Lithium battery fully automatic double-flanged forming machine and forming method

A technology of double-folding and lithium batteries, which is applied in battery assembly machines, secondary batteries, and secondary battery manufacturing. It can solve problems such as electrolyte leakage, wide battery width, and inability to meet product size requirements, so as to prevent leakage, The effect of meeting the product size requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

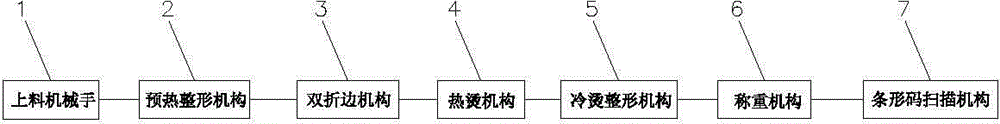

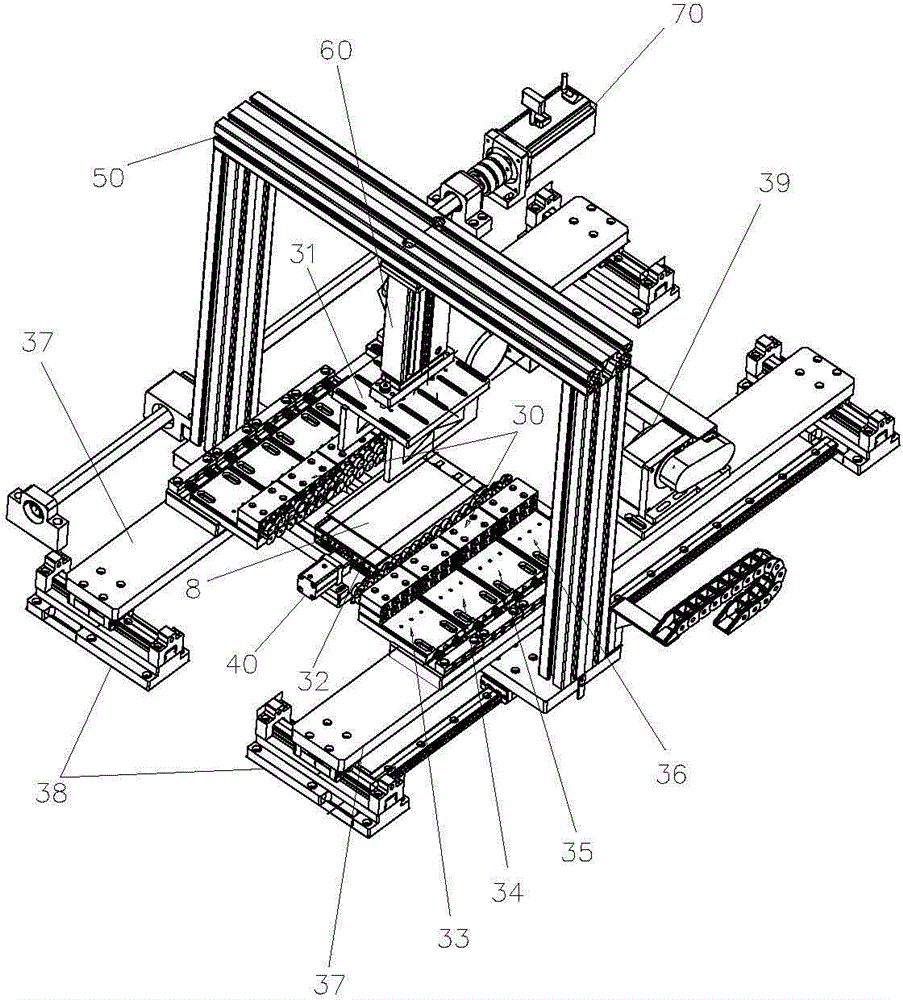

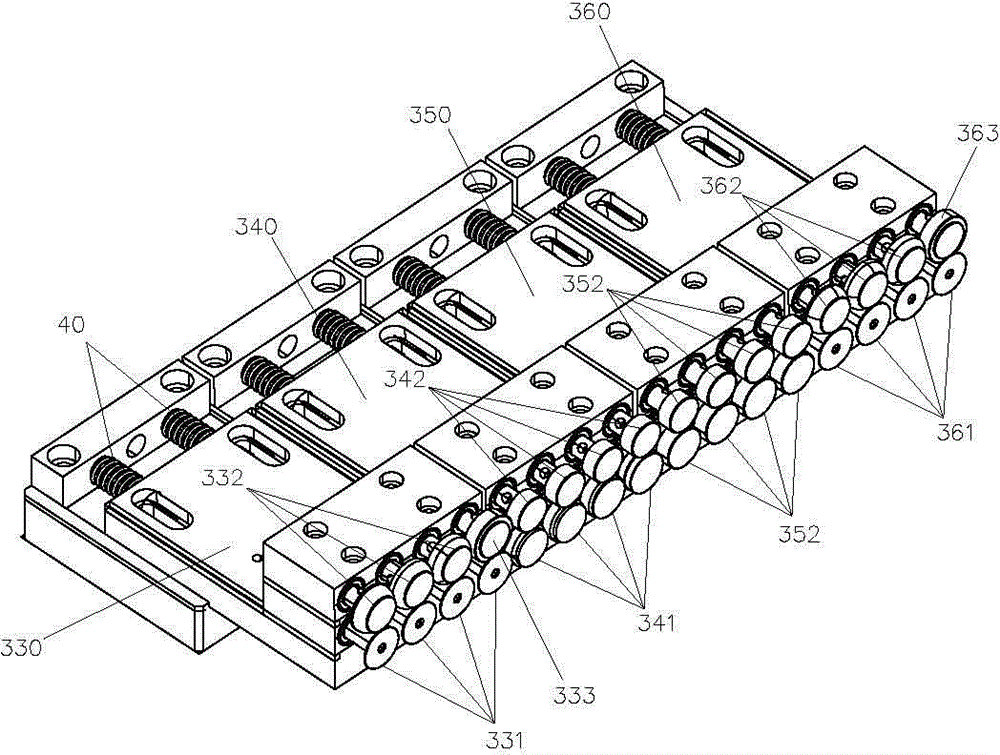

[0041] Such as Figure 1 to Figure 3 As shown, the lithium battery automatic double-folding forming machine of the present invention has a structure as follows: it includes a feeding manipulator 1, a preheating shaping mechanism 2, a double-folding mechanism 3, and a blanching mechanism 4 arranged in sequence from front to back. , cold perm shaping mechanism 5, weighing mechanism 6 and bar code scanning mechanism 7; The double folding mechanism 3 includes the battery clamp 32 that can move back and forth, the trimming device 31 that can move up and down; Lithium battery 8 is sandwiched in the battery The clamp 32 and the trimming device 31 are arranged above the battery clamp 32, and the left and right sides of the battery clamp 32 are symmetrically provided with a double-folding device 30 that can move left and right; the double-folding device 30 includes a first set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com