UP (unsaturated polyester) /alumina thermal conductive insulating material with longer storage life and preparation method of UP/alumina thermal conductive insulating material

A heat-conducting insulating material, aluminum oxide technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems that restrict the smooth progress of industrial production and high loss rate, and achieve good thermal conductivity, improve bonding force, and high finish Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of a UP / alumina thermally conductive insulating material with a longer storage period, comprising the following steps:

[0027] Step 1. According to the above weight ratio, weigh UP, alumina, initiator, silane coupling agent and propylene glycol in sequence, and set aside;

[0028] Step 2. Place the UP and alumina weighed in step 1 in a vacuum drying oven for drying and dehydration treatment for 20-30 hours. After taking them out, dry them and store them for later use;

[0029] Step 3, add the UP and alumina obtained after the drying and water removal treatment in step 2, and the initiator, silane coupling agent and propylene glycol weighed in step 1 into the kneader, and mix at room temperature while the kneader is kept sealed. Refining for 25-35 minutes, the finished heat-conducting insulating material is obtained, sealed and stored in a cool place.

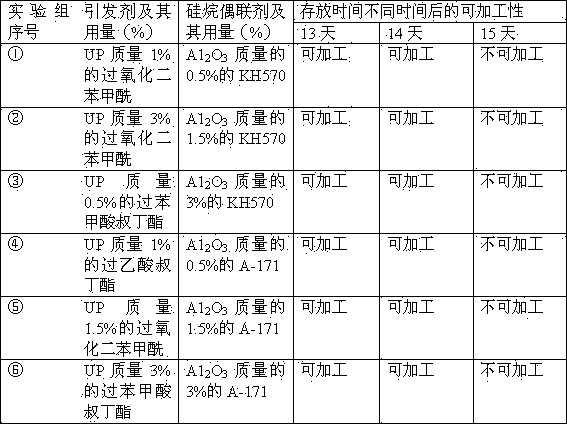

[0030] In the technical scheme of the present invention, in order to prepare the storage-resista...

Embodiment 1

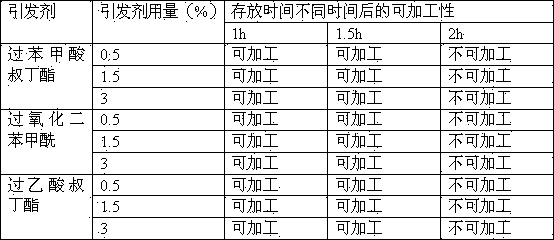

[0033] This embodiment mainly tests and experiments the machinability of existing heat-conducting and insulating materials under different storage times.

[0034] The raw materials used are: carboxyl-terminated UP (that is, UP commonly used in the prior art), A1 2 o 3 , Initiator dibenzoyl peroxide or tert-butyl perbenzoate or tert-butyl peracetate.

[0035] This embodiment includes nine experimental groups in total

[0036] ①Carboxy-terminated UP, A1 2 o 3 , UP quality 0.5% dibenzoyl peroxide;

[0037] ②Carboxy-terminated UP, A1 2 o 3 , UP quality 1.5% dibenzoyl peroxide;

[0038] ③Carboxy-terminated UP, A1 2 o 3 , UP quality 3% dibenzoyl peroxide;

[0039] ④ carboxy-terminated UP, A1 2 o 3 , tert-butyl perbenzoate with 0.5% UP quality;

[0040] ⑤Carboxy-terminated UP, A1 2 o 3 , tert-butyl perbenzoate with 1.5% UP quality;

[0041] ⑥Carboxy-terminated UP, A1 2 o 3 , tert-butyl perbenzoate with UP quality 3%;

[0042] ⑦Carboxy-terminated UP, A1 2 o 3 , te...

Embodiment 2

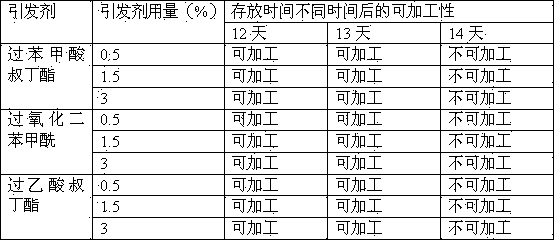

[0051] In this embodiment, the main test and experiment is the processability of the thermally conductive insulating material prepared by using hydroxyl-terminated UP as a raw material under different storage times.

[0052] The raw materials used are: hydroxyl-terminated UP, A1 2 o 3 , Initiator dibenzoyl peroxide or tert-butyl perbenzoate or tert-butyl peracetate.

[0053] This embodiment includes nine experimental groups in total

[0054] ①Hydroxy-terminated UP, A1 2 o 3 , UP quality 0.5% dibenzoyl peroxide;

[0055] ② Hydroxyl-terminated UP, A1 2 o 3 , UP quality 1.5% dibenzoyl peroxide;

[0056] ③Hydroxy-terminated UP, A1 2 o 3 , UP quality 3% dibenzoyl peroxide;

[0057] ④Hydroxy-terminated UP, A1 2 o 3 , tert-butyl perbenzoate with 0.5% UP quality;

[0058] ⑤ Hydroxyl-terminated UP, A1 2 o 3 , tert-butyl perbenzoate with 1.5% UP quality;

[0059] ⑥ Hydroxyl-terminated UP, A1 2 o 3 , tert-butyl perbenzoate with UP quality 3%;

[0060] ⑦Hydroxy-terminat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com