Cloth Curtain Forming Machine

A curtain sheet and forming machine technology, applied in the field of cloth curtain sheet forming machines, can solve the problems of inability to perform light level atmosphere, optical students are cold and dull, and achieve the effects of rapid production, simplified production process, and stable molding production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

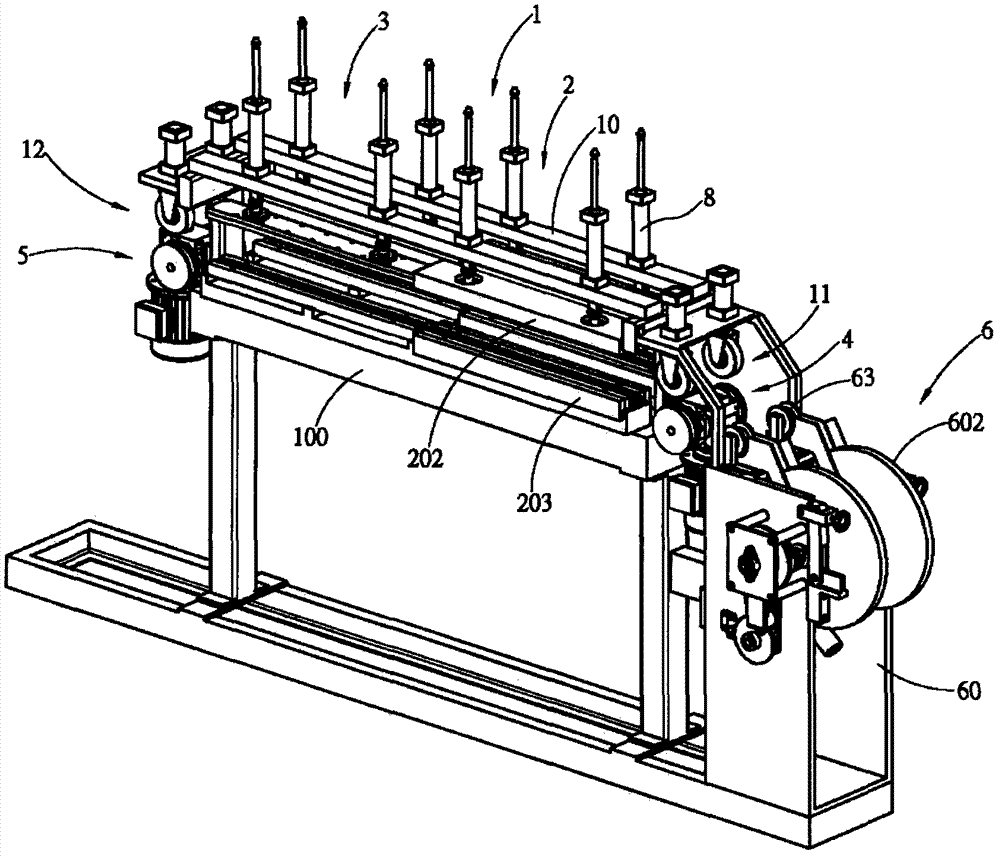

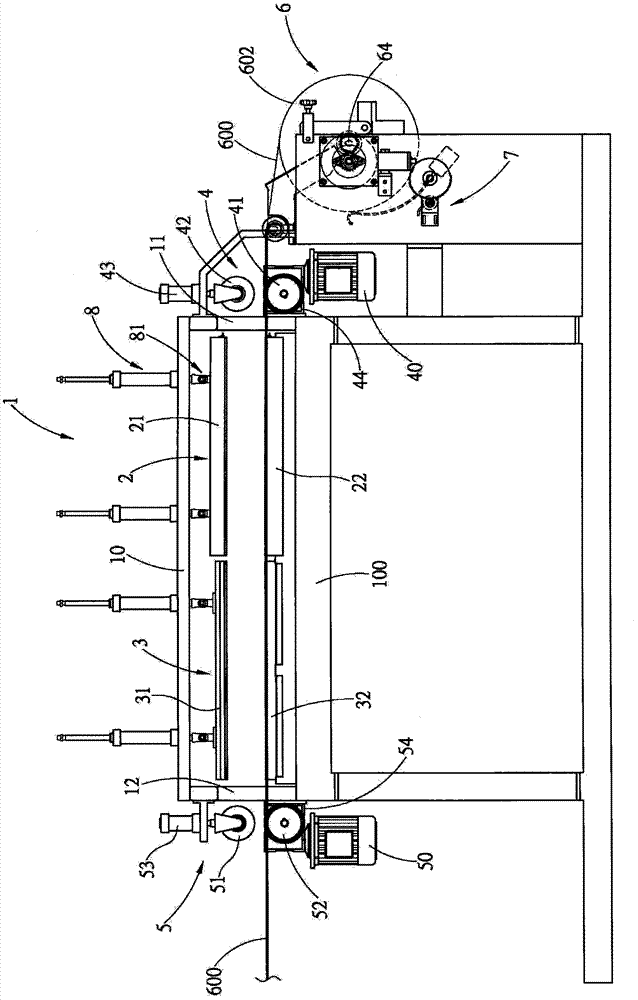

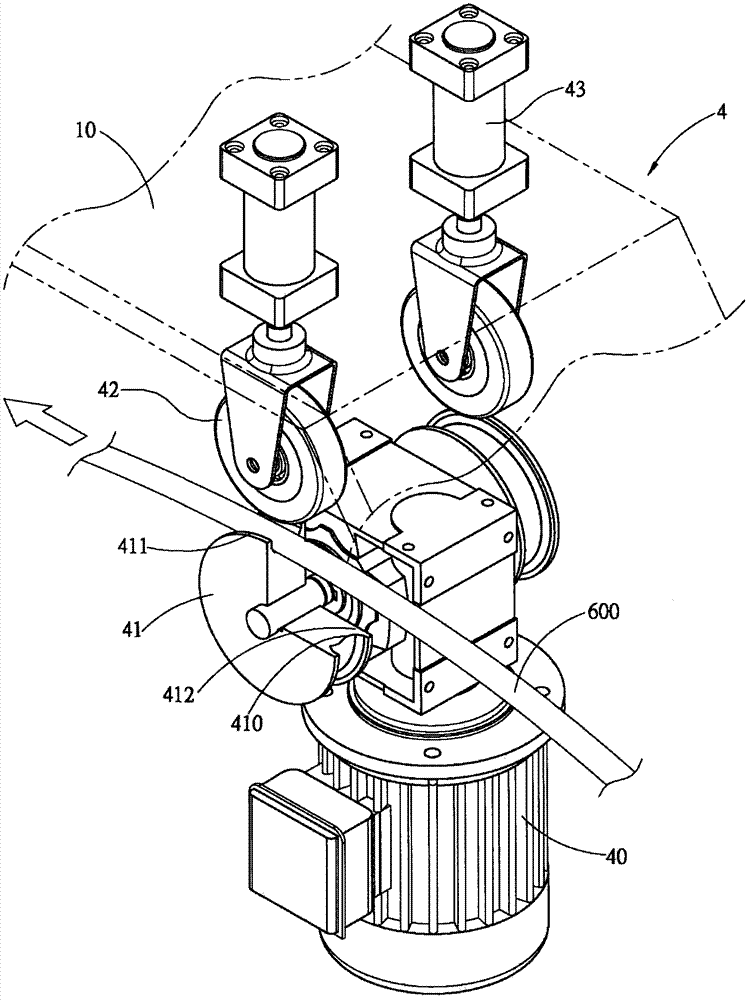

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this description, the principle of the present invention will be described through embodiments. Other aspects, features and advantages of the present invention will become clear at a glance through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings. Before describing the specific embodiments in detail below, for the convenience of reading, the specific symbols of each element in the drawings are arranged as follows:

[0050] Hot work track 1 frame 10 frame 100

[0051] Straddle seat 101 straddle pillow 102 positioning hole 103

[0052] Feeding port 11 Lifting port 12 Traversing slot 13

[0053] Ironing module 2 spreading path 20 template 201, 301

[0054] Heat insulation cover 202,203 upper module 21,31 lower module 22,32

[0055] Coupling ends 210, 220, 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com