Cold perm process and uv glue used in this process

A process, cold stamping technology, applied in the direction of adhesives, printing, printing devices, etc., to achieve the effect of simple manufacturing process, lower production cost, and faster hot stamping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

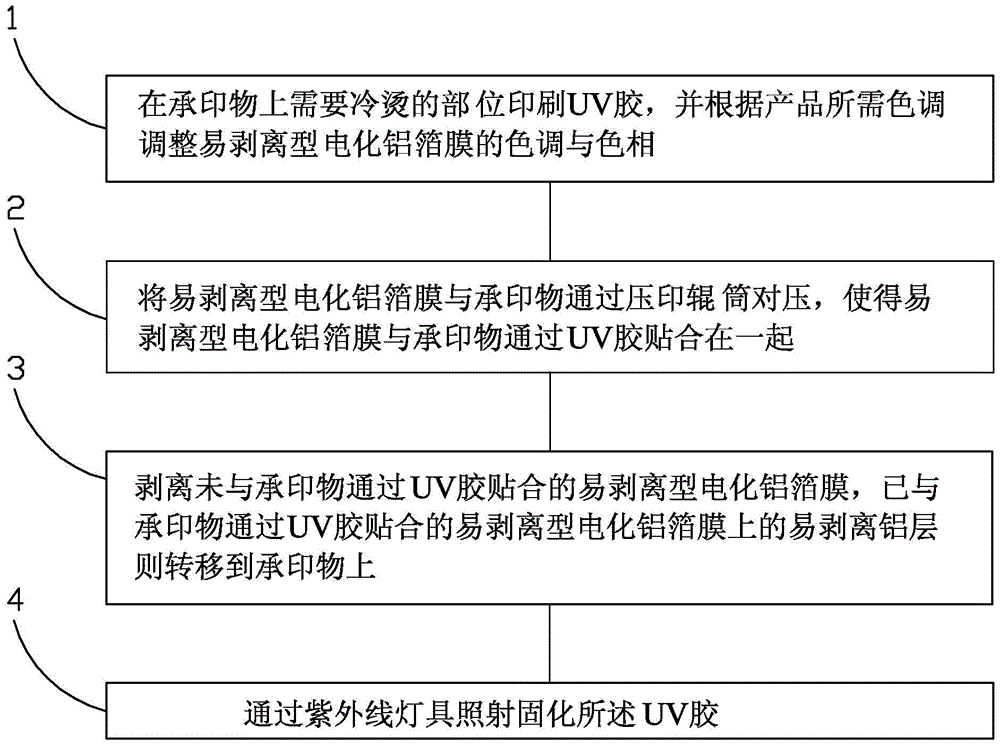

[0025] see figure 1 , the present invention provides a kind of cold perm technique, comprises the following steps:

[0026] Step 1. Print UV glue on the part of the substrate that needs to be cold stamped, and adjust the color tone and hue of the easy-peelable anodized aluminum foil film according to the color tone required by the product.

[0027] The weight components of the UV glue include: 70-80% polyurethane acrylic resin, 8-15% pure solid acrylic resin, 8-15% photoinitiator and 1-3% auxiliary agent, and, The viscosity of the UV glue is greater than 10Pa.s, and the fluidity is greater than 38mm 3 / s. Wherein, the surface of the substrate printed with UV glue can be: ordinary coated paper, gray-backed white paper, aluminum foil or alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com