Unfolding, edge folding and carton sealing device for carton forming machine

A carton forming machine and side sealing technology, which is applied in packaging, papermaking, transportation and packaging, etc., can solve the problems of heavy workload, unfavorable cartons, and loose hemming and pasting, and achieve labor saving, high work efficiency, and hemming good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific examples are given in conjunction with the accompanying drawings to describe in detail as follows, but the present invention is not limited thereto.

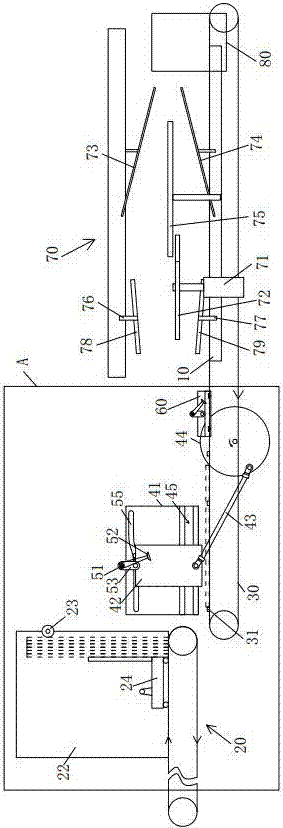

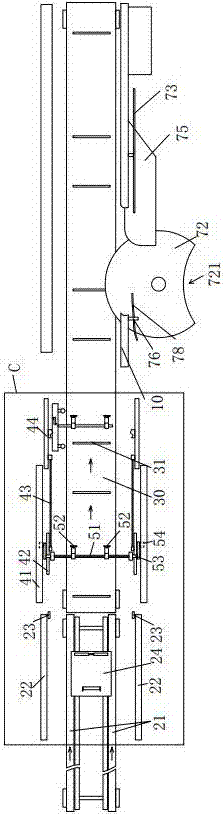

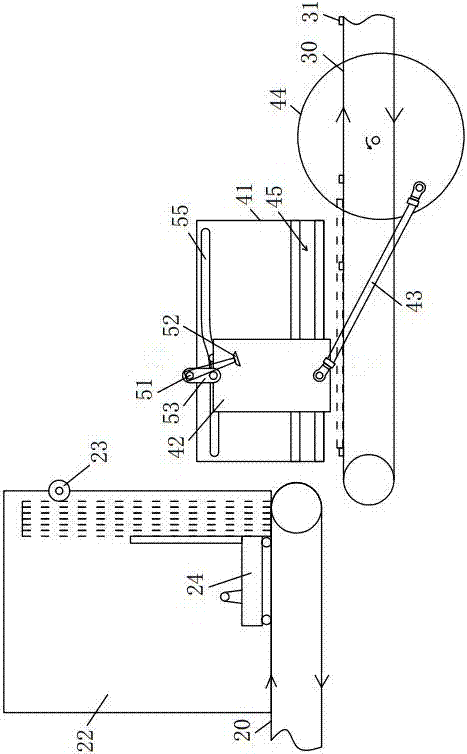

[0025] reference Figure 1 to Figure 6

[0026] An unfolding, folding, and sealing device for a carton forming machine includes a frame. One side of the frame is provided with an input mechanism 20 for slowly forwarding stacked carton boards in a vertical state. The output end of the input mechanism is lower The side is provided with a conveying mechanism 30 for conveying horizontal carton boards one by one in a horizontal state. On the upper side of the input end of the conveying mechanism, a suction box linkage mechanism for sucking the carton boards from the input mechanism to the conveying mechanism one by one, the conveying mechanism On the front side of the suction box linkage mechanism is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com