Flip LED integrated chip with high break-over voltage

An integrated chip, high-conductivity technology, used in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as poor high-voltage resistance performance of LED integrated chips, and achieve a small footprint, low manufacturing cost, and wide distribution area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

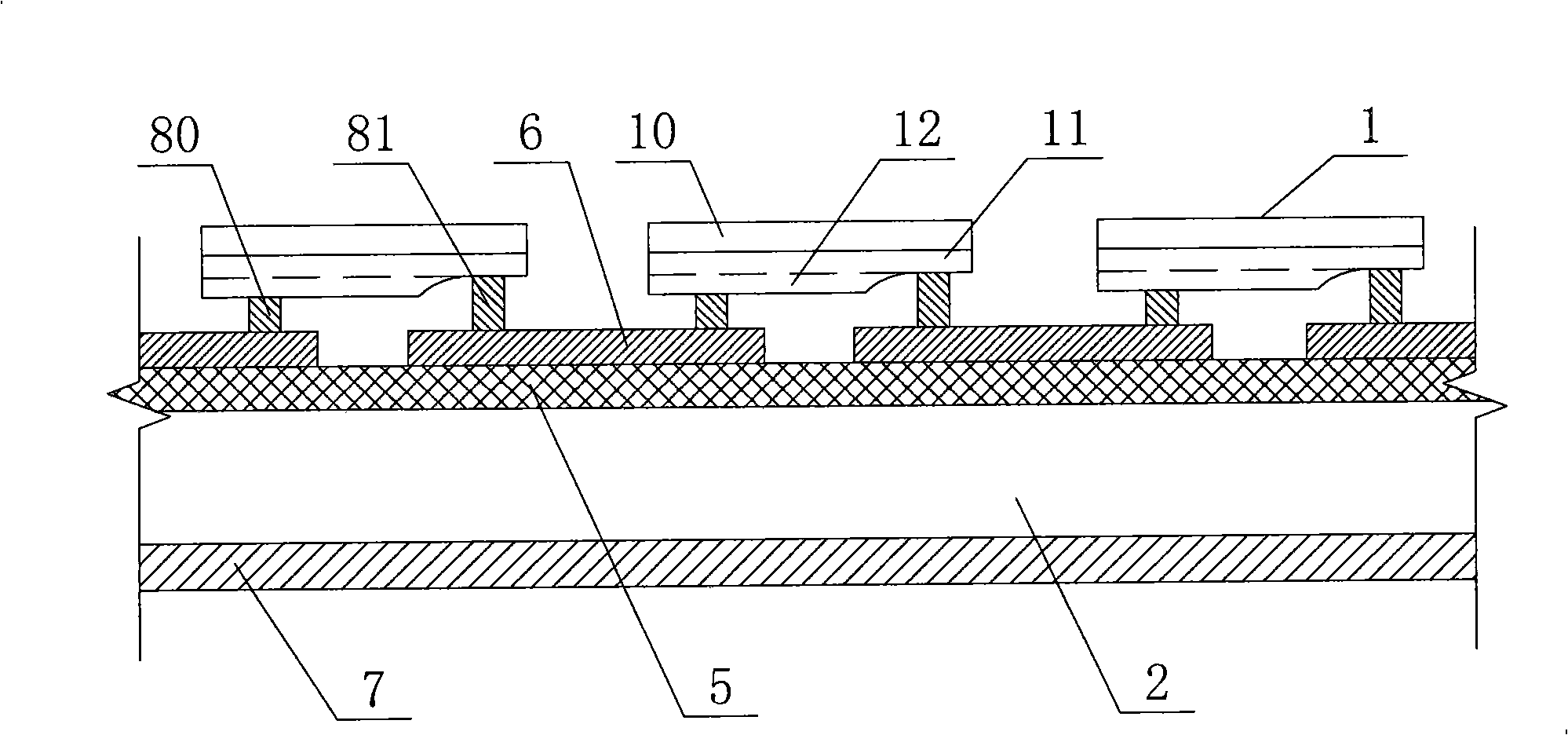

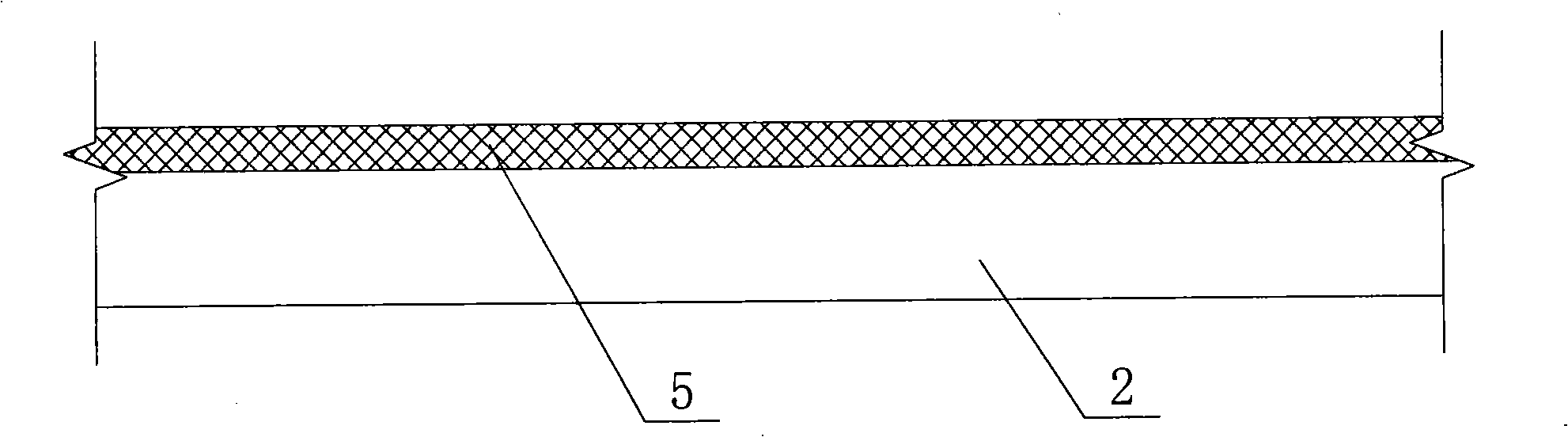

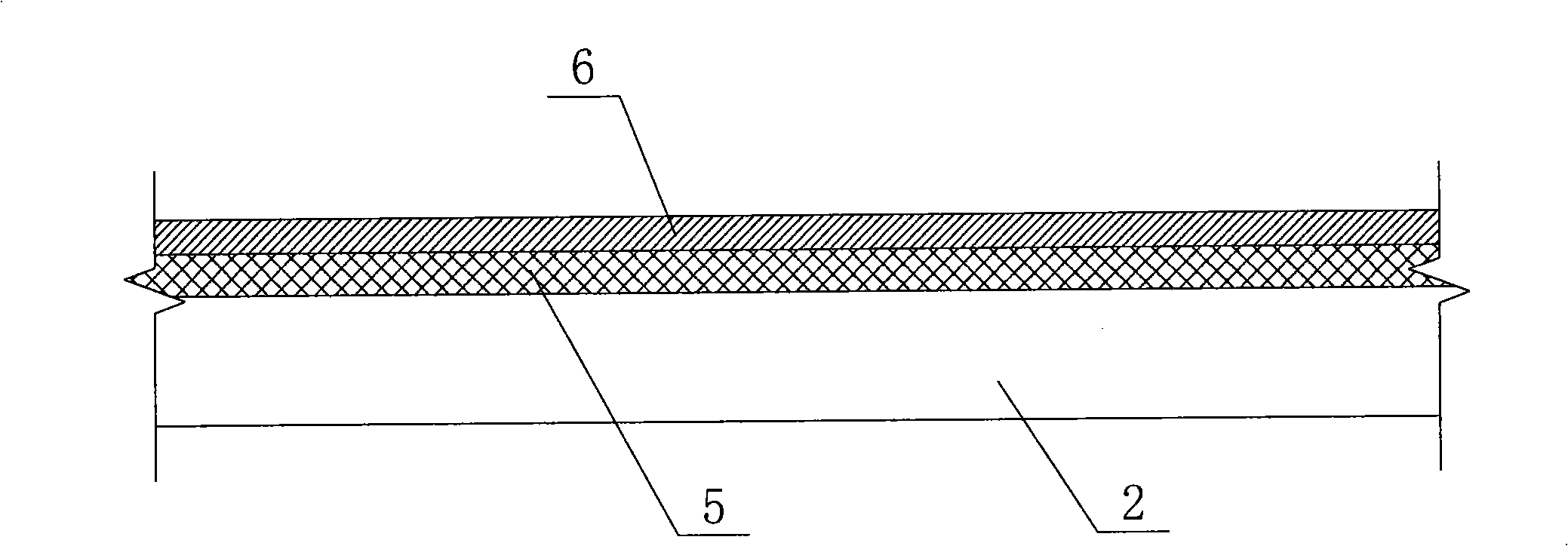

[0048] like figure 1 As shown, the high turn-on voltage flip-chip LED integrated chip of this embodiment includes several LED bare chips 1 and a silicon substrate 2, and the LED bare chips 1 include sapphire (Al 2 o 3 ) substrate 10 and gallium nitride (GaN) N-type epitaxial layer 11, P-type epitaxial layer 12, certainly, described substrate 10 also can be the substrate of other materials such as silicon carbide (SiC), described silicon substrate 2 is a P-type silicon substrate, and a thermally conductive insulating layer II 5 is deposited on the silicon substrate 2. The thermally conductive insulating layer II 5 is composed of a silicon nitride layer. The thermal conductivity of silicon nitride is very high, and its thermal conductivity is higher than that of Generally, the heat-conducting adhesive is more than 100 times higher, and the thickness of the heat-conducting insulating layer II 5 is thin, so the thermal conductivity is good, and it can play a good role in heat con...

Embodiment 2

[0060] like Image 6 As shown, the high turn-on voltage flip-chip LED integrated chip of this embodiment includes several LED bare chips 1 and a silicon substrate 2, and the LED bare chips 1 include sapphire (Al 2 o 3) substrate 10 and gallium nitride (GaN) N-type epitaxial layer 11, P-type epitaxial layer 12, certainly, described substrate 10 also can be the substrate of other materials such as silicon carbide (SiC), described silicon substrate 2 is a P-type silicon substrate, and a layer of N+ diffusion layer 3 is diffused inwardly on the front side of the silicon substrate 2, and a layer of thermally conductive insulating layer I4 is grown on the N+ diffused layer 3, and on the thermally conductive insulating layer I4 A thermally conductive insulating layer II5 is formed, the thermally conductive insulating layer I4 is composed of silicon dioxide, and the thermally conductive insulating layer II5 is composed of silicon nitride. The thermal conductivity of silicon dioxide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com