25wt.% of Cu, 0.05wt.%-0.2wt.% of Mn, less than or equal to 0.3wt.% of Fe, 0.01wt.%-0.03wt.% of Ti, and the balance of Al and impurities with the content being less than 0.05wt.%. The aluminum alloy prepared by the method has excellent mechanical properties andsurface quality, especially has high bake hardening performance, and is especially suitable for an outer plate of a covering part for the automobile body.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Edge folding device of full-automatic four-door robot edge rolling equipment

InactiveCN108637059AEasy to operateImprove Tool Change EfficiencyShaping toolsVehicle componentsCar doorEngineering

The invention provides an edge folding device of full-automatic four-door robot edge rolling equipment. The device comprises an edge folding roller and a roller adjusting mechanism, the edge folding roller comprises a first roller and a second roller, the axis position of the first roller is connected with the axis position of the second roller through a connecting device, the first roller and thesecond roller each are of a circular truncated cone structure, the lower bottom surface of the first roller and the lower bottom surface of the second roller are arranged on the adjacent sides, the side face of the first roller and the side face of the second roller are used for edge folding, the roller adjusting mechanism comprises a roller fixing unit, a fixing arm and a vertical angle adjusting unit. According to the edge folding device of the full-automatic four-door robot edge rolling equipment, the horizontal angle and the vertical angle of the edge folding roller can be effectively andquickly adjusted, the positions of the first roller and the second roller can be quickly exchanged, intelligent adjustment is achieved, the operation is convenient, and the tool changing efficiency in the edge folding process is effectively improved.

Owner:GAOJIN TIANJIN AUTOMOTIVE EQUIP CO LTD

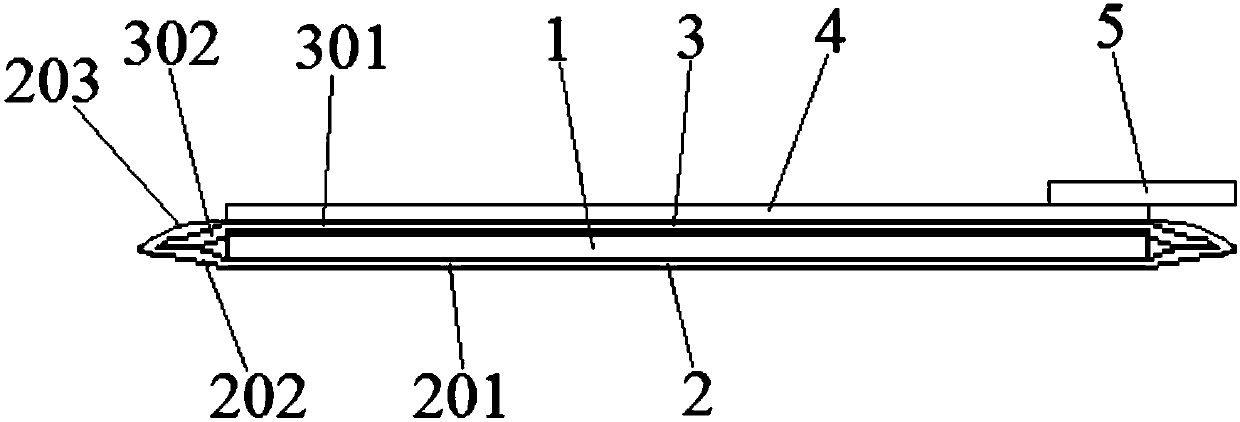

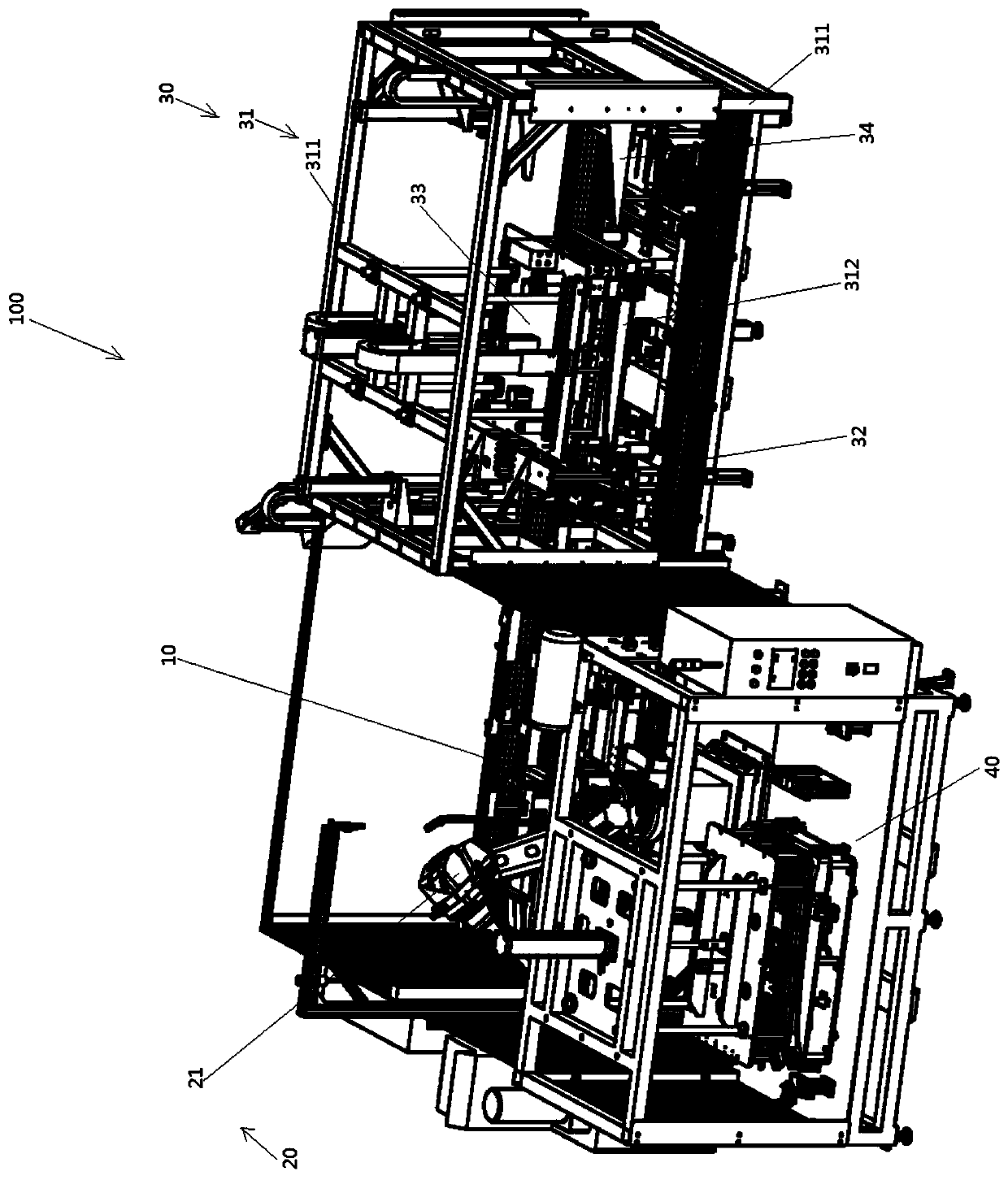

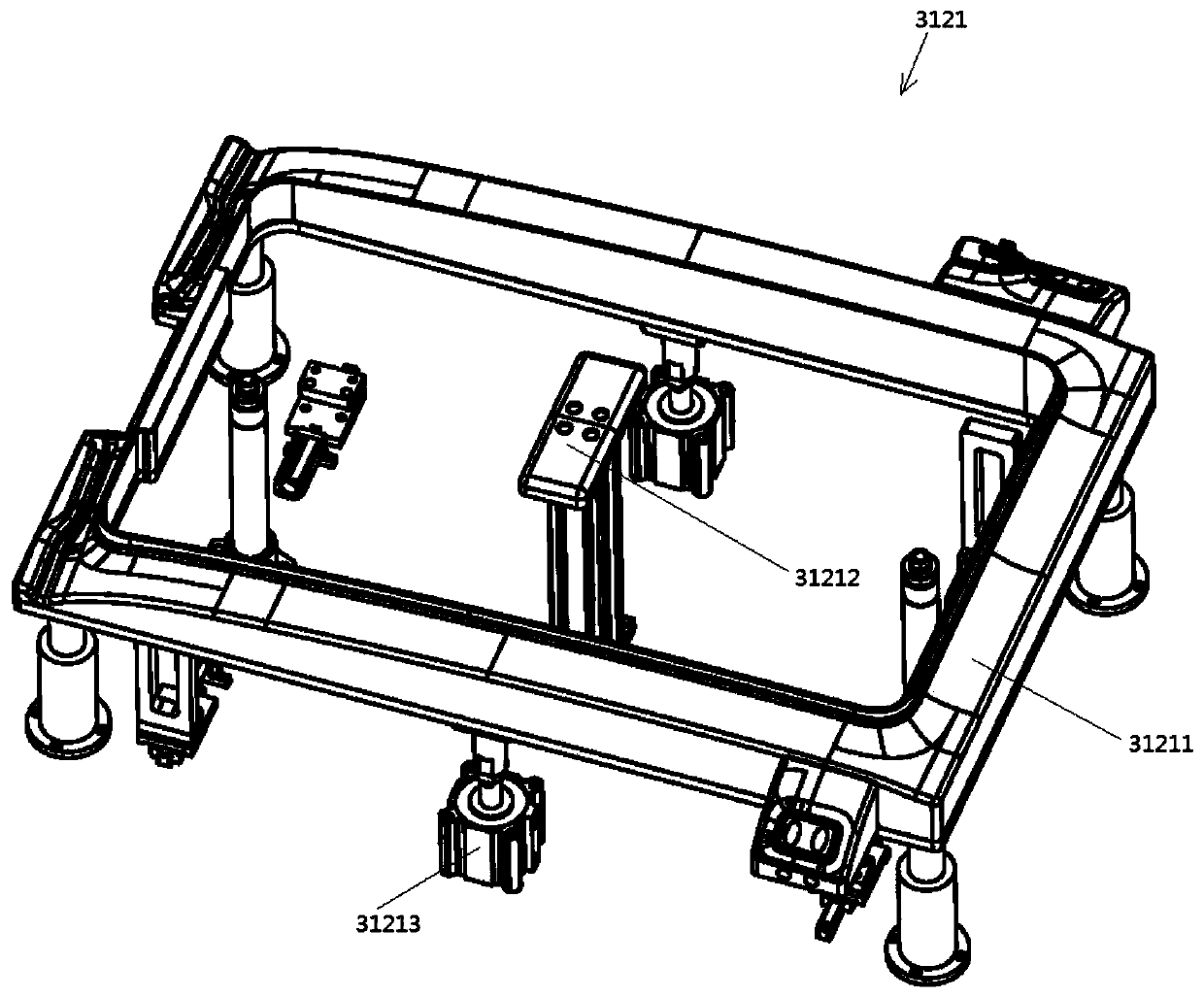

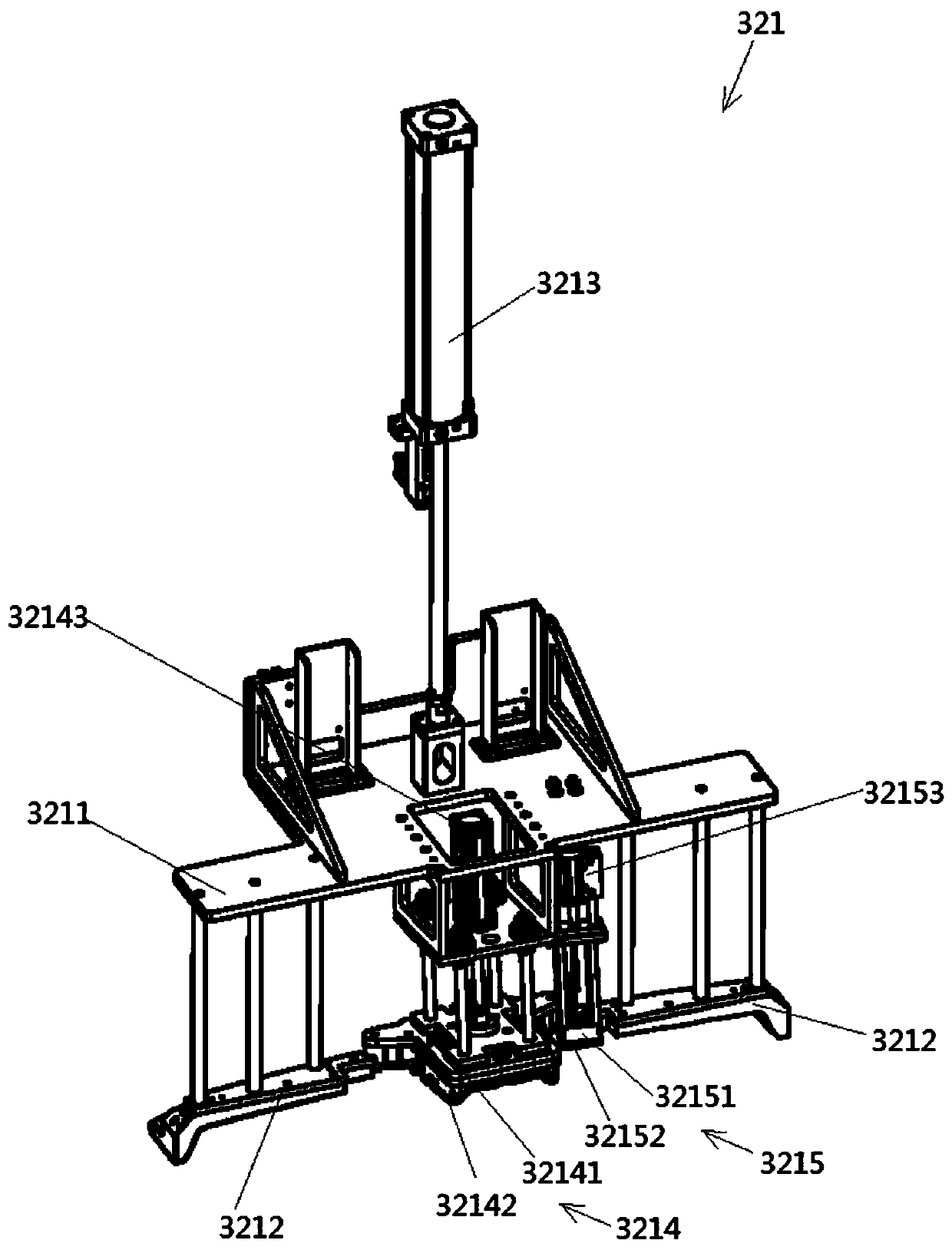

Cell edge sealing and finishing forming device and cell shaping technology

PendingCN108461803AIncrease the level of automationIncrease productivityAssembling battery machinesFinal product manufactureHot stampingEngineering

The invention provides a cell edge sealing and finishing forming device and a cell shaping technology. The device comprises a sliding rail, a cell clamp arranged on the sliding rail and moving synchronously with the sliding rail, a glue dropping mechanism, a vertical binding mechanism, a hot stamping mechanism and a cold ironing shaping mechanism, wherein the glue dropping mechanism, the verticalbinding mechanism, the hot stamping mechanism and the cold ironing shaping mechanism are arranged outside the sliding rail in sequence; a to-be-processed cell is clamped in the cell clamp, so that thecell moves forwards along the sliding rail to be positioned before the mechanisms to complete glue dropping, edge folding, hot melting and cold bonding, and finishing of cell wrapping films and sealed edges is achieved. Due to the cooperation of the sliding rail and the mechanisms, requirements of production modes of single-edge folding and two-edge folding technologies can be met, uninterruptedand continuous battery trimming and forming are achieved, the automation level is high, and the production efficiency is high.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Aviation clean bag and manufacturing method thereof

InactiveCN103303613AImprove waterproof performanceImpenetrableEnvelopes/bags making machineryRefuse receptaclesState of artAviation

The invention discloses an aviation clean bag and a manufacturing method thereof. Two ends of a bag body are sealed; folded edges are arranged on two sides of the bag body; the bag body is made of PE coated paper and comprises a white plastic paper layer and a film layer arranged on the white plastic paper layer; and a tearing mark line is arranged at at least one end of the bag body. Compared with the prior art, the aviation clean bag is good in water-proof performance, cannot be permeated by water, doesn't have a water leakage condition, and improves the product quality; besides, the aviation clean bag manufactured with the method is high in processing efficiency and good in sealing effect and edge-folding effect; the tearing mark line can be manufactured on the bag body conveniently and rapidly, so that the manufactured aviation clean bag is guaranteed to be torn easily, and the use effect of a product is enhanced.

Owner:TONGLING FOUNDER PLASTICS TECH

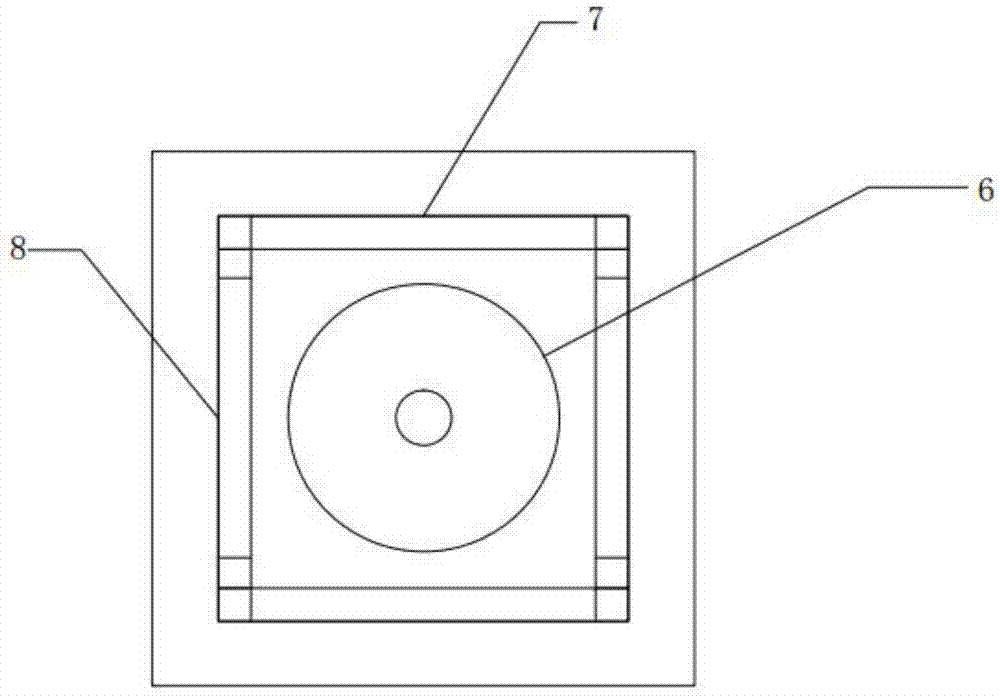

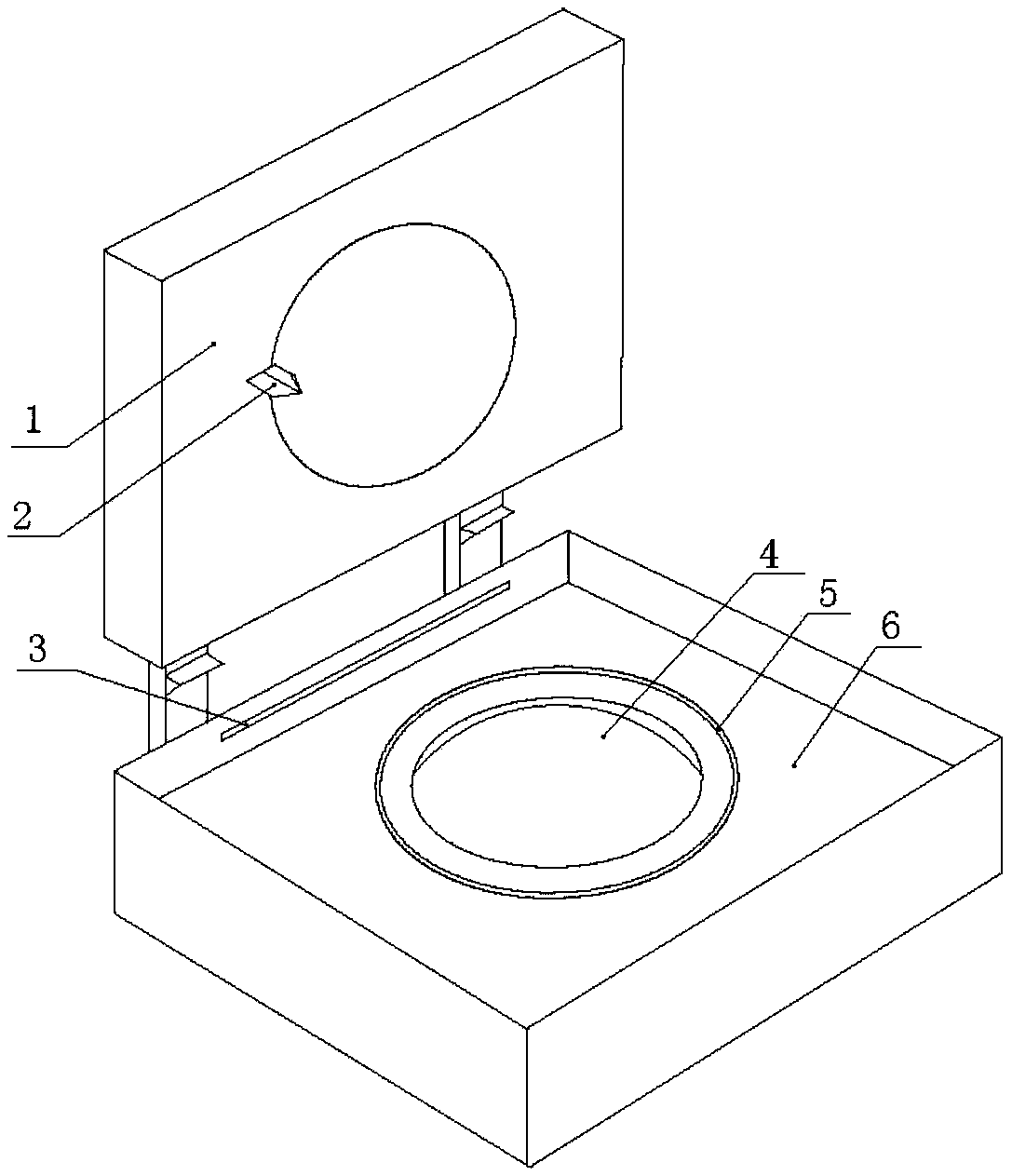

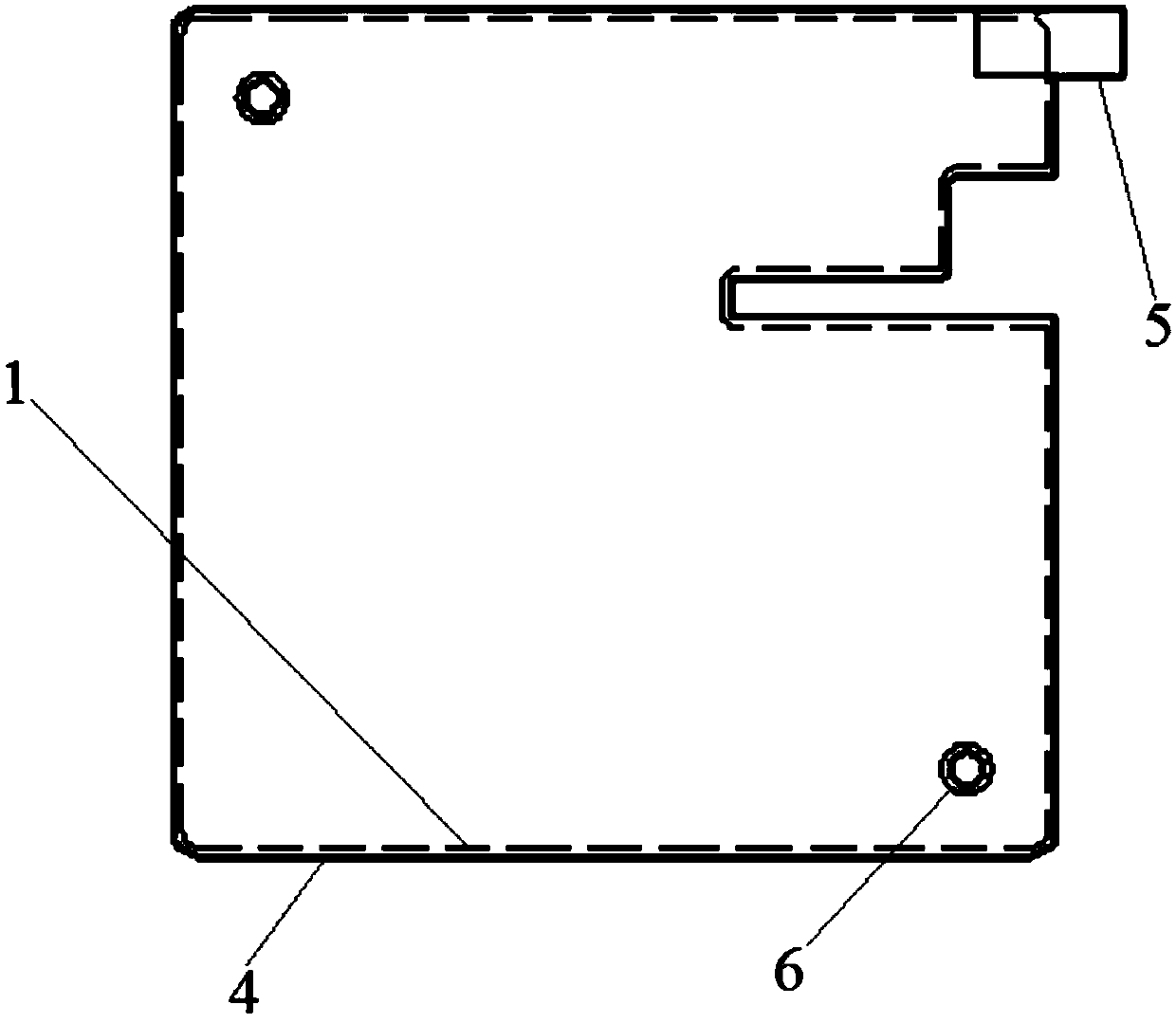

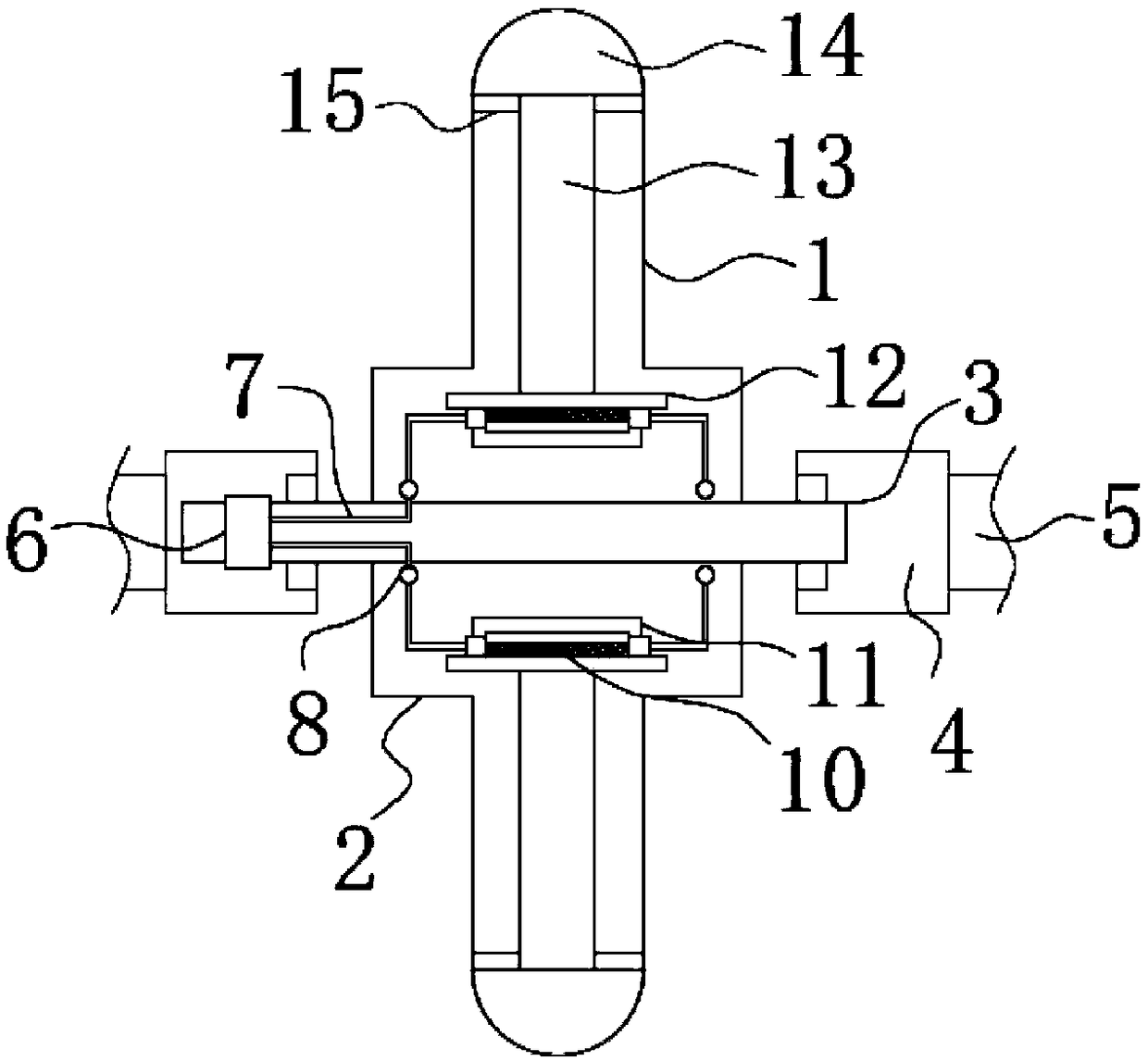

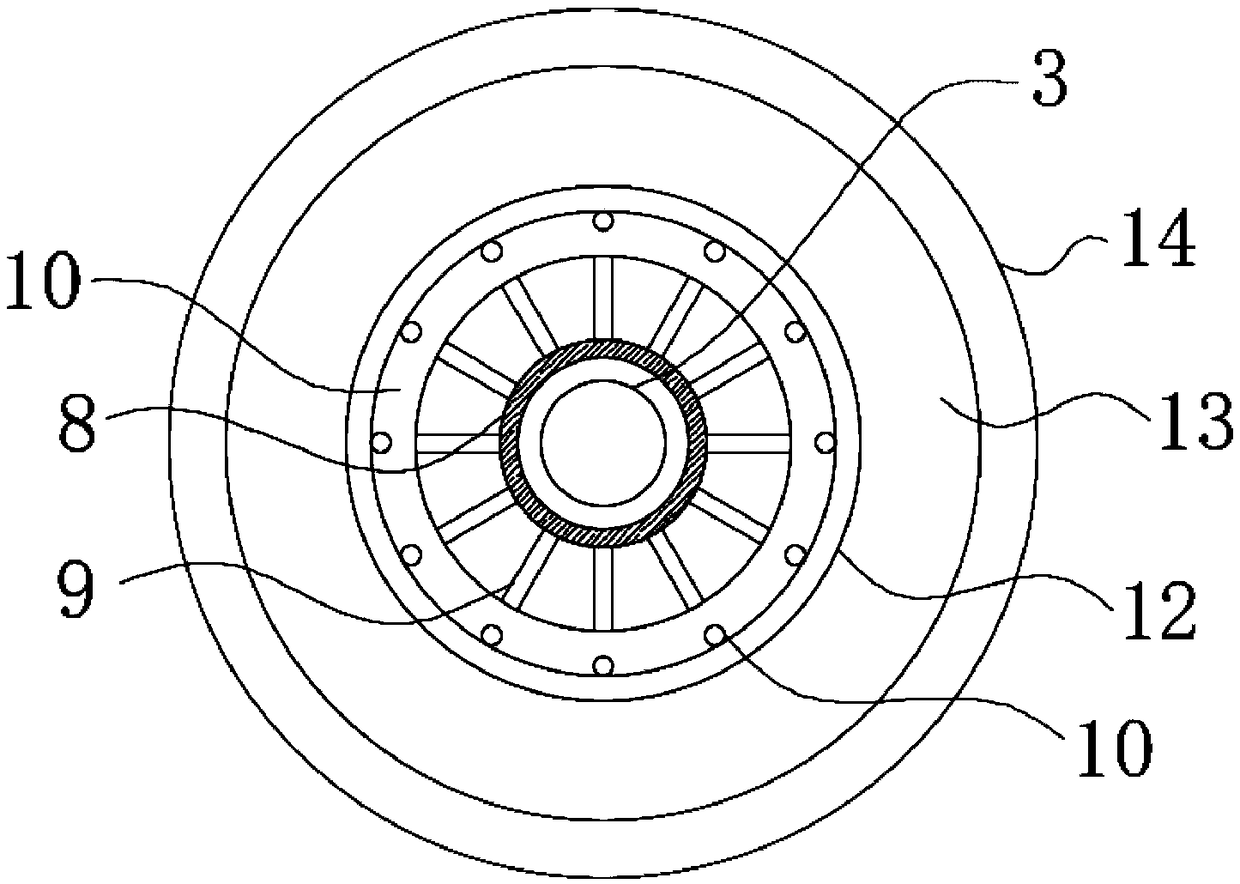

Wafer film covering device

ActiveCN109659269AAvoid deformationAvoid wrinklesSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectrical equipment

The invention relates to the technical field of electric appliance element manufacturing, and specifically relates to a wafer film covering device. The device comprises a bottom box, a feeding hole isformed in a side wall of the bottom box. The bottom box is provided with a placing groove used for placing a wafer. An annular cutting hole is formed outside the containing groove and concentric withthe containing groove, a cover body is hinged to one side of the bottom box, a cylindrical cutter is vertically arranged on the cover body in a sliding mode, the cutter can drive the edge covering mechanism, a cutting spring is arranged between the cutter and the cover body, and a cylindrical pressing column is arranged on the inner side of the cover body. The problems that in the prior art, whena thin film is cut, a peripheral thin film is deformed and wrinkled under the acting force of the rotating direction, and the efficiency is not high due to the fact that the peripheral thin film needs to be manually wrapped on a wafer are solved.

Owner:ANHUI LONGXINWEI TECH CO LTD

Edge covering type ferrite product and processing method thereof

PendingCN109545495AEasy to useGuaranteed functionInorganic material magnetismInductances/transformers/magnets manufactureState of artAdhesive

The invention relates to an edge covering type ferrite product and a processing method thereof. The ferrite product comprises a ferrite, and a single-sided adhesive and a double-sided adhesive which are adhered to the two sides of the ferrite respectively. The edges of the double-sided adhesive are adhered to the edges of the single-sided adhesive, and the edges of the ferrite are completely covered between the single-sided adhesive and the double-sided adhesive. During the machining, the ferrite is subjected to machine-shaping at first, then the single-sided adhesive and the double-sided adhesive are adhered to the two side surfaces of the ferrite respectively, and the edges of the double-sided adhesive are adhered to the edges of the single-sided adhesive. Compared with the prior art, the ferrite are subjected to edge covering by means of the double-sided adhesive and the single-sided adhesive, thus the normal use of the ferrite is ensured, the adhesion of the ferrite product and a flexible circuit board is facilitated, and the falling of particles on a cross section of the ferrite edges formed by laser cutting or die stamping can be avoided, thereby ensuring the normal functionsof the circuit board and a mobile phone, and being easy in machining.

Owner:上海昊佰智造精密电子股份有限公司

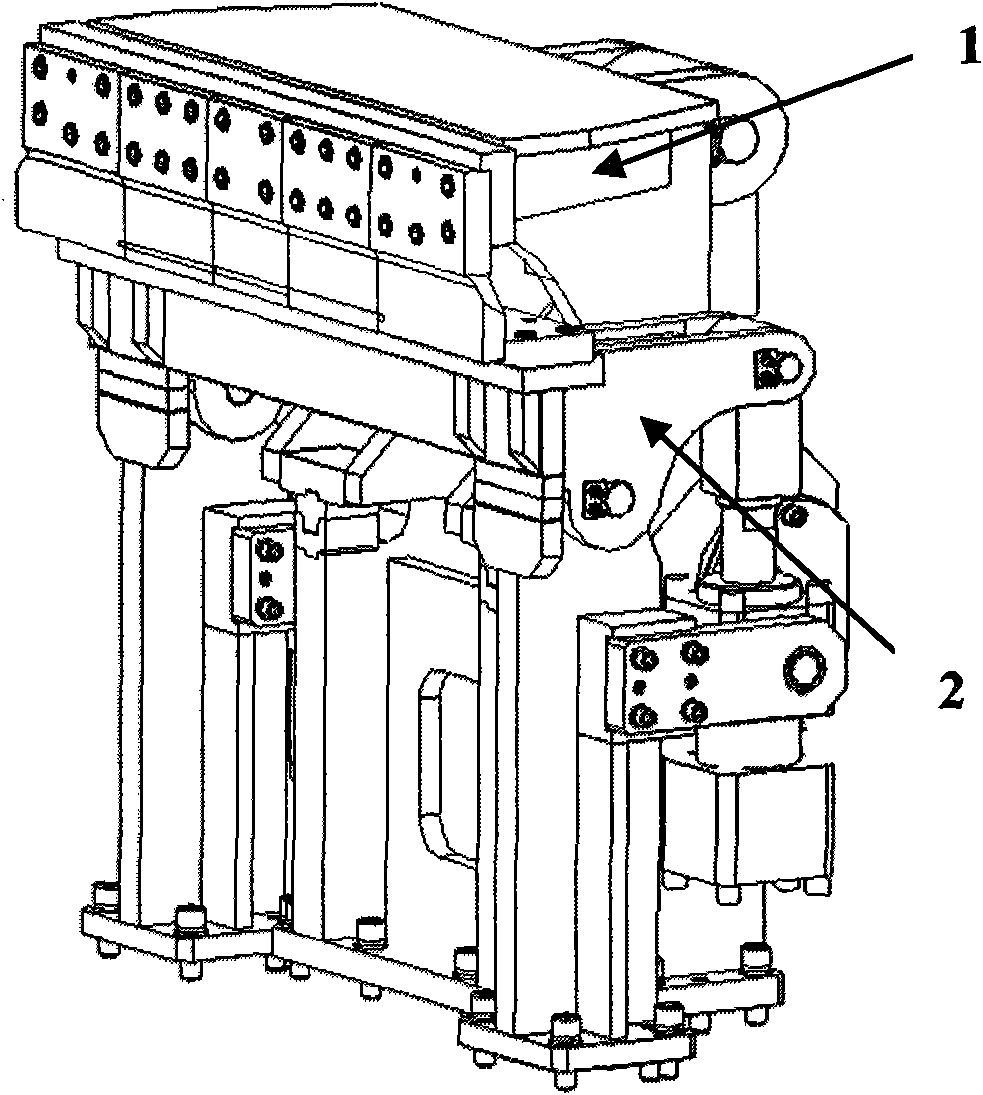

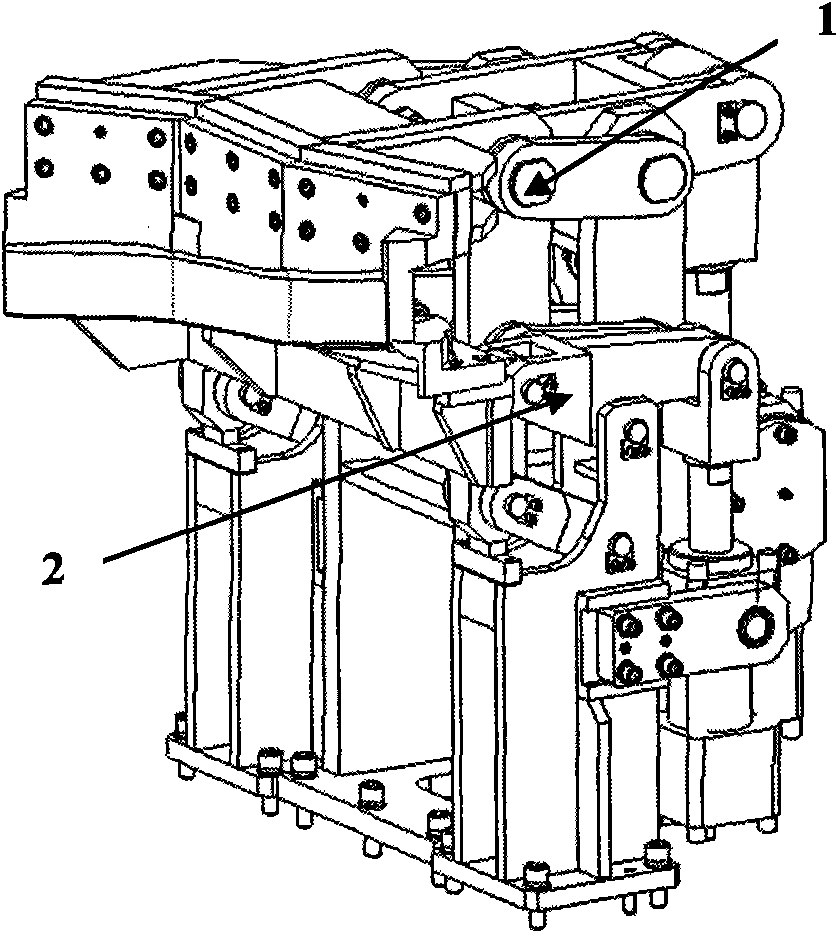

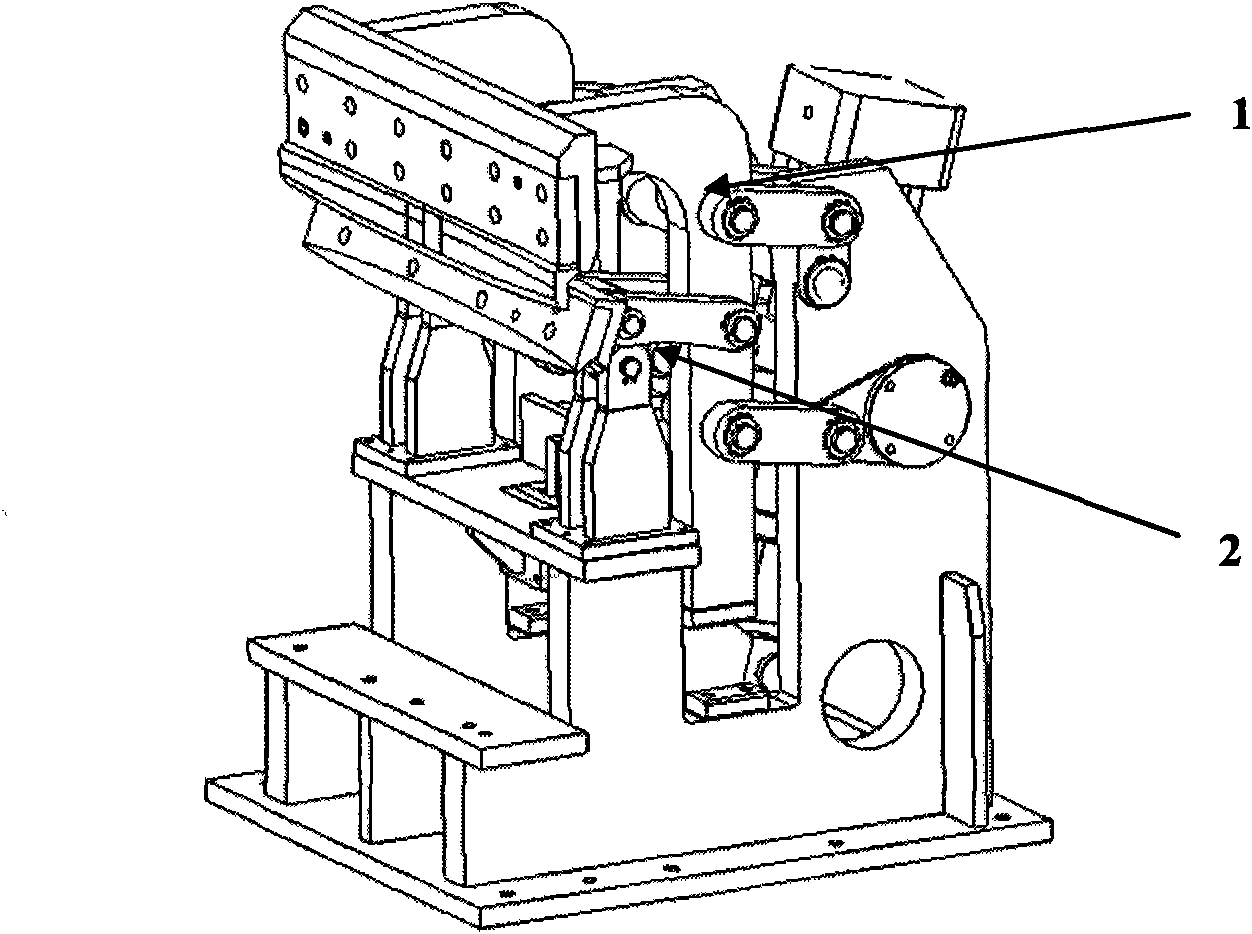

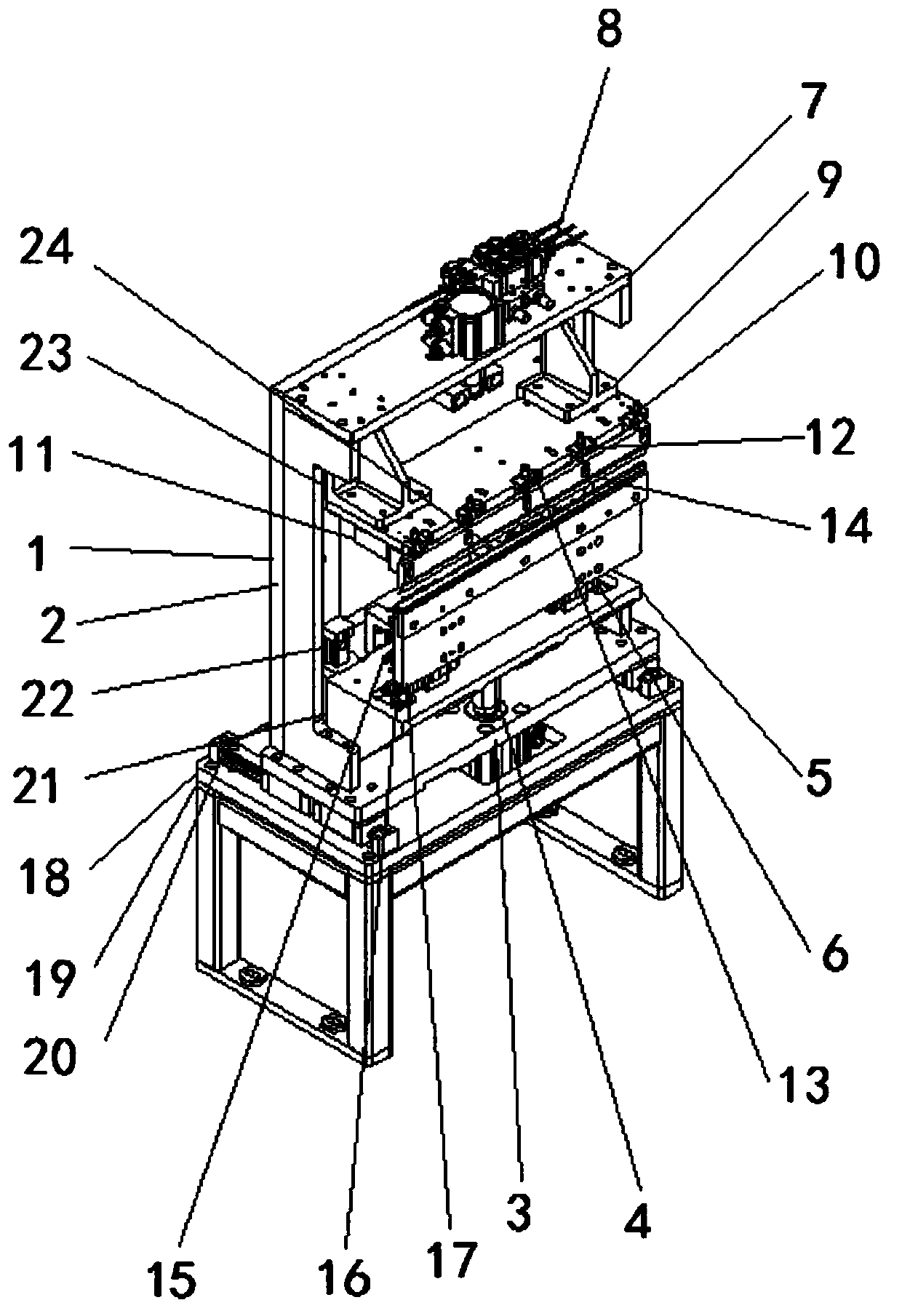

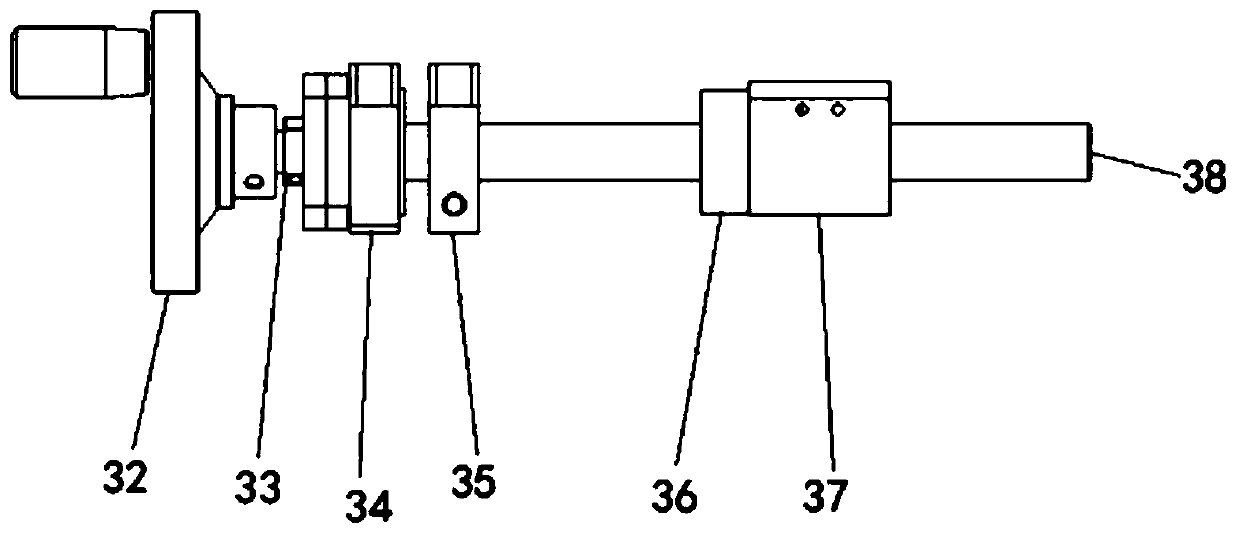

Primary binding and prebinding four-rod linkage binding device

The invention provides a primary binding and prebinding four-rod linkage binding device, comprising a primary binding tool assembly, a prebinding tool assembly, a primary binding lever, a primary binding and prebinding linkage rod, primary-binding four rods, prebinding four rods, a hydraulic cylinder and a support, wherein the primary binding tool assembly is respectively connected with the primary binding lever and the primary-binding four rods; the prebinding tool assembly is respectively connected with the primary binding and prebinding linkage rod and the prebinding four rods; the primarybinding and prebinding linkage rod is respectively connected with the primary binding lever and the prebinding tool assembly; the primary binding lever and the hydraulic cylinder are arranged on the support; the hydraulic cylinder pushes the primary binding lever to rotate and simultaneously pushes the primary binding tool assembly and the prebinding tool assembly to move. The primary binding andprebinding four-rod linkage binding device of the invention changes a lever linkage mechanism into the four-rod linkage mechanism, so no matter how complex the bond profile of a part is, the prebinding of each point of the profile can obtain relative ideal digging angles, thereby achieving better binding effect.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

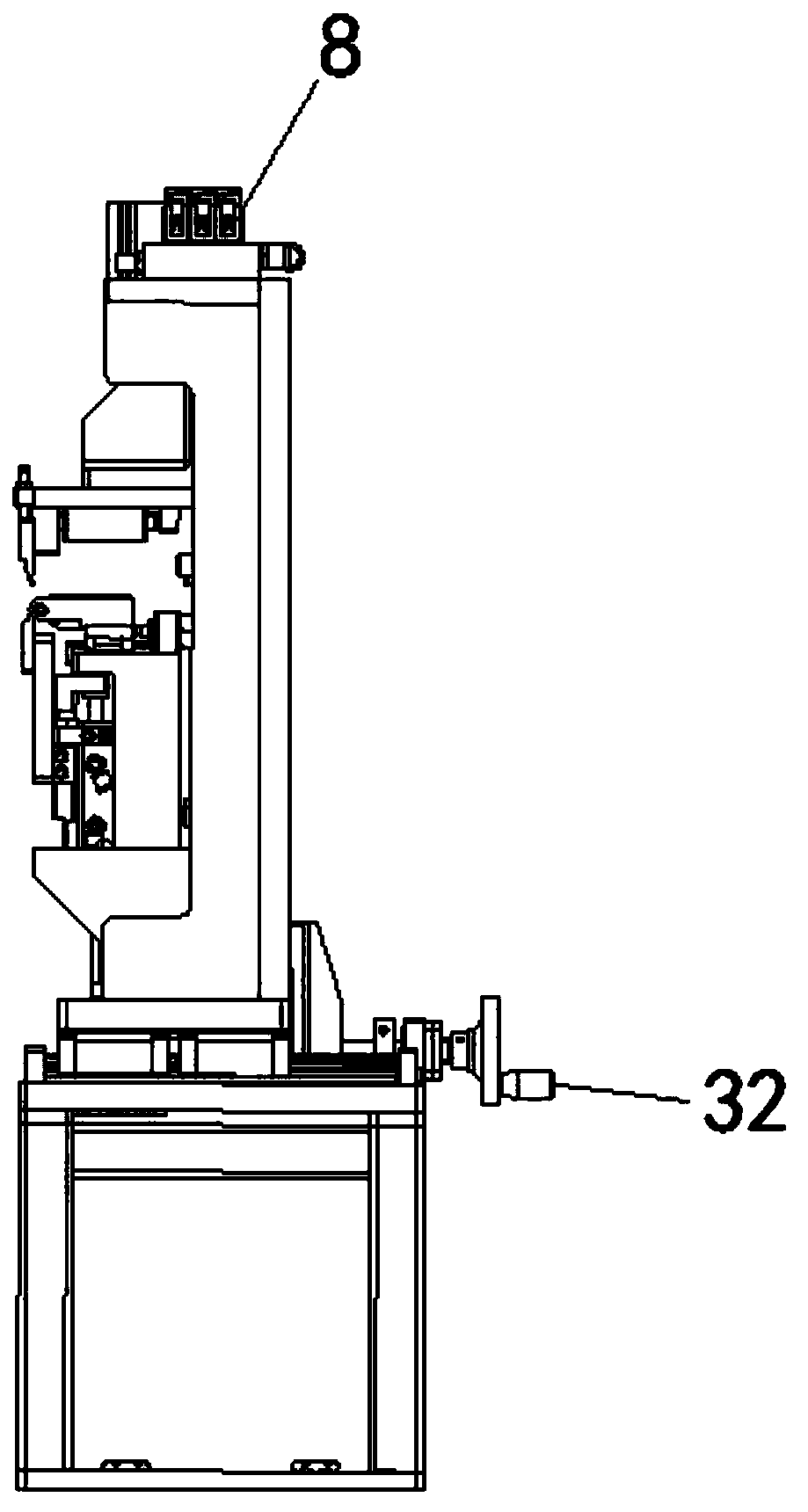

270-degree edge folding mechanism for soft package lithium battery

PendingCN110459812AIncrease production capacitySimple structurePrimary cell manufactureAssembling battery machinesProduction lineEngineering

The invention discloses a 270-degree edge folding mechanism for a soft package lithium battery, which comprises a cutting main plate, wherein the front of the cutting main plate is fixedly equipped with a cutting supporting plate, the bottom end of the cutting supporting plate is fixedly equipped with a cutting bottom plate, the top end of the cutting bottom plate is fixedly equipped with an air cylinder, and the top end of the air cylinder is fixedly equipped with a first lower lifting main plate. According to the 270-degree edge folding mechanism for the soft package lithium battery, the original structure that only an upper folding knife is used for pushing and folding in the original two-folding mechanism is replaced by the arranged roller structure for edge folding, so that the edge folding effect is more ideal, and the edge folding speed is higher. In addition, the 270-degree edge folding mechanism is provided with an adjustment assembly, so that fine adjustment and model changing of equipment are accurate and convenient, the production efficiency of the edge folding mechanism is improved as far as possible under the condition that the accurate edge folding function is guaranteed, the mechanism structure is further simplified under the condition that the target efficiency is met, the novel edge folding mechanism with optimal performance, optimal price and simplest structure is obtained, and a high-quality edge folding mechanism is provided for the novel production line.

Owner:深圳市中基自动化股份有限公司

Folding sheet covering machine

The invention discloses a folding sheet covering machine, comprising a frame which is provided with a feeding device, a covering device and a discharging device. The covering device comprises a side edge wrapping mechanism which is arranged beside the feeding conveyor belt and used for wrapping the side edge of the folding sheet, an upper edge wrapping mechanism for wrapping the upper edge of thefolding sheet, and a pressure roller mechanism for covering. The side edge wrapping mechanism comprises a first driving member, a second driving member, and a third driving member fixedly arranged onthe output shaft of the second driving member, wherein the output shaft of the first driving member is provided with a limiting block, the output shaft of the third driving member is provided with a first pushing block, the upper edge wrapping mechanism comprises a fourth driving member, a fifth driving member which is fixedly disposed on the output shaft of the fourth driving member, a limiting plate for limiting the position of face paper, a second pushing block is disposed on the output shaft of the fifth driving member, and a hoisting mechanism is arranged between the frame and the upper edge wrapping mechanism. The invention provides a folding sheet covering machine capable of automatically completing the work of edge wrapping and covering.

Owner:浙江浩达智能装备股份有限公司

Rotating device for sewing hemming

PendingCN109763274AControl rotation angleRealize the limit functionWork-feeding meansSewing-machine control devicesMechanical engineeringTextile industry

The invention relates to the technical field of textile industry, and discloses a rotating device for sewing hemming. The device comprises a workbench, wherein a support plate is fixedly connected tothe top of the workbench, and a baffle is fixedly connected to the top of the workbench and located on the right side of the support plate. According to the rotating device for sewing hemming, a to-be-hemmed workpiece is placed on the workbench, and hemming sewing treatment can be performed on the workpiece on the workbench; when one edge of the workpiece is hemmed and needs to be rotated to the adjacent edge for hemming, an air cylinder drives a rotating plate to move downwards until the rotating plate and convex blocks press the workpiece, a driving device is started, the rotating plate is driven to rotate around an output shaft of the driving device, and the workpiece also rotates around the output shaft of the driving device; limiting grooves and limiting devices are arranged and can realize a rotation limiting function, hemming can be performed continuously by controlling the rotating angle of the rotating plate, manual angle turning is not needed, and production efficiency is high.

Owner:苏州匠博智能科技有限公司

Box pasting machine with automatic feeding function

PendingCN112917993APrevent slippingImprove practicalityBox making operationsPaper-makingMotor driveElectric machinery

The invention discloses a box pasting machine with an automatic feeding function. The box pasting machine comprises a workbench and a mounting plate, the upper surface of the workbench is provided with the mounting plate, the upper surface of the mounting plate is provided with a feeding box, one side of the feeding box is fixedly provided with a feeding motor, the output end of the feeding motor is fixedly connected to a rotating shaft, a paper rubbing roller is arranged in the middle of the rotating shaft, an adjustable limiting plate is arranged inside the paper rubbing roller, and a mounting box is arranged on the upper surface of the mounting plate. According to the box pasting machine, through the arrangement of the feeding motor, the rotating shaft, the paper rubbing roller and the adjustable limiting plate, an adjusting plate body and a supporting inclined plate are adjusted to a proper distance by rotating an adjusting handle according to the thickness of box paper, then the feeding motor drives the paper rubbing roller to rotate through the rotating shaft to rub the box paper placed on the upper surface of the supporting inclined plate to a conveying belt, and by arranging the adjustable limiting plate, the device can be adjusted according to the thickness of the paper, so that the practicability of the device is improved.

Owner:和图(上海)艺术包装有限公司

Edge-folding and press-fit mechanism for surface sealing machine

PendingCN108583051AImprove hemming effectAvoid affecting the bonding effectBook making processesCasing-inCardboardEngineering

The invention discloses an edge-folding and press-fit mechanism for a surface sealing machine. The essential of the technical scheme is as follows: the edge-folding and press-fit mechanism comprises asupport, a lower folding plate and upper folding plates, wherein two upper folding plates are arranged; a slantwise pressing device used for driving the upper folding plates to slide slantwise from top to bottom is arranged on the support or the lower folding plate, and the slantwise pressing device comprises a slantwise pressing swing arm and a slantwise pressing cylinder; a conveying device used for conveying the edge-folded finished products is arranged on the lower folding plate, and the conveying device comprises a conveying wheel, a conveying belt and a conveying motor; a drive press roll, a driven press roll and a press roll motor are arranged on the support, and a support roll used for supporting paper plates subjected to gap press-fit is rotationally connected to the support; a bearing device used for bearing the paper plates falling off via the support roll is arranged at one side of the discharge end of each of the drive press roll and the driven press roll, and each bearing device comprises two bearing blocks, a bearing drive assembly and a counting sensor. The mechanism is capable of overcoming the shortages of complex structure, large machine body, too large floor area, high finished product rejection rate and low automation degree of the existing mechanism.

Owner:浙江容健科技有限公司

Skylight frame edge covering device

PendingCN111002597AGood hemming effectImprove hemming effectDomestic articlesStructural engineeringMechanical engineering

The invention provides a skylight frame edge covering device which is characterized by comprising a skylight frame edge covering mechanism; the skylight frame edge covering mechanism comprises a firstpressing unit, a flanging unit and a second pressing unit. The first pressing unit comprises a first pressing block and a pressing driving component used for driving the first pressing block to rotate forwards or backwards; the flanging unit comprises a flanging block and a flanging driving component used for driving the flanging block to move forwards or backwards and move downwards or upwards;the second pressing unit comprises a telescopic connecting assembly and a second pressing block, wherein the telescopic connecting assembly is provided with a connecting rod arranged on the flanging block in a penetrating mode and a spring arranged on the connecting rod in a sleeving mode; the second pressing block is fixed to the bottom of the connecting rod and connected with the flanging blockthrough the spring, and the shape of the second pressing block is matched with the shape of a skylight frame; the first pressing block is movably connected with the flanging block, and the flanging block comprises an L-shaped part and a hook-shaped part.

Owner:CENMOY AUTOMATION TECH SHANGHAI CO LTD

Flanging device for flanging machine

The invention discloses a flanging device for a flanging machine. The device comprises a flanging disc, wherein a boss is arranged at the center of the flanging disc, and a connecting shaft runs through the center of the boss; rotating blocks are arranged at two ends of the connecting shaft, a rotary connector is arranged in one rotating block, and is provided with a connecting wire; the connecting wire runs through the through hole in the connecting shaft and is connected with an annular wire; the annular wire is positioned outside the connecting shaft, and is connected with a heat wire through a branch wire; an insulation board is arranged on the side, close to the connecting shaft, of the heat wire, and a heat conductive plate is arranged on the side, far from the connecting shaft, of the heat wire; and the side, far from the heat wire, of the heat conductive plate is fixedly connected with one side of the heat conductive plate, and a heat conductive connecting block is fixedly connected with the other side of the heat conductive plate. According to the flanging device, the disc-shaped flanging plate enables the flanging disc to flange a plastic bag along a bent groove, the plastic bag can be flanged more uniformly, and the plastic bag flanging quality can be improved.

Owner:ZHENJIANG COLLEGE

Edge folding method and edge folding device

The invention discloses an edge folding method and an edge folding device. The method comprises that panel veneer is placed on a main working panel, and is located by using an adjustable locating frame; the rocker arm of a turn over mechanism drives a working pressing plate to rotate, and a main working pressing plate presses on and bends the panel veneer in a rotating process to achieve edge folding; and a turn-over mechanism carries out reset turning over to enable the main working pressing plate to reset. The edge folding device controls the edge folding angle of the panel veneer by controlling the air pressure of an air cylinder, and can carry out edge folding to panel veneer with different width. The edge folding method and the edge folding device further have the advantages of being simple in structure, convenient to operate, low in production cost and good in folding effect.

Owner:凌琰

Multi-station cloth edge folding device for clothing processing

PendingCN114275592APrevent rotationInhibit sheddingMechanical cleaningPressure cleaningGear wheelTransmission belt

The invention relates to the technical field of costume processing equipment, in particular to a multi-station cloth edge folding device for costume processing, which comprises a worktable, a cloth frame is arranged on one side of the upper surface of the worktable, a protective cover is fixedly connected to the front surface of the cloth frame, and a driving motor is fixedly connected to one side, away from the cloth frame, of the protective cover; the side, close to the protective cover, of the cloth frame is rotationally connected with a driving rotating shaft, the driving rotating shaft is sleeved with a first transmission belt, a belt double-wheel is inserted into the other end of the first transmission belt, and the rear surface of the belt double-wheel is fixedly connected with a transmission gear; the anti-reverse wheel is clamped by the self-locking plate, and the winding turntable is locked by the self-locking plate, so that the wound cloth is prevented from falling off to the bottom surface and being manually wound again, and the problems that the cloth is stretched from the winding wheel to be in contact with the ground to become dirty, and the winding efficiency is high due to the fact that the winding wheel is extremely easy to rotate when the cloth is cut off are solved. And meanwhile, the problem that winding needs to be conducted again manually is solved.

Owner:连云港奥恒制衣有限公司

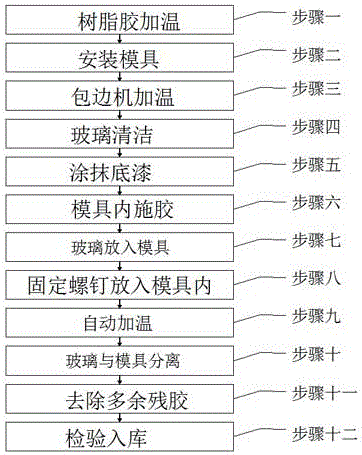

Automatic installation process for sealing strip edge of automobile glass frame

The invention discloses an automatic installation process for a sealing strip edge of an automobile glass frame. The process comprises the following steps: 1, heating resin adhesive; 2, installing a die; 3, heating a covering machine; 4, cleaning glass; 5, painting a primer; 6, performing gluing in the die; 7, putting the glass into the die; 8, putting fixing screws into the die; 9, performing automatic heating; 10, separating the glass from the die; 11, removing extra residual adhesive; and 12, performing inspection and warehousing. By applying the automatic installation process for the sealing strip edge of the automobile glass frame, the sealing strip edge of the automobile glass frame can be automatically covered, so that the production efficiency is improved, manpower is saved, and the covering effect is good.

Owner:上海车功坊智能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com