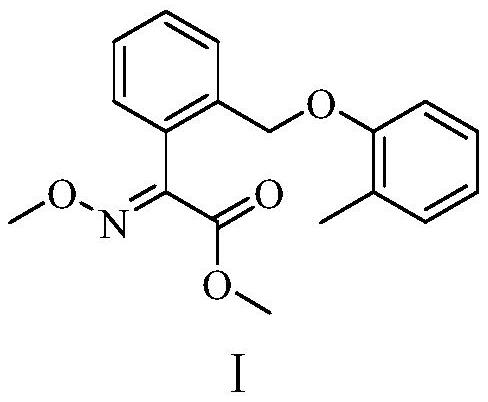

Preparation method of kresoxim-methyl

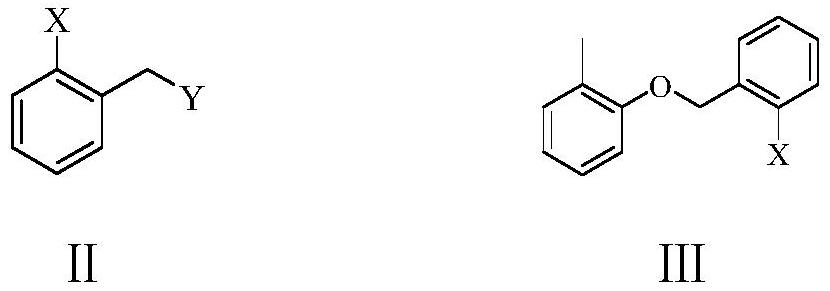

A kresoxim-methyl and compound technology, which is applied in the direction of ether preparation, carboxylic acid ester preparation, and ester reaction to prepare ether, etc., can solve the problems of many side reactions, high equipment requirements, low product purity and yield, etc. Elimination of side reactions, elimination of side reactions, and easy-to-react effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1: 2-(2-methylphenoxymethyl)bromobenzene (Ⅲ 1 ) preparation

[0069] To a 1000 ml four-necked flask connected with stirring, a thermometer, a constant pressure dropping funnel and a reflux condenser, add 400 g of 1,2-dichloroethane, 82.8 g (0.6 mol) of potassium carbonate, 108.2 g (1.0 mol) ) 2-methylphenol, heated, kept between 40 and 45°C, added dropwise 215.8 grams (1.05 moles) of 2-chloromethylbromobenzene (Ⅱ 1 ), the dropwise addition was completed in about 3 hours, after which the reaction was stirred at 45 to 55°C for 2 hours, cooled to 20-25°C, filtered, the filter cake was washed with 1,2-dichloroethane, 100 grams each time, and the organic phases were combined, Distillation recovery solvent, underpressure distillation (145-165 ℃ / 1-2mmHg) obtains 259.2 grams of 2-(2-methylphenoxymethyl) bromobenzene (Ⅲ 1 ), yield 93.4%, gas phase purity 99.8%.

[0070] The NMR data of the resulting product are as follows:

[0071] 1 H NMR (400MHz, DMSO-d 6 ):δ:

...

Embodiment 2

[0073] Example 2: 2-(2-methylphenoxymethyl)bromobenzene (Ⅲ 1 ) preparation

[0074] In a 1000 ml four-neck flask connected with stirring, a thermometer, a constant pressure dropping funnel and a reflux condenser, add 500 g of dichloromethane, 82.8 g (0.6 mol) of potassium carbonate, 108.2 g (1.0 mol) of 2-methyl Phenol, heated, kept between 30 and 35°C, added dropwise 262.5 grams (1.05 moles) of 2-bromomethyl bromobenzene (Ⅱ 2 ), the dropwise addition was completed in about 3 hours, thereafter 35 to 40°C stirred and reacted for 2 hours, cooled to 20-25°C, filtered, the filter cake was washed with dichloromethane, 100 grams each time, the organic phases were combined, the solvent was recovered by distillation, and the Pressure distillation (145-165 ℃ / 1-2mmHg) obtains 257.6 grams of 2-(2,5-dimethylphenoxymethyl) bromobenzene (Ⅲ 1 ), yield 92.8%, gas phase purity 99.8%.

Embodiment 3

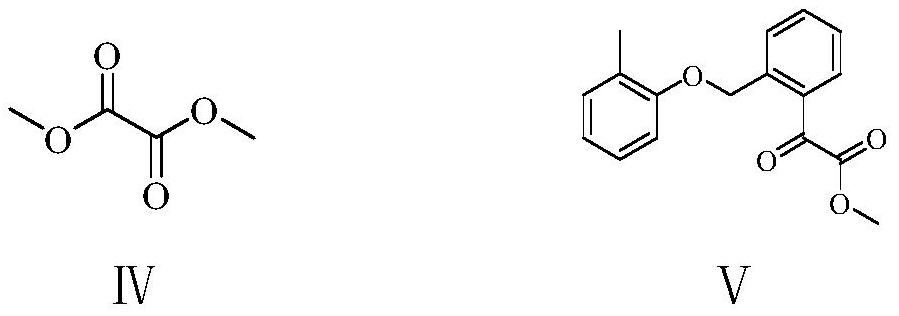

[0075] Embodiment 3: the preparation of 2-(2-methylphenoxymethyl) phenyl oxalate methyl ester (V)

[0076] Under nitrogen protection, 150 grams of tetrahydrofuran, 2.7 grams (0.11 moles) of magnesium powder, 0.5 grams of 1,2-dibromoethane, 1.5 grams of 2 prepared in Example 1 were added to a 500 milliliter four-necked flask equipped with a stirring and thermometer. -(2-methylphenoxymethyl)bromobenzene(Ⅲ 1 ), 0.05 gram of iodine, after triggering the Grignard reaction at 40-45°C for 0.2 hours, 26.2 grams (0.1 moles in total) of 2-(2-methylphenoxymethyl) prepared in Example 1 were added dropwise between 40-45°C ) Bromobenzene(Ⅲ 1 ) and 100 g of tetrahydrofuran, drop it in 2 hours, then stir and react at 45-50° C. for 3 hours to obtain a reaction solution containing Grignard reagent. Cool to 20-25°C, transfer the resulting reaction solution containing the Grignard reagent to a constant pressure dropping funnel, keep it between 20-25°C, and add it dropwise to a solution containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com