Preparation method of modified starch for glass fiber cloth

A glass fiber and starch technology, used in textiles and papermaking, can solve the problem of high cost, reduce production costs and meet the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

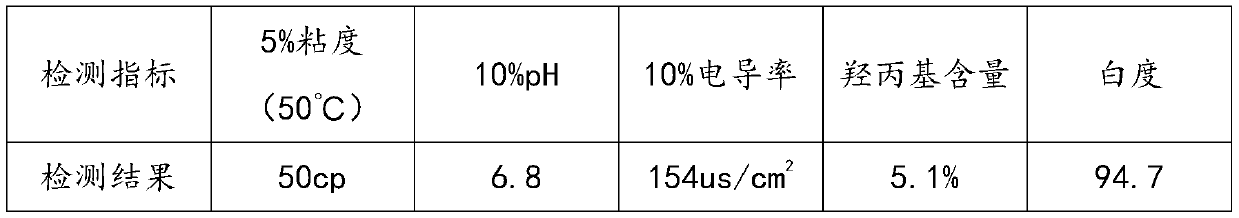

Image

Examples

Embodiment 1

[0018] 1) Feeding, in parts by mass, fully dissolve 9 parts of sodium chloride in 140 parts of water, add 100 parts of starch to make starch milk and stir for 30-60 minutes;

[0019] 2) Etherification and denaturation, after the starch milk in step 1) is stirred evenly, after the concentration is 2-3wt% alkali solution is added dropwise to adjust the pH to 11.4, then 9 parts of propylene oxide is added in parts by mass, and 2-3wt% alkali solution, maintaining the pH at 11.4, and adjusting the pH to 7 after reacting at 39° C. for 20 h. The lye with a concentration of 2-3wt% is prepared from soda ash. The proportion of this concentration is to maintain the reaction efficiency on the one hand, and on the other hand to prevent starch gelatinization when added. Of course, soda ash can also be other substances that can adjust pH replace;

[0020] 3) Oxidation treatment. After the starch etherification in step 2) is completed, add 0.1 part of copper sulfate in parts by mass, add 4 p...

Embodiment 2

[0025] This embodiment provides a method for preparing modified starch for glass fiber cloth,

[0026] 1) Feeding, in parts by mass, fully dissolve 7 parts of sodium chloride in 180 parts of water, add 100 parts of starch to make starch milk and stir for 30-60 minutes;

[0027] 2) Etherification and denaturation, after the starch milk in step 1) is stirred evenly, after adding a concentration of 2-3wt% lye dropwise to adjust the pH to 11.8, add 5 parts of propylene oxide in parts by mass, and use 2-3wt% alkali solution, maintain the pH at 11.8, and adjust the pH to 8 after reacting at 40°C for 16 hours;

[0028] 3) Oxidation treatment. After the starch etherification in step 2) is completed, add 0.2 parts of copper sulfate in parts by mass, add 5 parts of hydrogen peroxide with an effective content of 27%, react for 6 hours, and add 0.2 parts of sodium metabisulfite to terminate the reaction.

[0029] 4) Drying. After the starch milk oxidation in step 3) is completed, cyclone...

Embodiment 3

[0031] 1) Feeding, in parts by mass, fully dissolve 9 parts of sodium chloride in 200 parts of water, add 100 parts of starch to make starch milk and stir for 30-60 minutes;

[0032] 2) Etherification and denaturation, after the starch milk in step 1) is stirred evenly, after adding 2-3wt% lye dropwise to adjust the pH to 12, add 10 parts of propylene oxide in parts by mass, and use 2-3wt% alkali solution, maintain the pH at 12, and adjust the pH to 6 after reacting at 38°C for 16 hours;

[0033] 3) Oxidation treatment. After the starch etherification in step 2) is completed, add 0.2 parts of copper sulfate in parts by mass, add 5 parts of hydrogen peroxide with an effective content of 27%, react for 6 hours, and add 0.2 parts of sodium metabisulfite to terminate the reaction.

[0034] 4) Drying. After the starch milk oxidation in step 3) is completed, cyclone washing and drying are carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com