Patents

Literature

124results about How to "Satisfy insulation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

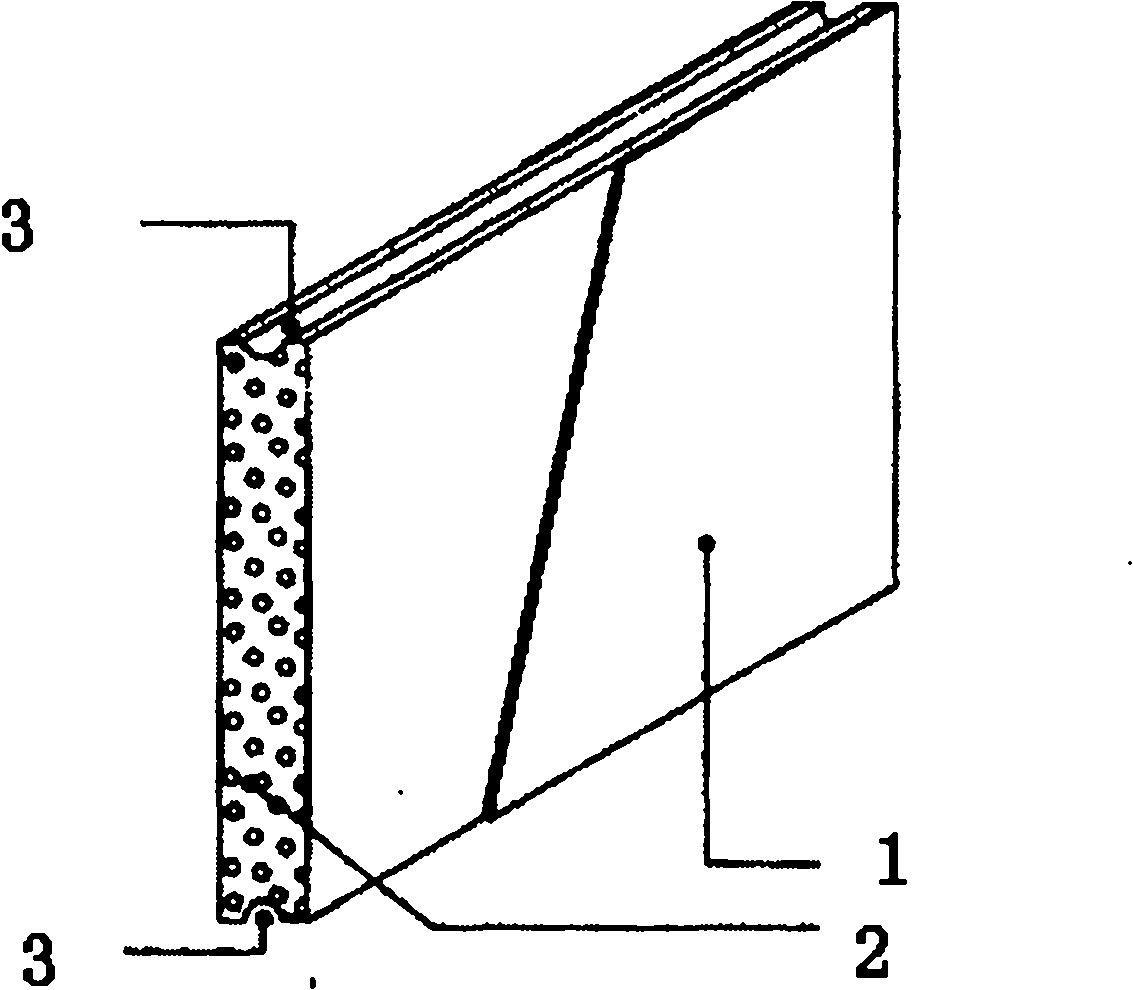

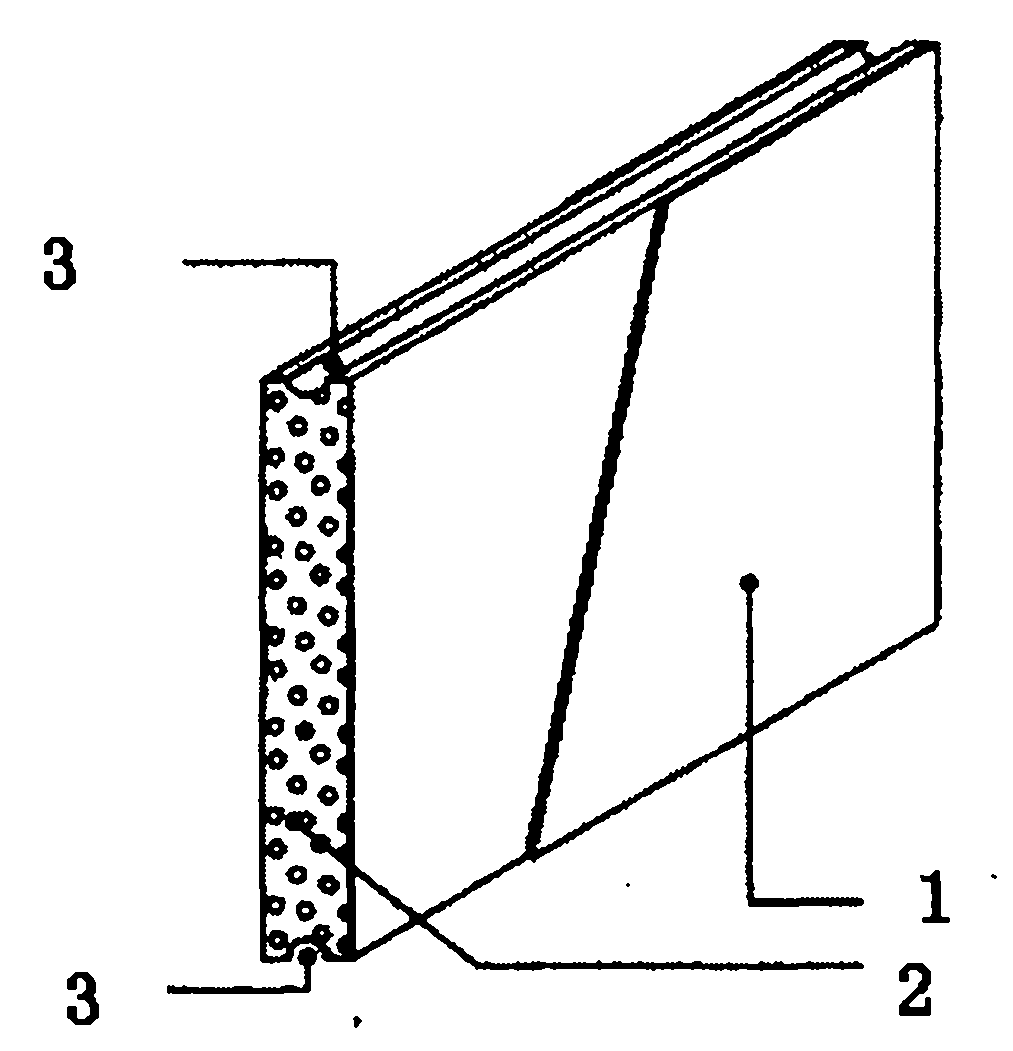

Pearlite thermal-insulating fireproof board for exterior wall of building

InactiveCN102418390ASatisfy insulation performanceLow thermal conductivityClimate change adaptationInsulation improvementFiberPolymer science

The invention relates to a pearlite thermal-insulating fireproof board for the exterior wall of a building, which has the advantages that the fireproof performance is improved, the heat conducting coefficient is reduced and the flexibility and the strength are enhanced; and the requirements on the thermal-insulating performance of the exterior wall of the building are well satisfied, the energy is saved by 65 percent and the A-degree fireproof requirement is satisfied. The pearlite thermal-insulating fireproof board is made of the following raw materials by volume weight per cubic meter of products: 80-120kg of light modified expanded pearlite with volume weight per cubic meter being 65kg, 3-5kg of modified hollow beads with volume weight per cubic meter being 110kg, 2-6kg of 200-mesh sodium bentonite, 0.3-1.5kg of silica aerogel particles, 0.5-2kg of reinforced polypropylene (PP) fibers, 1-3kg of ceramic fibers, 0.3-1.5kg of asbestos wool, 20-30kg of inorganic modified water glass adhesive, 3-5kg of polyvinyl acetate adhesive, 0.5-3kg of modifier, 1-3kg of water repellent and 0.5-2kg of silicon aluminum powder, wherein the total percent of the volume weight per cubic meter of products is 100 percent. The pearlite thermal-insulating fireproof board is made through agitating, pressing, demolding, forming and drying processes. The coefficient of heat conductivity is as low as 0.045W / m.K.

Owner:LUOYANG SENHAO IND & TRADE

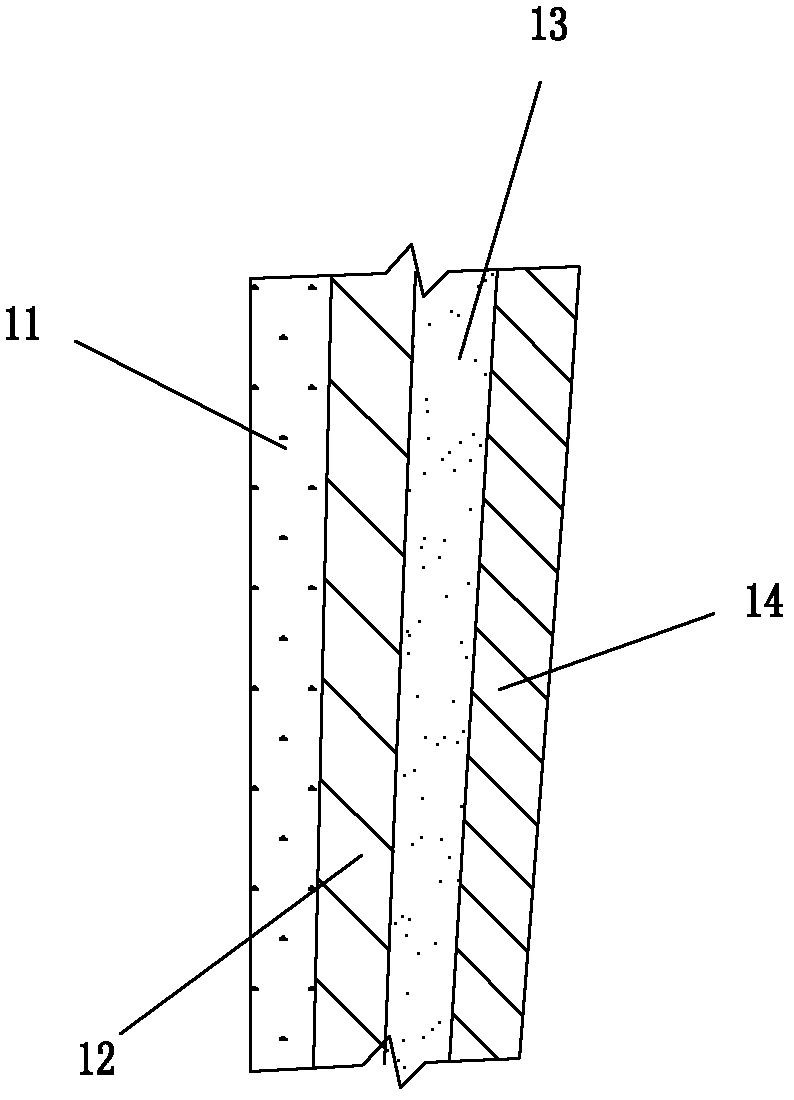

Energy-saving, low-carbon and heat-insulation composite wallboard, and production method and equipment thereof

The invention provides an energy-saving, low-carbon and heat-insulation composite wallboard, and a production method and production equipment thereof. The energy-saving, low-carbon and heat-insulation composite wallboard is characterized by consisting of two surface boards and a core board arranged between the two surface boards, wherein the core board is prepared from polystyrene foamed plastics, fly ash, cement, sand, admixture and water. The invention also provides the production method and production equipment of the energy-saving, low-carbon and heat-insulation composite wallboard. The energy-saving, low-carbon and heat-insulation composite wallboard has the advantages of light weight, thin body, impact resistance, compression resistance, heat preservation, heat insulation, water proofing, fire proofing, sound insulation, shock proofing, explosion absorption, easy cutting, slotting, no need of plastering, fast dry operation, labor saving and the like.

Owner:上海康尼建材科技有限公司

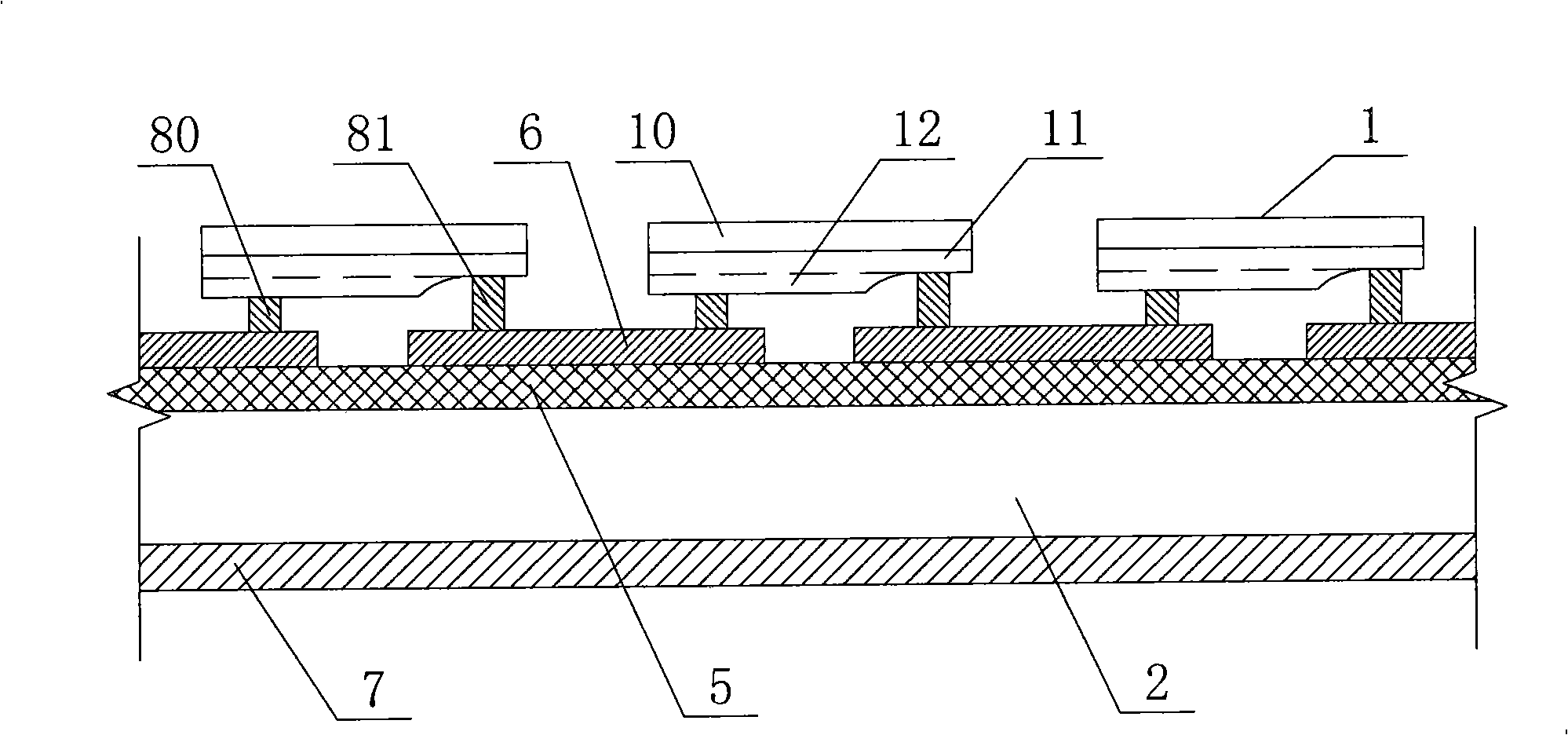

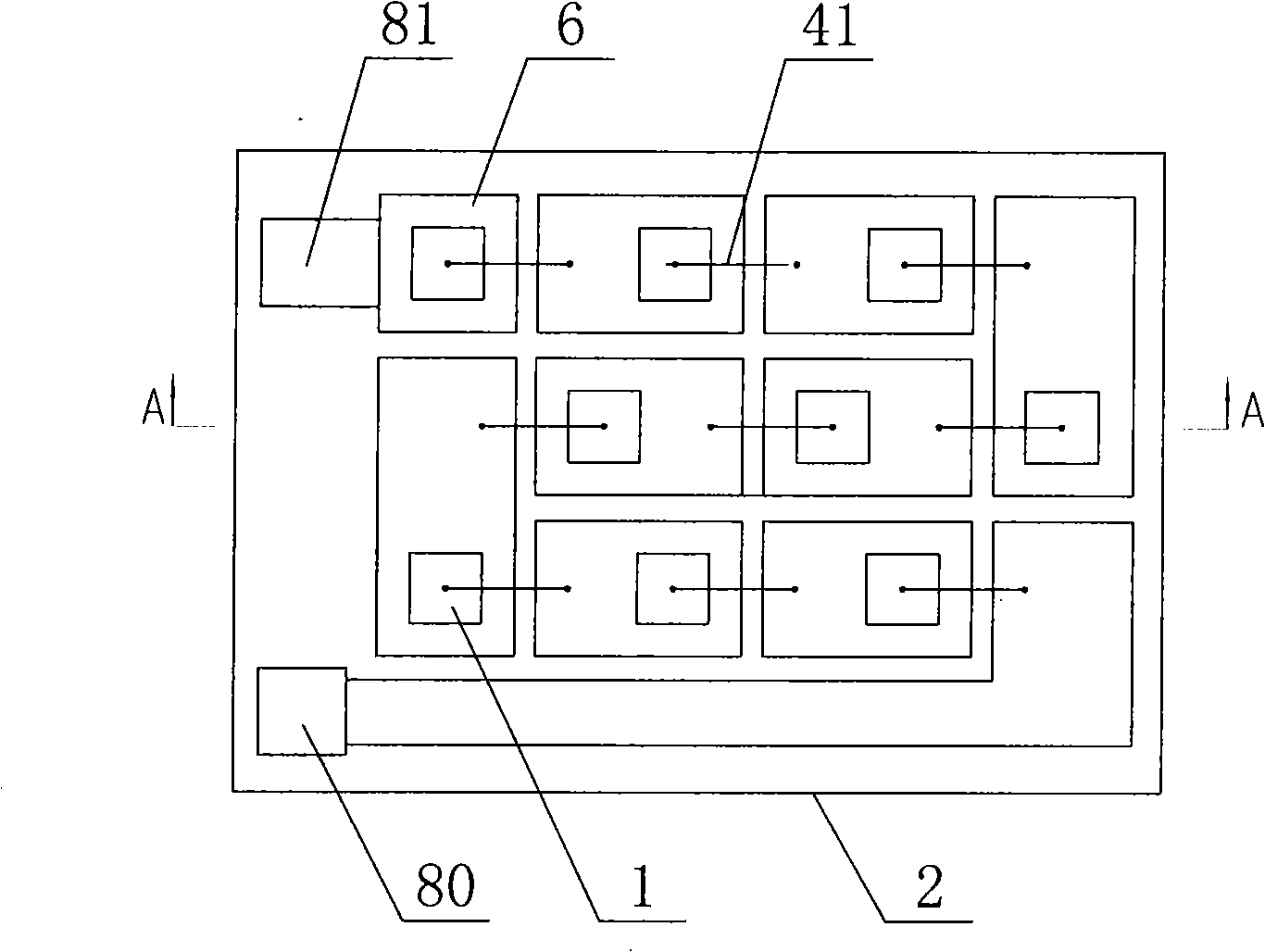

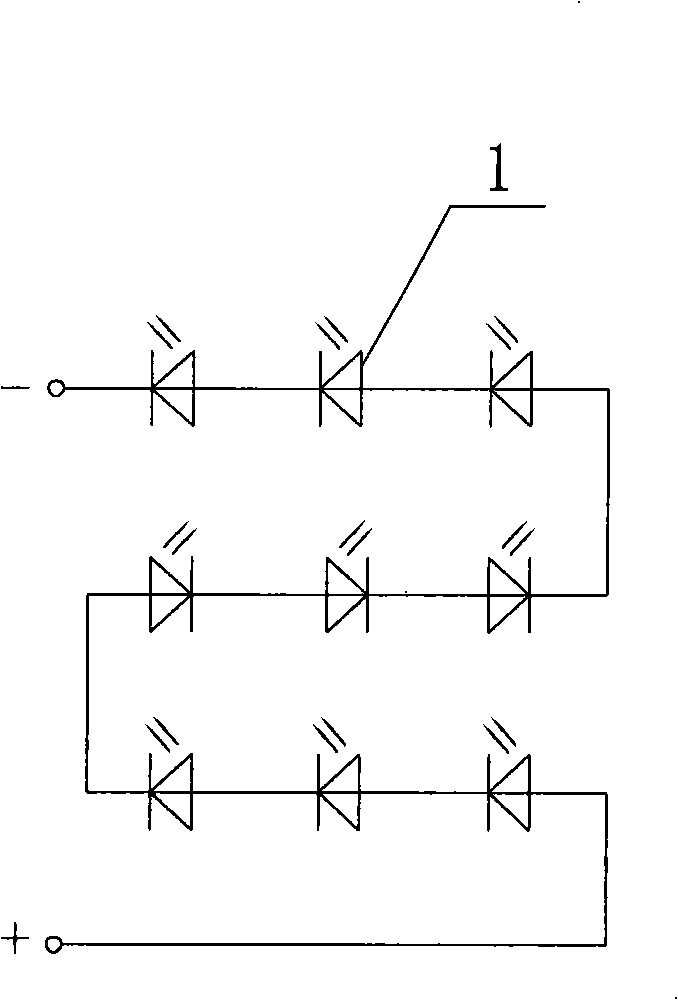

Flip LED integrated chip with high break-over voltage

InactiveCN101308838AEasy to integrateLarge distribution areaSemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

The invention discloses a high break-over voltage LED flip-chip and the fabrication method thereof, which is easy to integrate, low in cost, good in heat dissipation effect and good in high voltage resistance. The integrated chip comprises a plurality of LED flip-chips(1) and a plurality of silicon bulks(2); each LED flip-chip(1)is composed of an underlay(10), an N type epitaxial layer(11) and a P type epitaxial layer(12); at least one heat conduction insulated layer is developed on each silicon bulk(2); metal layers(6) are deposited on the heat conduction insulated layers; the corresponding N type epitaxial layers(11) and P type epitaxial layers(12) of the LED flip-chips(1) are reversely welded respectively on two separate metal layers through weld beads(80,81). The LED flip-chips (1) are connected into a circuit through the metal layers (6). The fabrication method includes the steps of forming the heat conducting insulated layer, the metal layers and an LED flip-chip enclosure.

Owner:NANKER GUANGZHOU SEMICON MFG

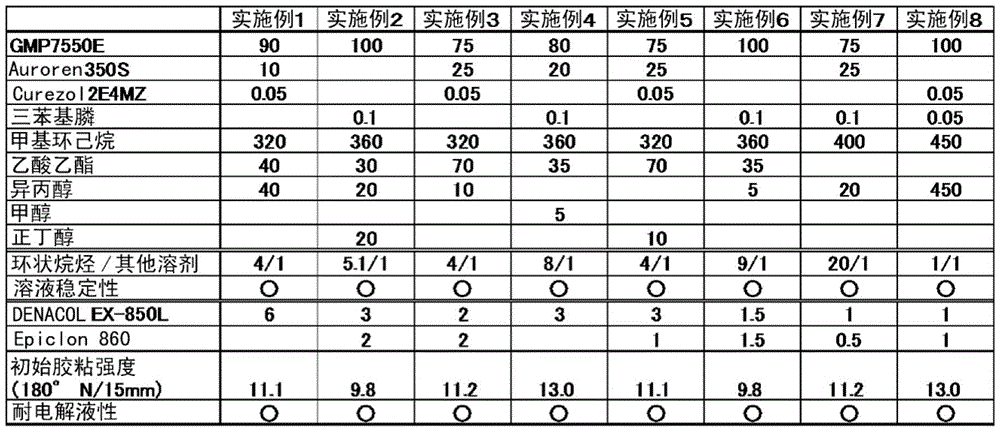

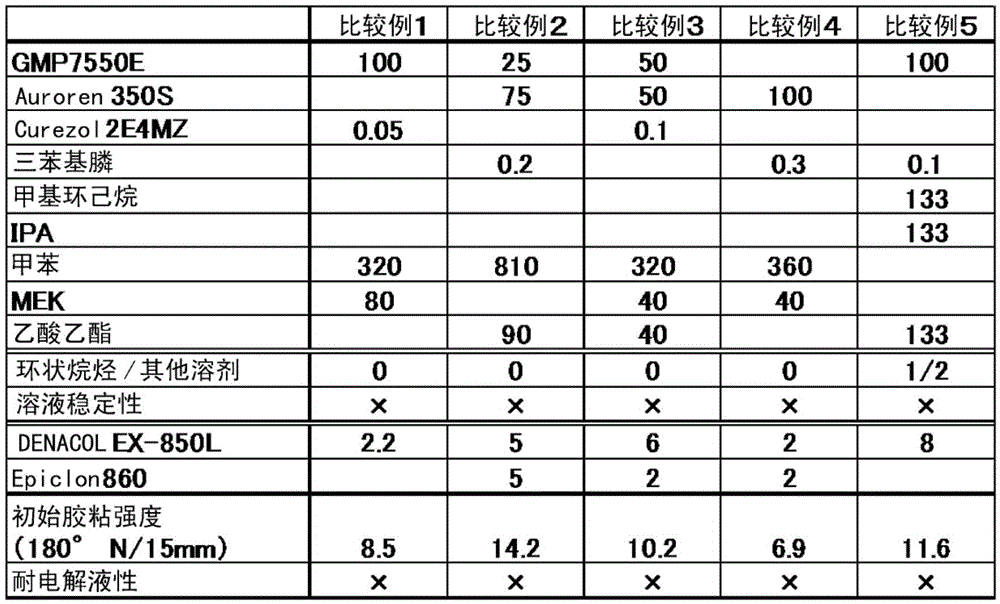

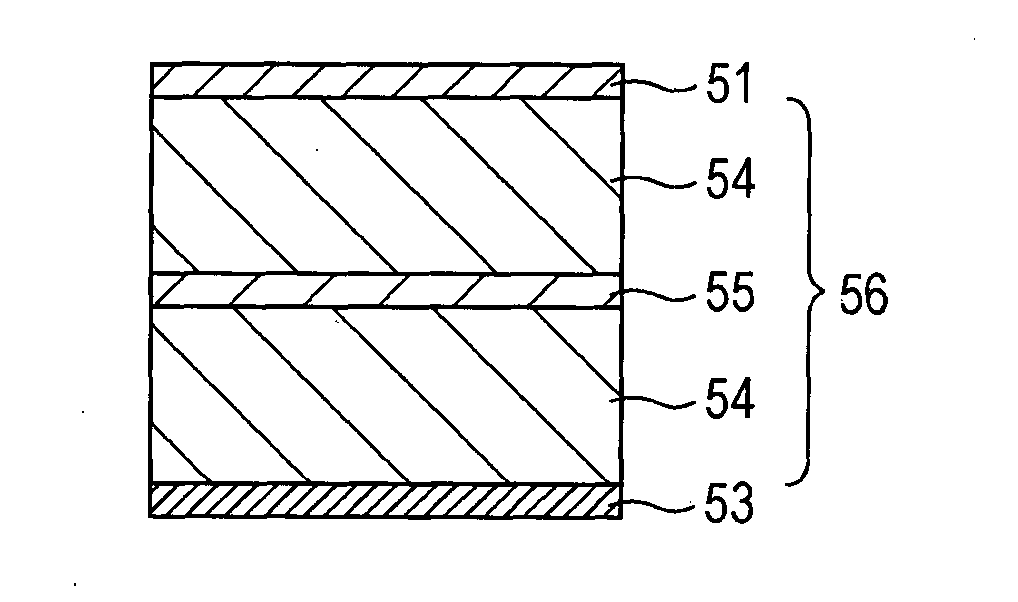

Laminate adhesive, stack using the same, and secondary battery

ActiveCN105658753AGood adhesivenessMeet moisture resistanceNon-macromolecular adhesive additivesCell electrodesPolyolefinAdhesive

By providing a heretofore unknown laminate adhesive, the present invention addresses the problem of providing an adhesive composition for laminate stacks, which provides excellent adhesion between a metal layer and a plastic layer and satisfies moisture resistance, heat resistance, insulation performance, durability, etc., further combined with electrolyte resistance in low-temperature curing, without causing delamination over time. The present invention also addresses the problem of providing a stack using the adhesive composition, and a secondary battery. The above problems are solved with a laminate adhesive containing a non-chlorine polyolefin resin (A), an epoxy compound (B), and an organic solvent (C) essentially containing a cyclic alkane compound and containing an ester solvent or an alcohol solvent, wherein the organic solvent (C) is constituted such that the ratio of the mass parts of the cyclic alkane compound to the mass parts of other solvents is in the range of 1 / 1 to 20 / 1, inclusive.

Owner:DIC CORP

Preparation method of high-thermal-conductivity low-specific-gravity flame-retardant organic silicon pouring sealant

InactiveCN107892898ALow conductivityImprove sexual functionNon-macromolecular adhesive additivesHeat conductingSealant

The invention provides a preparation method of a composite graphene high-thermal-conductivity low-specific-gravity flame-retardant organic silicon pouring sealant. A mixture is formed by mixing a component A and a component B in the weight ratio of 1:(1-2), the mixture is poured into equipment when the fluidity of the mixture remains, and then room-temperature curing molding or heating curing molding is conducted. The component A comprises, by weight, 47.4-61.6% of vinyl silicone oil, 3-12% of modified heat-conducting micro-powder, 0.4-0.6% of catalyst and 35-40% of flame-retardant agent. Thecomponent B comprises, by weight, 41.99-57.992% of vinyl silicone oil, 3-12% of graphene composite heat-conducting filler, 4-6% of hydrogen-containing silicone oil, 0.005-0.008% of inhibitor and 35-40% of flame-retardant agent. By means of surface treatment and compounding of different kinds of heat-conducting filler, the graphene composite heat-conducting filler is prepared, and the dispersion problem of the heat-conducting filler and organic silicon rubber is improved; the graphene composite heat-conducting filler can improve the heat-conducting performance of the organic pouring sealant; bysimulating different particle sizes and using compounds obtained according to different particle sizes, the organic silicon pouring sealant is high in thermal conductivity and low in specific gravity.

Owner:青岛科孚纳米技术有限公司

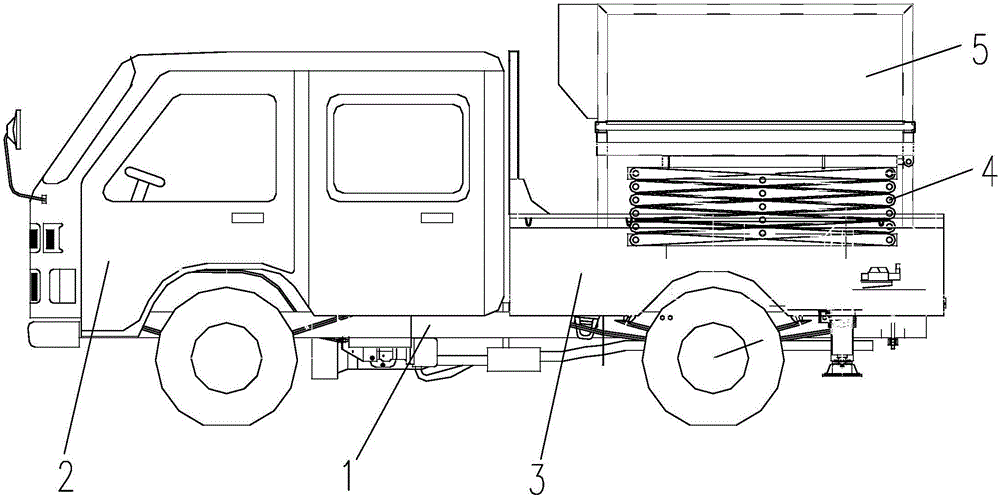

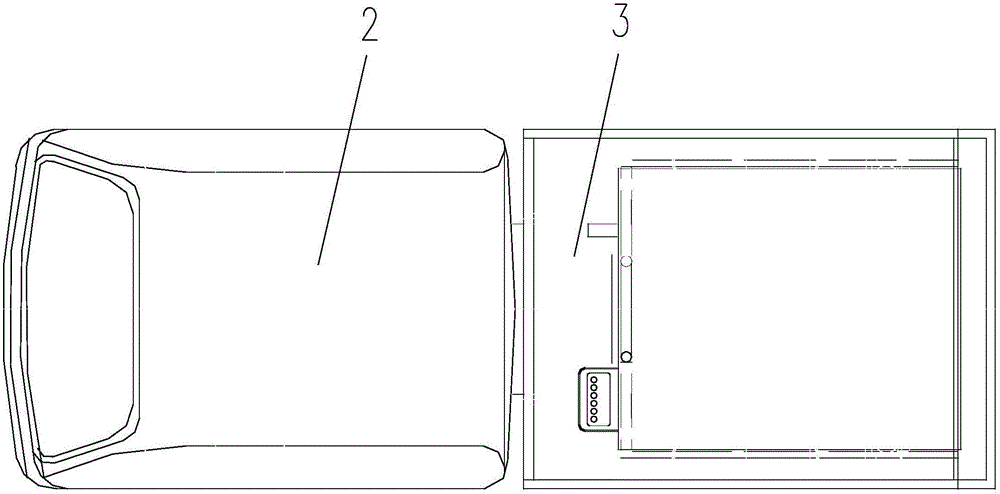

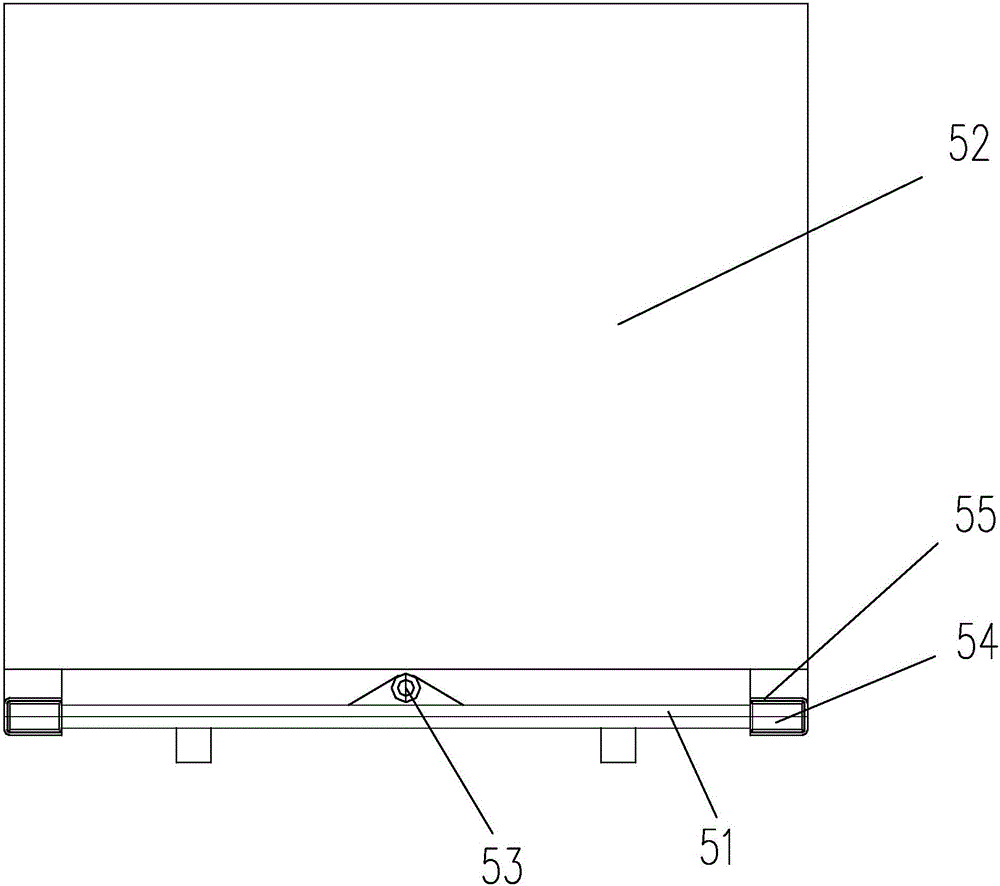

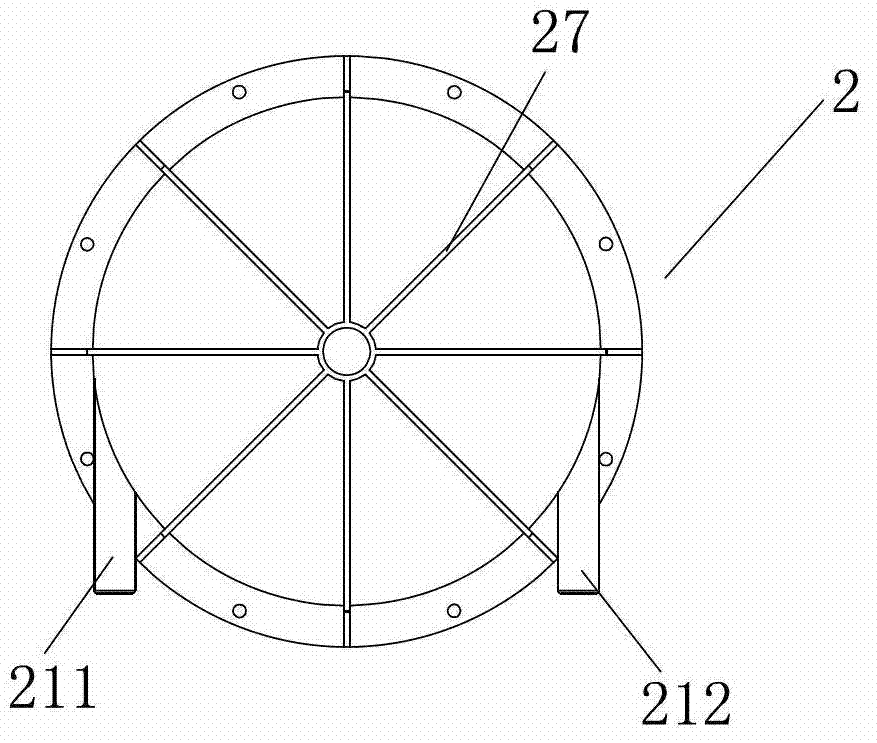

Shear-fork type insulation overhead work platform car

The invention provides a shear-fork type insulation overhead work platform car which is simple in structure, convenient to operate, and capable of improving operation reliability and safety. The shear-fork type insulation overhead work platform car comprises a car body which is provided with a car head and a carriage; a platform assembly is arranged in the carriage and connected with the carriage through a shear-fork mechanism; the platform assembly comprises a bracket, an enclosing platform and a push oil cylinder, wherein the bracket and the enclosing platform are both made of glass fiber reinforced plastics; a pair of guide rails are arranged on the two sides of the bracket; a pair of guide sleeves are arranged on the two sides of the bottom face of the enclosing platform; the guide sleeves are cooperatively arranged on the guide rails in a sleeving mode; the push oil cylinder is located between the enclosing platform and the bracket; a cylinder body of the push oil cylinder is arranged on the bracket; and a hydraulic rod of the push oil cylinder is connected with the enclosing platform, so that the enclosing platform is horizontally arranged on the bracket in a movable mode. The shear-fork type insulation overhead work platform car can act in an electrified mode during work, and is suitable for operation of overhead line structures on country roads of rural areas, thereby improving the working efficiency and lowering the labor intensity.

Owner:JIANGSU ELECTRIC POWER CO +3

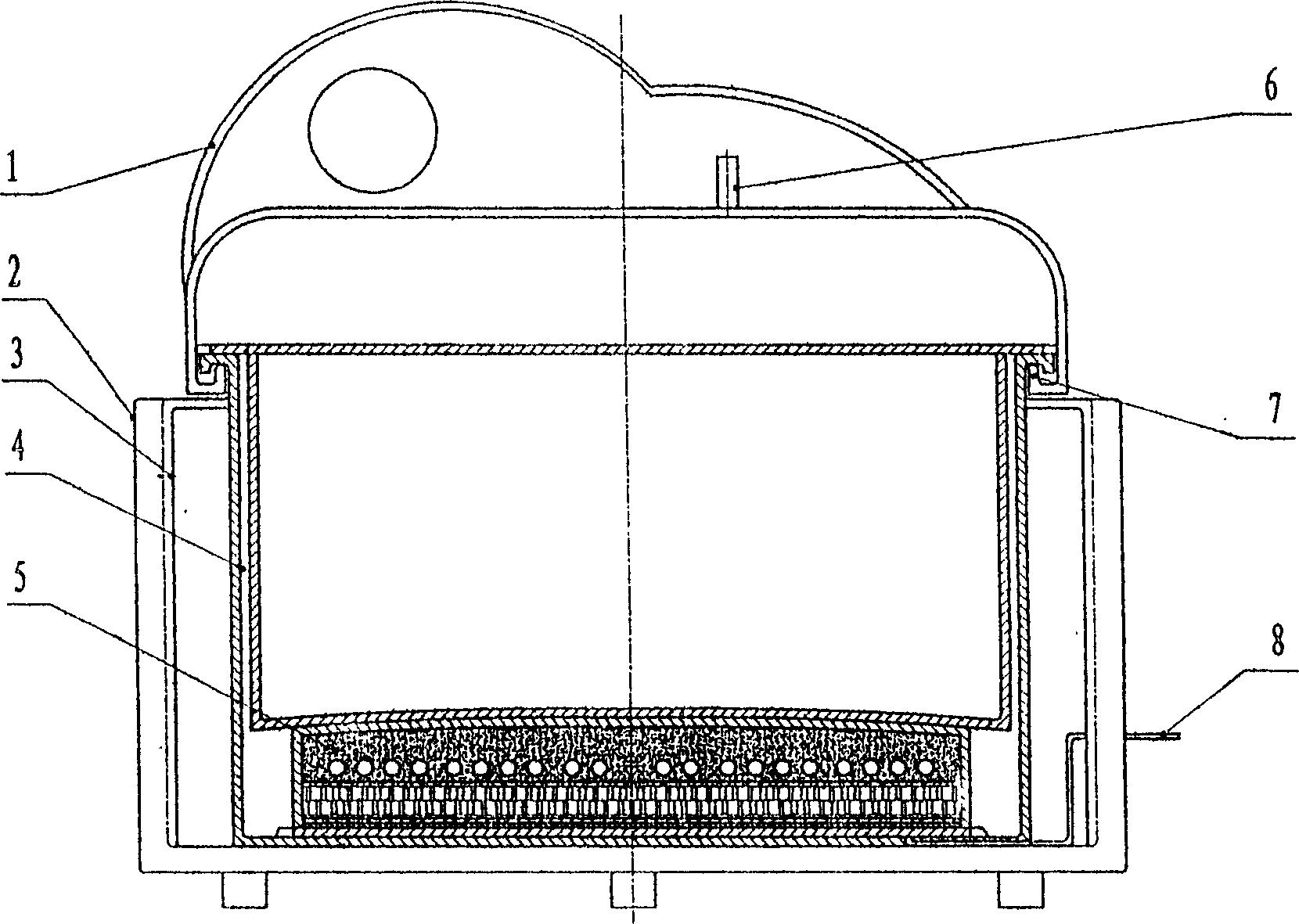

Electromagnetic water heater

InactiveCN102788414AHigh outputSatisfy insulation performanceWater heatersMetallic materialsUltimate tensile strength

The invention discloses an electromagnetic water heater which comprises a shell for accommodating various components. The shell at least accommodates a heating water disc, an induction coil corresponding to the heating water disc, a water pipe and a circuit device, the water pipe is connected with the heating water disc, and the circuit device is connected with the induction coil. The electromagnetic water heater is characterized in that the heating water disc is provided with an upper water cover and a lower water cover, and a heating plate is arranged between the upper water cover and the lower water cover; a water tank is arranged on the upper water cover and / or the lower water cover respectively; and the upper water cover and the lower water cover are made of nonmetal materials, and the heating plate is made of magnetic-permeable metal materials. The heating water disc is made of nonmetal materials, so that the requirement on heat insulation is met, and structural strength of the electromagnetic water heater is improved.

Owner:梁衍宁

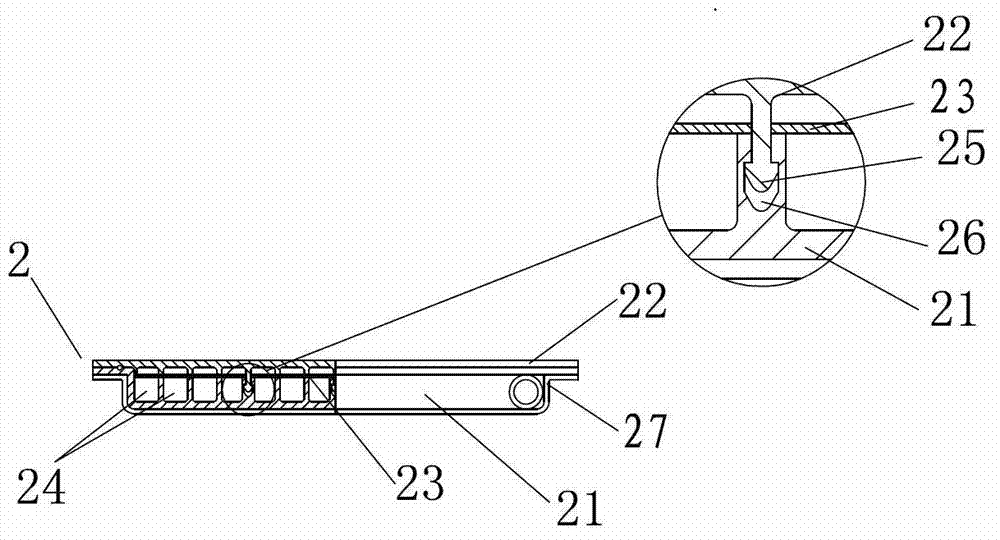

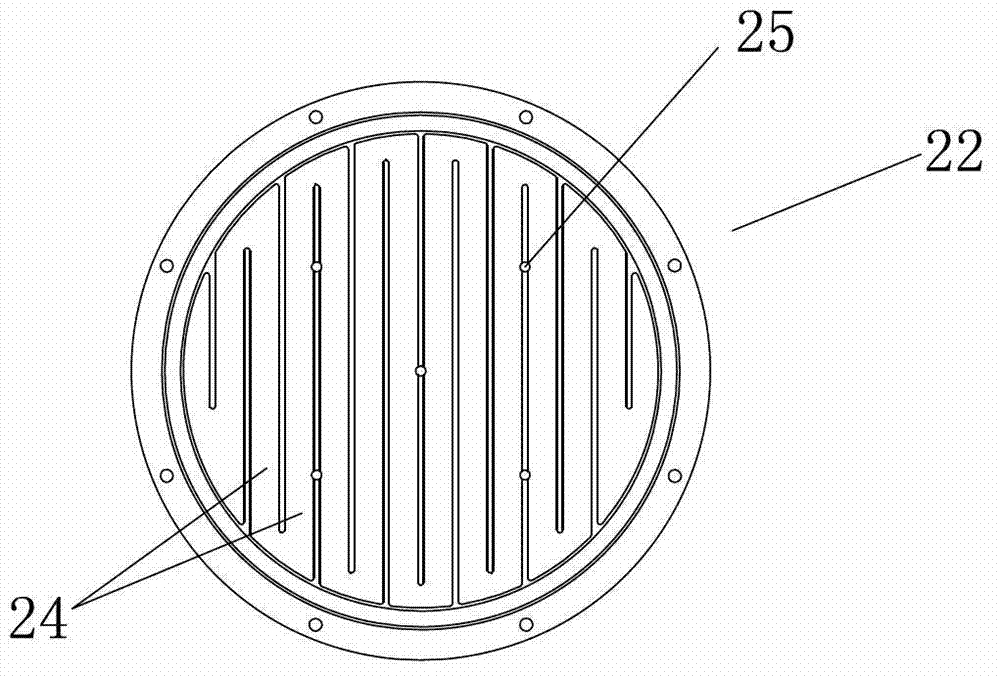

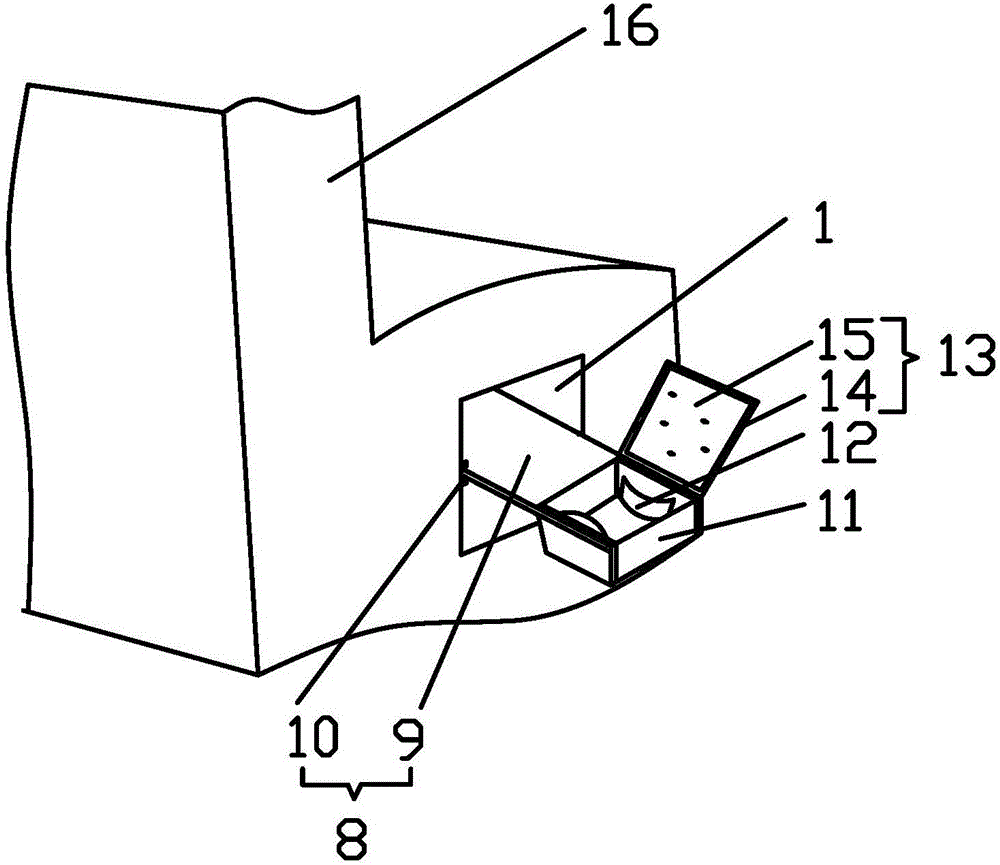

Metallic reflection type insulating layer for nuclear class device and pipe

ActiveCN105065859ASuppresses convective heat transferImprove insulation effectThermal insulationNuclear energy generationOptoelectronicsMetal

The invention discloses a metallic reflection type insulating layer for a nuclear class device and a pipe. The metallic reflection type insulating layer comprises an outer insulating box and reflection foil pieces arranged in the outer insulating box. The reflection foil pieces include the first reflection foil pieces and the second reflection foil pieces, wherein the first reflection foil pieces and the second reflection foil pieces are alternately arranged. Hemispherical first concave bubble-shaped parts and hemispherical first convex bubble-shaped parts which are alternately arranged are pressed on each first reflection foil piece. Hemispherical second concave bubble-shaped parts and hemispherical second convex bubble-shaped parts which are alternately arranged are also pressed on each second reflection foil piece, wherein the diameter of the second convex bubble-shaped parts is larger than that of the first convex bubble-shaped parts. The insulating performance of the metallic reflection type insulating layer is better.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

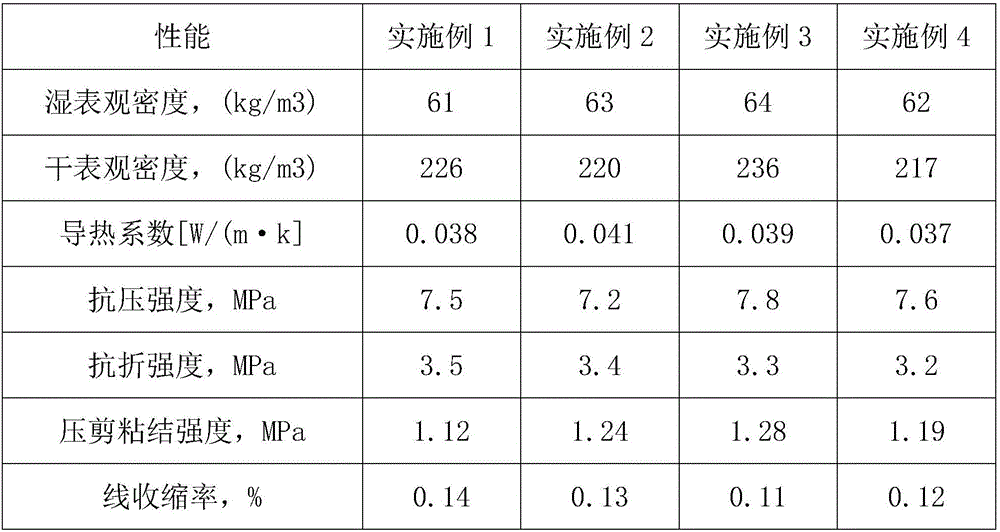

Anti-cracking heat-preserving wall construction material and preparation method thereof

The invention discloses an anti-cracking heat-preserving wall construction material and a preparation method thereof. The anti-cracking heat-preserving wall construction material is prepared from, by weight, 400-600 parts of cement, 40-70 parts of silica powder, 80-220 parts of ash-calcium powder, 80-160 parts of expanded vermiculite, 60-100 parts of sand, 60-100 parts of hollow glass beads, 40-80 parts of rock wool threads, 30-80 parts of modified fly ash, 60-120 parts of polyphenyl particles, 10-20 parts of wood fiber, 5-10 parts of polypropylene fiber, 30-60 parts of polyvinyl alcohol, 40-80 parts of dispersible latex powder and 10-20 parts of cellulose ether. The anti-cracking heat-preserving wall construction material solves the problem that finishing mortar prepared from an existing outer wall heat-preserving material is prone to cracking and poor in durability, and truly achieves heat preservation, heat isolation and high anti-cracking performance.

Owner:MAANSHAN TIANJINYUN PAINT IND

Preparation method of exterior wall bonding powder polystyrene granule insulating mortar

The invention discloses a preparation method of exterior wall bonding powder polystyrene granule insulating mortar, relates to the preparation of architectural insulating material and needs to provide a preparation method of an architecture exterior wall insulating material. The preparation method has the technical scheme that ordinary portland cement, flyash, white lime, construction gypsum, cellulose ether, rubber powder, starch ether, xylon and polypropylene (pp) fibre are adopted and is characterized in that the ordinary portland cement, the flyash, the white lime, the construction gypsum, the cellulose ether, the rubber powder, the starch ether, the xylon and the pp fibre are mixed to be polystyrene granules by the weight ratio of 650:200:100:50:515:1:3:1 in sequence; during the preparation of the mortar, a mortar mixer is switched on, 35-40 kg of water is poured into the mortar mixer, 25 kg of rubber powder is poured in mortar mixer and is stirred for 3-5 min, 150-200 L of polystyrene granules is poured in the mortar mixer and is stirred continuously for 3 min, the mixture is poured out after being stirred evenly and can be used after the stir, and the mortar has to be used during 4 hours. The invention is used for preparing architecture exterior wall insulating materials.

Owner:SHANGHAI SHENGXUAN NEW BUILDING MATERIALS

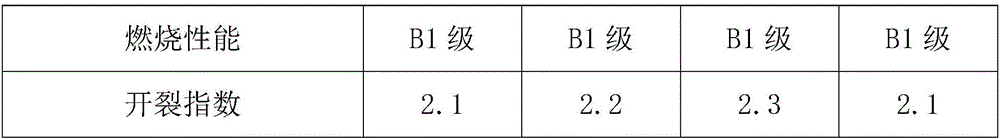

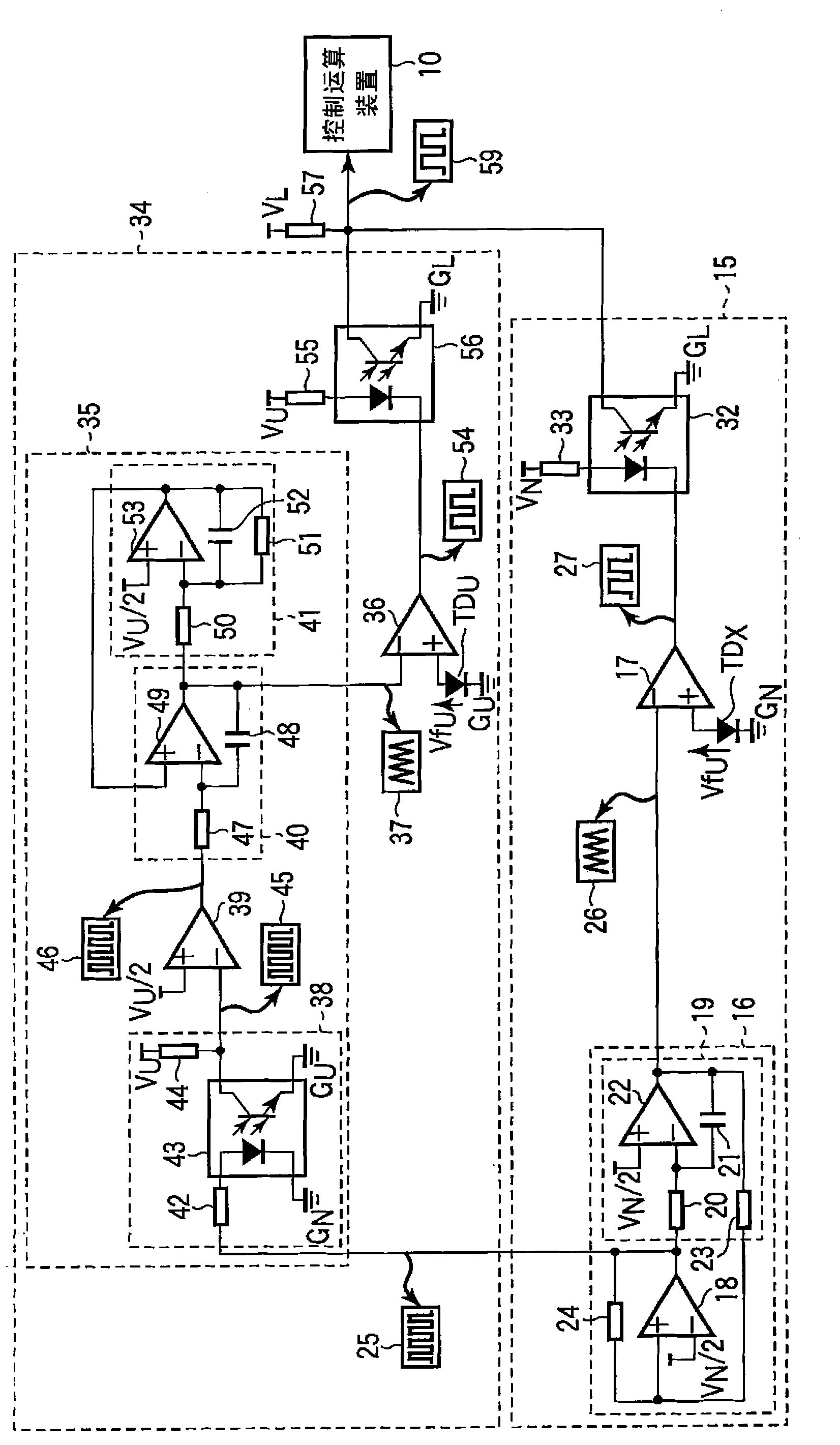

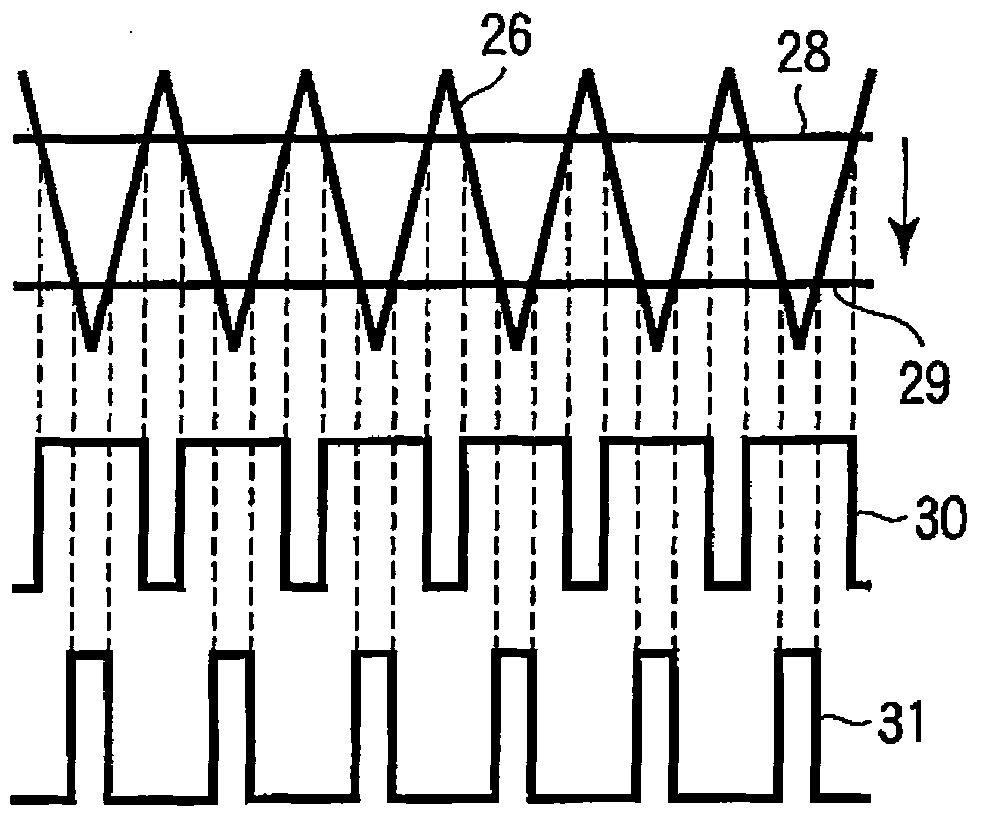

Temperature detecting circuit

InactiveCN101983322AIncrease costSatisfy insulation performanceThermometer with A/D convertersElectric devicesPwm signalsVIT signals

Provided is a temperature detecting circuit which suppresses cost increase at minimum by adding a small number of components and meets requirements of insulation and high response. The temperature detecting circuit (15) outputs a first PWM signal, which corresponds to the temperature of a first temperature sensor (TDX), as a signal insulated from the first temperature sensor (TDX) from a photo interrupter (32). A temperature detecting circuit section (34) outputs a second PWM signal, which corresponds to the temperature of a second temperature sensor (TDU), as a signal insulated from the second temperature sensor (TDU) from a photo interrupter (56). A processing device (10) calculates a higher temperature of the temperatures detected by the first and the second temperature sensors (TDU, TDX), based on the PWM signal outputted from the photo interrupters (32, 56).

Owner:KK TOSHIBA

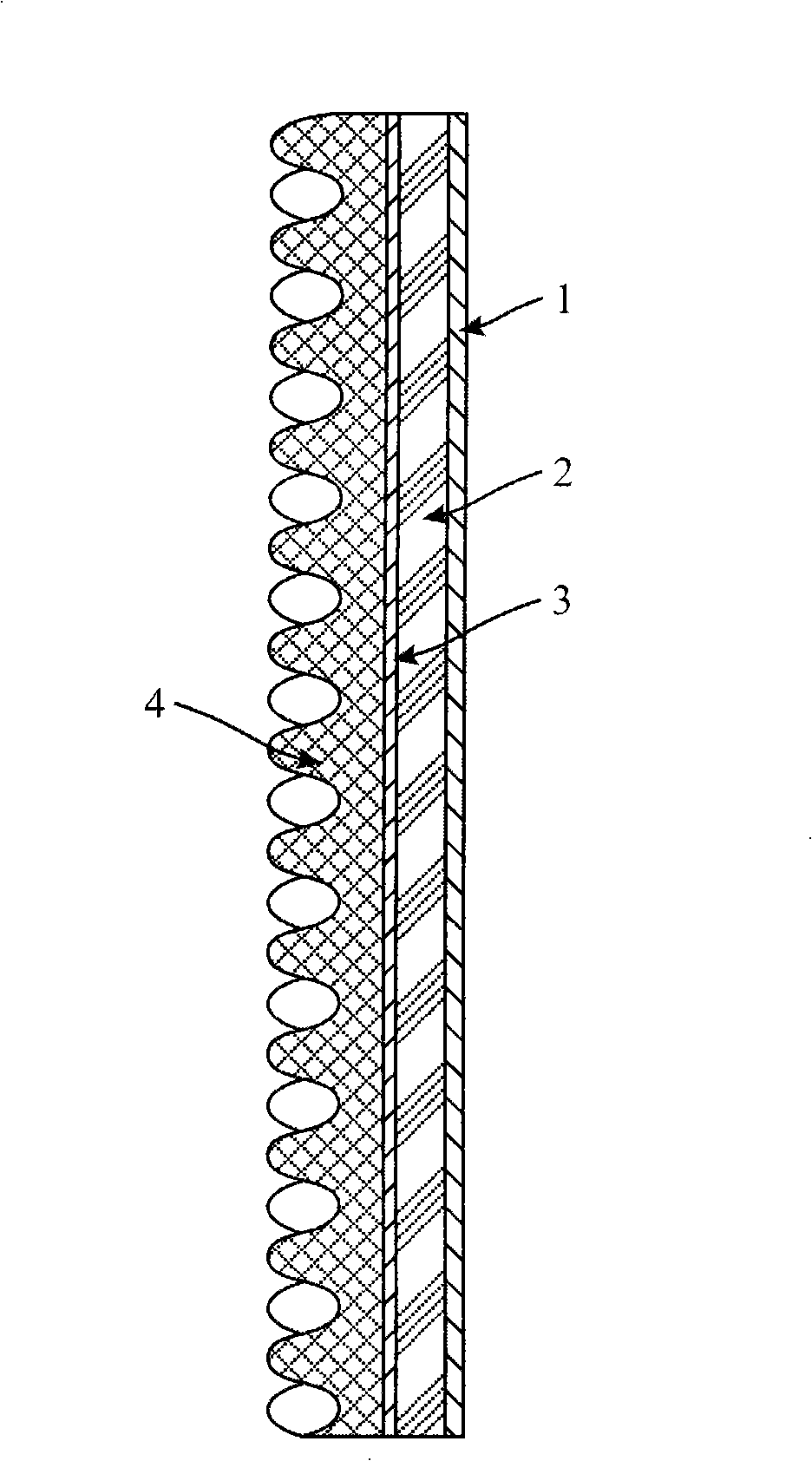

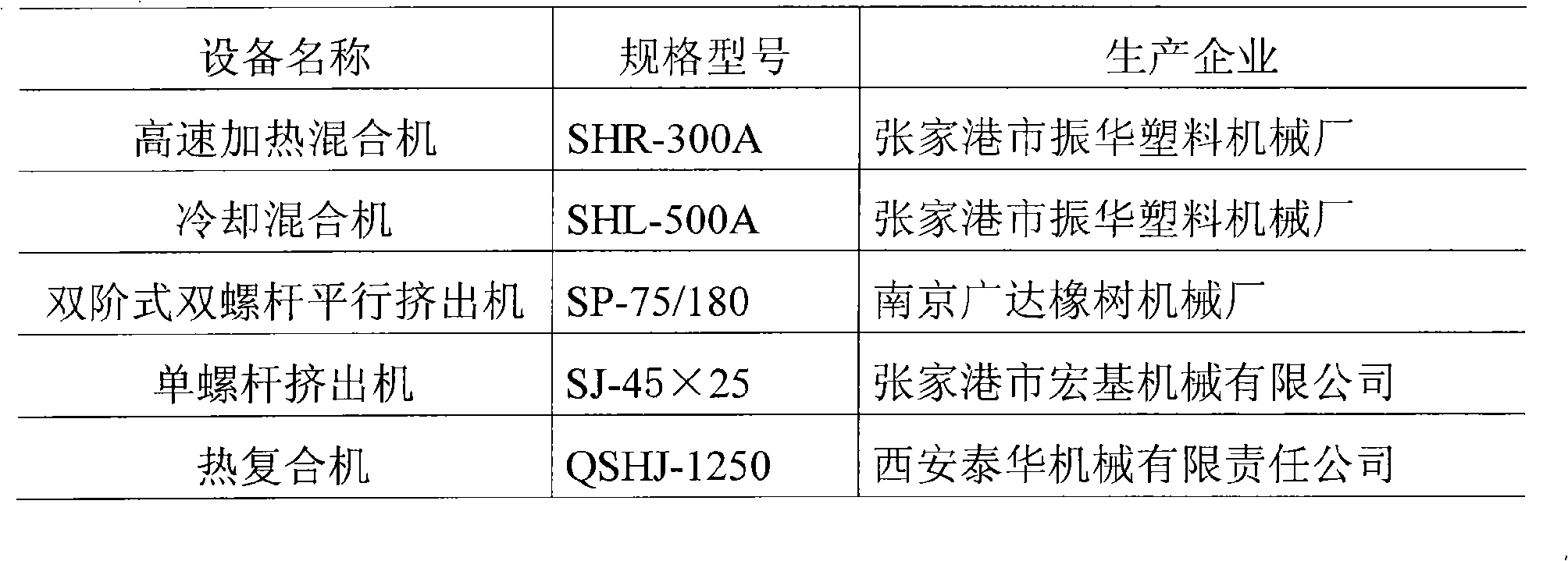

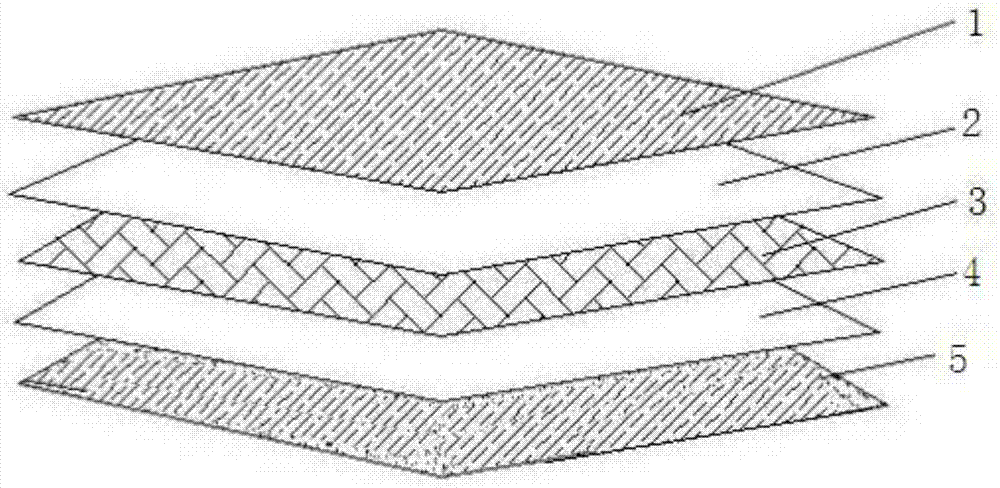

Multifunctional composite sheet material and process for making same

InactiveCN101306597ASimple preparation processLow costSynthetic resin layered productsLaminationMultiple functionRefrigerated temperature

The invention relates to a multifunctional composite sheet material and the production process thereof. The production process comprises the following steps: material preparation, hot mixing, cold mixing, extrusion granulation, extrusion output, lamination, aluminum foil attachment and finishing. The sheet material consists of four layers: aluminum foil, a substrate, fiber glass and polyurethane foam. The production process has the advantages of simple process, low cost and easy construction and maintenance. The product has sound-insulating and heat-insulating effects and good resistance to light radiation and thermal radiation. The multifunctional composite sheet material allows the building to meet the requirements for sound insulation, heat insulation, light radiation resistance and thermal radiation resistance. The multifunctional composite sheet material reflects ultraviolet ray in sunlight, ensures normal temperature difference and normal flow and running of oil and gas in a tube, slows down the light ageing and thermal ageing processes of a pipe network, and prolongs the service life of the equipment. Additionally, the multifunctional composite sheet material can efficiently prevent water-freezing and explosion of a pipe and substantially eliminate the noise during water drainage. The product provides good sound-insulating and heat-insulating effects and good resistanceto light radiation and thermal radiation in refrigerated warehouse in logistical refrigerators and special vehicles and ships.

Owner:成都科航建材科技发展集团有限公司

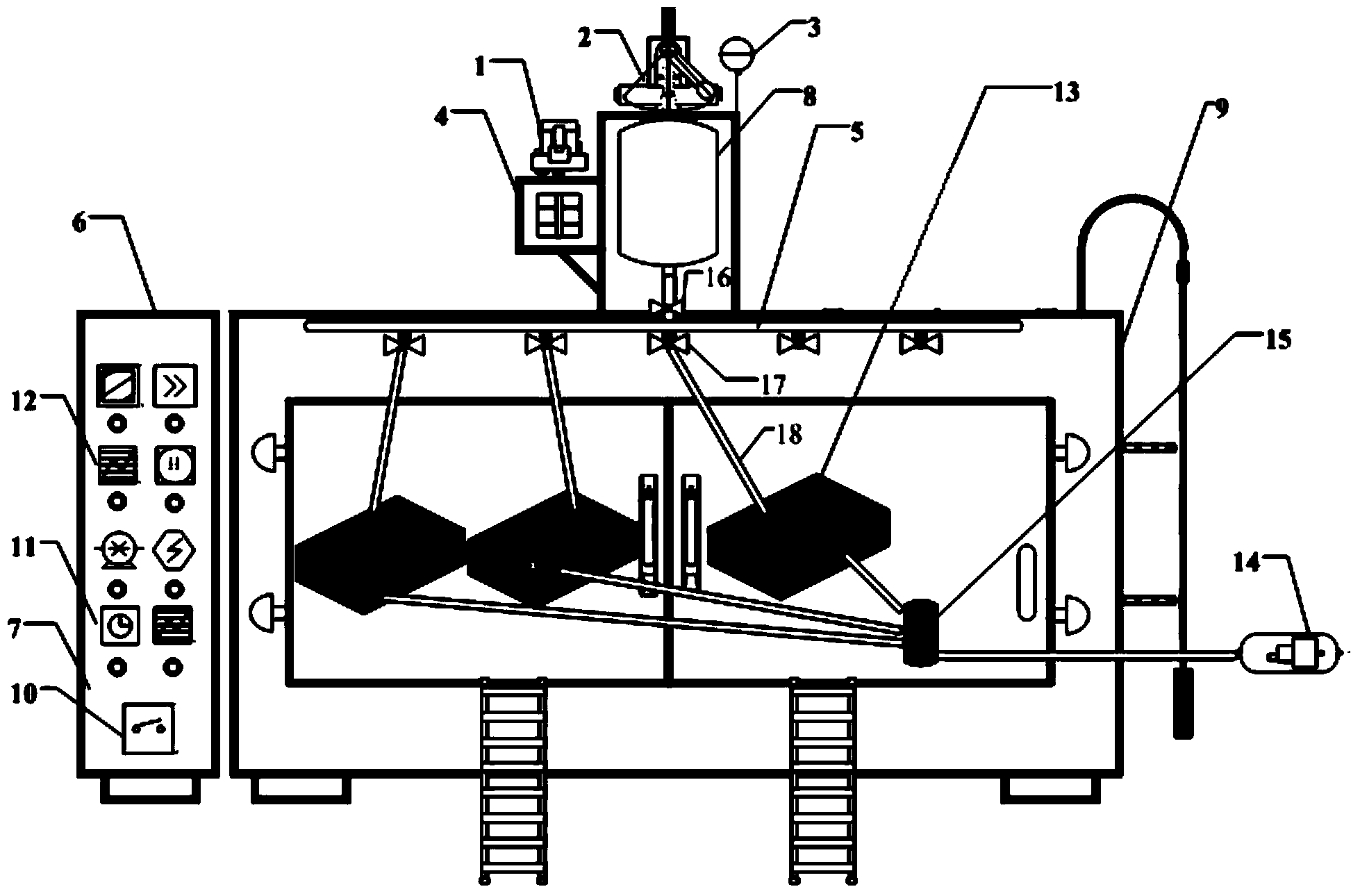

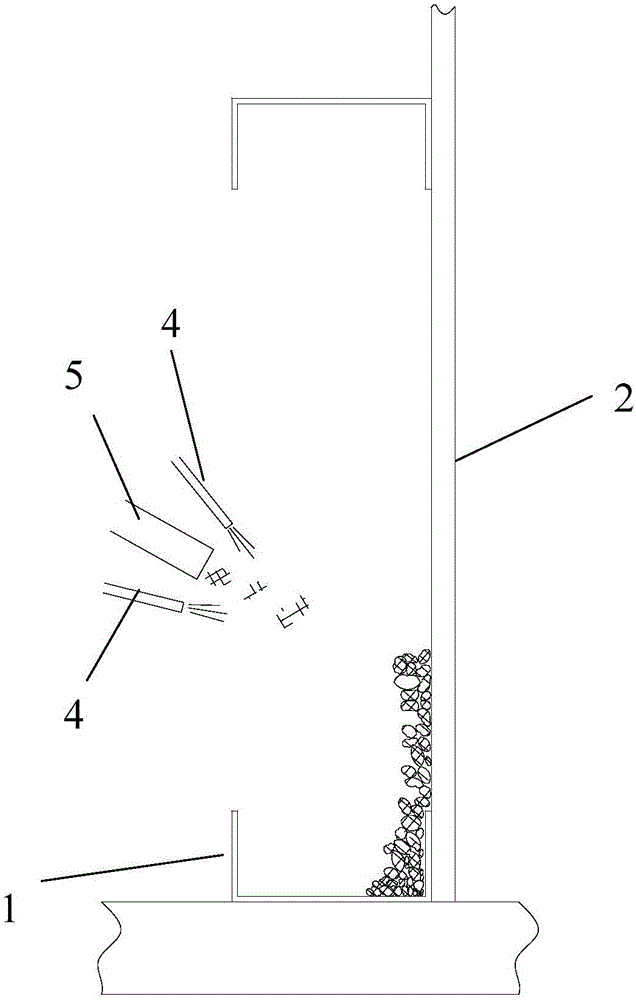

High-temperature RTM (resin transfer molding) integrated molding equipment

The invention provides high-temperature RTM (resin transfer molding) integrated molding equipment. The equipment comprises a resin tank, a high-temperature resin distributing pipeline and a curing tank, wherein the resin tank is arranged at the top of the curing tank in an integrated manner, the high-temperature resin distributing pipeline is arranged at the top part in the curing tank to meet the requirements of heat preservation property of the high-temperature resin distributing pipeline and the flowing property of the rein injection runners, the top part of the curing tank is provided with an opening at a glue outlet of the resin tank, three or more product molds can be placed in the curing tank, a mold vacuum pipeline is arranged outside the curing tank, the glue outlet of the resin tank is connected with the high-temperature resin distributing pipeline by a discharging valve, the high-temperature resin distributing pipeline is provided with three or more outlets, each outlet is connected with one mold through a resin distributing valve and a resin flowing pipeline, and each mold is connected with the mold vacuum pipeline by a liquid storage tank. According to the invention, high-temperature resin can be ensured to be fully poured and fed, the molding operation is convenient and the production efficiency is improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

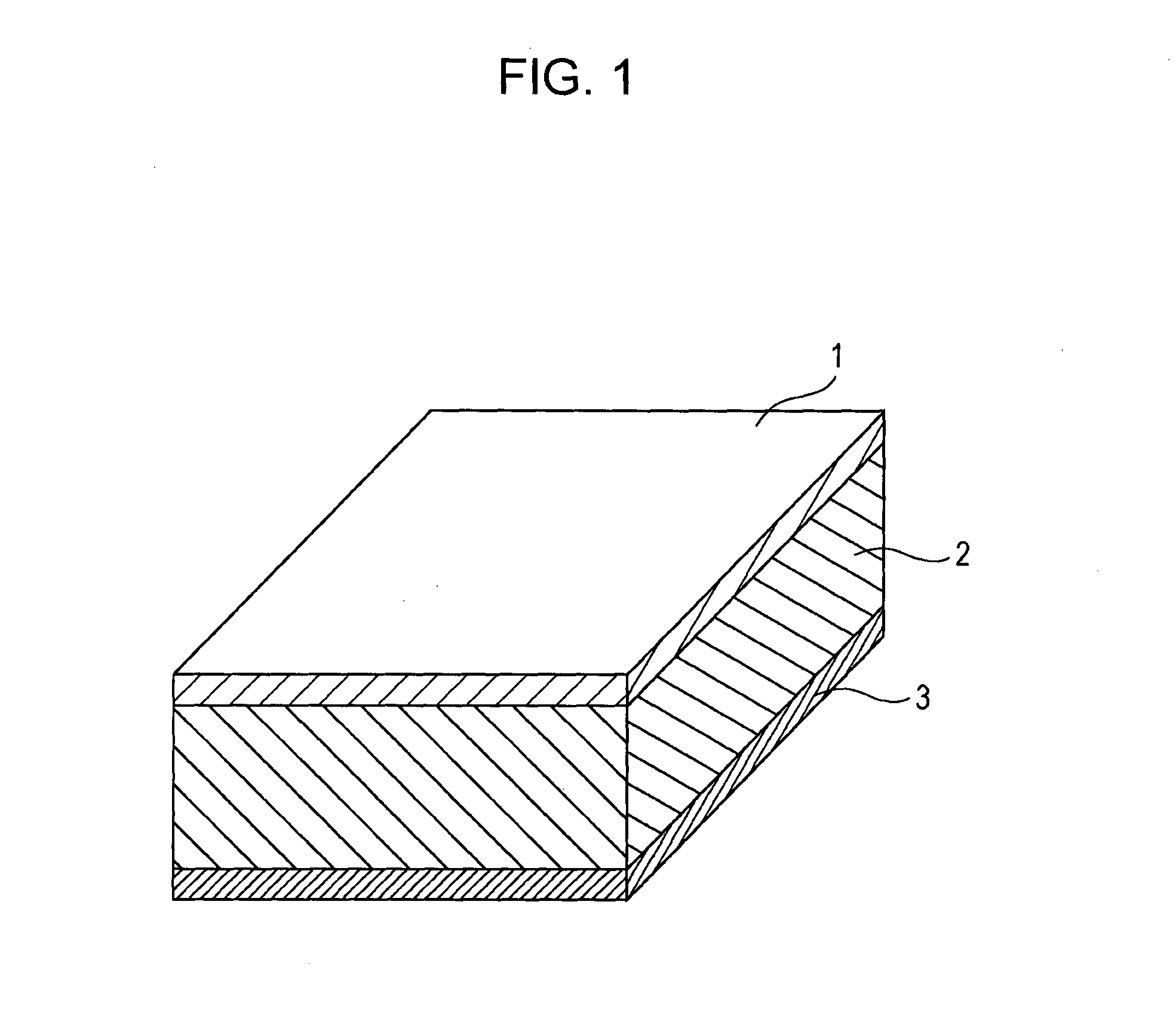

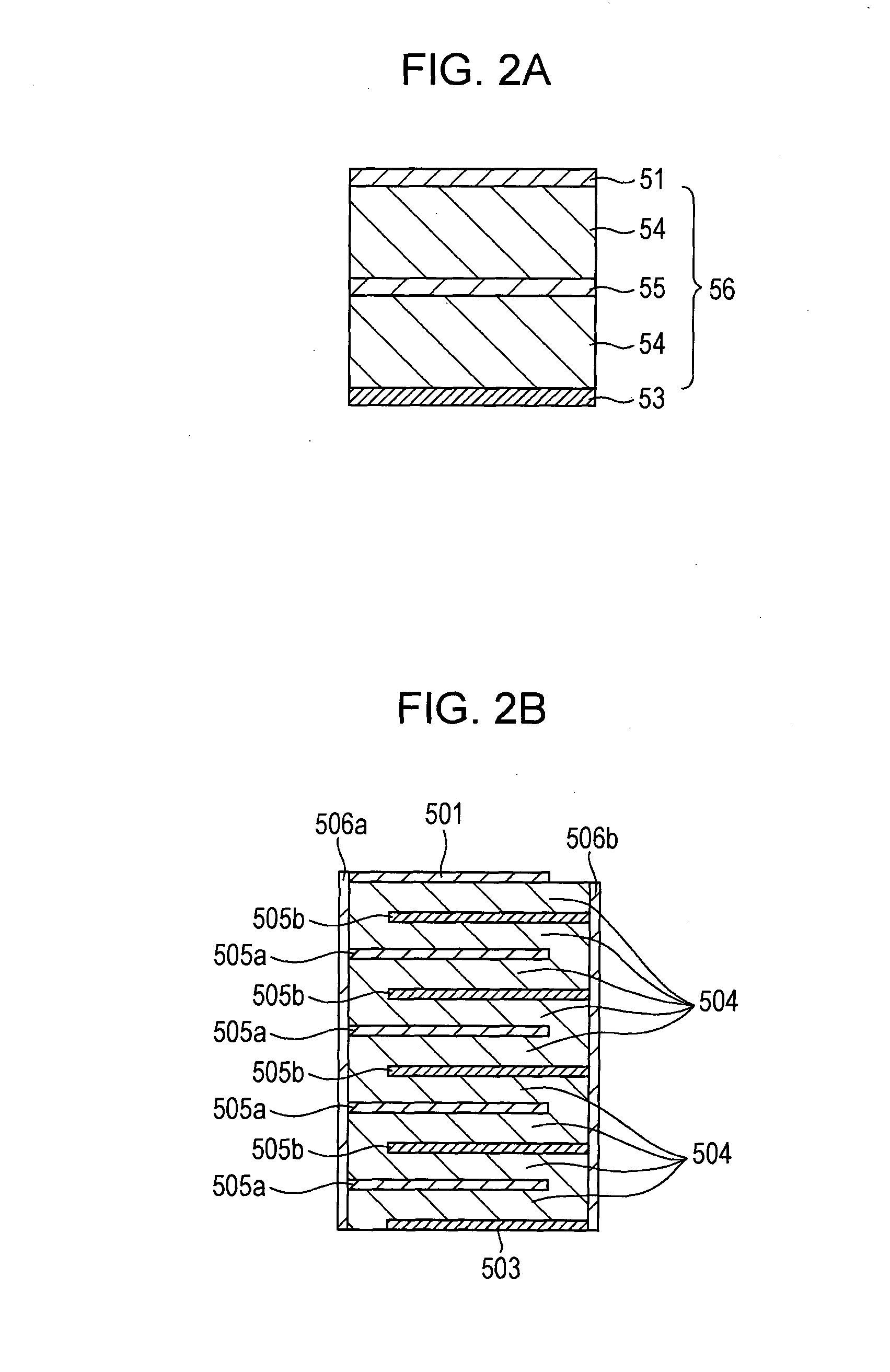

Piezoelectric material, piezoelectric element, and electronic apparatus

ActiveUS20150221856A1Satisfy insulation performanceSatisfactory piezoelectricityPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusAdditive ingredientPotassium

The present invention provides a piezoelectric material not containing lead and potassium, showing satisfactory insulation and piezoelectricity, and having a high Curie temperature. The invention relates to a piezoelectric material includes a main component containing a perovskite-type metal oxide represented by Formula (1): (NaxBa1-y)(NbyTi1-y)O3 (wherein, 0.80≦x≦0.94 and 0.83≦y≦0.94), and an additive component containing at least one element selected from Mn and Ni, wherein the content of the Ni is 0 mol or more and 0.05 mol or less based on 1 mol of the perovskite-type metal oxide, and the content of the Mn is 0 mol or more and 0.005 mol or less based on 1 mol of the perovskite-type metal oxide.

Owner:CANON KK

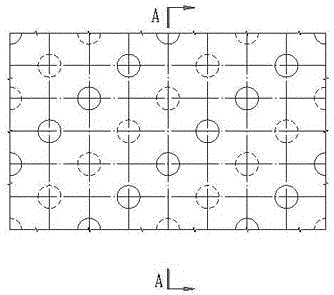

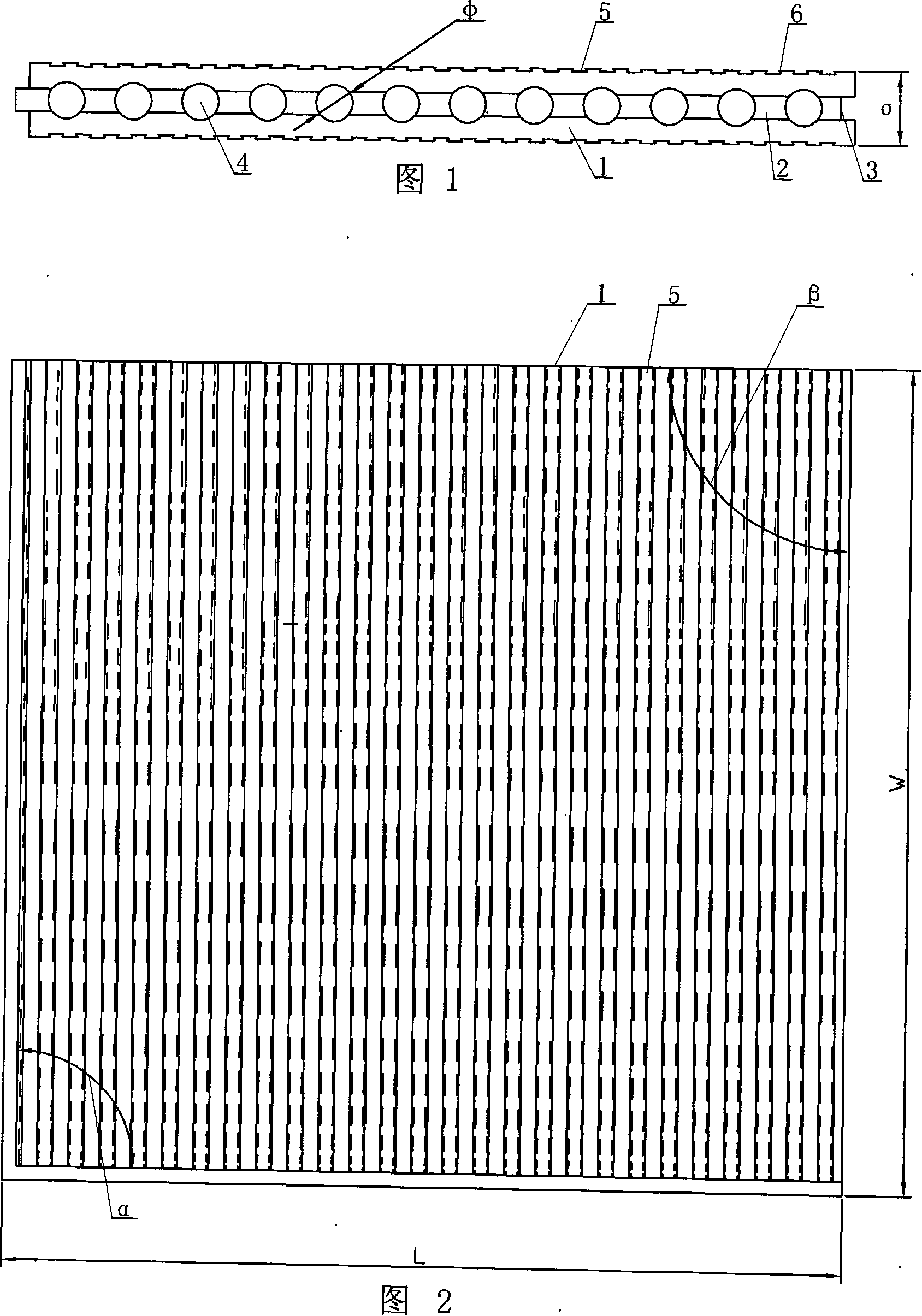

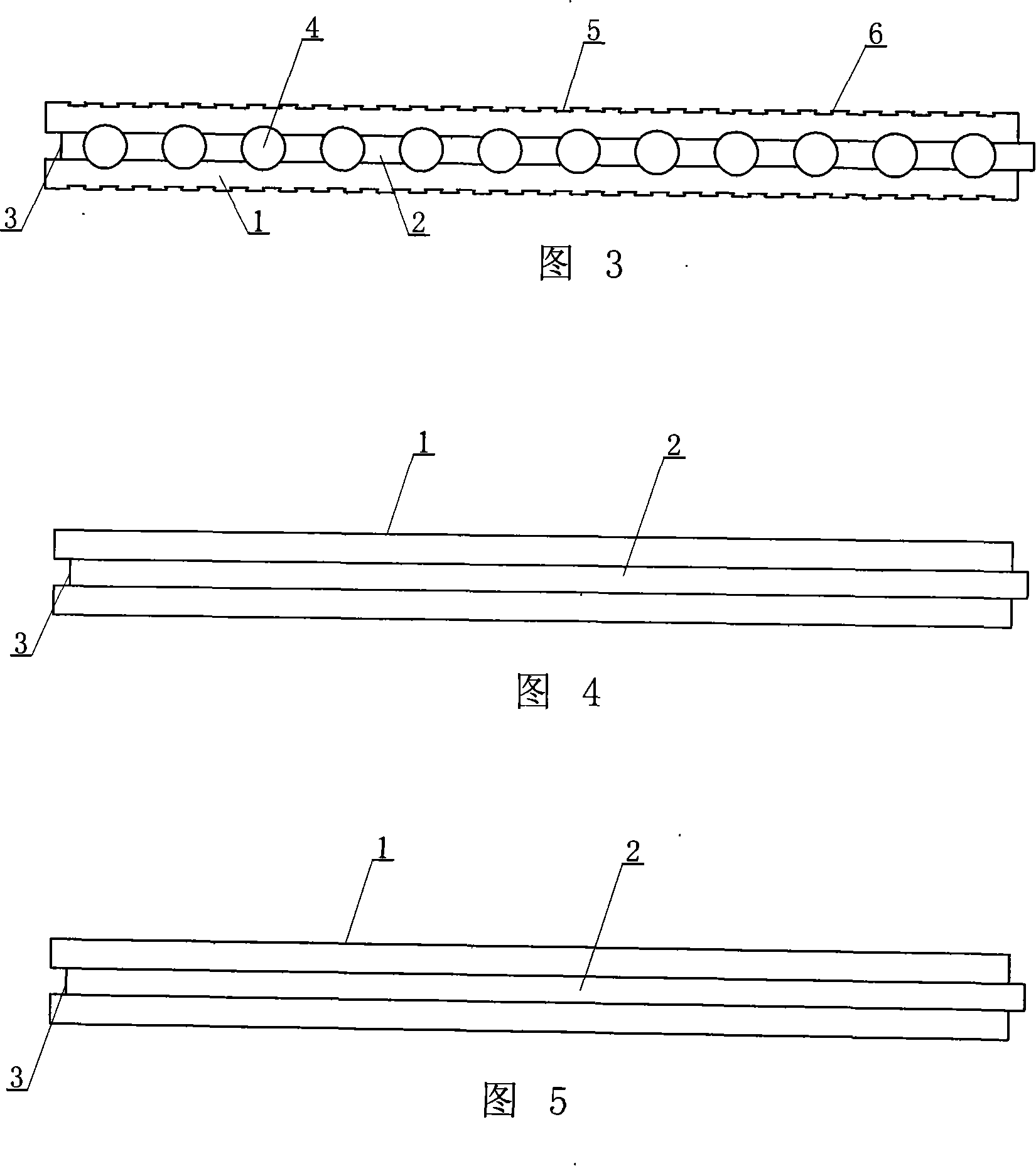

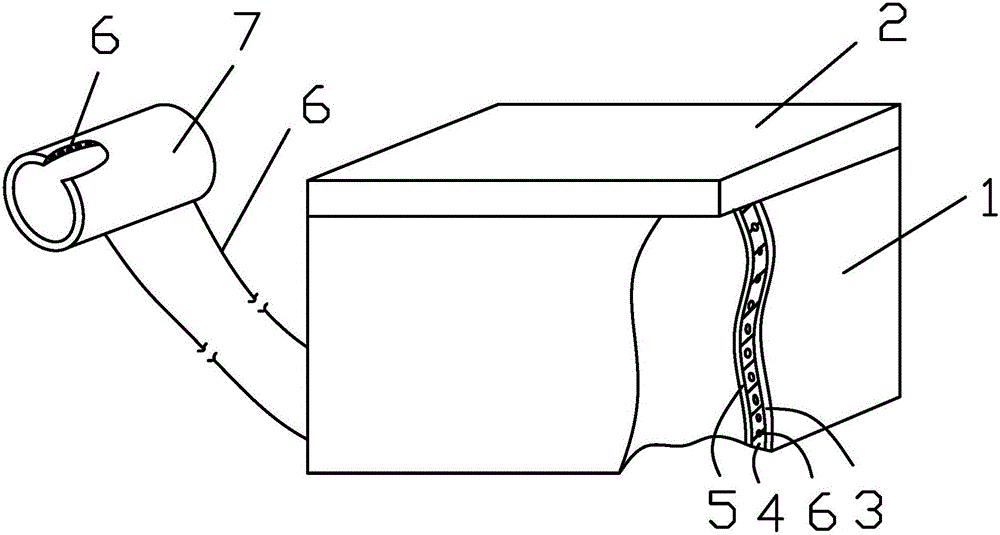

Energy-saving heat-preserving internal partition plate module of building

ActiveCN101109203AHave rigidity requirementsMeet the requirements of carrying capacityBuilding componentsGreek letter betaSmall footprint

An energy-saving heat-preservation module for inner partition wall boards for building, which relates to a module of building wall board and is for solving the problems such as complex structure, high overall weight, high cost and being only applicable for outer walls but not for inner walls for building associated with energy-saving heat-preservation module for walls. Wherein, at the two side ends where the two edges of an apex angle alpha of a PP module (1) are, inserting tenons (2) are provided; on the two side ends where the two edges of an apex angle beta on the diagonal line same with the apex angle alpha of the PP module (1) are, inserting slots (3) are provided; the inserting tenons (2) and the inserting slots (3) of two adjacent PP modules (1) match each other; a group of through holes (4) are provided on the two parallel side ends on the PP module (1), and the through holes (4) pass through the corresponding inserting tenons (2) and inserting slots (3). The invention has the advantages of the simple structure, the light weight, the low cost, the small footprint, the good heat preservation and sound proof effect as a whole, and can meet the requirement for rigidity of an inner partition wall.

Owner:HARBIN HONGSHENG ROOM ENERGY SAVING SYST RES CENT

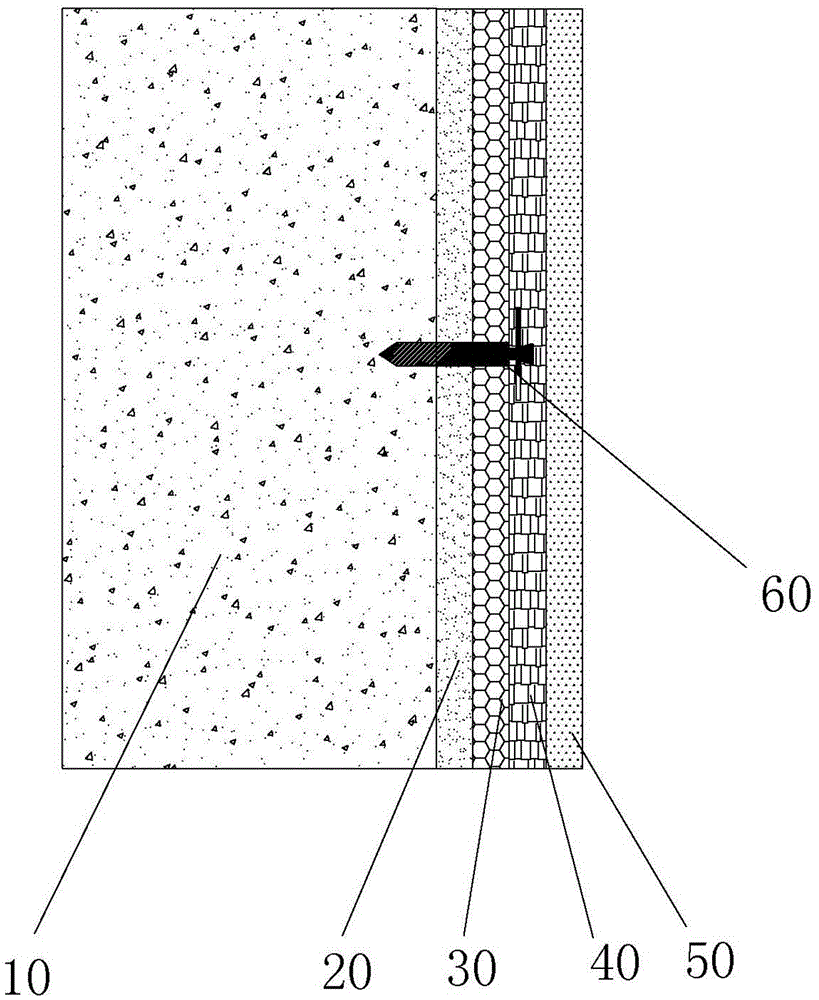

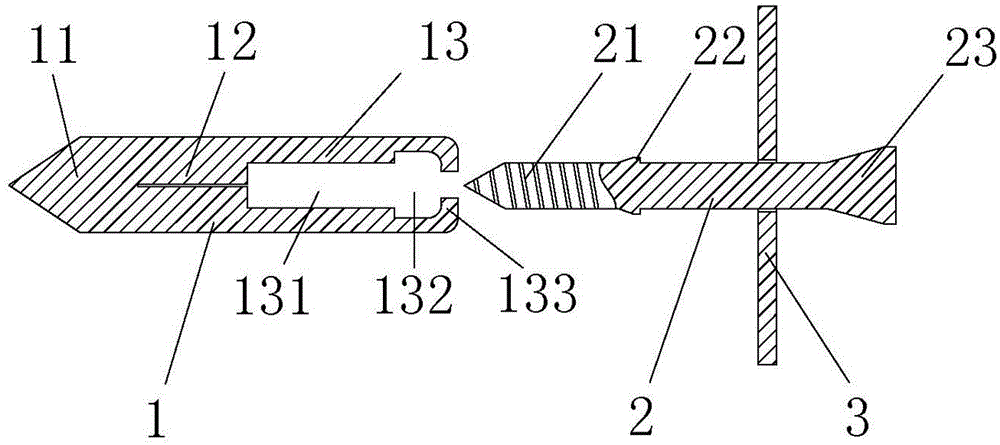

Inorganic thermal mortar external wall insulation system

ActiveCN104481038AMeet insulationMeet fire protectionCovering/liningsWallsUltimate tensile strengthFire prevention

The invention relates to an inorganic thermal mortar external wall insulation system and belongs to the technical field of new materials for construction. The inorganic thermal mortar external wall insulation system comprises a concrete wall or a masonry wall, wherein the concrete wall or the masonry wall is covered with multiple coatings; the multiple coatings sequentially comprise an interface mortar layer, an inorganic light-weight aggregate thermal mortar layer, a plastering anti-crack mortar layer and a finishing layer from inside to outside. The inorganic thermal mortar external wall insulation system can simultaneously meet the requirements on much performance such as thermal insulation, fire prevention, sound insulation, strength and anchorage of the wall; an anchorage piece has the advantages of convenience in use and high anchoring strength.

Owner:ANJI QILONG NEW BUILDING MATERIAL

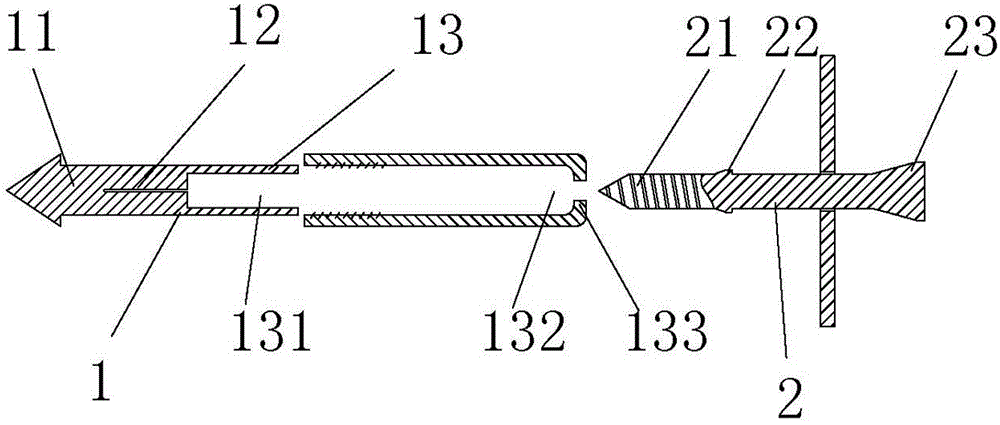

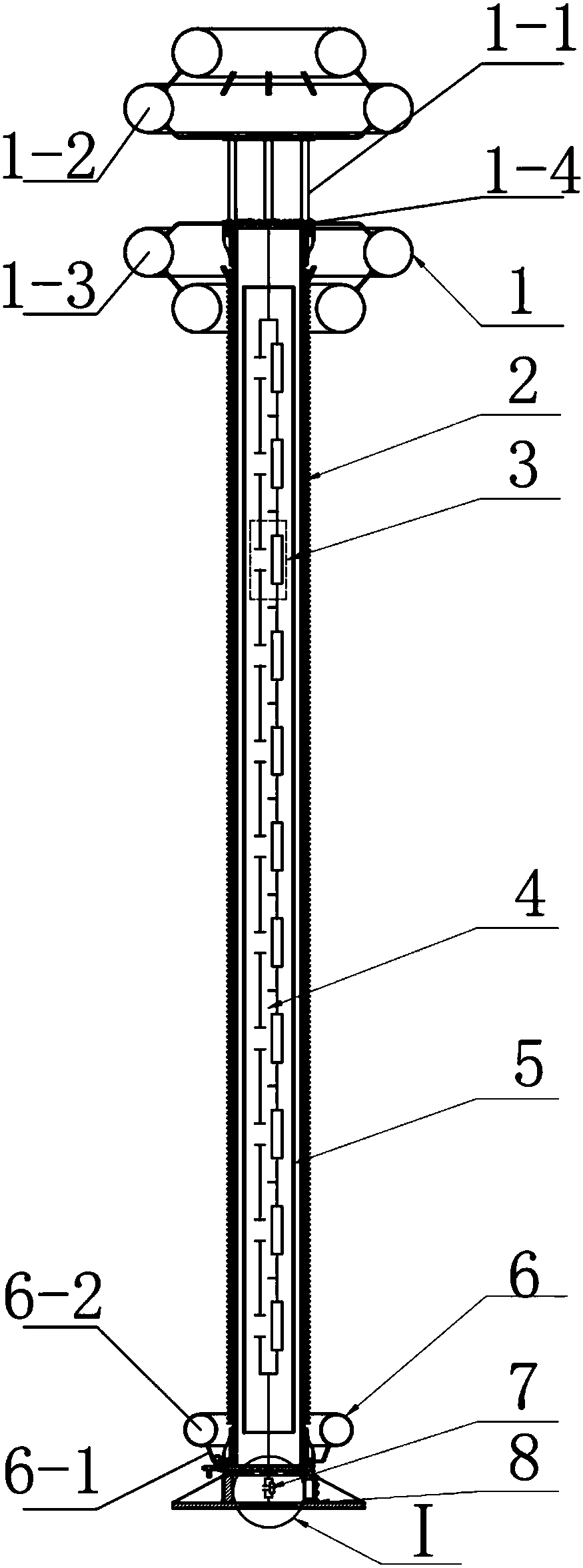

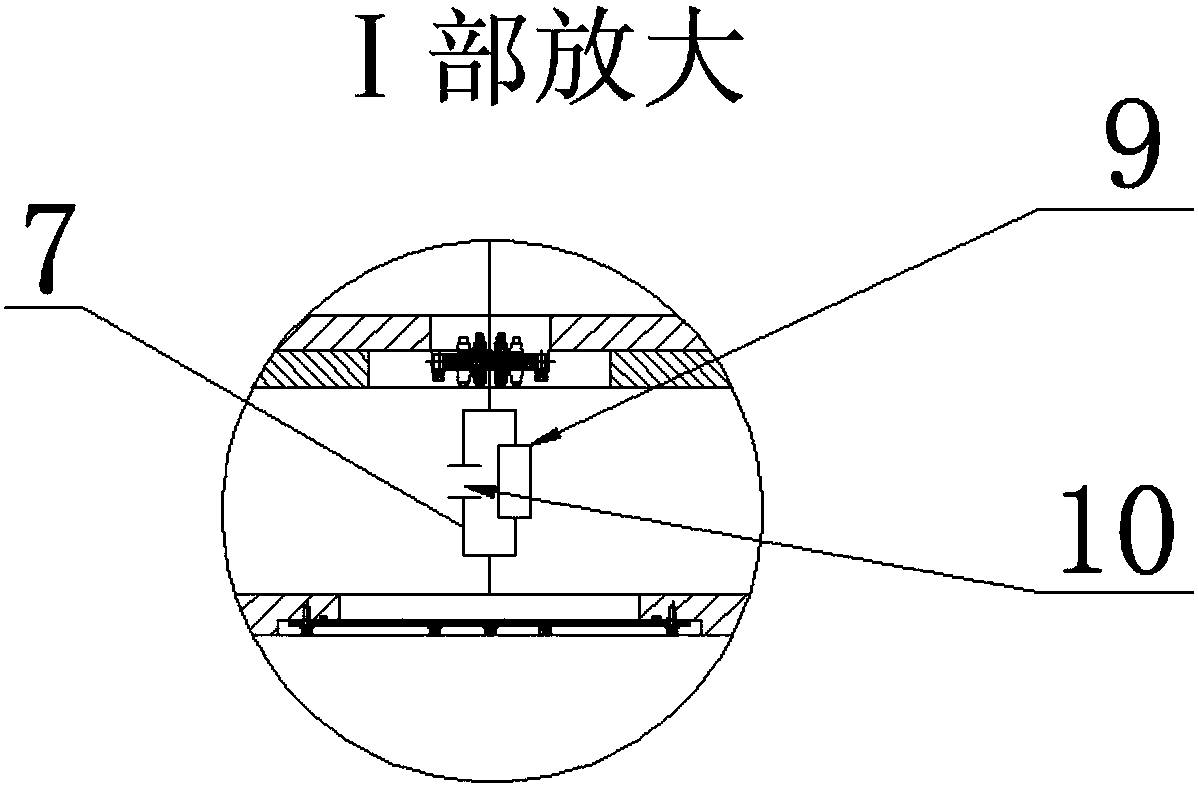

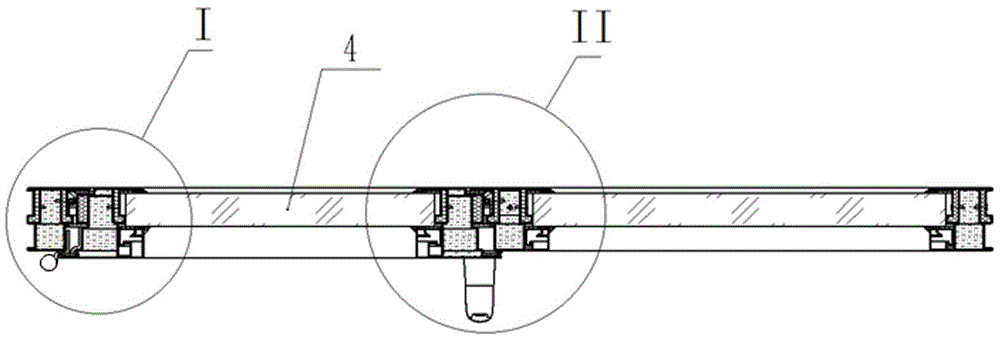

+/-1100kV direct current voltage divider

InactiveCN108627683AGuaranteed Dielectric StrengthUniform distribution of internal field strengthVoltage dividersLow voltageUltimate tensile strength

In the invention, a high voltage end grading ring component, a high voltage arm unit, a low voltage end grading ring component, a low voltage arm unit and a pedestal are included. The low voltage armunit is arranged on the pedestal. A first insulation hollow casing pipe and a second insulation inner pipe are included. The second insulation inner pipe is arranged in the first insulation hollow casing pipe. The high voltage arm unit is arranged in the second insulation inner pipe. The pedestal is connected to the first insulation hollow casing pipe. The low voltage end grading ring component isarranged on one end of the first insulation hollow casing pipe. The high voltage end grading ring component comprises a first support, two grading ring groups fixed to the first support and a high voltage end terminal. The first support is arranged on the other end of the first insulation hollow casing pipe. The grading ring groups form a spherical or ellipsoidal envelope structure. The two endsof the high voltage arm unit are connected to the high voltage end terminal and the other end of the low voltage arm unit. In the invention, a field intensity near a high voltage end is uniformly distributed and local electric field intensity is reduced.

Owner:STATE GRID CORP OF CHINA +3

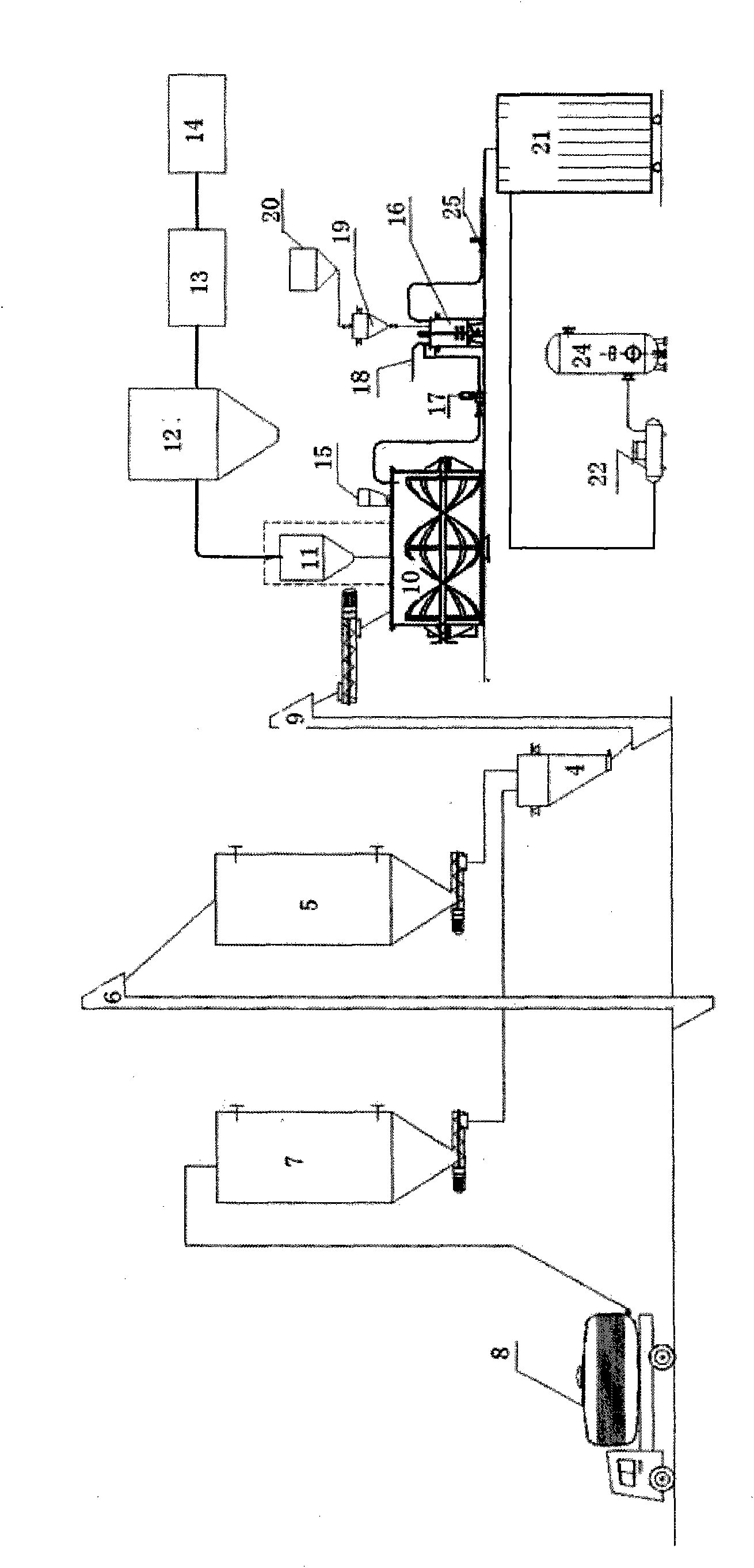

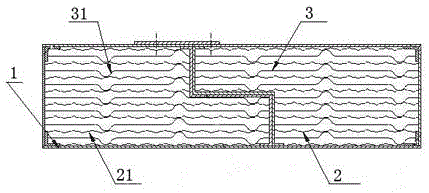

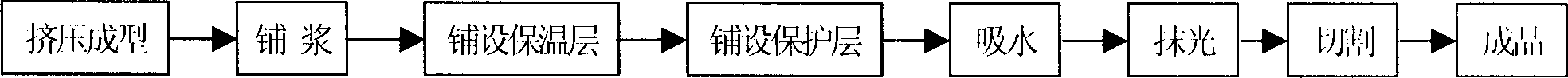

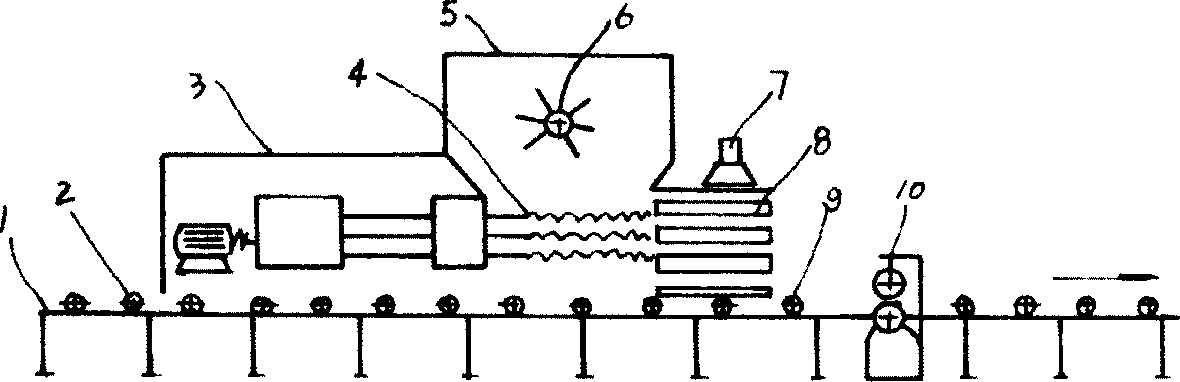

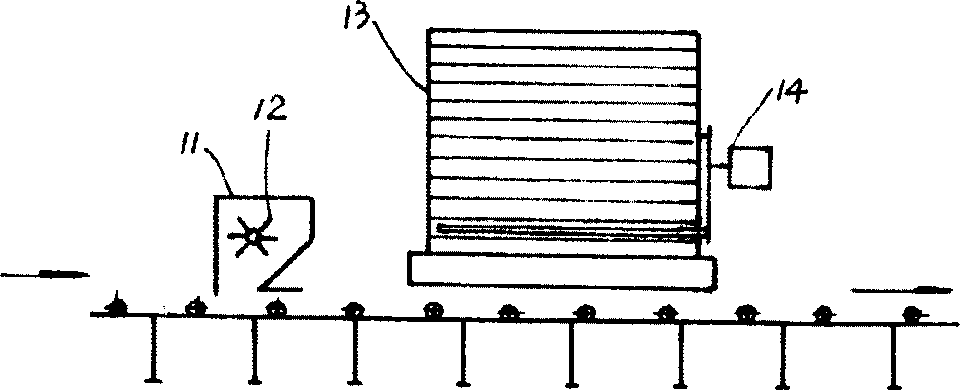

Composite wall plate producing process and system

InactiveCN1403257AQuality improvementImprove insulation effectWallsSurface layering apparatusBogieProduction line

The composite wall plate producing process includes extruding mortar to form, spreading heat insulating layer, spreading protecting layer, absorbing water, smoothing, cutting and curing. The equipment system for the said technological process includes extruder, heat insulating layer spreading machine, protecting layer spreading machine, automatic cutting machine, conveyer to connected foregoing equipment, curing bogie at the end of the automatic cutting machine, curing kiln and plate discharging platform. The present invention integrates the production steps and produce plate in an automatic production line.

Owner:于德海

Building material

The present invention relates to a building material, which comprises, by weight, 10-20 parts of fly ash, 2-3 parts of rubber particles, 5-10 parts of quicklime, 10-20 parts of calcium stearate, 10-20 parts of lightweight ceramic, 30-50 parts of nanometer silica, 1-3 parts of polyethylene, 5-7 parts of an organosilicon modified epoxy resin, 3-4 parts of a foaming agent, 3-7 parts of carbon cellulose, and 30-50 parts of water. According to the present invention, the building material can meet requirements such as water absorption, flame retardance, thermal insulation, strength and the like, and further has advantages of green environmental protection, great economic value, and great social value.

Owner:裴寿益

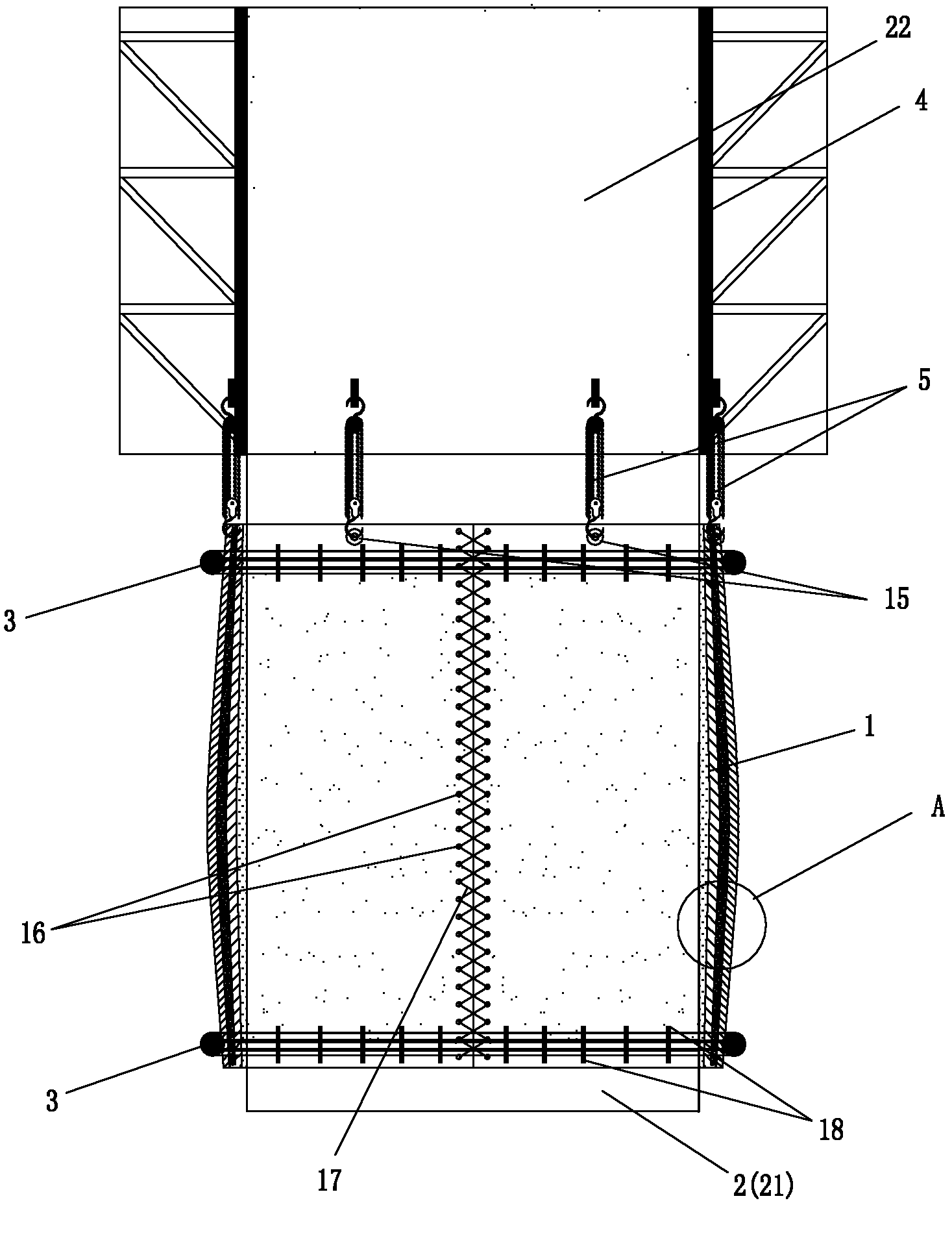

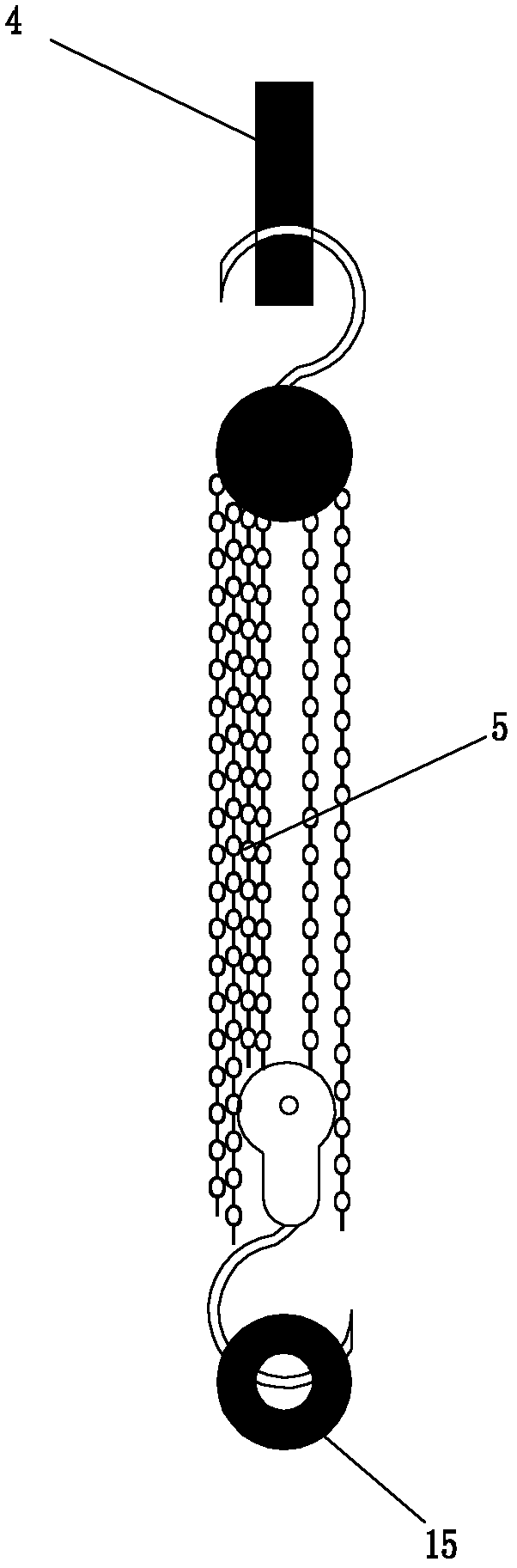

Thermal insulation method and concrete thermal insulation cover for winter construction of pier column

ActiveCN102535872AMeet insulationSimple operation processBuilding material handlingThermal insulationPlastic film

The invention relates to a concrete thermal insulation cover for the winter construction of a pier column. The concrete thermal insulation cover is used for circumferentially wrapping the poured construction section of the pier column and has a rectangular shape; one side of the concrete thermal insulation cover, which is contacted with the pier column, is an inner side; the concrete thermal insulation cover consists of a plastic film layer, a first covering cloth layer, a rock wool layer and a second covering cloth layer from the inner side to the outer side in turn; rubber band bundles for hermetically tightening and winding the upper end and the lower end on the outer side of the poured construction section are respectively arranged at the upper end and the lower end of the rectangular concrete thermal insulation cover along the edge; a plurality of lifting holes are formed in the edge of the upper end of the concrete thermal insulation cover; and each lifting hole is connected with a template of a construction section which is to be poured and is positioned above the concrete thermal insulation cover through a connecting member. The concrete thermal insulation cover can meet the requirement on concrete thermal insulation during the winter construction of the pier column, an operation process can be simplified, manual high-altitude operation is avoided, construction difficulty and risk are reduced, and construction safety and convenience are achieved.

Owner:CHINA FIRST HIGHWAY ENG +1

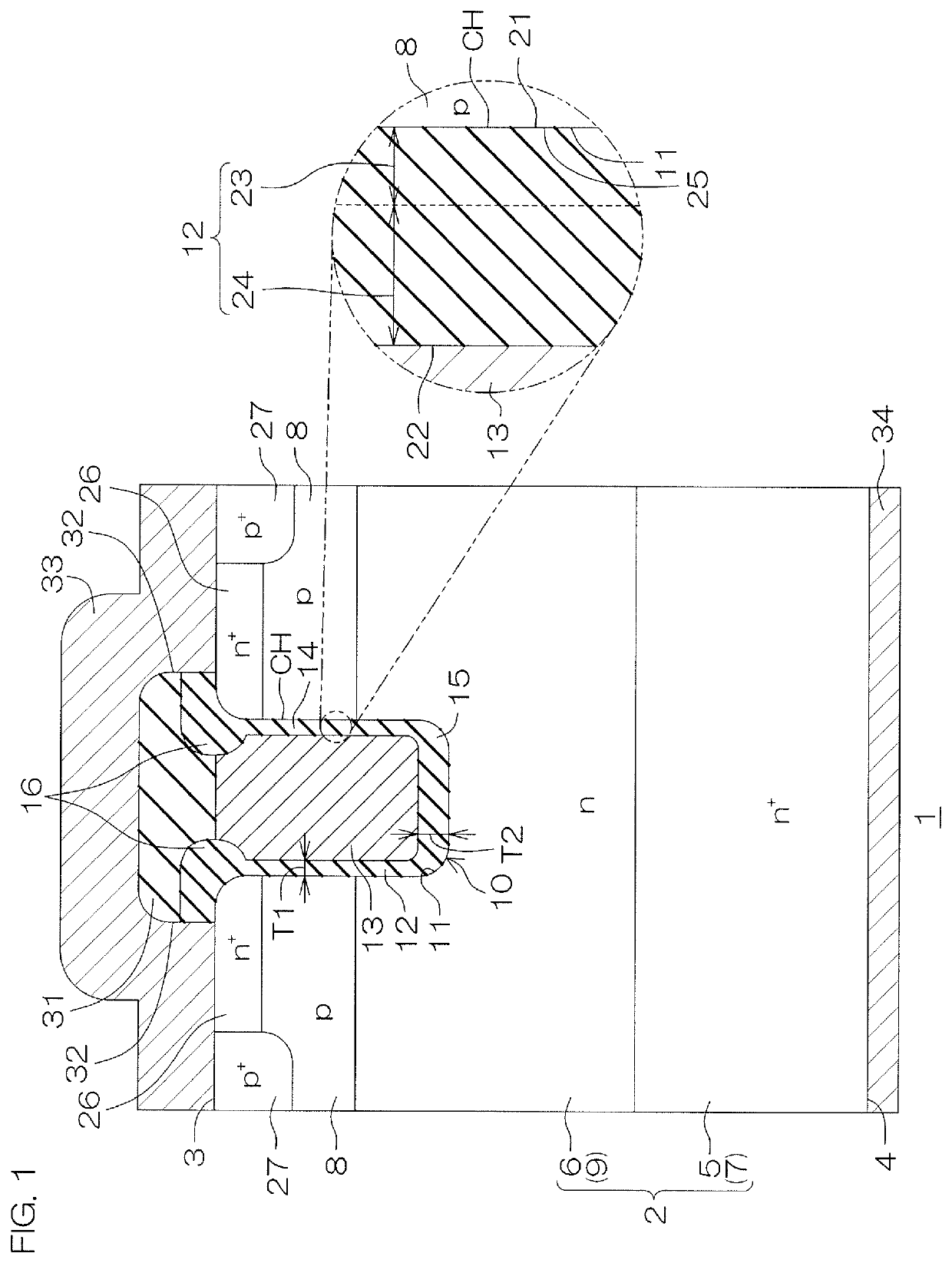

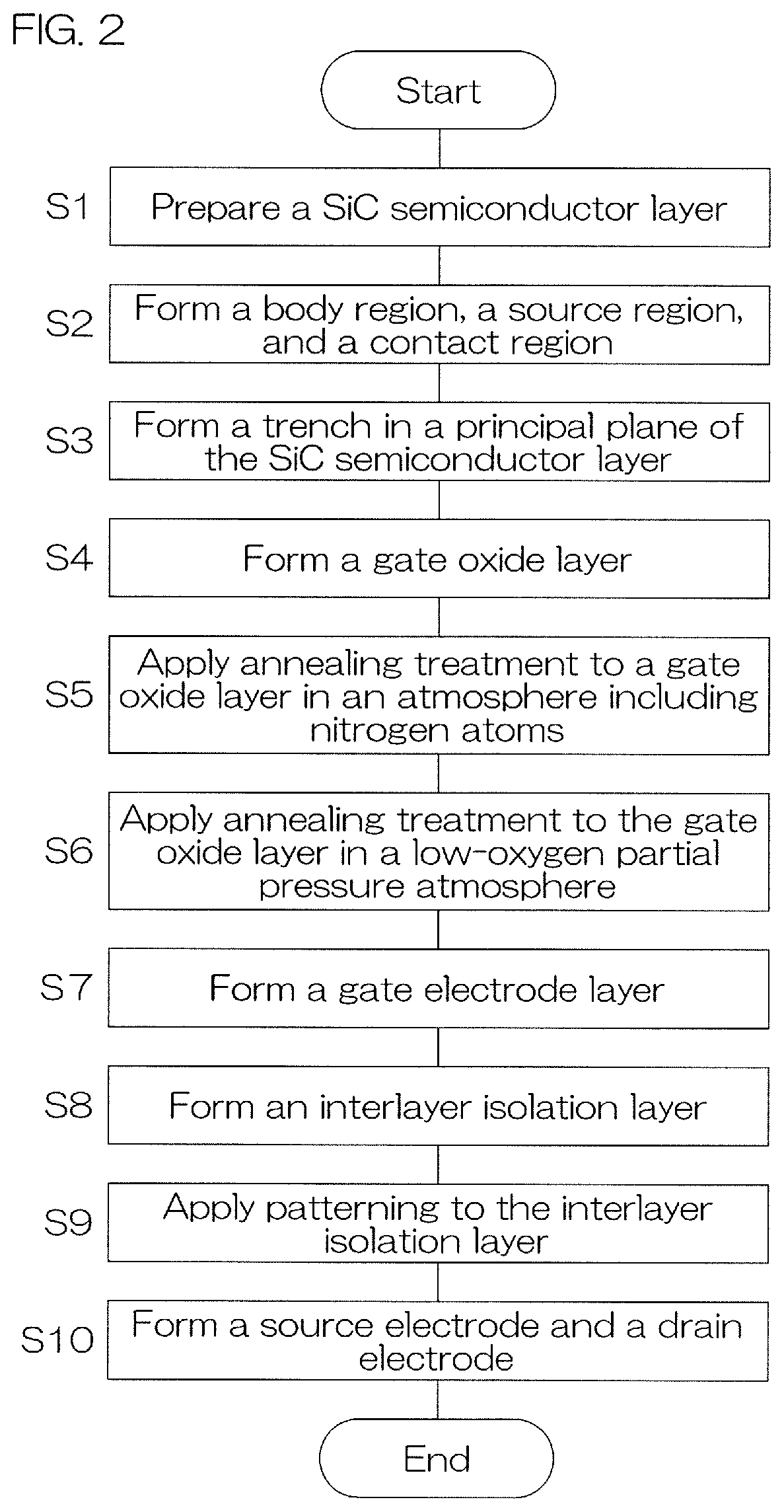

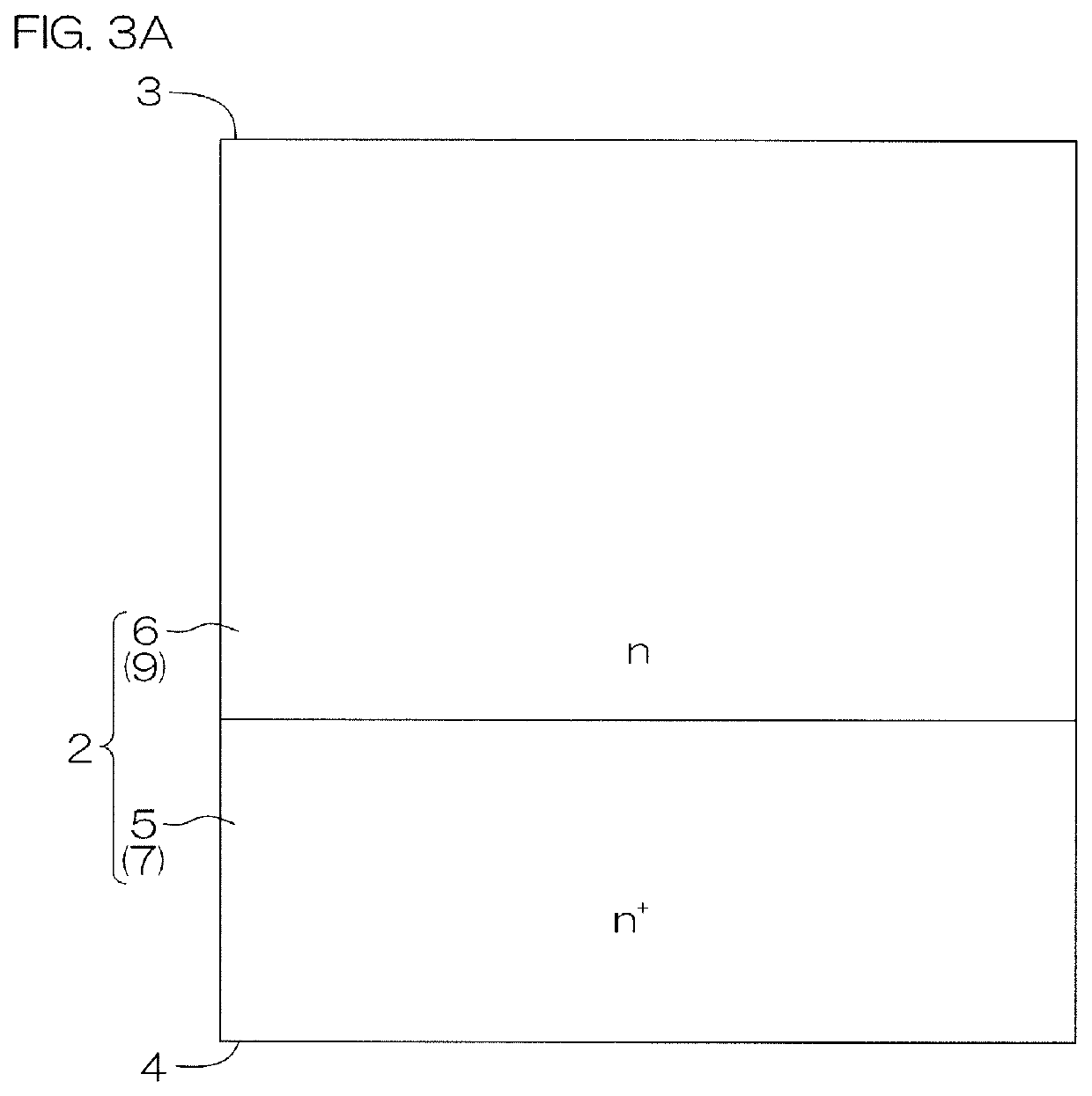

Semiconductor device and method for manufacturing same

ActiveUS20200403069A1Reduce interface defectsSatisfy insulation performanceTransistorSemiconductor/solid-state device manufacturingPhysicsEngineering

A semiconductor device includes a SiC semiconductor layer that has a carbon density of 1.0×1022 cm−3 or more, a SiO2 layer that is formed on the SiC semiconductor layer and that has a connection surface contiguous to the SiC semiconductor layer and a non-connection surface positioned on a side opposite to the connection surface, a carbon-density-decreasing region that is formed at a surface layer portion of the connection surface of the SiO2 layer and in which a carbon density gradually decreases toward the non-connection surface of the SiO2 layer, and a low carbon density region that is formed at a surface layer portion of the non-connection surface of the SiO2 layer and that has a carbon density of 1.0×1019 cm−3 or less.

Owner:ROHM CO LTD

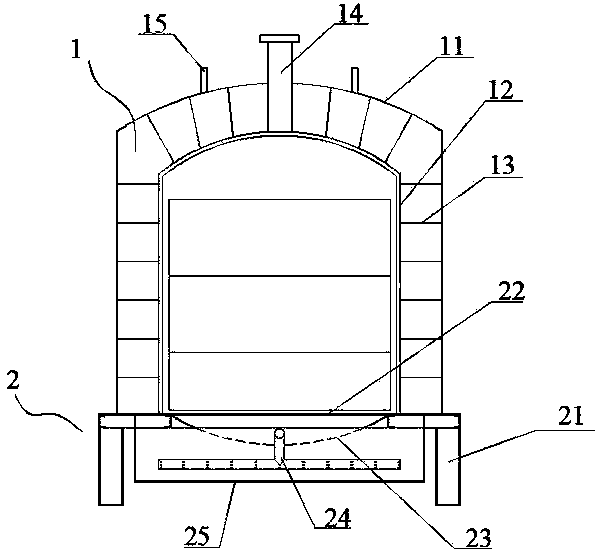

Movable stainless steel charcoal kiln

The invention relates to a carbonizing kiln, in particular to a movable stainless steel charcoal kiln. The movable stainless steel charcoal kiln comprises a movable kiln body and a pedestal, wherein the movable kiln body is arranged on the pedestal in a covering manner and comprises an stainless steel liner on the inner layer, a stainless steel frame on the outer layer, and a connecting rod for fixedly connecting the stainless steel liner with the stainless steel frame; flues are arranged at the tops of the stainless steel liner and the stainless steel frame; a plurality of hoisting rings are further arranged at the top of the stainless steel frame. In the invention, as the movable kiln body adopts the stainless steel liner, the kiln can withstand high-temperature working for a long time, tolerate the high temperature at 1200 DEG C, effectively preserve heat, meet the requirement of keeping the high temperature from 800 to 1000 DEG C during the carbonizing process, and produce the high-quality machine-made charcoal. After firing of the charcoal, the movable kiln body can be directly hoisted away, so as to greatly quicken the dissipation speed of the charcoal, and greatly increase the carbonizing efficiency as the whole carbonizing process can be shortened to 6 days.

Owner:江西友林能源科技有限公司

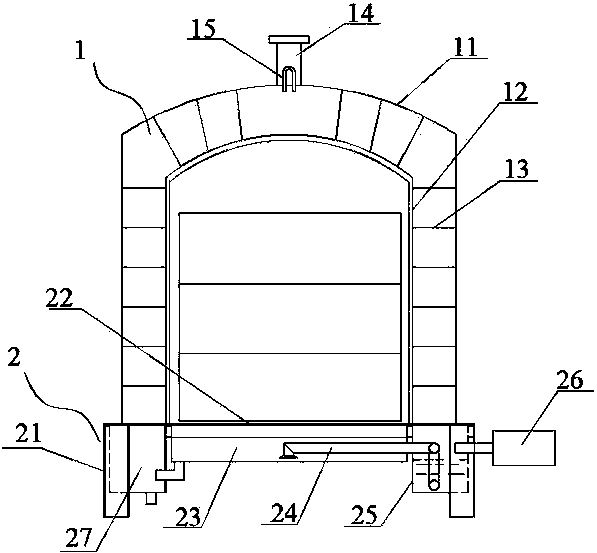

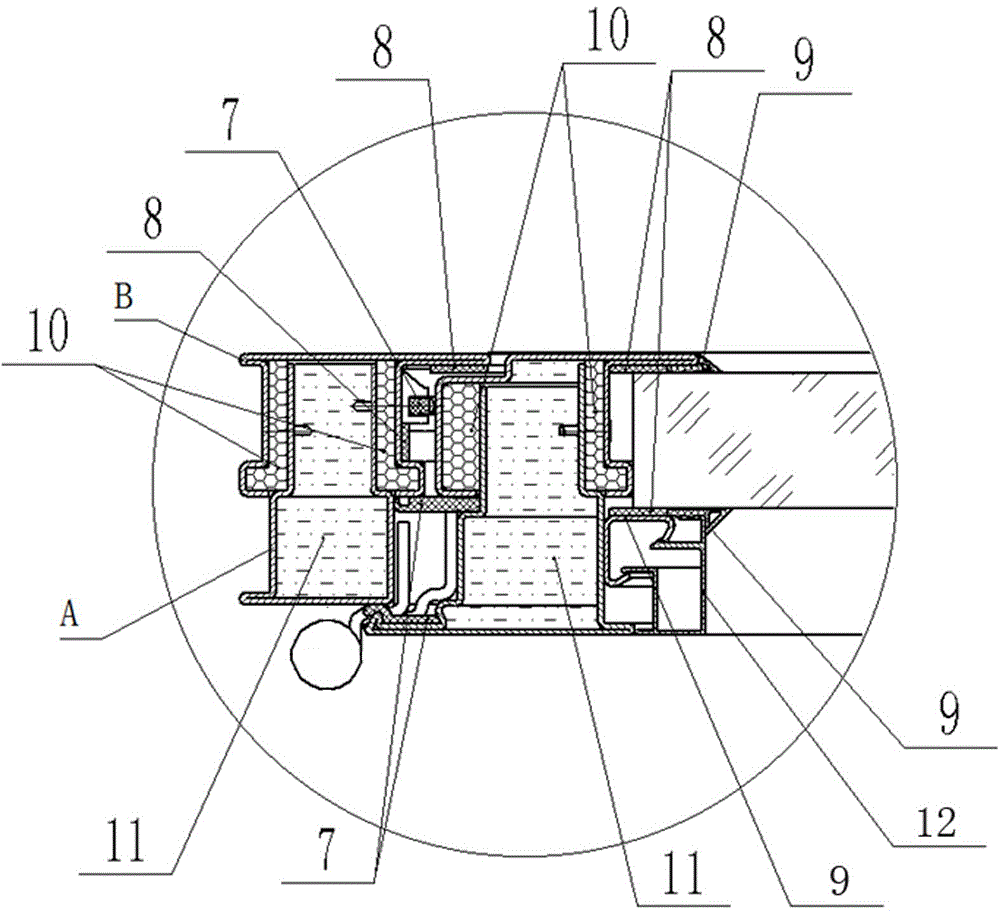

Multifunctional steel door window system and manufacturing method for window frame and window sash frame in system

ActiveCN106639817ALow costBeautiful appearanceFireproof doorsSealing arrangementsGreen buildingEngineering

The invention relates to steel door windows, in particular to a multifunctional steel door window system which can meet the requirements of fire resistance, fire prevention and energy conservation and a manufacturing method for a window frame and a window sash frame in the system. The multifunctional steel door window system comprises the window frame, a mullion, the window sash frame and glasses, a lockset and hinges which are matched with the window frame, the mullion and the window sash frame. The window frame and the window sash frame are connected with the hinges; a window frame sectional material, a mullion sectional material and a window sash frame sectional material comprise first bridge fracturing cold bending matching pieces and second bridge fracturing cold bending matching pieces; and inorganic bridge fracturing heat insulation sectional material strips are arranged between the matching faces of the first bridge fracturing cold bending matching pieces and the second bridge fracturing cold bending matching pieces and are fixed through screws to form a steel heat insulation composite sectional material. The steel and stainless steel door window system design is low in cost and environmentally friendly and has multiple functions of heat preservation, heat insulation, sound insulation, water resistance, fire resistance and the like. According to the door window system, the appearance is elegant, firmness, durability and multiple functions are achieved, the materials are environmentally friendly and can be recycled, and the door window system meets the national regulation requirement relating to a green building.

Owner:SHAN XI XIN MING GE FIRE PROTECTION SCI&TECH CO LTD

Vehicle-mounted heat-preservation device

ActiveCN105905018AMeet insulationSatisfy insulation performanceVehicle arrangementsEngineeringHolding tank

The invention discloses a vehicle-mounted heat-preservation device, and relates to the field of incubator structures. The vehicle-mounted heat-preservation device comprises a box body and a box cover, wherein the box body comprises an outer waterproof layer, a heat-preservation middle layer and an inner waterproof layer; a heating layer is arranged on the heat-preservation middle layer; the heating layer is filled with a heat conduction liquid; the heating layer is connected with a heat exchanger which is mounted on a vehicle heat radiator through a heat conduction tube; the heat radiator is mounted at the inlet of an engine heat radiator; the box body is arranged inside the bottom of a vehicle chair; the box cover is arranged on a side corresponding to the vehicle chair; a sliding device which is arranged in a horizontal manner is mounted inside the box body; the sliding device comprises a dragging plate and a sliding track; the dragging plate slides along the sliding track and the extending end of the dragging plate can extend out of the box body; the sliding track is arranged inside the box body; a holding tank which is accommodated inside the box body along with the dragging plate is arranged at the extending end of the dragging plate; arch-shaped convex elastic pieces are arranged inside the holding tank. By adopting the vehicle-mounted heat-preservation device, long-lasting heat preservation can be achieved, and requirements of preserving heat of meal, heating a milk bottle and refrigerating food can be met.

Owner:靖西市计量检定测试所

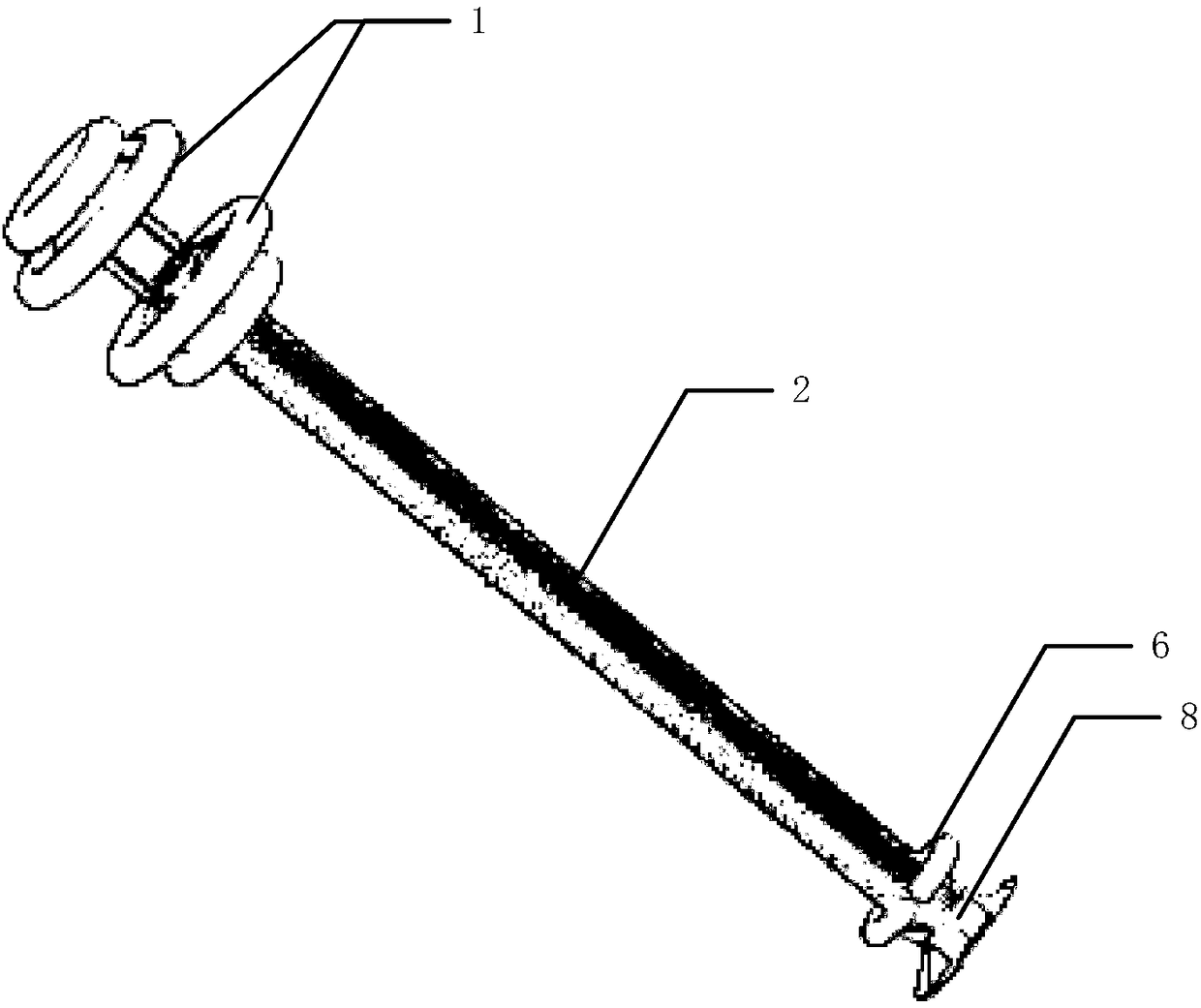

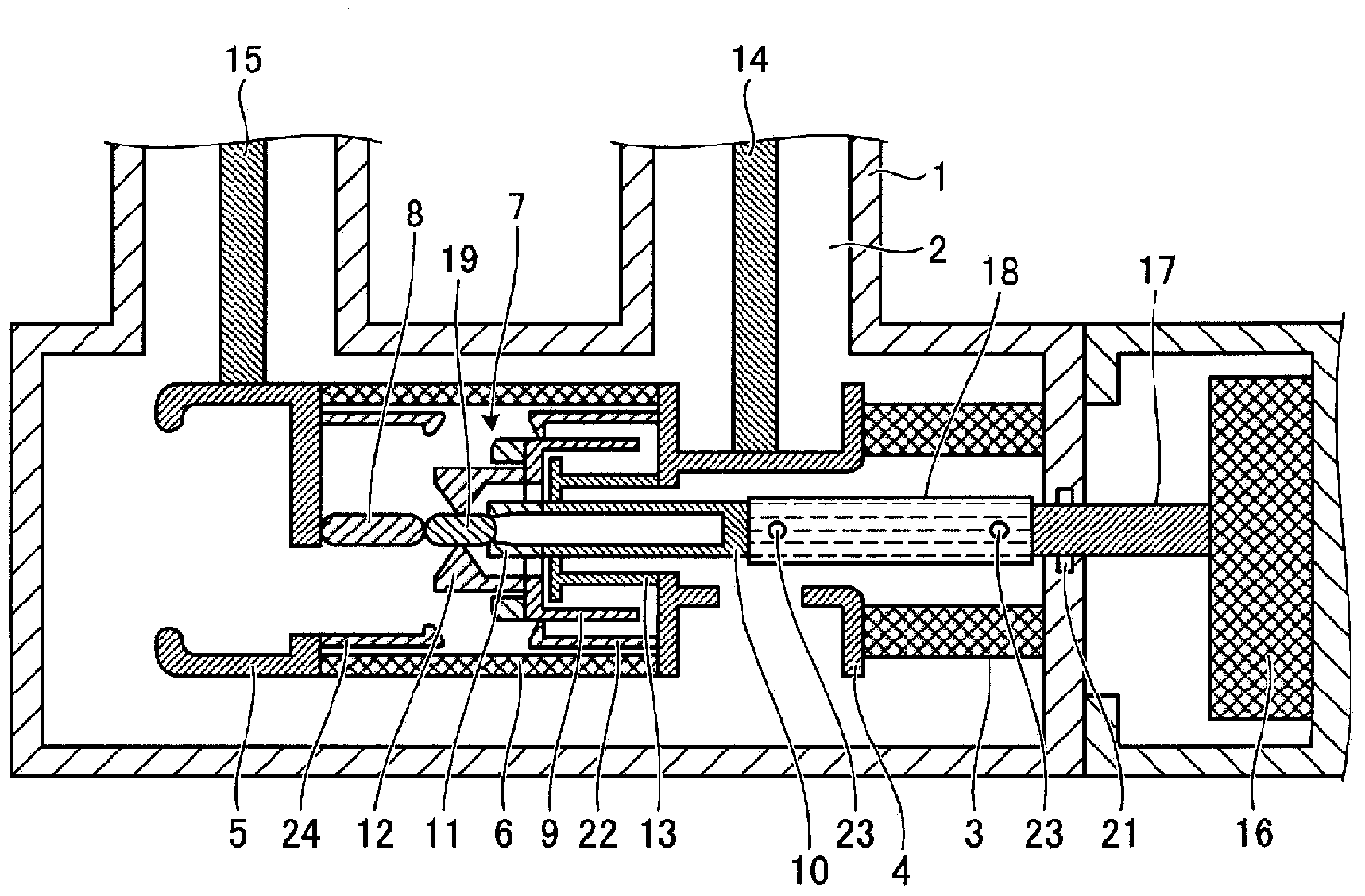

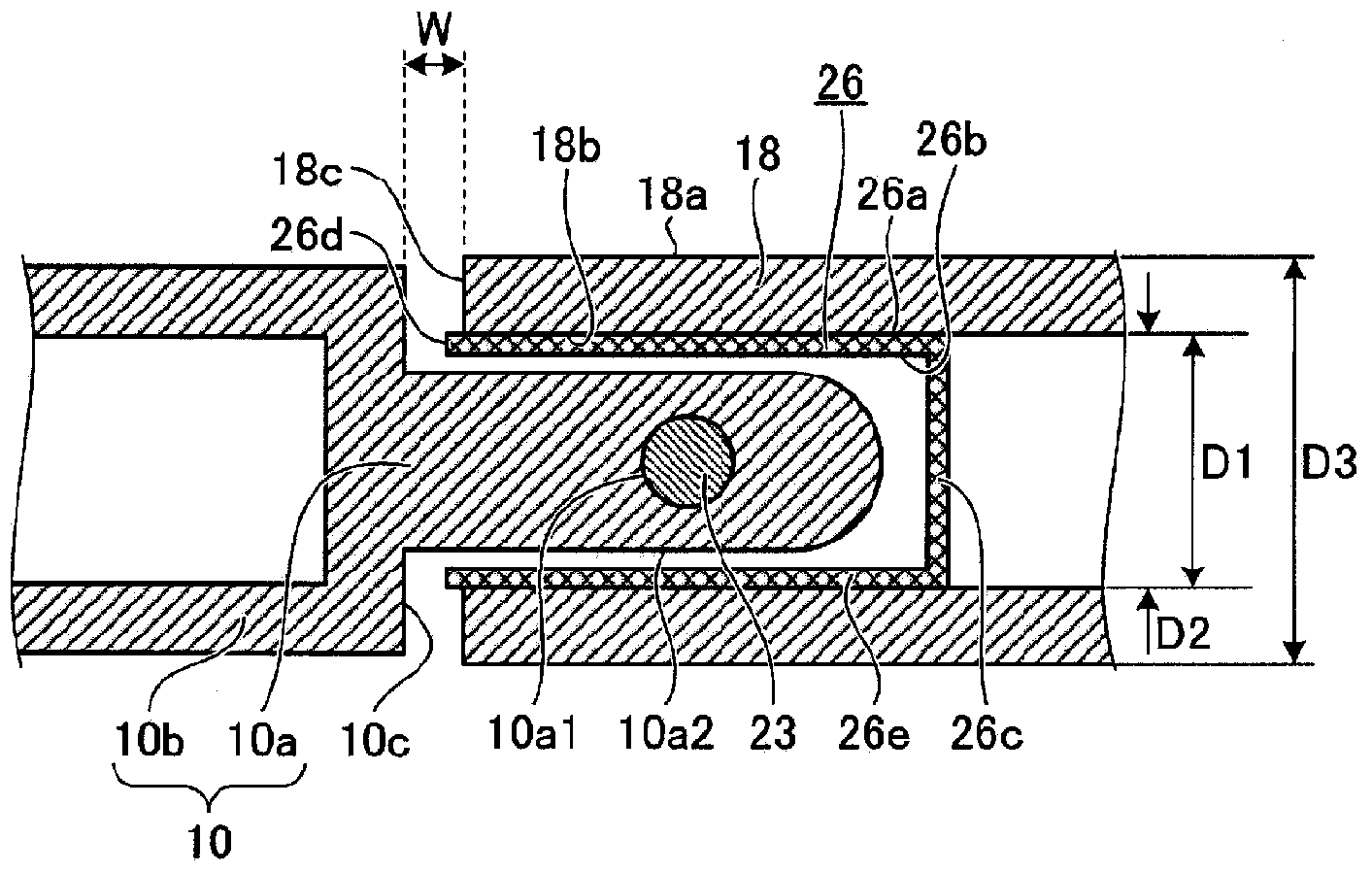

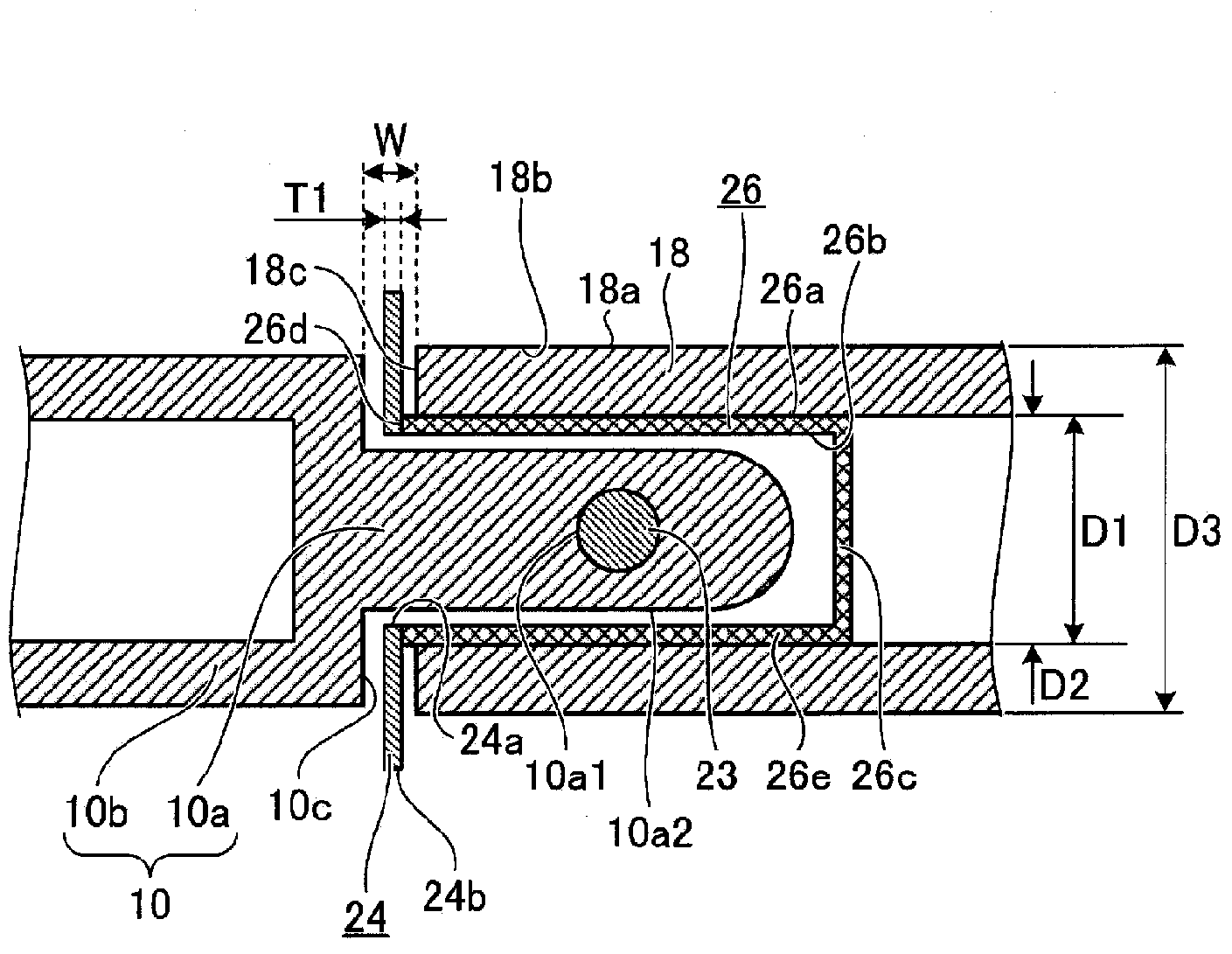

Gas circuit breaker

ActiveCN104380417AGuaranteed air tightnessSatisfy insulation performanceHigh-tension/heavy-dress switchesAir-break switchesCouplingPiston rod

A piston rod includes a large-diameter portion that is formed on the side of a movable contact, and a small-diameter portion that is formed on the side of an insulating operation rod relative to the large-diameter portion, and that is formed with an outer diameter smaller than the inner diameter of an inner peripheral surface of an insulating cylindrical member. The insulating cylindrical member includes a cylindrical portion that is interposed between the outer peripheral surface of the small-diameter portion and the inner peripheral surface of the insulating operation rod, a bottom portion that is arranged opposed to the distal end of the small-diameter portion, and a through hole through which a coupling pin is inserted through the piston rod and the insulating operation rod.

Owner:MITSUBISHI ELECTRIC CORP

Aluminum foil woven fabric and preparation method thereof

PendingCN107244107AImprove flame retardant effectComposite fastness is goodFlexible coversWrappersWoven fabricCalcium carbonate

The invention discloses an aluminum foil woven fabric which consists of an upper aluminum foil layer, a flame retardant adhesive layer, a flame retardant woven fabric layer, a film lamination layer and a lower aluminum foil layer which are arranged in sequence from top to bottom, wherein the upper and lower aluminum foil layers are high-purity aluminum foils with the aluminum content of 99 percent; the flame retardant adhesive layer is calcium carbonate-added polyurethane composite glue; the flame retardant woven fabric layer is a low-pressure high-density polyethylene woven fabric; the film lamination layer consists of low-density polyethylene particles; the upper surface of the flame retardant woven fabric layer is compounded with the upper aluminum foil layer through the polyurethane composite glue; the lower surface of the flame retardant woven fabric layer is compounded with the lower aluminum foil layer through the melted low-density polyethylene particles in an adhered manner. According to the aluminum foil woven fabric prepared through the method, on the premise of not affecting the compound fastness and the physical performance of the material, the flame retardancy of the whole material is improved, and heat insulation and preservation of buildings home and abroad and flame retardancy of special packaging materials are met; the aluminum foil woven fabric is heat-insulated, waterproof, breathable and reflexible, can meet a heat insulation requirement, and is wide in application range and high in economical benefit.

Owner:ZHEJIANG PENGYUAN NEW MATERIAL TECH GRP CO LTD

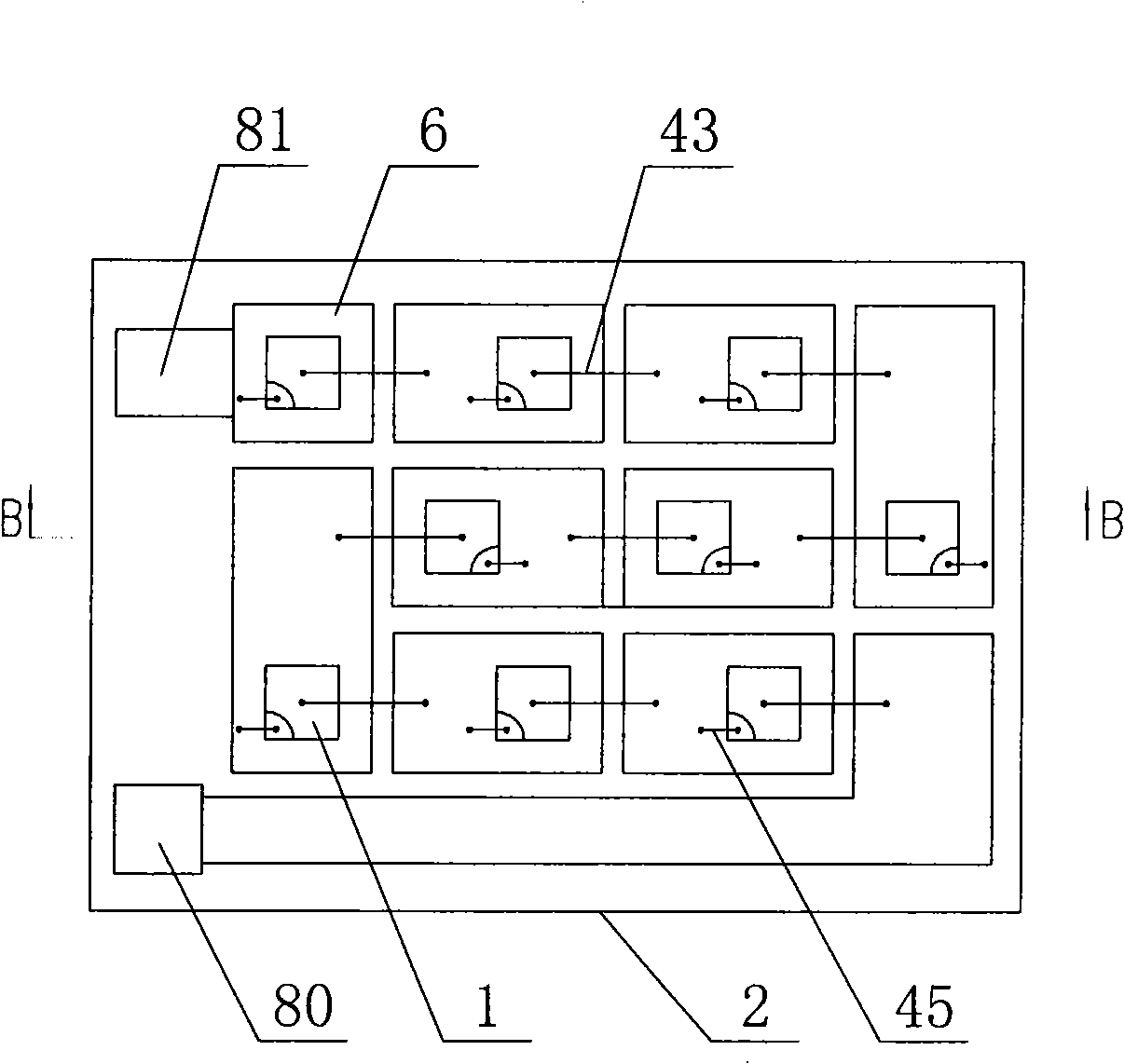

High on-stage voltage right-handed LED integrated chip and manufacturing method thereof

InactiveCN101330080AEasy to integrateLarge distribution areaSemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

The invention discloses a high continuity voltage up-mounted LED integrated chip with static protection which has the advantages of low cost, easy integration, good heat dissipation effect and high-pressure resistance and a manufacturing method thereof. The integrated chip comprises a plurality of LED bare chips (1) and silicon substrates (2), wherein, the LED bare chips (1) comprise substrates (10), N-type epitaxial layers (11) and P-type epitaxial layers (12), heat conducting insulating layers are formed on the front surfaces of the silicon substrates (2), metal layers (6) are deposited on the heat conducting insulating layers, the LED bare chips (1) are up-mounted on the metal layers (6) and are connected through the metal layers (6) to form a circuit, anode contacts (80) and cathode contacts (81) are led out from the metal layers (6). The manufacturing method comprises the following steps: forming the heat conducting insulating layers, forming the metal layer and encapsulating the LED bare chips, and is widely applicable to the LED bare chip field.

Owner:NANKER GUANGZHOU SEMICON MFG

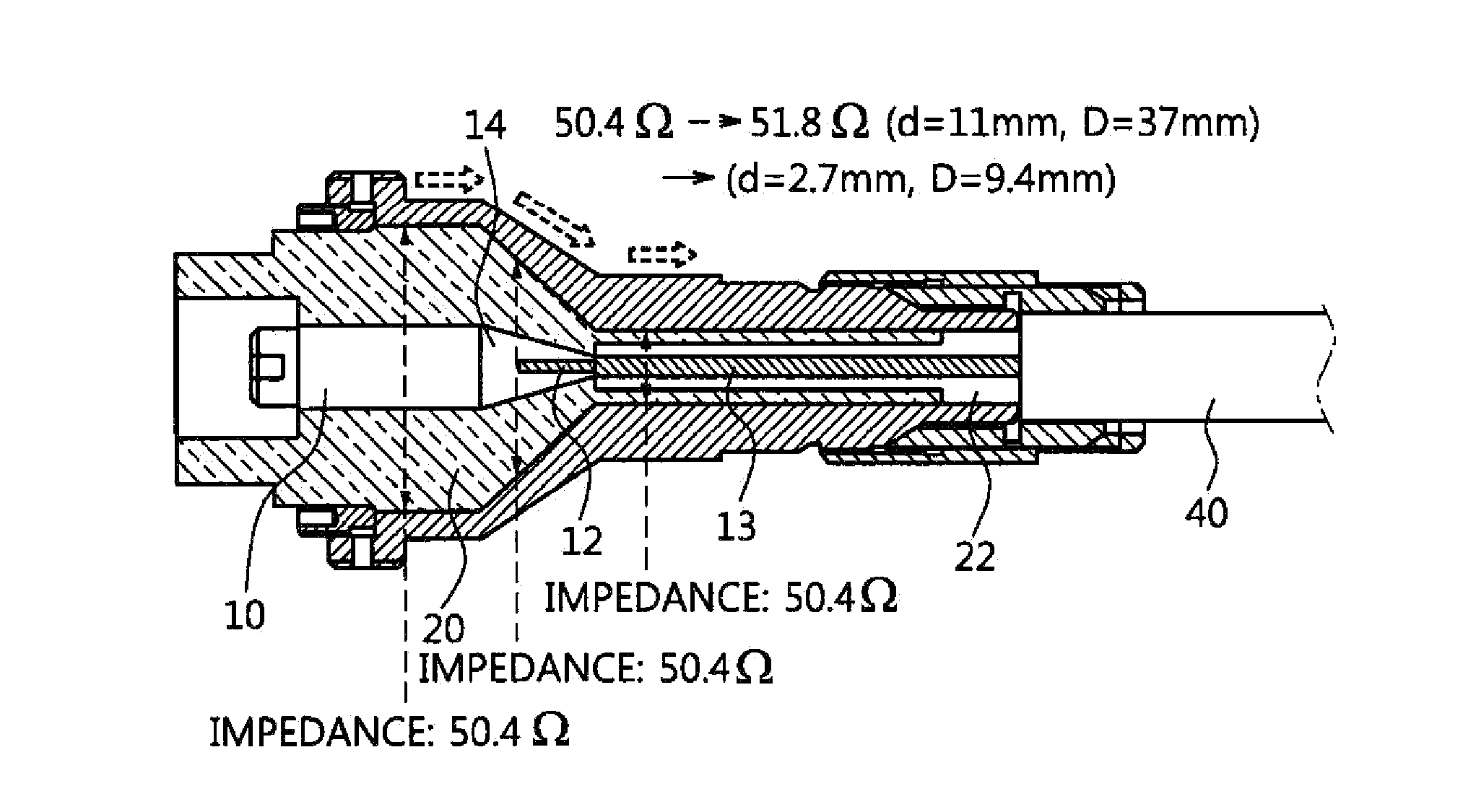

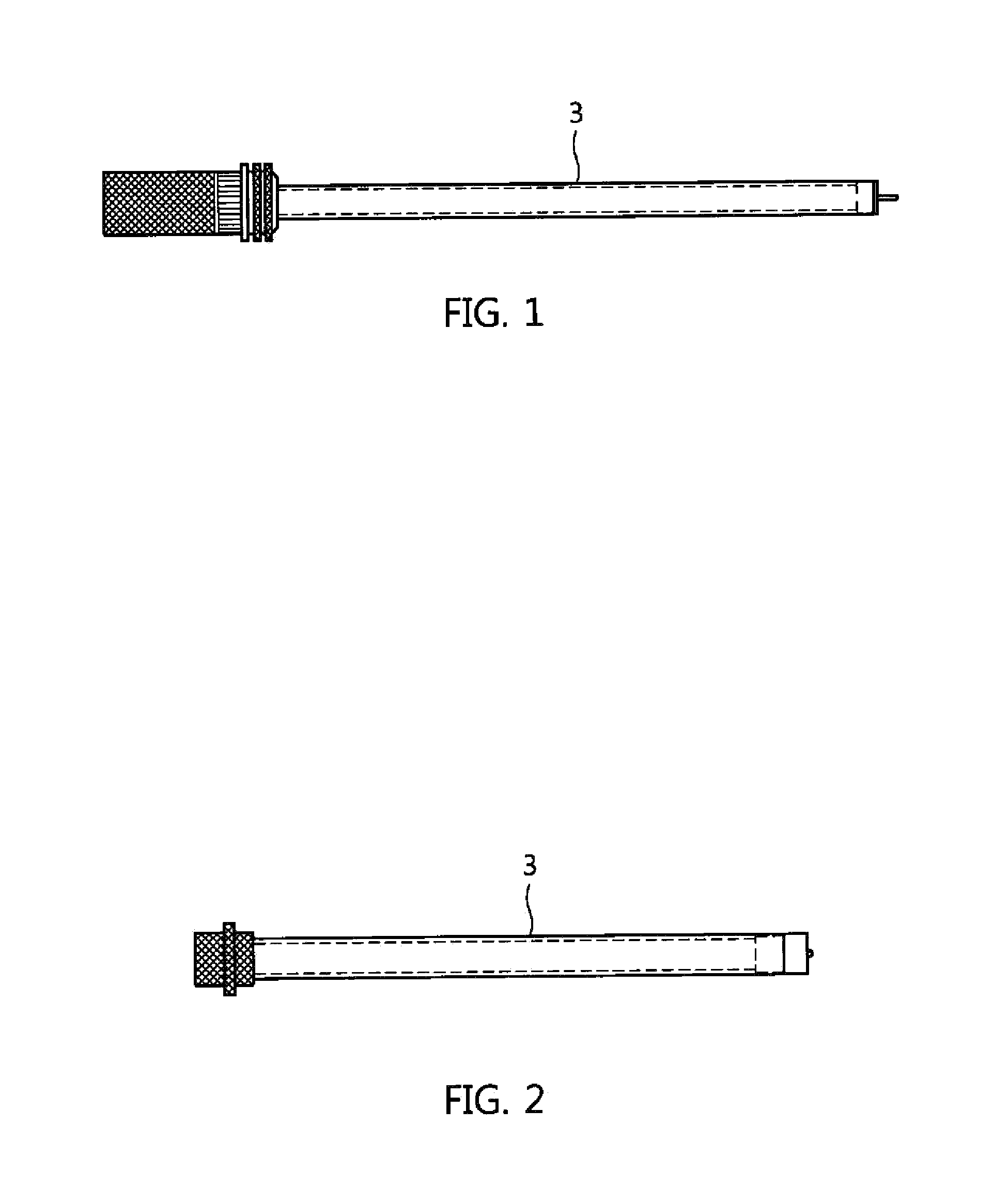

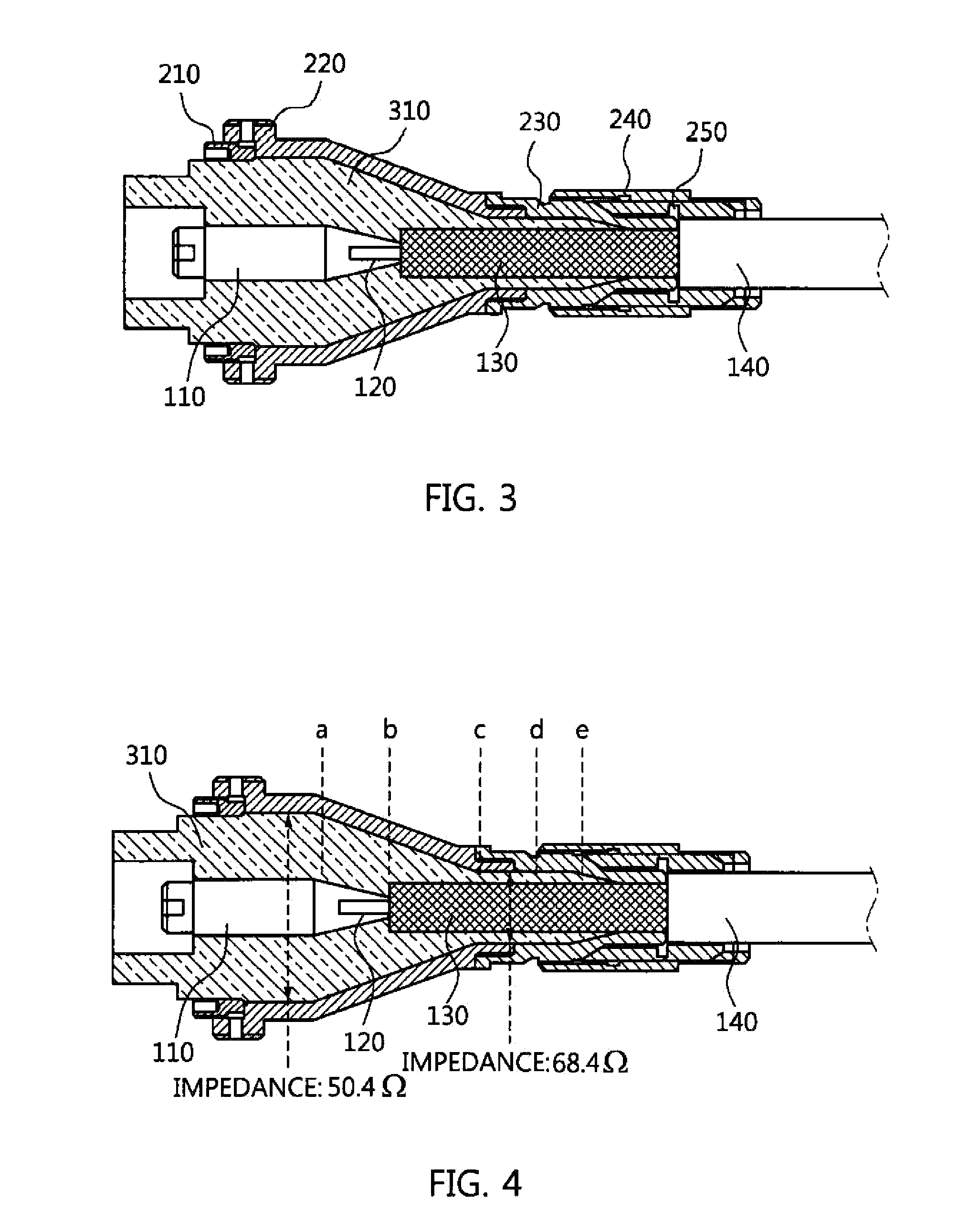

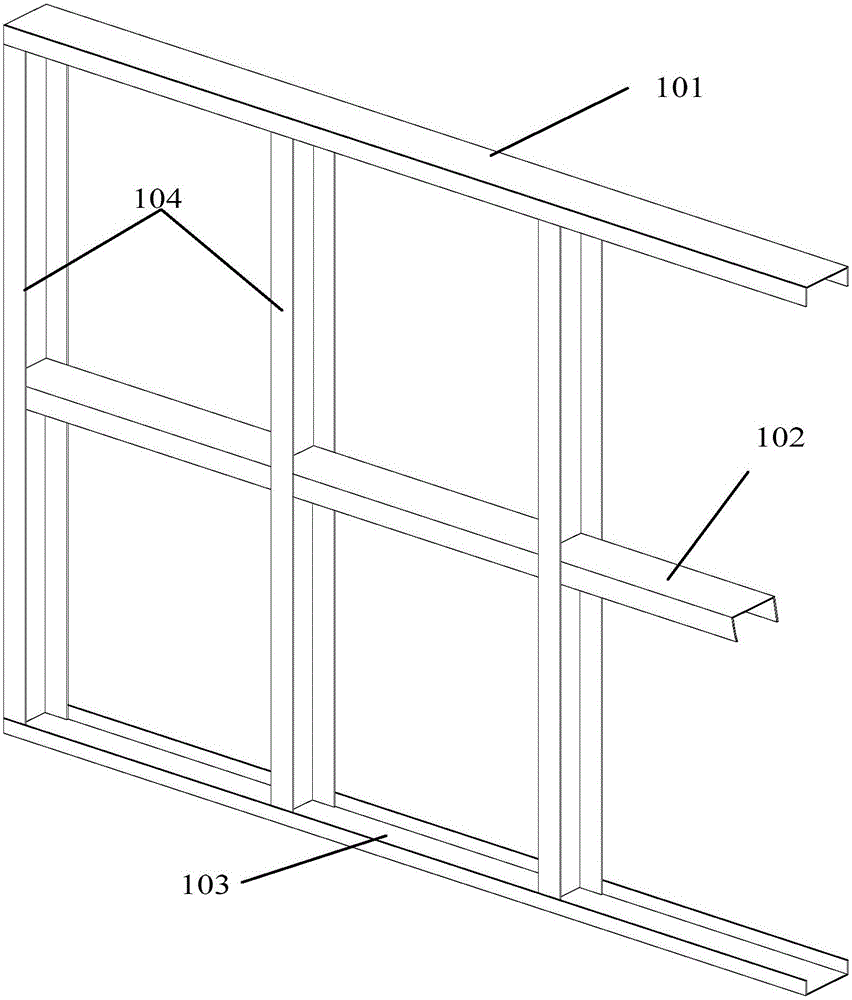

Coaxial cable and connector

InactiveUS20150004833A1Improve efficiencySatisfy insulation performanceCoaxial cables/analogue cablesElectrically conductive connectionsDielectricCoaxial cable

The coaxial cable includes a central conductor, a cable dielectric formed along the outer circumferential surface of the central conductor, and a protruding central conductor configured to protrude from one side of the central conductor and be exposed from the cable dielectric. The diameter of the central conductor is equal to the outer diameter of an end of a transition electrode formed on one side of a connector inner electrode. The connector includes a connector inner electrode configured to be selectively coupled to and separated from a coaxial cable having a central conductor, and provided with a transition electrode on one side thereof, and a connector dielectric formed along the outer circumferential surface of the connector inner electrode. The outer diameter of an end of the transition electrode is equal to the diameter of the central conductor of the coaxial cable.

Owner:ELECTRONICS & TELECOMM RES INST

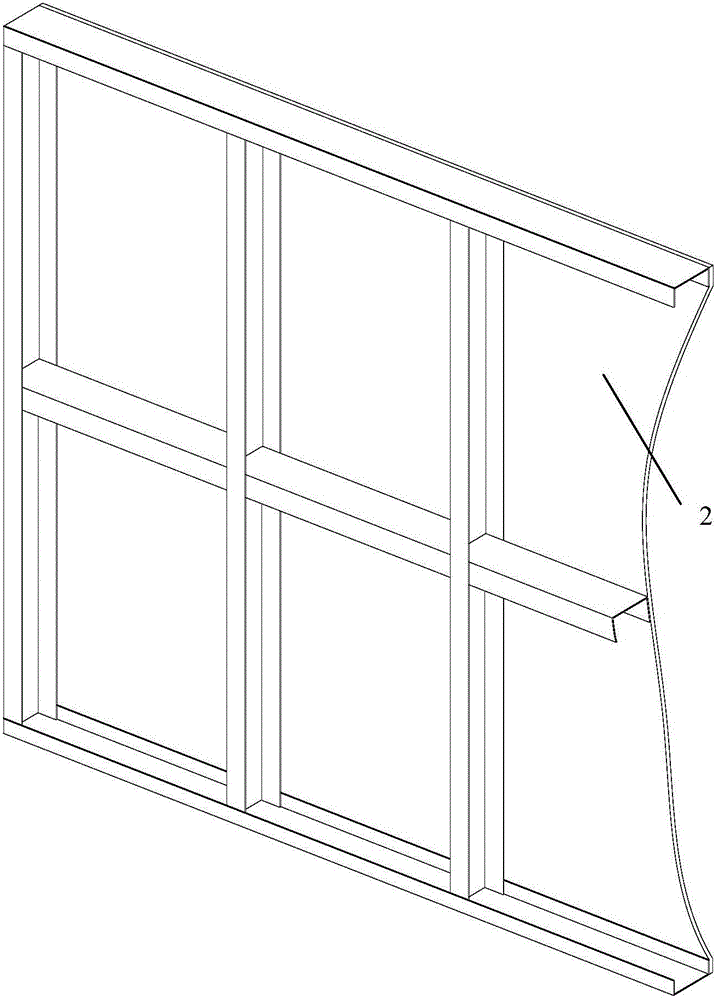

On-site spraying and filling fabrication method for inorganic fiber wall

ActiveCN107435399AImprove insulation effectImprove sound insulation performanceWallsFiberInsulation layer

The invention discloses an on-site spraying and filling fabrication method for an inorganic fiber wall, which is used for fabricating walls between top boards and bottom boards on site. The method comprises following steps: installing keels horizontally and vertically between a roof and a floor to form internal wall supports; fixedly mounting a shingle at one side of the internal wall supports to form a wall skeleton with one side open; inorganic fiber and binder are synchronously and uniformly sprayed on an inner side surface of the mounted shingle; the inorganic fiber is bonded with the shingle by means of the binder; the wall skeleton is filled with the inorganic fiber through spraying layer by layer and is bonded with the keels to form a heat insulation layer; after the filling is completed, binder is uniformly sprayed on the surface of the heat insulation layer; finally, a shingle is also fixedly installed on the other side of the internal wall supports to form an enclosed wall skeleton; therefore, a wall body is formed by the wall skeleton and the heat insulation layer thereof. The invention relates to the field of buildings and provides an on-site spraying and filling fabrication method for inorganic fiber walls having excellent heat insulation and sound insulation performance.

Owner:BEIJING NEW BUILDING MATERIALS PLC

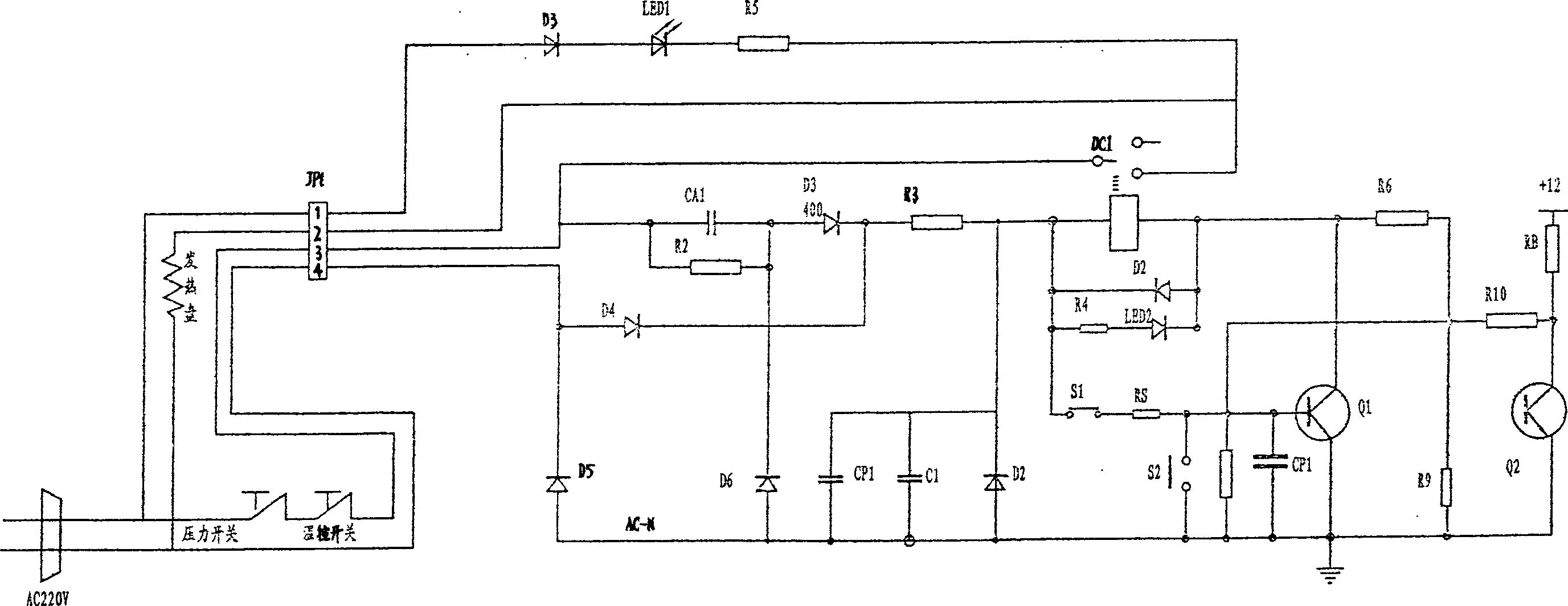

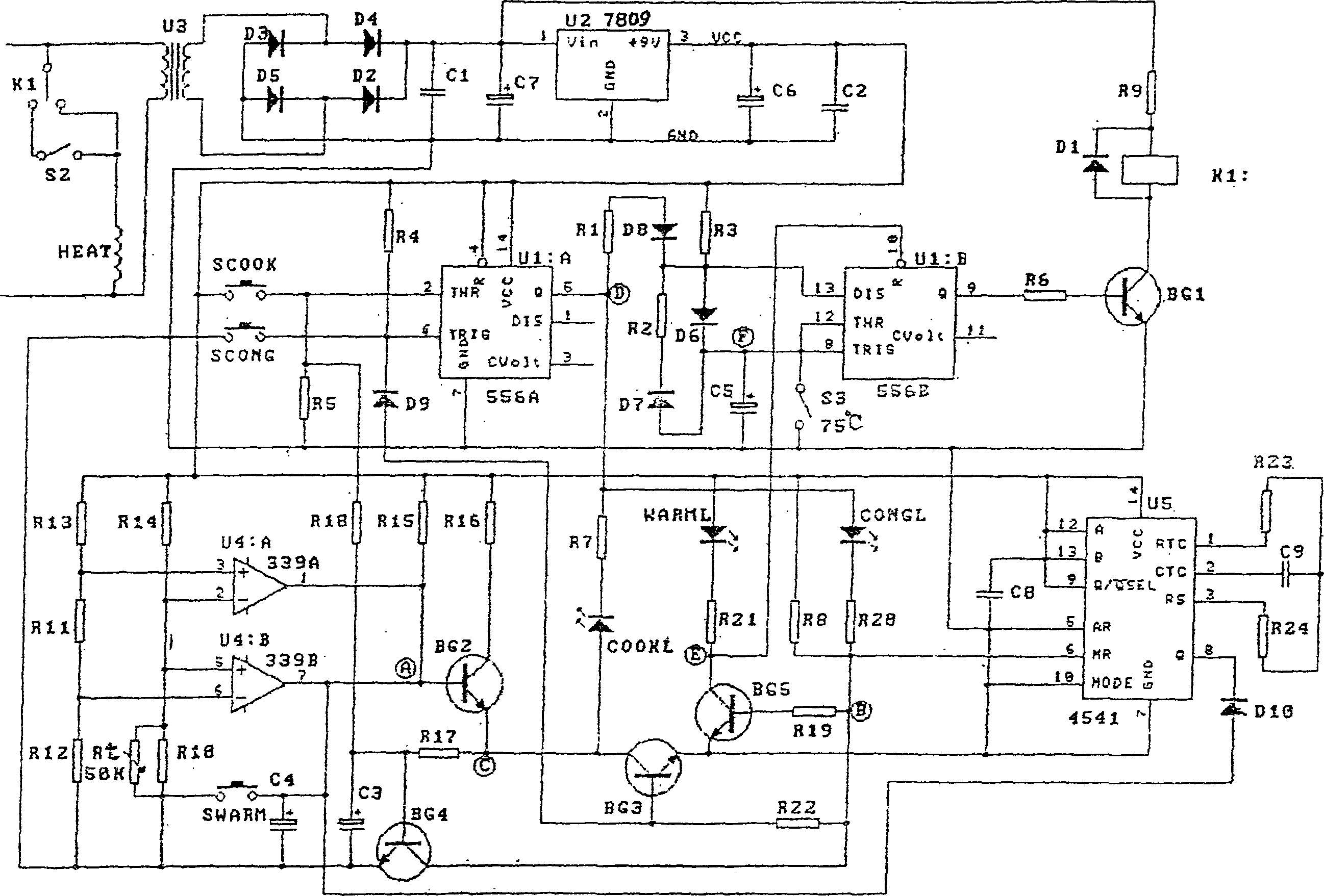

Heat-storing constant-pressure electric pressure cooker

The heat-accumulating constant pressure type electric pressure cooker consists of mainly cover, outer casing, outer pot, inner pot, heating and energy accumulating tray, pressure release valve, cover locking mechanism, control circuit system and other parts. The heating and energy accumulating tray consists of casing, heating layer with heating resistor wire and heat accumulating insulation layer, and is installed via one installation board to the bottom of the cooker. The electric pressure cooker has simple on-off type control circuit system, outer pot with rigid bottom, and temperature inducing controlled pressure switch. The electric pressure cooker has simple structure, low cost, high reliability, high safety, low power consumption, environment friendship and other advantages. With constant pressure, the electric pressure cooker has its cooked food possessing good taste.

Owner:何顺文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com