Patents

Literature

30 results about "Cold ironing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold ironing, or shore connection, shore-to-ship power (SSP) or alternative maritime power (AMP), is the process of providing shoreside electrical power to a ship at berth while its main and auxiliary engines are turned off. Cold ironing permits emergency equipment, refrigeration, cooling, heating, lighting and other equipment to receive continuous electrical power while the ship loads or unloads its cargo. Shorepower is a general term to describe supply of electric power to ships, small craft, aircraft and road vehicles while stationary.

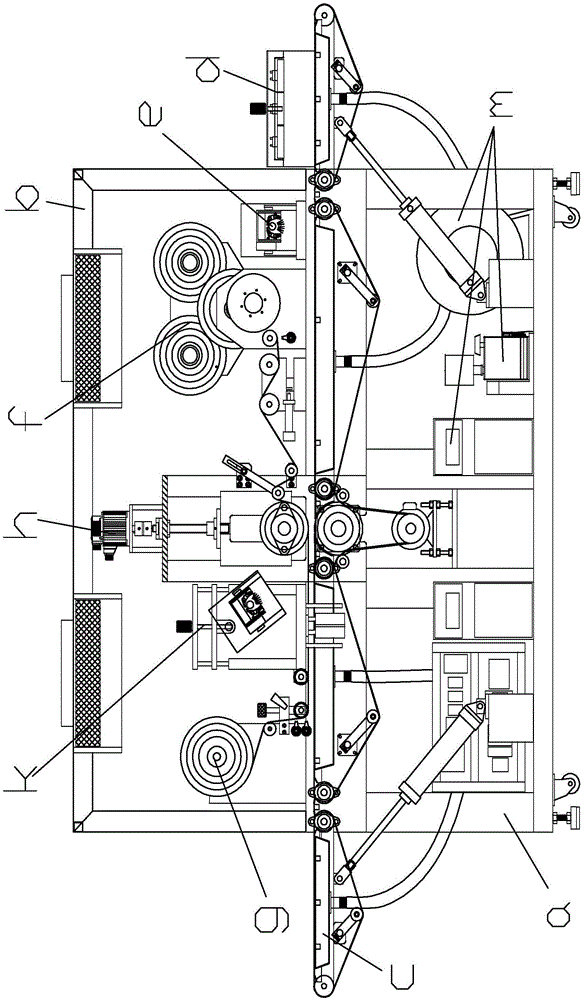

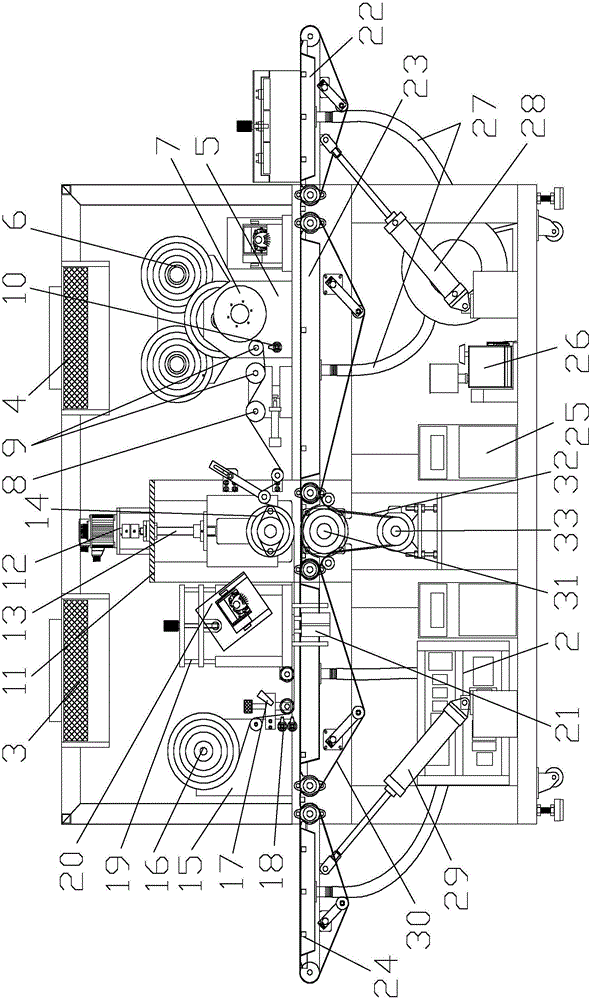

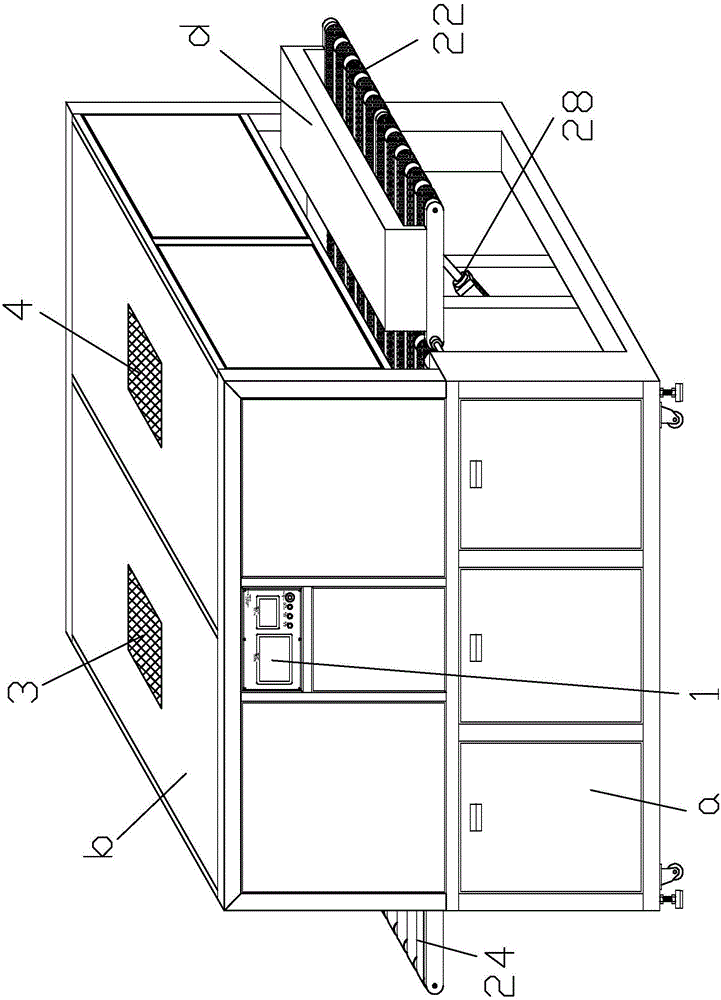

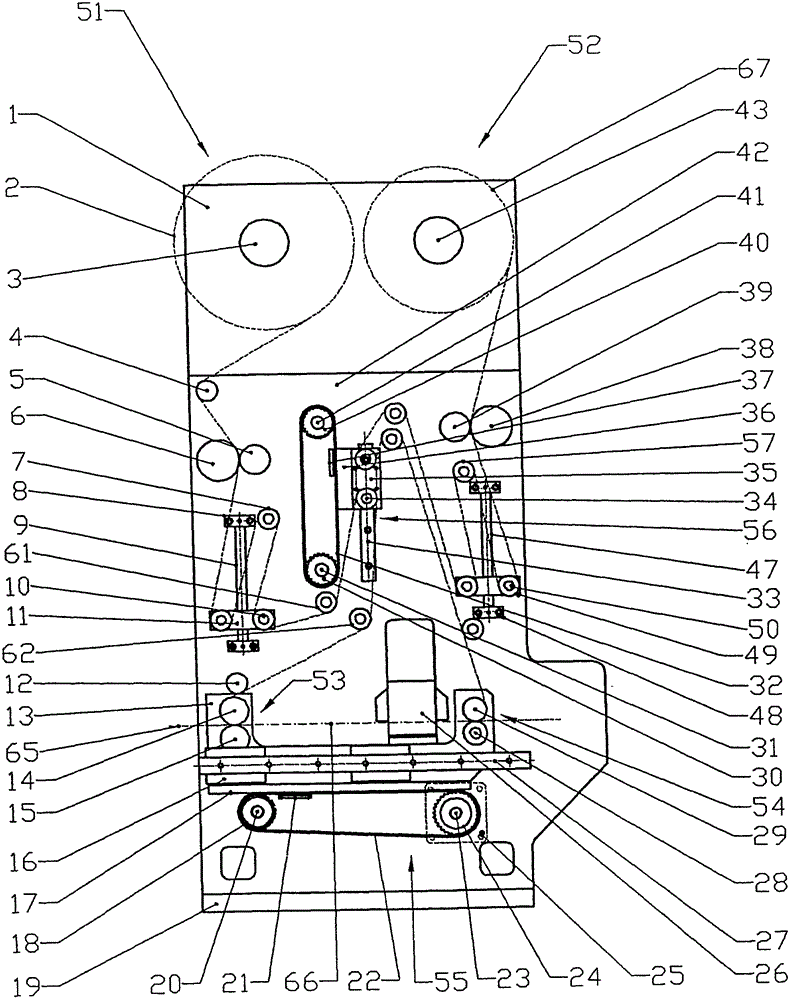

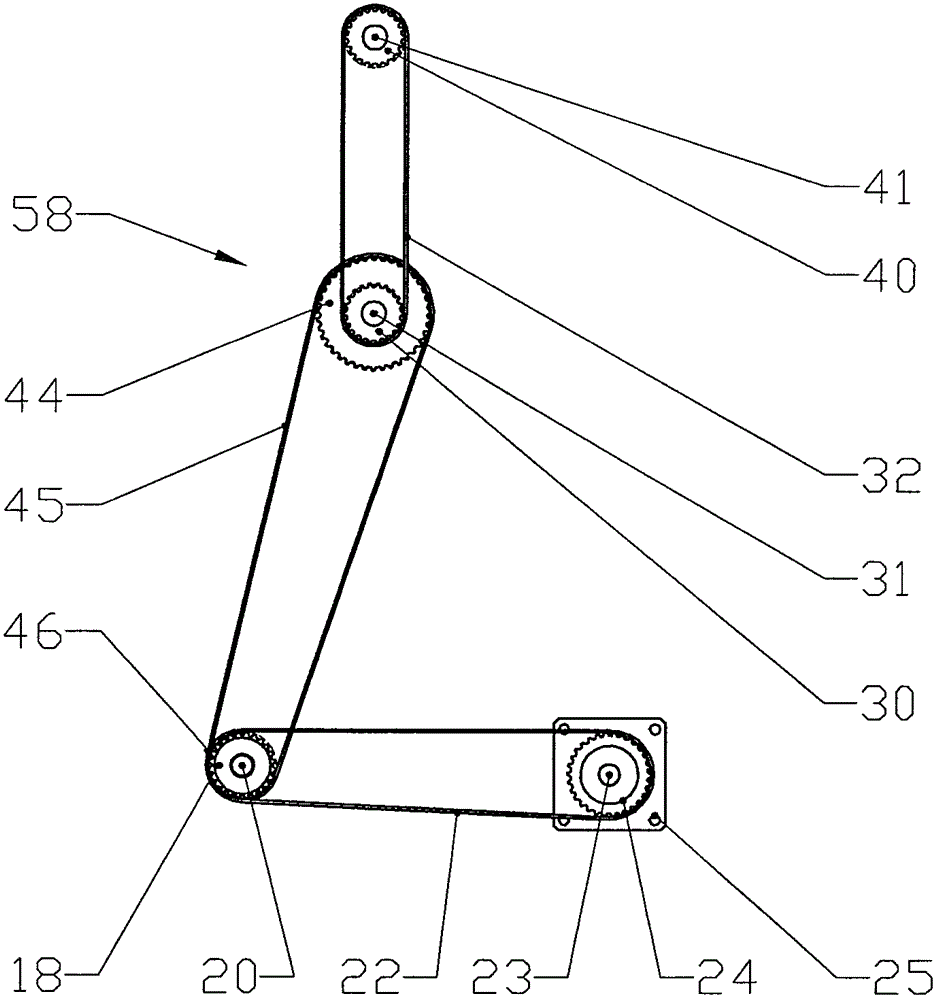

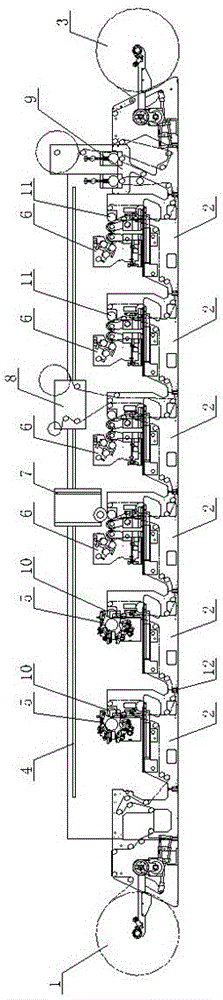

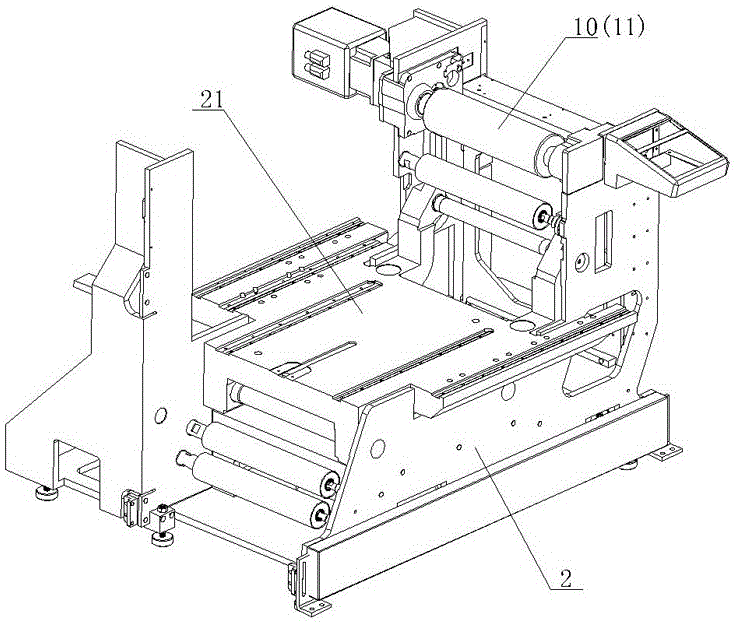

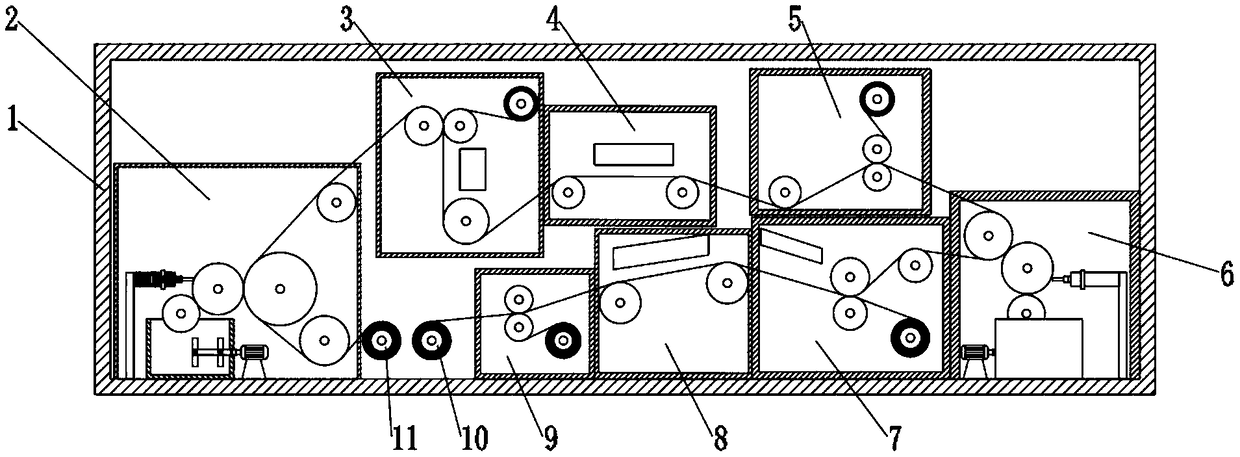

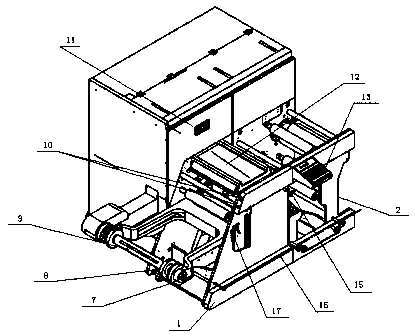

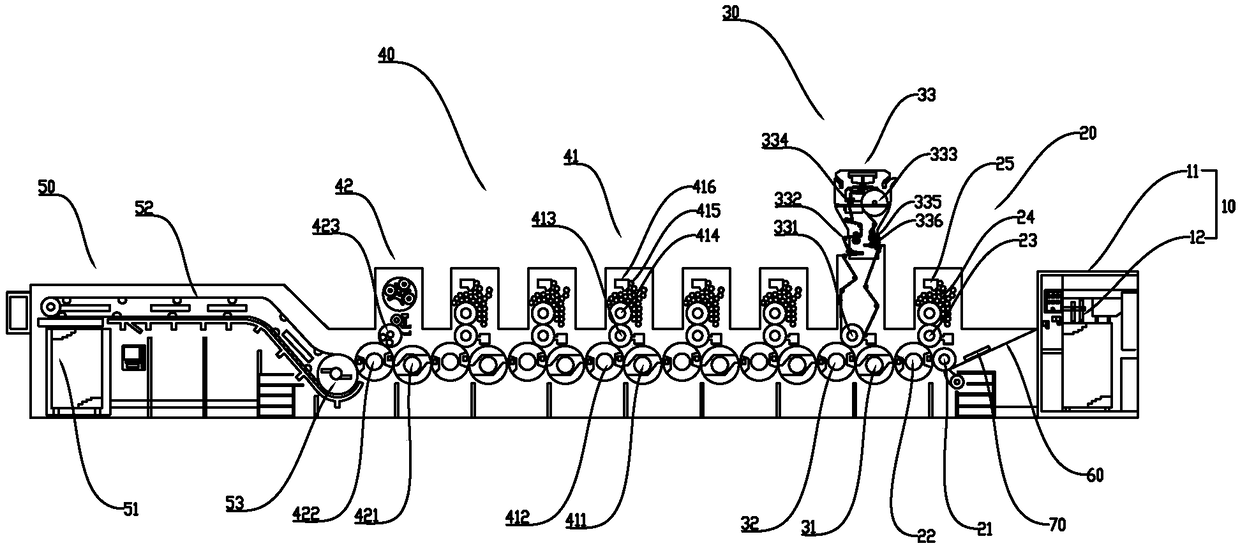

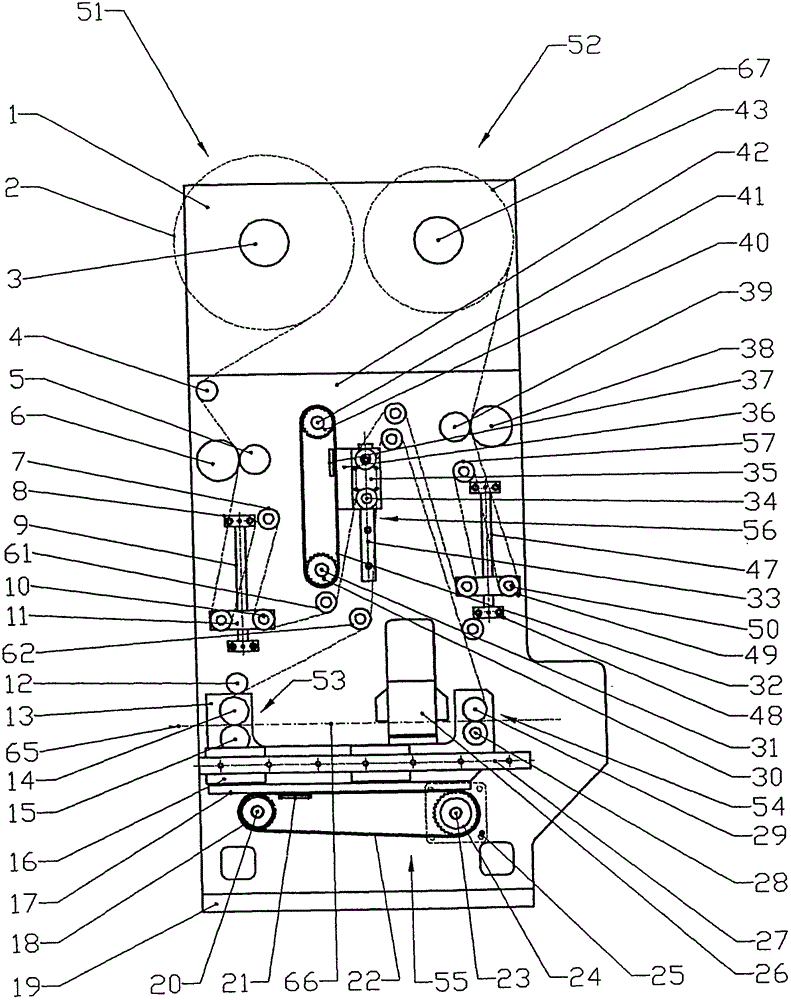

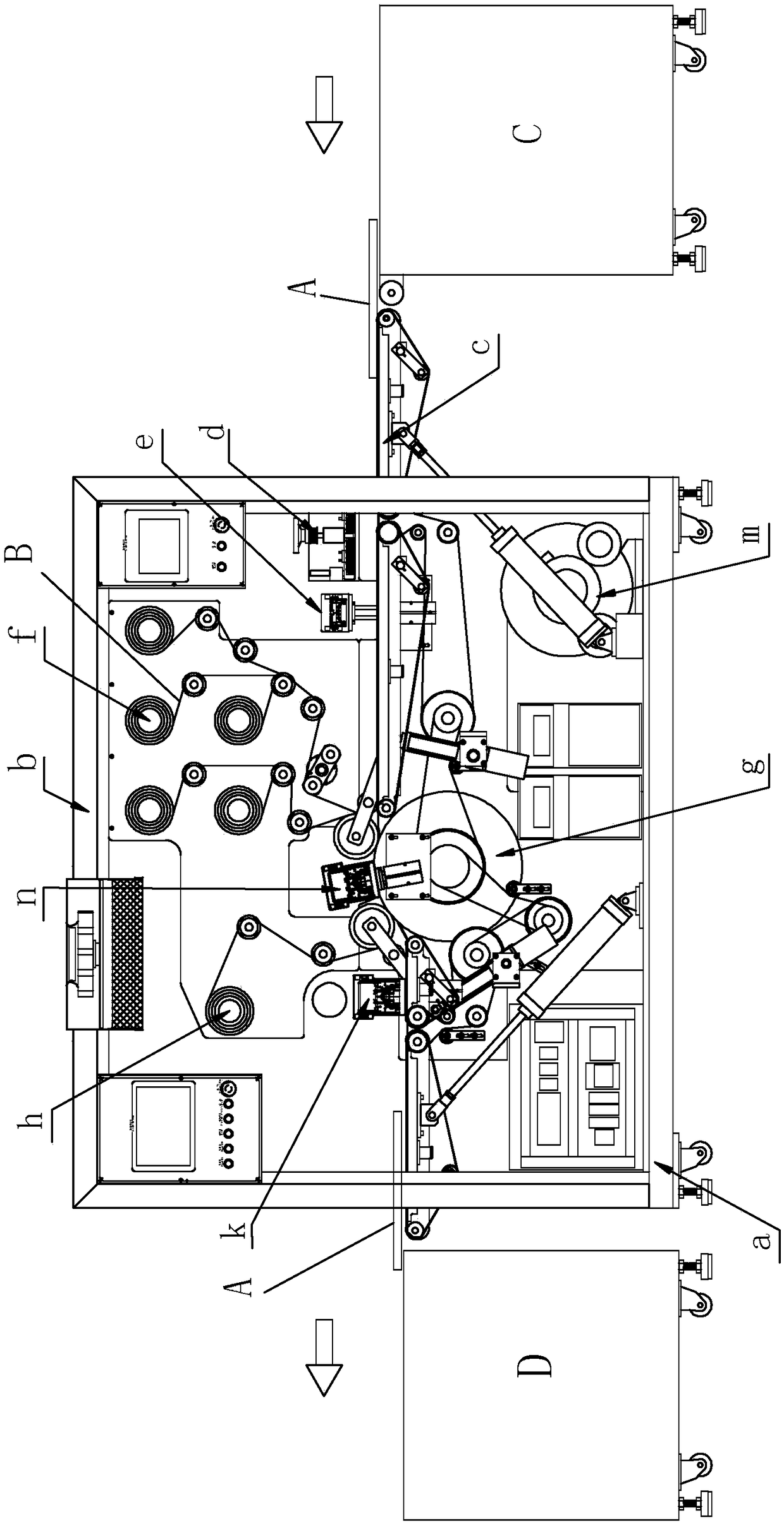

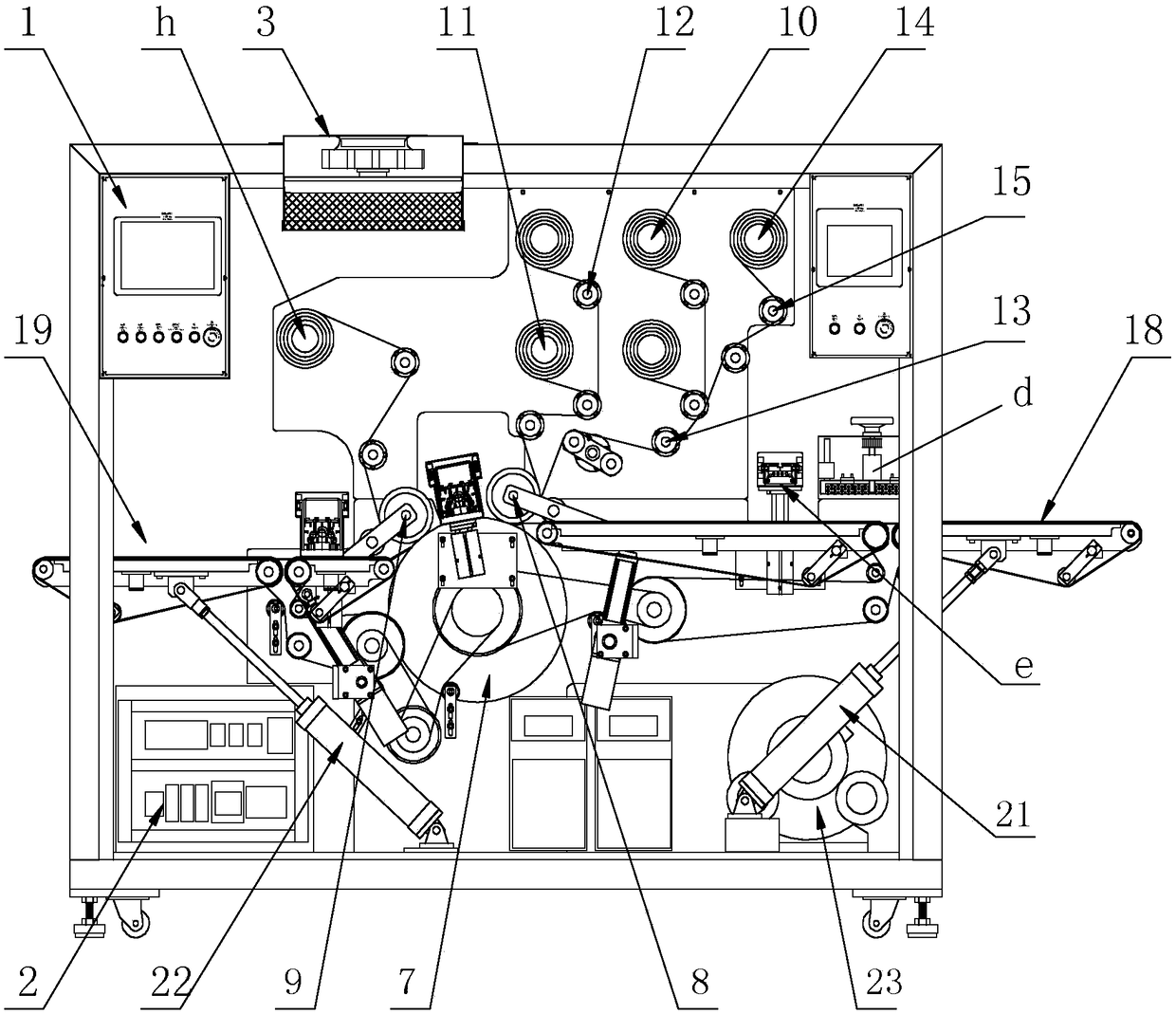

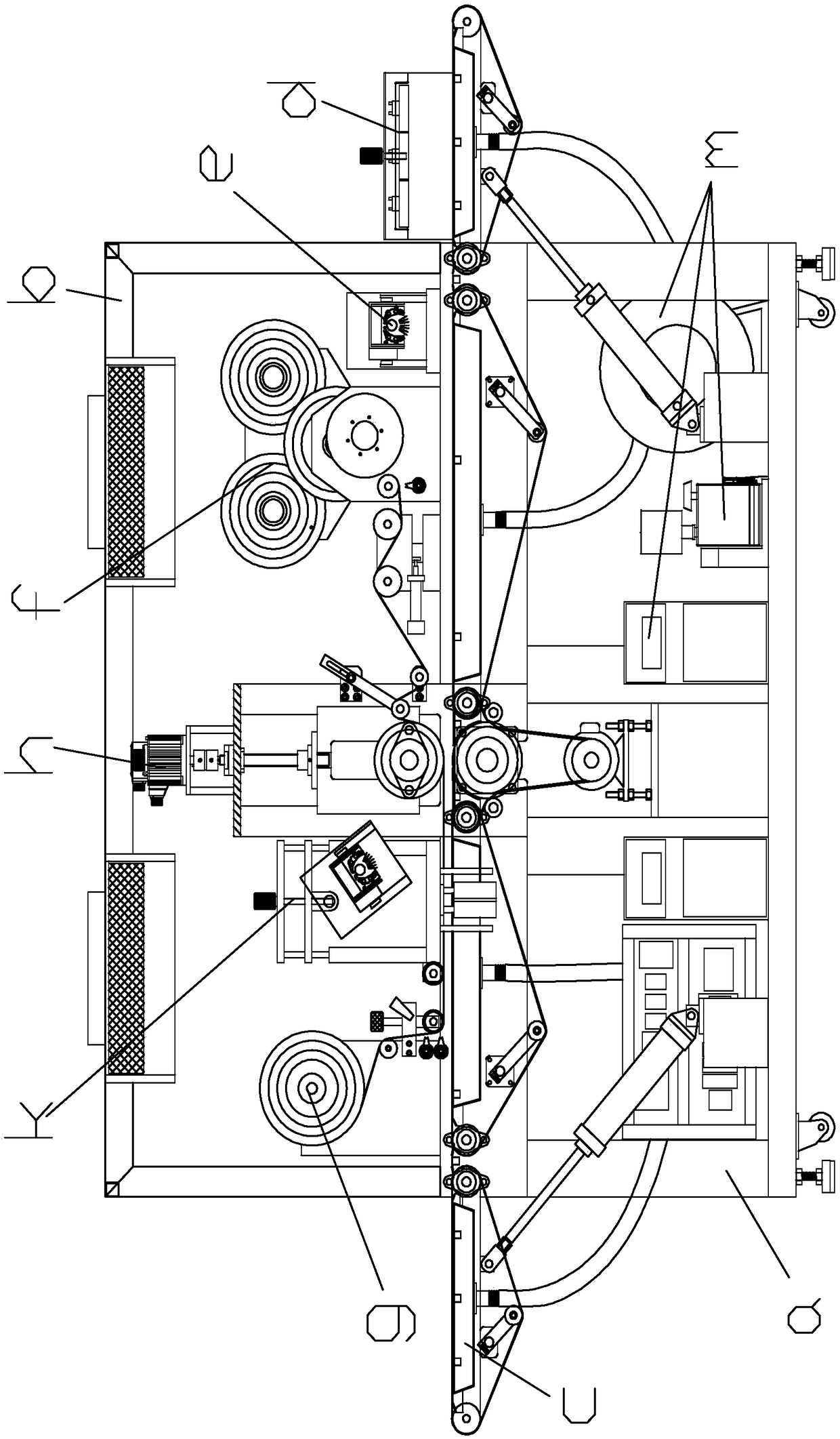

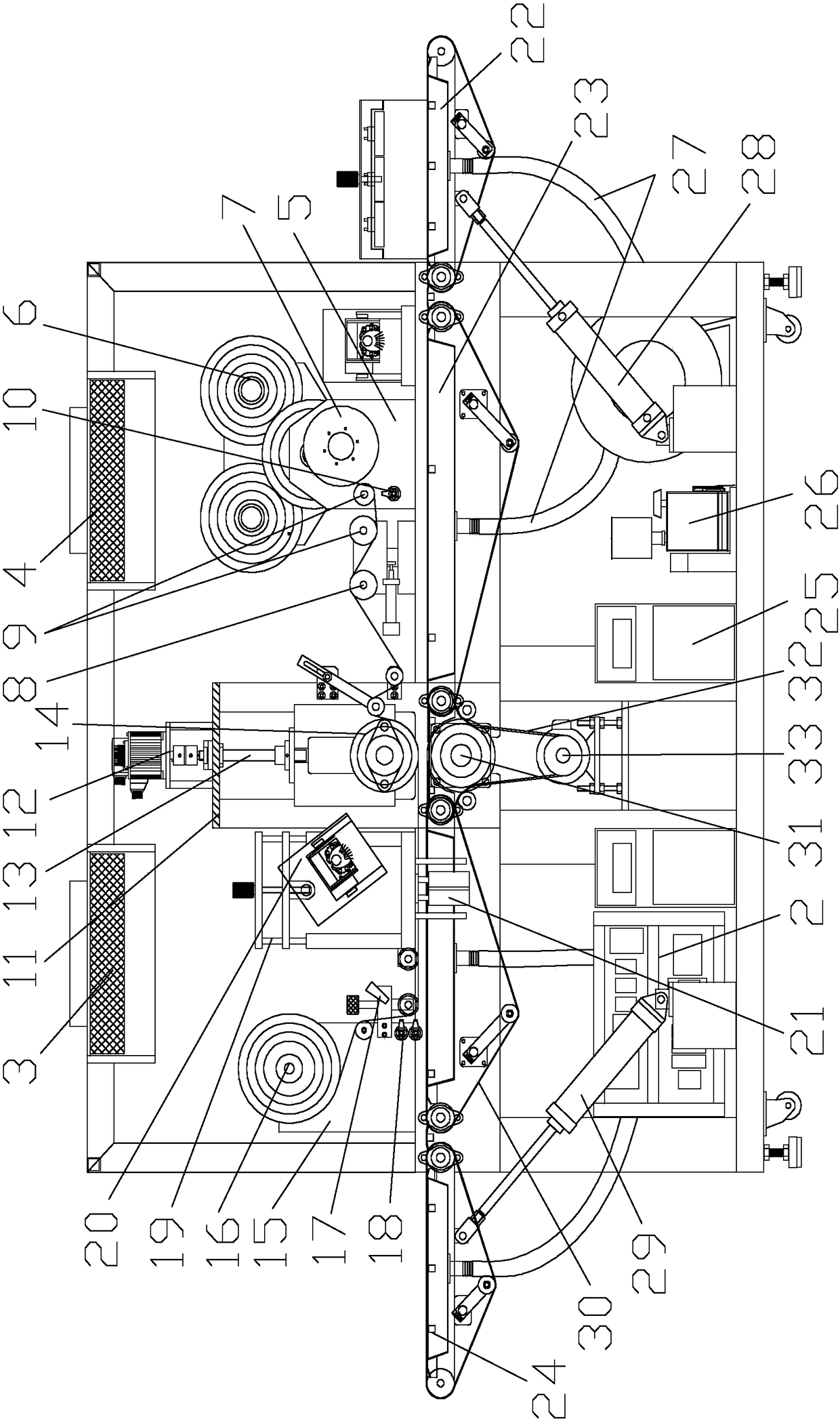

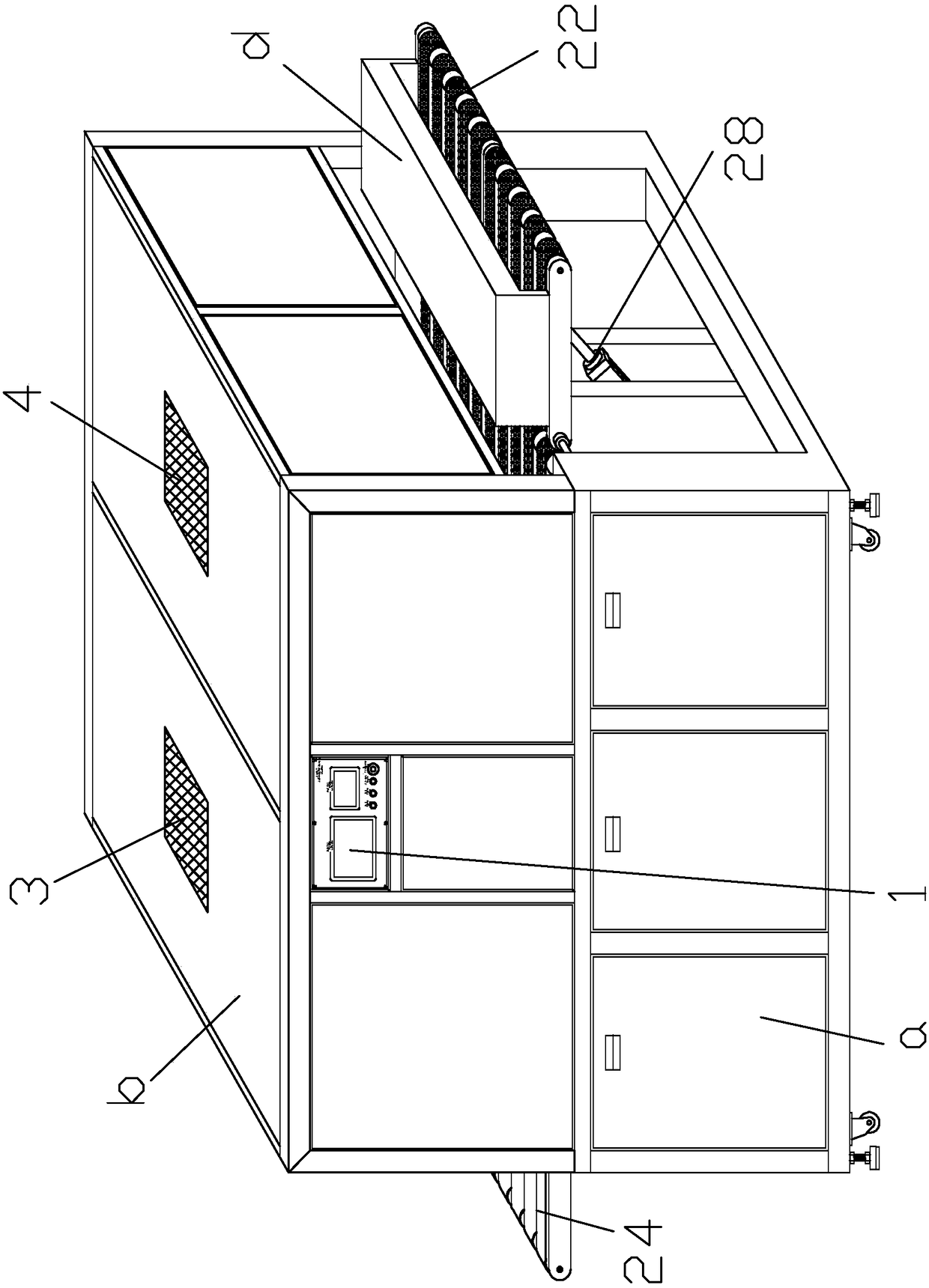

Full-automatic silk screen cold-ironing printing machine

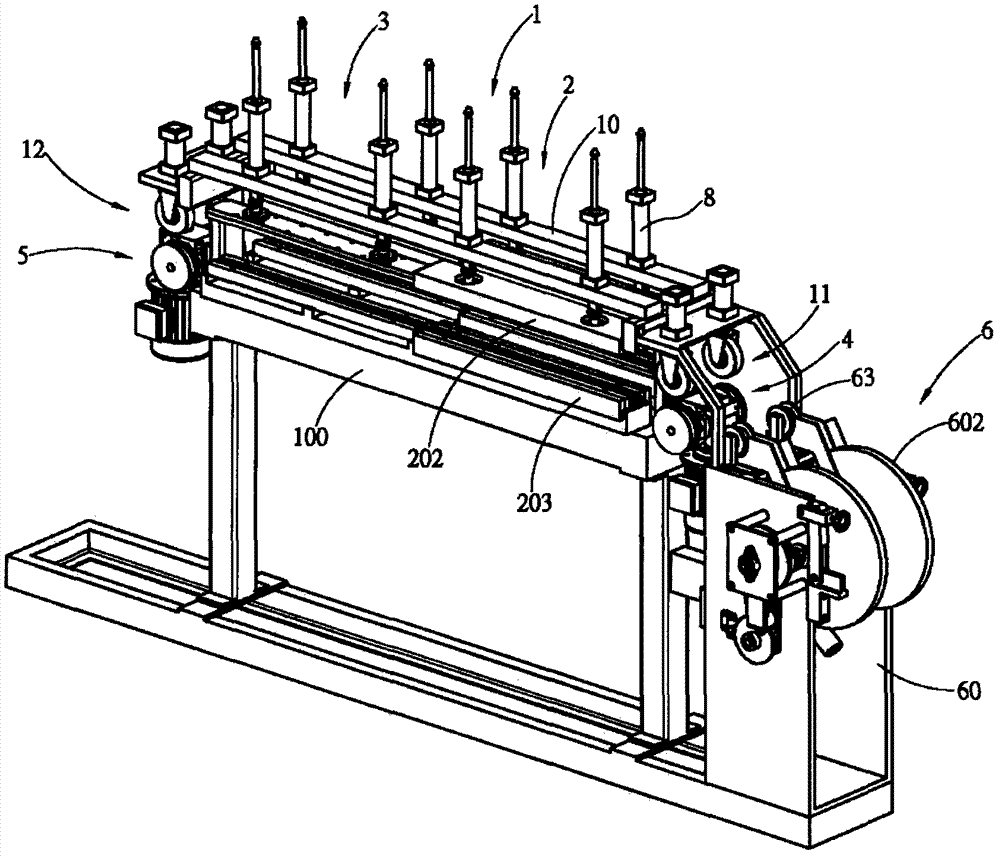

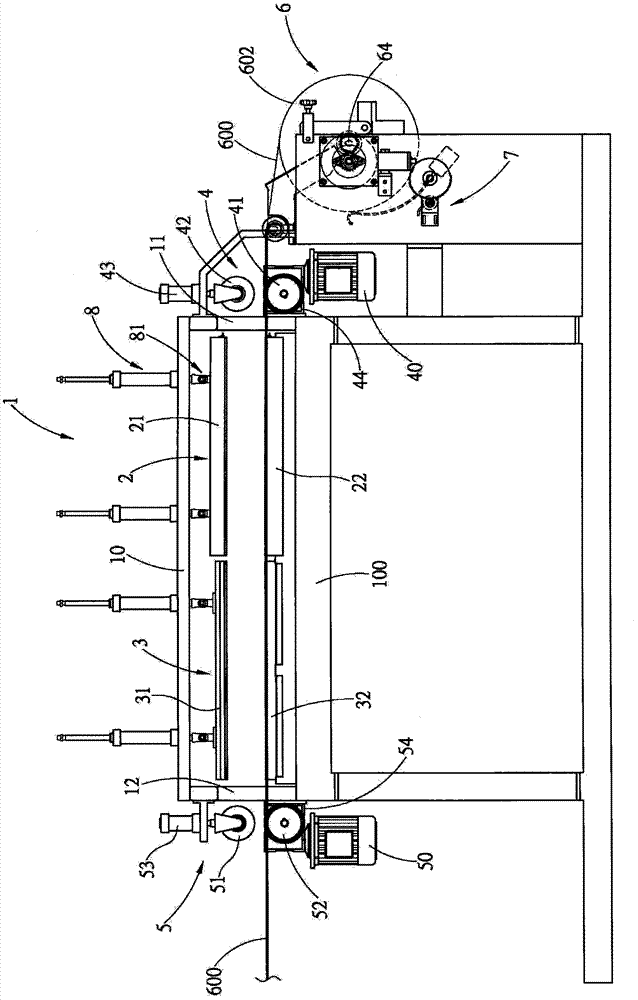

ActiveCN105856819AAvoid pollutionPrevent problems that easily cause substrate deformationTransfer printingFresh airAluminum foil

The invention relates to the technical field of surface special printing equipment and particularly relates to a full-automatic silk screen cold-ironing printing machine. The full-automatic silk screen cold-ironing printing machine comprises a frame body, a seal box, a conveyor belt mechanism, an infrared preheater, a vacuum suction mechanism for adsorbing a printing stock onto the conveyor belt mechanism, and a front end curer, an aluminum foil storer, an aluminum foil recoverer, a cold-ironing printing rubber covered roller mechanism and a rear end curer which are positioned in the seal box, respectively, wherein a fresh air port and an exhaust port are formed on the seal box. According to the invention, not only can a relatively tight printing environment be formed on a machine through the seal box to prevent pollution from an external environment, but also air-cooling treatment on a printed article in the seal box can be performed through the fresh air port and the exhaust port according to the demand, so that the problem that the printing stock is easy to deform as the temperature is over-high can be effectively prevented; by virtue of a negative pressure effect of the vacuum suction mechanism, the printing stock or a finished product can be adsorbed onto the conveyor belt mechanism, and the problem of preventing the printing stock or the finished product from deviating or deforming in a conveying process can be effectively prevented.

Owner:万军霞

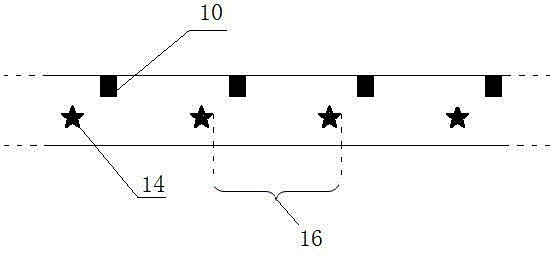

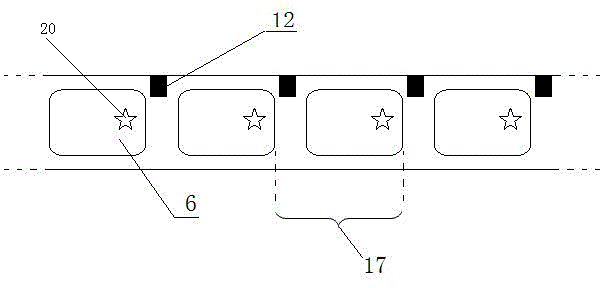

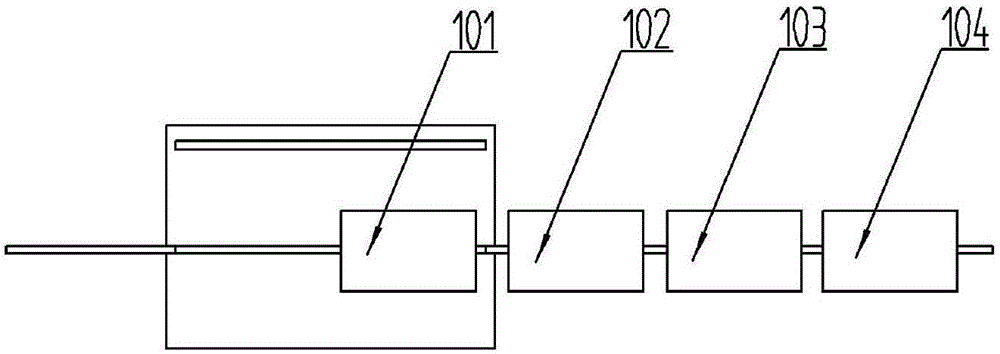

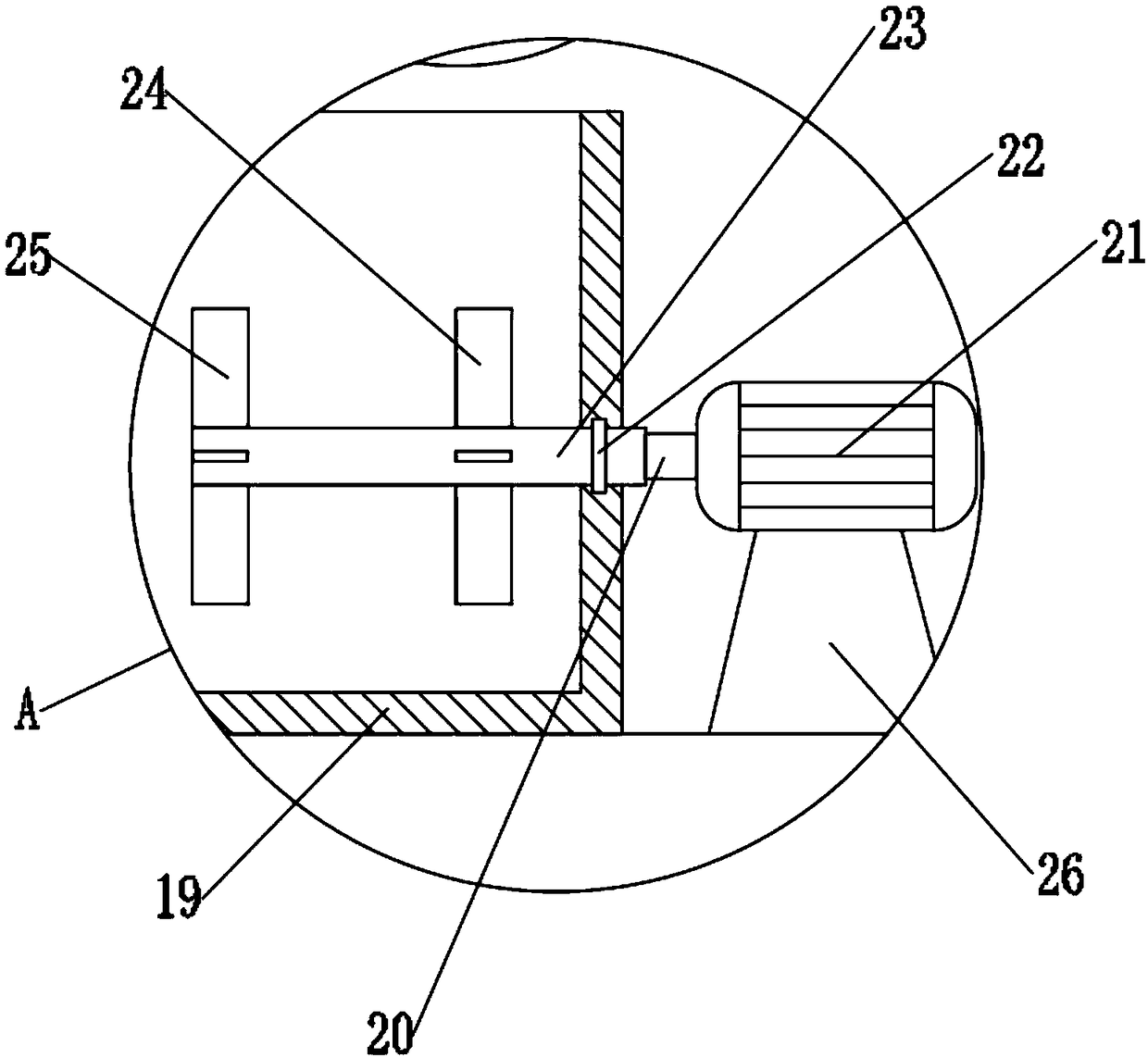

Double-positioning cold-ironing system

InactiveCN104553273ARealize double positioning cold ironingTransfer printingTrademarkLaser patterning

The invention provides a double-positioning cold-ironing system which comprises a displacement roller driven by a motor, a compression roller of the displacement roller, an electric eye A reading a cold-ironing film cursor and an electric eye B reading a presswork cursor. The electric A and the electric B are respectively communicated with a computer control unit and respectively transmit the read cursor signals to the computer control unit. The computer control unit controls the motor and drives the displacement roller to move ahead or backward according to the difference value between the two cursor signals so that fine tuning and calibration can be conducted. The double-positioning cold-ironing system can use the cold-ironing film repeatedly for many times and transfer the whole trademarks like laser patterns designed in advance to the specified fixed position on the presswork so that positioning cold ironing can be realized.

Owner:XIAMEN QIANRUN TECH

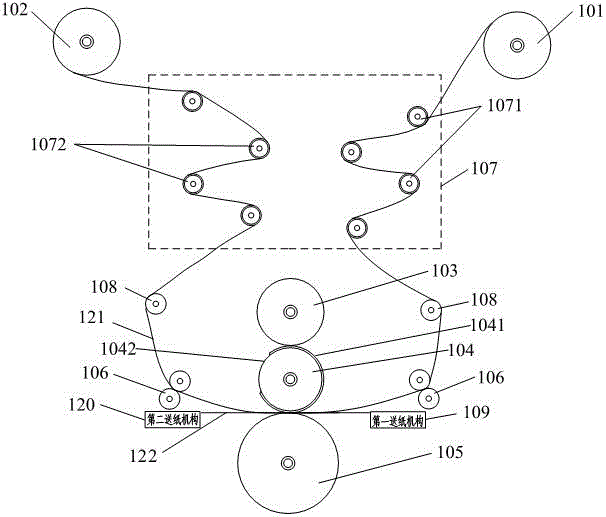

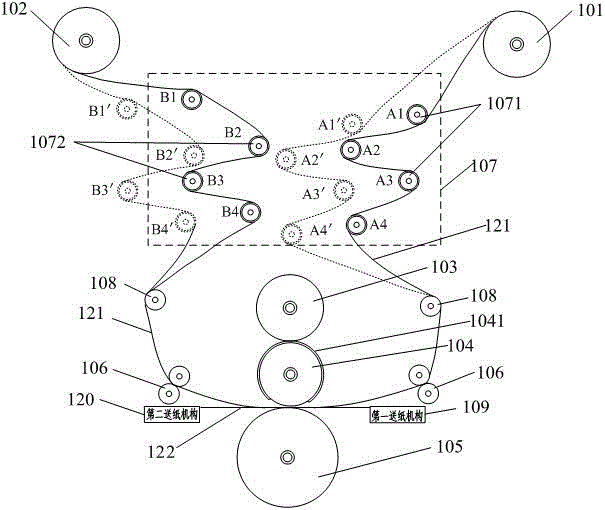

Cold-ironing type gold stamping technology and gold stamping mechanism thereof

ActiveCN102717616AExact matchLow input costRotary pressesBronze printingUltraviolet lightsRoom temperature

A cold-ironing type gold stamping technology comprises the steps as follows: printing material with a layer of glue coated on pictures and texts and aluminum foil material are processed through rotary rolling combination, ultraviolet light box irradiation and rotary rolling stripping; an aluminum foil is imprinted on the corresponding pictures and the texts on the printing material due to the rolling combination and the sticking action of glue; and then room temperature cold-ironing operation is carried out under the ultraviolet light irradiation, and the printing material with the pictures and the texts achieving gold stamping effect is obtained finally. A cold-ironing type gold stamping mechanism of the cold-ironing type gold stamping technology adopts the structure as follows: an aluminum foil unreeling device and a scrap material winding are arranged at the upper part between a front wallboard and a rear wallboard, and a rotary rolling combination device and a rotary rolling stripping device are respectively arranged at the lower part between the front wallboard and the rear wallboard through a combination stripping wallboard; an ultraviolet light box is arranged between the rotary rolling combination device and the rotary rolling stripping device; and the combination stripping wallboard is connected with a simultaneous movable transmission device through a lower guide rail sliding block. The cold-ironing type gold stamping technology and the cold-ironing type gold stamping mechanism can accurately achieve the matching of cold stamping pressure time and cold stamping temperature, and improve the stamping fastness and the definition of a graphic profile, as well as the printing effect and the printing quality.

Owner:ZHEJIANG WEIGANG TECH CO LTD

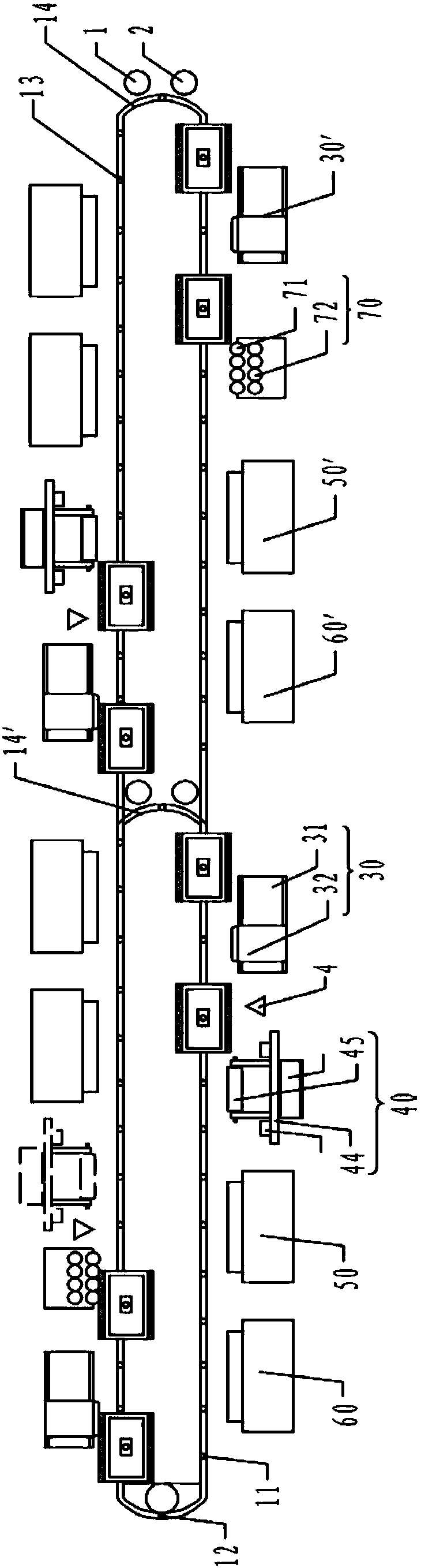

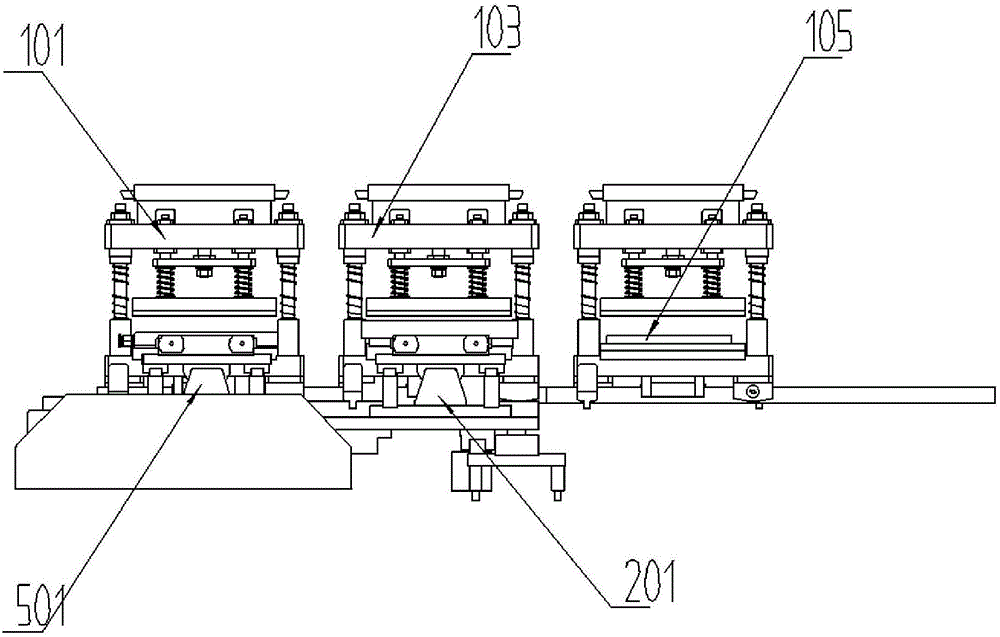

Lithium battery fully automatic double-flanged forming machine and forming method

ActiveCN103985896APrevent leakageMeet size requirementsAssembling battery machinesFinal product manufactureElectrolyte leakageEngineering

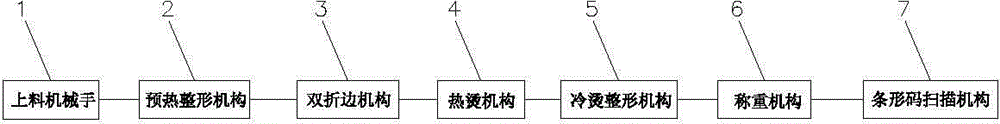

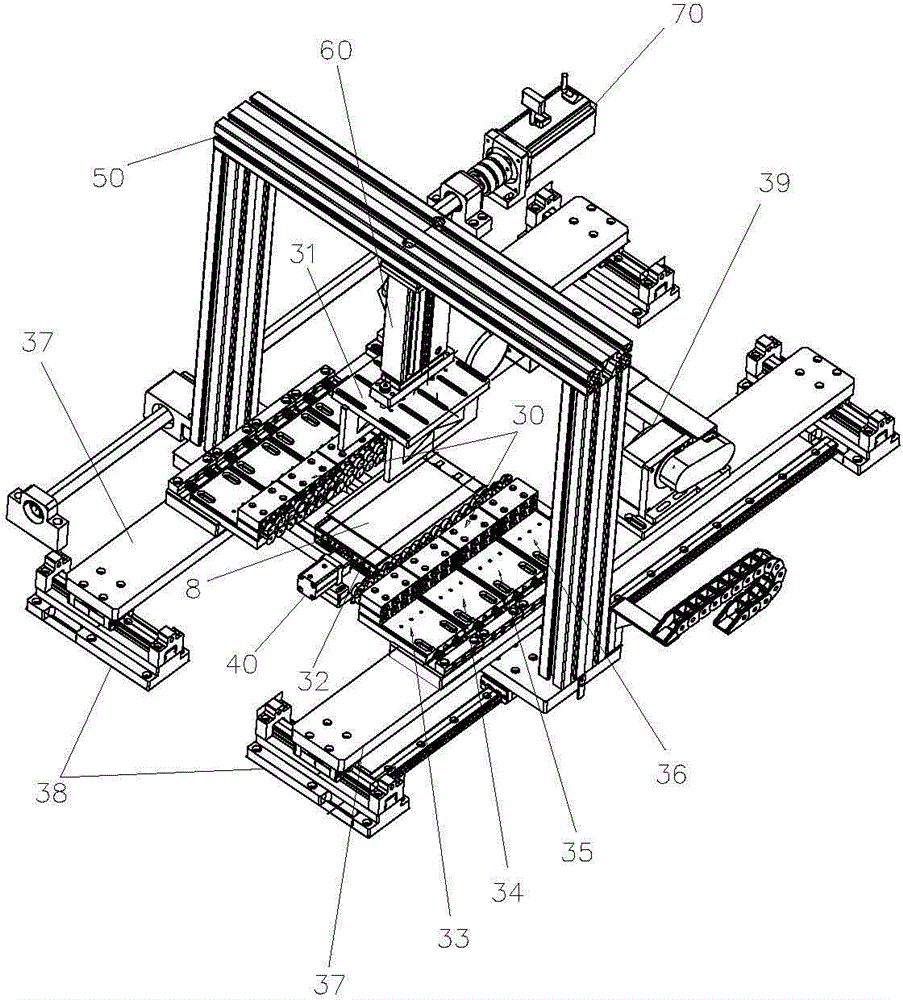

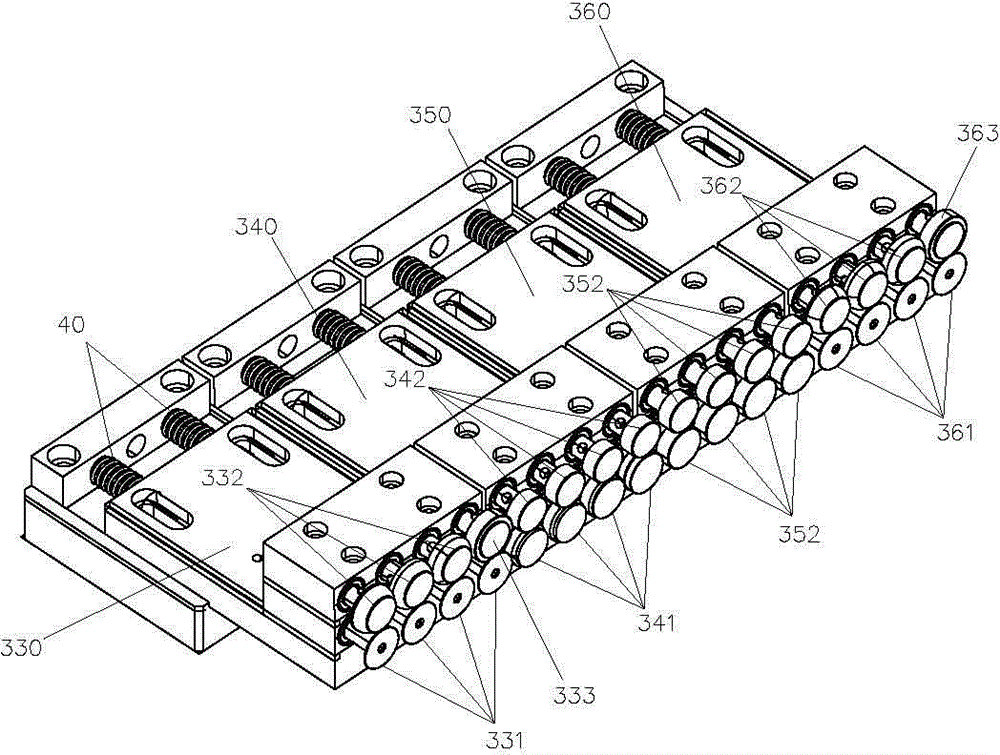

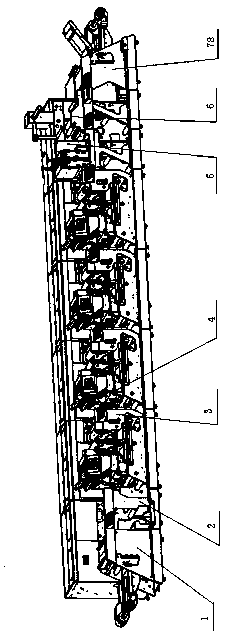

The invention relates to the technical field of lithium battery production equipment, in particular to a lithium battery fully automatic double-flanged forming machine and a forming method. The lithium battery fully automatic double-flanged forming machine comprises a feeding mechanical hand, a preheating shaping mechanism, a double-flanged mechanism, a hot ironing mechanism, a cold ironing shaping mechanism, a weighing mechanism and a bar code scanning mechanism in sequential arrangement from the front side to the back side. The lithium battery automatic double-flanged forming is realized through adopting a rolling wheel forming mode of a first group rolling wheel forming device, a second group rolling wheel forming device, a third group rolling wheel forming device and a fourth group rolling wheel forming device, the electrolyte leakage is effectively prevented, and the product dimension requirements can also be met.

Owner:江苏阿李动力科技有限公司

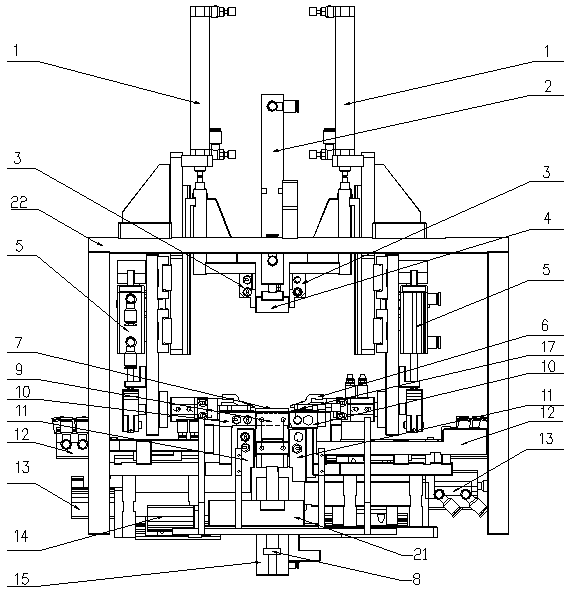

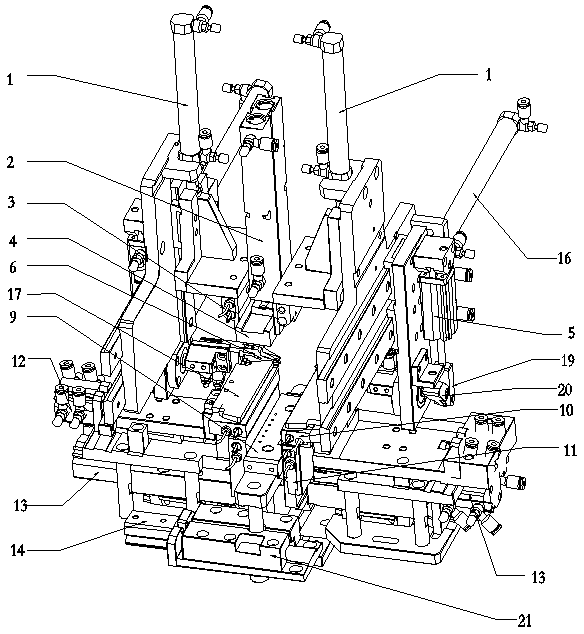

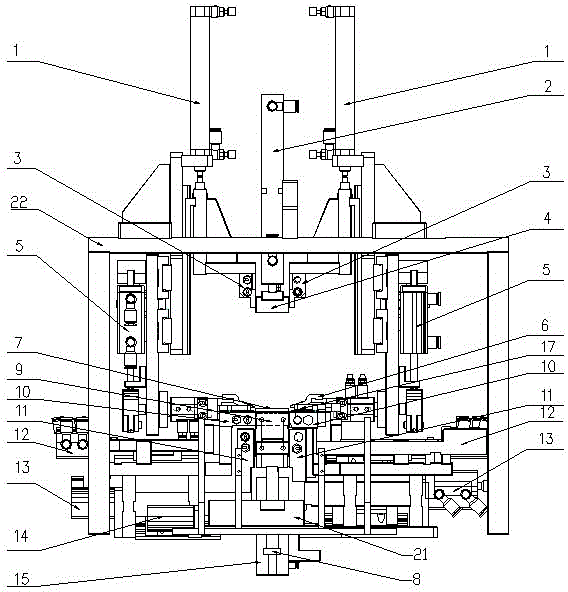

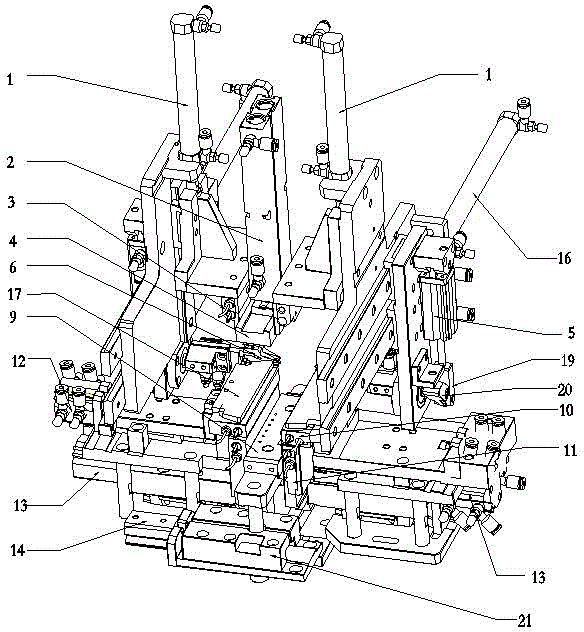

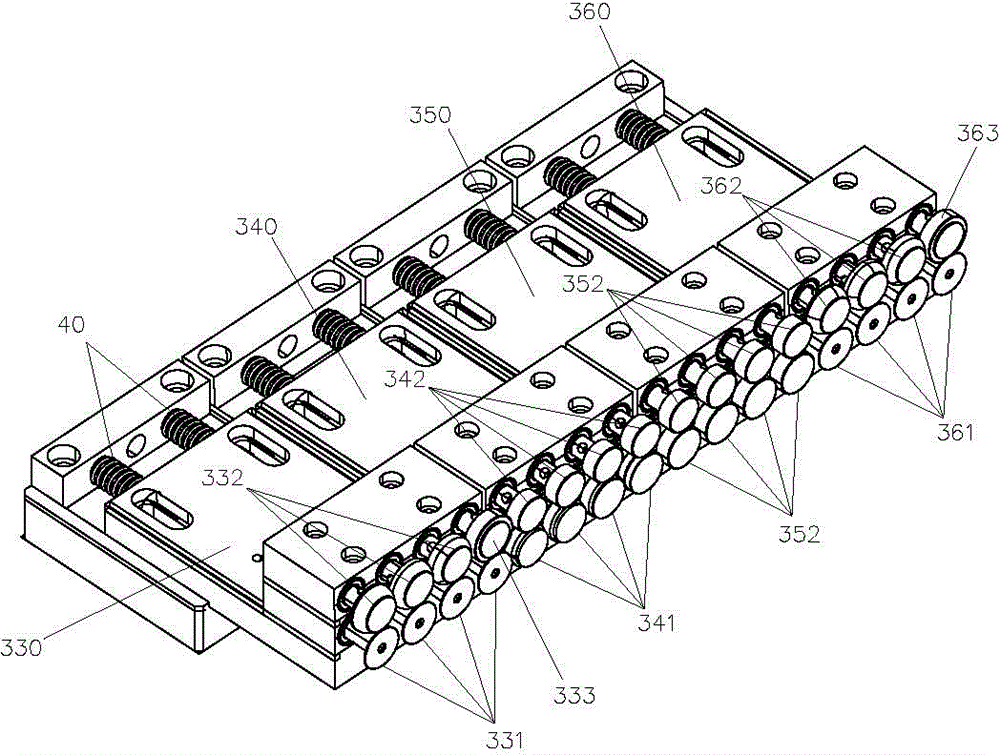

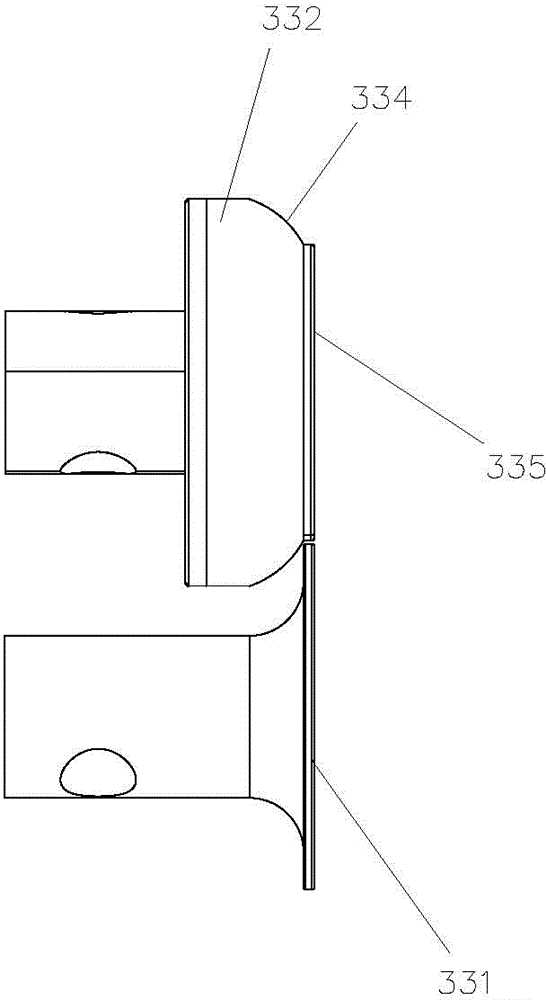

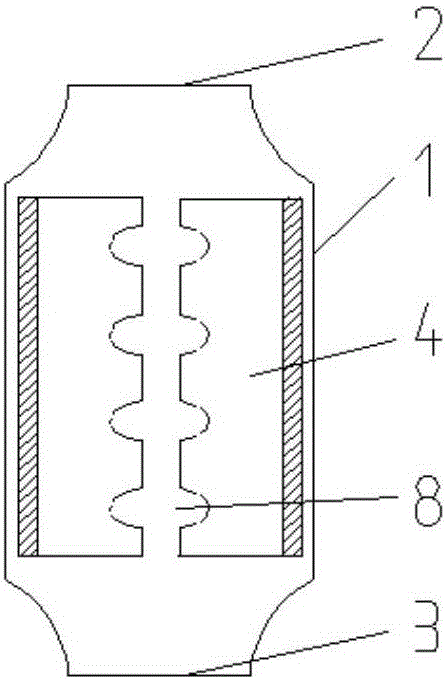

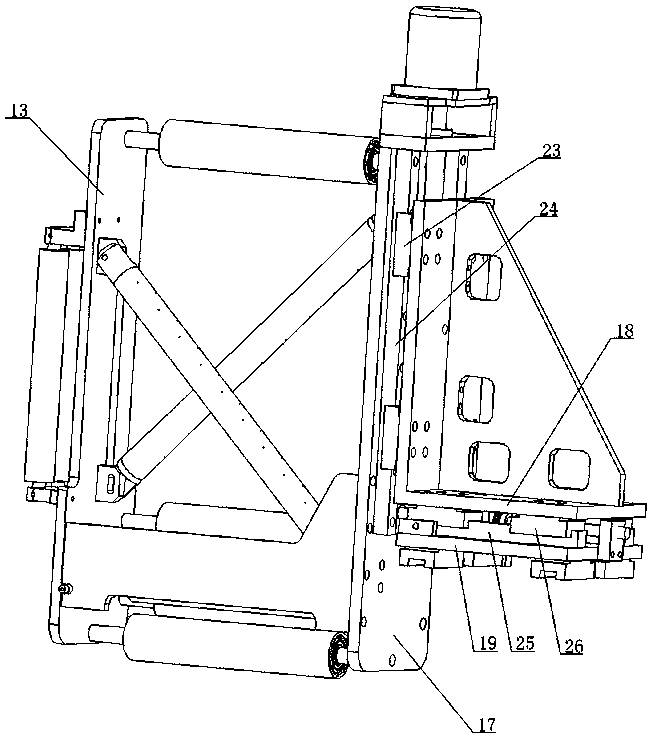

Soft package lithium battery aluminum plastic film preheating flanging mechanism

ActiveCN103413899AImprove the heating effectImprove fitSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringPlastic film

The invention relates to a soft package lithium battery aluminum plastic film preheating flanging mechanism, which comprises a rack. The upper part of the rack is provided with a press fixture, which is fixed on a No.3 drive element able to move vertically. No.1 heating blocks are disposed on both sides of the press fixture and are fixed on No.2 drive elements able to move vertically. The lower part of the rack is provided with a fixation fixture, which is fixed on a No.6 drive element able to move vertically. Both sides of the fixation fixture are respectively provided with No.3 heating blocks, No.2 heating blocks and cold ironing blocks in a bottom-up order. The No.3 heating blocks are fixed on No.7 drive elements able to move horizontally, the No.2 heating blocks are fixed on the rack, and the cold ironing blocks are fixed on No.1 drive elements able to move horizontally. The rear sides of the cold ironing blocks are provided with clamping jaws, which are fixed on No.4 drive elements able to move vertically through a link mechanism. And the No.4 drive elements are fixed on a No.5 drive element able to make horizontal movement longitudinally.

Owner:江苏利元亨智能装备有限公司

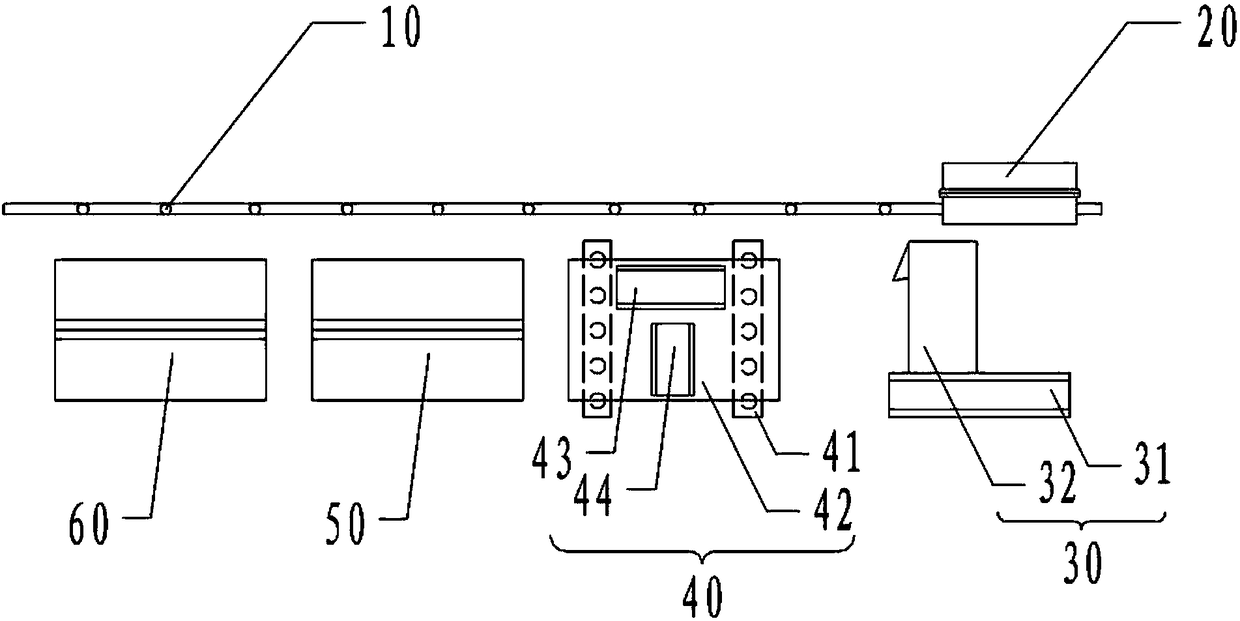

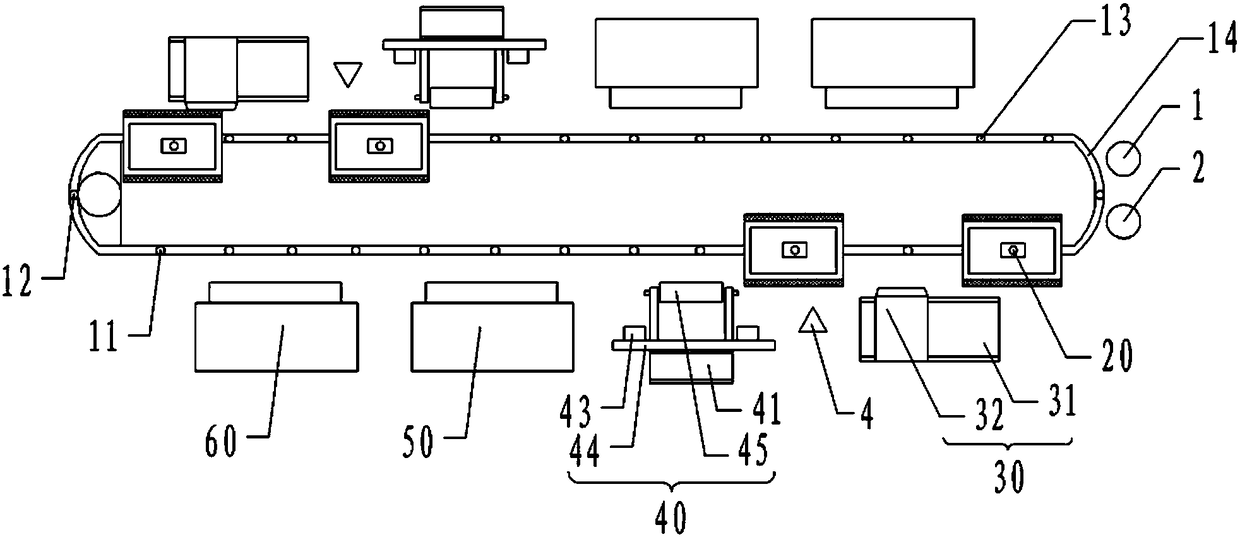

Cell edge sealing and finishing forming device and cell shaping technology

PendingCN108461803AIncrease the level of automationIncrease productivityAssembling battery machinesFinal product manufactureHot stampingEngineering

The invention provides a cell edge sealing and finishing forming device and a cell shaping technology. The device comprises a sliding rail, a cell clamp arranged on the sliding rail and moving synchronously with the sliding rail, a glue dropping mechanism, a vertical binding mechanism, a hot stamping mechanism and a cold ironing shaping mechanism, wherein the glue dropping mechanism, the verticalbinding mechanism, the hot stamping mechanism and the cold ironing shaping mechanism are arranged outside the sliding rail in sequence; a to-be-processed cell is clamped in the cell clamp, so that thecell moves forwards along the sliding rail to be positioned before the mechanisms to complete glue dropping, edge folding, hot melting and cold bonding, and finishing of cell wrapping films and sealed edges is achieved. Due to the cooperation of the sliding rail and the mechanisms, requirements of production modes of single-edge folding and two-edge folding technologies can be met, uninterruptedand continuous battery trimming and forming are achieved, the automation level is high, and the production efficiency is high.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Method of manufacturing planar relief noble metal cards

ActiveCN108215632AImprove visual effectsMeet needsDecorative surface effectsOrnamental structuresSheet filmColor printing

The invention relates to a method of manufacturing planar relief noble metal cards. The method includes the following steps: 1) rolling and cutting noble metal raw materials to form foils, and performing oil pressing onto the surface of the foils to form design patterns; 2) performing fine sculpture on a shaping surface of a mold by means of a laser machine according to the design patterns, thus forming design patterns having 3D effect on the shaping surface of the mold; 3) press-printing a cold ironing film onto the shaping surface of the mold having the 3D effect, and performing cold ironingtransferring onto surface of a photographic film or the noble metal foil, wherein the 3D effect is formed on the position of the cold ironing film on the photographic film or the noble metal foil andcorresponding positions of the design patterns; 4) performing color printing to the corresponding positions of the design patterns on the cold ironing film; 5) laminating the photographic film and the foil and performing mould shaping. In the method, the shaping surface of the mold is sculptured and the cold ironing film covers the mold, then the cold ironing film is transferred onto the photographic film and the foil, so that the planar relief 3D effect is formed on the surface of the noble metal card. The method can improve vision effect of the cards, satisfies user demands and has advantages on market promotion.

Owner:SHENZHEN JINBAOYING CULTURE

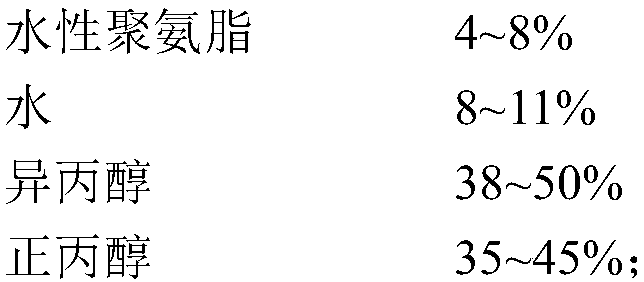

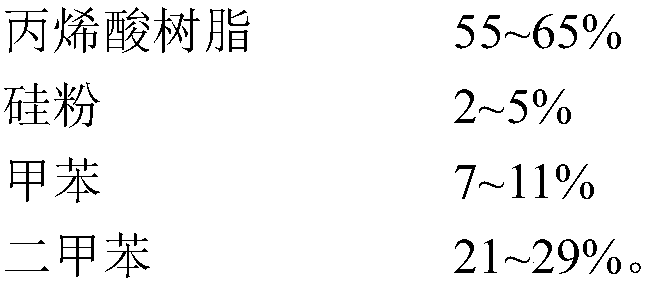

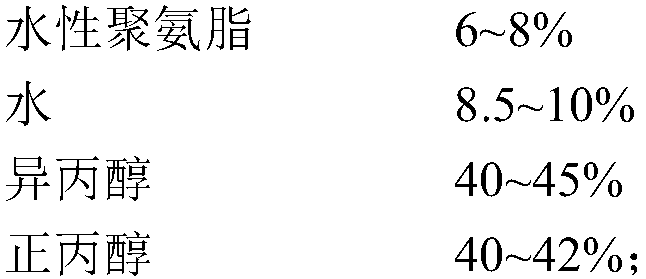

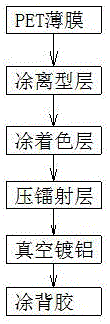

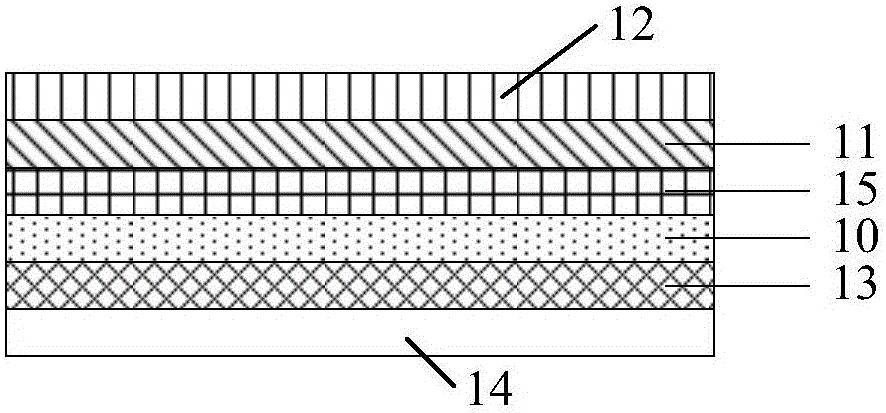

Cold ironing membrane for hose and production process of cold ironing membrane

InactiveCN107936278AImprove water resistanceReduce the ratioPolyurea/polyurethane coatingsMedia layerChemistry

The invention relates to the technical field of cold ironing membranes and particularly relates to a cold ironing membrane for a hose and a production process of the cold ironing membrane. The cold ironing membrane consists of a separation layer, a color layer, an aluminum plated layer and a medium layer in an overlapped manner, in addition, the separation layer, the color layer and the medium layer are made of raw materials of specific weight percentages respectively, and the cold iron membrane can be relatively well adhered to a hose substrate and has the characteristic of environment protection; the production process of the cold ironing membrane comprises steps of preparing materials of the separation layer, the color layer and the medium layer, and performing coating and aluminum plating; the advantage of simple production process is achieved.

Owner:DONGGUAN K LASER TECH

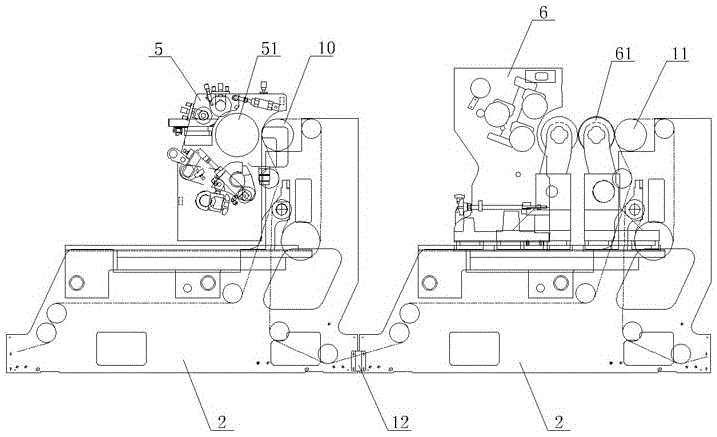

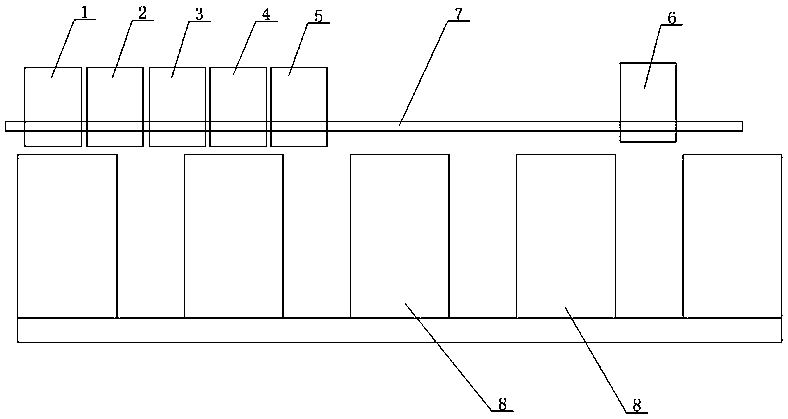

Intelligent printing unit carrying out multi-mode printing based on offset print platform

InactiveCN106393953AMeet needsRotary lithographic machinesLaserElectrical and Electronics engineering

The invention discloses an intelligent printing unit carrying out multi-mode printing based on an offset print platform. The offset print platform is composed of a plurality of printing bases which are connected in a front-back manner. The offset print platform is characterized in that each printing base is exchangeably provided with an offset print head component or a flexible print head component, and the offset print head components and the flexible print head components are designed in an independent modular manner. The intelligent printing unit can achieve multi-process and multi-functional printing to meet printing requirements of various high-grade printing products, meanwhile, according to working requirements, the functional components are selected at will to carry out silk printing, reverse printing, cold ironing, laminating, vanishing, die cutting, digitalizing, laser treating and other actions, and the intelligent printing unit is high in intelligentization degree and meets customer needs and the development tendency of future printing better.

Owner:ZHEJIANG ZHONGTE MACHINERY TECH CO LTD

A soft-pack lithium battery aluminum-plastic film preheating and folding mechanism

ActiveCN103413899BImprove the heating effectImprove fitSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringPlastic film

The invention relates to a soft package lithium battery aluminum plastic film preheating flanging mechanism, which comprises a rack. The upper part of the rack is provided with a press fixture, which is fixed on a No.3 drive element able to move vertically. No.1 heating blocks are disposed on both sides of the press fixture and are fixed on No.2 drive elements able to move vertically. The lower part of the rack is provided with a fixation fixture, which is fixed on a No.6 drive element able to move vertically. Both sides of the fixation fixture are respectively provided with No.3 heating blocks, No.2 heating blocks and cold ironing blocks in a bottom-up order. The No.3 heating blocks are fixed on No.7 drive elements able to move horizontally, the No.2 heating blocks are fixed on the rack, and the cold ironing blocks are fixed on No.1 drive elements able to move horizontally. The rear sides of the cold ironing blocks are provided with clamping jaws, which are fixed on No.4 drive elements able to move vertically through a link mechanism. And the No.4 drive elements are fixed on a No.5 drive element able to make horizontal movement longitudinally.

Owner:江苏利元亨智能装备有限公司

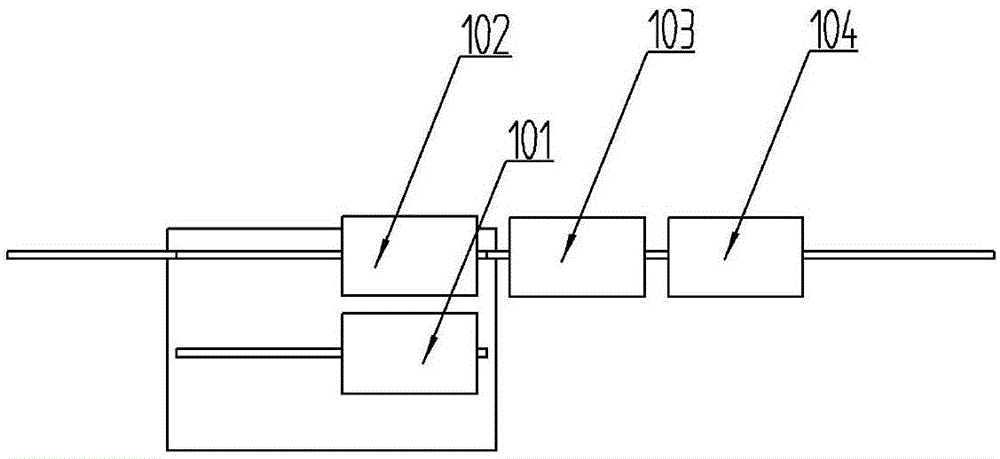

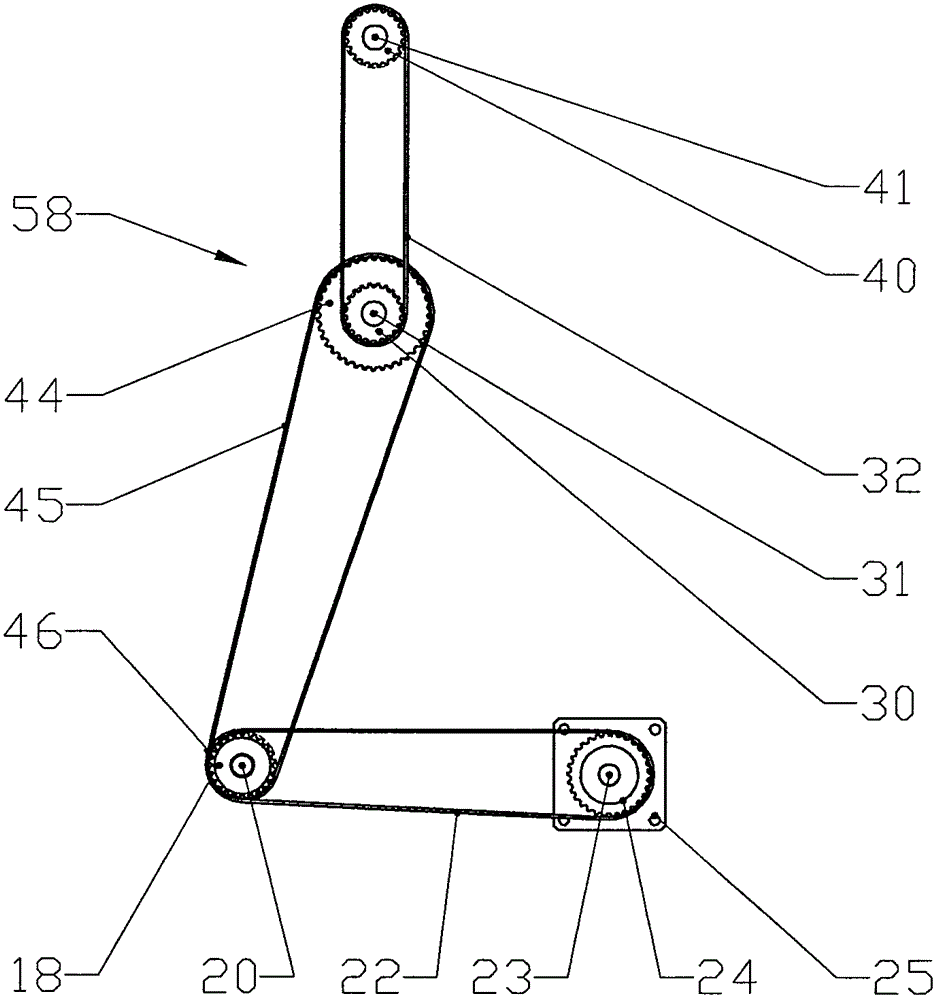

Lithium battery double-flanged mechanism

ActiveCN103985907ARealize automatic double folding formingPrevent leakageAssembling battery machinesFinal product manufactureElectrolyte leakageEngineering

The invention relates to the technical field of lithium battery production equipment, in particular to a lithium battery double-flanged mechanism, which comprises a feeding mechanical hand, a preheating shaping mechanism, a double-flanged mechanism, a hot ironing mechanism, a cold ironing shaping mechanism, a weighing mechanism and a bar code scanning mechanism in sequential arrangement from the front side to the back side. The lithium battery automatic double-flanged forming is realized through adopting a rolling wheel forming mode of a first group rolling wheel forming device, a second group rolling wheel forming device, a third group rolling wheel forming device and a fourth group rolling wheel forming device, the electrolyte leakage is effectively prevented, and the product dimension requirements can also be met.

Owner:东莞工至科技有限公司

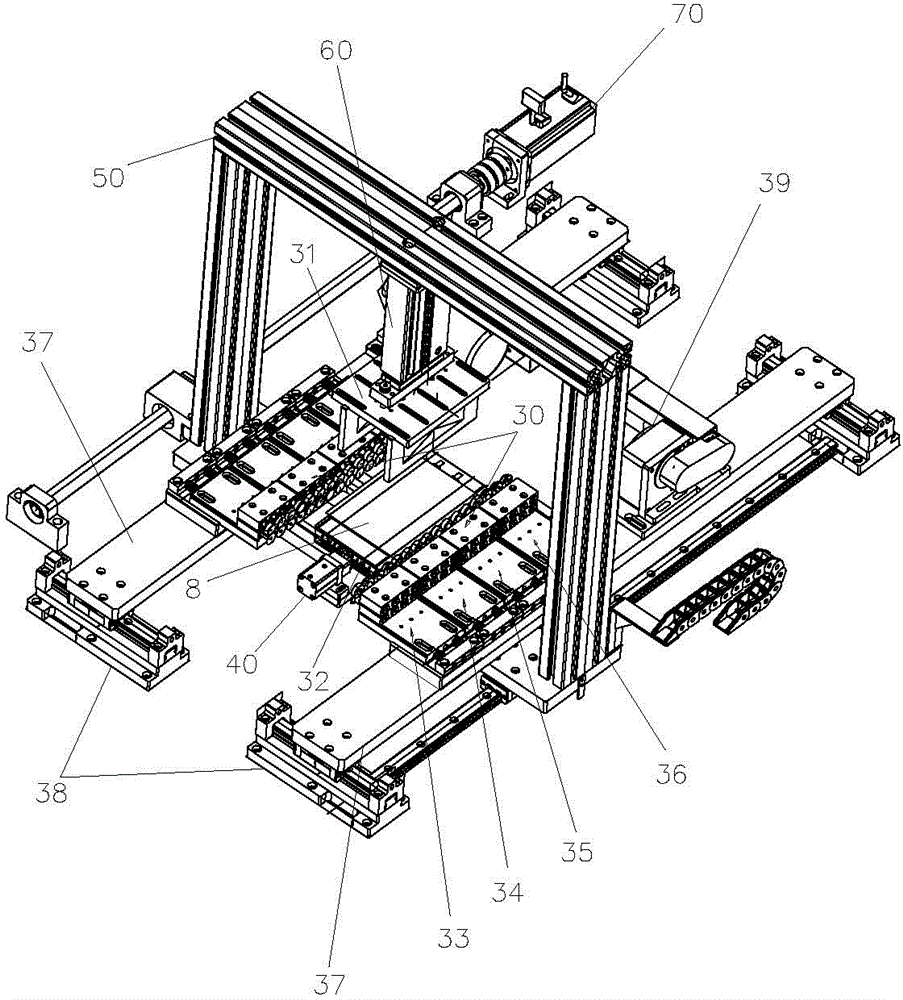

Hot ironing and cold ironing switching mechanism for battery cells and hot ironing and cold ironing technology for battery cells

ActiveCN106410284AReduce excess spaceLow costFinal product manufactureElectrolyte accumulators manufactureButt jointEngineering

The invention relates to a hot ironing and cold ironing switching mechanism for battery cells and a hot ironing and cold ironing technology for the battery cells. The hot ironing and cold ironing switching mechanism is characterized by comprising a big plate capable of moving in the front and back direction and a station switching mechanism; a front guide rail and a back guide rail are arranged on the upper surface of the big plate, a first station is arranged on the front guide rail, a second station is arranged on the back guide rail, the first station comprises a first hot ironing station and a first cold ironing station, and the second station comprises a second hot ironing station and a second cold ironing station; the station switching mechanism comprises a driving device, the moving end of the driving device is fixedly connected with the big plate, and the big plate is driven to move in the front and back direction, so that the front guide rail or the back guide rail is in butt joint with a feeding station. The mechanism of the two hot ironing stations and the two cold ironing stations is adopted for switching of hot ironing and cold ironing, in this way, the space and cost of the mechanism are reduced, and efficiency is also improved.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

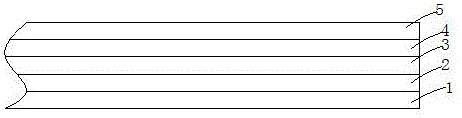

UV-energy-curing cold-ironing-technology alumite thermoprinting film

InactiveCN108819527AAvoid wastingSolve the problem of sticky bottomNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAcrylic resinSolvent

The invention discloses a UV-energy-curing cold-ironing-technology alumite thermoprinting film. The UV-energy-curing cold-ironing-technology alumite thermoprinting film comprises a base layer, a peeling layer, a color layer, an electroplated layer and a glue layer, wherein the base layer, the peeling layer, the color layer, the electroplated layer and the glue layer are sequentially connected; theglue layer comprises UV glue; the UV glue is prepared from, by weight, 65-80 parts of polyurethane acrylic resin, 15-30 parts of vinyl resin, 10-30 parts of pure solid acrylic resin, 5-10 parts of adhesion promoter, 25-45 parts of solvent, 5-10 parts of initiating agent and 1-5 parts of assistant. According to the alumite thermoprinting film, when the UV glue is cured, a easy-to-peel alumite foilfilm after being peeled is not required to conduct synchronous delivering, the corresponding film use length of a peeling-easy alumite foil film corresponding to a part which is not required to be coldly ironed in the film feeding direction can be wound or stop to be delivered through a foil film rewinding device at this moment, the next step is not required to continue to be carried out, possible waste of the peeling-easy alumite foil film in the next step can be effectively avoided, and thus the production cost is greatly reduced.

Owner:江苏良玉激光新材料有限公司

Overprinting method for performing secondary printing on cold-ironing film

InactiveCN109049968ASave handling timeLabor savingRotary pressesPrinting press partsManufacturing lineDirect production

The invention discloses an overprinting method for performing secondary printing on a cold-ironing film. According to the overprinting method for performing secondary printing on the cold-ironing film, an equipment shell, a first gluing device, a first printing device, a first drying device, a first separation device, a second gluing device, a second printing device, a second drying device, a second separation device, a material receiving device and an emptying device are provided; the emptying device is arranged on one side of the internal part of the equipment shell; the emptying device is fixedly connected with the equipment shell; the first gluing device is arranged on one side of the emptying device; and the first gluing device is fixedly connected with the equipment shell. Accordingto the overprinting method for performing secondary printing on the cold-ironing film, overprinting of secondary printing is directly connected with one side printing to form an automatic production line; after positioning of the secondary printing is adjusted simply, products can be directly produced, the carrying time of materials after primary printing is saved, the positioning adjusting time of the secondary printing after primary printing is saved, the labor force is greatly reduced and the production efficiency of the products is improved.

Owner:HANGZHOU WEICHENG PRINTING

A cold ironing device and method for saving cold ironing foil

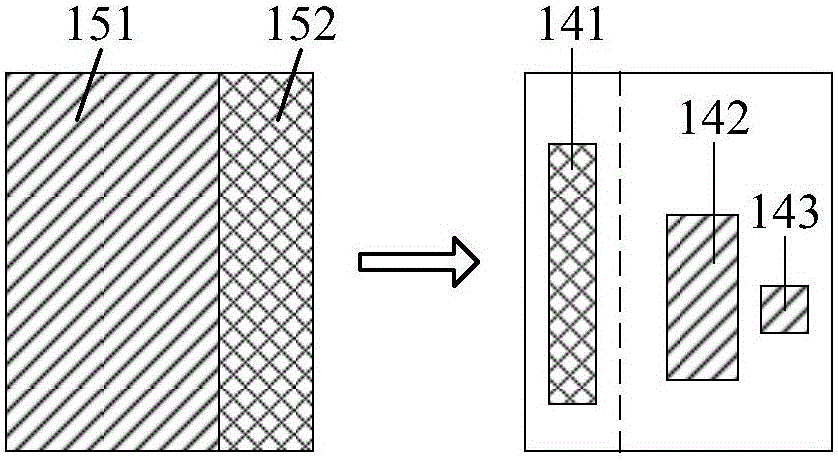

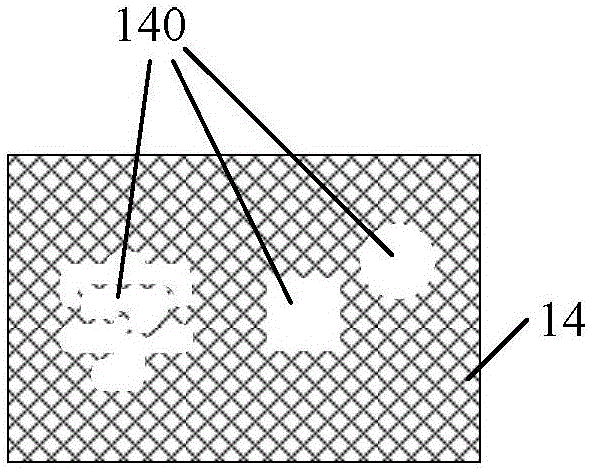

ActiveCN103264575BIncrease the lengthShorten the lengthRotary pressesBronze printingPulp and paper industryMotive power

The invention discloses a cold wave device and a method for saving cold wave foils. The cold wave device comprises a foil supply roller, a foil withdrawing roller, a rubber roller, an impressing roller, a motive power roller, a regulating mechanism, a support frame and a controller, wherein rubber cloth and rubber cloth interleaving paper in the shape corresponding to patterns to be transferred are arranged on the rubber roller, and the rubber cloth covers the rubber roller and the rubber cloth interleaving paper. According to the invention, the rubber cloth interleaving paper in the shape corresponding to the patterns to be transferred is arranged on the rubber roller, when the part of the rubber roller without the rubber cloth interleaving paper rotates to a position in press fit with the cold wave foils, the motive power roller tightly clamps the cold wave foils so that the conveying of the cold wave foils between the rubber roller and the impressing roller stops. Meanwhile, the length of a cold wave foil supply part is prolonged by the regulating mechanism, and the length of a cold wave foil withdrawing part is shortened by the regulating mechanism, so when the cold wave foils do not need to be impressed on the paper, the transferring of the impressing part of the cold wave foils stops, the paper feeding speed, the foil supply speed and the foil withdrawing speed cannot be influenced, the production efficiency is ensured, and the cold wave foils are saved.

Owner:SHENZHEN JINJIA GRP +1

Combined printing machine

The invention relates to the technical field of printing machines, in particular to a combined printing machine. The combined printing machine comprises an unwinding unit, a paper feeding unit, an offset print printing unit, an offset print ink unit, a die cutting unit, a waste discharging unit and a rolling unit. The combined printing machine is suitable for printing adhesive stickers, coated paper, paperboards, aluminum foils, plastic films and other substrates. The machine adopts a unit type module combination manner and can be used for 4-8 color printing. Each color set can select any oneprinting manner from glue printing, flexible printing, silk printing and cold ironing. The overall machine adopts shaft-free transmission, an automatic registering system and a pre-registering systemare allocated, the registering accuracy at the high speed (150 m / min) is guaranteed, the rejection rate is low, and the combined printing machine is ideal equipment for printing various high-middle grade daily use chemical products, wine labels, medicine labels, packaging boxes, self-adhesive labels and the like.

Owner:景德镇市中景印机有限公司

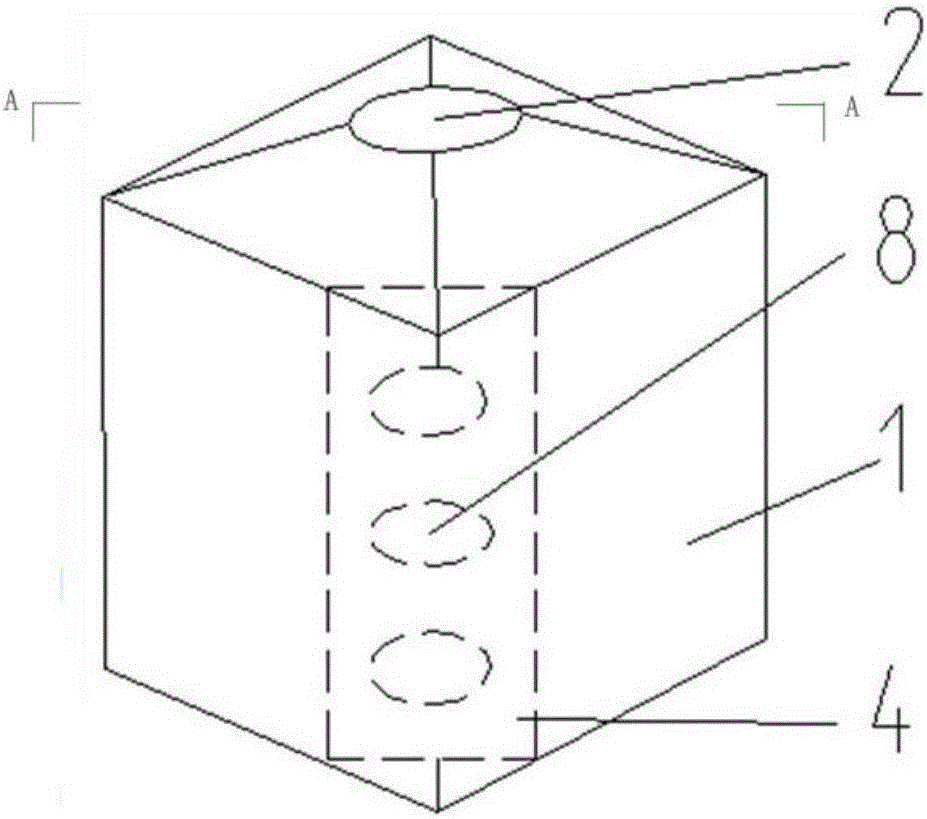

Aluminum foil flexible intermediate bulk container with inner tie bar

InactiveCN105857964AGuaranteed molding effectImprove airtightnessLarge containersEngineeringAluminum foil

The invention discloses an aluminum foil flexible intermediate bulk container with an inner tie bar. The aluminum foil flexible intermediate bulk container comprises a bag body, wherein a feeing inlet is formed in the upper end of the bag body; a discharging outlet is formed in the lower end of the bag body; the bag body comprises an inner bag and an outer bag; the outer bag is a plastic woven bag; the inner bag is made of an aluminum film; and the inner tie bar is vertically arranged in the inner bag, propped against the four opposite angles inside the inner bag, and fixed in the inner bag in a cold ironing manner. The bag body composed of the plastic woven bag and the aluminum film is high in impermeability, good in barrier property and excellent in anti-swelling property, and the bag type meets transportation requirements; through the inner tie bar arranged in the aluminum foil flexible intermediate bulk container, the molding effect of the aluminum foil flexible intermediate bulk container is guaranteed and a plenty of space is saved, so that the aluminum foil flexible intermediate bulk container can be utilized for transportation of small-particle and fine powder cargos as well as cargos with high sanitary requirements, and the application range of the aluminum foil flexible intermediate bulk container is expanded; and the inner tie bar is fixed in the bag body by adopting the cold ironing technology, so as to solve the problem that the inner tie bar cannot be additionally mounted in the bag body.

Owner:SHIJIAZHUANG NEW GOLD ALUMINUM PACKAGING CO LTD

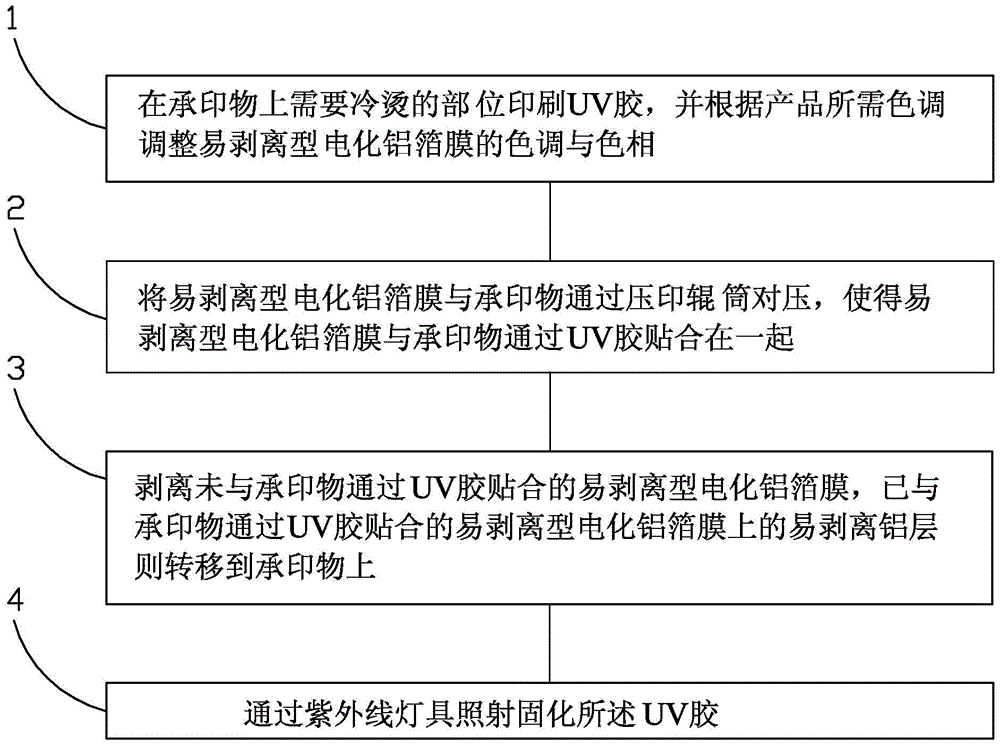

Cold perm process and uv glue used in this process

ActiveCN103770486BAvoid wastingSolve the problem of sticky bottomPolyureas/polyurethane adhesivesOther printing apparatusUltravioletEngineering

Owner:SHENZHEN BAIXINGLONG CREATIVE PACKAGING

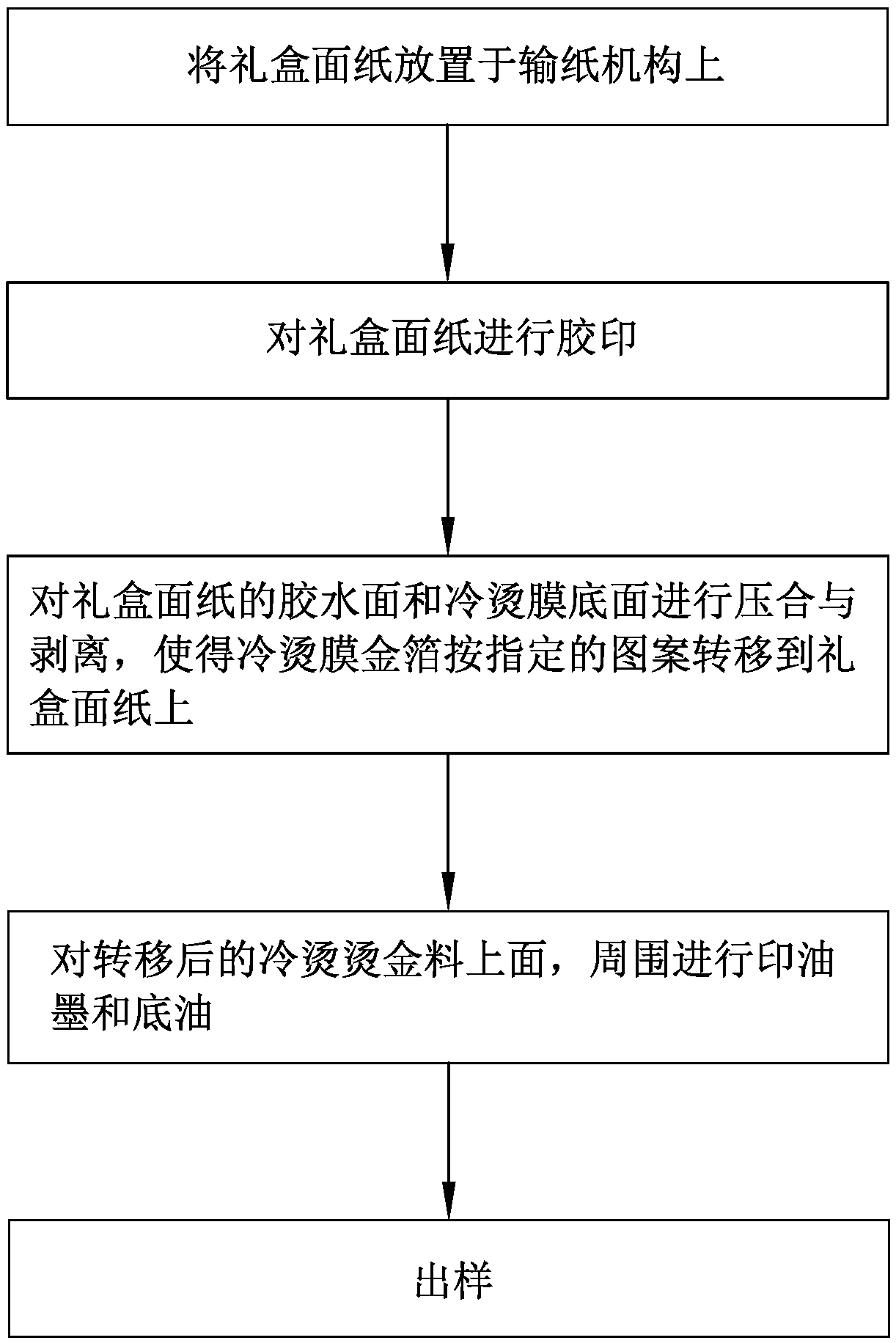

Gift box packing cold-ironing device and processing technology thereof

InactiveCN108909171AAvoid blushingRealize in-line printingRotary pressesHot stampingPulp and paper industry

The invention discloses a gift box packing cold-ironing device and a processing technology thereof. The gift box packing cold-ironing device comprises a paper delivering mechanism, a glue water printing mechanism, a cold-ironing film transferring mechanism, an oil ink printing mechanism and a paper collecting mechanism; the paper delivering mechanism is connected with the glue water printing mechanism through a conveying belt; and the glue water printing mechanism, the cold-ironing film transferring mechanism, the oil ink printing mechanism and the paper collecting mechanism are in rolling connection. The problems of gold flying, gold dropping, powder dropping, deckle edges and reverse pulling in hot stamping are solved, circumstances of stamping ink piling and inaccurate registration printing alignment in a printing process are improved, the problem of white marks after film covering is avoided, meanwhile, line printing is realized by cold ironing, the capacity is greatly improved, the labor is reduced, and the cost is saved.

Owner:SHENZHEN YUTO PACKAGING TECH

Cold ironing film

InactiveCN106515247AReduce the cost of plate makingHigh stamping precisionNatural rubber adhesivesNon-macromolecular adhesive additivesSurface layerStearic acid

The invention relates to a cold ironing film. The film comprises a PET thin film, the PET thin film is coated with a release layer, the release layer is coated with a coloring layer, a laser layer is arranged on the coloring layer in a mould pressing manner, a vacuum aluminizing layer is arranged on the laser layer, and is coated with gum, and the material of the gum comprises, by weight, 80 parts of natural rubber, 20 parts of butadiene rubber br9000, an auxiliary material and an addition agent; the auxiliary material comprises, by weight, 5 parts of indirect zinc oxide, 1 part of stearic acid, 0.2 part of coumarone resin and 7 parts of solar oil Sunpar2280; the strength of the gum on the surface layer of the cold ironing film is high, and impact resistance is achieved.

Owner:谢志明

Full-automatic production equipment of bubble cap capsule stitching for bag making and working method thereof

InactiveCN108819345AReduce laborChange the way of manual workBag making operationsPaper-makingOperation modeEngineering

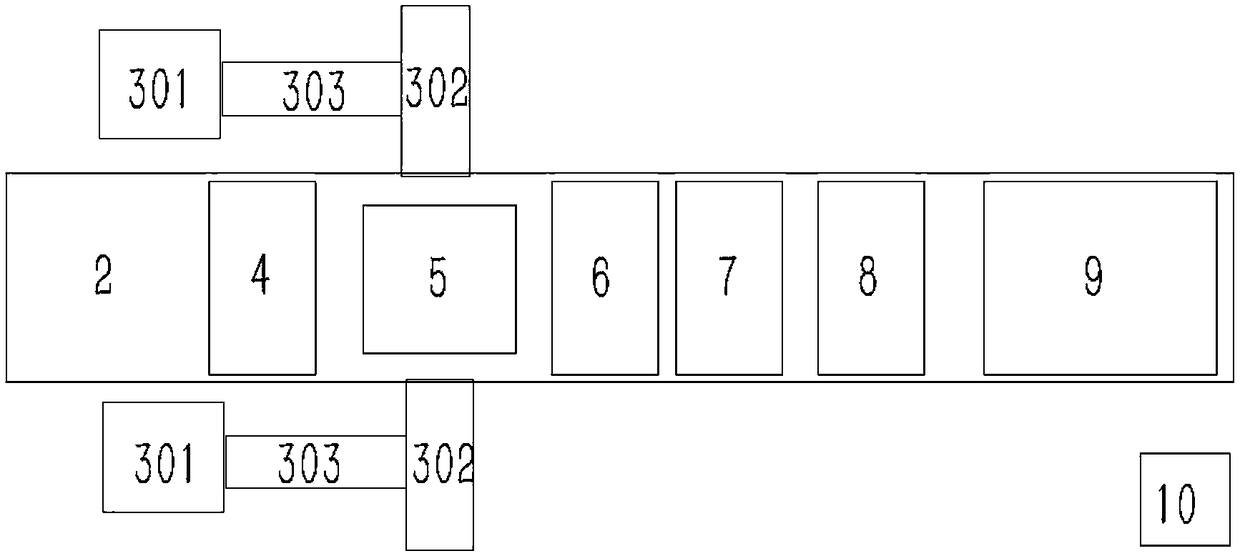

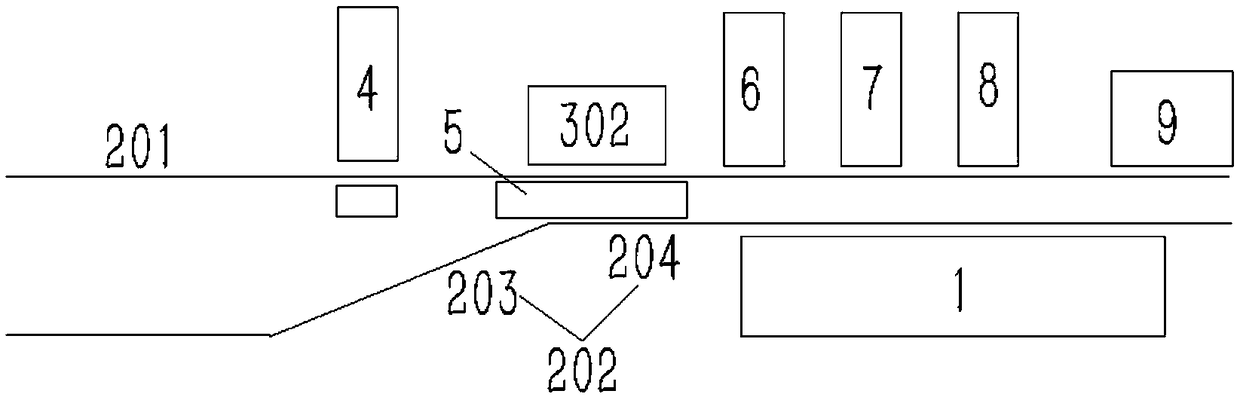

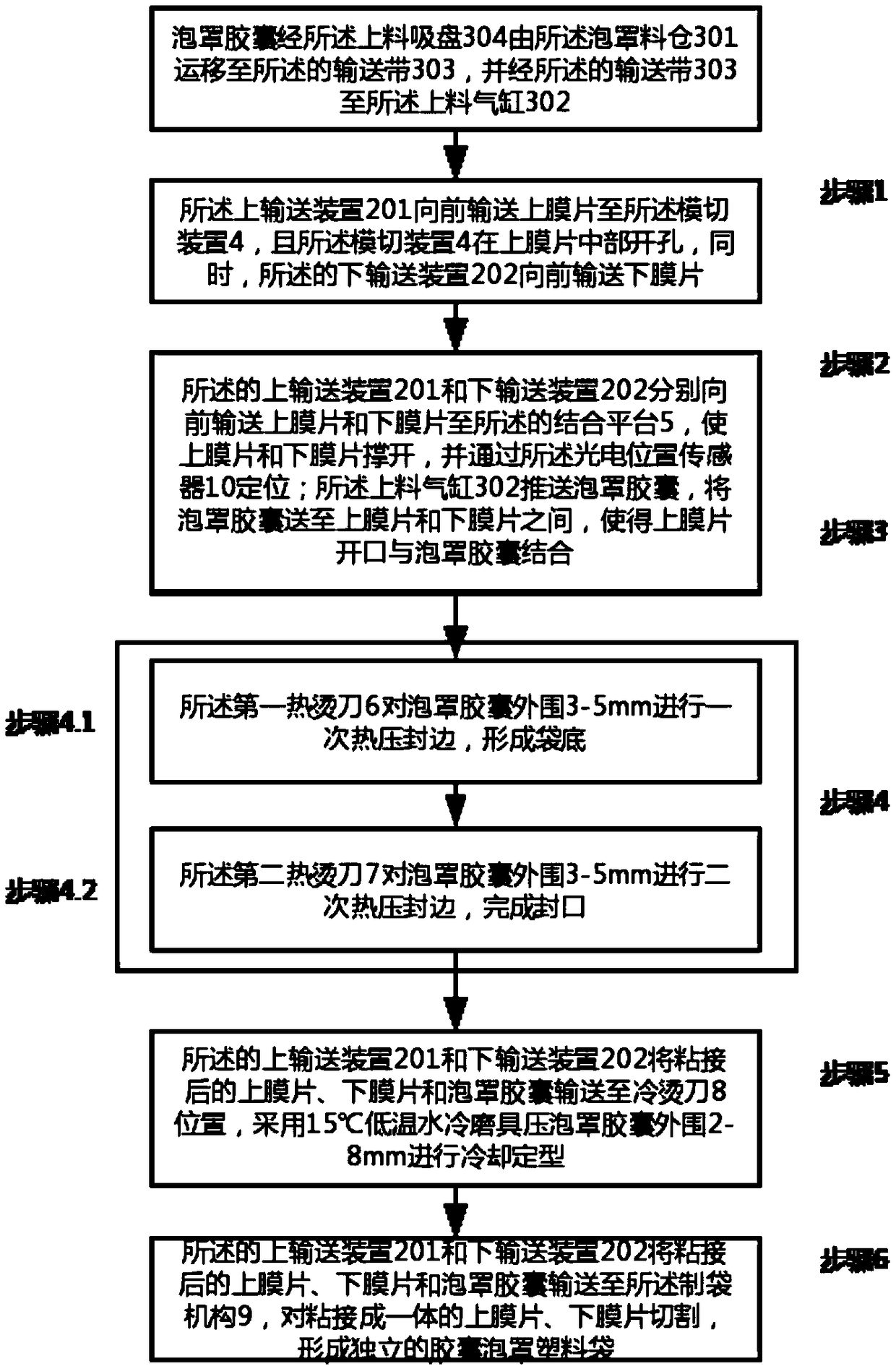

The invention discloses full-automatic production equipment of bubble cap capsule stitching for bag making, and meanwhile discloses a working method of the full-automatic production equipment of bubble cap capsule stitching for bag making. The full-automatic production equipment comprises a rack and further comprises a conveying device, a bubble cap feeding mechanism, a die cutting device, a combined platform, a first hot ironing knife, a second hot ironing knife, a cold ironing knife and a bag making mechanism which are arranged on the rack. The full-automatic production equipment has the beneficial effects that conveying, die cutting, combining, sealing and bag making work of upper diaphragms, lower diaphragms and capsule bubble caps is completed automatically, a traditional manual operation mode is changed, on the one hand, the labor amount of operating workers is greatly lowered, and on the other hand, rapid production is achieved to improve the production efficiency.

Owner:雅珂迪包装科技(苏州)有限公司

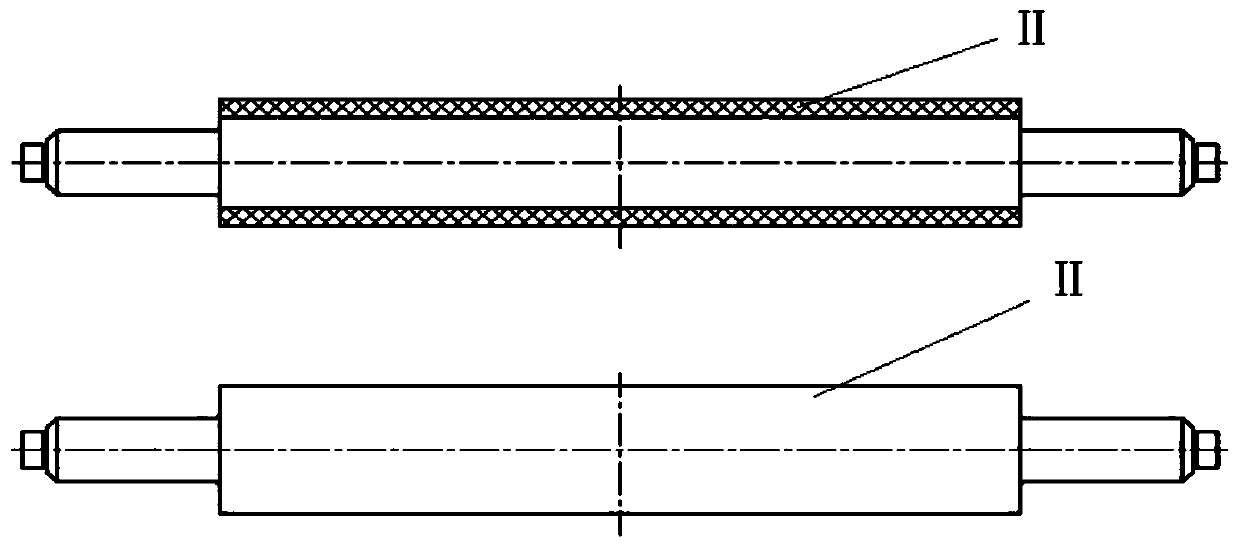

Deviation preventing roller and deviation preventing system formed same

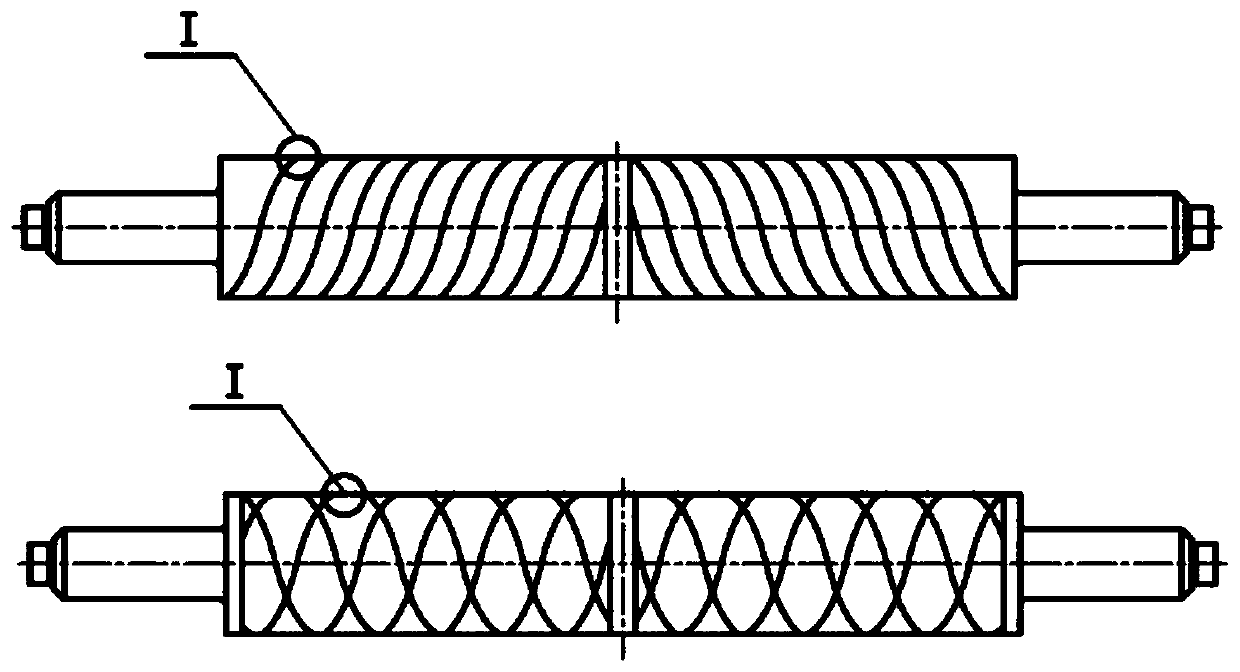

ActiveCN110370787ASimple structurePrevent lateral driftRotary pressesPrinting press partsManufacturing technologySurface layer

The invention discloses a deviation preventing roller. The surface of the deviation preventing roller is coated with an elastic surface layer. The deviation preventing roller forms a structure of bilateral symmetry with the middle line as the boundary. On each side, starting from the middle line of the deviation preventing roller, one ring-shaped deviation preventing structure is arranged in the elastic surface layer of the deviation preventing roller every preset distance. The ring-shaped deviation preventing structures are ring-shaped flesh cuts formed in the elastic surface layer. Only fresh cut lines are formed on the elastic surface layer. The elastic surface layer keeps smooth without pits. The invention further discloses a deviation preventing system provided with the deviation preventing roller. The deviation preventing roller is applicable to various kinds of printing equipment, and is simple in structure, simple in manufacturing technology, low in manufacturing cost and convenient to popularize. The deviation preventing roller and the deviation preventing system particularly have the best effect of being used in electrification aluminum foil in the cold ironing printing process, side deviation of the electrification aluminum foil can be effectively prevented, then the printing quality of printed products is improved, and flaw printed products are prevented from beingproduced.

Owner:SHANGHAI YOCO PRINTING MACHINERY

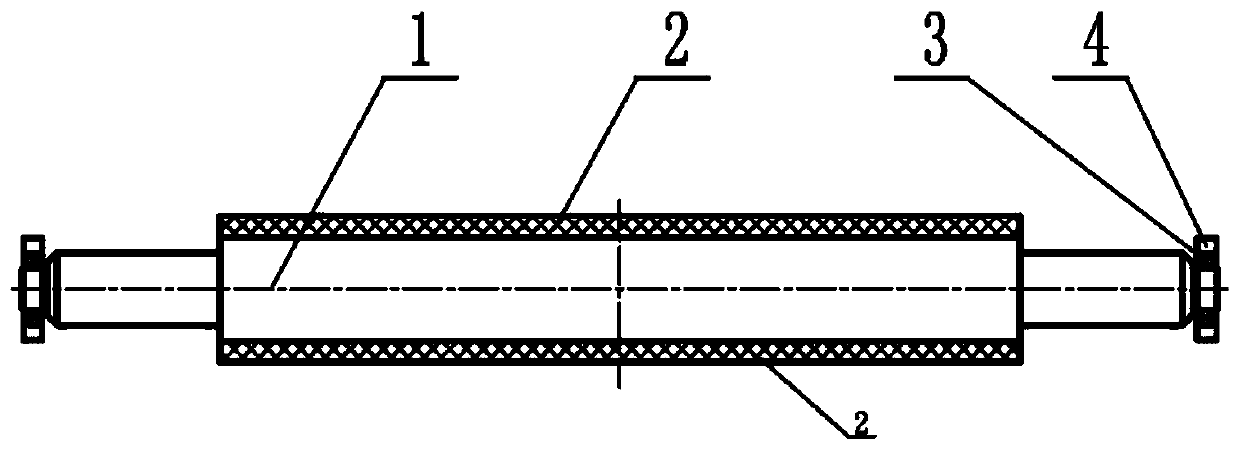

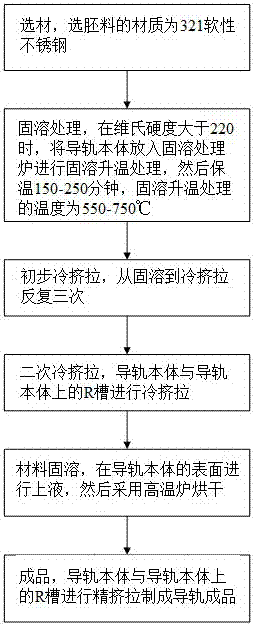

A manufacturing process of special guide rails for stacking freezers

The invention discloses a manufacturing process of a special guide rail for a stacking refrigerator, which comprises the following specific steps: material selection, solid solution treatment, primary cold extrusion, secondary cold extrusion, material solid solution and finished product. Through the above method, the manufacturing process of the special guide rail for stacking refrigerators provided by the present invention uses stainless steel as the material to save costs, but the strength of stainless steel cannot be enhanced by hot rolling and other means, and the stainless steel material of the guide rail is strengthened by cold extrusion The surface hardness increases the wear resistance and prolongs the service life, thereby ensuring the quality of the product.

Owner:常熟市南方不锈钢链条有限公司

Cold-ironing type gold stamping mechanism

ActiveCN102717616BExact matchLow input costBronze printingRotary pressesRoom temperatureUltraviolet lights

A cold-ironing type gold stamping technology comprises the steps as follows: printing material with a layer of glue coated on pictures and texts and aluminum foil material are processed through rotary rolling combination, ultraviolet light box irradiation and rotary rolling stripping; an aluminum foil is imprinted on the corresponding pictures and the texts on the printing material due to the rolling combination and the sticking action of glue; and then room temperature cold-ironing operation is carried out under the ultraviolet light irradiation, and the printing material with the pictures and the texts achieving gold stamping effect is obtained finally. A cold-ironing type gold stamping mechanism of the cold-ironing type gold stamping technology adopts the structure as follows: an aluminum foil unreeling device and a scrap material winding are arranged at the upper part between a front wallboard and a rear wallboard, and a rotary rolling combination device and a rotary rolling stripping device are respectively arranged at the lower part between the front wallboard and the rear wallboard through a combination stripping wallboard; an ultraviolet light box is arranged between the rotary rolling combination device and the rotary rolling stripping device; and the combination stripping wallboard is connected with a simultaneous movable transmission device through a lower guide rail sliding block. The cold-ironing type gold stamping technology and the cold-ironing type gold stamping mechanism can accurately achieve the matching of cold stamping pressure time and cold stamping temperature, and improve the stamping fastness and the definition of a graphic profile, as well as the printing effect and the printing quality.

Owner:ZHEJIANG WEIGANG TECH CO LTD

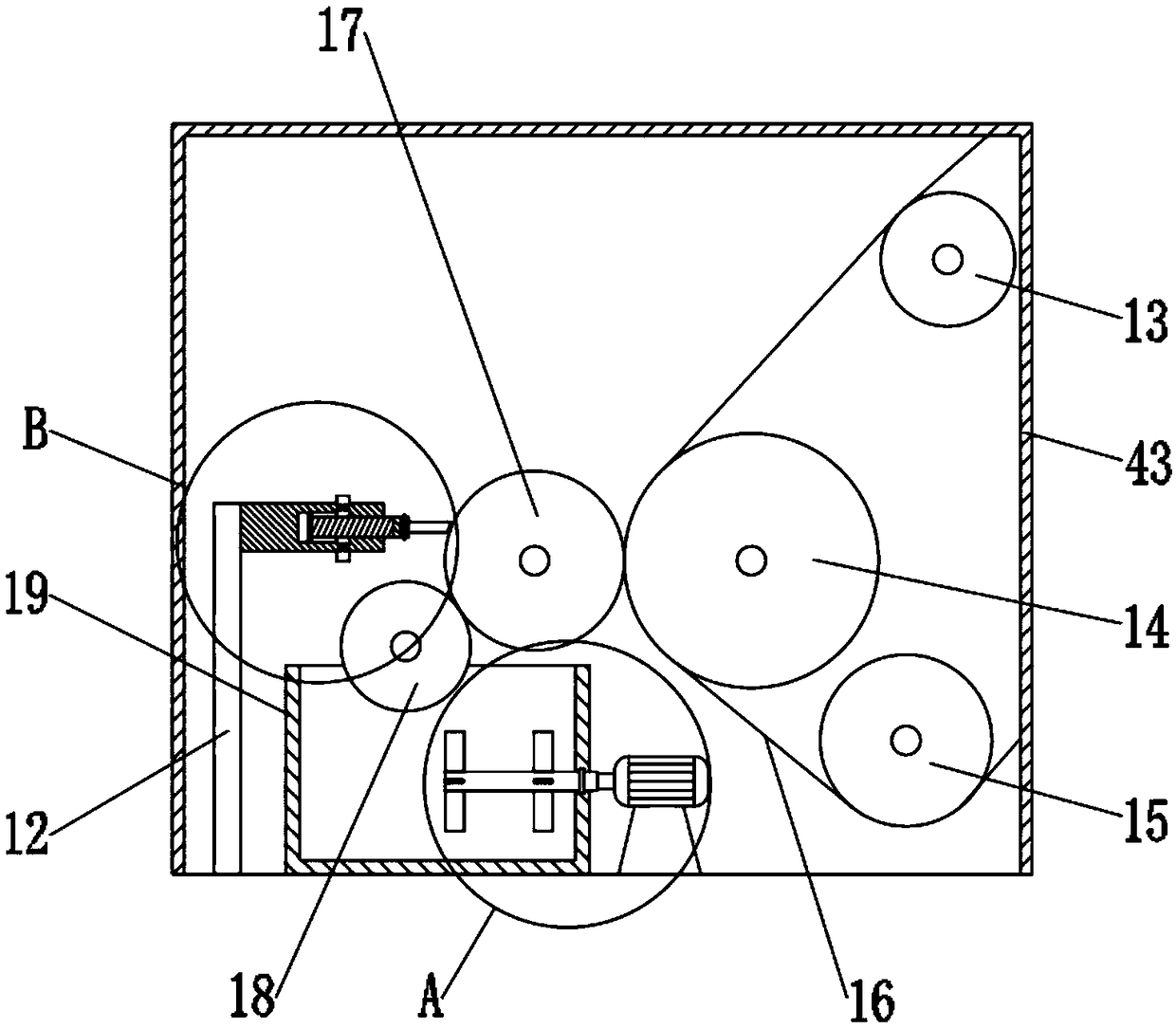

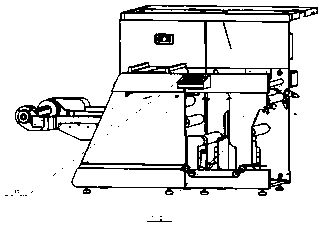

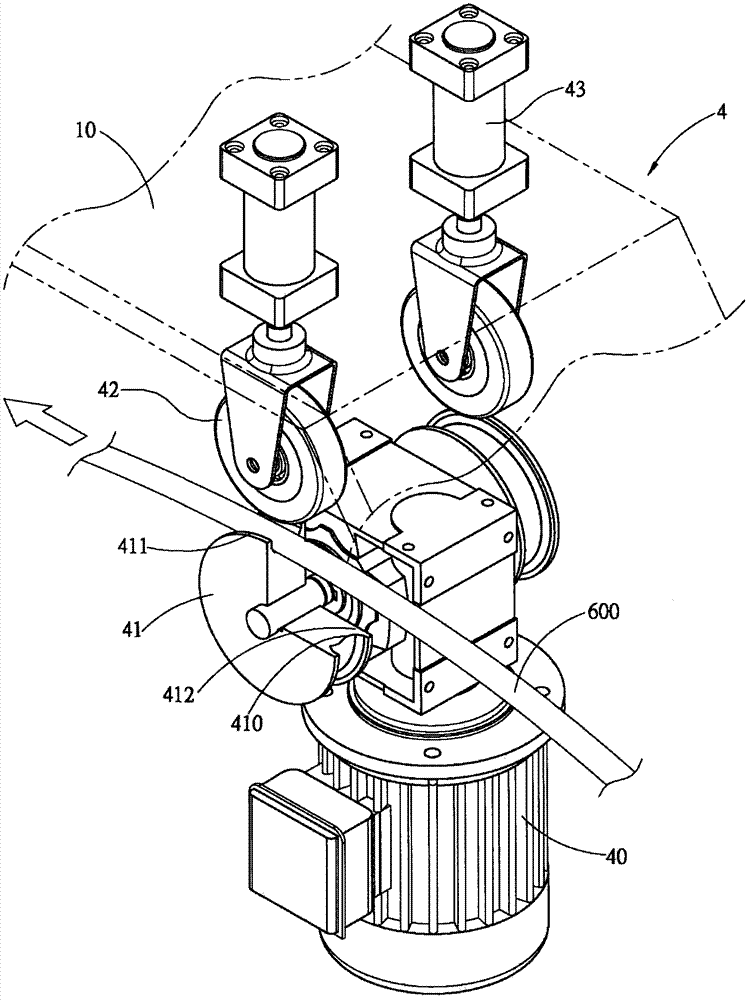

A rotary wheel type automatic cold ironing machine

ActiveCN106515208BIntegrity guaranteedCompact structureRotary pressesBronze printingHot stampingEngineering

Owner:万军霞

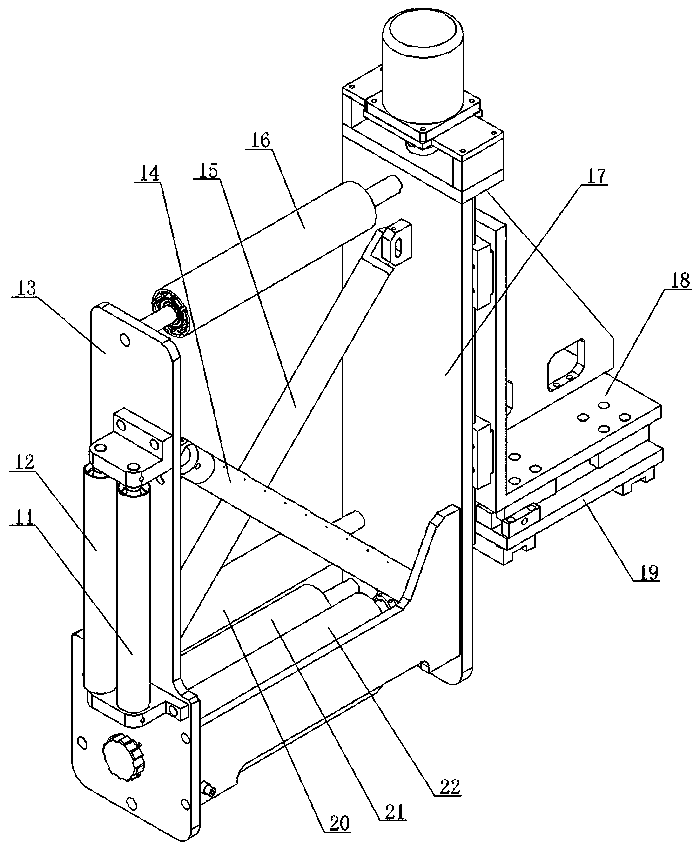

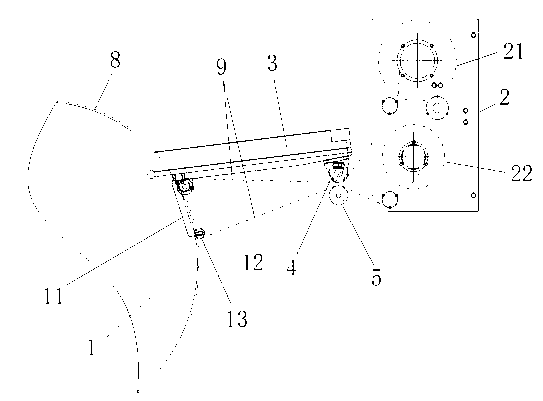

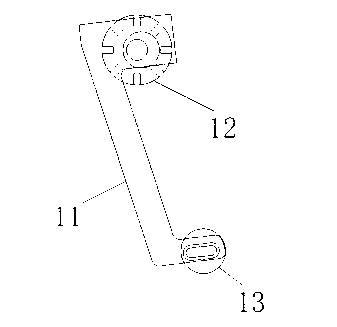

Flexo printing machine removable manipulator platform

ActiveCN105172327BSimple structureScreen printersRotary letterpress machinesScreen printingMovable type

The invention discloses a removable manipulator platform for a flexo printing machine, which is characterized in that it is composed of a cold ironing manipulator part, a laminating manipulator part, a varnish manipulator part, a die-cutting manipulator part, a screen printing manipulator part and an anti-printing manipulator part. The manipulator parts are set freely on the lateral guide rails above the printing unit of the flexo printing machine. The manipulator parts include lateral sliding plates, vertical sliding plates and vertical sliding plates. On the horizontal sliding plate, the vertical sliding plate is slidably arranged on the vertical sliding plate through the vertical sliding rail assembly. The present invention is used in matching with flexographic printing machines, and can be moved to the working position individually or in multiple combinations to perform the manipulator action during operation, so that the flexographic printing machine can arbitrarily and selectively carry out cold foiling, lamination, lightening, etc. while performing flexographic printing. Oil, die cutting, silk screen, reverse printing and other actions greatly improve the application range of the flexo printing machine and simplify the equipment structure.

Owner:ZHEJIANG WEIGANG TECH CO LTD

Structural gold stamping membrane suitable for cold ironing, and production method and anti-counterfeiting method thereof

The invention discloses a structural gold stamping membrane suitable for cold ironing. The structural gold stamping membrane comprises base materials, a gum layer, release paper, a release layer, a metal clad layer and a color lump layer, wherein the release layer is coated on the first surface of the base materials; the metal clad layer is positioned on the surface, which is not in contact with the base materials, of the release layer; the metal clad layer, the release layer and the base materials are provided with coincident penetration areas; the color lump layer is positioned between the second surface of the base materials and the gum layer and comprises color lumps with two or more than two colors; the release paper is positioned on the surface, which is not in contact with the color lump layer, of the gum layer. The structural gold stamping membrane can simplify a collection process and improve anti-counterfeiting reliability.

Owner:李峰 +1

Cloth Curtain Forming Machine

The invention discloses a cloth curtain sheet forming machine, and in particular provides a forming machine which has a hot working process of a preformed material belt of full-process sequential high and low temperature and whole-surface contact hot and cold ironing press and stably forms curtain sheets of which sections are provided with curves. The cloth curtain sheet forming machine comprises a hot ironing module, a cold ironing module and a hot working rail which is aligned and combined to be linear; one end of the hot working rail is fed with a glued cloth material belt by a feeding device; and the material belt is subjected to hot melt ironing press in a surface contact mode in the process of passing through the hot working rail, is subjected to cold ironing forming to stably form the curtain sheet of which the section is provided with the curve, and is output by an extraction device positioned at the other end.

Owner:崇竣实业股份有限公司

A fully automatic screen cold stamping machine

ActiveCN105856819BAvoid pollutionPrevent problems that easily cause substrate deformationTransfer printingFresh airEngineering

Owner:万军霞

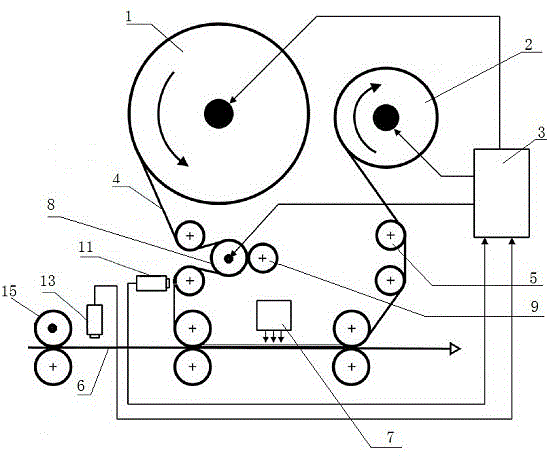

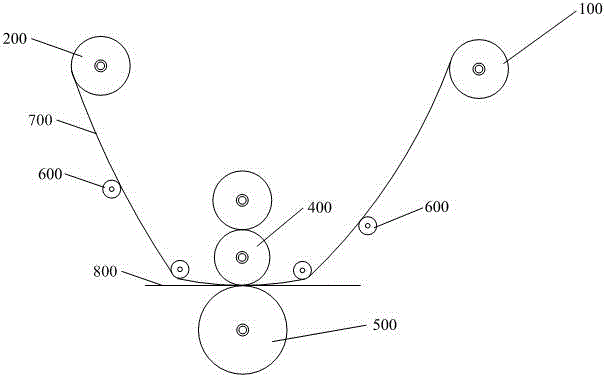

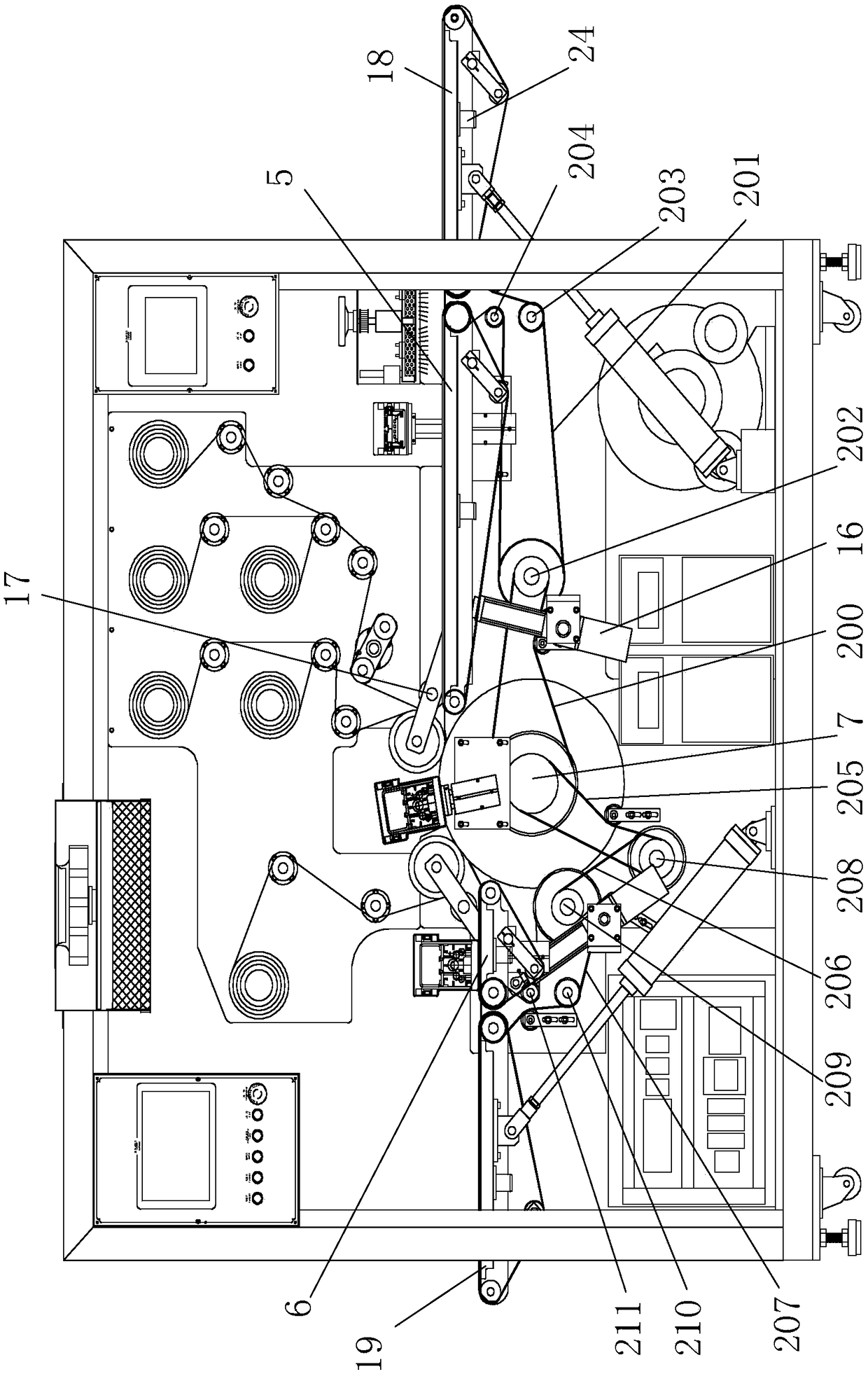

Satellite type rotating cold ironing device and cold ironing printing method

ActiveCN103171270ASolve the problem of inaccurate acceleration and deceleration alignmentTransfer printingDuplicating/marking methodsPaper recyclingDeformation Problem

The invention provides a satellite type rotating cold ironing device and a cold ironing printing method which is conducted according to the satellite type rotating cold ironing device. The cold ironing device comprises a printing return pulley. Main printing materials rotate along the printing return pulley. A rotatable composite wheel and a separating wheel abut the main printing materials against the printing return pulley. The cold ironing device further comprises a cold ironing supply shaft and a cold ironing paper recycling shaft. Cold ironing paper is guided to the composite wheel from the cold ironing supply shaft, is composited with the main printing materials on the printing return pulley and is recycled to the cold ironing paper recycling shaft through the separating wheel. The satellite type rotating cold ironing device and the cold ironing printing method solve a physical deformation problem of the cold ironing paper materials and increase anti-pulling capability and anti-deformation capability of the main printing materials.

Owner:韩文杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com