A solar cell composite material screen secondary stretching net reuse process

A technology of solar cells and composite materials, applied in printing plate preparation, printing, etc., can solve problems such as inability to change, waste, and screen scrapping, and achieve tension attenuation and screen shrinkage, save plate making costs, and reduce scrap rates. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

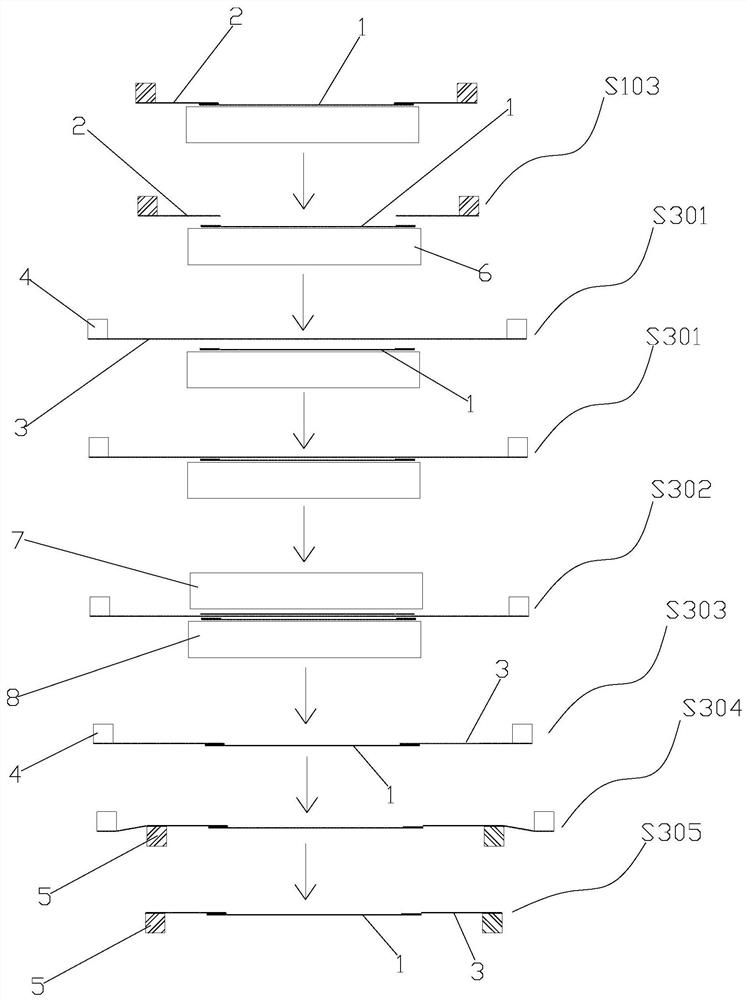

[0027] Such as figure 1 As shown, a solar cell composite material screen secondary stretching net reuse process includes the following steps:

[0028] S1, peeling off the old screen, using the plane peeling machine 6 to peel off the hot melt adhesive on the screen that needs to be reused, so that the stainless steel wire mesh 1 and the old polyester mesh 2 are separated;

[0029] S2, combined false frame production, prepare a new polyester net 3 and a fixed frame 4 (hollow aluminum frame), stick this new polyester net 3 on the fixed frame 4, new polyester net 3 and fix The frame 4 is combined into a combined false frame, specifically, the polyes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com