Cold ironing film

A cold-foil film and film technology, applied in the direction of copying/marking, adhesive type, printing, etc., can solve the problems of insufficient adhesive strength on the surface of the cold-foil film, affecting the life and performance of the cold-foil film, and unrecognizable laser patterns, etc., to achieve The hot stamping area is large, the hot stamping precision is high, and the effect of wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

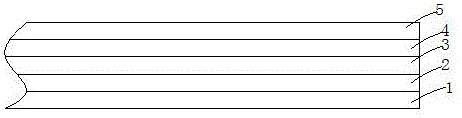

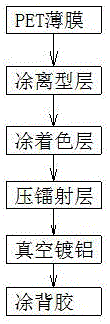

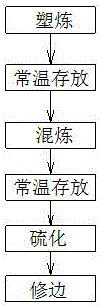

[0019] Such as figure 1 , figure 2 Shown, a kind of cold perm film, comprises PET film 1, is coated with release layer 2 on PET film 1, is coated with colored layer 3 on release layer 2, molded laser layer on the colored layer 3, the laser layer There is a vacuum aluminized layer 4 on the top, and the back glue 5 is coated on the vacuum aluminized layer 4. The coloring step in the coloring layer 3 is: first add the coloring solvent, then add the toner, stir for 10 minutes, and then add the coloring layer paint , when the ambient temperature is ≥ 25°C, stir for 1 hour, and when the ambient temperature is <25°C, stir for 1.5 hours; the proportion of resin and solvent must be accurate to 10g, the proportion of toner must be accurate to 1g, and the solid content of the paint should be controlled at 21 ±0.5%, the viscosity is controlled at 18±1 second; the coloring solvent is one of butanone, ethyl ester, propyl ester, butyl ester and ethanol.

[0020] As an improvement of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com