Cell edge sealing and finishing forming device and cell shaping technology

A molding device and cell technology, applied in the field of battery manufacturing equipment and automation equipment, can solve the problems of CCD detection device not being able to perform comprehensive detection and narrow space, and achieve the effects of convenient subsequent ironing, high production efficiency and high automation level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

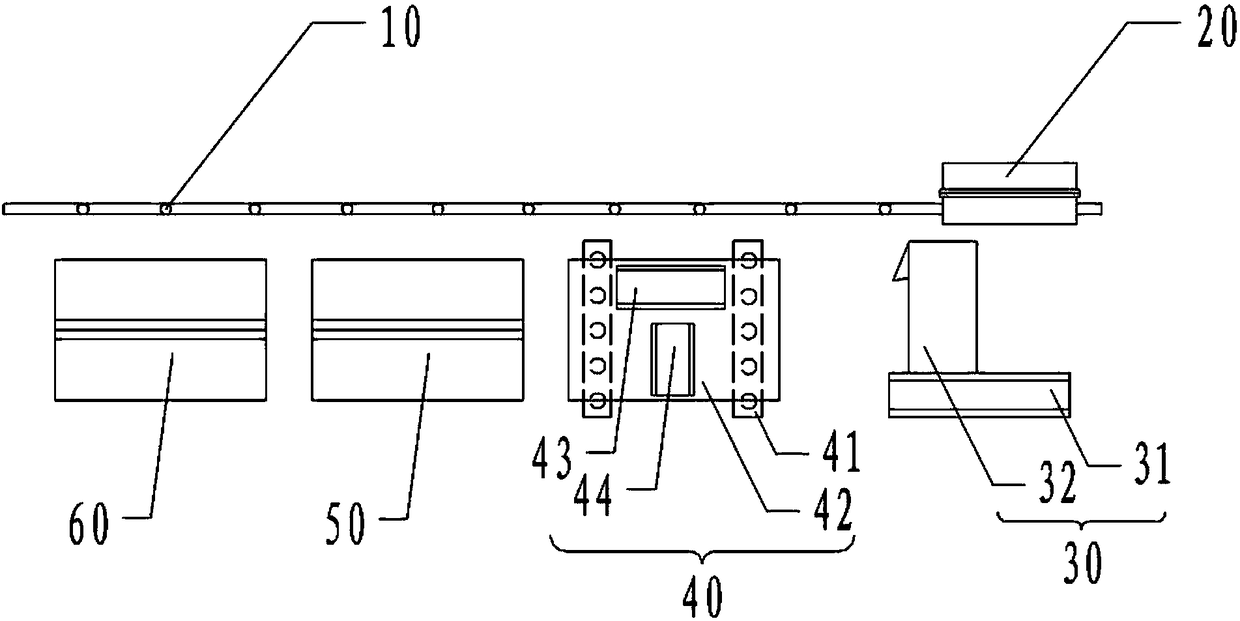

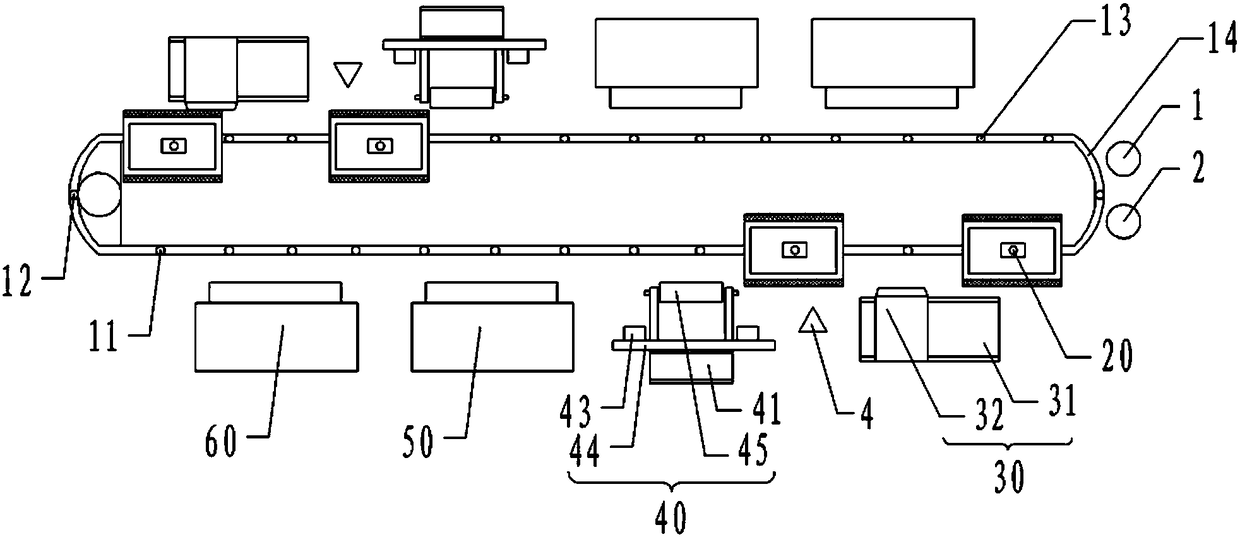

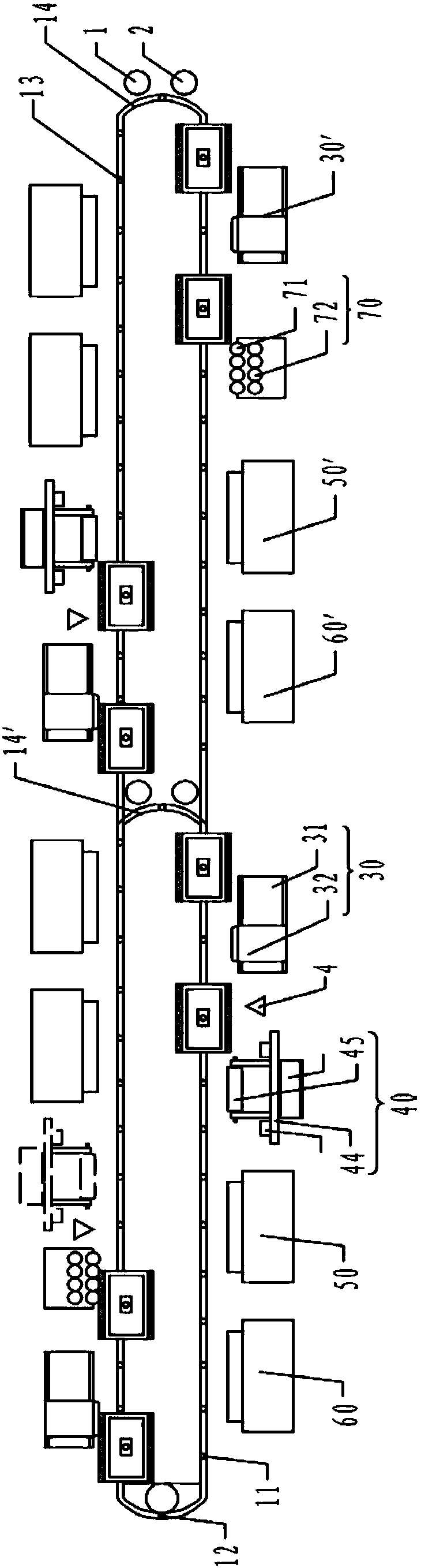

[0036] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0037] During the production process of the battery cell, the battery cell needs to be coated. The purpose of the coating is to seal the battery cell, prevent electrolyte leakage, and at the same time play an insulating and protective role. In the high-automatic cell forming machine, when the cell coating is finished, there will be a glue-applying mechanism to directly seal the film edges on both sides. At the same time, in order to ensure the sealing effect, a protective internal glue-pasting position will be reserved when cutting the edge The edge banding ensures that the glue will not overflow. However, if the reserved edge banding is not processed, it will not only affect the appearance, but also increase the battery area, which is not conducive to adapting to various products. Therefore, it is necessary to repair the edge banding of the cell coating throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com