Cold ironing membrane for hose and production process of cold ironing membrane

A production process and technology of cold foiling film, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of the printing image falling off, insufficient adhesion of cold foiling film, affecting the packaging effect, etc., to improve the adhesion performance, suitable for large Scale application, the effect of promoting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

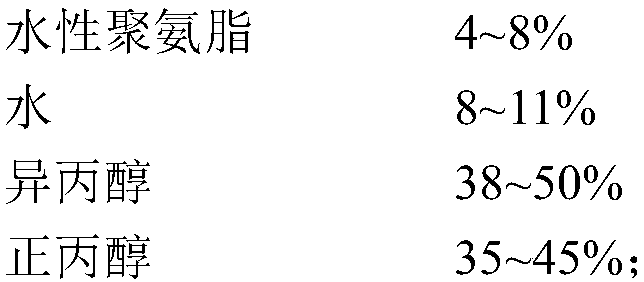

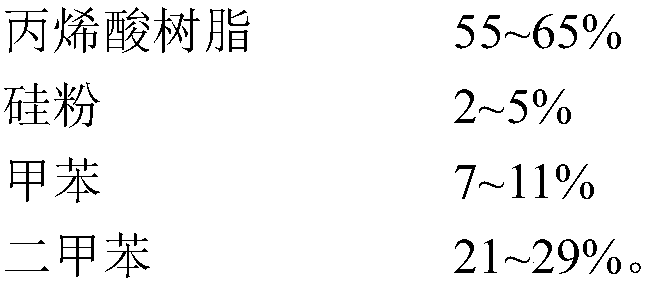

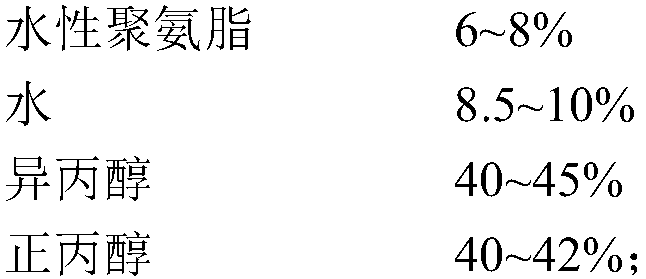

[0040] A cold ironing film for hoses in this embodiment includes a separation layer, a color layer, an aluminum coating layer and a medium layer that are laminated, wherein the separation layer is composed of the following raw materials in weight percentage: water-based polyurethane 4%, 11% of water, 45% of isopropanol, 40% of n-propanol; wherein, the color layer is made up of the following raw materials in weight percentage: 40% of acrylic resin, 55% of methyl ethyl ketone, 5% of n-butyl acetate; wherein, the medium layer is composed of The following components are composed in weight percent: 55% of acrylic resin, 5% of silicon powder, 11% of toluene, 28.97% of xylene, and 0.03% of auxiliary agent;

[0041] The production process of the cold perm film is as follows:

[0042] Step 1, preparation of separation layer ingredients: according to the weight percentage of each raw material in the separation layer of this embodiment, respectively weigh water-based polyurethane, water,...

Embodiment 2

[0049] A cold perm film for hoses in this embodiment includes a separation layer, a color layer, an aluminum coating layer and a medium layer that are laminated, wherein the separation layer is composed of the following raw materials in weight percentage: water-based polyurethane 8%, Water 8%, isopropanol 50%, n-propanol 44%; Wherein, color layer is made up of the raw material of following percentage by weight: Acrylic resin 49%, methyl ethyl ketone 45%, n-butyl acetate 6%; Wherein, medium layer is made of The composition of the following weight percentages: 65% of acrylic resin, 2% of silicon powder, 7% of toluene and 26% of xylene;

[0050] The production process of the cold perm film is as follows:

[0051] Step 1, preparation of separation layer ingredients: according to the weight percentage of each raw material in the separation layer of this embodiment, respectively weigh water-based polyurethane, water, isopropanol and n-propanol, and then add them to the first agitato...

Embodiment 3

[0058]A cold perm film for hoses in this embodiment includes a separation layer, a color layer, an aluminum coating layer and a medium layer that are laminated, wherein the separation layer is composed of the following raw materials in weight percentage: water-based polyurethane 5%, Water 9%, isopropanol 45%, n-propanol 40%; Wherein, color layer is made up of the raw material of following percentage by weight: acrylic resin 45%, butanone 52%, n-butyl acetate 3%; Wherein, medium layer is made of The following components by weight percentage are composed: 65% of acrylic resin, 3% of silicon powder, 8% of toluene and 24% of xylene;

[0059] The production process of the cold perm film is as follows:

[0060] Step 1, preparation of separation layer ingredients: according to the weight percentage of each raw material in the separation layer of this embodiment, respectively weigh water-based polyurethane, water, isopropanol and n-propanol, and then add them to the first agitator in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com