Patents

Literature

33 results about "Carbon density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are a number of ways to determine or describe the density of activated carbon. The density of dry activated carbon is normally between 200 and 650 kg/m³. The density is very dependent on the raw material, the production process, the activation process (activation by steam of chemicals) and the activity of the final product.

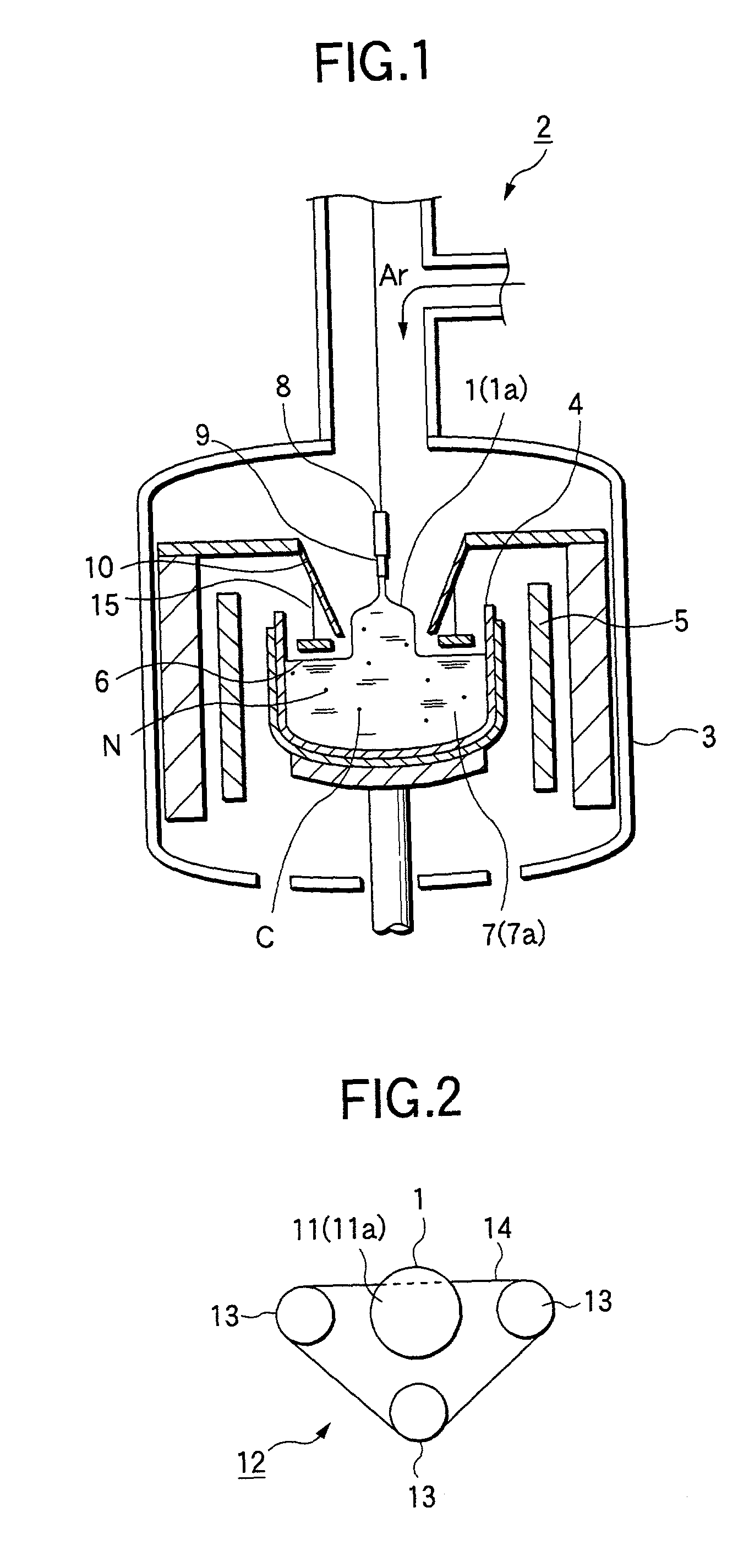

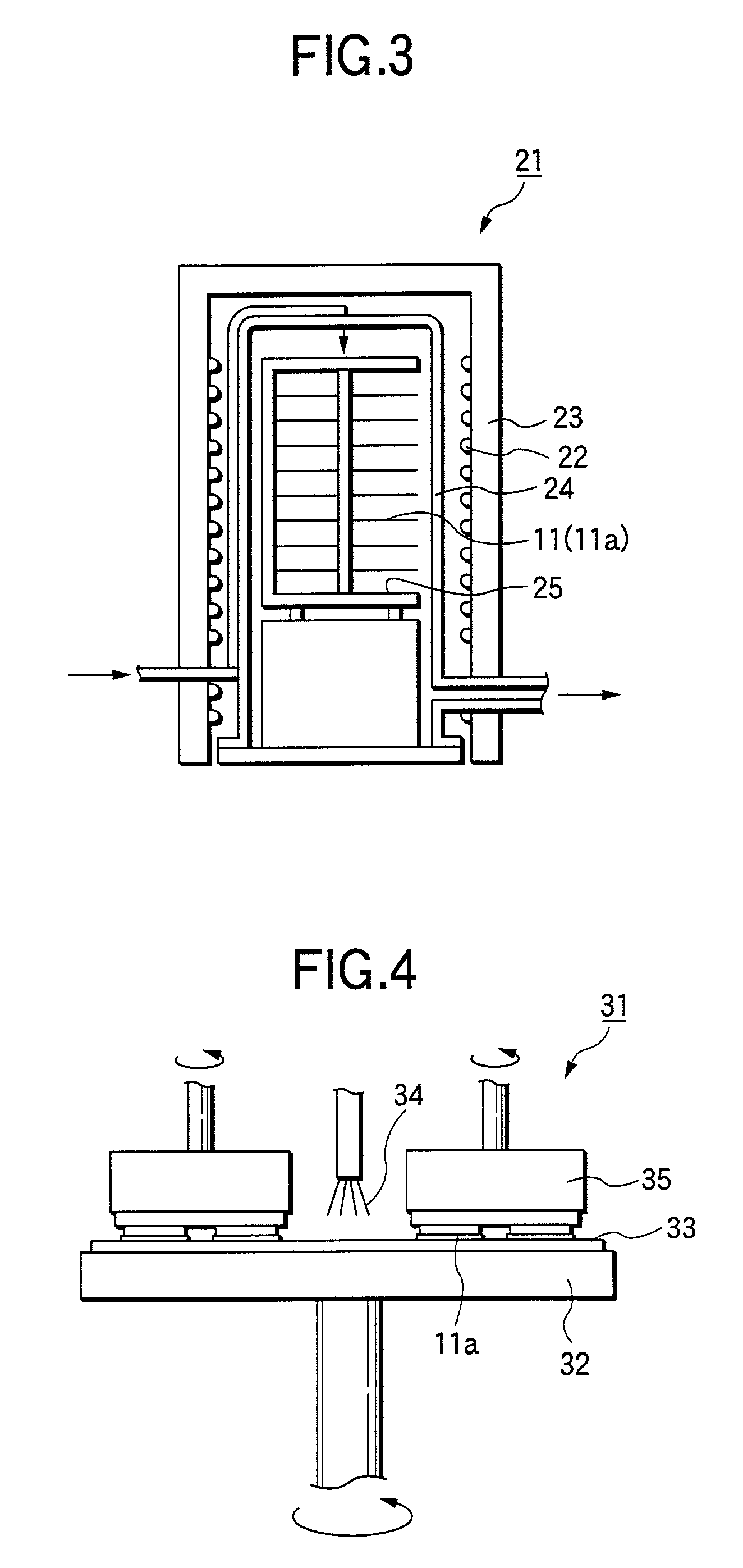

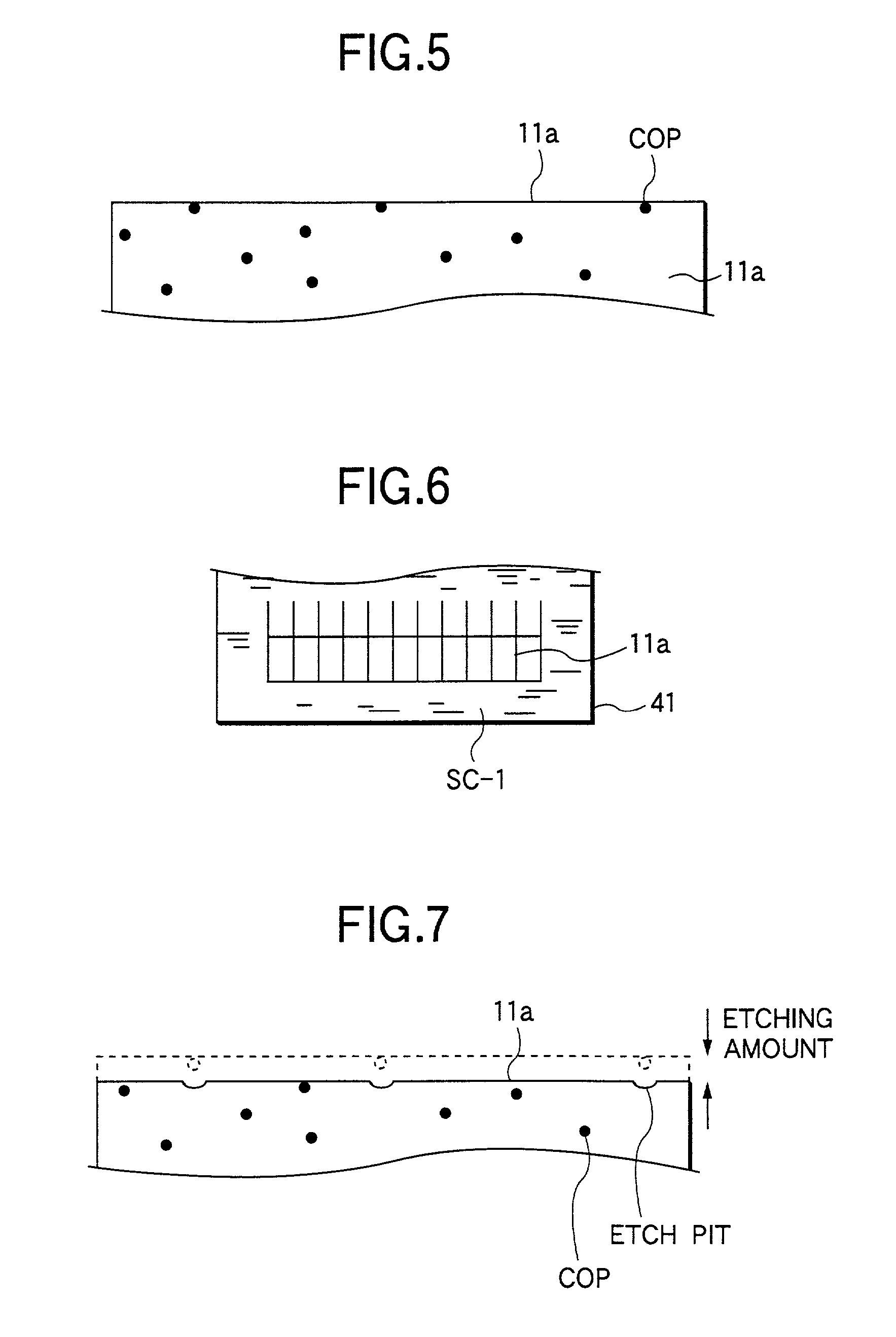

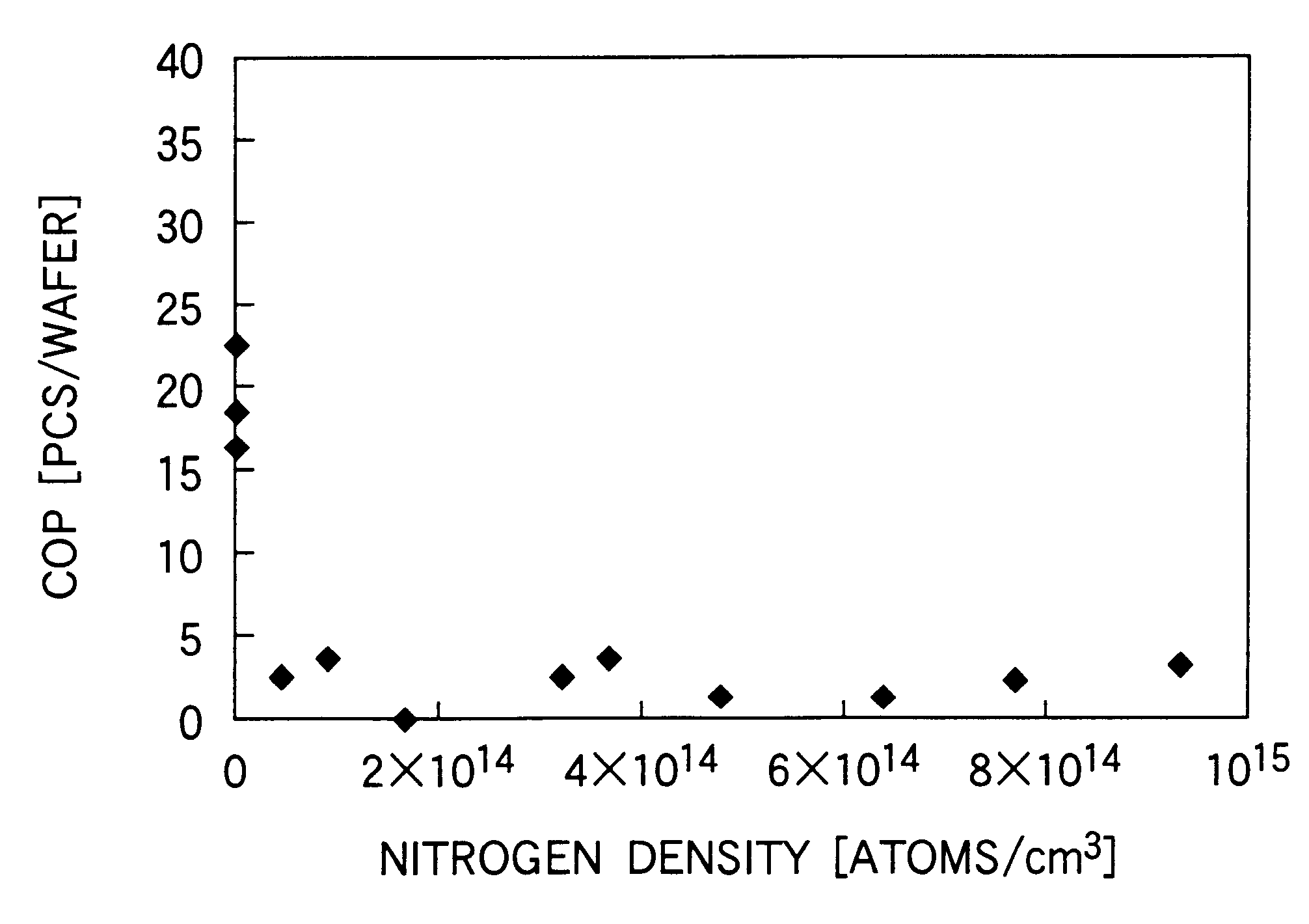

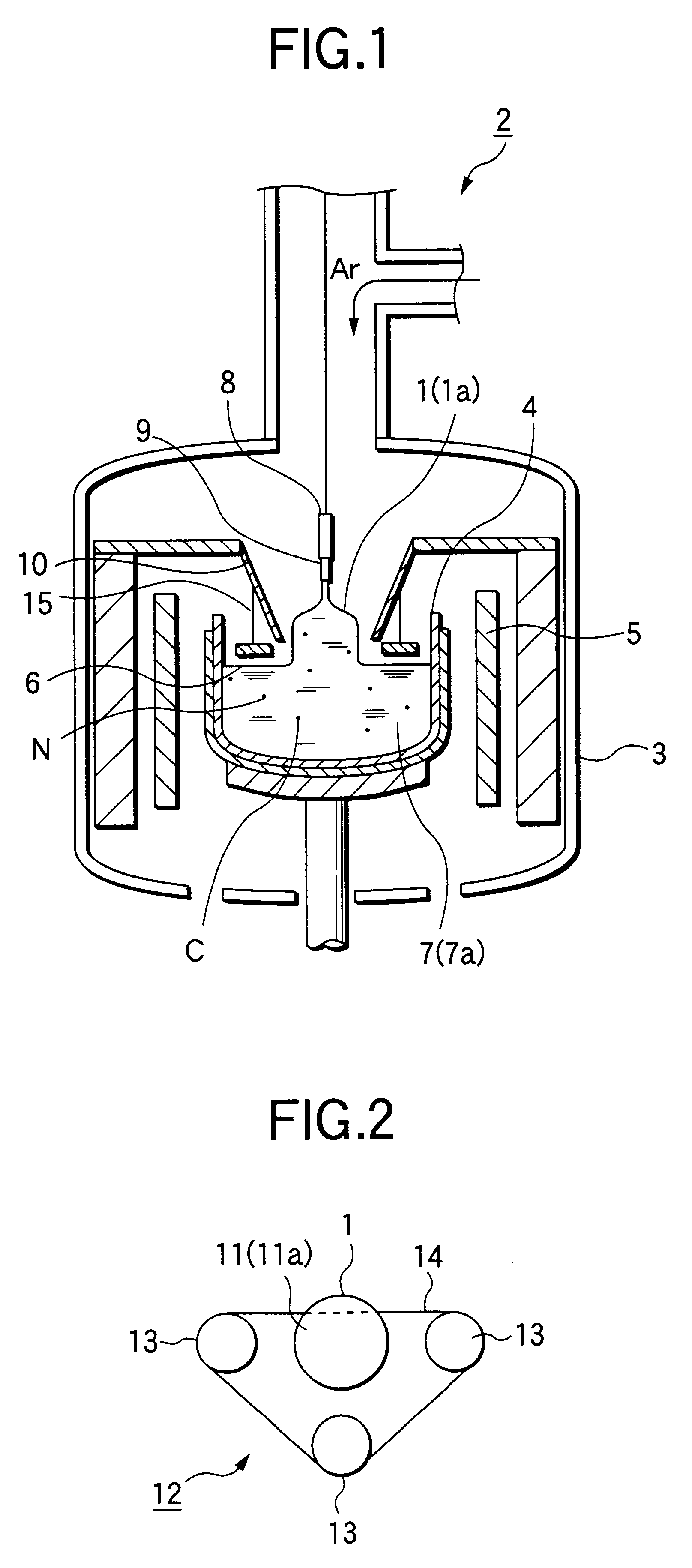

Method of fabricating a single crystal ingot and method of fabricating a silicon wafer

InactiveUS20010029883A1Polycrystalline material growthBy pulling from meltCzochralski methodNitrogen

A method of fabricating a silicon single crystal ingot and a method of fabricating a silicon wafer using the ingot, characterized in that: the method is structured in such a manner that the silicon single crystal ingot is pulled up from the silicon fused liquid 7 in which nitrogen N and carbon C are doped in polycrystalline silicon, by using the Czochralski method, and its nitrogen density is 1x1013-5x1015 atoms / cm3, and the carbon density is 5x1015-3x1016 atoms / cm3.

Owner:COVALENT MATERIALS CORP

Method of fabricating a single crystal ingot and method of fabricating a silicon wafer

InactiveUS6517632B2Polycrystalline material growthBy pulling from meltCzochralski methodCarbon density

A method of fabricating a silicon single crystal ingot and a method of fabricating a silicon wafer using the ingot, characterized in that: the method is structured in such a manner that the silicon single crystal ingot is pulled up from the silicon fused liquid 7 in which nitrogen N and carbon C are doped in polycrystalline silicon, by using the Czochralski method, and its nitrogen density is 1x1013-5x1015 atoms / cm3, and the carbon density is 5x1015-3x1016 atoms / cm3.

Owner:COVALENT MATERIALS CORP

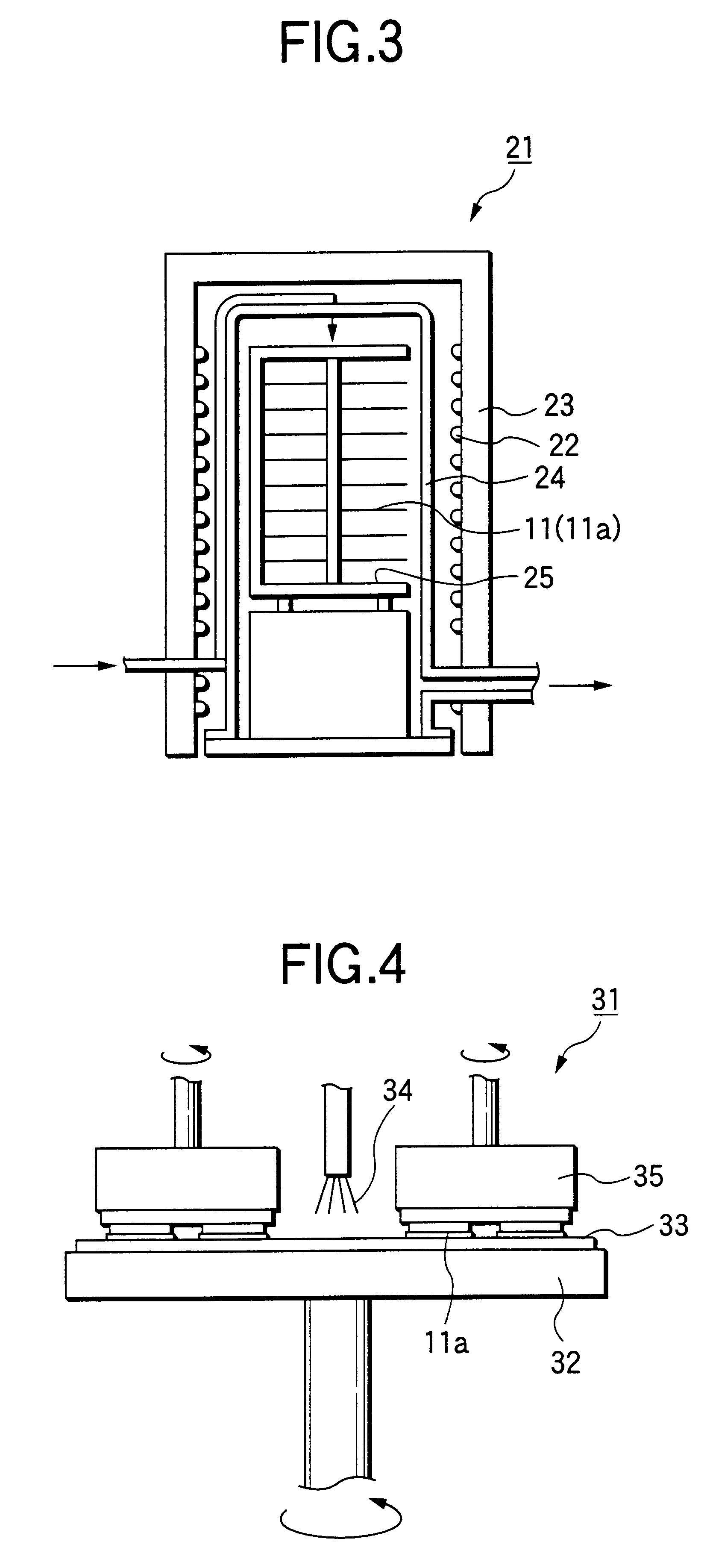

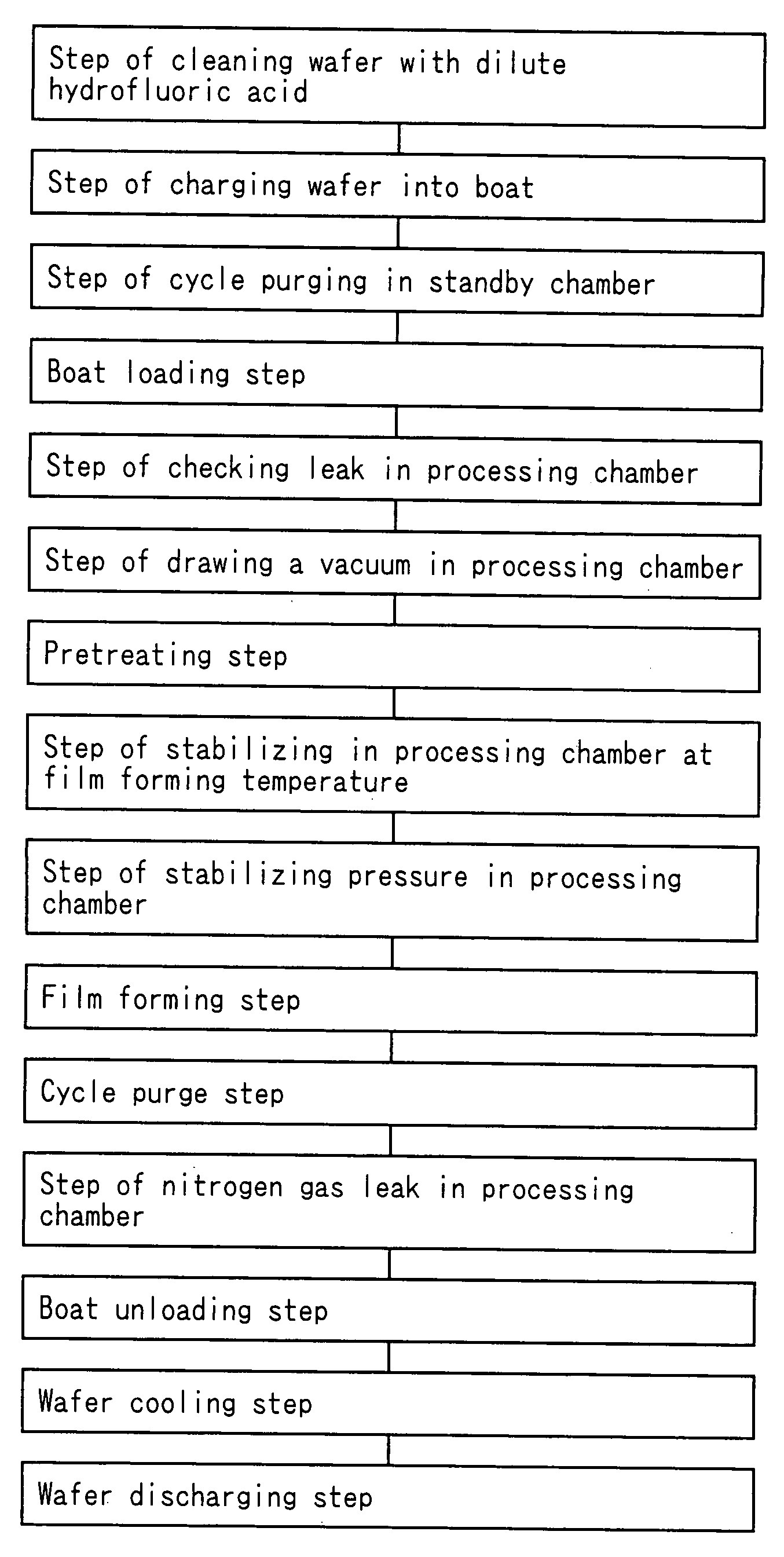

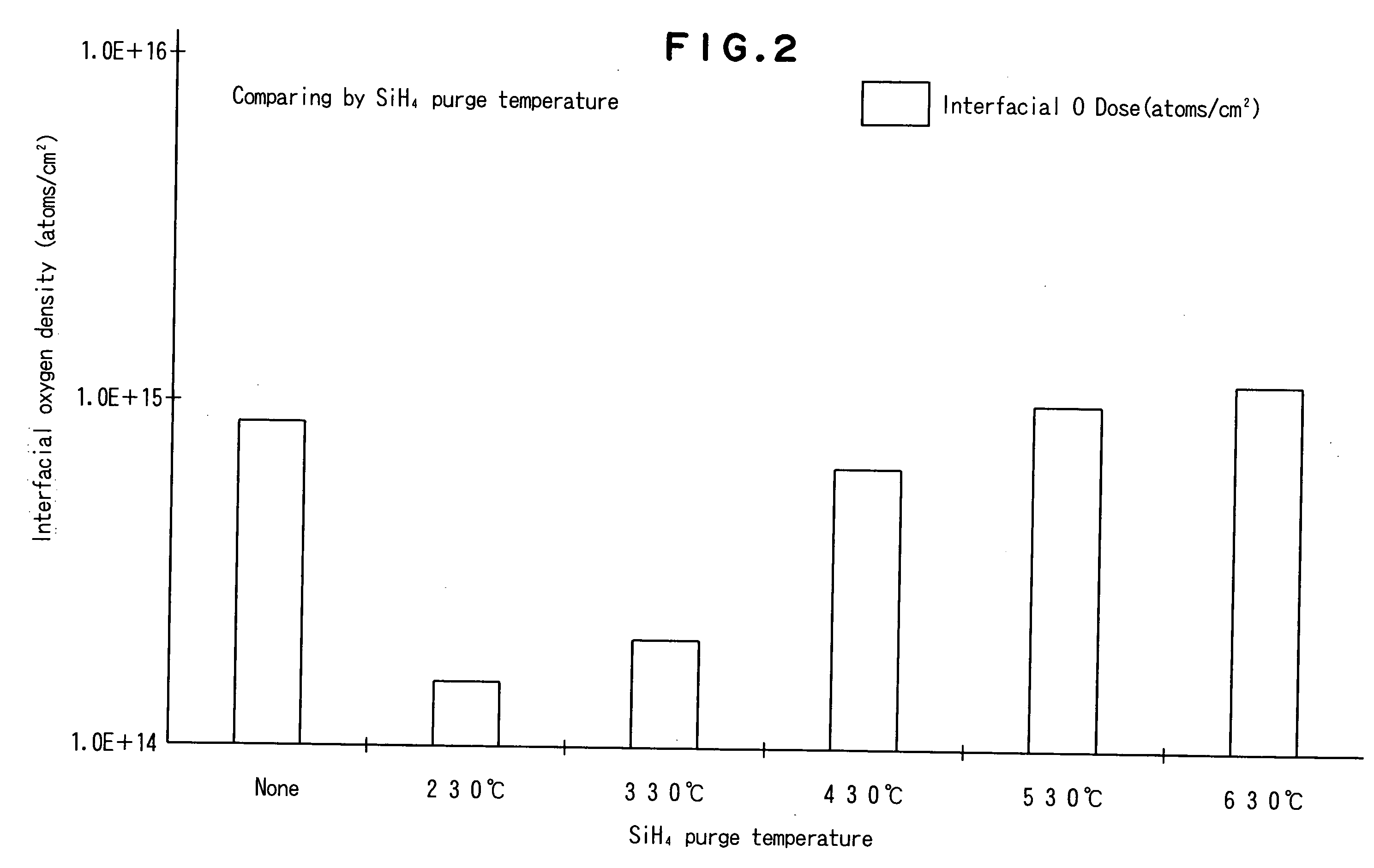

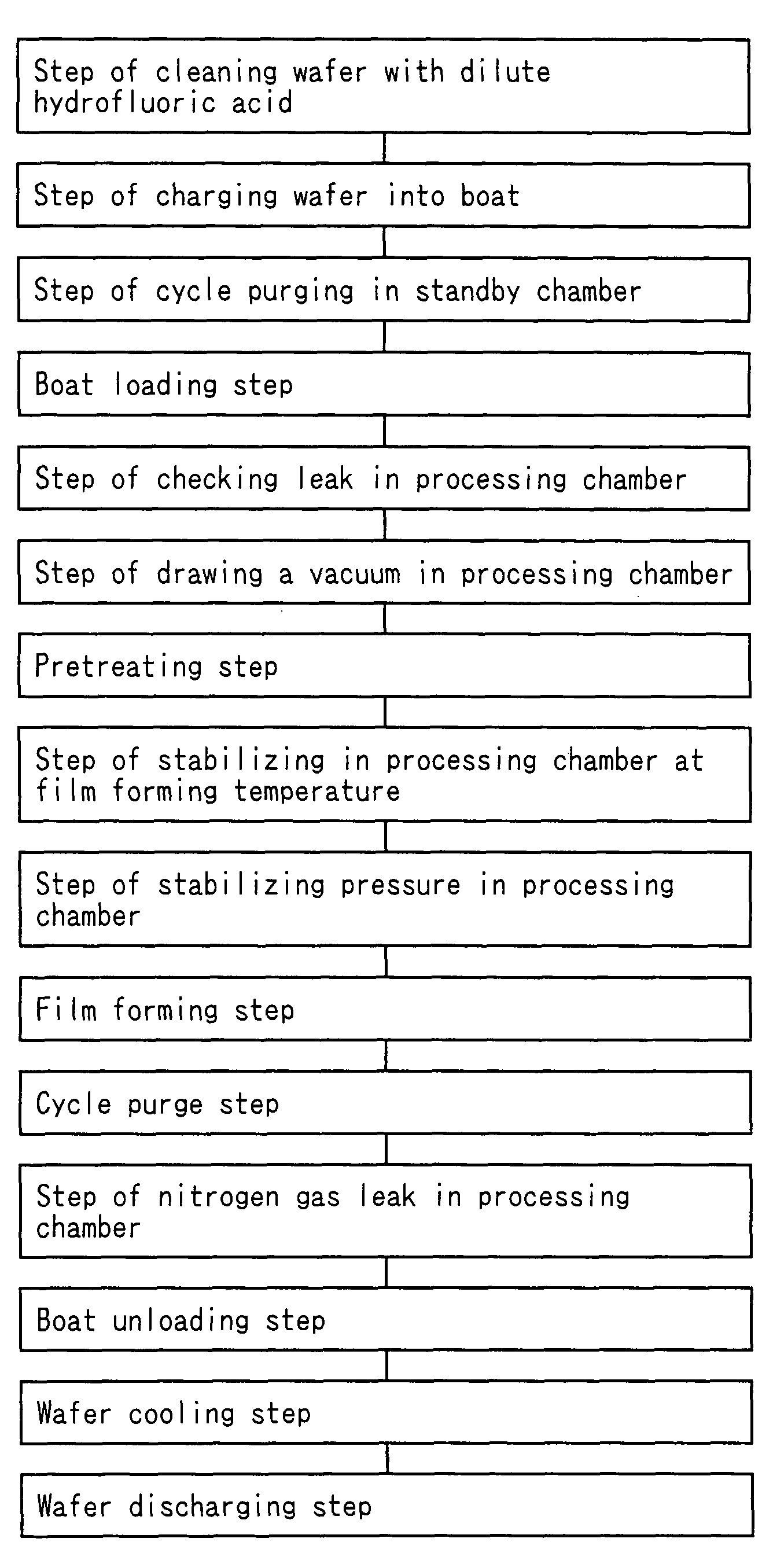

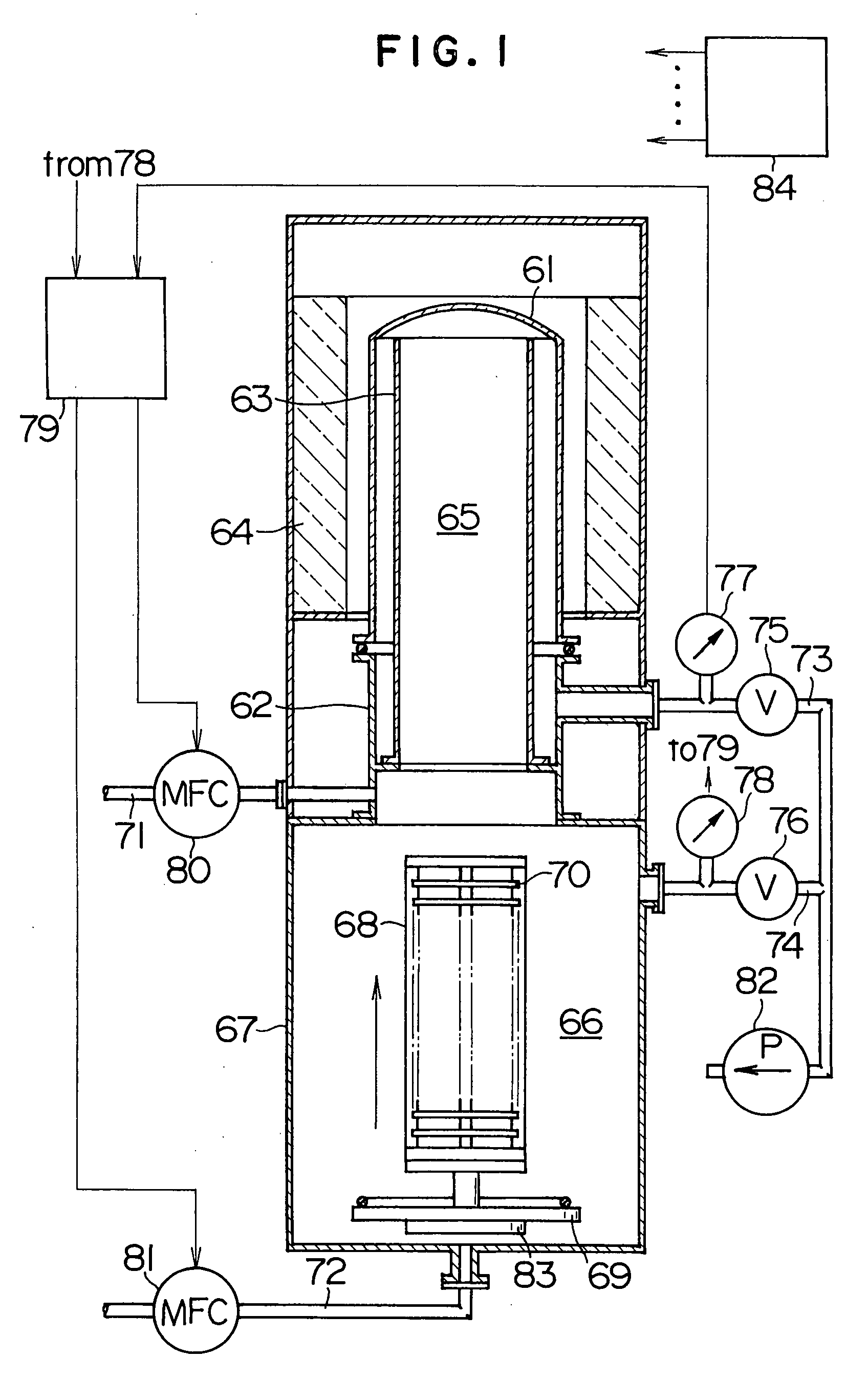

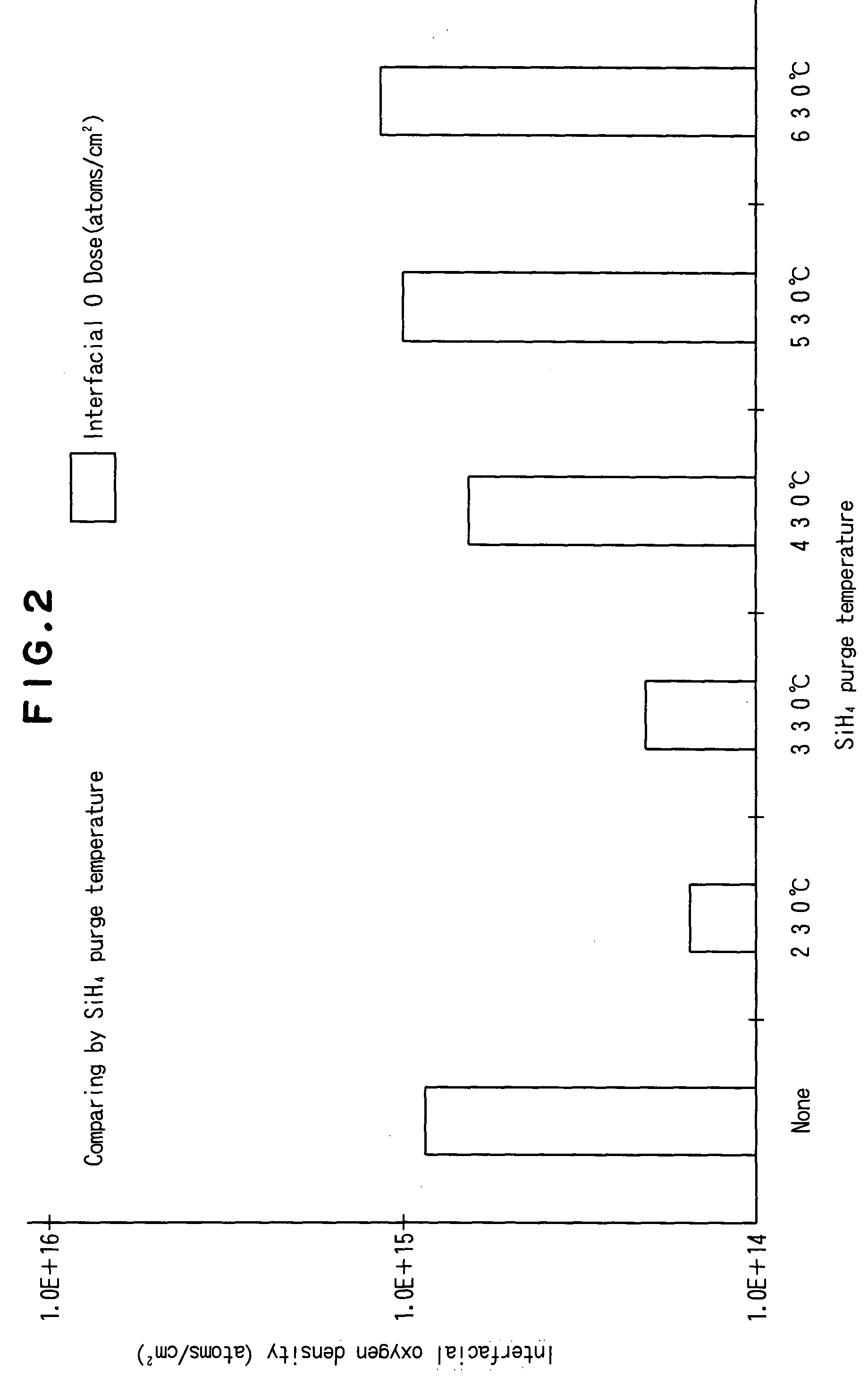

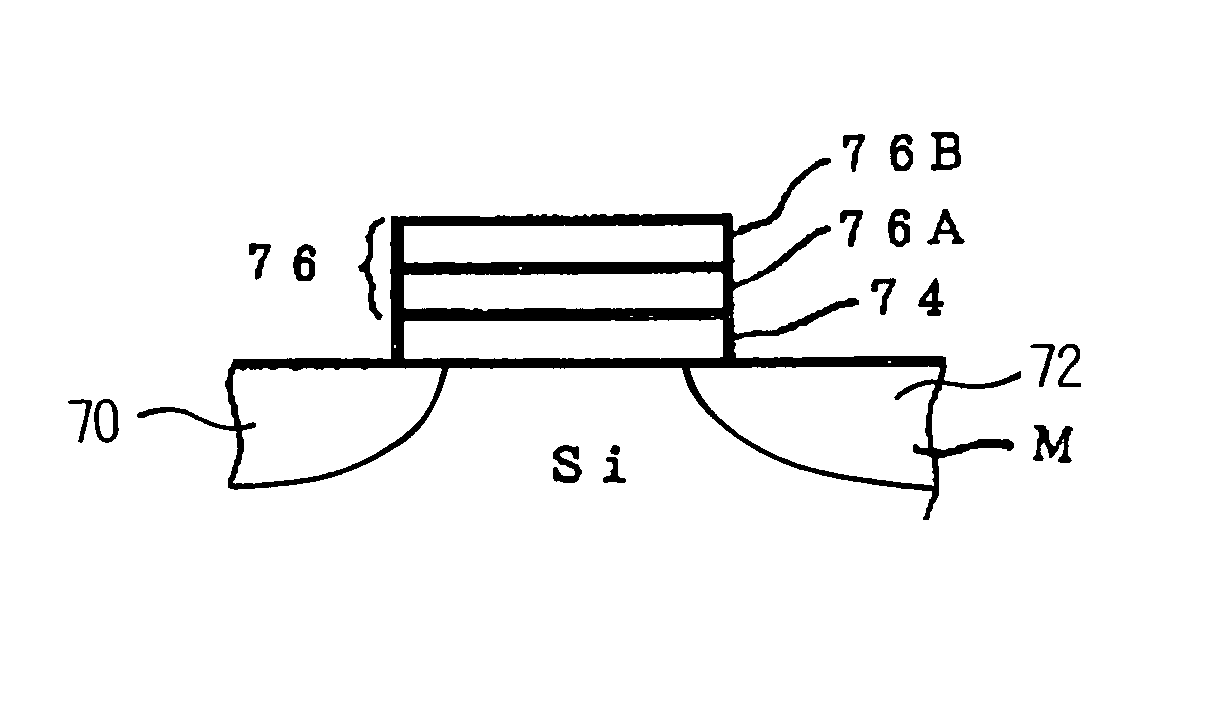

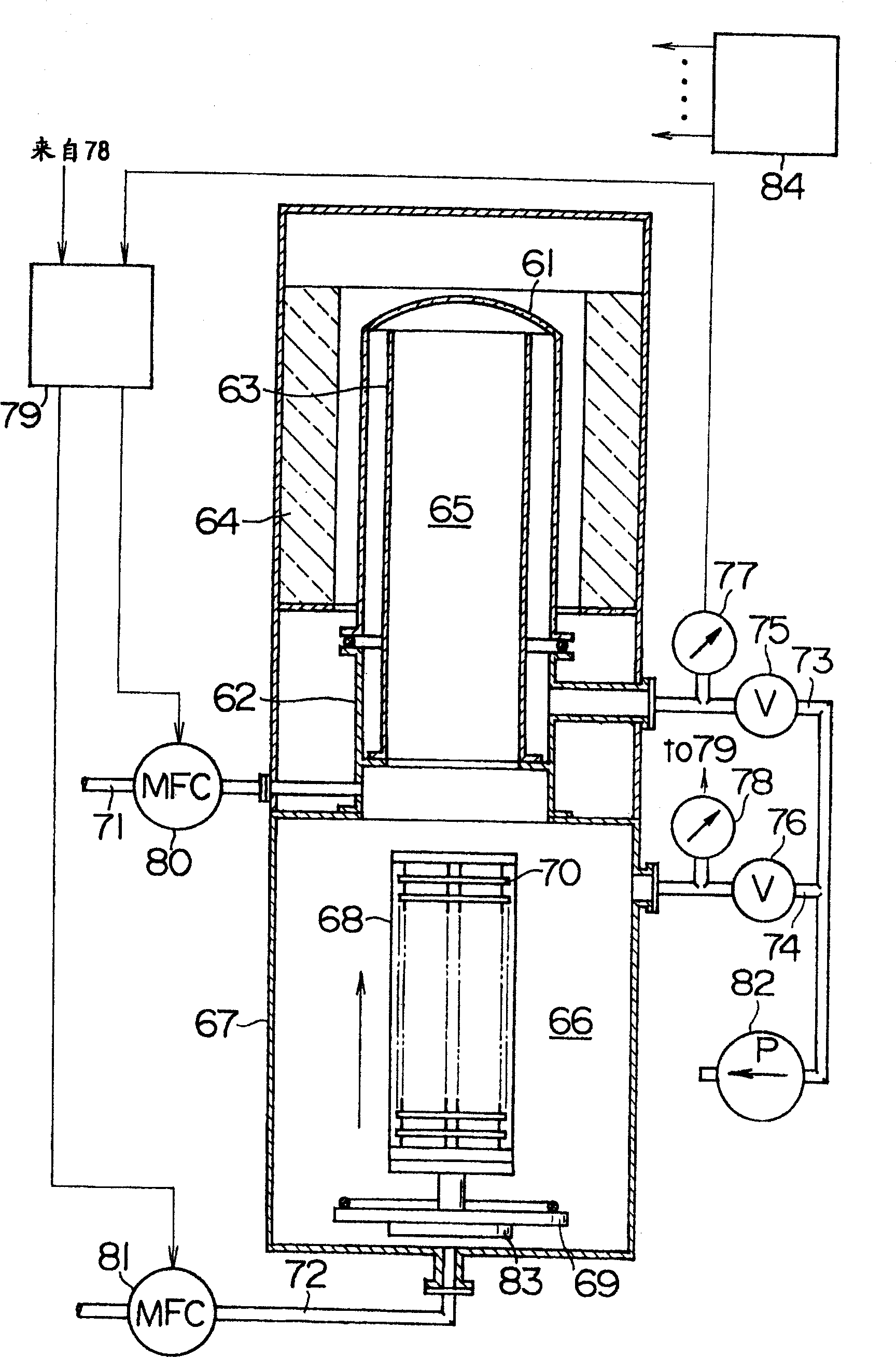

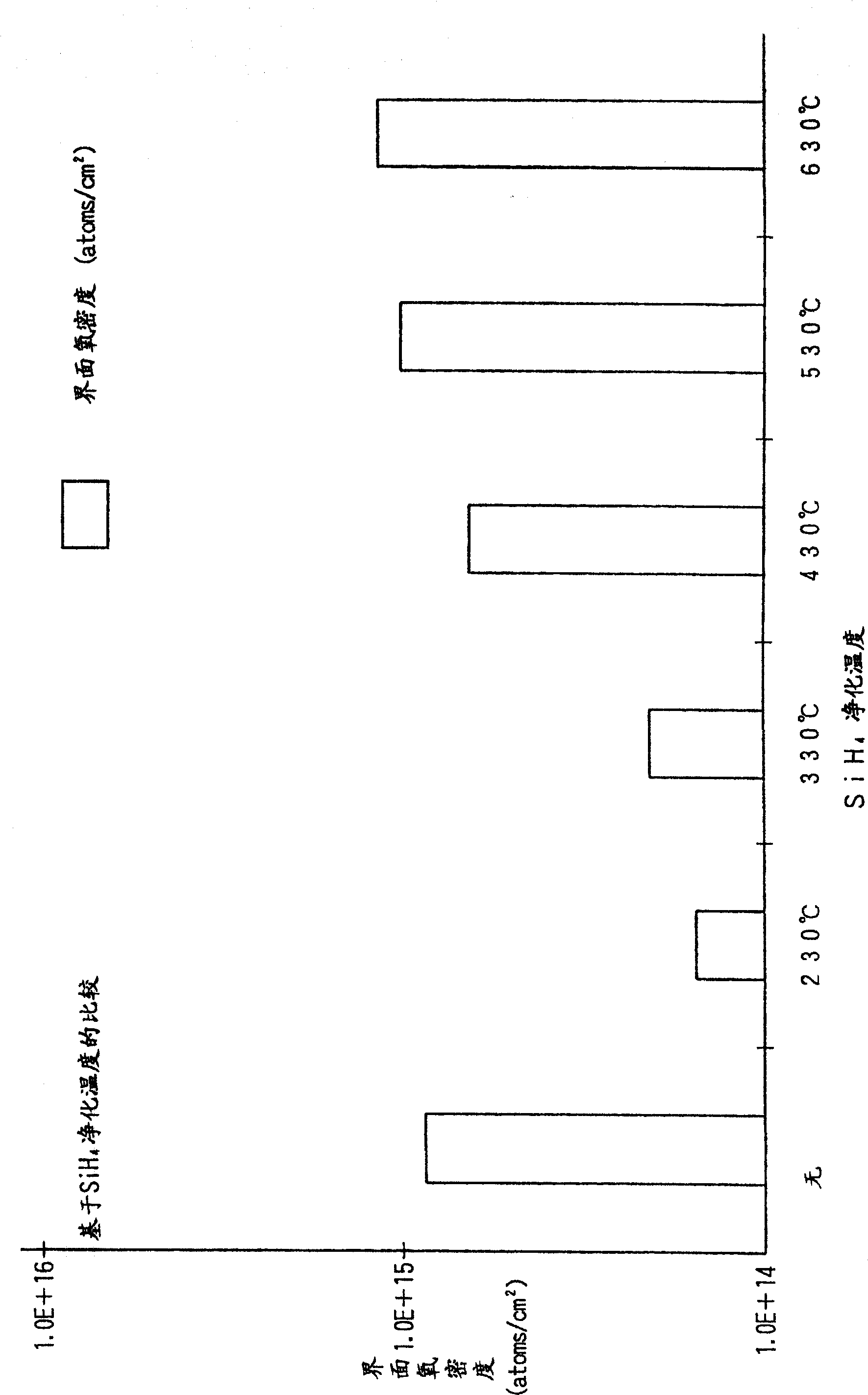

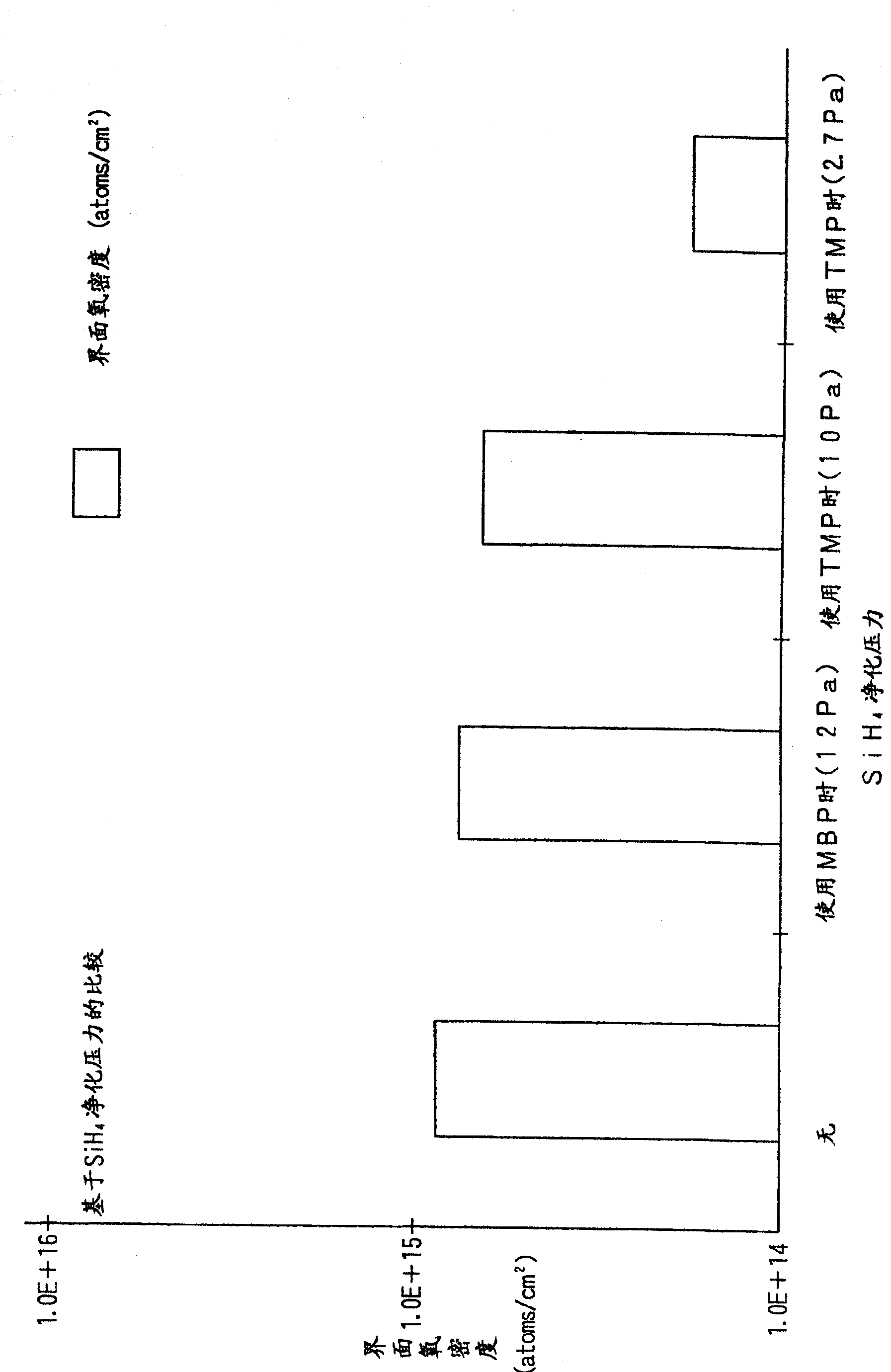

Semiconductor device manufacturing method and substrate processing apparatus

ActiveUS20090117752A1Satisfy cleanlinessQuality improvementPolycrystalline material growthSemiconductor/solid-state device manufacturingHydrogenCarbon density

A high quality interface is formed at a low oxygen-carbon density between a substrate and a thin film while preventing heat damage on the substrate and increase of thermal budget. This method includes a step of loading a wafer into a reaction furnace, a step of pretreating the wafer in the reaction furnace, a step of performing a main processing of the pretreated wafer in the reaction furnace, and a step of unloading the wafer from the reaction furnace after the main processing. Hydrogen gas is continuously supplied to the reaction furnace in the period from the end of the pretreating step to the start of the main processing and at least during vacuum-exhausting an interior of the reaction furnace.

Owner:KOKUSA ELECTRIC CO LTD

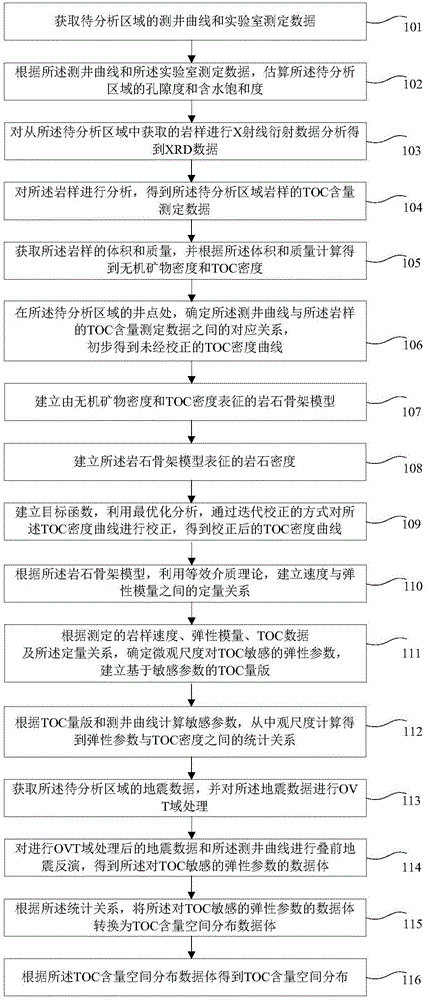

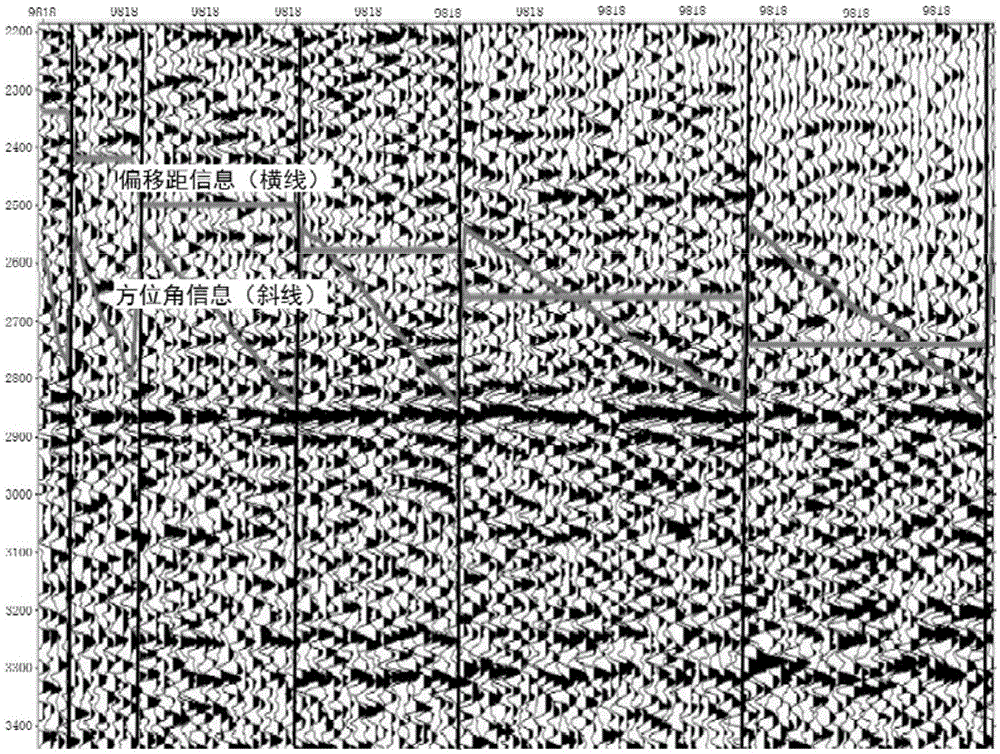

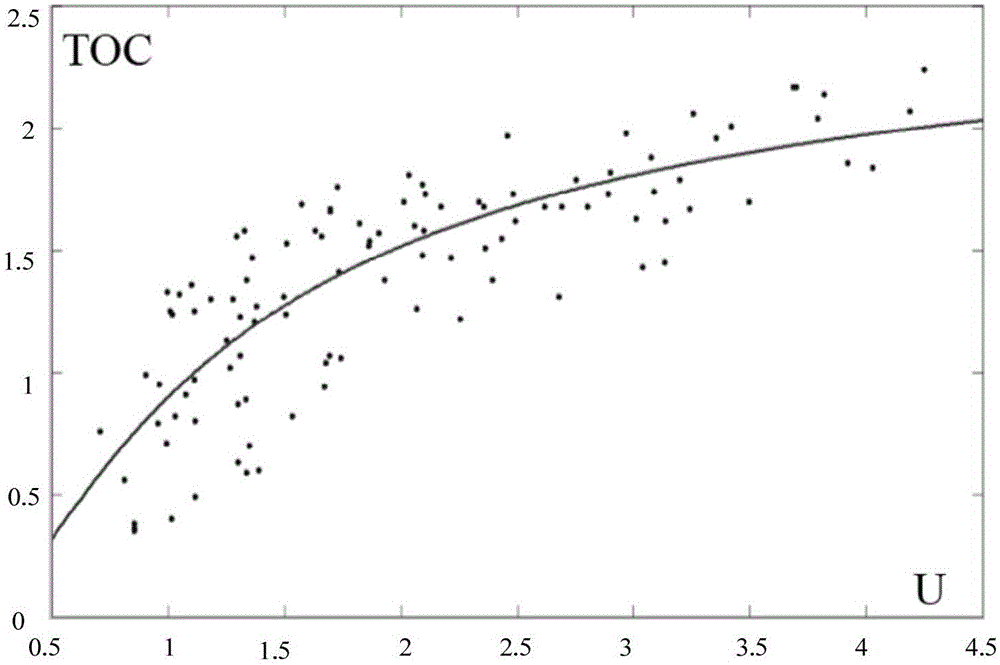

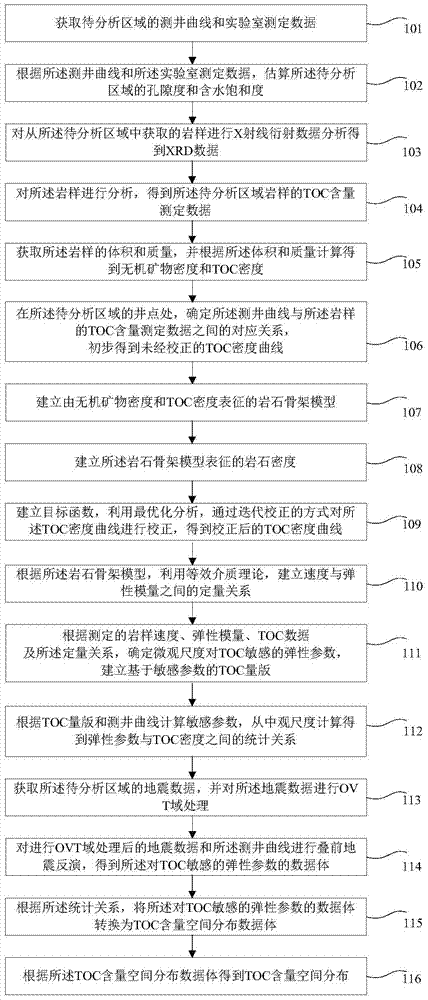

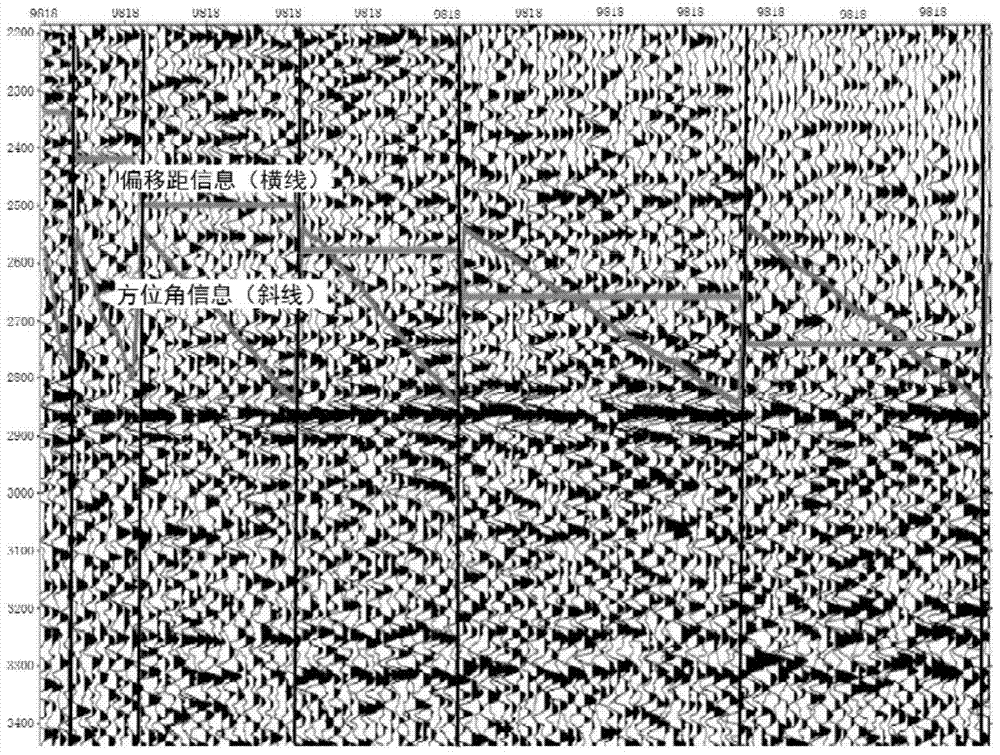

Method and device for determining TOC content

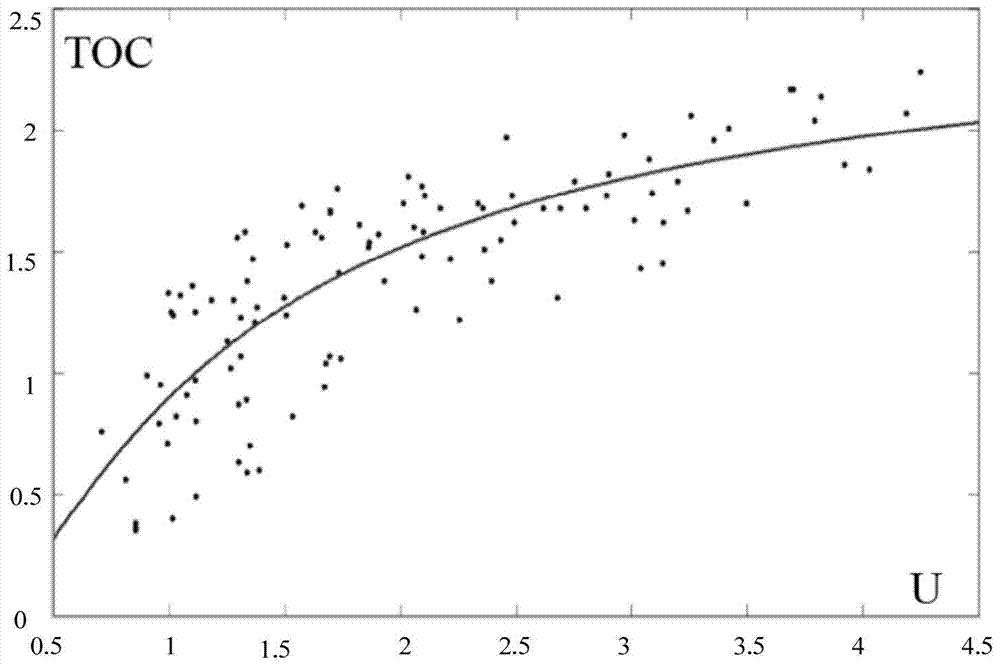

ActiveCN105158796AAccurate predictionSolve low technical problemsEarth material testingSeismic signal processingDensity curveCarbon density

The invention provides a method and device for determining TOC content. The method comprises the following steps: establishing a TOC optimally-estimated mineral rock physical model by utilizing data of laboratory-measured X-ray diffraction data, organic carbon density and logging density curve and the like; obtaining accurate TOC distribution on a well through an optimization iteration method; establishing a TOC quantity version by utilizing actually-measured TOC data and an equivalent medium model; determining TOC sensitivity elastic parameters; and finally, carrying out prestack elastic parameter inversion on earthquake reflection gather obtained through OVT region processing. The method and device for determining the TOC content realize the purpose of quantitatively forecasting space distribution of the TOC content by utilizing well-seism integration through statistical fitting, and solve the problem of not high TOC content forecasting result; and through using the laboratory-measured data and the rock physical model effectively, the estimated result is not only matched with the laboratory-measured value at the places of rock samples, but also can predicate the TOC content at the places without sampling points accurately.

Owner:PETROCHINA CO LTD

Production method of straw carbon

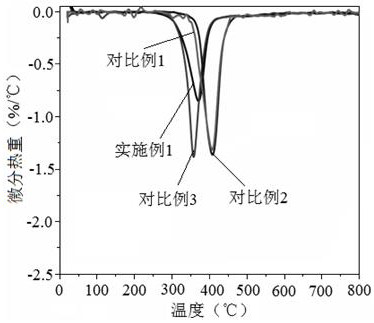

InactiveCN103937517AEasy to produceBiofuelsSpecial form destructive distillationMetallurgyDecomposition

The invention discloses a production method of straw carbon. The straw carbon is obtained by performing compression forming on combustible plants such as straws and continuously carbonizing the straws in a carbonizing furnace. The method comprises the following steps: compressing raw materials, putting the compressed raw materials into a circulating feeding device, feeding the raw materials into the carbonizing furnace, adjusting the temperature in the carbonizing furnace, discharging water and tar from the raw materials and gas such as CO generated in a production process, adjusting the temperature in the carbonizing furnace to be 650 DEG C, at the moment, and performing dry distillation on the raw materials at the high temperature to form the carbon; discharging a finished product from the furnace and cooling for later use. According to the method, the circulating feeding device serves as a carrier for feeding the raw materials into the furnace and a carrier for discharging the finished product from the furnace, is capable of feeding the raw materials into the furnace while discharging the finished product, and is cyclically used to ensure the continuous production; a gas decomposition device is capable of decomposing water, steam, combustible gas and the like generated in the carbonizing process of the raw material from the raw materials, and the substances generated in the carbonizing process are discharged from the carbonizing furnace in a heated vaporization manner; the problems of low carbon density and heat value and high rejection rate and cost of an existing product are solved.

Owner:南阳市宣溢环保设备股份有限公司

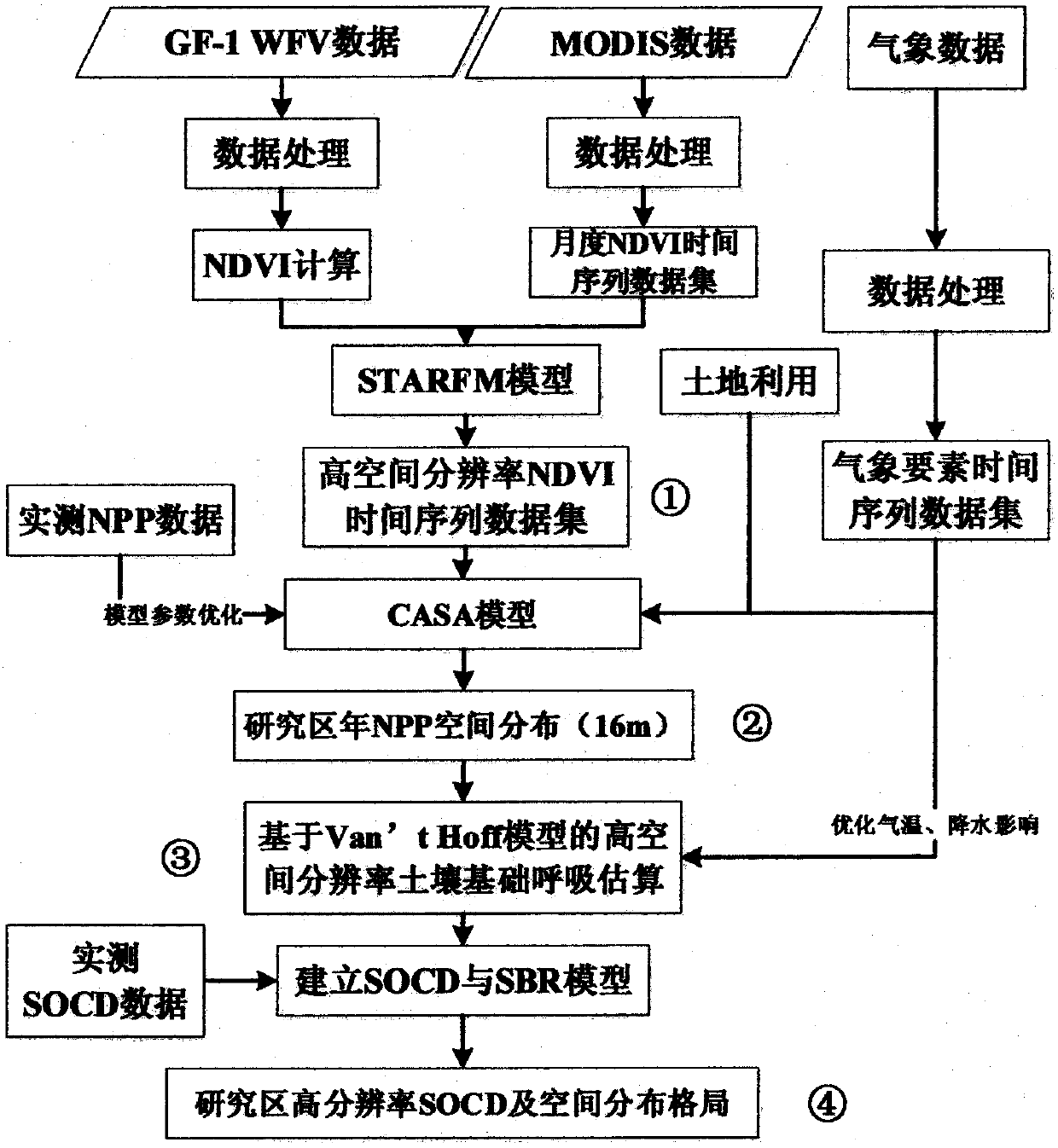

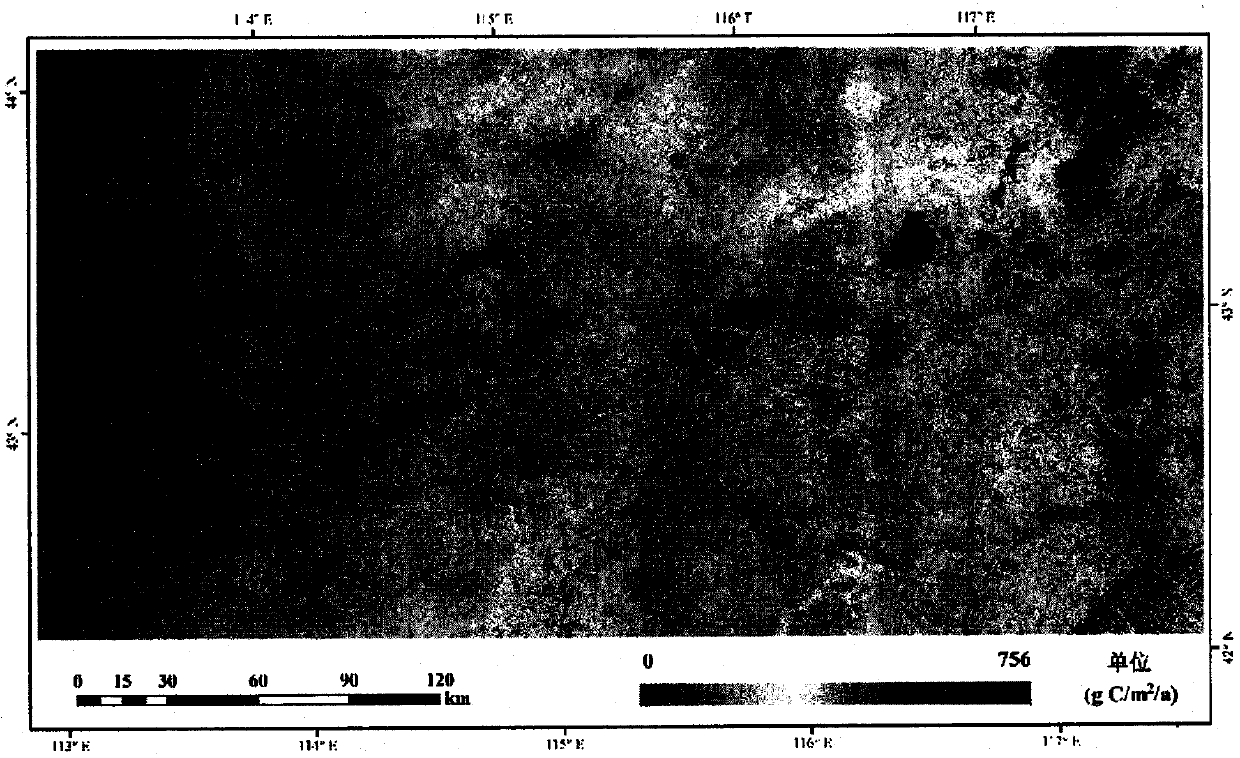

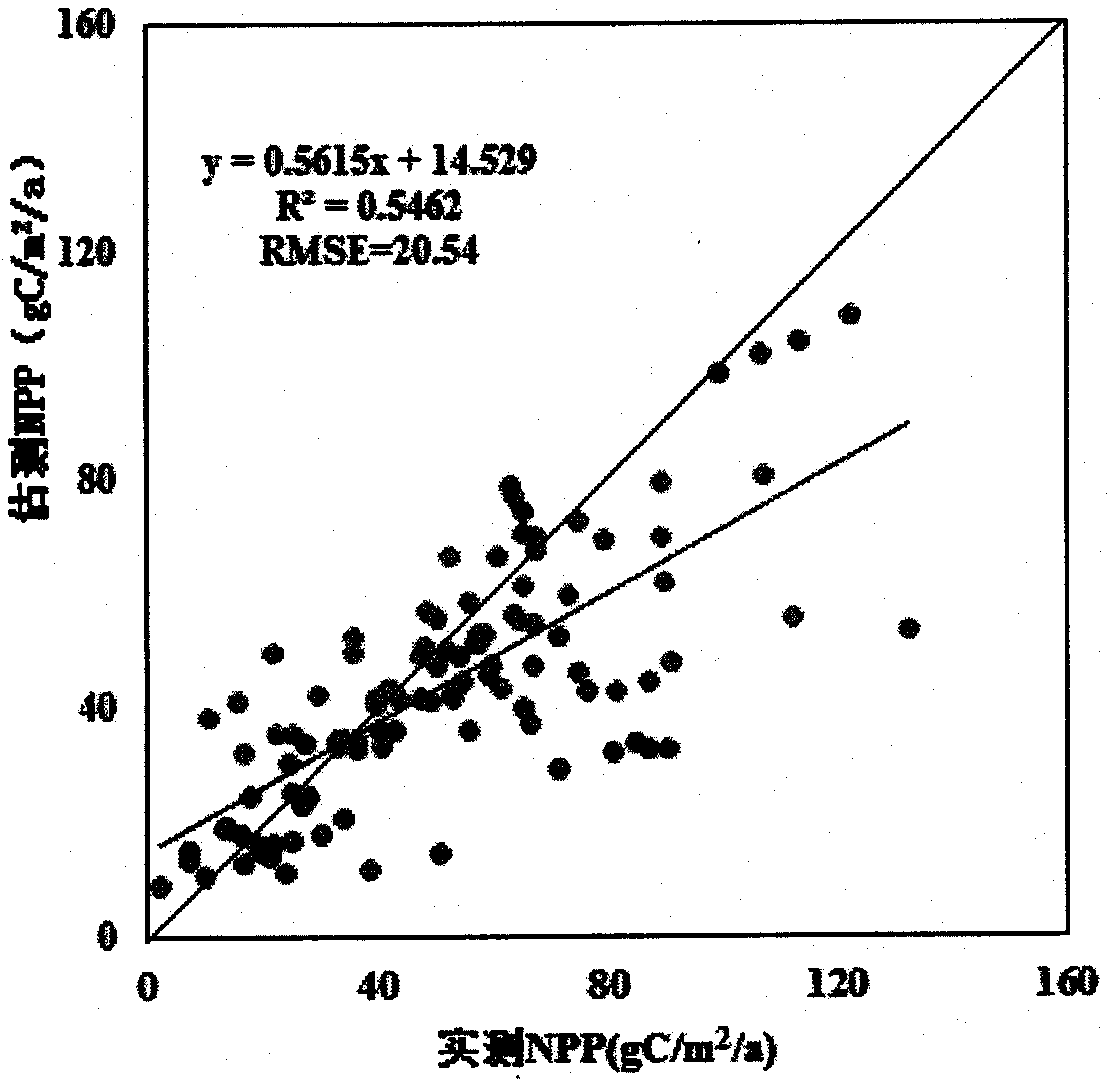

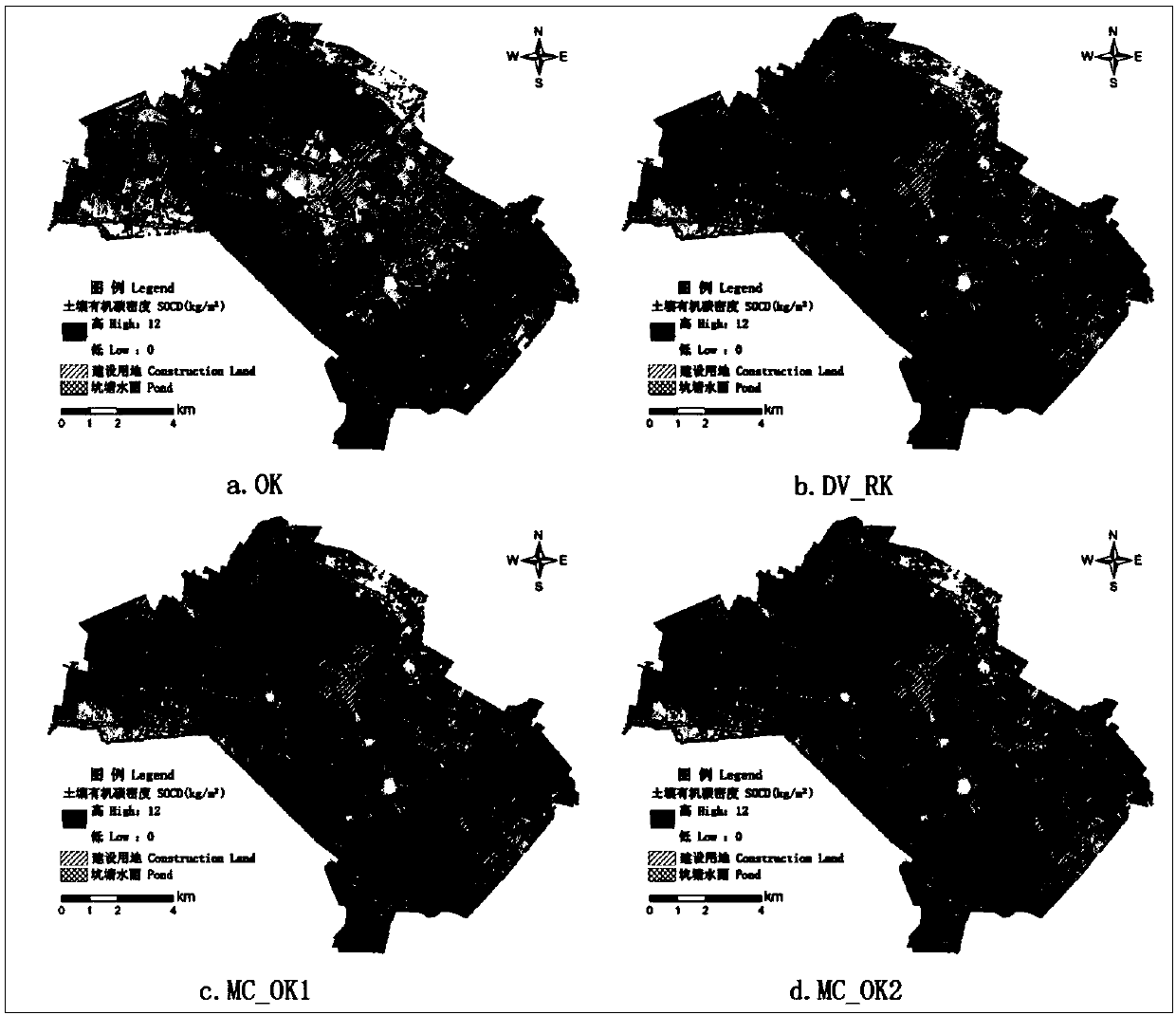

A high-space remote sensing estimation method for soil organic carbon density in a desertification region

ActiveCN109933873AGood application effectSolve the problem of density extrapolationSpecial data processing applicationsModel parametersHigh temporal resolution

The invention discloses a high-space remote sensing estimation method for soil organic carbon density in a desertification region, by optimizing main model parameters in a soil organic carbon densityestimation process, and fusing the advantage of high spatial resolution of GF-1WFV data and the advantage of high temporal resolution of MODIS data, high-space (16m) and high-precision estimation of the organic carbon density of the soil in the desertification region are realized; and by utilizing remote sensing techniques, the problem of soil organic carbon density scale extrapolation can be wellsolved; the spatial heterogeneity of the organic carbon density distribution of the soil in the sand can be reflected more finely; possibility is provided for multi-scale soil respiration long-term quantitative estimation, scientific data reference is provided for land degradation monitoring and evaluation of desertification areas and implementation work of desertification control engineering, and the application capacity of domestic remote sensing data is improved.

Owner:RES INST OF FOREST RESOURCE INFORMATION TECHN CHINESE ACADEMY OF FORESTRY

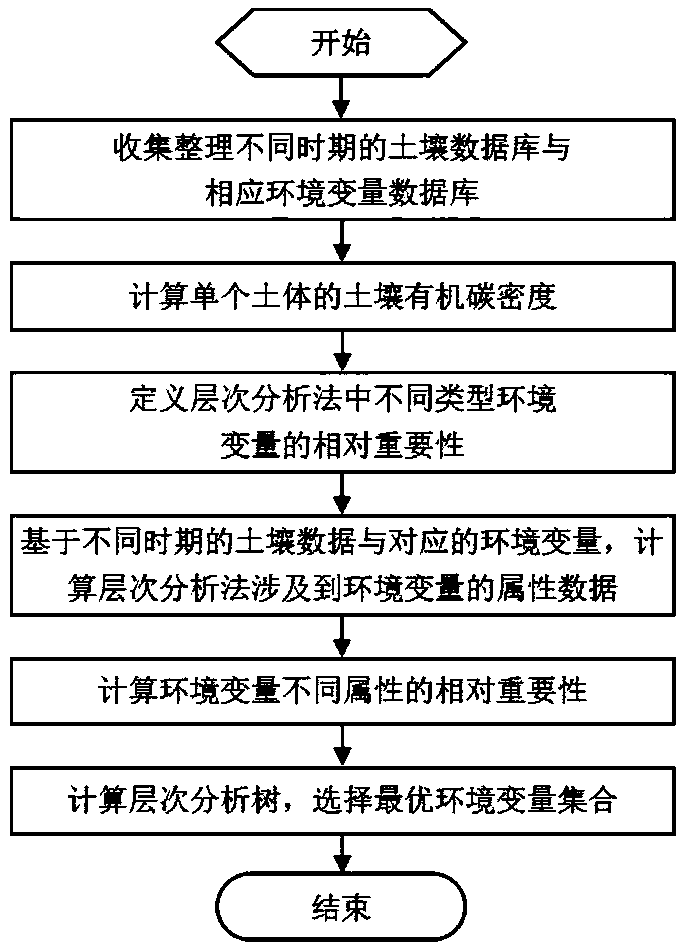

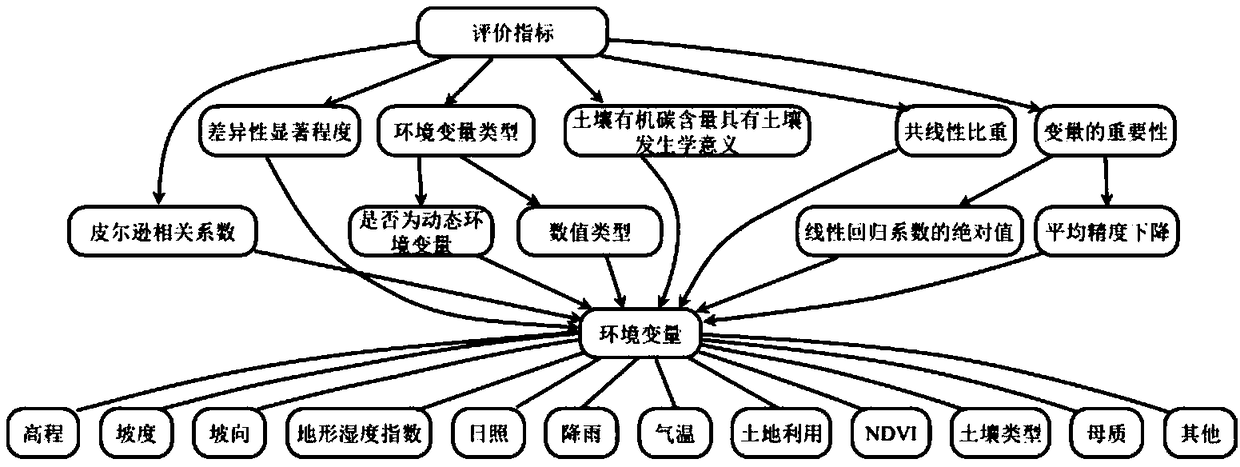

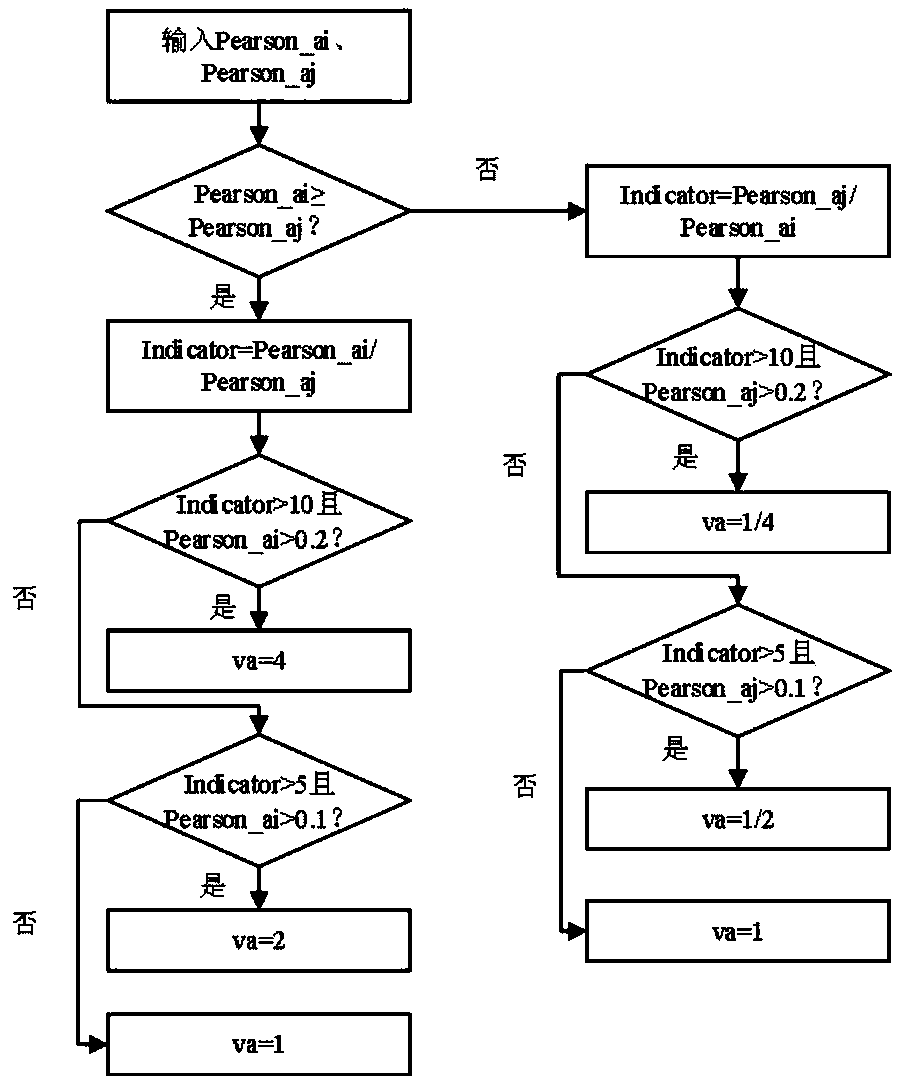

Optimal environment variable screening method for time-space dynamic prediction of soil organic carbon pool

ActiveCN108764527AQuantify the degree of influenceMultiple periodsForecastingComplex mathematical operationsScreening methodSpecific time

The invention relates to an optimal environment variable screening method for time-space dynamic prediction of a soil organic carbon pool. Soil databases in different periods, and dynamic and static environment variable sets are collected and sorted; and according to the timeliness of soil data, an effective time period, namely, "a time slice" for simulating the soil carbon pool is stipulated. Various attribute information of various dynamic and static environment variables is analyzed according to soil organic carbon density information in different landscape areas, so that an analytic hierarchy process and expert knowledge are used for constructing an effective optimal environment variable set in the specific time slice.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

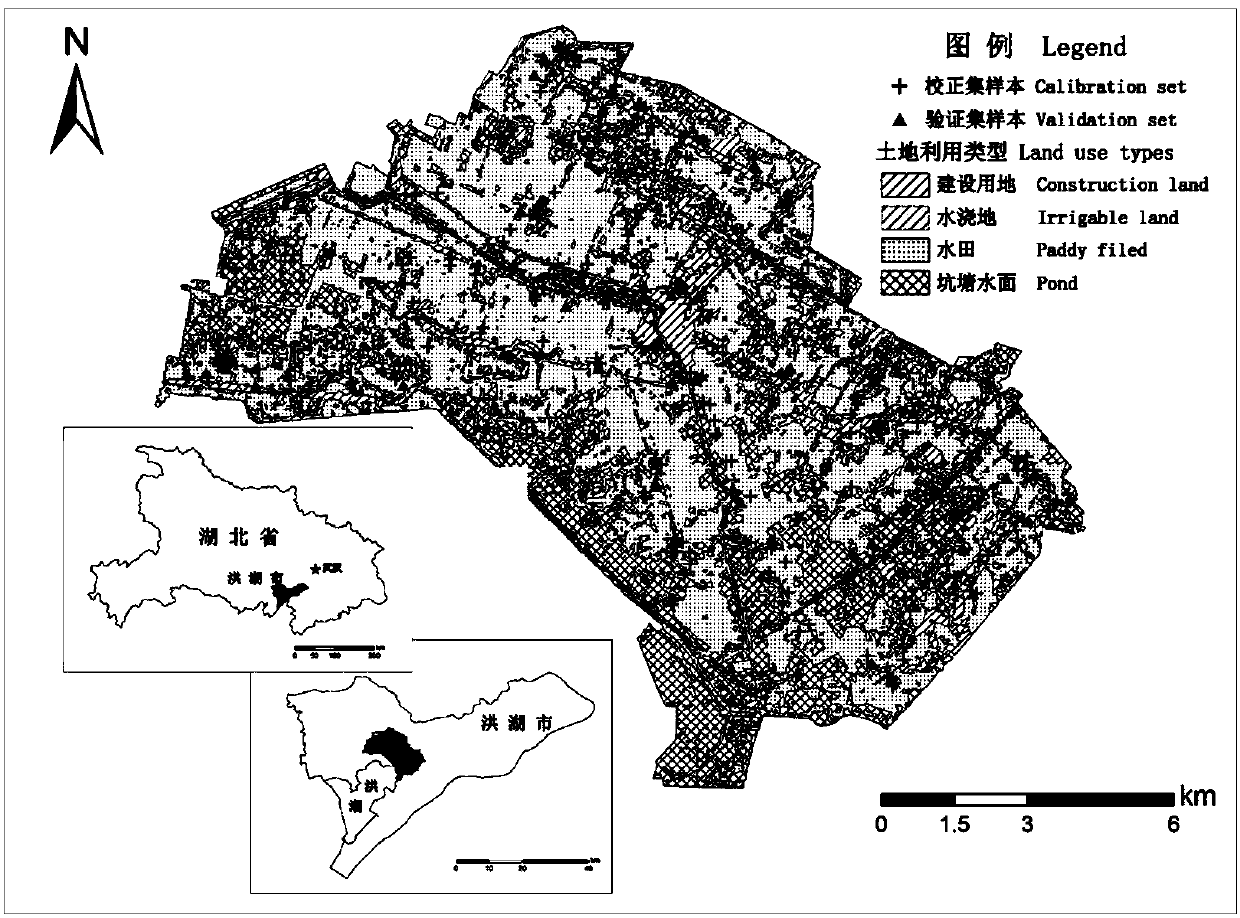

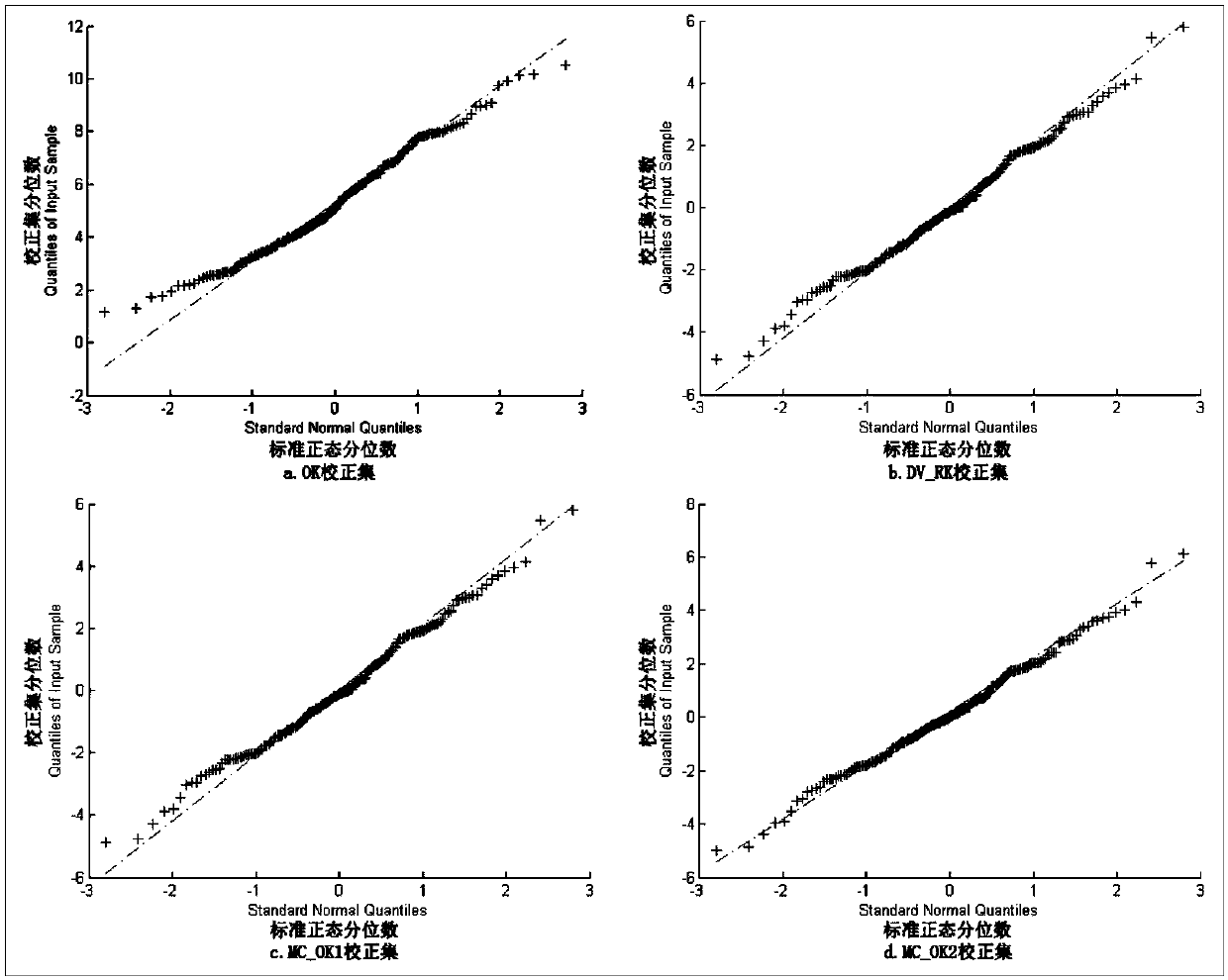

Soil organic carbon density spatial heterogeneity-considered Kriging interpolation model

ActiveCN107194054AReduce the impactImprove reliabilityClimate change adaptationDesign optimisation/simulationSpatial heterogeneityPredictive methods

The invention discloses a soil organic carbon density spatial heterogeneity-considered Kriging interpolation model. According to the Kriging interpolation model, influences, on common Kriging methods, of low-spatial heterogeneity and spatial abnormal values are reduced by combining land utilization information; and according to different trend term functions, the Kriging interpolation model comprises a virtual variable regression Kriging method, a mean centralized Kriging method and a median centralized Kriging method. By utilizing the model, high-precision SOCD prediction and mapping are realized, and finally, an optimum prediction method and a prediction result thereof are selected according to model evaluation indexes. The reliability, prediction rationality, prediction precision and decision coefficient R2 of the model are remarkably improved; and meanwhile, the model realizes high-precision SOCD spatial mapping, so that significance is provided for realizing precision agriculture and improving the agricultural production efficiency.

Owner:WUHAN UNIV

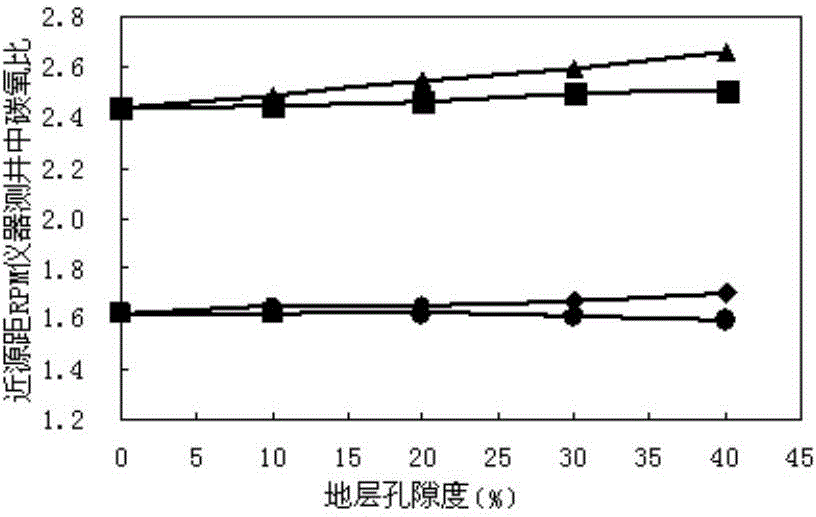

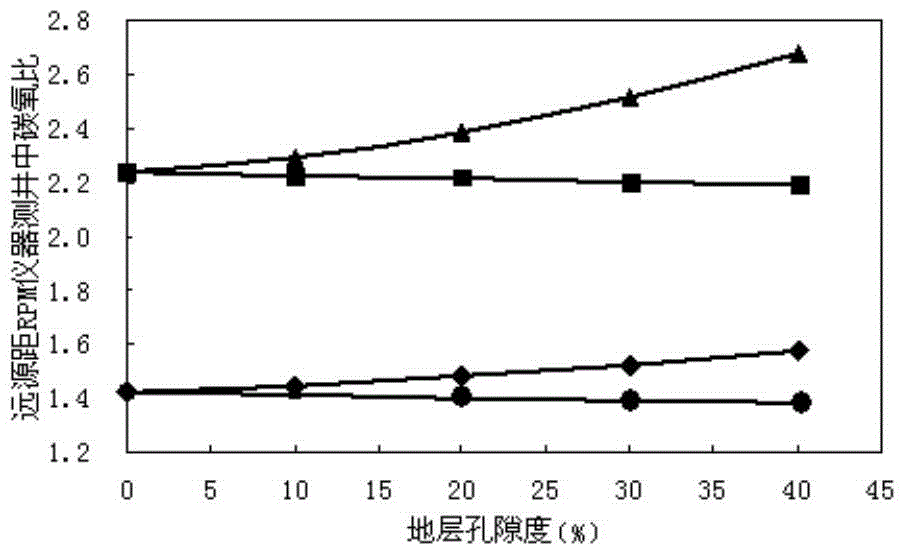

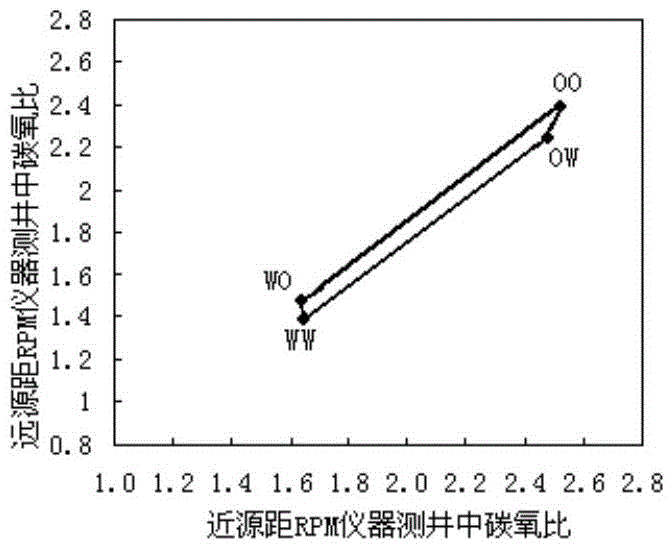

Method for calculating wellbore water-holding capacity and formation water saturation in RPM well logging

ActiveCN104929627AAccurate calculationQuick calculationBorehole/well accessoriesCalcium in biologyCarbon density

The invention relates to a method for calculating wellbore water-holding capacity and formation water saturation in RPM well logging. The method comprises the steps that a regular chart of the changes of the carbon-oxygen ratio along with formation porosity in RPM well logging is obtained only considering the sizes of a wellbore and a casing pipe; a carbon-oxygen ratio calculation formula is obtained according to the sizes of the wellbore and the casing pipe in RPM well logging; the carbon-oxygen ratio in RPM well logging is obtained when water filling is conducted on a wellbore water filling formation and oil filling is conducted on a wellbore water filling formation; the carbon-oxygen ratio in RPM well logging is obtained when oil filling is conducted on a wellbore oil filling formation and water filling is conducted on a wellbore oil filling formation; carbon density and oxygen density of water in the wellbore and carbon density and oxygen density of oil in the wellbore are calculated; the carbon-oxygen ratio in RPM well logging is calculated when influence factors comprise the wellbore, the casing pipe and gravel; the carbon-oxygen ratio in RPM well logging is calculated when the influence factors comprise the wellbore, the casing pipe, the gravel and mud; the carbon-oxygen ratio in RPM well logging is calculated when influence factors comprise the wellbore, the casing pipe, the gravel, the mud and calcium; a cross plot of near-far carbon-oxygen ratio is built; the wellbore water-holding capacity and the formation water saturation are obtained according to the cross plot of the near-far carbon-oxygen ratio.

Owner:CHINA NAT OFFSHORE OIL CORP +1

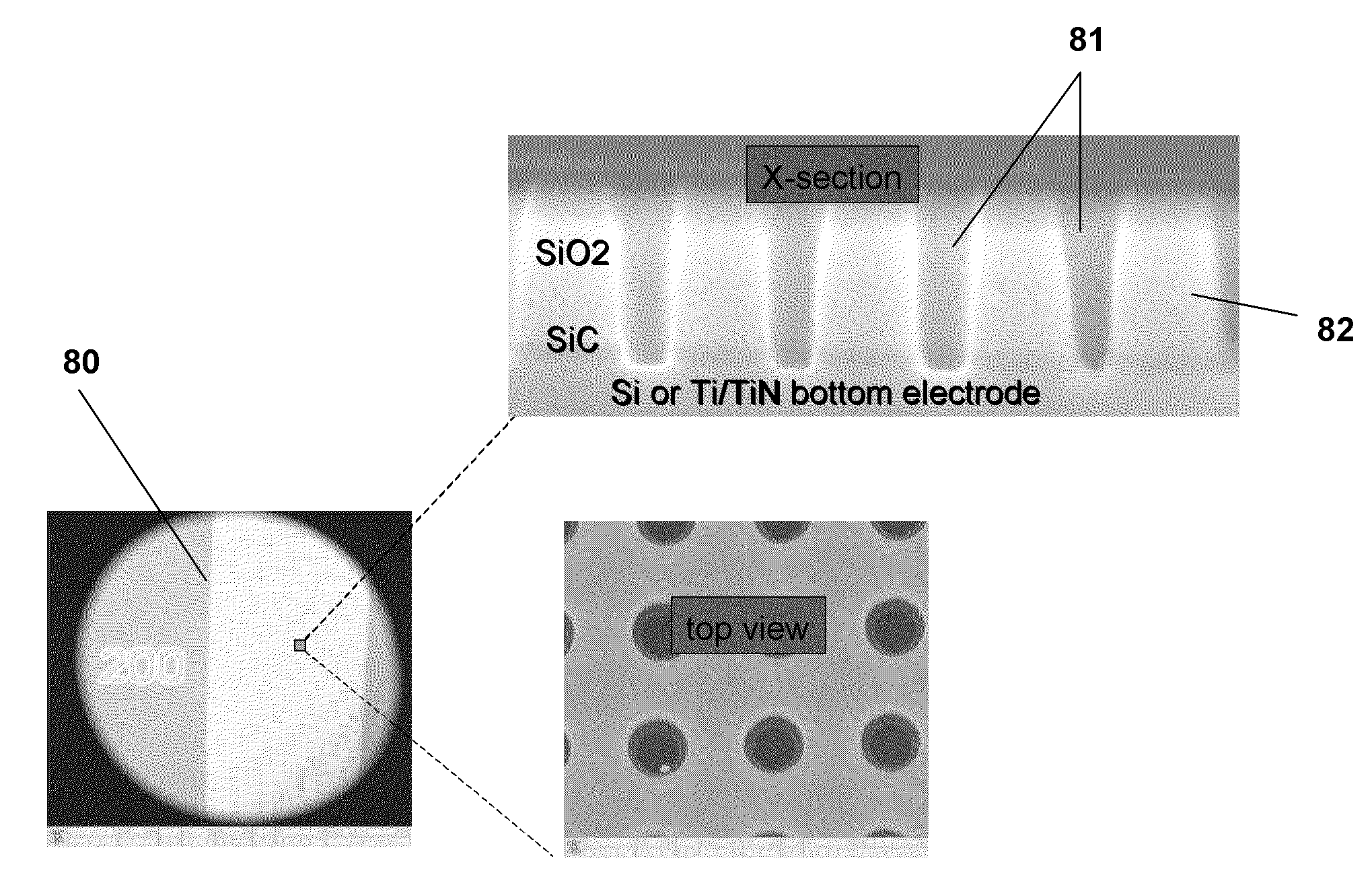

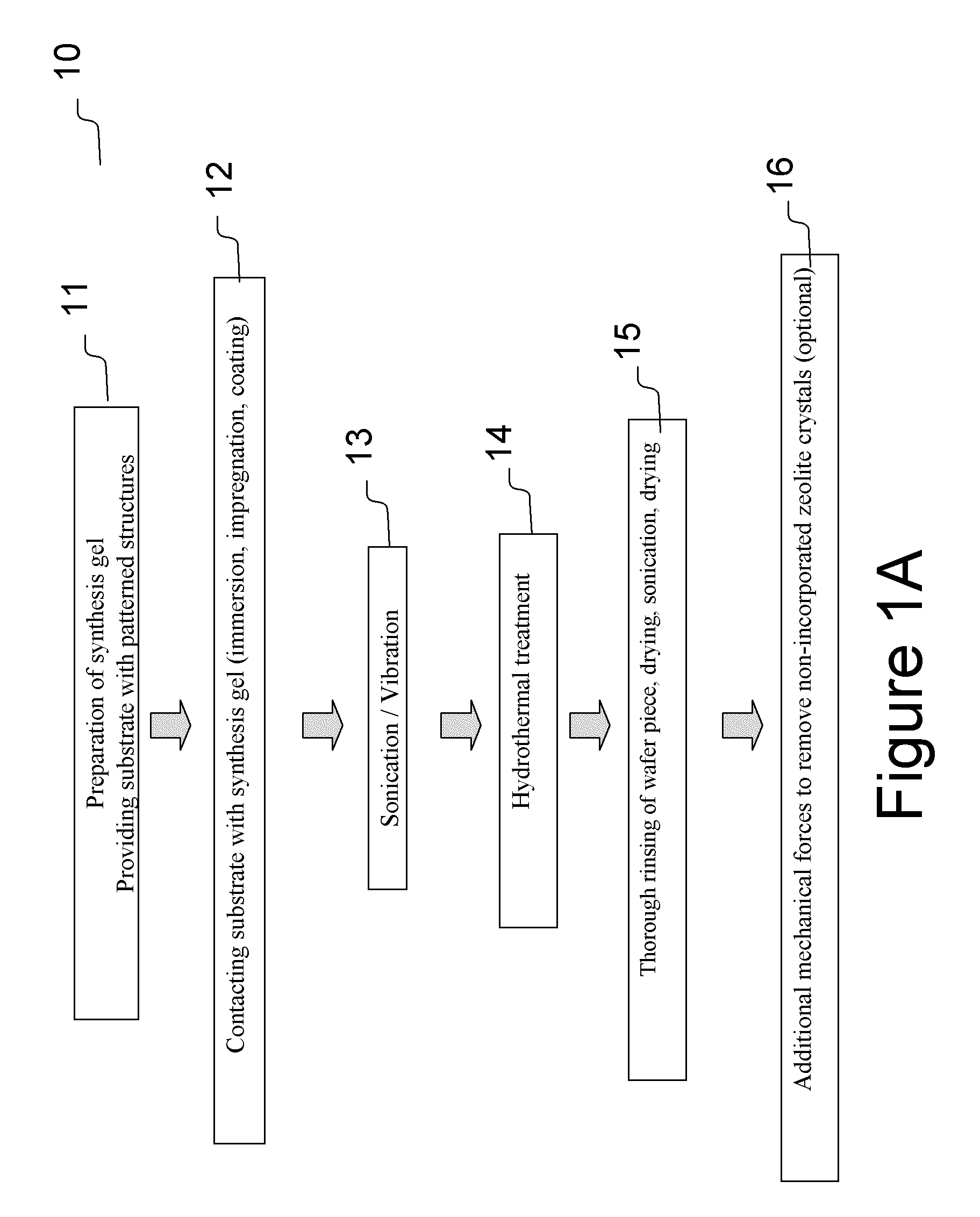

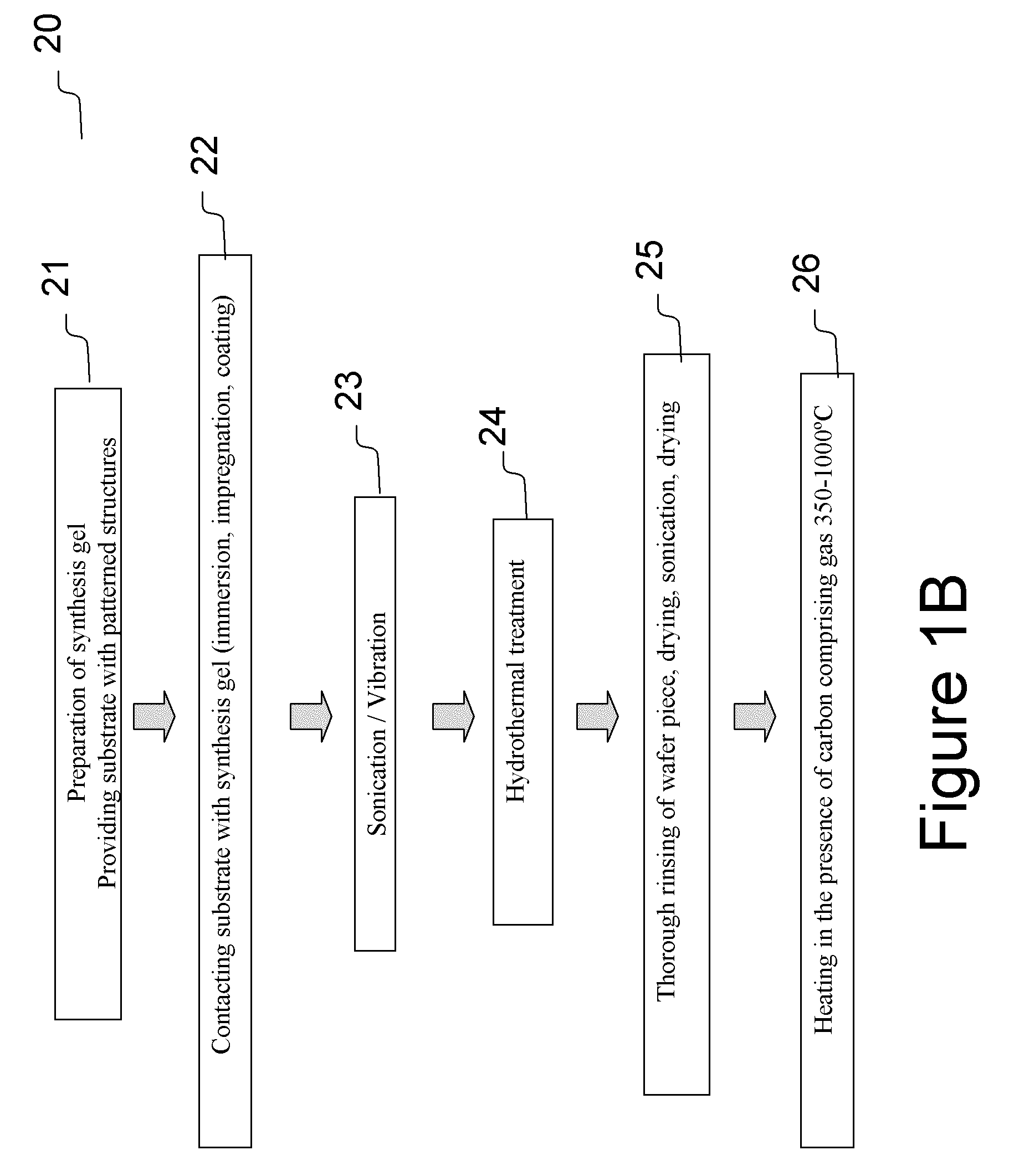

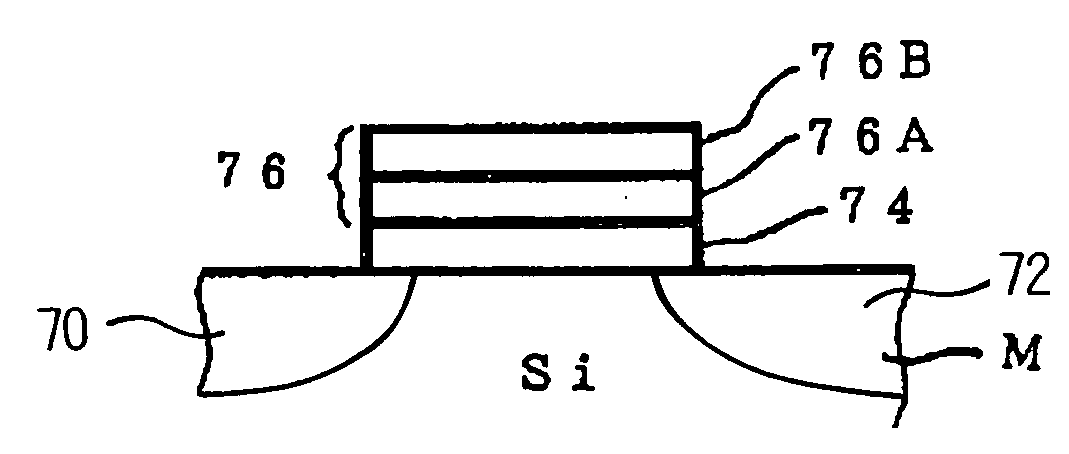

Synthesis of zeolite crystals and formation of carbon nanostructures in patterned structures

InactiveUS20090243103A1High yieldHigh densityMaterial nanotechnologySemiconductor/solid-state device detailsHigh carbonCarbon density

A method is provided for incorporating zeolite crystals in patterned structures, the zeolite crystals having pores (channels) with an orientation which is defined by the topology of the zeolite crystal type and the geometry of the patterned structure, resulting in pores parallel with the length axis of the patterned structures. The patterned structures may be vias (vertical contacts) and trenches (horizontal lines) in a semiconductor substrate. These zeolite crystals can advantageously be used for dense and aligned nanocarbon growth or in other words growth of carbon nanostructures such as carbon nanotubes (CNT) within the pores of the zeolite structure. The growth of CNT is achieved within the porous structure of the zeolite crystals whereby the pores can be defined as confined spaces (channels) in nanometer dimensions acting as a micro-reactor for CNT growth. A method for growing carbon nanostructures within zeolite crystals is also provided, by adding, after creation of the zeolite crystals, a novel compound within the porous structure of the zeolite crystals whereby said novel compound is acting as a carbon source to create the carbon nanostructures. The improved growth method gives a significantly higher carbon density (yield) compared to state of the art techniques.

Owner:KATHOLIEKE UNIV LEUVEN +1

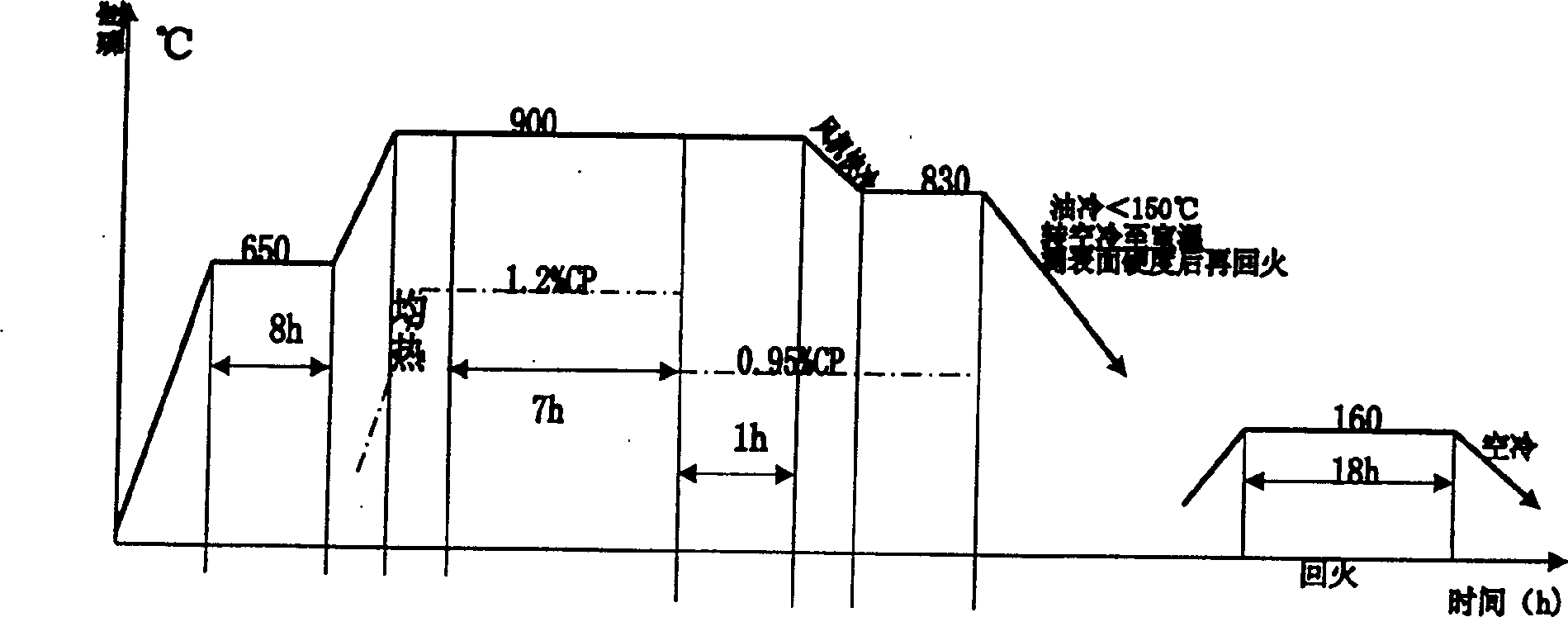

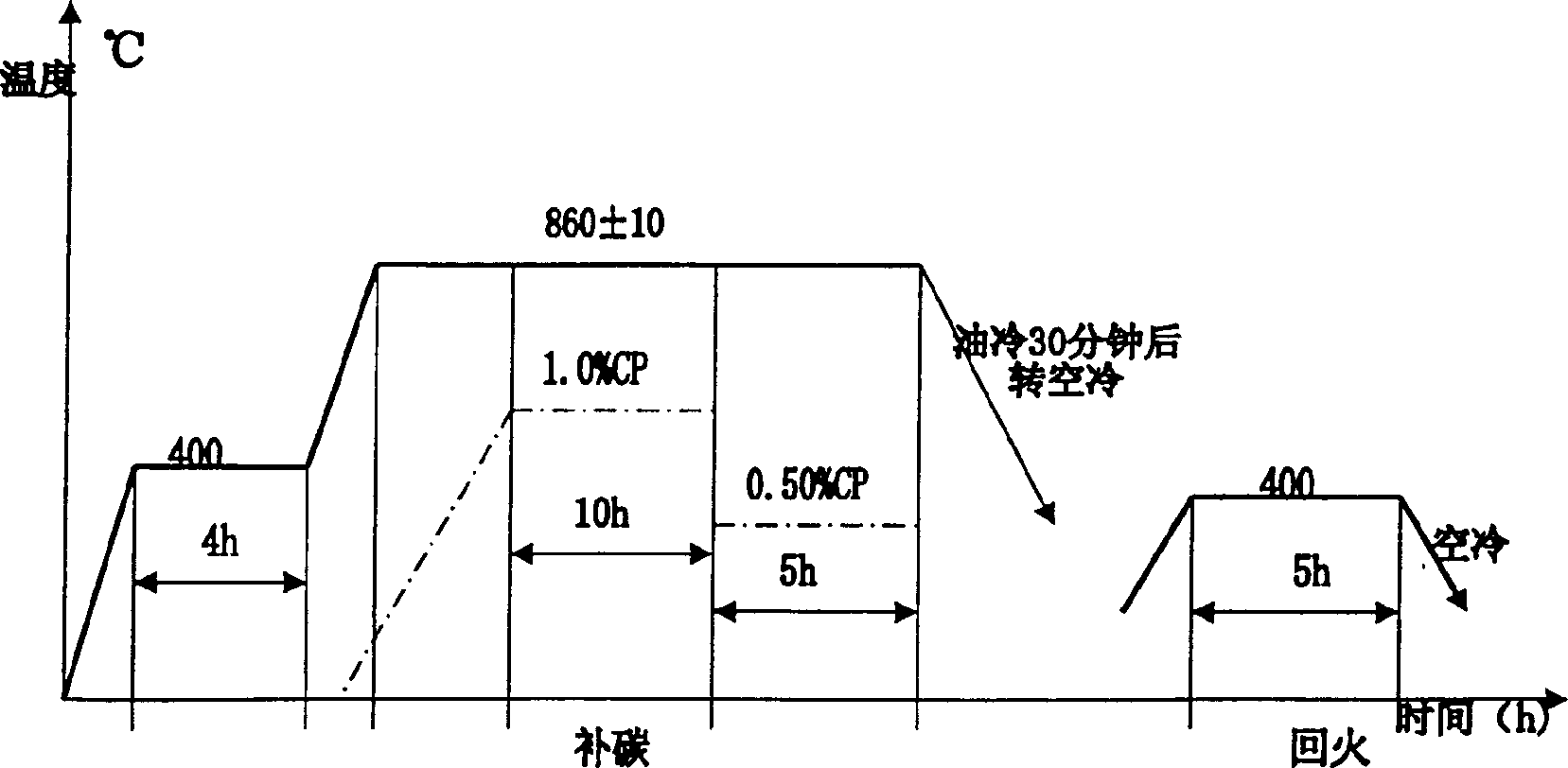

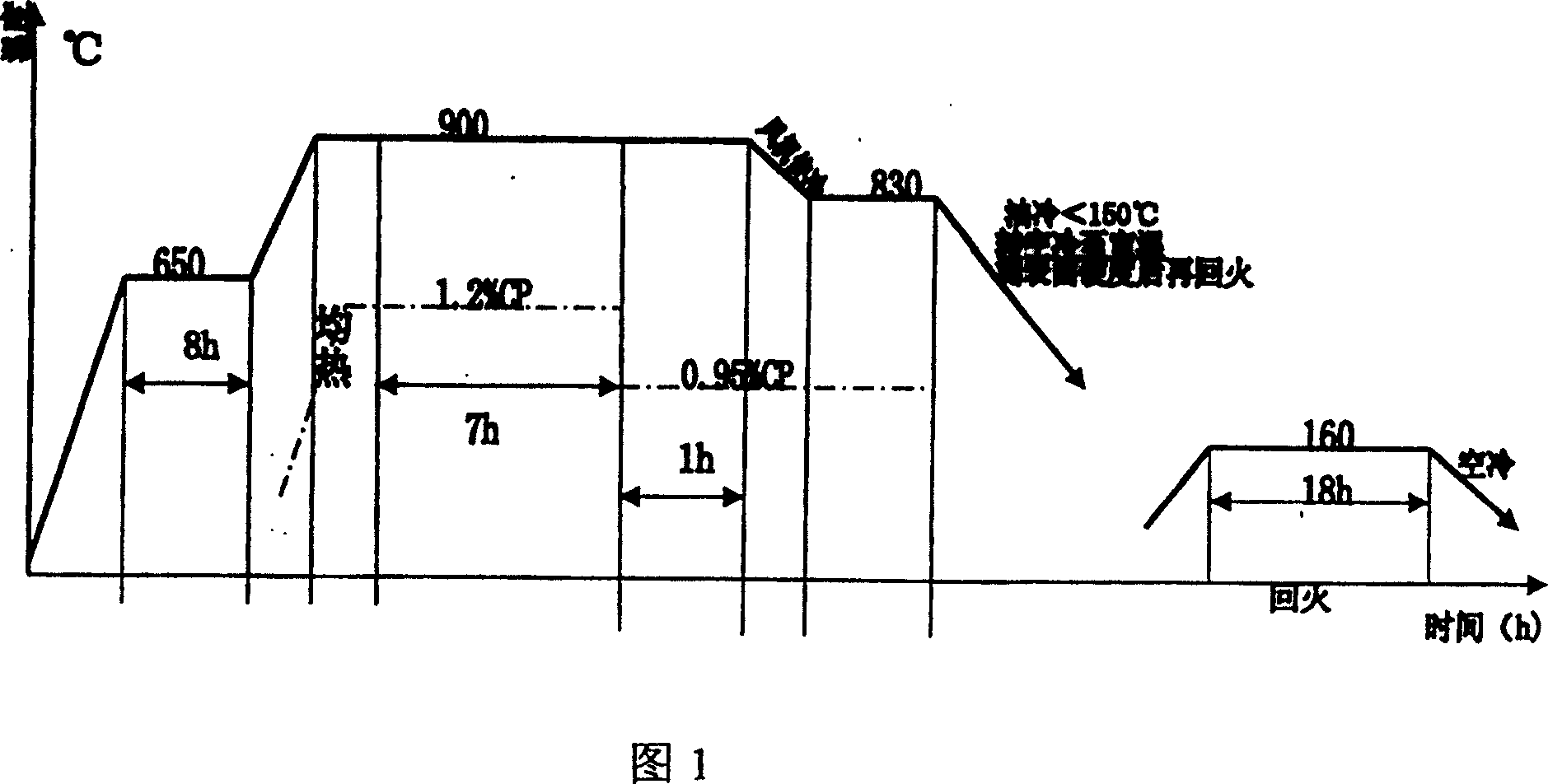

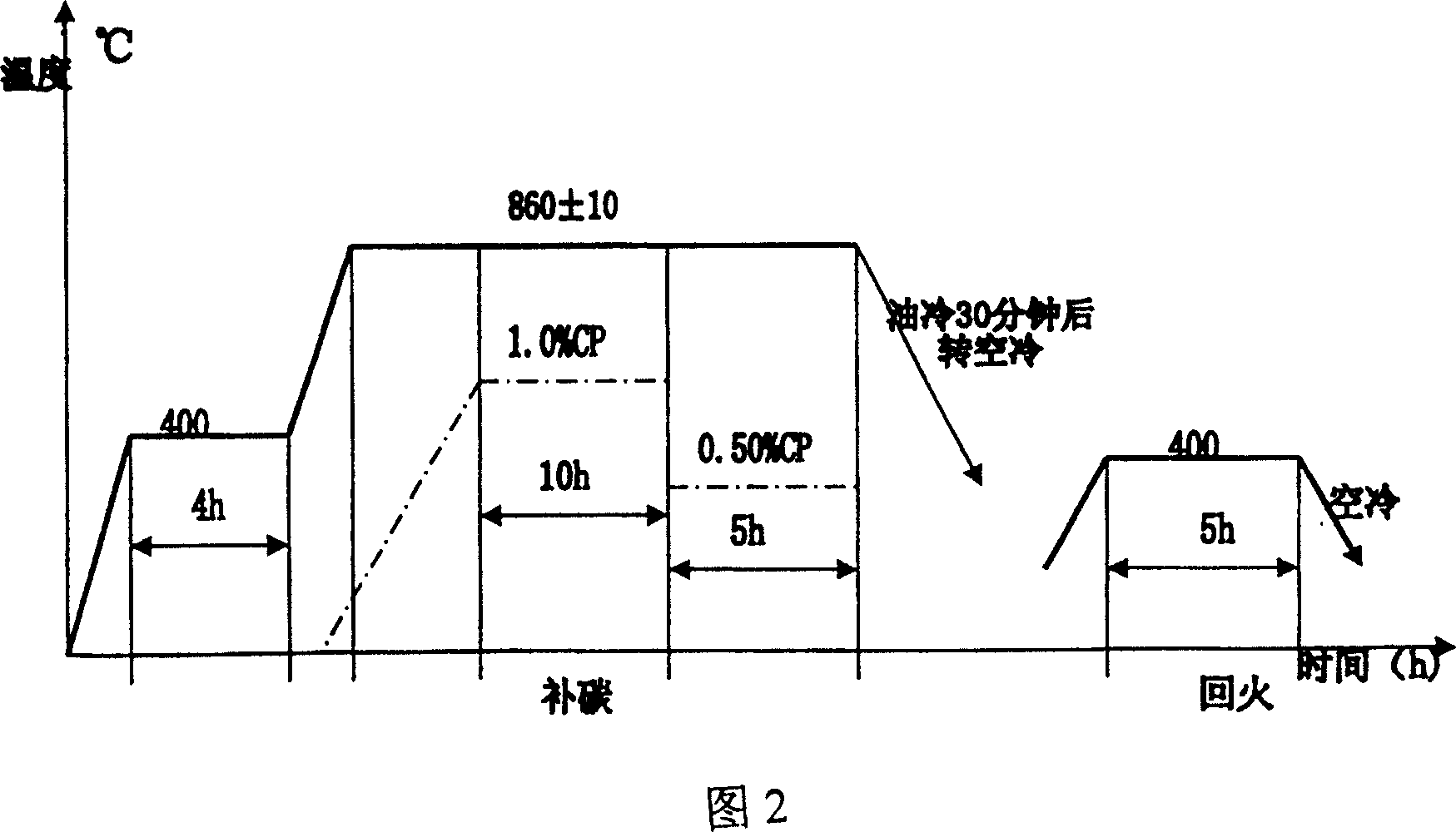

Method for supplementing carbon on machine element surface

The invention discloses a technique for surface carburization on a mechanic device, which is characterized in including the quality and structure feature of devices that need to be carburized, and the steps of analyzing raw carbon-density distinction of its cross section and designing the carburization technique; shoving, heating, carburizing and supplying carbon on the basis of technological requirements, with technological parameter 780-900 deg., 0.3-1.05CP, 5-20H; quick cooling with a fun or oven based on the technological requirements, after the temperature dropped, quenching and lonnealing and / or power-frequency quenching for one time and checking the ruggedness and / or checking a peeling test with a coupon to said device. The invention is pretty simple, economical, and broad used, available to heavy and large parts with different material qualities and degrees of decarburization, explored a new approach to healings qualities of large equipment.

Owner:SINOVEL WIND GRP

Semiconductor device manufacturing method and substrate processing apparatus

ActiveUS8293646B2Satisfied with the effectIncreased budgetPolycrystalline material growthSemiconductor/solid-state device manufacturingHydrogenCarbon density

A high quality interface is formed at a low oxygen-carbon density between a substrate and a thin film while preventing heat damage on the substrate and increase of thermal budget. This method includes a step of loading a wafer into a reaction furnace, a step of pretreating the wafer in the reaction furnace, a step of performing a main processing of the pretreated wafer in the reaction furnace, and a step of unloading the wafer from the reaction furnace after the main processing. Hydrogen gas is continuously supplied to the reaction furnace in the period from the end of the pretreating step to the start of the main processing and at least during vacuum-exhausting an interior of the reaction furnace.

Owner:KOKUSA ELECTRIC CO LTD

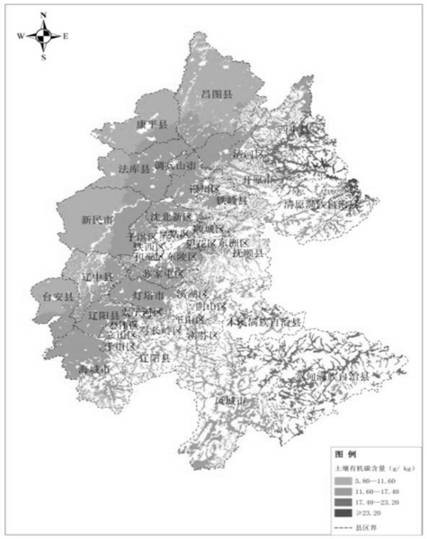

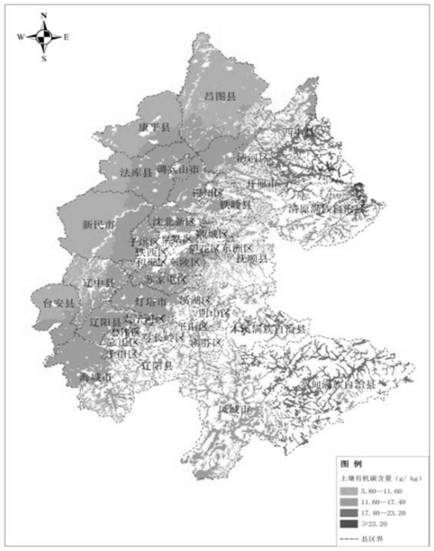

Soil organic carbon spatial-temporal variation and carbon sequestration potential estimation method and system

PendingCN114169161AAccurate assessment of carbon sequestration potentialAccurately ascertain the spatio-temporal distribution of fertilityDesign optimisation/simulationCAD numerical modellingSoil scienceCarbon density

The invention discloses a soil organic carbon spatial-temporal variation and carbon sequestration potential estimation method and system. The method comprises the steps that soil census data in a predetermined area is collected for several times; establishing a semi-variance function theoretical model, wherein the semi-variance function theoretical model is used for reflecting the spatial-temporal variation of the organic carbon content; acquiring organic carbon density and reserve change data of each time of soil census data; establishing an organic carbon balance model of the soil census data; according to the semi-variance function theoretical model, the organic carbon density and reserve change data and the organic carbon balance model, organic carbon spatial-temporal variation and carbon sequestration potential estimation data of the soil are obtained, and soil organic carbon spatial-temporal variation and carbon sequestration potential estimation is completed. According to the method, the spatial and temporal distribution rule of the soil fertility can be accurately ascertained, the soil carbon sequestration potential is accurately evaluated, and a theoretical basis is laid for soil conservation and sustainable and efficient utilization.

Owner:辽宁省农业发展服务中心

Low-smoke-density PC/ABS composition and preparation method thereof

The invention provides a PC / ABS (polycarbonate / acrylonitrile butadiene styrene) composition with low smoke density and a preparation method thereof. The composition comprises the following components in parts by weight: 50 to 80 parts of PC resin; 10 to 40 parts of ABS resin; 5 to 10 parts of porous ceramic; 0.1 to 1 part of an antioxidant; and 0.1 to 1 part of a lubricant. Due to the fact that the carbon density of PC is very high, PC / ABS can generate some unsaturated carbides and form dense smoke during combustion, compared with the prior art, according to the low-smoke-density PC / ABS composition; due to the fact that the porous ceramic component is added, the obvious smoke suppression effect is achieved, the porous structure can adsorb most dense smoke released during PC / ABS combustion, wherein the smoke density is reduced, and the effect is remarkable.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Method for producing environment-friendly coal from straws

InactiveCN102504907APrevent excessive carbonationIncrease carbon densityBiofuelsSolid fuelsRural areaCarbon density

The invention discloses a method for producing environment-friendly coal from straws. The method comprises the following steps of: preparing raw materials, grinding, primarily forming, pre-heating, grinding again, heating, activating, cooling, sieving and packaging. The invention has the benefits that the method effectively prevents excessive carbonization, increases carbon density and reduces defective rate; and the coal product is characterized in having a smooth surface and being not liable to fracture and uniformly carbonized. The method utilizes waste straws in rural areas to produce straw-derived coal, so as to achieve the purpose of turning waste into treasure, prevent environmental pollution and save resources.

Owner:TONGREN HUIMIN GASIFIER

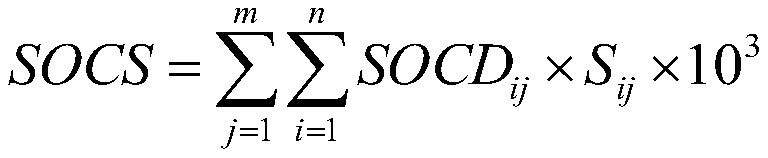

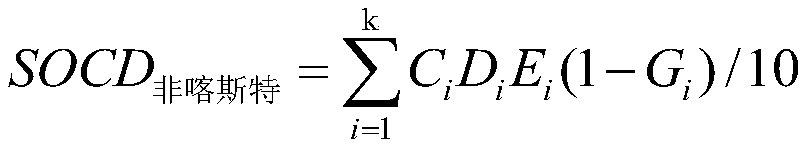

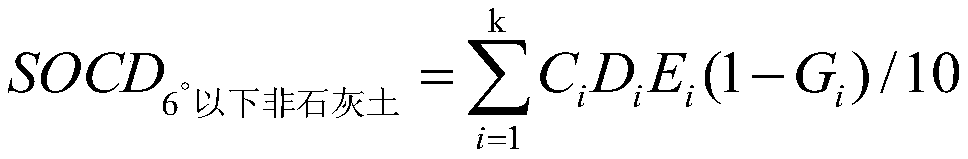

Method for estimating soil organic carbon in karst area

ActiveCN110174506AExposure EliminationSolve problems such as large calculation errorsGeometric CADEarth material testingSoil typeBedrock

The invention discloses a method for estimating the soil organic carbon in a karst area. The method comprises the steps of: 1, establishing an estimation model of the soil organic carbon in the karstarea; 2, modifying the soil depth; 3, deducting the bedrock exposing rate of different types of soil and positive and negative landforms; 4, modifying soil organic carbon density (SOCD) estimating formulas of the different types of soil and the positive and negative landforms; and 5, modifying a soil organic carbon storage (SOCS) estimating method. The method has the beneficial effects that the technical problems that the carbon content of karst soil carbon pools is significantly higher than the actual situation, the calculation error is large and the like during the soil organic carbon calculation in the karst area in the prior art are solved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

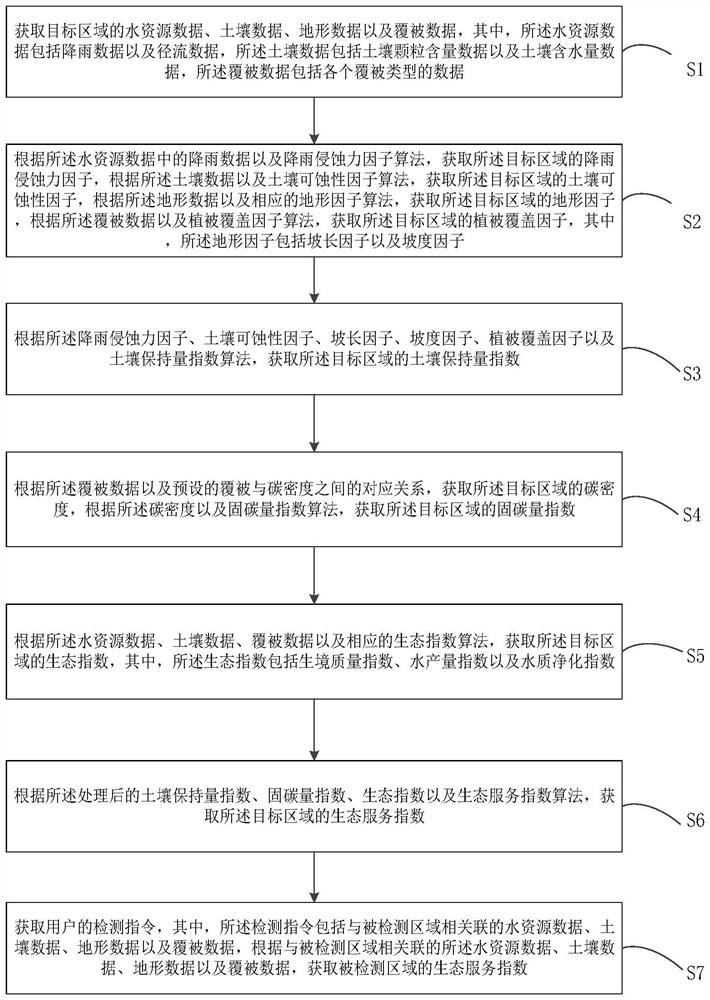

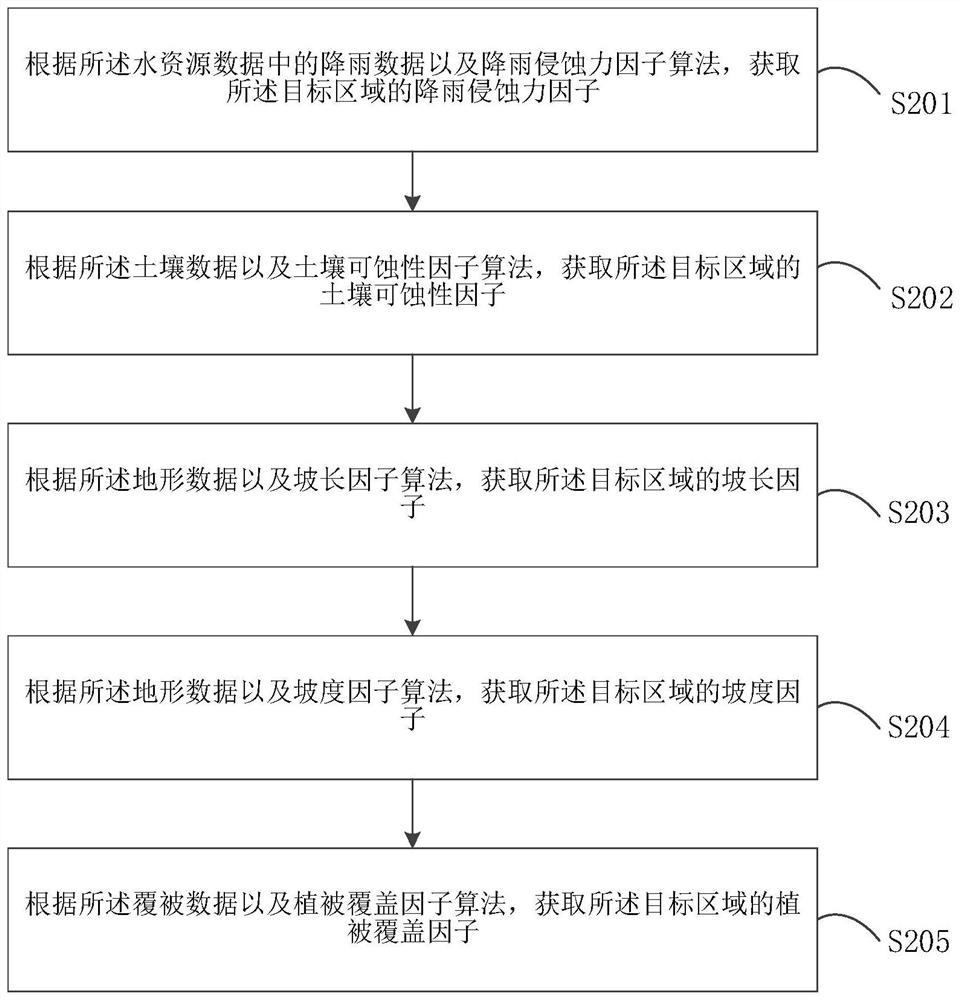

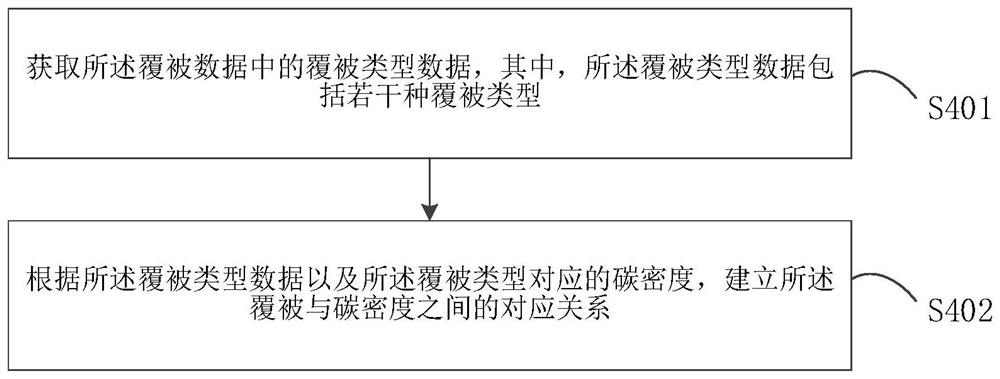

Coastal zone resource environment bearing capacity evaluation method based on ecosystem function

PendingCN113919743ARealize scientific testingGrasp in timeClimate change adaptationResourcesEnvironmental resource managementWater resources

The invention relates to the technical field of environment detection, in particular to a coastal zone resource environment bearing capacity evaluation method based on ecological system functions. The method comprises the following steps: acquiring water resource data, soil data, topographic data and covering data of a target area; obtaining an index factor according to the water resource data, the soil data, the topographic data and a corresponding index factor algorithm; according to the index factor and a soil conservation index algorithm, obtaining a soil conservation index of the target area; according to the coating data and a preset corresponding relation between the coating and the carbon density, obtaining the carbon density of the target area, and according to the carbon density and a carbon sequestration index algorithm, obtaining a carbon sequestration index of the target area; according to the water resource data, the soil data, the covering data and a corresponding ecological index algorithm, obtaining an ecological index of the target area; and obtaining an ecological service index of the target area according to the processed soil retention amount index, the carbon sequestration amount index, the ecological index and an ecological service index algorithm.

Owner:GUANGZHOU INST OF GEOGRAPHY GUANGDONG ACAD OF SCI

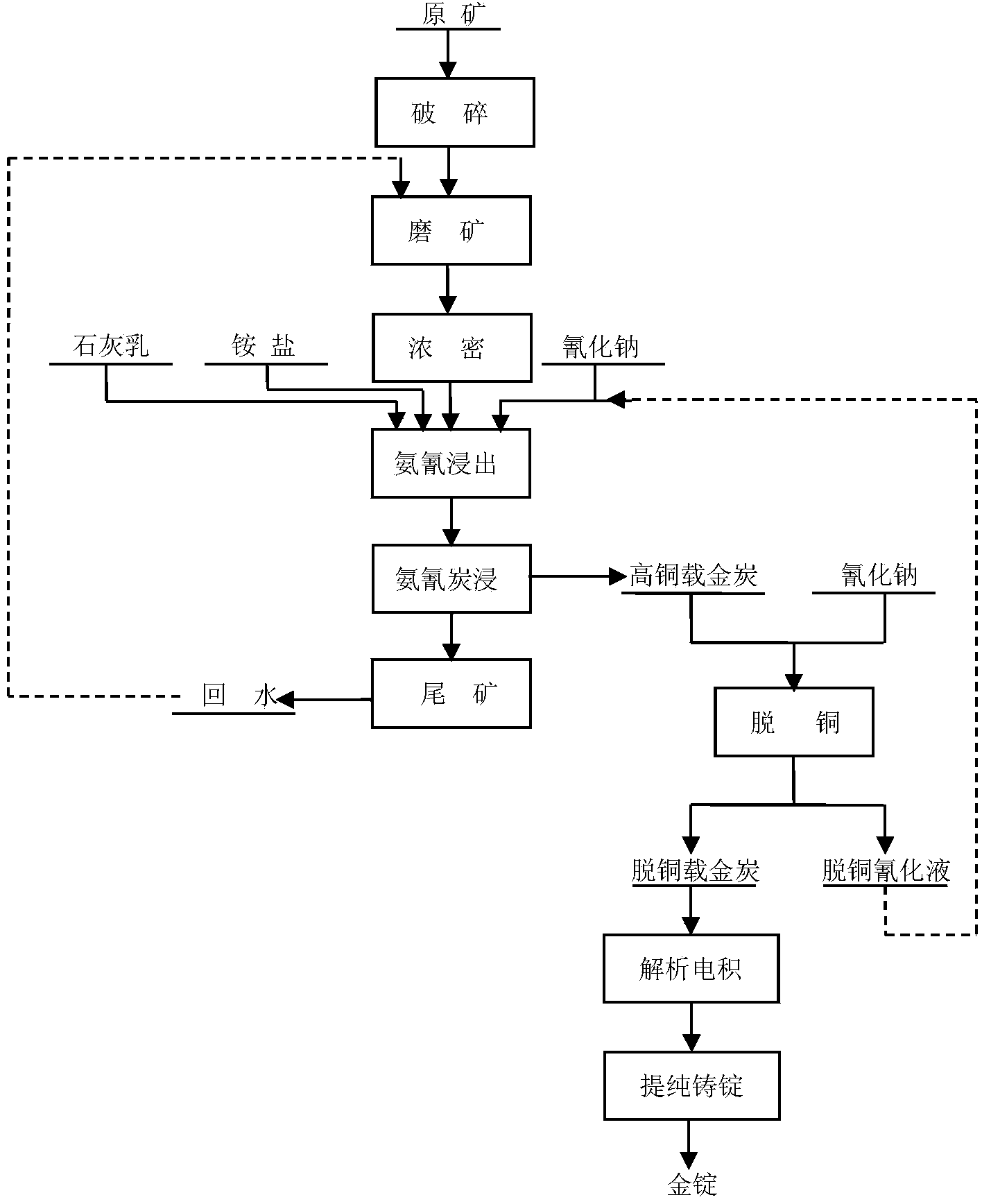

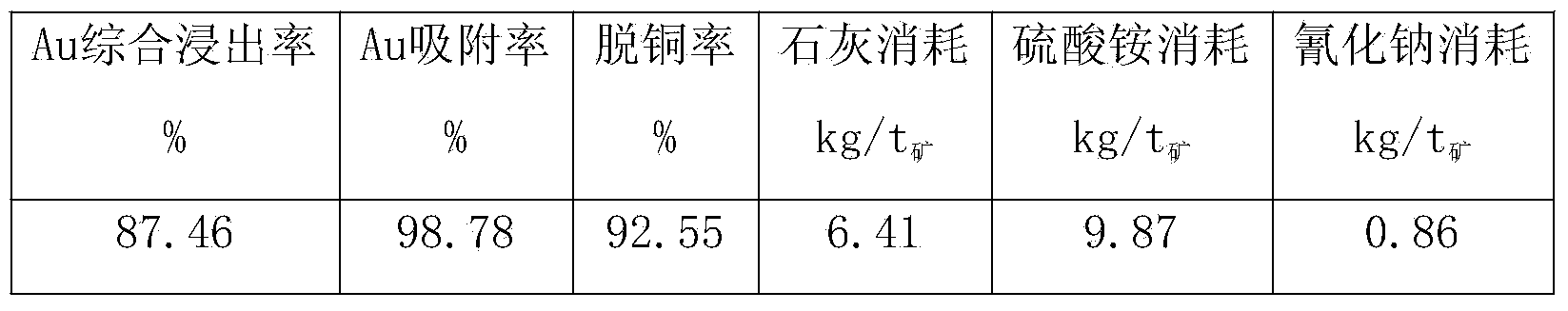

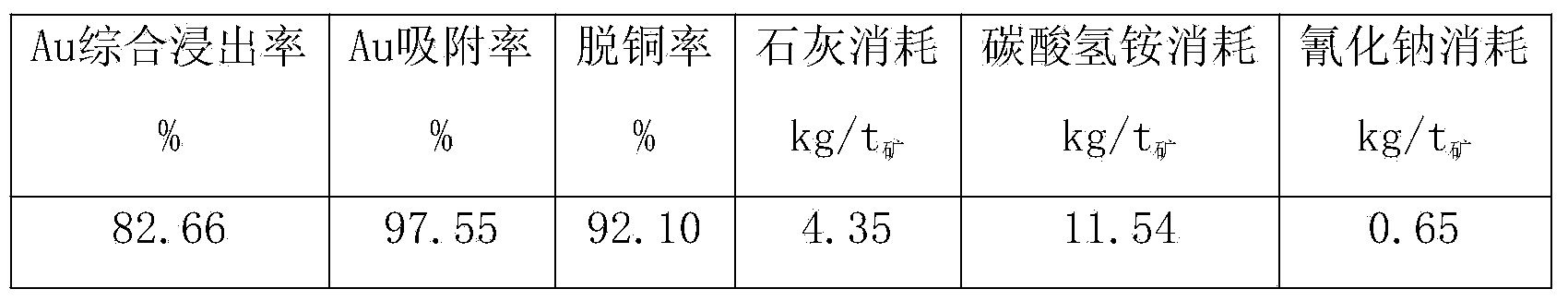

Process for extracting gold from gold ore containing copper by using ammonia, cyanide and carbon

InactiveCN104388672AShort processLess investmentPhotography auxillary processesProcess efficiency improvementDesorptionSlurry

The invention relates to a process for extracting gold from gold ore containing copper by using ammonia, cyanide and carbon. The process sequentially comprises the following steps: smashing, grinding and thickening, i.e. smashing and grinding the gold ore containing copper until the ground gold ore containing copper with grain size of -0.075 mm accounts for 80-95% and then thickening to obtain thickened ore slurry, wherein the concentration is controlled at 35-48%; extracting while inhibiting copper extraction, i.e. adding lime milk, ammonium salt and sodium cyanide in the thickened ore slurry and extracting while inhibiting copper extraction for 12-36 hours while controlling the pH value at 7-11, the total ammonia concentration at 200-1000 ppm and the total cyanide concentration at 20-500 ppm to obtain extraction ore slurry; carrying out carbon extraction on the extraction core slurry for 24-48 hours while controlling the carbon density at 10-30 g / L to obtain gold loaded carbon with high copper content and tailings; and decoppering and extracting gold, i.e. adding sodium cyanide with the concentration of 3-20% to the gold loaded carbon with high copper content according to the liquid-carbon ratio of (3-10) to 1, decoppering for 10-48 hours to obtain decoppered gold loaded carbon and decoppered cyanide solution, carrying out high-temperature non-cyanide desorption and electro winning, purification and ingot making on the decoppered gold loaded carbon to produce gold ingots, and recycling tailing water and decoppered cyanide solution. The process for extracting gold from gold ore containing copper by using ammonia, cyanide and carbon disclosed by the invention has the advantages of short process flow, small investment, low operation and control difficulty, small consumption of reagents, low production cost and the like, and is suitably applied to difficultly-beneficiated-and-smelted gold ore containing copper, and the influence of copper on gold extraction procedures is thoroughly overcome.

Owner:ZIJIN MINING GROUP

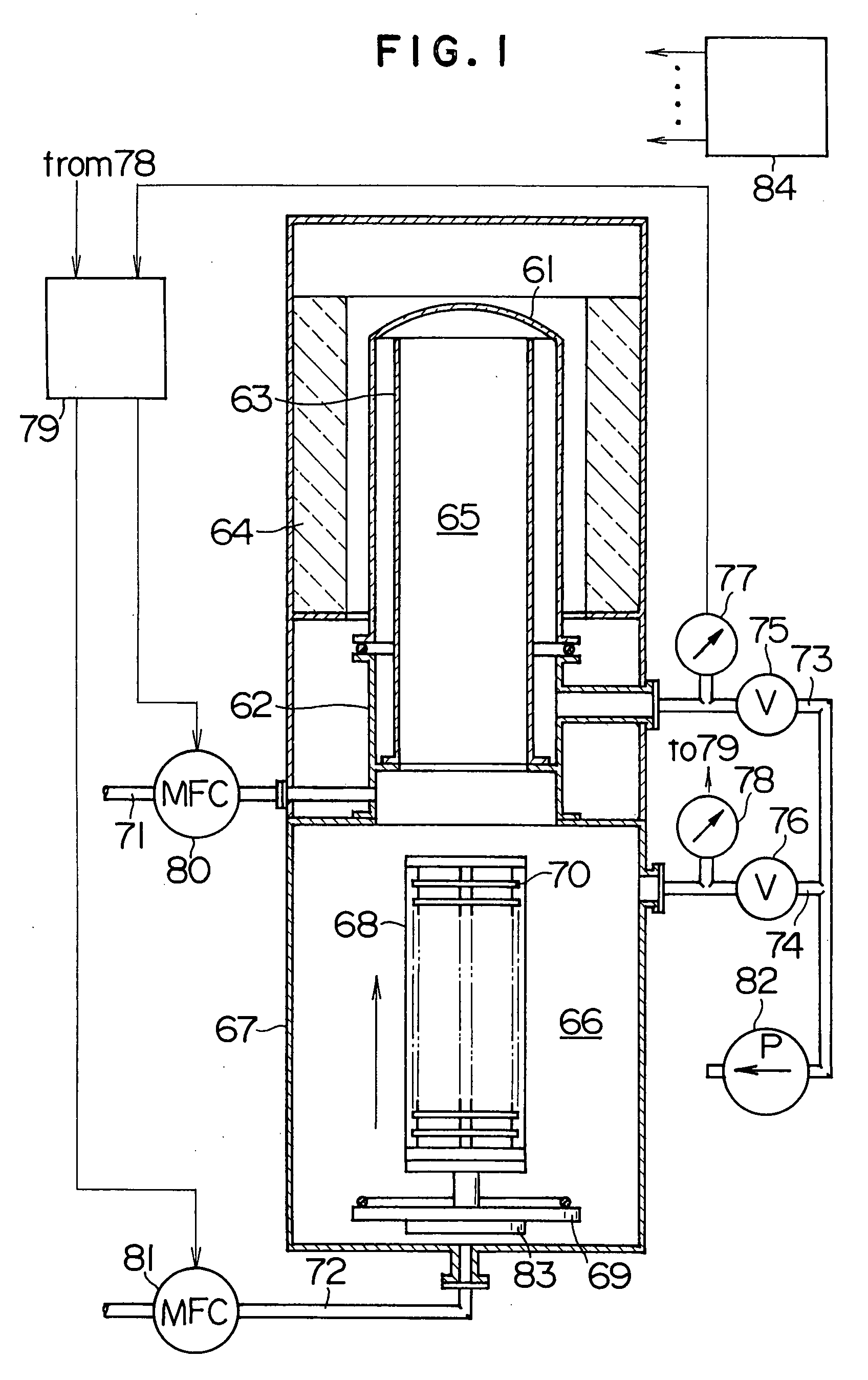

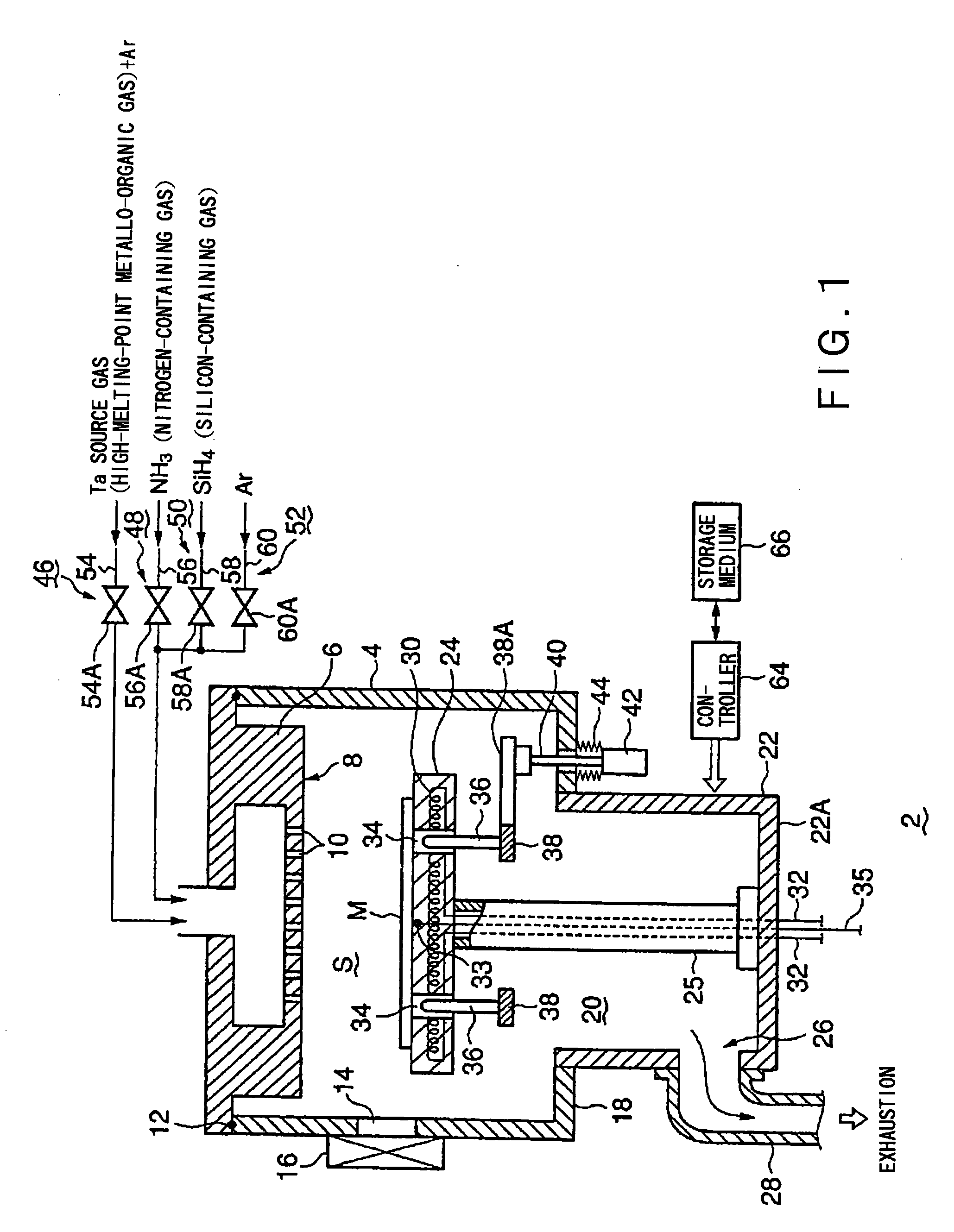

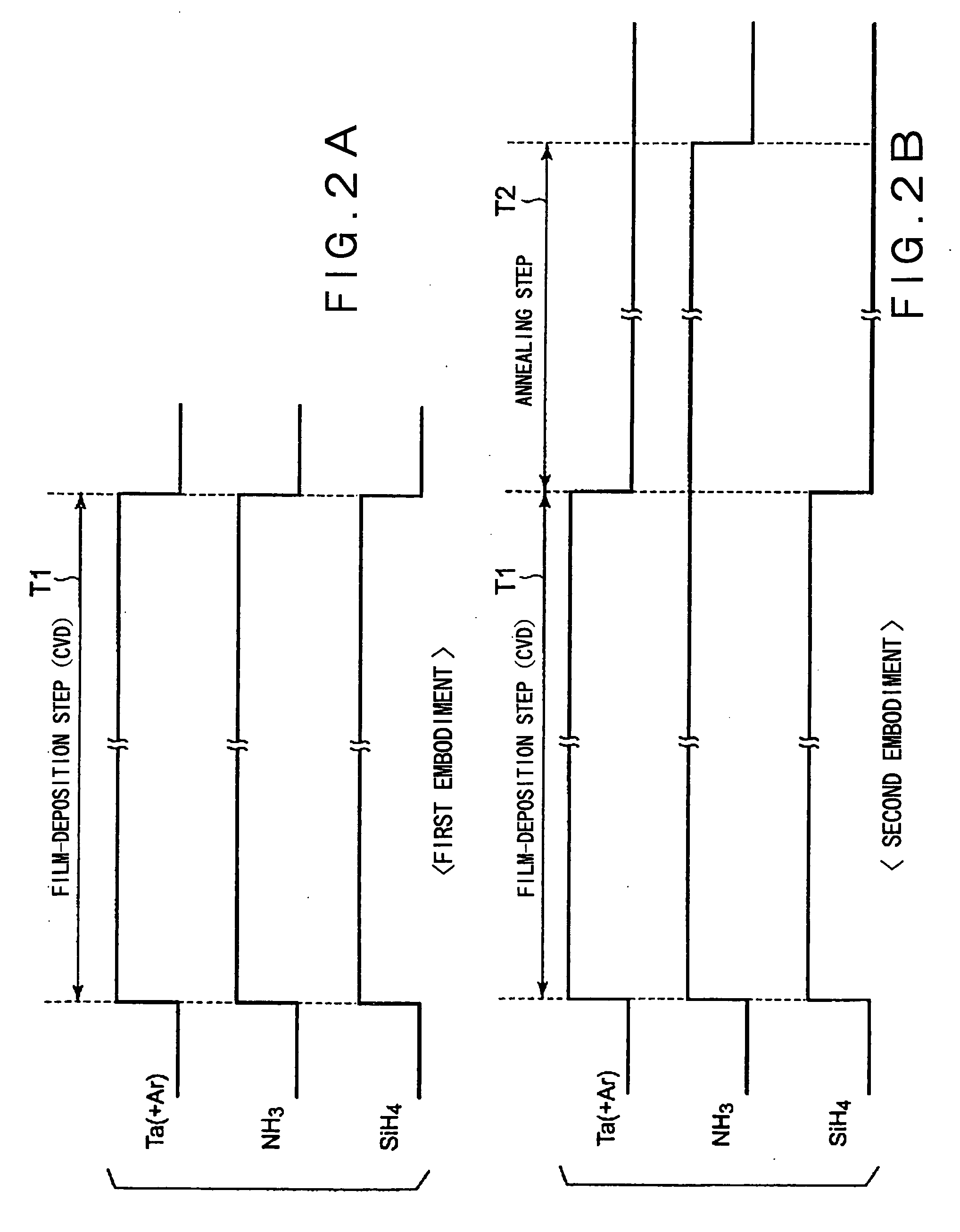

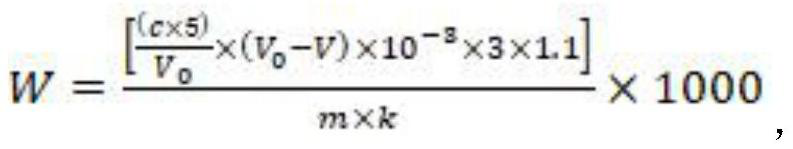

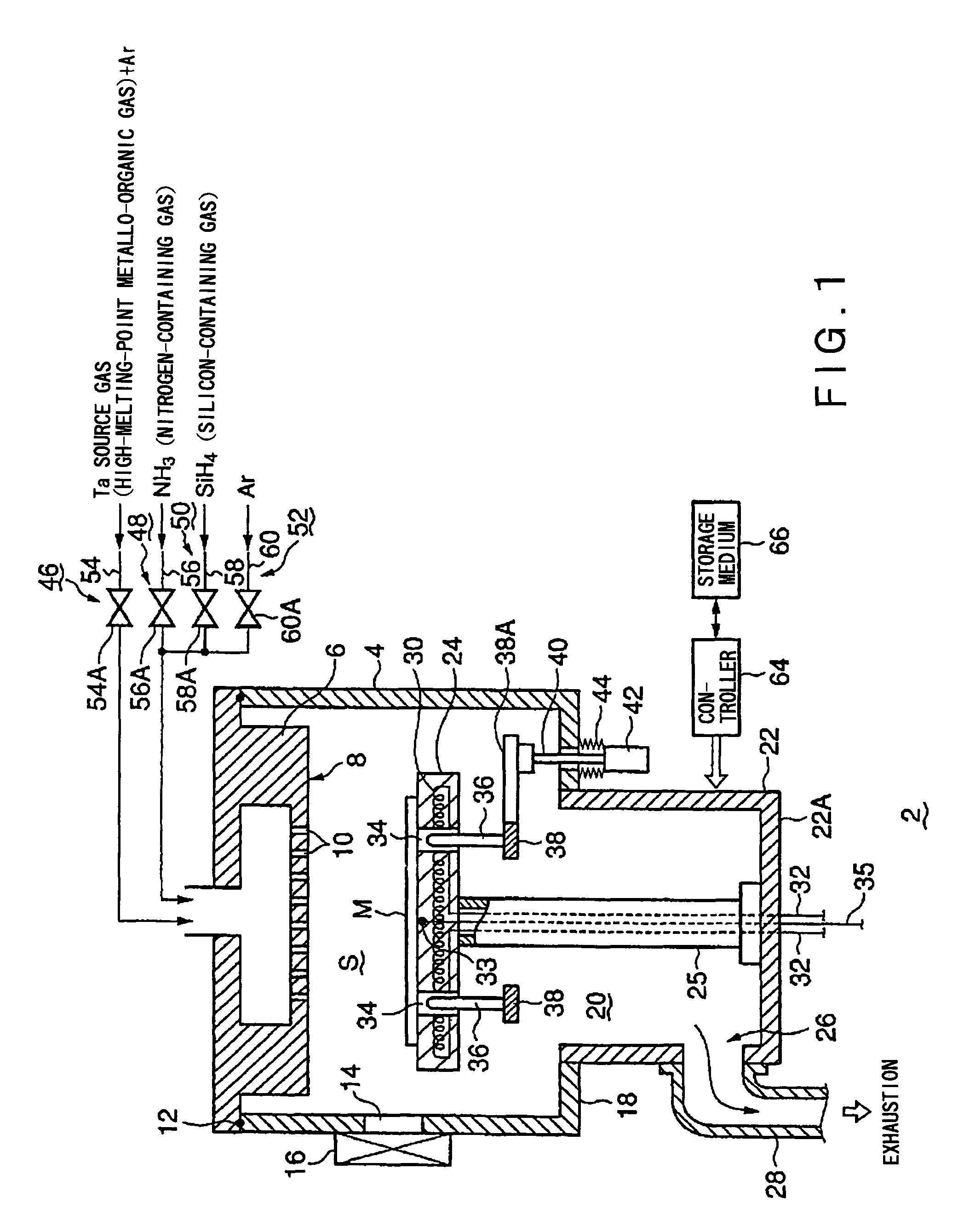

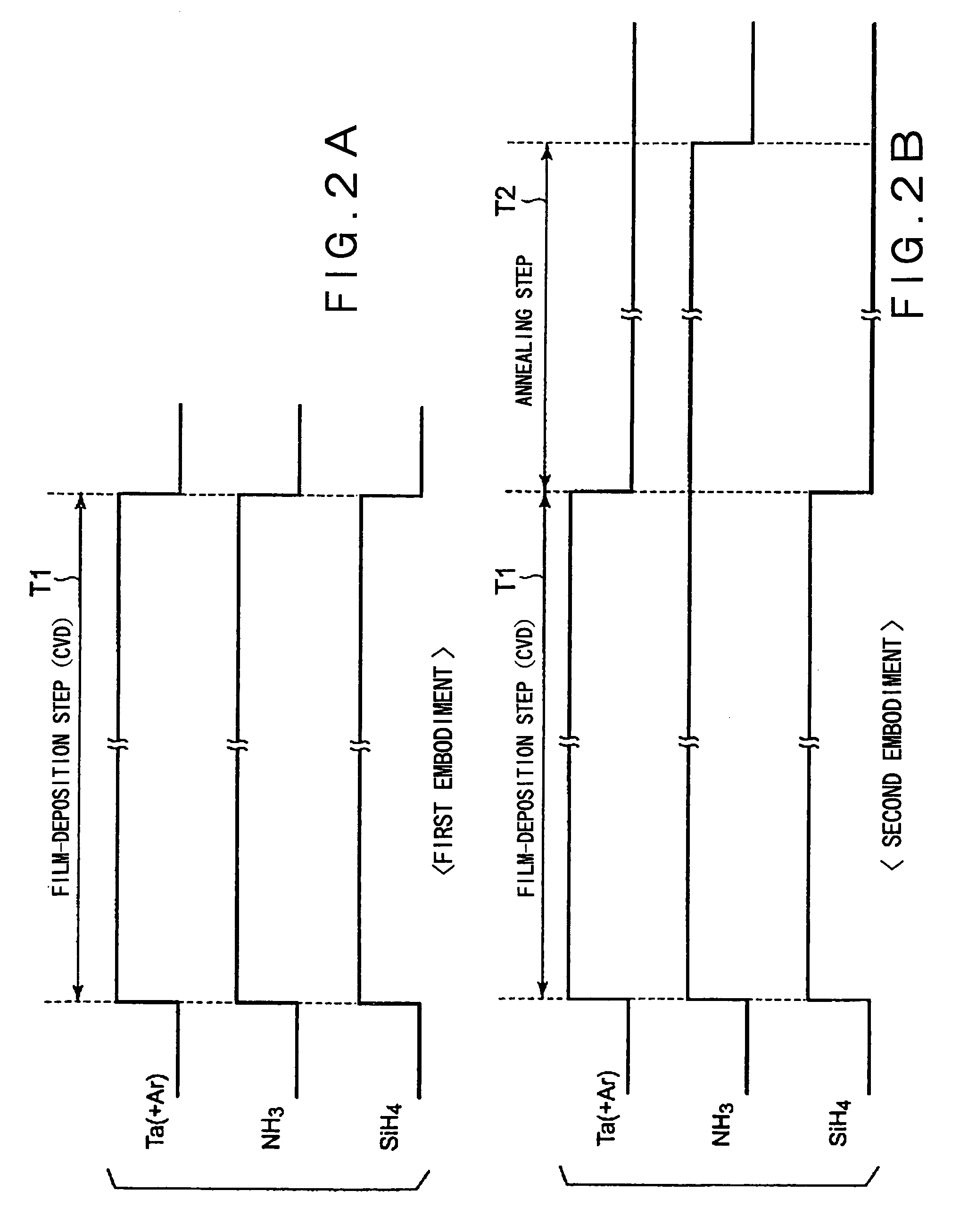

Method of Film Deposition and Film Deposition System

InactiveUS20090140353A1Lower work functionReduce the valueLiquid surface applicatorsSemiconductor/solid-state device manufacturingNitrogenMetallic materials

The present invention is a method of film deposition that comprises a film-depositing step of supplying a high-melting-point organometallic material gas and a nitrogen-containing gas to a processing vessel that can be evacuated, so as to deposit a thin film of a metallic compound of a high-melting-point metal on a surface of an object to be processed placed in the processing vessel. A partial pressure of the nitrogen-containing gas during the film-depositing step is 17% or lower, in order to increase carbon density contained in the thin film.

Owner:TOKYO ELECTRON LTD

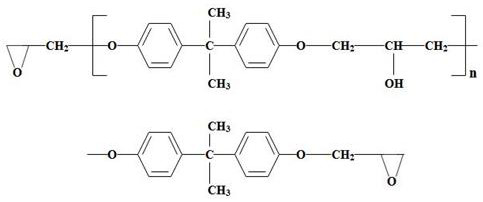

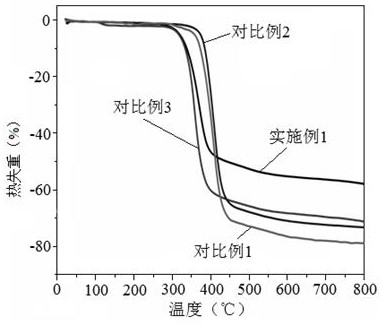

Calcined kaolin-based composite flame retardant for epoxy resin and its preparation and application

ActiveCN110628079BImprove flame retardant performanceIncrease carbon residueEpoxyIn situ polymerization

The invention discloses a calcined kaolin-based composite flame retardant for epoxy resin and its preparation and application. The composite flame retardant uses calcined kaolin particles as a basic component, and ammonium polyphosphate produced by in-situ polymerization is formed on the surface of kaolin and Kaolin combines to form a composite structure. Using phosphoric acid and urea as raw materials, the composite flame retardant was prepared by in-situ polymerization on the surface of calcined kaolin. Adding it to epoxy resin can improve the flame retardant performance of epoxy resin, effectively reduce the thermal weight loss rate and heat release rate of epoxy resin, and improve its carbon residue and carbon density. The preparation method of the present invention is simple and easy to operate, low in cost, and ingenious in preparation ideas. Through in-situ polymerization, kaolin and ammonium polyphosphate produced by in-situ polymerization are closely and uniformly combined. The composite flame retardant has the characteristics of halogen-free, high efficiency, and environmental friendliness. The scope of application of kaolin and epoxy resins.

Owner:LANZHOU UNIVERSITY

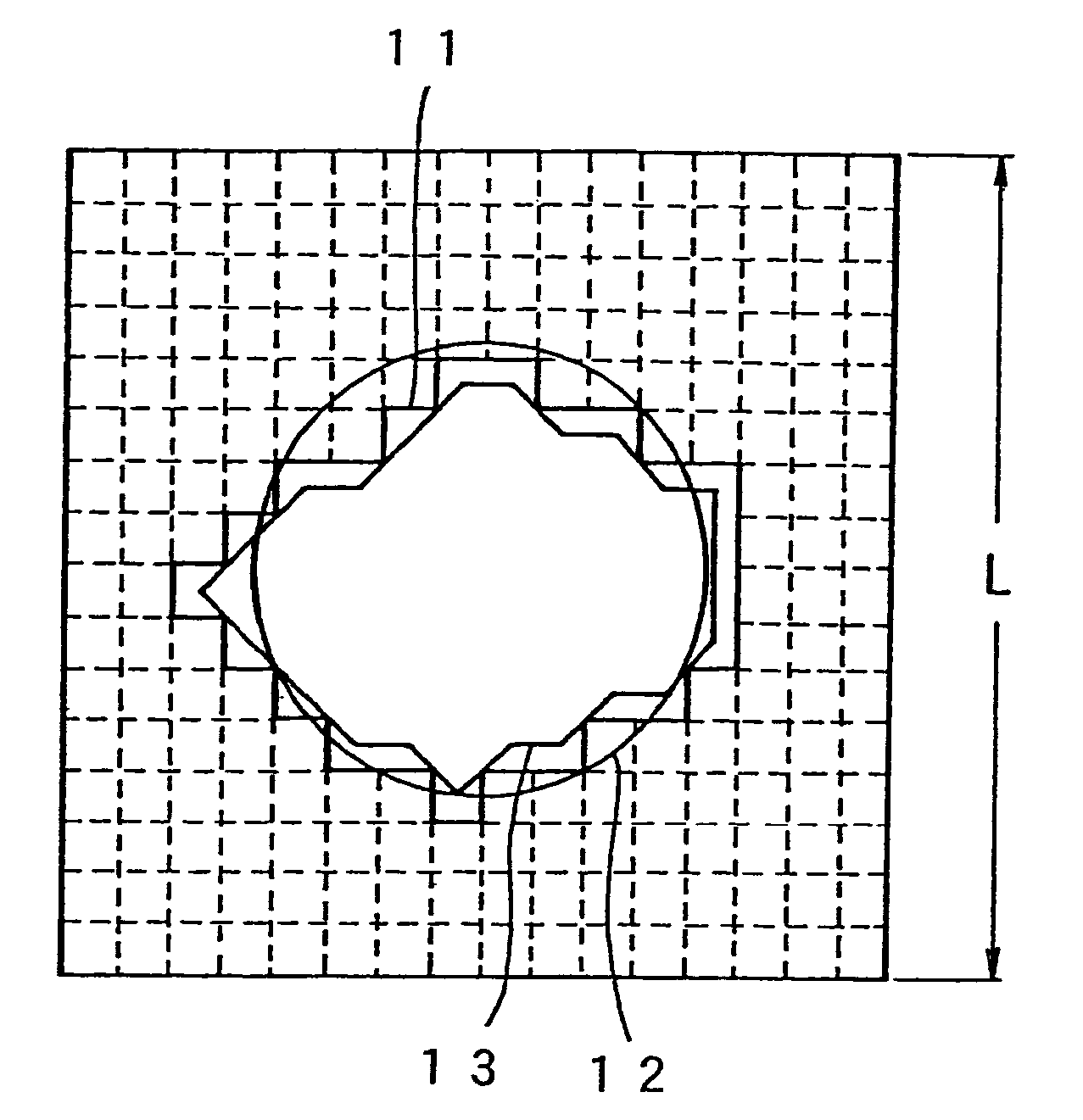

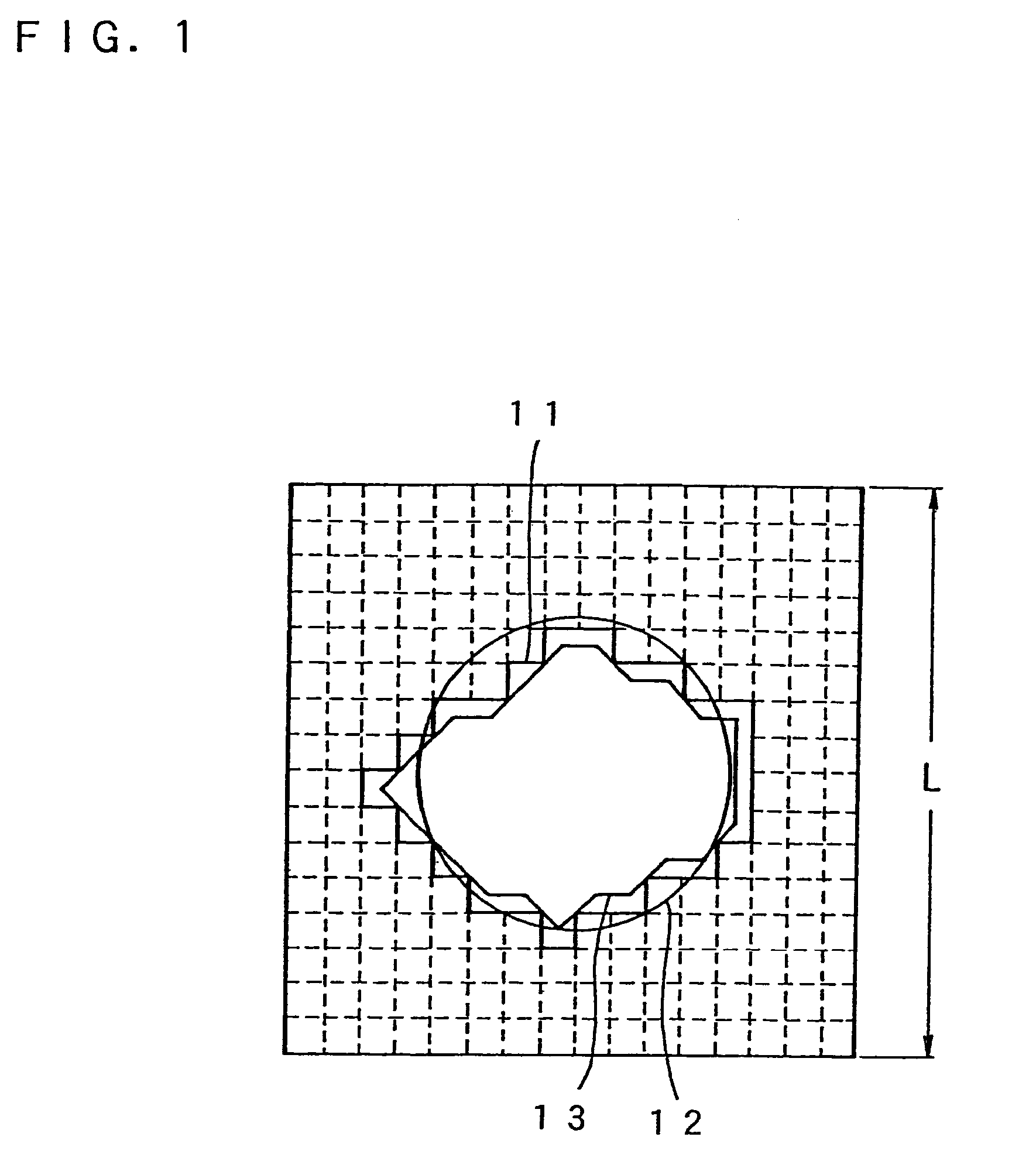

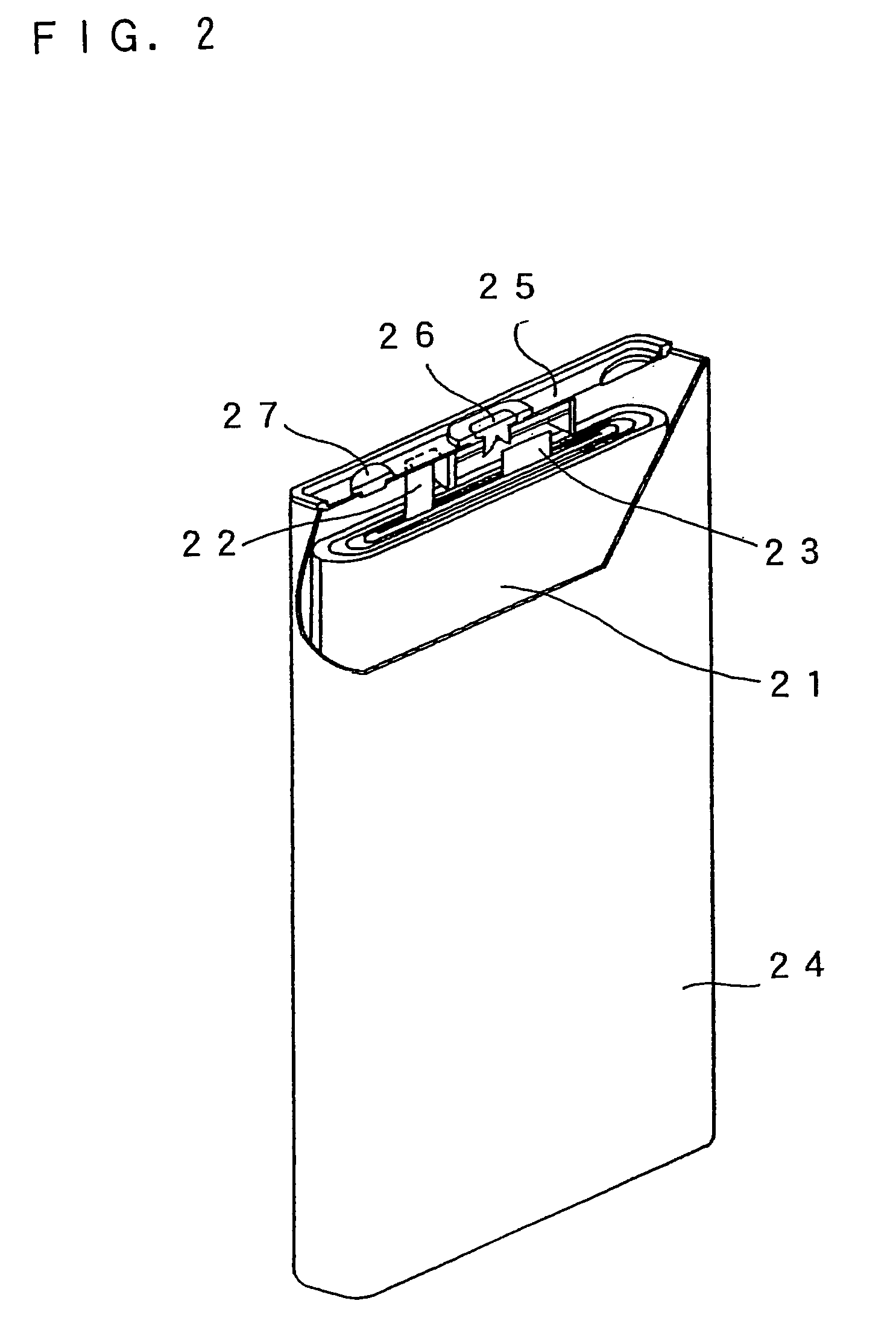

Negative electrode and lithium ion secondary battery using the same

InactiveUS7144659B2Reduce irreversible capacityExcellent high rate charge/discharge characteristicConductive materialSecondary cellsLithiumFiber

A negative electrode for a lithium ion secondary battery comprising a material mixture layer comprising a carbonaceous material comprising a spherical natural graphite and a graphitized carbon fiber, wherein the material mixture layer has a carbon density of not less than 1.6 g / cm3; the spherical natural graphite has: (1) an interplanar spacing d002 between the (002) planes determined by an X-ray diffraction pattern of 0.3354 to 0.3357 nm, (2) a mean particle circularity of not less than 0.86, and (3) a mean particle size of 5 to 20 μm; the graphitized carbon fiber has: (1) a mean fiber length of 20 to 200 μm, and (2) a mean aspect ratio of 2 to 10; and the amount of the graphitized carbon fiber is 50 to 90% by weight of whole of the carbonaceous material.

Owner:GK BRIDGE 1

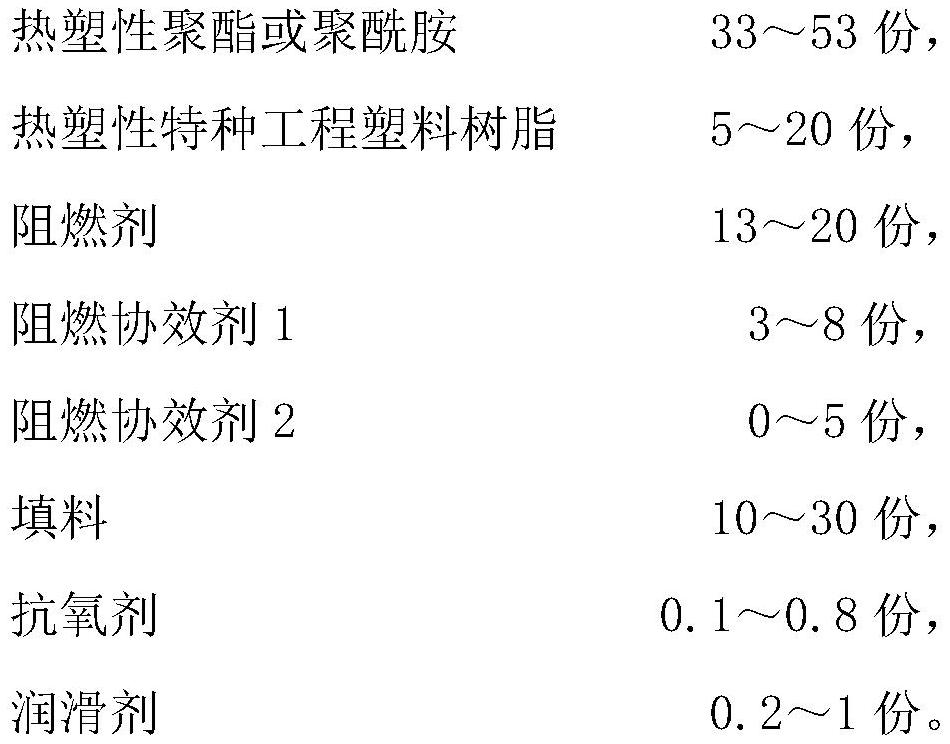

Fire-insulation flame-retardant polyester material and preparation method thereof

The invention provides a fire-insulation flame-retardant polyester material and a preparation method thereof. The material comprises the following components in parts by weight: 33-53 parts of thermoplastic polyester or polyamide, 5-20 parts of thermoplastic special engineering plastic resin, 13-20 parts of a flame retardant, 3-8 parts of a flame retardant synergist 1, 0-5 parts of a flame retardant synergist 2, 10-30 parts of a filler, 0.1-0.8 part of an antioxidant and 0.2-1 part of a lubricant. The method for preparing the polyester material is simple and easy to implement, the characteristics that the polyester / polyamide material and the special engineering plastic are high in melting point, and the glass fibers form a penetrating network to support polymer melt are utilized, and the supporting material cannot collapse in the combustion process to form through holes to be burnt through; and the special engineering plastic has high carbon forming rate, and the flame-retardant synergists are added, so that the carbon forming density can be further improved. The material can form carbon in time in the continuous combustion process of a workpiece made of the material, so that the original workpiece form is maintained, the workpiece is not burnt through, and a fire insulation effect is achieved.

Owner:SHANGHAI KUMHOSUNNY JINSHAN PLASTICS CO LTD

Method and device for determining toc content

ActiveCN105158796BAccurate predictionSolve low technical problemsEarth material testingSeismic signal processingX-rayCarbon density

The present invention provides a method and device for determining TOC content, wherein the method includes: establishing a mineral petrophysical model for optimal estimation of TOC by using laboratory-measured X-ray diffraction data, organic carbon density, logging density curve and other data, The accurate TOC distribution on the well is obtained through optimization and iteration, the TOC volume plate is established by using the measured TOC data and the equivalent medium model, and the TOC sensitive elastic parameters are determined. Finally, the pre-stack elastic parameter inversion is carried out on the seismic reflection gathers processed in the OVT domain. Statistical fitting is used to achieve the purpose of quantitatively predicting the spatial distribution of TOC content by combining well-seismic data and solving the technical problem that the prediction result of TOC content is not high. It is consistent with the measured value in the laboratory, and it can predict the TOC content of the no-sample point more accurately.

Owner:PETROCHINA CO LTD

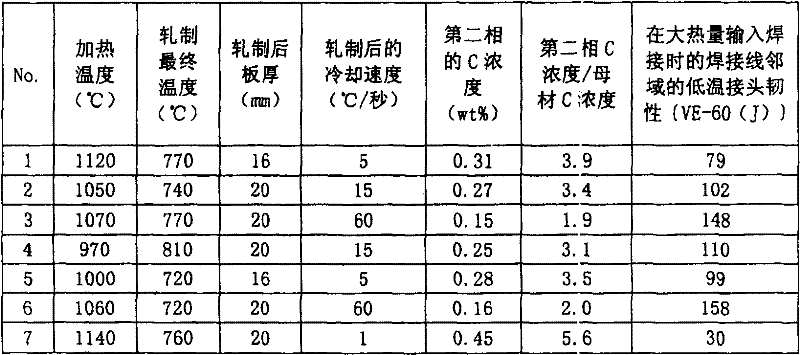

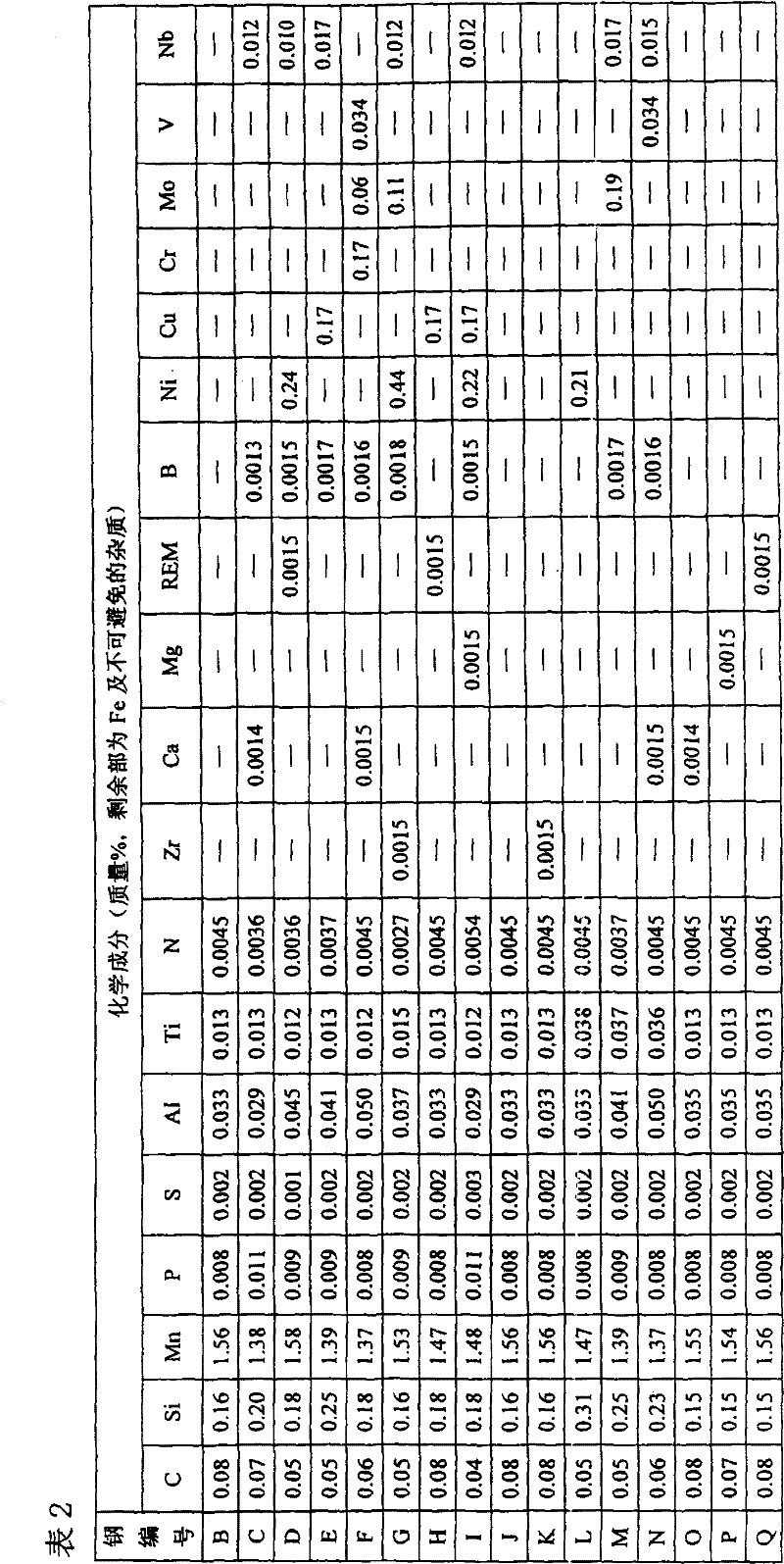

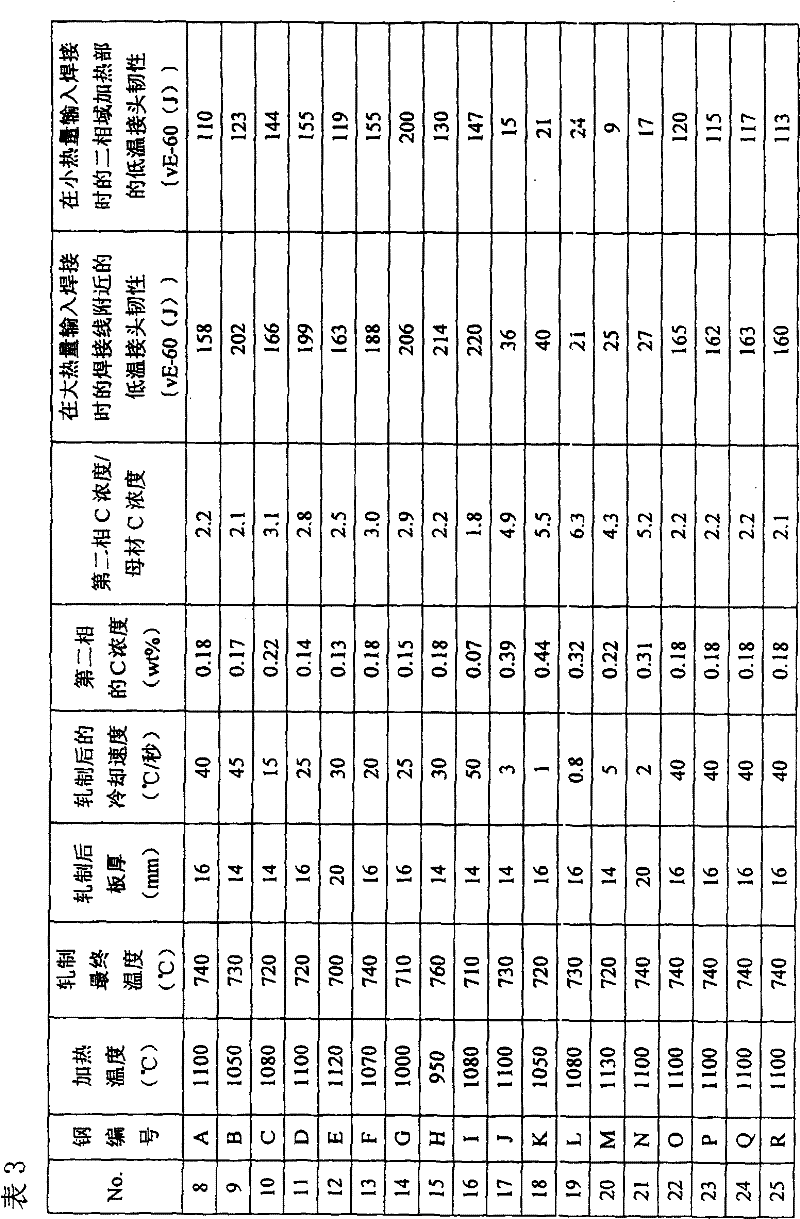

Welding joint steel plated with excellent low-temperature flexibility

ActiveCN1995432BImprove low temperature toughnessWelding/cutting media/materialsSoldering mediaCarbon densityWeld line

The invention discloses a steel board, which comprises the following parts: 0.005-0.10% C, less than 0.7% Si, 0.5-2% Mn, less than 0.1% Al, 0.005-0.03% Ti and 0.001-0.01% N, wherein the microscopic tissue is composed of ferrite and other tissues with even density as 4 times as carbon density in the steel board.

Owner:KOBE STEEL LTD

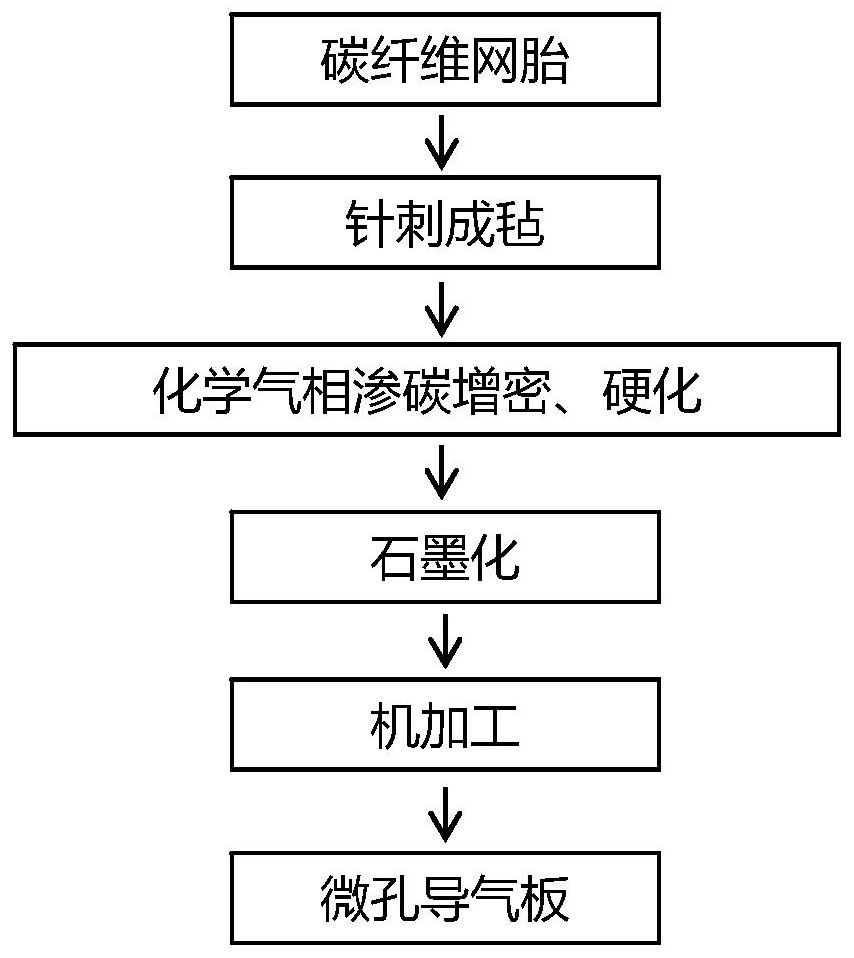

A rapid method for preparing carbon/carbon composites with high thermal conductivity

The invention discloses a method for rapidly preparing carbon / carbon composite materials with high thermal conductivity. Water and a dispersant are uniformly stirred according to a mass percentage of 100: (0.1-0.5), and then 10-60wt of water is added .% of the mesophase pitch-based chopped carbon fiber is mixed, and ultrasonic vibration is used to promote the dispersion of the fiber; the prepared chopped carbon fiber aqueous solution is poured into a graphite mold and placed below 0°C to freeze into a solid block, and the moisture is removed by freeze-drying And the porosity in the chopped carbon fiber reinforcement is reduced by pressure forming; the prepared chopped carbon fiber reinforcement is repeatedly impregnated with pitch-carbonization, and subjected to high-temperature graphitization treatment to obtain a carbon / carbon composite material with high thermal conductivity. The raw materials involved in the present invention are easy to obtain, the process is simple, the production cycle is short, and the production cost is low. The density and thermal conductivity of the prepared carbon / carbon composite material are high, and the thermal conductivity in the vertical pressure forming direction at room temperature is 322- 368W / m×K, significantly higher than traditional heat dissipation materials such as aluminum and copper.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

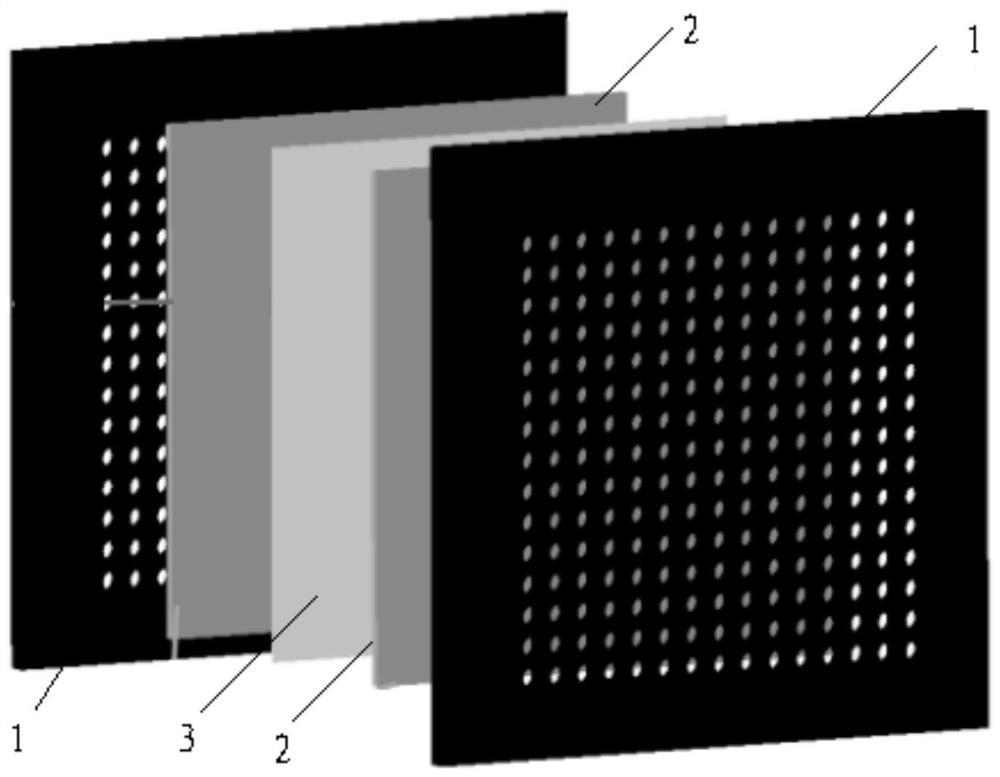

A jig for preparing ultra-thin carbon/carbon composite panels

A fixture for preparing an ultra-thin carbon / carbon composite material panel, the fixture includes a hollow graphite plate and a microporous air guide plate; The ultra-thin carbon / carbon composite material blank, the microporous air guide plate, and the hollow graphite plate are stacked in sequence, and the hollow graphite plates on both sides are clamped along the stacking direction. The fixture structure of the present invention is simple and reasonable, and an effective channel for carbon source gas can be constructed between the hollow graphite plate and the ultra-thin carbon / carbon composite material blank, and the carbon source gas can be evenly directed to the ultra-thin carbon / carbon composite material blank, solving the problem of blank In order to solve the problem of bulk chemical vapor carburizing density uniformity and deformation, an ultra-thin carbon / carbon composite panel with uniform density and flat surface was prepared, with a density of 1.7‑2.0g / cm 3 , with a thickness of 0.2‑0.8mm.

Owner:CENT SOUTH UNIV

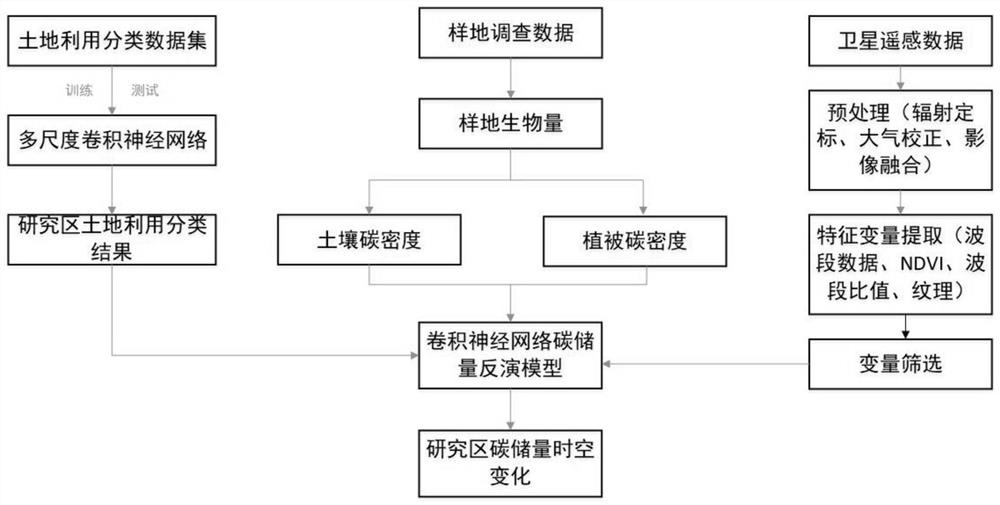

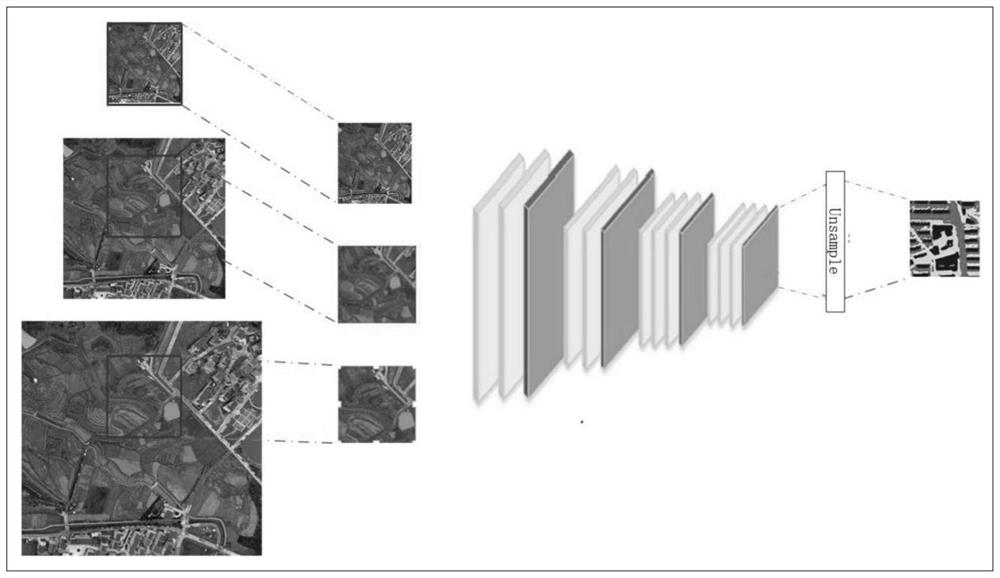

A Quantitative Estimation Method of Land Use Change and Carbon Stock Based on Remote Sensing Data

ActiveCN112836610BFitting Nonlinear RelationshipsFit closelyScene recognitionNeural architecturesAlgorithmNetwork output

The invention discloses a method for quantitatively estimating land use change and carbon storage based on remote sensing data, comprising the following steps: downloading images; preprocessing images; classifying land use; Correlation analysis is carried out between the medium carbon storage and each eigenvalue, and the eigenvalues with significant correlation are selected for modeling; the selected eigenvalues are normalized as the input layer of the convolutional neural network, and the calculated carbon The density is put into the network output layer for network training, and the trained model is used to quantitatively estimate the carbon storage of the area to be studied. The present invention is based on a layered learning framework of a multi-scale convolutional neural network, enabling better land use classification results. Based on different eigenvalues in images and carbon density obtained from ground survey data, the nonlinear relationship between characteristic variables and carbon storage can be better fitted, and the final quantitative estimation of regional carbon storage can be improved.

Owner:平衡机器科技(深圳)有限公司

Method of film deposition

InactiveUS7960278B2Lower work functionReduce the valueLiquid surface applicatorsSemiconductor/solid-state device manufacturingCarbon densityNitrogen

The present invention is a method of film deposition that comprises a film-depositing step of supplying a high-melting-point organometallic material gas and a nitrogen-containing gas to a processing vessel that can be evacuated, so as to deposit a thin film of a metallic compound of a high-melting-point metal on a surface of an object to be processed placed in the processing vessel. A partial pressure of the nitrogen-containing gas during the film-depositing step is 17% or lower, in order to increase carbon density contained in the thin film.

Owner:TOKYO ELECTRON LTD

Semiconductor device manufacturing method and substrate treating apparatus

ActiveCN100521092CEasy to cleanImprove qualitySemiconductor/solid-state device manufacturingHydrogenCarbon density

Owner:KOKUSA ELECTRIC CO LTD

Method for supplementing carbon on machine element surface

ActiveCN1304624CAvoid economic lossImprove bindingSolid state diffusion coatingIntermediate frequencyCarbon density

The invention discloses a technique for surface carburization on a mechanic device, which is characterized in including the quality and structure feature of devices that need to be carburized, and the steps of analyzing raw carbon-density distinction of its cross section and designing the carburization technique; shoving, heating, carburizing and supplying carbon on the basis of technological requirements, with technological parameter 780-900 deg., 0.3-1.05CP, 5-20H; quick cooling with a fun or oven based on the technological requirements, after the temperature dropped, quenching and lonnealing and / or power-frequency quenching for one time and checking the ruggedness and / or checking a peeling test with a coupon to said device. The invention is pretty simple, economical, and broad used, available to heavy and large parts with different material qualities and degrees of decarburization, explored a new approach to healings qualities of large equipment.

Owner:SINOVEL WIND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com