Preparation method of high tension coating for oriented silicon steel

A technology of oriented silicon steel and high tension, applied in the direction of coating, anti-corrosion coating, etc., can solve the problems of large-scale industrial application, complex production process, high technical requirements, etc., to achieve guaranteed coating effect, high bonding strength, Effect of anti-stripping insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

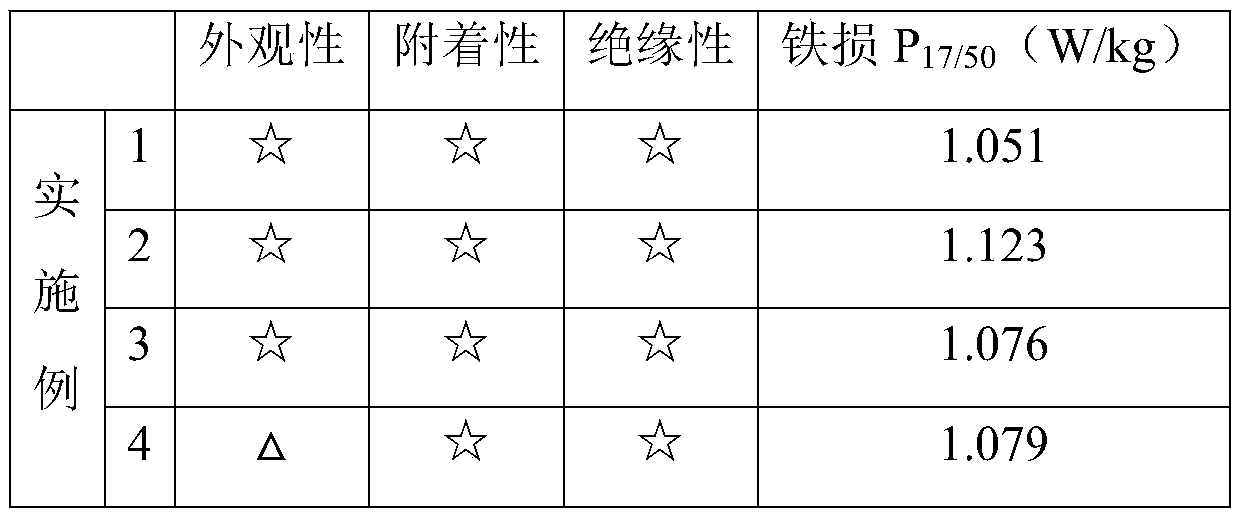

Embodiment 1

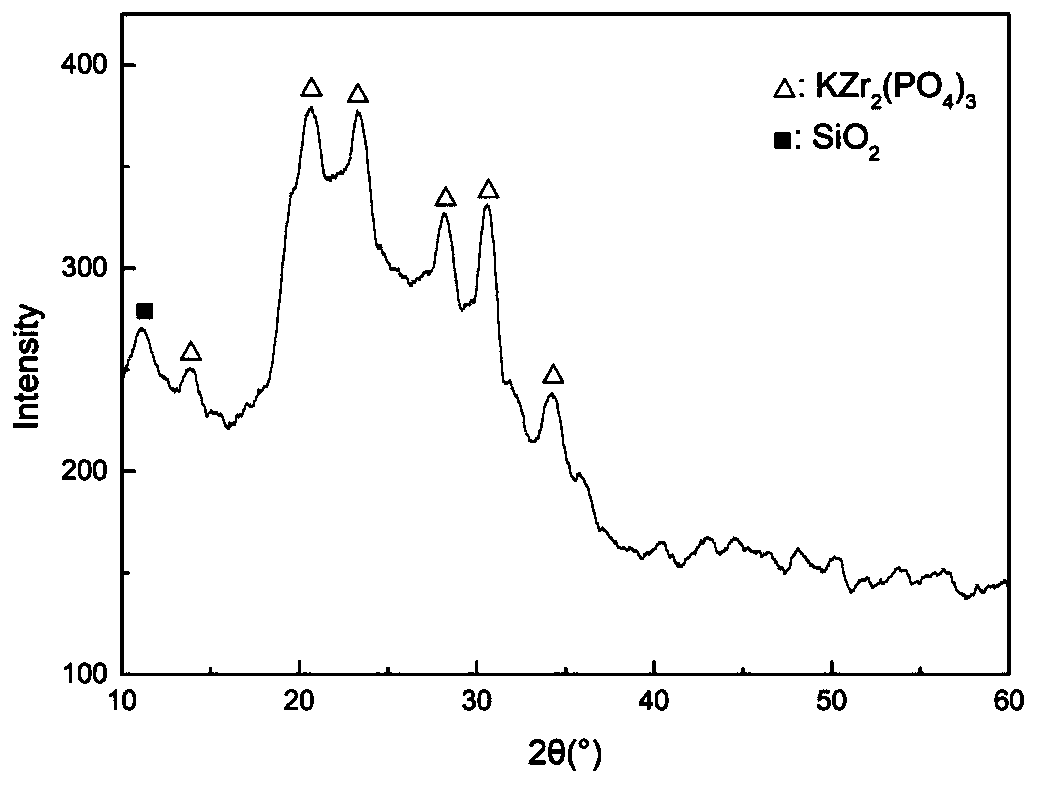

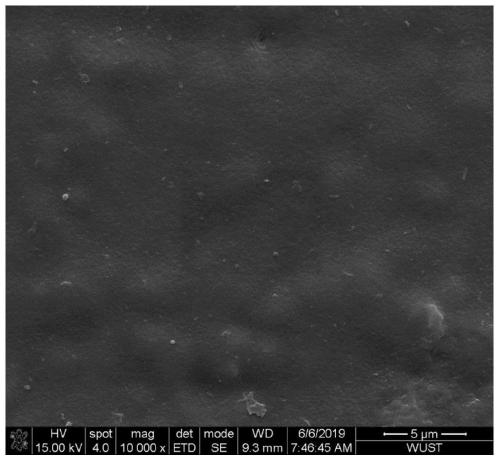

[0041] A method for preparing a high-tensile coating for oriented silicon steel. The steps of the preparation method described in this embodiment are:

[0042] Step 1. Determining the composition of the high tension coating solution for grain-oriented silicon steel

[0043] The components and contents of the high-tension coating solution for oriented silicon steel are: aluminum dihydrogen phosphate is 30-35 wt%, silica sol is 35-40 wt%, chromic anhydride is 2-2.5 wt%; potassium dihydrogen phosphate is 0.8-1.6 wt%, zirconium oxychloride 1.3-2.5 wt%, and deionized water 20-24 wt%.

[0044] Step 2. Preparation of High Tension Coating Solution for Oriented Silicon Steel

[0045] According to the components and content of the high tension coating solution for oriented silicon steel, first add the zirconium oxychloride into the deionized water, stir until dissolved to obtain a zirconium oxychloride solution; then add the phosphoric acid dichloride Add aluminum hydrogen, silica so...

Embodiment 2

[0049] A method for preparing a high-tensile coating for oriented silicon steel. The steps of the preparation method described in this embodiment are:

[0050] Step 1. Determining the composition of the high tension coating solution for grain-oriented silicon steel

[0051] The components and contents of the high-tension coating solution for oriented silicon steel are: aluminum dihydrogen phosphate is 35 to 40 wt%, silica sol is 25 to 30 wt%, chromic anhydride is 2.5 to 3.0 wt%; potassium dihydrogen phosphate is 1.6-2.4 wt%, zirconium oxychloride 2.5-3.8 wt%, and deionized water 22-26 wt%.

[0052] Step 2. Preparation of High Tension Coating Solution for Oriented Silicon Steel

[0053] According to the components and content of the high tension coating solution for oriented silicon steel, first add the zirconium oxychloride into the deionized water, stir until dissolved to obtain a zirconium oxychloride solution; then add the phosphoric acid dichloride Add aluminum hydrogen...

Embodiment 3

[0057] A method for preparing a high-tensile coating for oriented silicon steel. The steps of the preparation method described in this embodiment are:

[0058] Step 1. Determining the composition of the high tension coating solution for grain-oriented silicon steel

[0059] The components and contents of the high-tension coating solution for oriented silicon steel are: aluminum dihydrogen phosphate is 20-25 wt%, silica sol is 40-45 wt%, chromic anhydride is 3.0-3.5 wt%; potassium dihydrogen phosphate is 2.4-3.2 wt%, zirconium oxychloride 3.8-5.0 wt%, and deionized water 24-28 wt%.

[0060] Step 2. Preparation of High Tension Coating Solution for Oriented Silicon Steel

[0061] According to the components and content of the high tension coating solution for oriented silicon steel, first add the zirconium oxychloride into the deionized water, stir until dissolved to obtain a zirconium oxychloride solution; then add the phosphoric acid dichloride Add aluminum hydrogen, silica ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com