Thermal insulation method and concrete thermal insulation cover for winter construction of pier column

A technology of thermal insulation cover and pier, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of increasing the difficulty of construction, the danger of construction, the large number of materials, the difficulty of construction, etc., so as to avoid artificial high altitudes. The effect of operation, simplifying the operation process, reducing the difficulty and danger of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

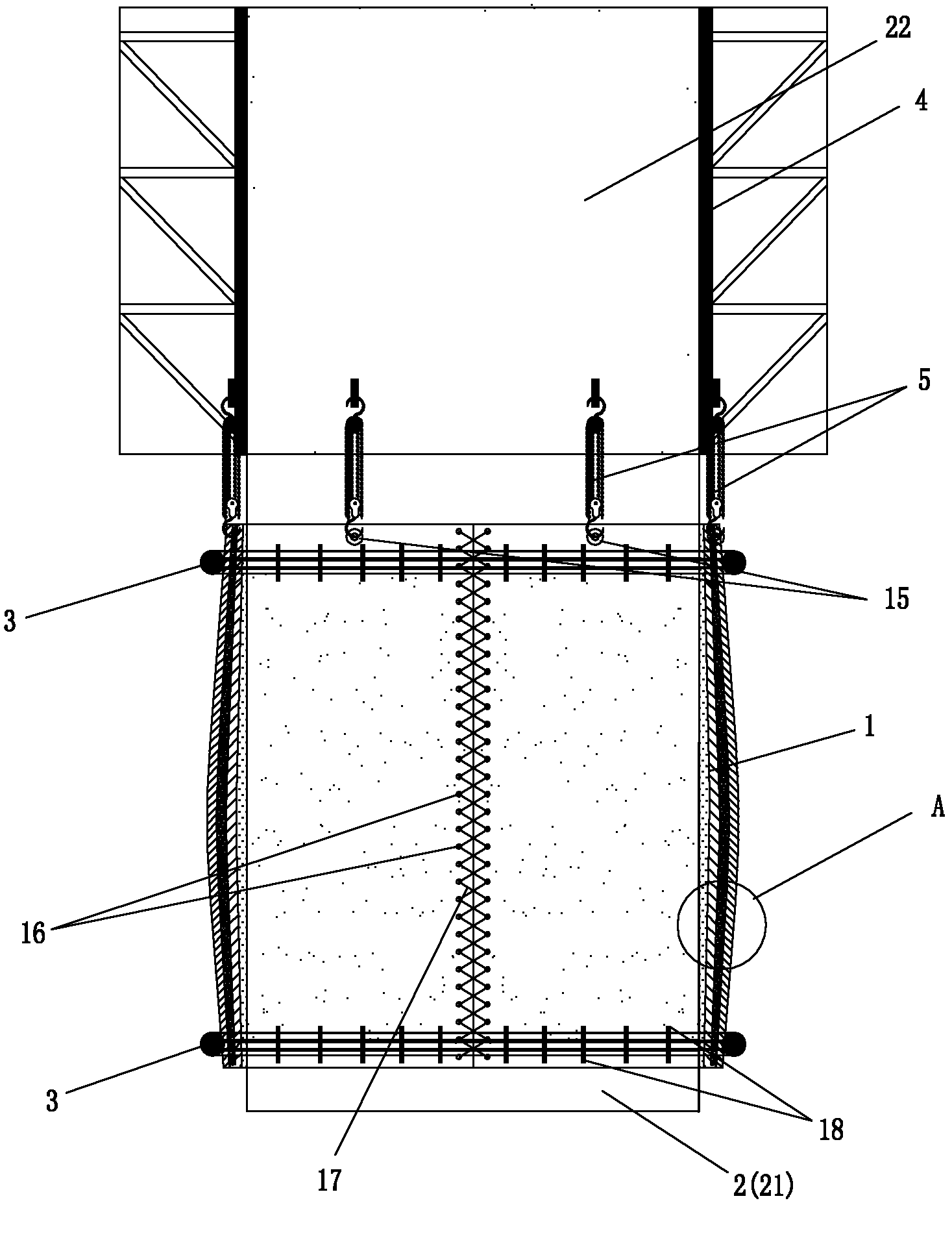

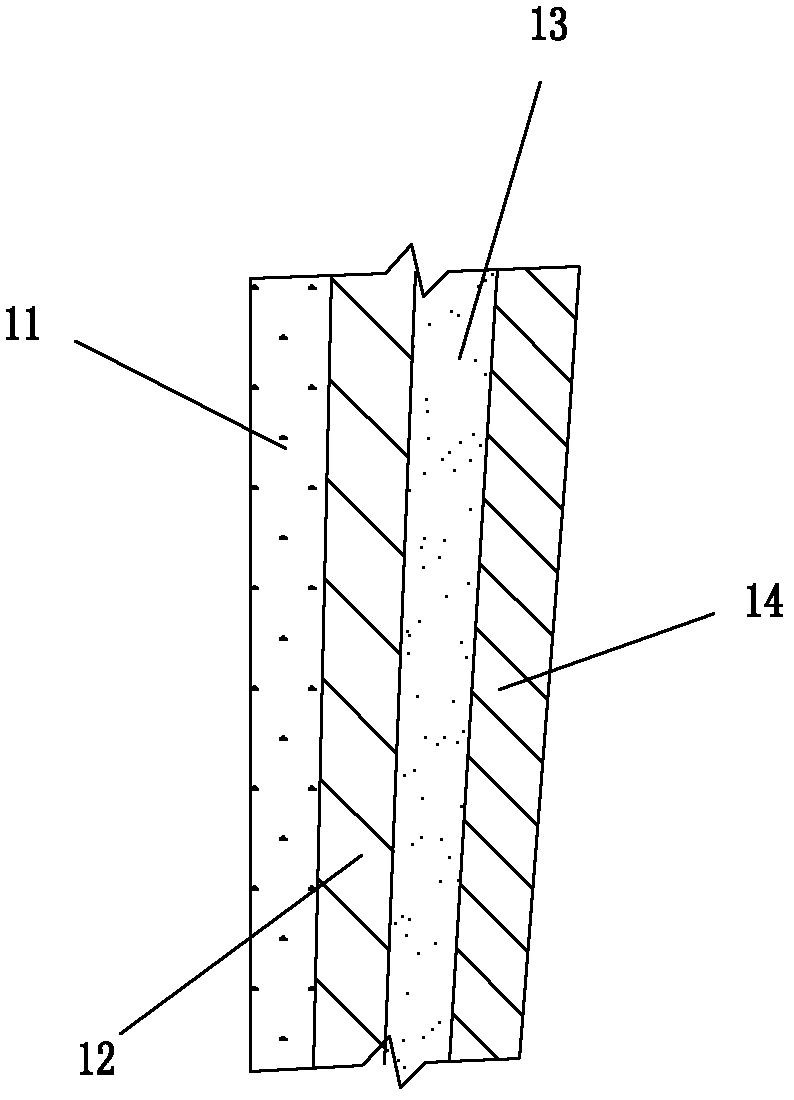

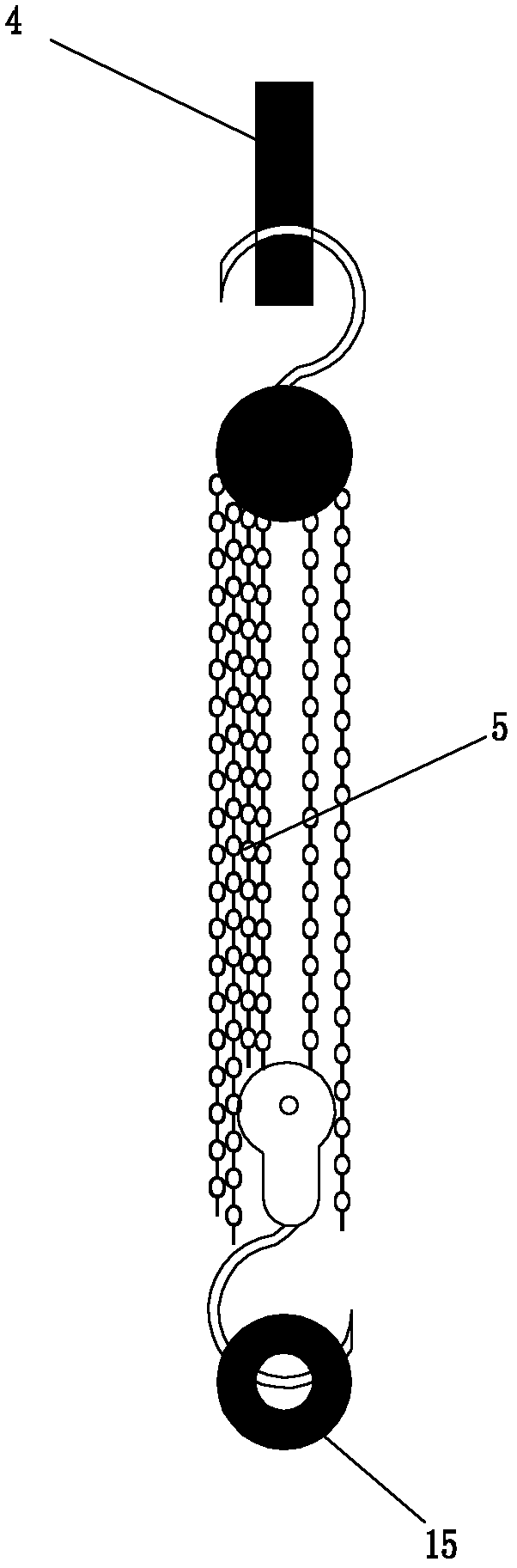

[0026] The present invention proposes a heat preservation method for pier column construction in winter, and the pier column refers to a high pier or a tower column; figure 1 As shown, a rectangular concrete insulation cover 1 composed of four layers of insulation materials is wrapped around a section of construction section 21 that has been poured along the circumference of the pier column 2. The upper and lower ends of the concrete insulation cover 1 are respectively covered by rubber Tendons 3 are tightly wound around the outside of the poured construction section 21; the upper end of the concrete insulation cover 1 is connected to the template 4 located above the concrete insulation cover 1 to be poured in the construction se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com