Heat-storing constant-pressure electric pressure cooker

An electric pressure cooker and heat storage technology, which is applied to pressure cookers and other directions, achieves the effects of simple production, complex structure, and ecological environment protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

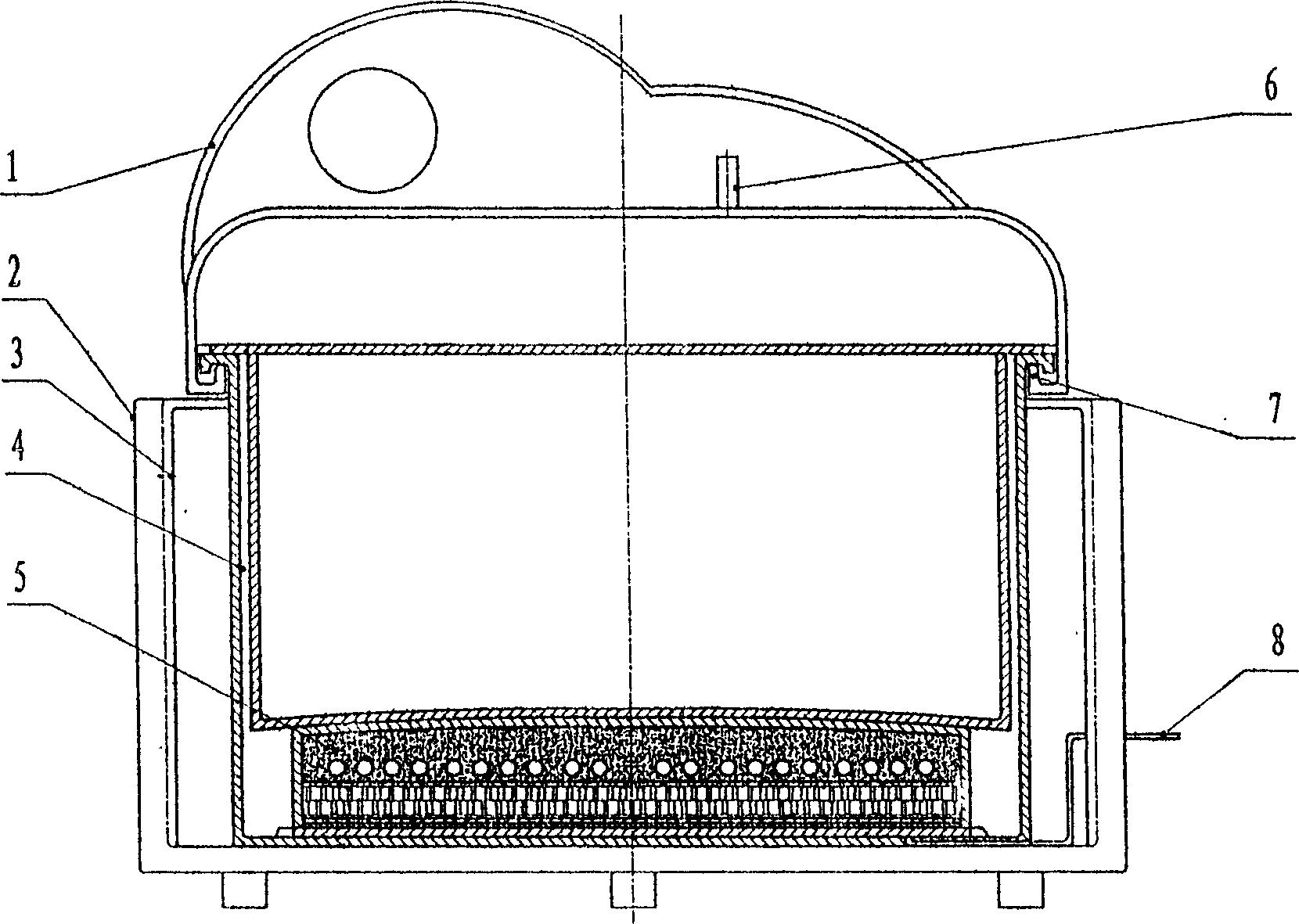

[0029] exist figure 1 Among them, the pot cover (1) seals the entire pot body, and a sealing ring is provided between the pot cover (1) and the inner pot (4), and the pot cover (1) is closed by locking the pot cover lock mechanism (7). After completion, the entire inner pot (4) is in a completely sealed state, and no steam will leak out; the heating energy storage plate (5) is under the inner pot (4), and its convex surface is closely attached to the concave of the inner pot (4) to generate heat. The energy storage plate (5) and the outer pot (3) are fixed and rigidly installed and coordinated, and the heating resistance wire is drawn out from the lower part of the heating energy storage plate (5), and is connected to an external power socket after passing through the circuit control element to form an electrical control system (8 ); the socket button is designed at the proper position of the electric pressure cooker for easy operation.

[0030] When the control key of the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com